3D printed ceramic tiles

Studio RAP will 3D print 4,000 ceramic tiles for a new architecture project

3D printing news News Studio RAP will 3D print 4,000 ceramic tiles for a new architecture project

Published on October 12, 2020 by Aysha M.

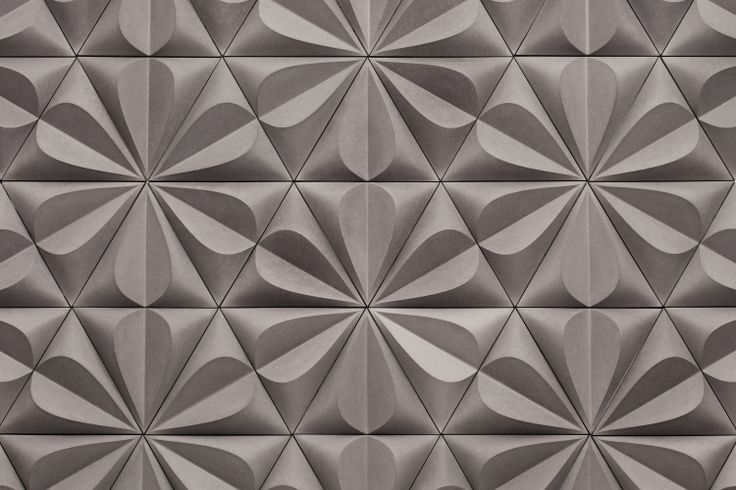

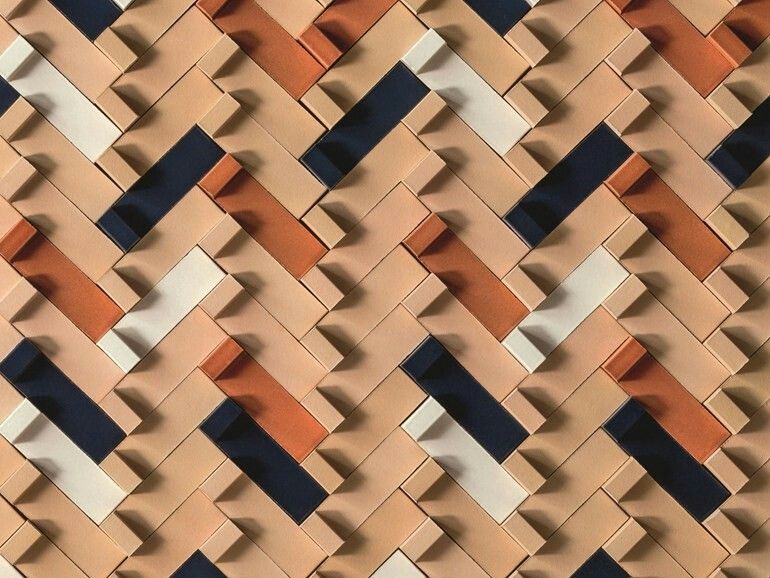

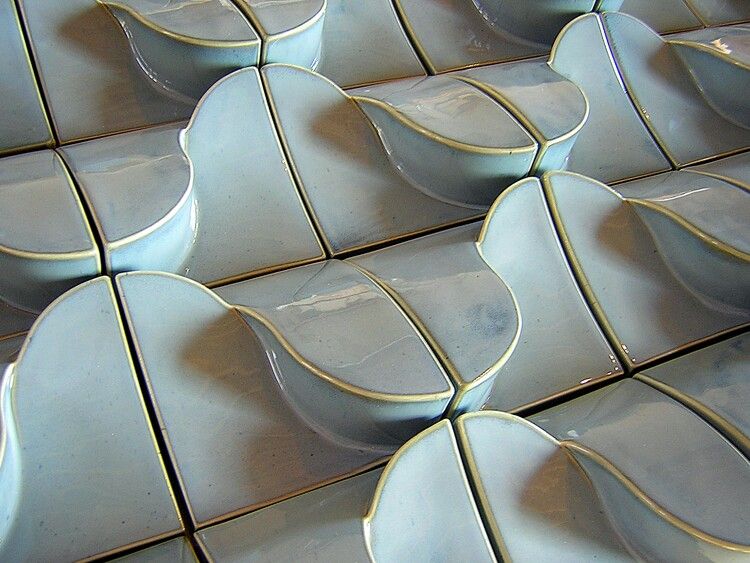

In the Netherlands, more precisely in Delft, studio RAP is building an architectural structure that will incorporate 3D printed ceramic tiles. Called “New Delft Blue”, the project pays homage to Delft Blue, the famous Dutch porcelain, that has been invented in the 17th century. The project combines clay 3D printing, computational design and artisanal glazing. The result is quite impressive, with 4,000 tiles to be integrated in the final structure!

Renowned for its finesse and quality, Delft Blue is a Dutch tradition that has left its mark on the country’s architecture and decoration. It is not surprising to see additive manufacturing interested in it and adding its touch in terms of creativity and complexity of form and geometry. One example is the 3D printed vases by Olivier van Herpt, who combined cobalt blue and clay and then extruded them to form, layer by layer, unique decorative elements. This time, studio RAP focuses on the architecture sector and uses 3D printing technology to cover the lush courtyard of a residential building.

The 3D printed ceramic tiles cover the gates of a new residential building (Image credits: Studio RAP)

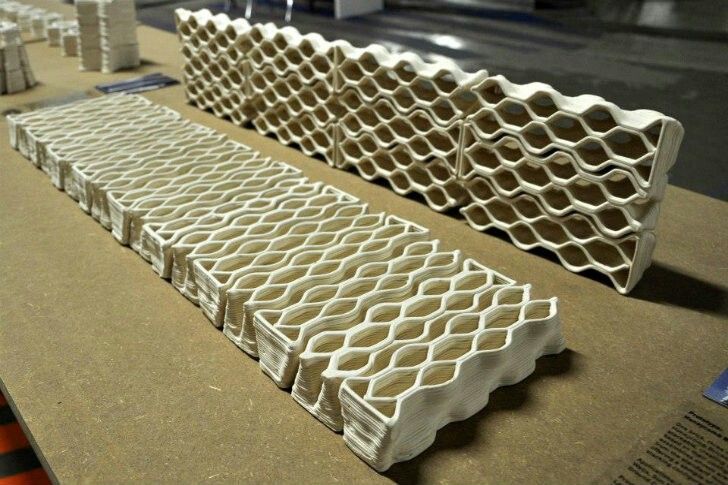

