3D printed arcade buttons

3D Printing | Arcade Button Control Box

3D Printing

Save Subscribe

Please sign in to subscribe to this guide.

You will be redirected back to this guide once you sign in, and can then subscribe to this guide.

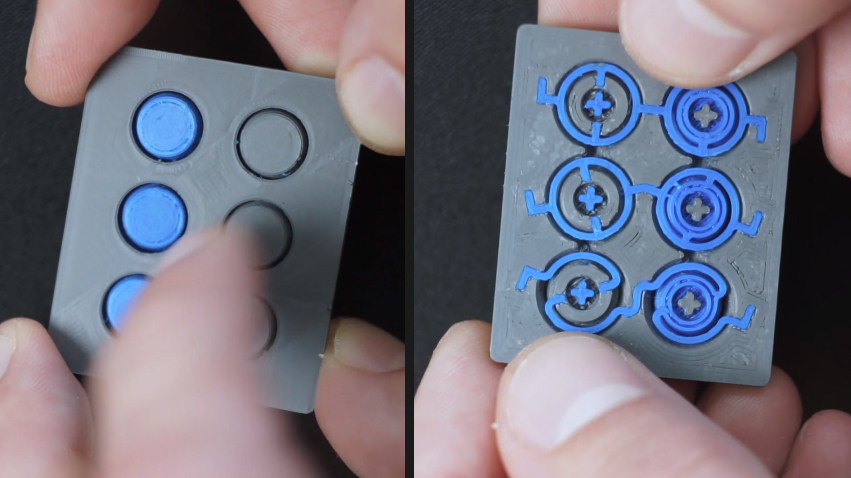

3D Printed Parts

This enclosure I designed for this project is a two piece design. The enclosure and the "snap-on" cover. There are several version of the enclosure that feature a number of different buttons layouts. For example, 2 by 2, 3 by 2 and a 4 by 4 button layout. You can choose which ever enclosure best suits your project.

Filaments

You can use regular PLA filament or composite and strong materials. Just be aware the tolerance may vary when using materials other than PLA.

Download STLs from YouMagine

Download STLs from Pinshape

Download STLs from Thingiverse

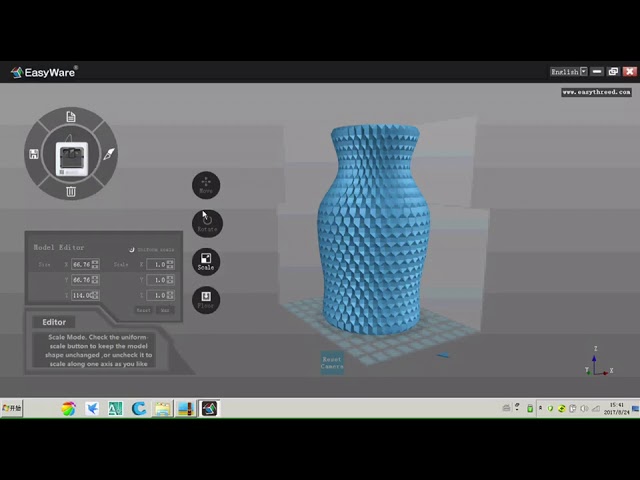

Modify Case Design

If you'd like to make adjustments to the case, you can download the Fusion 360 Archive for free and modify the model using your preferred CAD modeling program (STEP, IGHS, Solidworks, STLs, etc. ). The design is parametrically driven with User Parameters, so it's very really update values such as the tolerances, thickness, height and number of buttons. The design will automatically update and scale depending on the values. Watch my "Layer by Layer" tutorials to get an in-depth walkthrough of the model.

Download Fusion 360 Source

User Parameters

This is a list of the available parameters that you can quickly modify. To get these, simply open the "Change User Parameter" dialog under the Modify toolset.

- across & down: these control the amount of arcade buttons in the case.

- spacing: the amount of space between the arcade buttons.

- offset: the amount of "padding" around the outer edge of the case.

- height: overall height of the case.

