Biggest 3d printing

Largest 3D printers in 2022 for XXL prints

Large-scale 3D printers are able to print massive objects thanks to their gigantic build volumes. This guide covers some of the largest 3D printers in the world that are commercially available.

Last update June 23, 2022

We removed discontinued products and updated the BLB Industries The BOX lineup, which has been replaced by The Industry MAGNUM. We also added MASSIVit's latest solution, the Massivit 10000.

Table of contents

Handpicked related content

Large scale 3D printers (XXL): 2022 selection

BIG-Meter V4

F1000

BigRep ONE v4

400 Series WORKBENCH XTREME

T3500

MAGNUM

Massivit 10000

MAMA

3D printing furniture

3D printing large prototypes

3D printing production series

Customized large scale 3D printers

What are the best large scale 3D printers?

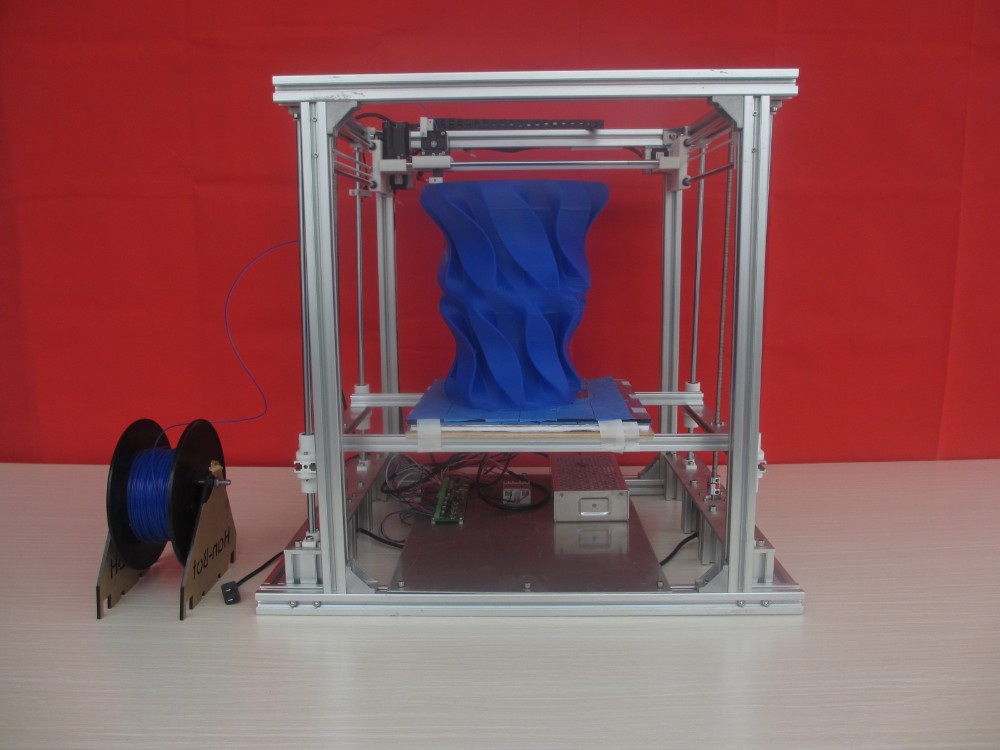

Large-scale 3D printers have been in the spotlight for quite some time. When we say large scale, we mean it– these machines can 3D print objects of over 1 square meter. They can be used to 3D print pieces of furniture, large prototypes, or several series of smaller objects in one go.

The professional 3D printers featured in our article are basically super-sized versions of ordinary desktop 3D printers. They almost all use extrusion 3D printing technology (FFF) and work the same way as regular desktop printers.

Our “largest 3D printers” selection does not include construction 3D printers, which fit into a different category.

Handpicked related content

If these large scale 3D printers (XXL) are too big, check out our other selections:

- Large format 3D printers (XL)

- Large volume 3D printers (L) for desktops/benchtops

- Large resin 3D printers (L)

Large scale 3D printers (XXL): 2022 selection

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. | |

|---|---|---|---|---|---|

| Modix This brand is a certified partner from our network. | BIG-Meter V4 | 1010 × 1010 × 1010 mm39.76 × 39.76 × 39.76 in | Israel | $ 13,50013 723 €11,975 £2,012,256 ¥ | Buy |

| CreatBot | F1000 | 1000 × 1000 × 1000 mm39.37 × 39.37 × 39.37 in | China | $ 29,99930 494 €26,610 £4,471,531 ¥ | Buy |

| BigRep | BigRep ONE v4 | 1005 × 1005 × 1005 mm39.57 × 39.57 × 39.57 in | Germany | $ 30,00030 000 €26,611 £4,471,680 ¥ | Quote |

| 3D Platform | 400 Series WORKBENCH XTREME | 1000 × 1500 × 700 mm39.37 × 59.06 × 27.56 in | United States | $ 49,99950 823 €44,351 £7,452,651 ¥ | Quote |

