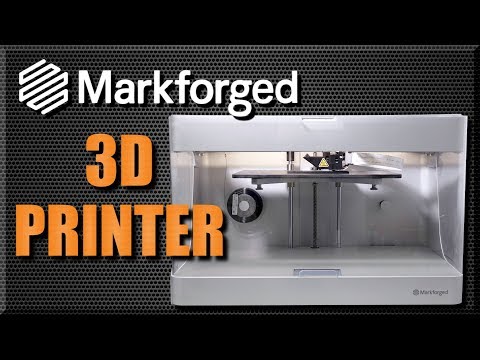

Onyx one 3d printer

Onyx One Desktop 3D Printer

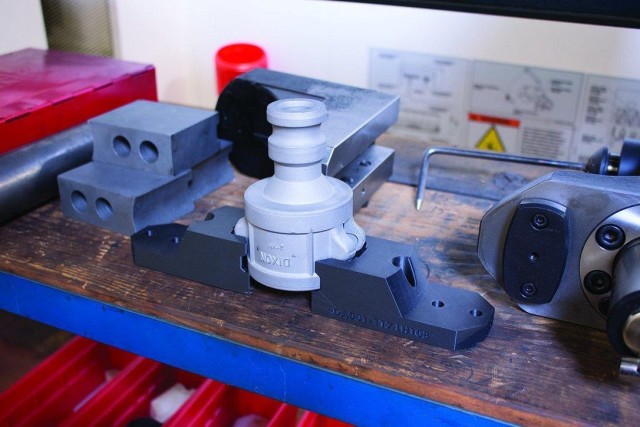

A bulletproof desktop 3D printer designed by engineers for engineers — the Onyx One prints accurate, beautiful, manufacturing-grade parts.

An FFF Printer for Engineers & Designers

The Onyx One brings professional-grade reliability, part quality, and accuracy to a desktop FFF form factor. Hit print and get a quality part out every time.

Built to Last

A unibody aluminum chassis and precision-machined components deliver lights-out reliability over thousands of print hours.

Precise, Beautiful

Print precise parts with best-in-class surface finish thanks to Onyx, Markforged’s extremely versatile micro carbon fiber filled nylon material.

Specs

Precision-built so you can 3D print precise parts.

Physical Dimensions

| Width | 584 mm |

| Depth | 330 mm |

| Height | 355 mm |

| Weight | 15 kg / 34 lbs |

Build Volume

| Width | 320 mm |

| Depth | 132 mm |

| Height | 154 mm |

Printer primary Specs

- Printing Process

- Fused Filament Fabrication (FFF)

- Z Layer Resolution

- 100 μm - 200 μm

- Printing Media

- Composite Base Filaments

- Internal Part Geometry

- Closed Cell Infill, Triangular Default

- Print Bed

- Precision Ground Composite

Materials

Compatible Materials

- Onyx™

System Details

About the Onyx OneThe Onyx One is an advanced FFF desktop 3D printer – built to reliably produce strong parts for you. It’s built around an aluminum unibody frame that delivers high accuracy and repeatability. A hardened extrusion system enables the Onyx One to print Onyx — a micro carbon fiber filled nylon filament that destroys traditional extrusion systems — reliably over thousands of print hours. The machine is built to be easy to operate and maintain — from easy-to-reach wear components (like nozzles and feed tubes) to usability focused features like the print bed, which can be removed and replaced with 10 μm repeatability.

Download Datasheet

Markforged Onyx One and Onyx Pro Buyer’s Guide

If FFF (Fused Filament Fabrication) technology is capable of replicating the detail and geometries of your designs, Markforged’s Onyx 3D printer series is an exceptional choice when your parts need to be incredibly strong.

The Markforged Onyx One and Onyx Pro are desktop-class FFF 3D printers designed for composite engineering applications. If you’re keen to know more about them, you’ll find a variety of useful information below.

The Onyx 3D printer series is so-called “Onyx” because these printers print Markforged’s proprietary Onyx filament as the base filament.

Onyx filament is part nylon and part chopped carbon fibre. It’s jet black, twice as strong as ABS and boasts far superior abrasion resistance.