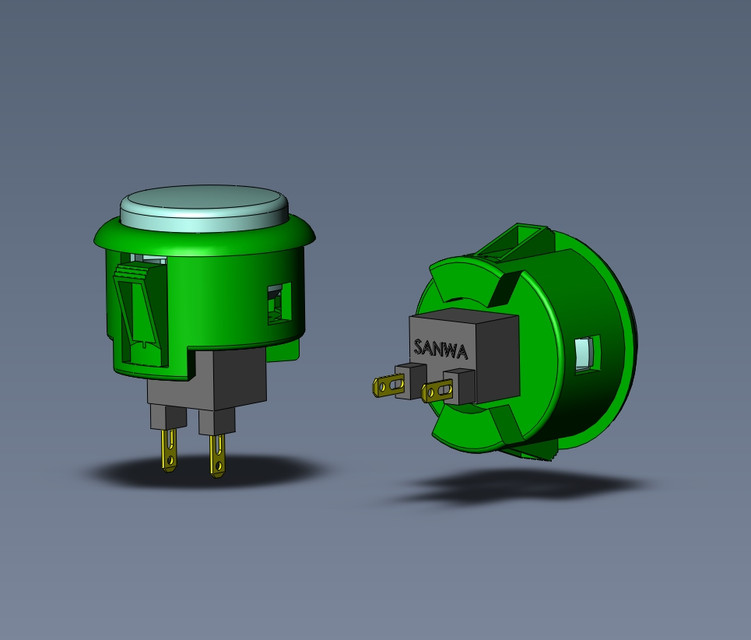

- diameter: the diameter of the arcade button's cutout.

- hole: the diameter hole on the four standoffs for the Adafruit Feather board.

- gap: the "gap" or clearance between the surfaces that touch (snap fitting cover)

- shell: the thickness of the enclosure.

- lipcut: the width of the opening in the lip of the cover (allows clearance for the Feather)

Software Assembly

This guide was first published on Jun 28, 2017. It was last updated on Jun 28, 2017.

This page (3D Printing) was last updated on Nov 13, 2022.

Text editor powered by tinymce.

Free STL file DBSF24-Lite A.K.A 24MM Arcade Button casing for cherryMX style switch・3D printing design to download・Cults

DBSF30-Lite A.K.A 30MM Arcade Button casing for cherryMX style switch

Free

PS4 Controller/DS4 holder for modular mounting system

Free

Razer Tartarus v2 Thumbstick Mod

Free

Nintendo Switch Rail Protector with Stand

Free

Best 3D printer files of the Various category

Star Wars Fiddler 10 (Droids)

€4

AYVA Guitar

€4. 90

90

Steampunk Snail

€1.55

Phone Speaker

€0.76

Rick Sanchez - LowpolyPOP Figurine Collection

€2

Irish ThugLife

€3

peq box airsoft

Free

Stience Gun from Disenchantment

€4

Best sellers of the category Various

Gremlin 640mm FPV Plank

€0.98

ItsLitho "Swirl" personalized lithophane Christmas ball

€1.90

Polestar 2 cup holder

€5.85

Ciberpunk 2077 Rebecca's Gun "Guts"

€4 -25% €3

Targaryen Crown - Viserys - House Of The Dragon

€11. -20% €9.33 66

66

Middle Finger Keyholder

€1

Mickey Christmas night light lithophane

€3.50

Halloween Haunted House Lamp w 3d Moon-NO SUPPORT or PAINTING NEEDED

€6.87

Articulated Rayquaza Flexible Pokemon Dragon

€1

ItsLitho "Drop" personalized lithophane Christmas ball

€1.90

Gyarados - Articulated Seasnake

€1.50

Adderini - 3D Printed Repeating Slingbow / Crossbow Pistol

€6.25

ItsLitho "Creamy" personalized lithophane Christmas ball

€1.90

RS-X-Bow "Government - 1911" style

€6. 25

25

articulated shenron

€3

Speeder-Pad support on FLSUN V400 and FLSUN SuperRacer

€3

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

STL file Arcade button・Template for download and 3D printing・Cults

LOVE TO THE MOON

3. 67 €

67 €

Latch kit for screen doors RV

1.96 €

Pipe construction kit

€5.88

2D Skull Art

2.69 €

Baby Jesus

€2.78 -fifty% 1.39 €

Primo pump for American Maid bottle

2.01 €

Wall hanger with half moon

2.46 €

American flag stencil

0.93 €

Best 3D printer files in Game category

Phenix

9 €

Humber Scout Car 1/56(28mm)