| Tractus3D | T3500 | ⌀ 1000 x 2100 mm | Netherlands | $ 59,00049 900 €52,335 £8,794,304 ¥ | Quote |

| The Industry | MAGNUM | 1500 × 1200 × 1200 mm59. 06 × 47.24 × 47.24 in 06 × 47.24 × 47.24 in | Sweden | $ 135,000129 990 €119,750 £20,122,560 ¥ | Quote |

| MASSIVit 3D | Massivit 10000 | 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in | Israel | upon request | Quote |

| Modix This brand is a certified partner from our network. | MAMA | 2000 × 5000 × 1000 mm78.74 × 196.85 × 39.37 in | Israel | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Modix This brand is a certified partner from our network. | BIG-Meter V4 | 1010 × 1010 × 1010 mm39.76 × 39.76 × 39.76 in | 1030.3 L | Israel | $ 13,50013 723 €11,975 £2,012,256 ¥ | Buy on Modix |

| CreatBot | F1000 | 1000 × 1000 × 1000 mm39.37 × 39.37 × 39.37 in | 1000 L | China | $ 29,99930 494 €26,610 £4,471,531 ¥ | Buy on CreatBot |

| BigRep | BigRep ONE v4 | 1005 × 1005 × 1005 mm39.57 × 39.57 × 39.57 in | 1015.08 L | Germany | $ 30,00030 000 €26,611 £4,471,680 ¥ | Get a quote |

| 3D Platform | 400 Series WORKBENCH XTREME | 1000 × 1500 × 700 mm39.37 × 59.06 × 27.56 in | 1050 L | United States | $ 49,99950 823 €44,351 £7,452,651 ¥ | Get a quote |

| Tractus3D | T3500 | ⌀ 1000 x 2100 mm | 1649.34 L | Netherlands | $ 59,00049 900 €52,335 £8,794,304 ¥ | Get a quote |

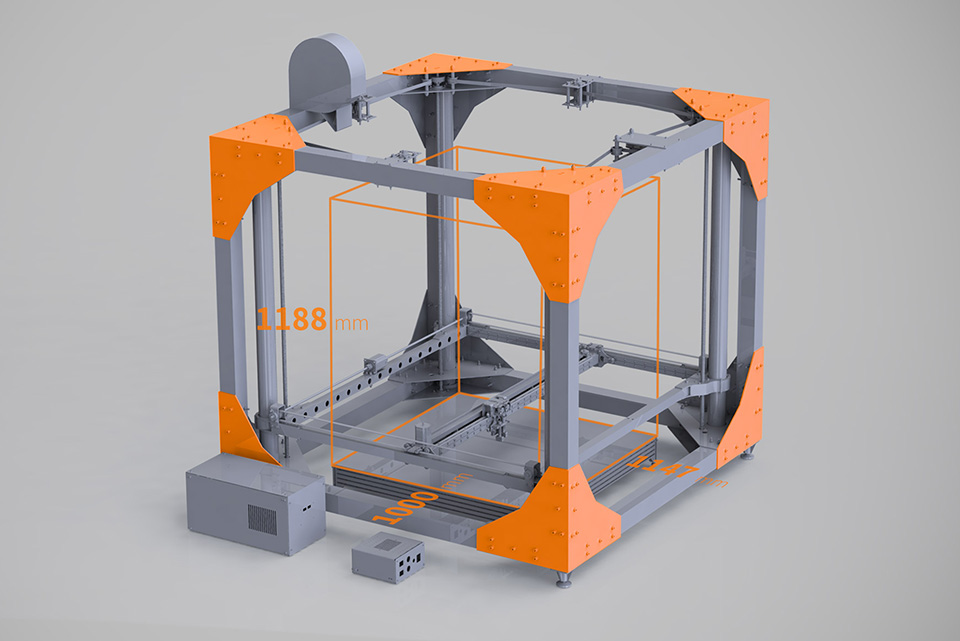

| The Industry | MAGNUM | 1500 × 1200 × 1200 mm59. 06 × 47.24 × 47.24 in 06 × 47.24 × 47.24 in | 2160 L | Sweden | $ 135,000129 990 €119,750 £20,122,560 ¥ | Get a quote |

| MASSIVit 3D | Massivit 10000 | 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in | 2364.3 L | Israel | upon request | Get a quote |

| Modix This brand is a certified partner from our network. | MAMA | 2000 × 5000 × 1000 mm78.74 × 196.85 × 39.37 in | – | Israel | upon request | Get a quote |

Overview of the best large scale professional 3D printers

The Modix BIG-Meter offers over one cubic meter of build volume. As all Modix printers do, the BIG-Meter is delivered as a self-assembly kit, which contributes to the printer’s relatively low price point.

This large scale 3D printer comes with a dual extruder (E3D Aero and E3D Volcano print heads), full automatic bed leveling (bed tile and bed mapping), a Wi-Fi controller, and a range of industrial-grade components. The print bed heats up to 120°C.

The print bed heats up to 120°C.

