Kyocera 3d printer

Kyocera Unveils “CAM” Customized 3D Printing for Medical Device Prototypes at MD&M West | News

San Diego, Calif. – August 5, 2021 – Kyocera, a leader in ceramics-based medical devices, will unveil its “CAM” (ceramic additive manufacturing) customized 3D printing service for cost-effective prototypes of new medical device designs at the MD&M West Medical Expo in Anaheim, Calif., August 10-12, the world’s largest annual convention for medical product designers and manufacturers. Kyocera’s new service utilizes both zirconia and alumina materials in a wide variety of shapes, a size range of 200 x 105 x 40mm and wall thickness of 0.25-10mm. The simple 3-step process rapid-produces samples: simply send a 3D CAD file, complete a consultation the next day and then prototypes are created in 1-2 weeks*. Additionally, Kyocera will also be showcasing its wide range of ceramics-based medical technologies during the expo.

Rapid Custom Samples with CAM

Incorporating 60+ years of product development expertise, Kyocera’s engineers consult on each new project and devise the most cost-effective method for a 3D printed prototype of new medical device designs. With that consultation and 3D printing using zirconia and alumina, Kyocera is able to produce virtually any kind of customized prototype in 1-2 weeks. Kyocera’s ceramics offer scratch resistance, higher rigidity, temperature resistance, longer lifetime, high-voltage insulation, lighter weight, and superior thermal management, providing an overall lower cost of ownership. 3D capabilities include:

- Shapes: Curved, Square, Angled, Sharp edges, Angled holes, Negative draft, Threads, Textures, Tiny holes

- Materials: Zirconia, Alumina

- Size: 200 x 105 x 40 mm

- Tolerance: +/-0.050 mm (as-fired)

- Wall Thickness: 0.25 – 10 mm

- Interlocking Assembly

- Smooth Surface

Additive Manufacturing and More @ Kyocera Booth #2363 MD&M West

According to MD&M West, the global medical device manufacturing market is expected to exceed $200 billion by 2025, largely due to an aging population, chronic disease and advancements in technology to help various conditions. Kyocera continues to use its unique ceramic “superhero” materials to help advance medical technologies. The Company’s Fine Ceramics provide a highly durable, long-lasting, non-reactive material that can be found in solutions for genetic sequencing; microfluidic tools; X-ray, PET, MRI and CT scan machines; pacemakers and cardiac monitors; neuromodulation devices; surgical tools; drug testing devices and orthopedic joint replacement systems. Information on these innovative ceramic medical solutions and more will be on display at Kyocera’s booth throughout the show.

Kyocera continues to use its unique ceramic “superhero” materials to help advance medical technologies. The Company’s Fine Ceramics provide a highly durable, long-lasting, non-reactive material that can be found in solutions for genetic sequencing; microfluidic tools; X-ray, PET, MRI and CT scan machines; pacemakers and cardiac monitors; neuromodulation devices; surgical tools; drug testing devices and orthopedic joint replacement systems. Information on these innovative ceramic medical solutions and more will be on display at Kyocera’s booth throughout the show.

Click to learn more about Kyocera’s medical solutions. To schedule a dedicated booth appointment or for more information on “CAM,” please email [email protected].

*Rapid production in 7-14 days if hard grinding or polishing is not required. Each project production timeline will be estimated based on consultation.

About KYOCERA

Kyocera Corporation (TOKYO: 6971), the parent and global headquarters of the Kyocera Group, was founded in 1959 as a producer of fine ceramics (also known as “advanced ceramics”). By combining these engineered materials with metals and integrating them with other technologies, Kyocera has become a leading supplier of industrial and automotive components, semiconductor packages, electronic devices, smart energy systems, printers, copiers, and mobile phones. During the year ended March 31, 2021, the company’s consolidated sales revenue totaled 1.5 trillion yen (approx. US$13.8 billion). Kyocera is ranked #603 on Forbes magazine’s 2021 “Global 2000” list of the world’s largest publicly traded companies, and appears on The Wall Street Journal’s latest list of “The World’s 100 Most Sustainably Managed Companies.”