6,50 €

Italian sports car

4. 49 €

49 €

Lego parts - lego car

3 €

Tom Nook Animal Crossing

4.89 €

a10-Wartog

Free

AMONG US - REACTOR

0,64 €

Year of the Ox

Free

Bestsellers in the Game category

CRAMER Truggy RC 4x4 Full 3D Printed

€7.50

Cute flexi unicorn

1.05 €

Bicycle

1.40 €

GIANT CROCODILE HINGED

4.31 €

USS EnterSurprise - Play container for tiny F14 jet fighters

3. 91 €

91 €

Enourmous Imperial heavy tank

10 €

Space Dwarf All - terrain vehicle

15.67 €

Vodfolk Explorer

9.79 €

Good flexi dragon

1.77 €

Dancing Skeleton

3.43 €

Lazy Cat

3.91 €

Heavy Imperial Fire Support Weapon [Preliminary Support]

5 €

Savages Fotianna

9.79 €

Catafrac Heavy Armored Warriors - Civil War Wargear Pack

2,50 €

Lev Fu

5.50 €

Snake and rattlesnake

3. 91 €

91 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments. Here are 4 solutions available to everyone:

-

AD: Disable the AdBlock banner blocker and click on our advertising banners.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

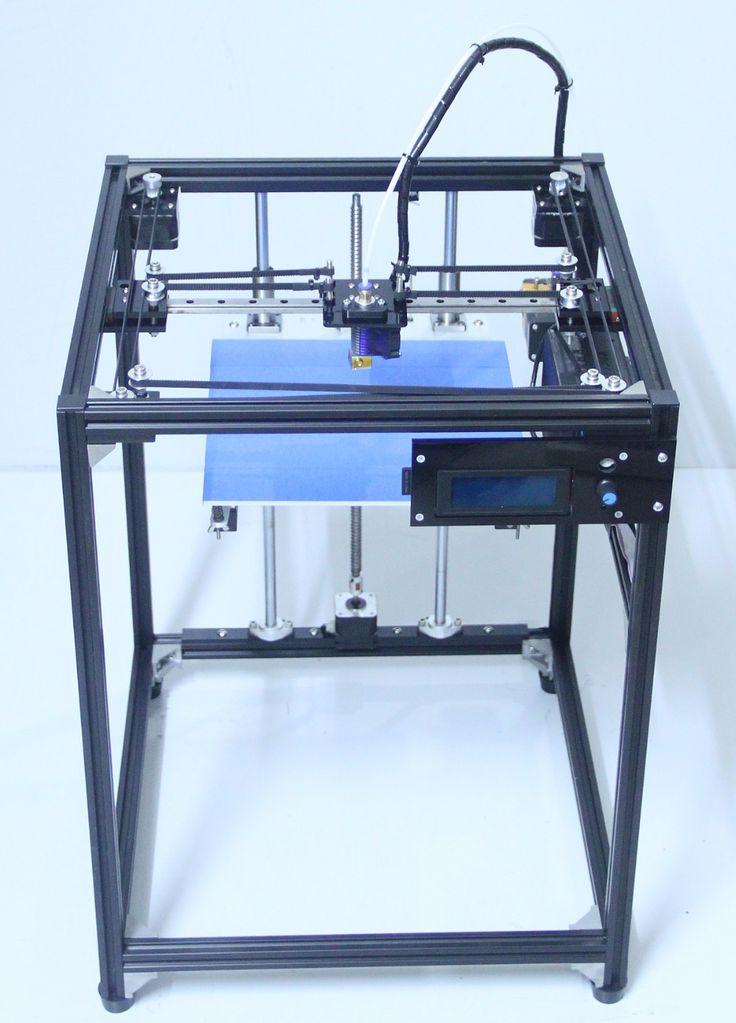

The Complete Guide to 3D Printing [Part 2]

3D printing is used in a variety of industries, both for rapid prototyping and short-term production.

In various industries, a key application of 3D printing is the rapid prototyping of new parts during R&D. No other technology has the capability to instantly produce plastic or metal parts - even in non-factory conditions.

3D printers can be used in-house by companies, while some businesses prefer to order 3D printed prototypes through service bureaus.