Buy on Modix Get a quote Add to comparison

The F1000 from CreatBot offers a full cubic meter of fully enclosed and heated (60°C) build volume. There’s also a filament chamber that can hold two spools of up to 5kg each and heat up to 45°C or 65°C.

Its dual nozzles are able to heat up to 420°C, while the print bed heats up to 100°C. Compatible materials range from standard PLA and ABS to PETG and carbon fiber-filled and flexible materials.

Buy on CreatBot Get a quote Add to comparison

The BigRep ONE, currently in its third generation of upgrades and updates, is one of the only large-sized 3D printers to provide independent dual extrusion (IDEX). IDEX can cut production times in half thanks to duplication or mirror modes.

The printer’s large touchscreen grants access to the webcam and allows users to resume prints even after a power outage. The filament holder is able to hold multiple spools of up to 8kg.

Contact manufacturer Get a quote Add to comparison

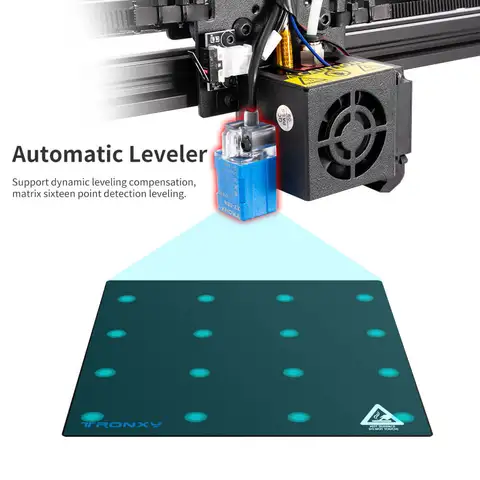

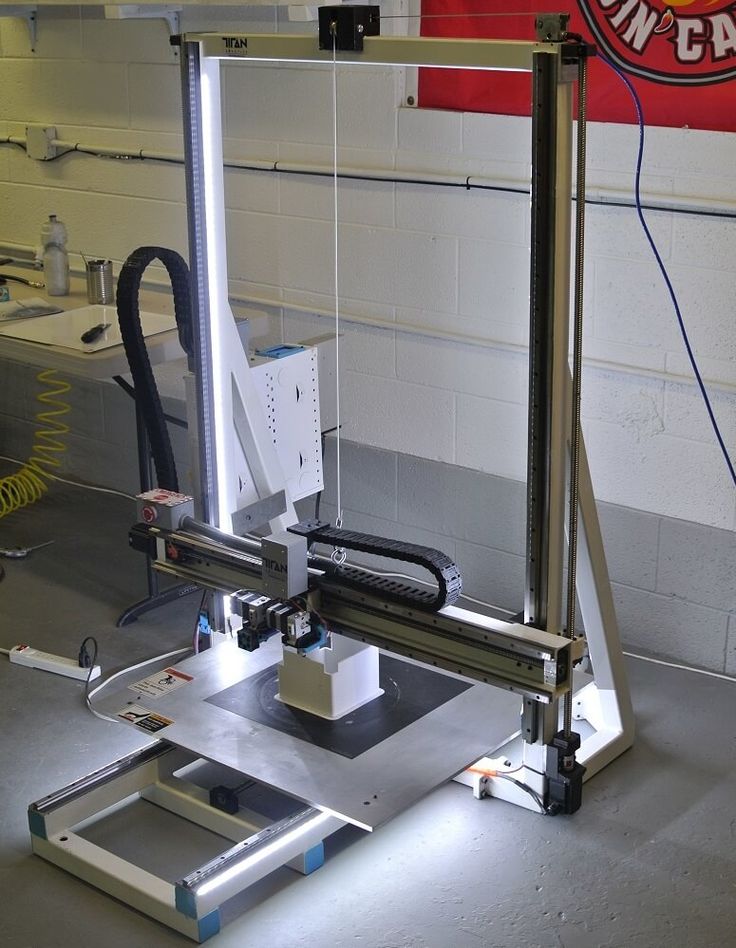

This large format 3D printer with dual extrusion is customizable. Various extruders are available, and it’s possible to add an enclosure. The enclosure can be heated and/or include an air filter as well.

Various extruders are available, and it’s possible to add an enclosure. The enclosure can be heated and/or include an air filter as well.

It’s possible to choose from two different control systems; with Wi-Fi or with Ethernet connectivity. The automatic leveling probe touches over 400 points on the print bed to ensure optimal calibration.

Contact manufacturer Get a quote Add to comparison

The T3500, a huge delta 3D printer, offers a massive build size that can 3D print to an exact scale of 1:1 up to 2.1 meters high.

The large-scale Tractus3D T3500 can 3D print exotic materials with its hot-end extruder capable of reaching up to 300°C. This 3D printer features a heated bed and can be equipped with an optional dual extruder.

