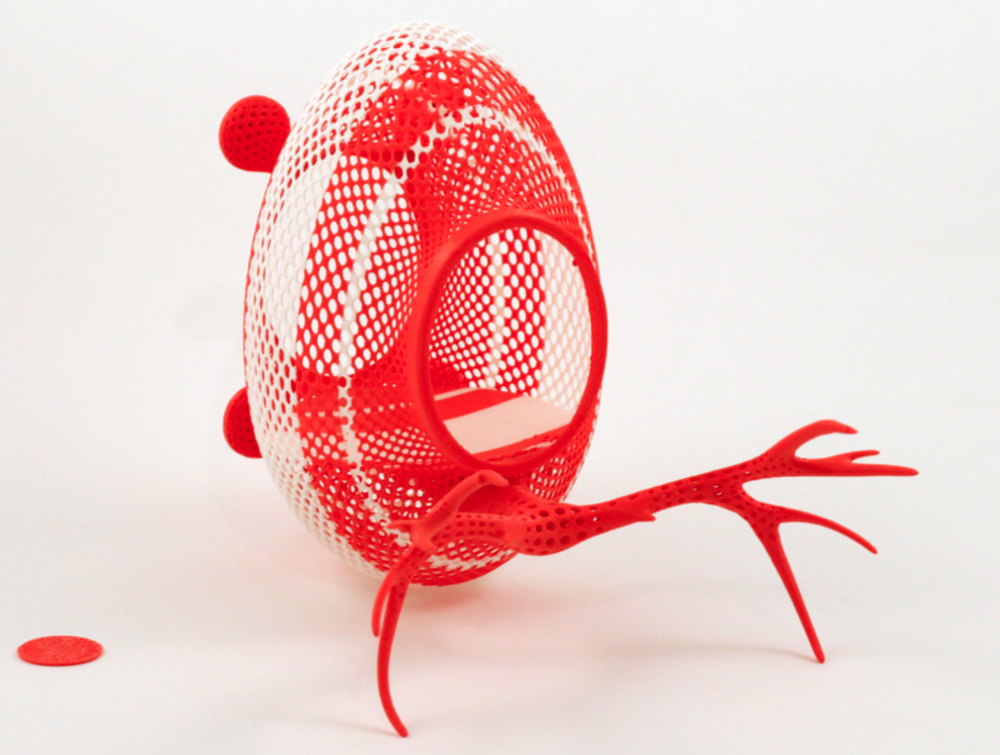

Bird feeder 3d print

🐦 Best STL files 3D printed of birdhouses・Cults

🐦 Best STL files 3D printed of birdhouses

Download free birdhouses 3D files

Discover our selection of STL files of beautiful 3D printable nest boxes and birdhouses to add a touch of 3D printing to your garden, balcony or even window sills. You will find in this collection all the 3D models to help birds and watch them!

Birdhouse

Free

Bird fat ball house feeder

Free

Mushroom fat ball birdhouse feeder

Free

Birdhouse

Free

The Light Sky Bird Temple

Free

Mangeoire à oiseaux Support boule de graisse / Bird feeder fat ball holder

Free

Harry Potter Birdhouse

Free

Birdhouse

Free

Gnomes Birdhouse

Free

Bird feeder

Free

Ramshackle Birdhouse

Free

Bird Water Trough

Free

CUTE CARAVAN BIRDHOUSE

€2. 32

Bird feeder on PET bottle 38 mm

Free

Birdhouse feeder

Free

Multicolor mushroom fat ball birdhouse feeder

Free

Birdhouse 16eme

Free

nesting box for chickadees/birdhouses

Free

Birdhouse -3 pieces

€3.80

Bird Feeder

Free

Vogel Futterspender / Bird food dispenser

Free

Easy Print Bird Box

Free

Bird Feeder - Pole Mounted

Free

Little Bird Feeder Air Temple

Free

Flowing Bird Temple

Free

Birdbath

Free

Nesting box flower pot

Free

SodaStream Bird Feeder with Roof

Free

Simple Bird House

Free

Easy to refill PET-bottle Bird feeder

Free

Drop birdhouse

€0. 50

50

Bird Feeder

Free

Tiny Birdhouse

Free

Bird House - Simple print no supports needed

Free

Bird Feeder (Parametric)