The KUKA robotic arm is behind the 3D printing process of the ceramic tiles. Once the piece has hardened, it gets glazed -covered with blue and white layers that give it the final aesthetic touch. According to the team behind the project, the material chosen offers both high durability and low maintenance. It also specifies that it opted for an algorithmic approach for the 3D design of the tiles, which allowed it to take into account certain manufacturing constraints when generating the tile geometry (maximum overhang, width, height and depth, shrinkage constraints and internal support structure). The vault is 4 meters wide, 8 meters high and 12 meters deep, hence studio RAP is additively manufacturing 4,000 tiles in total.

The vault is 4 meters wide, 8 meters high and 12 meters deep, hence studio RAP is additively manufacturing 4,000 tiles in total.

Concerning the glazing method, studio RAP explains: “Because the tiles are 3D-printed, applying variation in their shape is rather cheap. By applying a runny glaze on white-burning clay portions of the tile that are convex (hills) will remain white as the blue glaze pools in the concave (valley) areas of the tile. This poetic method of ‘painting with shape’ allows for smooth transitions between hues of blue and white that are impossible to produce otherwise.” The studio can thus obtain two-colored tiles that offer a unique visual effect to the future passageway. You can find more information about the beautiful project on the studio RAP’s official website.

The tiles are 3D printed and then covered with varnish. (Image credits: studio RAP)

What do you think about the beautiful design and the innovative manufacturing method of Studio RAP? Let us know in a comment down below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

3d Printed Tiles - Etsy.

de

deEtsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

Printer for printing photos on ceramic tiles.