Contact manufacturer Get a quote Add to comparison

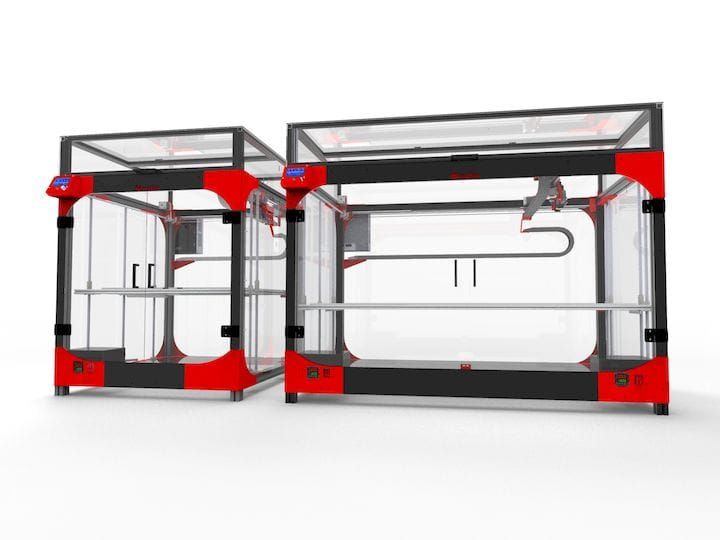

The Industry MAGNUM is a very large format 3D printer by The Industry (previously called BLB Industries), a manufacturer based in Sweden. This XXL 3D printer offers a build volume of 2. 16m³ and comes with a set of nozzles ranging from 2 to 8mm in diameter. The MAGNUM is based on the company’s previous model, the BLB Industries THE BOX.

16m³ and comes with a set of nozzles ranging from 2 to 8mm in diameter. The MAGNUM is based on the company’s previous model, the BLB Industries THE BOX.

Contact manufacturer Get a quote Add to comparison

The Massivit 10000 is an industrial large format 3D printer produced by MASSIVit 3D. MASSIVit 3D is a 3D printer manufacturer based in Israel. This 3D printer offers a build volume of 1420 x 1110 x 1500 mm.

Contact manufacturer Get a quote Add to comparison

Modix has nicknamed their printer “Personal Car Factory”, a quick way to indicate how big the MAMA (Modular Additive Manufacturing Assembler) system really is. It’s equipped with a high-speed pellet extruder, and is also capable of 3D printing with spools of filament.

This huge FFF 3D printer isn’t available yet.

Contact manufacturer Get a quote Add to comparison

Applications for large scale 3D printing

3D printing furniture

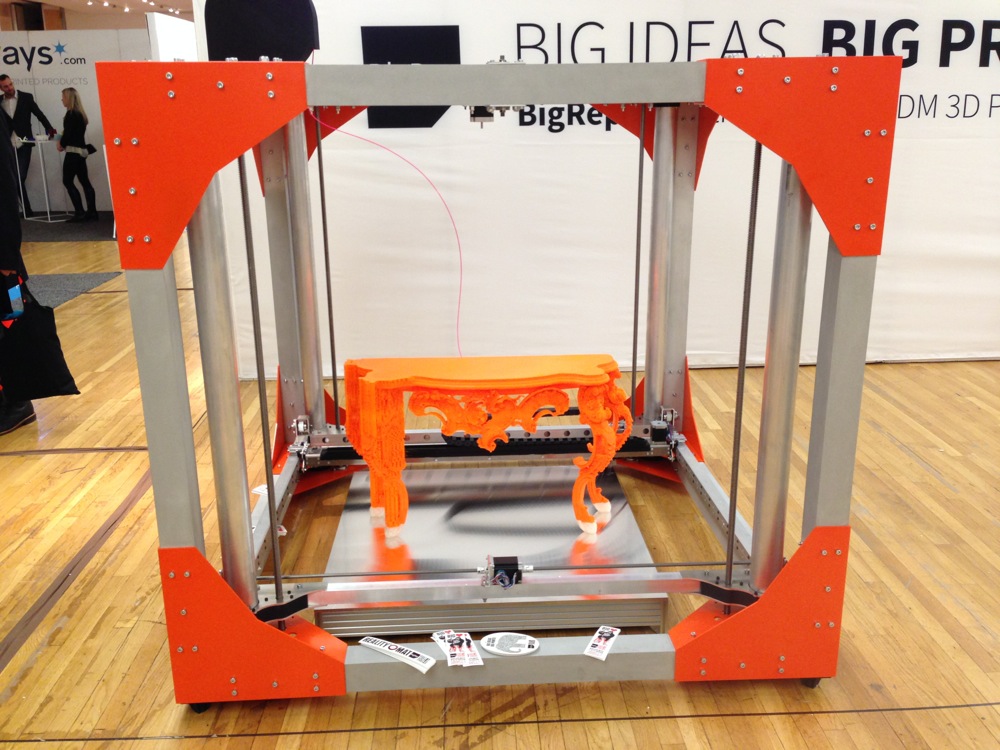

The largest 3D printers can be used to 3D print furniture in one go. This includes tables, chairs, and even bathtubs. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise.