Another neat thing about Onyx is its dimensional stability. It doesn’t warp and there’s no thermal deformation even in thin areas and overhangs.

Onyx is engineered to print anything. It’s a replacement for ABS and similar plastics for intensive applications. You can create industrial 3D printed parts from prototypes to final products, such as grippers, cases, bumpers and hinges.

Onyx needs no dyeing to hide internal honeycombs and no chemical baths or sanding to get rid of those annoying 3D printed ridges. Parts come off the printer just how you designed them, with no post-processing needed!

Onyx ProIn a nutshell: Printed parts can replace machined aluminium parts.

The Onyx Pro is the top-spec Onyx 3D printer. In addition to Onyx filament, it also prints fibreglass with a second extruder.

Using Onyx filament as the base material, the Onyx Pro reinforces parts with continuous strands of fibreglass. The result is parts that are 10x stronger than ABS (Onyx on its own is 2x stronger) with the abrasion resistance of carbon fibre.

The internal part geometry is closed cell infill with Continuous Fibre Reinforcement (CFF) which is a modified version of FFF with the addition of fibre. This means the closed cells are reinforced with fibreglass for consistent strength.

Parts that are reinforced with fibreglass can replace machined aluminium parts, offering an exciting range of possibilities for engineering applications.

Onyx OneIn a nutshell: Printed parts can replace high-performance plastic parts.

The Onyx One is the entry-level Onyx 3D printer. It only prints Onyx filament, so it lacks the ability to print fibreglass like the Onyx Pro.

Other than that significant difference, the Onyx One is the same as the Onyx Pro. That means you get the same 320 x 132 x 154 mm (12.6 x 5.2 x 6 in.) build volume and the same precision composite print bed designed for thousands of cycles.

Other specifications shared between the printers include a 100 μm – 200 μm Z resolution and the same physical dimensions (although the Onyx One is 1kg lighter at 15kg). The only significant difference is the Onyx One only prints Onyx filament.

Is Onyx filament enough for your use case? It can replace ABS and other plastics to create housings, mounts, grippers and non-mechanical parts. However, it can’t replace aluminium parts. For that, you want the Onyx Pro’s fibreglass reinforcement.

Need help choosing?

No problem. Give us a call on 01765 694 007 to discuss the Markforged Onyx One and Onyx Pro with our experts. Alternatively, email [email protected].

PA11 Onyx from Sinterit: material for SLS printing

The Polish company Sinterit, which recently developed and presented to the public a new SLS 3D printer Lisa Pro, offers a material for use in this device - PA11. This novelty is a high-performance polymer powder type, and the well-known nylon is used as the base. The developers dubbed the new product PA11 Onyx.

This novelty is a high-performance polymer powder type, and the well-known nylon is used as the base. The developers dubbed the new product PA11 Onyx.

According to Sinterit, the PA11 Onyx is quite unique. Its main purpose is 3D printing by selective laser sintering on desktop 3D printers. The main advantages of the material, defined as characteristics, are high resistance to:

- abrasive;

- chemical aggressors;

- blows.

That's why the PA11 is said to be a reliable and robust solution for industrial and electrical applications.

Initially, PA11 materials were not in high demand and were not distributed. The main reasons for this were inaccuracy issues with 3D printing, which used the previous generation of equipment working on SLS technology. According to Jane Kittanen, a designer who worked with Sinterit, the reason was problems in controlling the heating of the powder material on the large platform. This was the Achilles' heel of previous generation 3D printers. The designer notes that in desktop 3D printers, the platform is smaller and therefore completely different conditions are formed when printing. At the same time, for PA11, and not only for it, but also for other materials, it was this factor that opened up interesting prospects. nine0003

The designer notes that in desktop 3D printers, the platform is smaller and therefore completely different conditions are formed when printing. At the same time, for PA11, and not only for it, but also for other materials, it was this factor that opened up interesting prospects. nine0003

Sinterit PA11 Onyx is a lightweight bioplastic derived from plant materials. Compared to its sister nylon 12, it is characterized by the highest heat resistance, chemical inertness and flexibility of use for 3D printing by desktop 3D printer models. The material is also characterized by high impact resistance, which is achieved due to high elongation at break. Thus, PA11 Onyx is an ideal material suitable for use in harsh environments, as well as for protecting a variety of items, including electronic gadgets. nine0003