By combining these engineered materials with metals and integrating them with other technologies, Kyocera has become a leading supplier of industrial and automotive components, semiconductor packages, electronic devices, smart energy systems, printers, copiers, and mobile phones. During the year ended March 31, 2021, the company’s consolidated sales revenue totaled 1.5 trillion yen (approx. US$13.8 billion). Kyocera is ranked #603 on Forbes magazine’s 2021 “Global 2000” list of the world’s largest publicly traded companies, and appears on The Wall Street Journal’s latest list of “The World’s 100 Most Sustainably Managed Companies.”

Kyocera to Showcase Customized 3D Printing, Cordierite and More at Ceramics Expo in Cleveland

Kyocera Fine Ceramics at Ceramics Expo 2021.

Kyocera’s ceramics conduct heat, but not electricity; they resist abrasion and are impervious to corrosion; they can be machined to extremely precise dimensions and still withstand temperatures that would melt most metals.

CLEVELAND (PRWEB) August 31, 2021

Kyocera has been advancing Fine Ceramics for 60 years in healthcare, communication, automotive, renewable energy and space exploration, among other industries. A world leader in advanced ceramics, Kyocera will showcase a new customized 3D printing service for cost-effective ceramic prototyping, Cordierite ceramic for aerospace and Hi-Rel applications, and many other ceramics-based innovations at booth #726 during the American Ceramic Society’s 2021 Ceramics Expo, August 31-September 1 — the world’s largest annual, admission-free exposition for the advanced ceramic and glass community.

Kyocera’s new rapid, custom 3D printing service utilizes both zirconia and alumina materials in a wide variety of shapes and sizes. The simple 3-step process rapid-produces samples: simply send a 3D CAD file, complete a consultation the next day and then prototypes are quickly printed in 1-2 weeks*. Kyocera’s ceramics offer scratch resistance, higher rigidity, temperature resistance, longer lifetime, high-voltage insulation, lighter weight, and superior thermal management, providing an overall lower cost of ownership. 3D capabilities include:

Kyocera’s ceramics offer scratch resistance, higher rigidity, temperature resistance, longer lifetime, high-voltage insulation, lighter weight, and superior thermal management, providing an overall lower cost of ownership. 3D capabilities include:

- Shapes: Curved, Square, Angled, Sharp edges, Angled holes, Negative draft, Threads, Textures, Tiny holes

- Materials: Zirconia, Alumina

- Size: up to 200 x 105 x 40 mm

- Tolerance: +/-0.050 mm (as-fired)

- Wall Thickness: 0.25-10 mm

- Interlocking Assembly

- Smooth Surface

Cordierite Fine Ceramics and More Innovations

Kyocera’s latest innovations in Cordierite Fine Ceramics will also be highlighted at this year’s expo. Perfect for aerospace and Hi-Rel applications, Cordierite is found in the Subaru telescope in Hawaii where 18 individual Kyocera Cordierite components support a camera lens that looks at galaxies billions of light-years away. Lightweight, strong and highly versatile, Kyocera’s Cordierite is perfect for semiconductor equipment, optical components and robotic spacecraft, with these key features:

Lightweight, strong and highly versatile, Kyocera’s Cordierite is perfect for semiconductor equipment, optical components and robotic spacecraft, with these key features:

- Low coefficient of thermal expansion (CTE)

- Lightweight – approximately 70% weight reduction compared to conventional low-CTE glass+ via slim ribbed structure designed for high rigidity

- Highly versatile for complex parts

- Outstanding dimensional stability and rigidity

Additionally, Kyocera will showcase a number of other advanced ceramic innovations including:

- Highly specialized manufacturing for various industries: additive or machining; threaded holes, multiple holes

- Metallization technology, by which ceramics are “metallized” for soldering or brazing directly to metals

- Single-crystal sapphire, an ultra-hard, pure and transparent material used in applications ranging from highly scratch-resistant windows to LED substrates

- Heat-resistant ceramics used in foundries, gas turbines and automotive engines

- Chemical-resistant ceramics for pump, valve and seal components exposed to corrosive fluids