This includes tables, chairs, and even bathtubs. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise.

Hence, customized furniture is becoming more and more accessible thanks to extra-large 3D printers.

The BigRep One is in action. Source: QMES3D printing large prototypes

The professional large-scale 3D printers featured in our article can also be used to 3D print large prototypes. This enables businesses to test out their products before actually launching production. Industrial designers and engineers are able to perform more revisions in significantly less time.

They can test their future products extensively while at the same time reducing the production-to-market time.

3D printing production series

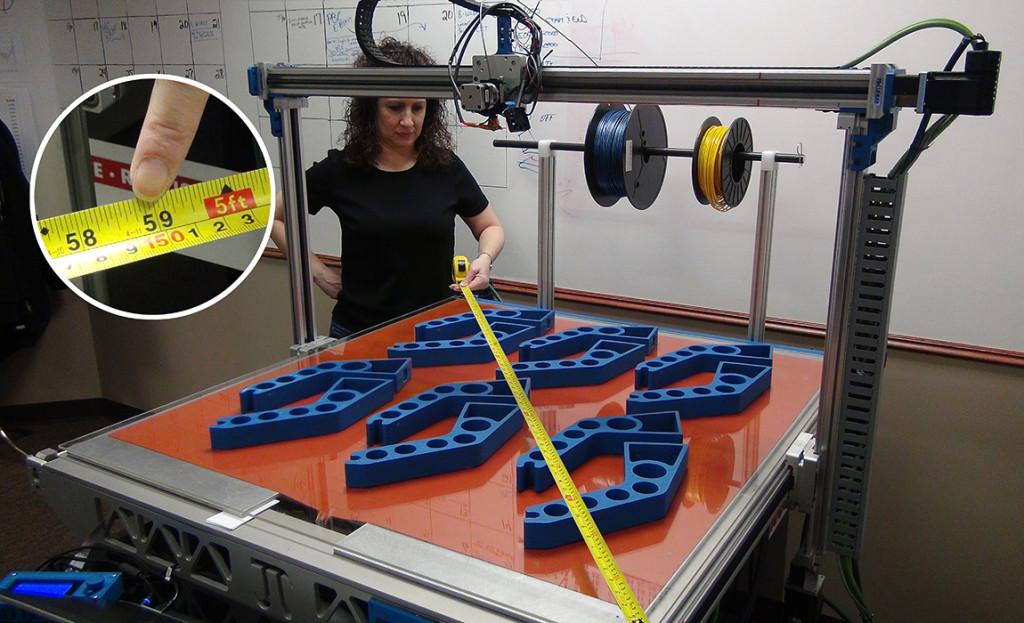

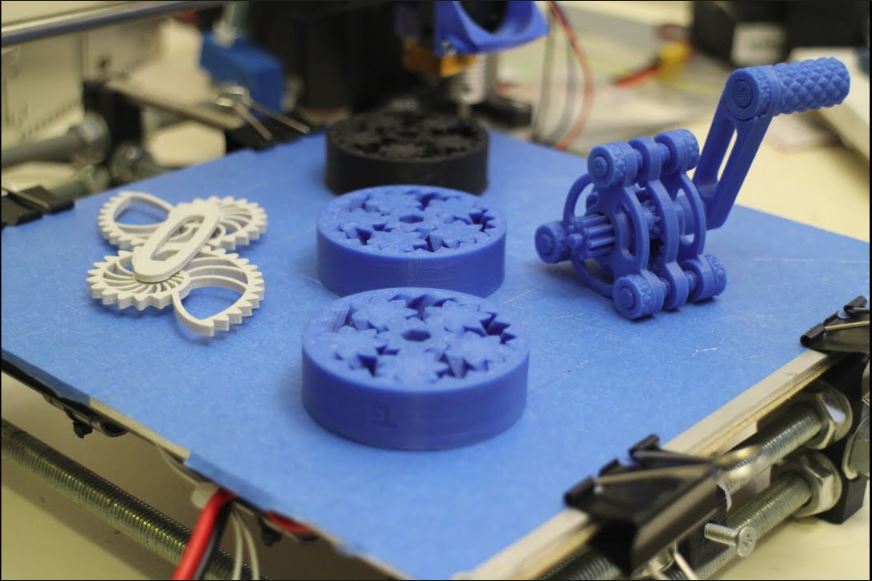

Large-scale 3D printers don’t have to exclusively 3D print large objects and prototypes. Their huge build platform also enables 3D printing big series of smaller objects.

Customized large scale 3D printers

There are several manufacturers that mainly offer tailored solutions rather than standardized 3D printer models. Tobeca, for instance, is a French team that builds 3D printers from scratch and is based entirely on their customers’ needs and requirements.

US-based Erectorbot also provides on-demand builds, although they do have a lineup of standard models. Then there’s Colossus, a company in Belgium that constructs 3D printers within shipping container-like structures. CNC Barcenas, a Spanish manufacturer, also offers tailored, large-scale 3D printers with a range of options to choose from.