(Printer for photoceramics) Market news • Office equipment

(Printer for photoceramics) Market news • Office equipment 11 years ago

by wipboss

A new printer from the EPSON brand, it is possible to make exclusive interiors. Make the design of your cozy bathroom or kitchen extraordinarily beautiful and attractive. Find out how this is possible by reading the article.

Hello!

Today you can see a lot of unusual things in technologies. We will touch upon the latest technologies in the field of repair and creation of a cozy interior in the room. Modern ideas for creating comfort in a room are very wide and endless. Today, people have become more educated in repairs and interior design, and accordingly their exactingness in the design of the premises has increased. And those who are faced with repair issues will definitely remember the time spent looking for a suitable tile. Since this is one of the most popular types of interior design in modern times, photographic tiles are used. With the help of such a solution, a bright and high-quality ceramic panel will appear in your interior, which will delight you with its beauty and unusualness for a long time. nine0003

nine0003

More recently, in order to manufacture photoceramic tiles, they resorted to expensive equipment and complex technologies. High-temperature processing was indispensable. This whole process required serious skills, professional craftsmen able to work with capricious equipment, where expensive consumables were used. This whole process took at least two days to produce one square meter. And the purchase of equipment in the amount of tens of thousands of dollars. nine0003

Here comes the solution to this problem - the instant photo tile printer. Thanks to this unique opportunity, anyone can master the process of making photographic tiles of exceptional quality at minimal cost even at home.

According to the new technology for the production of phototiles, special printers with direct printing on ceramics are used. It is enough just to apply the image to the surface of any ceramic tile, just like printing on plain paper. And you don't need a tile kiln. Sufficient durability of the image is achieved due to the formation of a very strong polymer layer on the ceramic surface. A high-quality pattern layer can be washed with any detergent without an abrasive content, while not losing its appearance of novelty for decades. Photos or drawings are exceptionally bright and clear, and the process of making a 1.5 square meter panel will take no more than 20 minutes. nine0003

A high-quality pattern layer can be washed with any detergent without an abrasive content, while not losing its appearance of novelty for decades. Photos or drawings are exceptionally bright and clear, and the process of making a 1.5 square meter panel will take no more than 20 minutes. nine0003

Ceramic printers are compact and easy to use even at home. Each printer comes with a DVD-ROM with the necessary drivers and proprietary software, with a supply of consumables for approximately 100 squares of photo tiles.

Printing is possible on any white ceramic tile, with any allowable size for a specific printer model. The quality of color printing on ceramics is ensured by a reliable print head and electronics from the EPSON brand. nine0003

A tile with a picture or a photo will harmoniously merge into the design of a bathroom or kitchen, the print quality is stable even for use on the facade of a house. With such a solution, your interior acquires individuality and originality. And also an unforgettable gift will be a print on a tile for your family and friends.

And also an unforgettable gift will be a print on a tile for your family and friends.

Good luck with your ideas in your space!

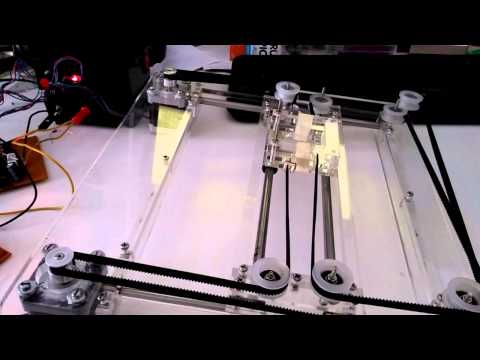

Watch this video on YouTube

Inventions

You may also like

Some of the most amazing 3D printing materials currently available

3D printing with classic materials such as plastic, metal or ceramics is widespread. In the meantime, there are many alternative materials that are not only unusual, but can make a 3D printed part even more special. In our selection, we introduce you to these unusual materials. From chocolate and salt to recycled plastic waste or ashes, now you can create the most extraordinary items. In some cases, these materials are even proving to be a great alternative to plastic, reducing overconsumption and the associated environmental impact. Today we're going to take a look at these amazing 3D printing materials. nine0003