Medical

3D printing can be used to make medical components such as titanium implants and surgical guides (SLM), 3D printed prostheses (SLS, FDM) and even 3D bioprinted human tissues. Components for medical equipment and technology - X-ray machines, MRI, etc. - can also be made by 3D printing.

SLA and SLS technologies are also widely used in the dental industry for model making, prostheses and restorations.

Aerospace

The aerospace industry has become a major consumer of 3D printing technology because it can produce very light parts with an excellent strength-to-weight ratio. Examples include things as simple as cab bulkheads (SLS) and down to revolutionary engine components (SLM) such as the 3D printed fuel injector tip designed and manufactured by GE.

Examples include things as simple as cab bulkheads (SLS) and down to revolutionary engine components (SLM) such as the 3D printed fuel injector tip designed and manufactured by GE.

Cars

Automotive companies regularly use 3D printers to make one-off parts and repairs, as well as rapid prototypes. Common 3D printed automotive parts include brackets, dashboard components, and antennas (FDM).

More extreme examples include vehicles with large 3D printed metal structural components, such as early models from automotive startup Divergent.

Jewelry and art

3D printing technologies such as SLA are widely used (as an indirect fabrication process) in the production and repair of jewelry, while almost all types of 3D printers can be used to create art and sculpture.

Engineering

Advances in additive manufacturing with high quality workmanship have expanded the scope of applications in construction and architecture. Concrete 3D printing, which is a bit like FDM but with very wide nozzle extruders, plays an important role in this industry, but more common 3D printing technologies such as SLM can be used for products such as bridge structures.

Concrete 3D printing, which is a bit like FDM but with very wide nozzle extruders, plays an important role in this industry, but more common 3D printing technologies such as SLM can be used for products such as bridge structures.

3D printing file formats:

3D printing parts can be designed with standard CAD software, but 3D printers can only read certain file formats. There are four main file formats for 3D printing.

STL: The most common file format for 3D printers, STL contains part geometry information in the form of tessellated triangles. It does not contain information such as color, material, or texture. The file size is proportional to the detail, which can be a problem.

OBJ: Less common than STL, the OBJ file format encodes the geometry of a 3D model and can include curves and free-form surfaces in addition to tessellation. It can also contain color, material, and texture information, making it useful for full color processes.

3MF: Invented by Microsoft, 3MF is an XML-based format with small file sizes and a good level of error prevention. It has not yet been widely adopted, but is supported by companies such as Stratasys, 3D Systems, Siemens, HP, and GE.

AMF: The successor to the STL format, AMF is much more compact and allows you to tessellate both curved and flat triangles, making it much easier to encode parts of various shapes. Since its inception, the format has been slowly adopted.

3D printing settings and specifications:

3D printing uses specific terminology that may not be clear to beginners. These terms refer to printer settings and/or specifications that can affect how 3D printed parts turn out.

Infill

When making 3D printed parts, it may be necessary to specify an infill percentage, which refers to the internal density of the part. A low infill percentage will result in a mostly hollow part with minimal material holding the mold together; a high infill percentage will result in a stronger, denser, and heavier part.

Layer Height

Layer height, sometimes referred to as z-resolution, is the distance between one 2D part layer and the next. A smaller layer height means finer resolution (and higher possible level of detail) along the z-axis, i.e. top down. A low layer height is an indication of a high quality printer, but users can set a higher layer height for faster, more economical printing.

Print speed

The printer's print speed, measured in millimeters per second, indicates the speed at which the machine can process the source material. Like the layer height, this value can either be a measure of the printer's maximum speed or be user-defined: slower print speeds usually result in more accurate prints.

Print temperature

When applied to processes such as FDM, print temperature generally refers to the temperature of the hot end, the part of the print head that heats the thermoplastic filament. Some FDM printers are also equipped with a heated print bed, the temperature of which is specified by the manufacturer. In both cases, the temperature is usually controlled by the user.

In both cases, the temperature is usually controlled by the user.

Resolution

In 3D printing, resolution almost always refers to the smallest possible movement along the X and Y axes (width and depth) of either the laser beam (SLA, SLM, etc.) or the print head (FDM). This value is more difficult to measure than the height of the layer, and it is not always proportional to it.