What is the largest 3D printed object? (2021 Update)

Posted By Kat Plewa on Dec 3, 2019 |

From 3D printed hearts to car restorations, Additive Manufacturing has numerous applications in many industries, but did you know that it is also possible to 3D print on a large scale? Concrete houses, bridges or even ship propellers, 3D printing keeps bringing absolutely new, innovative solutions. What is the largest 3D printed object yet? Let’s find out!

What is the largest 3D printed object yet? Let’s find out!

#6 Titanium Brake Caliper by Bugatti

The automotive industry is certainly one that makes the most of 3D printing technologies. One of the leaders, Bugatti, wasn’t waiting for their competitors to start benefiting from Additive Manufacturing. They are creating a new path of production using the Selective Laser Sintering (SLS) technique.

Thanks to 3D printing, Bugatti made a huge improvement in their brake caliper design and manufacturing. The brake produced with traditional methods weighed 4.9 kg and was made out of aluminum. Additive Manufacturing allowed the engineers to use titanium, which is much stronger and robust. Not only that, but they could also use new design methods bringing the weight of caliper down to 2.9 kg!

Only 3D technologies could allow Bugatti’s team to reduce weight and at the same time improve the quality of the 3D printed part. Additive Manufacturing is the true future of the automotive industry.

#5 Two-level villa

https://all3dp.com/1/3d-printed-house-homes-buildings-3d-printing-construction/

Chinese company HuaShang Tengda knows how to produce impressive extra-large projects. Our Top 6 list of the largest 3D printed objects wouldn’t be complete without a concrete 3D printed habitat.

The revolution of using additive manufacturing for houses is the speed of producing them. HuaShang Tengda managed to build a two-story villa in just 45 days! They developed dedicated hardware but also developed an innovative technique complementing 3D printing. First, the frame of the building was put up and then a 3D printer laid the concrete.

To produce this XL object 20 tons of concrete were used! This 3D printed house shows another advantage of Additive Manufacturing: lowering material waste, which reflects on the costs. Most impressive is still the timeframe. 3D printing can improve your production by making it faster and therefore bringing the costs down.

#4 The largest 3D printed bridge

//www.sculpteo.com/blog/2019/02/20/meet-the-longest-3d-printed-bridge-in-the-world/

Another outstanding project on our list is the world’s longest 3D printed bridge produced in Shangai. The previous bridge was built during the Sui Dynasty (581- 618 CE) and it took 11 years to complete it.

To compare, the 3D printed structure was manufactured in less than 19 days! To make the bridge, 68 slide pieces and 64 deck pieces were 3D printed. What is so striking about this bridge is not only the manufacturing speed but also the fact that it includes senor accumulating displacement data which will be used later to improve the design of future 3D printed bridges.

On top of that, the bridge is very strong. It was tested during inauguration when 100 people stood on it at the same time! This experiment truly proves that Additive Manufacturing is totally capable of producing complex constructions that can withstand tons of stress.

#3 World’s first 3D printed propeller

Another industry where 3D printing is a groundbreaking solution to improving the production process is the maritime sector. One of the latest developments is WAAMpeller. It is the first-ever 3D printed ship propeller. Where its unique name comes from?

WAAM is a technology invented especially for this project. WAAM is short for Wire Arc Additive Manufacturing. This 3D method melts metal wire with an electric arc, layer by layer. The WAAMpeller is built of nickel aluminum bronze alloy and composed of 298 layers. The final result was truly impressive and fully functional! The 3D printed propeller was installed on a workboat Stan Tug 1606.

#2 3D printing and space exploration: Aeon 1

Can Additive Manufacturing improve space exploration? Yes! In fact, there are many different ways where 3D technologies print new, better solutions to space travel. Relativity Space, a young American start-up, saw the potential of 3D printing.

They developed robotic arms that are capable of 3D printing with metal. What for? To manufacture a rocket engine: Aeon 1! Rocket engines are extremely hard to design and produce, they are made of multiple parts which raises the risk of failure. Thanks to 3D techniques, the design od a rocket engine could be rethought.

Usually, this component of a rocket has many parts, but thanks to 3D printing, it was composed only of 3 parts! That’s a huge leap forward in terms of material usage, functionality, production time, and costs. It only took one month to manufacture Aeon 1, compared to 6 months when made with traditional technologies. Also, having fewer parts means a shortened assembly time.

Aeon 1 was successfully fired up on numerous occasions, which proves that it’s fully functional and ready for further improvements.