3D printing material from the sea

Today, filaments are still the most commonly used 3D printing materials, mainly because FDM machines are readily available. But did you know that some threads are made from shellfish and crustaceans? The French company Francofil offers materials from PLA and shells of mussels, scallops and oysters. Their shells come from recycled food service waste and are shredded to become threads. The materials are made in France and can be printed like regular PLA. nine0003

But did you know that some threads are made from shellfish and crustaceans? The French company Francofil offers materials from PLA and shells of mussels, scallops and oysters. Their shells come from recycled food service waste and are shredded to become threads. The materials are made in France and can be printed like regular PLA. nine0003

Photo: Francofil

Local Salt

Emerging Objects is an American company that uses new technologies with innovative materials to create impressive projects. Among the most prominent initiatives is Saltygloo, a salt 3D printed structure. The salt used was collected from San Francisco Bay. Due to climatic conditions, about 500,000 tons of sea salt are produced here annually. Salt has been used to additively manufacture lightweight structures on a large scale. In addition to Saltygloo, the company is known for other salt projects such as the GEOtube tower and building houses. nine0003

Photo: Matthew Millman

Chocolate is the sweetest 3D printable material

This 3D printable material may not be as exceptional as some of the others on the list, but it is certainly one of the most used. The chocolate 3D printing process is similar to FDM technology, but it has different cooling properties than plastic, so the process takes longer. The popularity of this technology has grown over the years, prompting many companies to develop various designs and even chocolate 3D printers. Among the best known is the collaboration between 3D Systems and Hershey's, one of the world's largest chocolate makers. We also featured some 3D printers that can make delicious sweets like mycusini or Print2Taste. If you want to know more about this technology, don't miss the video below. nine0003

The chocolate 3D printing process is similar to FDM technology, but it has different cooling properties than plastic, so the process takes longer. The popularity of this technology has grown over the years, prompting many companies to develop various designs and even chocolate 3D printers. Among the best known is the collaboration between 3D Systems and Hershey's, one of the world's largest chocolate makers. We also featured some 3D printers that can make delicious sweets like mycusini or Print2Taste. If you want to know more about this technology, don't miss the video below. nine0003

3D printed material from the ashes to remember your loved ones

Narbón is a Spanish company dedicated to introducing new technologies and innovations in the funeral industry. 3DMemories uses 3D printing to create original, unique and exclusive ceramic jewelry from the ashes, hair, DNA or skeletal remains of a loved one. To do this, the pattern must be processed and then combined with porcelain before the decorations can be 3D printed. Then the enamel is applied and the product is fixed. The service offers a wide range of products for men and women. Undoubtedly, 3DMemories with its range of jewelry is an exceptional way to remember a loved one. nine0003

Then the enamel is applied and the product is fixed. The service offers a wide range of products for men and women. Undoubtedly, 3DMemories with its range of jewelry is an exceptional way to remember a loved one. nine0003

Photo: Narbón

Wood-Based Threads

Wood or vegetable threads have also been available on the market for some time. For example, the Dutch company ColorFabb offers several alternative threads in this category. What started in 2014 with BambooFill has expanded in subsequent years with CorkFill and WoodFill. Wood fibers, usually blended with a PLA/PHA base, give parts a natural, high-quality finish. Whether used to make figurines, pieces of furniture, or wall decorations, the threads can be used anywhere the look of wood is desired. Since ColorFabb discontinued BambooFill, a similar product can be purchased in Wood Bamboo form from AzureFilm. According to the company, 40% of recycled wood is mixed with 60% of polymers for this purpose. However, to avoid problems when printing with this filament, it is recommended to reduce the print speed. nine0003

However, to avoid problems when printing with this filament, it is recommended to reduce the print speed. nine0003

Left: ColorFabb, Right: Azure Film

Other Uses for Linen

Another alternative to traditional filaments is a composite of PLA and linen from French manufacturer Nanovia. The company says the composite is not only a sustainable alternative to traditional filaments, but also offers the ability to achieve different shades of brown by applying different print settings. This can be achieved simply by changing the print temperature during production. As for the finish, the manufacturer recommends sealing the printed parts with UV protection to keep them intact for as long as possible. nine0003