Shells

Like wall thickness in injection molding, shell (or shell thickness) refers to the outer wall thickness of the 3D printed part. When 3D printing, users usually have to choose the number of shells: one shell = outer walls as thick as a 3D printer nozzle; 2 shells = twice the thickness, etc.

Color 3D printing:

Since 3D printing is primarily used as a prototyping tool, single color prints are sufficient for most applications. However, there are several options for color 3D printing, including high-end material inkjet printers, multi-extruder FDM printers, and post-processing options.

Inkjet Printing Technologies

Major 3D printing companies such as Stratasys, 3D Systems and Mimaki have developed 3D inkjet printers for printing materials and binders that can print 3D models in full color as well as 2D inkjet printers. However, these machines are expensive and the parts do not always have excellent mechanical properties.

Multi-extrusion

Several FDM 3D printers are equipped with two (or more) printheads, allowing you to simultaneously print on two spools of filament - different colors or even different materials - within the same print job. It's simple and affordable, but usually limited to two colors.

Filament replacement

Single extruder FDM 3D printer can produce multi-color prints. To do this, you need to pause printing at certain points and replace the spool of thread with a thread of a different color. This is a very slow method of applying color and does not allow precise control over where each color goes.

Adding color after printing

Many 3D printed parts can be dyed, tinted or painted after printing. While this adds another step to the process, it often strikes the best balance between quality and economy.

3D printed part post-processing:

Many 3D printed parts require at least some level of post-processing after leaving the print bed. This may include important processes such as the removal of supports, or additional cosmetic processes such as painting. Some processes apply to all or most 3D printing technologies, and some are specific to a particular technology.

Support Removal

3D printing technologies such as FDM and SLA require the installation of support structures (vertical struts between the printed layer and the part itself) to keep the printed object from breaking during the manufacturing process.

These supports must be removed when the part is finished. Some printers, such as dual-extrusion FDM machines, can print dissolvable support structures, allowing the support structures to be easily detached from the part using liquid chemicals. Insoluble supports must be manually cut from the part, leaving a mark that may need to be sanded down.

Insoluble supports must be manually cut from the part, leaving a mark that may need to be sanded down.

Wash and remove powder

Some 3D printing technologies (such as SLA) leave sticky marks on parts, while others (SLM, SLS) may leave powder marks. In these cases, the parts must be washed - manually or with a special machine - or the powder removed with compressed air.

Heat treatment

Many key 3D printing technologies print parts from materials that are not yet in their final chemical state after leaving the printing mold. Such details are sometimes called "green".

Many 3D printed metal parts require post-print heat treatment to increase layer fusing and remove contaminants. And bonded inkjet 3D printers, for example, produce parts that need to be stripped and sintered after printing to remove resin bond layers from inside metal parts.

Some 3D printed resin parts require post-curing after printing to increase their hardness and make them usable.

Surface Treatment

3D printed parts can be subjected to a wide variety of surface treatments, from textural treatments such as sanding and smoothing, to visual treatments such as painting and toning. Some technologies, such as FDM, can create a rather rough surface that requires sanding, while others, such as SLA, produce a much smoother surface.

Combination of 3D printing with other technologies:

3D printing does not have to be used as a separate process. Rather than being seen as a competitor to CNC machining and injection molding, it can actually complement these and other manufacturing processes.

Combination examples include:

- 3D print the main body of the part and then CNC mill the thin parts to tighter tolerances;

- 3D printable master pattern for investment casting or vacuum casting;

- 3D print the part and then injection mold using injection molding.

There are hybrid manufacturing systems that combine 3D printing with other technologies. For example, Mazak's INTEGREX i-400 AM and DMG MORI's Lasertec DED can perform both 3D printing and CNC milling.

For example, Mazak's INTEGREX i-400 AM and DMG MORI's Lasertec DED can perform both 3D printing and CNC milling.

Will 3D printing replace other manufacturing processes?

Analysts have long speculated about whether 3D printing could replace other manufacturing processes, including:

- Processing;

- Moulding;

- Casting.

However, despite the desire of AM equipment manufacturers to position 3D printing as an end-to-end manufacturing technology, in practice, 3D printing is still limited to some specific manufacturing operations, especially low-volume production of specific materials.