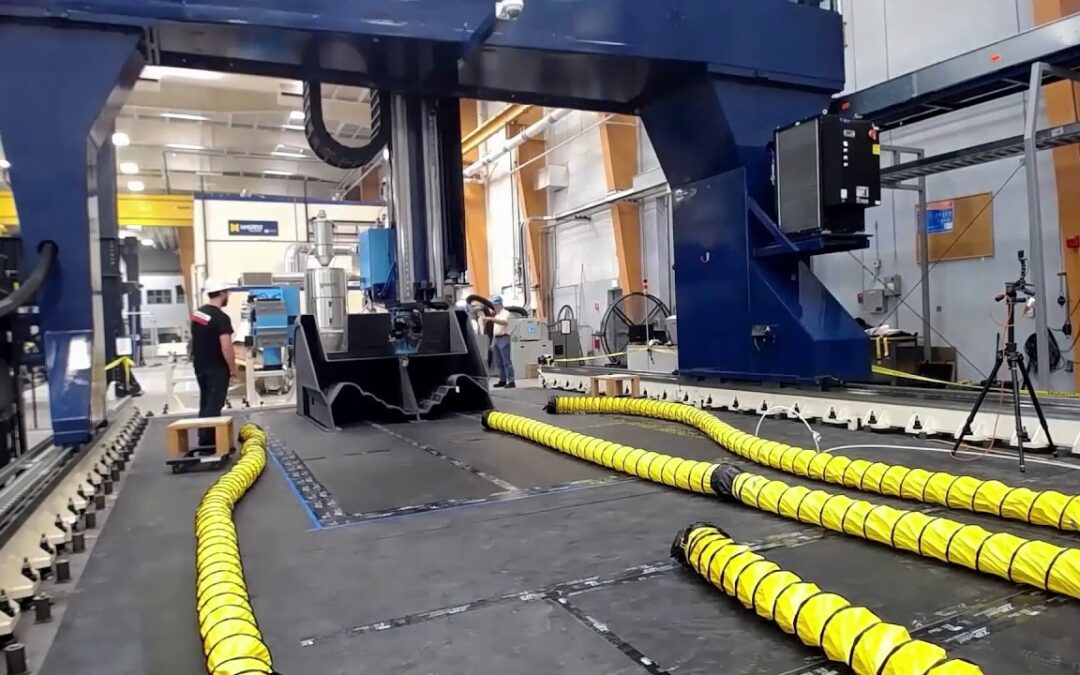

#1 Largest solid 3D printed object

The leader in aircraft manufacturing Boeing knows that producing aircraft is time-consuming and complicated. Not every tool needed to manufacture, for instance, wings, is available on the market. Special equipment is required for a plane to be built. This is exactly why 3D printing is the answer.

Not every tool needed to manufacture, for instance, wings, is available on the market. Special equipment is required for a plane to be built. This is exactly why 3D printing is the answer.

Thanks to 3D modeling, engineers from Oak Ridge National Laboratory (ORNL) in cooperation with Boeing were able to produce highly customized and at the same time, the largest ever solid 3D printed object. The part needed was a trim tool. The purpose of this tool is to hold Boeing 777x’s wing skin while it’s being machined and drilled. The tool holds the title of the largest 3D printed object in Guinness Records.

To be able to produce it, the researchers developed Big Area Additive Manufacturing (BAAM) 3D printer. The machine took only 30 hours, instead of 7 days, to produce a large-scale trim tool. The component is a combination of 80% ABS plastic and 20% carbon fiber. It weighs 745 kg, is 5.3 meters long, 1.5 meters wide and 0.5 meters tall. The 3D printed tool showcases how much potential lays in additive manufacturing for the aerospace industry.

What is the future of XL 3D printing?

As you see, there are some really impressive projects when it comes to the largest 3D printed object. From improving airplanes production, the longest bridges to building houses, Additive Manufacturing keeps on surprising us with its groundbreaking applications. And it definitely won’t stop there. Every year there are new solutions and projects that come up, such as the biggest yet 3D printed boat.

Big or small, if you have a 3D printing project, you can easily produce it with an online 3D printing service like Sculpteo. All you have to do is upload your file or contact us if you have any doubts.

Enjoyed this article? Don’t miss the next one! Subscribe to our Newsletter and follow us on Facebook now.

The largest 3D printer in the world has printed a boat

Now men don't have to bother with gifts. It will be enough to order a boat that a 3D printer can print.

The world's largest 3D printer is located at the University of Maine in the USA. In 72 hours, the polymer device printed a boat over 7 meters long and weighing 2.26 tons. Thus, the printing process immediately broke 3 world records, which were successfully recorded by representatives of the Guinness Book of Records:

In 72 hours, the polymer device printed a boat over 7 meters long and weighing 2.26 tons. Thus, the printing process immediately broke 3 world records, which were successfully recorded by representatives of the Guinness Book of Records:

1. The largest prototype polymer 3D printer;

2. Largest 3D printed solid object;

3. The largest 3D printed boat.

But at this point, the employees of the Center of Excellence and composites stop at going. They claim that this 3D printer can print and more global objects, up to 30 m long, 7 m wide and 3 m high. Performance super 3D printer is 226 kg of polymers per hour.

Read also: Transformer bed that will solve the problem of dividing the territory

pleasure. To create the entire installation and put it into operation, spent about $2.5 million. The bulk of the money was allocated by the US Army. Later on she plans to work closely with the company to create mobile shelters for soldiers, as well as bridges. Thus, the army will become one of main customers. The company received financial support in the amount of $500,000 from the Maine Institute of Technology.