- Gas nozzles for high-temperature furnace applications, supporting rings for semiconductor processing equipment, and sealing ring samples

- High purity Alumina (A480S) crucibles

- Mud pump liners

- Plastic injection over molding for textile components

“Today’s ceramics are a key material fueling innovations in electronics, IoT, automotive, aerospace and medical technologies, to name a few,” said Mr. Mark Wolf, Kyocera International, Inc.’s V.P. of Fine Ceramics Group. “Although lightweight, Kyocera’s ceramics are among the strongest and hardest known materials. They conduct heat, but not electricity; they resist abrasion and are impervious to corrosion; they can be machined to extremely precise dimensions and still withstand temperatures that would melt most metals. And now, we’re able to create rapid prototypes to help speed up the design and manufacturing process for tomorrow’s innovations.”

Mark Wolf, Kyocera International, Inc.’s V.P. of Fine Ceramics Group. “Although lightweight, Kyocera’s ceramics are among the strongest and hardest known materials. They conduct heat, but not electricity; they resist abrasion and are impervious to corrosion; they can be machined to extremely precise dimensions and still withstand temperatures that would melt most metals. And now, we’re able to create rapid prototypes to help speed up the design and manufacturing process for tomorrow’s innovations.”

Wolf will moderate a panel discussion, “Reimagining the Supply Chain: Lessons for Efficiency in the Wake of the COVID-19 Pandemic,” at 9:30am, August 31, at the Expo.

Kyocera offers ceramic materials in approximately 200 different formulations, including Aluminum Oxide, Aluminum Nitride, Cermet, Cordierite, Forsterite, Mullite, Sapphire, Silicon Carbide, Silicon Nitride, Steatite, Yttria, Zirconia, and others. The company has developed a wide range of proprietary process technologies that can incorporate dry-pressing, cold-isostatic pressing, hot-isostatic pressing, injection molding, tape casting, multilayering and/or metallizing ceramics.

Click to learn more about Kyocera’s Fine Ceramics solutions. To schedule a dedicated booth appointment or for more information on customized 3D printing, please email [email protected].

*Rapid production in 7-14 days if hard grinding or polishing is not required. Each project production timeline will be estimated based on consultation.

+Based on Kyocera research

About KYOCERA

Kyocera Corporation (TOKYO: 6971), the parent and global headquarters of the Kyocera Group, was founded in 1959 as a producer of fine ceramics (also known as “advanced ceramics”). By combining these engineered materials with metals and integrating them with other technologies, Kyocera has become a leading supplier of industrial and automotive components, semiconductor packages, electronic devices, smart energy systems, printers, copiers, and mobile phones. During the year ended March 31, 2021, the company’s consolidated sales revenue totaled 1.5 trillion yen (approx. US$13. 8 billion). Kyocera is ranked #603 on Forbes magazine’s 2021 “Global 2000” list of the world’s largest publicly traded companies, and appears on The Wall Street Journal’s latest list of “The World’s 100 Most Sustainably Managed Companies.”

8 billion). Kyocera is ranked #603 on Forbes magazine’s 2021 “Global 2000” list of the world’s largest publicly traded companies, and appears on The Wall Street Journal’s latest list of “The World’s 100 Most Sustainably Managed Companies.”

3d printer - Cartridge Master

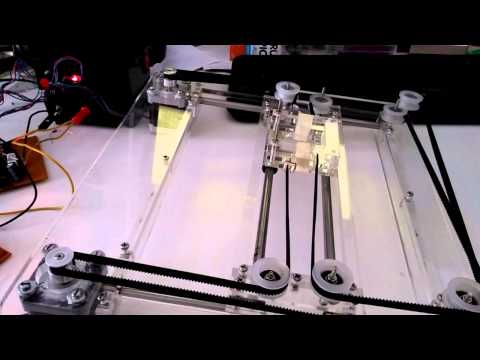

We have already more than felt the era of 3D technologies - 3D glasses, monitors, screens, TVs and much more, which does not affect our eyes in the most favorable way. In this article, we will not talk about simple visualization of objects, but about their creation in three-dimensional format using 3D printers.