PA11 Onyx tests have confirmed its performance. A 3D printed case for storing military goggles was used as an experience. These cases withstand the rigors of being used by soldiers in harsh environments. At the same time, the requirements for the case are very serious: it must be practical, durable and not react to any atmospheric phenomena. Studies have shown that a PA11 Onyx case can be opened and closed over a thousand times without showing any signs of wear. nine0003

At the same time, the requirements for the case are very serious: it must be practical, durable and not react to any atmospheric phenomena. Studies have shown that a PA11 Onyx case can be opened and closed over a thousand times without showing any signs of wear. nine0003

PA11 Onyx can also be used to print custom protective cases, cases, etc. It can be, for example, a case for a Rasberry Pi computer. According to Konrad Glowacki, founder of Sinterit, partners and customers of the company use a variety of gadgets in their lives. Including the Rasberry Pi, which simply needs a case that protects against negative external phenomena. PA11 Onyx fully complies with the requirements that apply to the material from which such cases can be made. In particular, these requirements include elasticity, shock and heat resistance. nine0003

The Sinterit Lisa Pro has a nitrogen chamber that can provide the PA11 Onyx with ideal conditions for 3D printing. The company announced that it is releasing the Lisa Pro in May 2018 and so far several samples have already been delivered.

The original Sinterit Lisa printer has been upgraded with a larger workspace thanks to a hardware and software upgrade. Now both of these 3D printers, together with P12, TPU materials, will be presented at Formnext 2018, which will be held in Frankfurt. They can be seen in hall 3.1, booth G41. nine0003

LLC "3D" from St. Petersburg - TIN, KPP, PSRN, information on participation in construction tenders and bidding for the supply of

Reason for complaint

Return Subscribe to changes

LIMITED LIABILITY COMPANY "3D"

Reliability indicators

Financial indicators

Income, thousand ₽

2021 6590.07% 14,124,000.00 RUB

2020 211 119.00 ₽

Expenses, thousand ₽

2021 8821.53% 18,809,000.00 RUB

2020 210,827.00 ₽

Pension fund insurance premiums, thousand ₽

2021 31.55% 310,879.77 RUB

2020 454,152.65 RUB

In 2021, the income of the LIMITED LIABILITY COMPANY "3D" increased by 6590. 07% and amounted to 14,124,000.00 ₽. Consumption increased by 8821.53% - 18 809000.00 RUB. For 2021, the organization contributed to the FIU 310,879.77 ₽, which is 31.55% lower than the previous year 2020.

07% and amounted to 14,124,000.00 ₽. Consumption increased by 8821.53% - 18 809000.00 RUB. For 2021, the organization contributed to the FIU 310,879.77 ₽, which is 31.55% lower than the previous year 2020.

Purchaser

Total amount under contracts with suppliers

0 ₽

There is no information about current tenders and completed purchases of LIMITED LIABILITY COMPANY "3D".

Procurement participant

Total amount under contracts with customers

4,019,506.05 RUB

76.98%3,094,135.00 RUB

COMMITTEE ON STATE PROCUREMENTS OF THE REPUBLIC OF DAGESTAN

16.37%657,794.50 ₽

MUNICIPAL BUDGET GENERAL EDUCATIONAL INSTITUTION SECONDARY EDUCATIONAL SCHOOL №93, BARABANSKY DISTRICT, NOVOSIBIRSK REGION

6.66%267,576.55 ₽

ST. PETERSBURG STATE BUDGETARY INSTITUTION "PETROGRADSKY YOUTH CENTER"

The company sold goods

Components (spare parts) of other electrical equipment that do not have independent groups0003

673

Natural polymers and polymers modified natural in primary forms, not included in other groups

27

Circles of grinding

10

Poles Protection

6

Princes

9000 43D PINDICAL PRECTIONA

3

LIMITED LIABILITY COMPANY "3D" participated in 6 purchases and became the winner in 3 of them.