Photo: Nanovia

Sugar 3D Printing

Sugar Lab was acquired by 3D Systems almost ten years ago and, as the name suggests, has focused on sugar 3D printing. Using the 3D Systems ChefJet Pro printer, the company creates intricately shaped candies and decorations. The Los Angeles-based company claims to be able to produce candy in all flavors and colors. Whether it's birthdays, weddings or Christmas parties, The Sugar Lab offers all sorts of 3D printed candies. As for quantity, the 3D printer seems to be capable of producing up to 100 candies a day. While The Sugar Lab is the most famous company using sugar as a printing material, other companies like The Modernist Cuisine are also trying their hand at 3D printing with sugar. nine0003

The Los Angeles-based company claims to be able to produce candy in all flavors and colors. Whether it's birthdays, weddings or Christmas parties, The Sugar Lab offers all sorts of 3D printed candies. As for quantity, the 3D printer seems to be capable of producing up to 100 candies a day. While The Sugar Lab is the most famous company using sugar as a printing material, other companies like The Modernist Cuisine are also trying their hand at 3D printing with sugar. nine0003

3D printing with glass

Glass has been popular in many industries for many years and is also used in additive manufacturing. Several researchers, such as those at MIT or Lawrence Livermore National Laboratory (LLNL), have developed 3D printing solutions to print on glass. For example, an MIT team has developed the G3DP2 machine, which can process 5 kg of glass per hour. With this machine, the researchers were able to create three-meter-high glass columns at Milan Design Week. Recently, the Glassomer startup has also unveiled its glass 3D printing technology. The company is developing a material made from fine glass powder and a plastic binder that can be processed on SLA printers. nine0003

The company is developing a material made from fine glass powder and a plastic binder that can be processed on SLA printers. nine0003

Photo: Glassomer

Recycled plastic filament

Sustainability is gaining more and more attention in additive manufacturing, and many companies are looking for alternatives. In recent years, several exciting products have been developed to make 3D printing more sustainable by making filaments from recycled plastic. One such project is Print The City by The New Raw, in which plastic from the waste of the people of Amsterdam and Thessaloniki is turned into 3D printed filament and used to print benches and other outdoor furniture. Another initiative is the Million Wave Project, which aims to produce recycled PET filaments for 3D printed prosthetic limbs for those in need. Another example is the ZUV tricycle, which was printed in Austria by EOOS using filaments made from 70kg of plastic waste from supermarkets in Vienna. nine0003

nine0003

Photo: New Raw

Ivory Inspired 3D Printing Material

Among the many materials used for 3D printing, there are some that have been specifically designed to meet specific requirements and solve old problems in an innovative way. One such material is Digory, which was developed by the University of Vienna in collaboration with Cubicure GmbH to meet the need for the restoration of ancient ivory monuments and objects. It is a synthetic resin containing calcium phosphate particles and silica powder. Researchers have developed this new material with ivory-like characteristics and properties to restore objects using 3D printing or SLA technology. The similarity between these two materials is striking - there is almost no difference! nine0003

The Digory material on the right is very similar to the real ivory on the left (photo courtesy of Vienna University of Technology).