Today it is not difficult to transfer text or an image from a monitor to a sheet of paper. Today's printers and scanners perform these tasks just fine. With the help of 3D printers, you can transfer a three-dimensional part, the model of which is made in certain applications. nine0003

Thanks to 3D printing, you can create the right prototype in the shortest possible time and subject it to all the necessary tests in order to avoid possible problems even before the creation of the original item.

3D printing technology dates back to the mid-1980s. The first models of 3D printers were very expensive, and therefore not widely used. But over time, their cost has slightly decreased, and the equipment market has "acquired" the first serial three-dimensional models. The principle of operation of a 3D printer is that a three-dimensional object is created from several hundreds, and sometimes thousands of layers of material. Gypsum, plastic, and even soft metals such as copper or aluminum can be used as a material. nine0003

Printing in 3D printers can be laser or inkjet. Laser sintering technology: fusible plastic powder is used as the raw material. With the help of a laser, a future part is cut out on this powder. The powder is gradually heated, melted, and then sintered. Then another layer of powder is poured, and the whole procedure is repeated again. With the help of laser sintering, you can get high-quality and fairly durable models in a short time. Particularly noteworthy is the fact that metal products can be printed in this way. In this case, metal shavings “rolled” in small polymer particles are used as the starting material. nine0003

In this case, metal shavings “rolled” in small polymer particles are used as the starting material. nine0003

Inkjet creation of a 3D model looks a little different. In some ways, it resembles the operation of a conventional printer. But instead of paint, heated plastic is squeezed onto the cooled platform. The substance hardens quite quickly, after which the next layer of the planned part is squeezed out.

NASA is planning to use these 3D printers in spacecraft that are going on long missions. At some point, astronauts may need a particular part to replace or repair. And then a compact printer with various source materials can fully replace an entire machine shop. nine0003

Do you still think that a 3D printer is nothing more than a toy in the hands of designers? And how do you like this fact:

During the London air show, Loskheed Martin presented to the public a functioning prototype of a stealth aircraft with a wingspan of 27 meters. Almost all of its details were created using a 3D printer. It took only a year and a half and 27 million dollars to manufacture the aircraft, which, by the standards of military equipment, is simply a ridiculous amount. The aircraft can rise to a height of twenty kilometers and move at supersonic speeds. Impressive, isn't it...

It took only a year and a half and 27 million dollars to manufacture the aircraft, which, by the standards of military equipment, is simply a ridiculous amount. The aircraft can rise to a height of twenty kilometers and move at supersonic speeds. Impressive, isn't it...

Every day, the possibilities of 3D printing are expanding, and the cost of units is becoming more affordable.

A 3d printer is very important in today's world. Long live 3d printers.

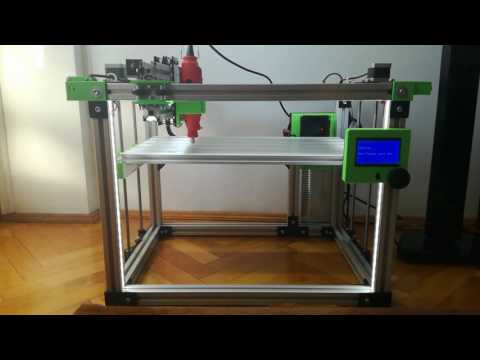

Cactus Micro C1 - the first affordable and compact 3D printer from CACTUS

Home/About the company/News

29 September 2017

Cactus Micro C1 - the first affordable and compact 3D printer from CACTUS nine0031

The concept of "3D" is firmly established in our daily lives. There is hardly a person now who has not heard about such a novelty as 3D printing at least once in his life.