Free

Bird Feeder (Parametric)

Free

Bird Suet Feeder - 2020

€2.19

Bird feeder for PET Bottle, Bird House 2.0

Free

Bird feeder for PET Bottle, Bird House 2.0

Free

bird house kuş evi

Free

Bubble Nest - Birdhouse

Free

Nesting box or house for small birds

Free

sodastream bird feeder

Free

Bird Feeder

Free

Old beerhouse birdfeeder

Free

Bird House Planter

Free

Autonomous bird feeder

Free

Bird feeder "Anna"

Free

Birdhouse

CUTE CARAVAN BIRDHOUSE

Birdhouse -3 pieces

CUTE CARAVAN BIRDHOUSE

Here is our selection of the best 3D printer files of birdhouses and bird feeders, all these creations are from the STL file site Cults and are 100% printable in 3D.

This collection includes free or paid STL files of superb nesting boxes and feeders created by the designers of our community. 3D printing allows you to make an extreme variety of shapes to help birds in the best way. All you need to do is download the 3D models and then launch 3D printing to attract many birds to your garden. In most cases the models are 100% 3D printable, you just have to fix the result to the branch of a tree or to the end of a stick. But other materials may also have to be mixed with 3D printing, such as empty bottles or wooden boards.

The 3D designers who propose their creations on the 3D file download platform Cults have really competed in ingenuity to make all these objects, if you download them, don't forget to post pictures of the result! We are very curious to see your pictures of these objects with a nest inside or birds perched on your brand new feeder printed in 3D.

For The Birds - Collections - glitchpudding

by glitchpudding, last updated

These 3D printed birdhouses and bird feeders will make you popular with the feathered crowd. (Bird Feeder 4.0 by printednest)

155 194

226 261

87 106

1844 2361

12472 16086

714 890

1336 1391

2425 2977

703 733

360 520

2733 3137

73 85

3D printed bird feeder

November came, the last month of autumn - snow began to fall more and more often outside the window. And although this snow melted time after time, the approach of winter began to be felt more strongly every day. Birds came out of the forest, mostly tits, but once I saw bullfinches in the trees. The tits constantly began to look into the windows, demanding food, and the sparrows, to arrange a loud party on the tree opposite.

And although this snow melted time after time, the approach of winter began to be felt more strongly every day. Birds came out of the forest, mostly tits, but once I saw bullfinches in the trees. The tits constantly began to look into the windows, demanding food, and the sparrows, to arrange a loud party on the tree opposite.

The fact is that for several years in a row I have been hanging a feeder outside the window for the winter. Every time I try to make something interesting out of improvised materials, so that both birds and people, especially small ones, and my pet cat Timofey, will like it.

I will post a large number of photos of birds accumulated over several years at the end of this review, but for now let's return to the feeder.