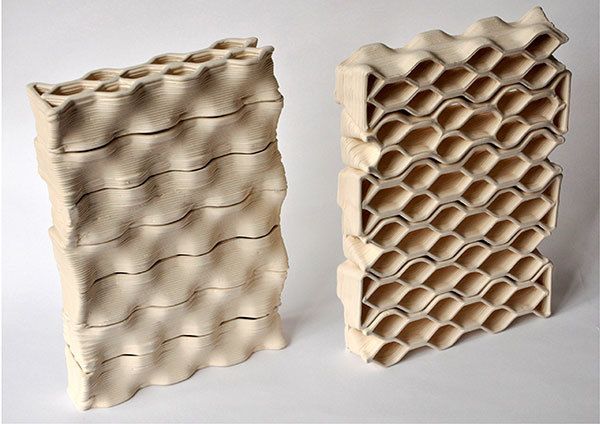

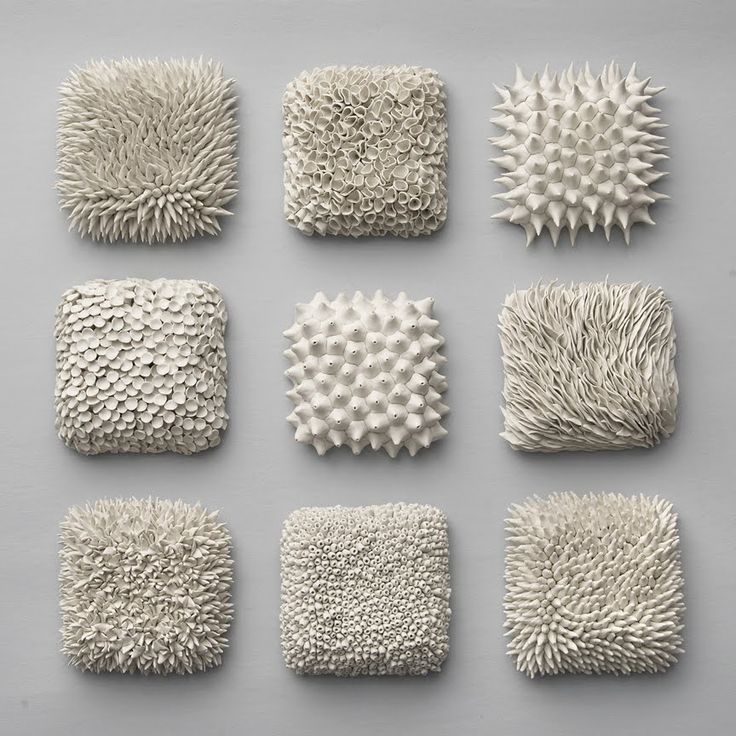

Clay as a more sustainable material for 3D printing

One of the unusual 3D printing materials that has certainly attracted attention in recent years is clay. Technically, this is a subset of ceramic 3D printing that, although difficult to print, is known for its incredible properties, in particular the use of clay was especially popularized by the work of the Italian company WASP. For example, we recently saw WASP and Honda use 3D clay printing to create greener vehicles. There are many other uses, although many of them focus on sustainability due to the clay's properties. This can be seen in projects such as archiREEF terracotta tiles for coral restoration in Hong Kong, or 3D printed clay containers designed to reduce food waste. nine0003

Technically, this is a subset of ceramic 3D printing that, although difficult to print, is known for its incredible properties, in particular the use of clay was especially popularized by the work of the Italian company WASP. For example, we recently saw WASP and Honda use 3D clay printing to create greener vehicles. There are many other uses, although many of them focus on sustainability due to the clay's properties. This can be seen in projects such as archiREEF terracotta tiles for coral restoration in Hong Kong, or 3D printed clay containers designed to reduce food waste. nine0003

Photo: Jonathan Keep

Diamond - 3D printing of the hardest material on Earth

It may surprise many that one of the hardest materials on Earth, diamond, can actually be printed. Back in 2019, Sandvik Additive Manufacturing announced the first ever 3D printed diamond composite. It is not shiny, but will allow manufacturers to 3D print super-hard material, which will help revolutionize, especially in the tool industry. Diamond is often used in industries such as mining and drilling, machining, and medical implants, especially for its wear-resistant properties, but it is difficult to process. Sandvik claims that this breakthrough in composites will now allow very complex shapes to be 3D printed, and the company has high hopes for its use in the near future. nine0003

Diamond is often used in industries such as mining and drilling, machining, and medical implants, especially for its wear-resistant properties, but it is difficult to process. Sandvik claims that this breakthrough in composites will now allow very complex shapes to be 3D printed, and the company has high hopes for its use in the near future. nine0003

Human cell printing

When it comes to 3D printing in the medical sector, people often think of bioprinting. In bioprinting, cellular structures, including human structures, are made from bioink loaded with stem cells. As with conventional 3D printing, the biomaterial can be applied layer by layer to create things like skin, tissues, bones, and even organs. Although it is still in its infancy as a technology when it comes to creating viable long-term solutions, we have already seen a number of interesting projects using this technology. Notably, the researchers have been experimenting with 3D printing of organs, including the heart, kidneys, pancreas, and liver.