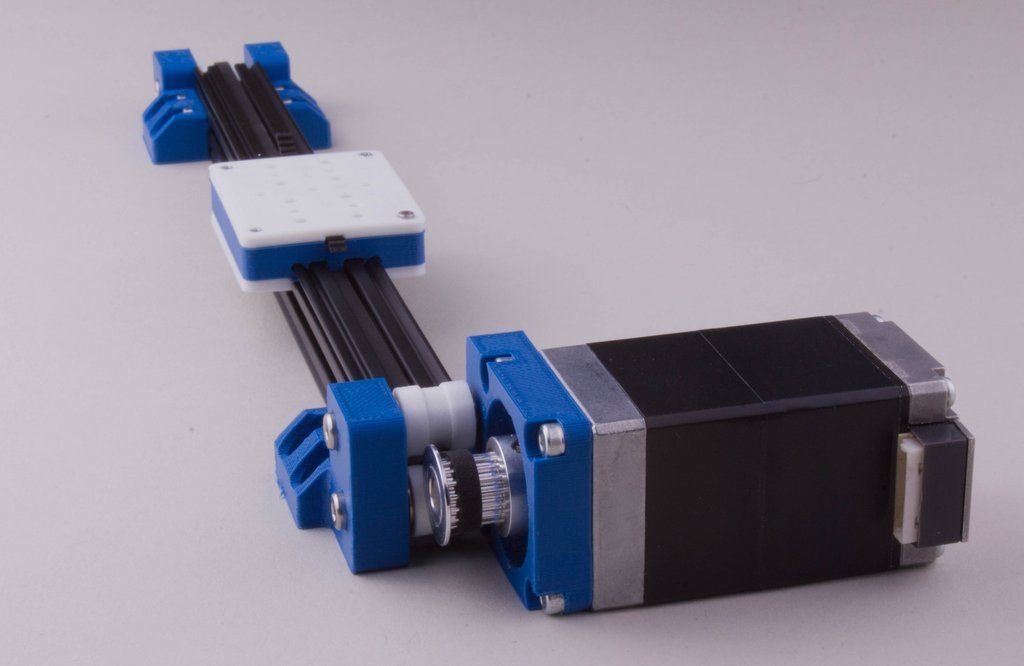

3D printers are becoming more affordable and versatile. Today, there are many different 3D printing technologies. The new Micro C1 3D printer uses FDM technology, which makes it possible to create not only models, but also final parts. This technology has proven itself well and has become widespread. nine0003

Today, there are many different 3D printing technologies. The new Micro C1 3D printer uses FDM technology, which makes it possible to create not only models, but also final parts. This technology has proven itself well and has become widespread. nine0003

The Cactus Micro C1 is very compact and lightweight, measuring only 20 cm in height and width, fits in a backpack and weighs no more than 1.4 kg. You can easily take it with you to visit friends, school, laboratory, creative studio, office. He will become an indispensable assistant. Currently, the range of possibilities and applications of 3D printing is constantly growing. Everything turned out to be subject to these technologies:

- Modeling in architecture and industrial design

- Prototyping parts and mechanisms

- Aeromodelling and car modeling

- Training and education

- Costume and cosplay

- Artistic use - art objects, figurines and parts thereof

- Printing jewelry, bijouterie

- Printing toys and figurines

- Assistant in minor repairs and everyday life

Cactus Micro C1 is incredibly light and easy to use: 4 magnets on the table and inside the printer save time and position and secure the print table. This technology will save you from waiting for the table to heat up, cool down and use glue. Be sure - the table will be in its place. nine0003

This technology will save you from waiting for the table to heat up, cool down and use glue. Be sure - the table will be in its place. nine0003

Cactus Micro C1 is very easy to use and understandable even to a child. It works under any operating system - macOS, Windows, Linux. Using the simplest commands, printer settings are easily changed.

Cactus Micro C1 only works with environmentally friendly and non-toxic materials such as PLA, PLA PRO, PET-G, FLEX, WOOD. That is why you can not worry about the health of children and adults when working with it.

Cactus Micro C1 is an affordable and compact printer for every home and beyond. It will also handle small batches and save money as it can produce up to 5 times more products in the same time than a large professional 3D printer. nine0003

Develop your imagination, make the world special!

Cactus, we make the impossible possible.

Specifications:

Weight: 1.4 kg

Printer size: 20x20x20 cm

Platform adhesion: 100%

3D printing technology: FDM

Print area: 10x10x10 cm

Layer thickness: 100 µm

Thread diameter: 1.