In some areas, 3D printing has certainly outpaced other processes. For example, rapid prototyping with inexpensive plastics like ABS now dominates 3D printing, as ABS is cheaper to print than machined. 3D printing also seems to have established itself as the ideal tool for making objects such as patient-specific titanium medical implants: the speed and geometric flexibility of 3D printing is hard to beat in these specific situations.

In addition, 3D printing is an ideal tool for making objects such as patient-specific titanium medical implants.

Despite this, processes such as CNC machining currently remain the best for producing high quality parts and prototypes from engineering materials such as POM, PEI, PPS and PEEK, with surface finishes far superior to 3D printing. . In addition, processes such as injection molding are still infinitely faster for mass production of simple plastic parts.

In addition, while additive manufacturing is one of the most significant technological advances in manufacturing, placing it in a stronger position in manufacturing in general, more established processes such as CNC and injection molding are also being improved to produce higher quality parts. .

3D printing will continue to take an increasing share of manufacturing jobs, but it will not completely replace other technologies.

What did 3D printing look like 10 years ago?

A decade ago, the nascent 3D printing industry was gearing up for what it believed would be a 3D printing revolution: a 3D printer in every home, allowing families to print new items they might need, such as a spare part for a refrigerator, a new toy for kids, or even components to build a second 3D printer.

In 2012-2014, FDM 3D printer manufacturers such as MakerBot actively promoted their 3D printers in the consumer market, trying to convince ordinary people that a 3D printer can improve their home life and work. However, it was clear that these companies were trying to exploit the novelty factor of 3D printing and that their products had no practical application; a 2012 MakerBot press release seems to prove it: Make an entire chess set at the touch of a button. Friends, classmates, colleagues and family members will see what you are doing and say "Wow!".

Just a few years later, this so-called 3D printing revolution clearly failed, and many 3D printer manufacturers began to rethink their goals, moving from consumer to professional and industrial markets, where there were more concrete (and profitable) applications of additive technology.

In addition, those who were already working in the professional and industrial fields - companies such as 3D Systems and Stratasys - began to try to destroy the image of 3D printing as a prototyping technology, positioning it as a viable mass production tool (which, obviously, , could be more profitable for the 3D printing industry, as manufacturers would have to fill entire factories with 3D printers, buy 3D printer management software, and hire 3D printing consultants).

What will 3D printing look like in 10 years?

3D printing companies have abandoned the prospect of putting a 3D printer in every home. However, in 10 years, they can expect some form of additive manufacturing to appear in more factories.

Although there is less talk about 3D printing today than in 2012, the technology continues to gain momentum in the professional and industrial world.

According to a recent report, market research firm 3DPBM Research expects the value of additive metal manufacturing to rise from $1.6 billion in 2020 to $30 billion by 2030, and this is largely due to the repositioning of AM as a manufacturing tool and the development of more high-performance engineering materials. (That said, 3D printing will remain a valuable prototyping tool in many industries, and prototyping applications will benefit just as much from technological advances.)

However, not only metal AM is being developed. Technologies such as HP's Multi Jet Fusion have opened up new possibilities for plastic printing, and innovators such as Carbon have developed new high-speed processes in the photopolymerization category. Niche areas such as 3D bioprinting and micro 3D printing are also regularly opening up new opportunities, and composite 3D printing (such as continuous carbon fiber 3D printing) is also on the rise: IDTechEX predicts that by 2030, the market size of composite 3D printing will be $1.7 billion

Niche areas such as 3D bioprinting and micro 3D printing are also regularly opening up new opportunities, and composite 3D printing (such as continuous carbon fiber 3D printing) is also on the rise: IDTechEX predicts that by 2030, the market size of composite 3D printing will be $1.7 billion

In short, 3D printing will gradually become a serious competitor to other manufacturing processes in many disciplines.

How to outsource 3D printing services?

Investments in 3D printing hardware and software are not suitable for all businesses, so many successful companies outsource their 3D printing needs to third parties, such as online 3D printing service bureaus (for one-time projects) or prototyping partners and production, such as 3ERP (for one-time projects or repeat orders).

When outsourcing 3D printing services, it is important to consider whether your business needs design and manufacturing services or just manufacturing services. (Keep in mind that a poorly executed 3D model may fail for 3D printing).