Thus, the army will become one of main customers. The company received financial support in the amount of $500,000 from the Maine Institute of Technology.

The aim of this project was the idea of using 3D printing in shipbuilding. The printed boat was named "3Dirigo" and have already tried it in the pool. Soon the ship will set sail. It is worth noting that about $40 thousand was spent on its printing.

US Senator Angus King noted that the printing of the 3Dirigo polymer boat was truly a great event in the field of technology, because it opens up many new opportunities. In addition, Angus joked that the first great event for the university was admission at 1965 year of the famous writer Stephen King.

And we recall that in April 2019 in Israel for the first time it was possible to print a living heart on a 3D printer. They made it from human fat cells, which they turned into stem cells of the cardiovascular muscle. The size of the printed heart was about 2.5 cm. Scientists note that in the future it will be possible to print absolutely any human organ in this way, depending on the individual characteristics of the body of each patient.

Scientists note that in the future it will be possible to print absolutely any human organ in this way, depending on the individual characteristics of the body of each patient.

INTERESTING

FAVORITE

Load more

- Advertisement -

Top 10 biggest 3D printers in the world

Share on Facebook Share on Twitter Share on Vkontakte

Have you ever wondered how big 3D printers can be? If this has happened to you, then it's time to satisfy your curiosity, we will tell you about Top 10 3D printers in the world. The selection criterion was the size of the object that can be created in the chamber (or workspace) of the 3D printer .

At the end of the article you will find a slider with examples of the work of 3D printers included in this top ten.

So, let's start with the smallest large printer in our top ten.

10. Norsk Titanium

This 3D printer was created by the American company "Fabrisonic" . The technology by which it works is direct metal deposition. The size of 3D printed parts is 120 x 120 x 180 cm. Although the maximum length of the product can be up to 215 cm according to the company.

9. ExOne Exerial

This is Dual Chamber 3D Printer, each chamber measures 220 x 120 x 70 cm, can use metal, ceramic and sand as material, the latter is used to create sand cores and molds .

8. Voxeljet VX4000

The chamber measures 4 x 2 x 1 m and is currently the largest industrial machine, mainly used for making sand molds.

7. D-shape

The working surface of this 3D printer is a 6 x 6 meter aluminum frame. To create three-dimensional objects, a special sand material is applied layer by layer, the layers are fixed with a special binder.

To create three-dimensional objects, a special sand material is applied layer by layer, the layers are fixed with a special binder.

The printer was patented in 2006 by Enrico Dini, founder of the British company "Monolite UK Ltd" . The first model of the printer used epoxy resin as a binder, but Dini later switched to using a magnesium-containing substance. After making this change, he again patented the 3D printer in 2008. In the future, Dini wants to use the 3D printer to create full scale buildings.

6. Sciaky EBAM 300

The size of the working chamber of this 3D printer is 7.620 x 2.743 x 3.353 m. The electron beam melts the metal, which is fed in the form of a wire, and a three-dimensional object is created layer by layer according to the CAD model. Sciaky EBAM 300 works with metals such as titanium, titanium alloys, inconel 718 and 625, tantalum, niobium, stainless steel, 2319 and 4043 aluminum alloy, 4340 steel, zircalla and others.

5. KamerMaker

This printer was one of the very first large scale 3D printers, it uses fusing technology. With his help, the first 3D printed house was built on one of the canals of Amsterdam. The sizes of printed objects reach dimensions of 2 x 2 x 3.5 m, bioplastics and bioplastics are used as materials. This is an open public project that anyone can join.

4. WASP GigaDelta

This 3D printer can grow objects up to 8-10 meters high. The creator of this machine, Massimo Moretti, dreamed of building houses using clay as a material and with minimal energy consumption. Now the company is developing a printer with a special extruder. After the work is completed, it will be possible to create objects up to 12 meters high.

3. Cincinnati Incorporated's BAAMCI

Workspace is 25 cubic meters.

This huge thermoplastic machine was created to print the "Strati" car for "Local Motors" , which was shown at an international technology event in Chicago in 2014. Now the creators of BAAM are working on the next, even larger version of the machine, its name will be "Bertha" .

Now the creators of BAAM are working on the next, even larger version of the machine, its name will be "Bertha" .

2. BetAbram P1

Working space 288 cubic meters.

Slovenian company BetAbram manufactures (on request) 3D printers in three sizes for house printing. The largest of them has a span of 9 x 16 m (the average is 12 x 6 m, and the smallest is 4 x 3 m). The printer works according to the extrusion method, the layer thickness is 25 centimeters, but it can be more. The material used is concrete.

1. WinSun

And here is the winner of the Biggest 3D Printer, this is "Winsun" from China. He can create furniture and houses that can be up to 5 stories high. The material used is recycled concrete construction waste. The process of building buildings in this way is more environmentally friendly, unlike the traditional one.

And this Chinese 3D printer is also associated with a scandal: Dr.

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).