Six months ago

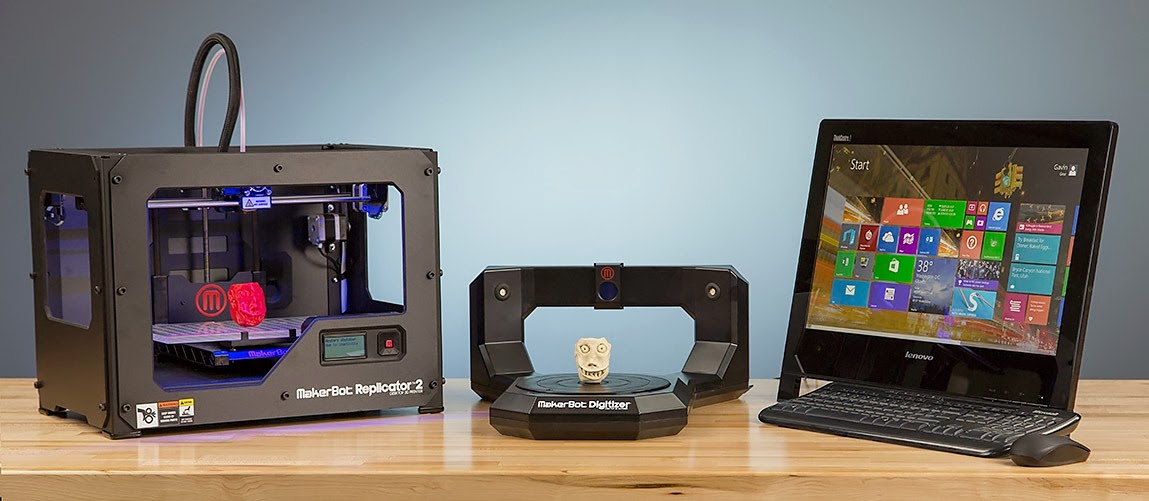

In June of this year I bought a nice 3D printer and decided that the new feeder must be printed on it. The possibilities of 3D printing opened up unlimited scope for imagination. The new feeder was sometimes presented as a fantastic castle

The new feeder was sometimes presented as a fantastic castle

then in the form of a space object

or something completely unthinkable abstract

But as the days passed, winter steadily approached, and the concept of the feeder did not go beyond sluggish sketches. Implementation was greatly hampered by common sense and lack of free time. And if it was not a pity to donate a couple of kilograms of plastic for the benefit of poor birds, then they could not carve out free time for the feeder project. Yes, and the printing time of such volumes was depressing. And finally, when the birds had already begun to brazenly knock on the window

and even the cat looked at the face in bewilderment, I made a compromise decision.

The concept of the feeder

First, it was decided to take as a basis the last year's design of plastic plates, bought at Thank you from Sberbank in Nadomarket

Secondly, print all connections in a contrasting color, taking into account the improvement in the functionality of the product, so to speak, “according to the results of operation of previous years”

The third, practical task was to acquire skills in designing movable 3D models for printing on a 3D printer.

The requirements “based on the results” were as follows:

- The structure must be movable in order to have convenient access to all the plates

- At the same time, a strong wind should not turn it into a twitching epileptic (last year the wire on which the cups hung was frayed twice by the wind )

- The feeder should have comfortable seating for small birds - sparrows, tits, bullfinches. At the same time, the pigeons should be uncomfortable there. Let's not beat off bread from old women who feed pigeons and crows near the entrances.

- And finally, the design should make it difficult for birds to get inside. Last year, "cute" sparrows got into the habit of climbing right into the cup. At the same time, they simply threw most of the seeds outside, and shitted them into a cup.

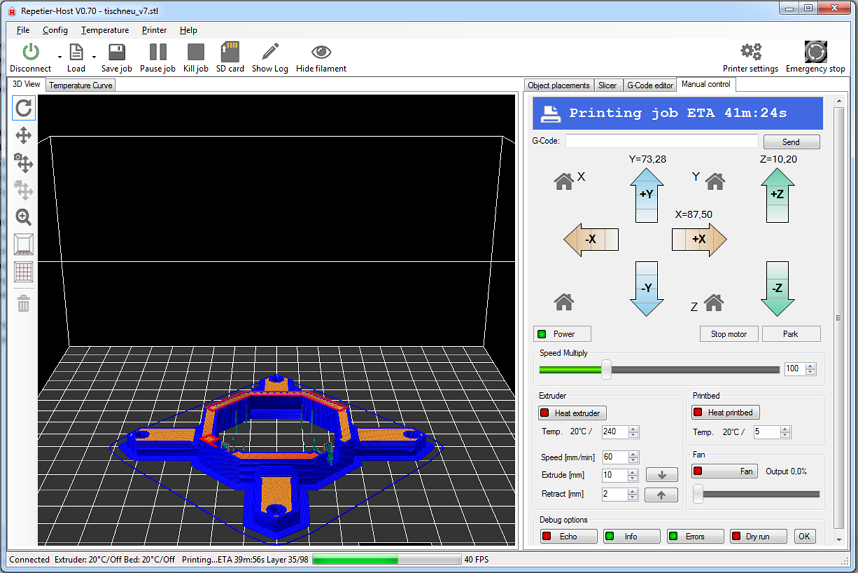

3D project

To ensure the first and second points, I decided to use joints on bearings 604 and 606, which were purchased a long time ago on aliexpress, I don’t remember for what purpose))

We will print only yellow parts. Connectors and perches for birds

Connectors and perches for birds

View of all details. But most need to be printed in triplicate

Printing and assembly

The November holidays came very successfully with a completely incomprehensible reason, but giving an extra day off.

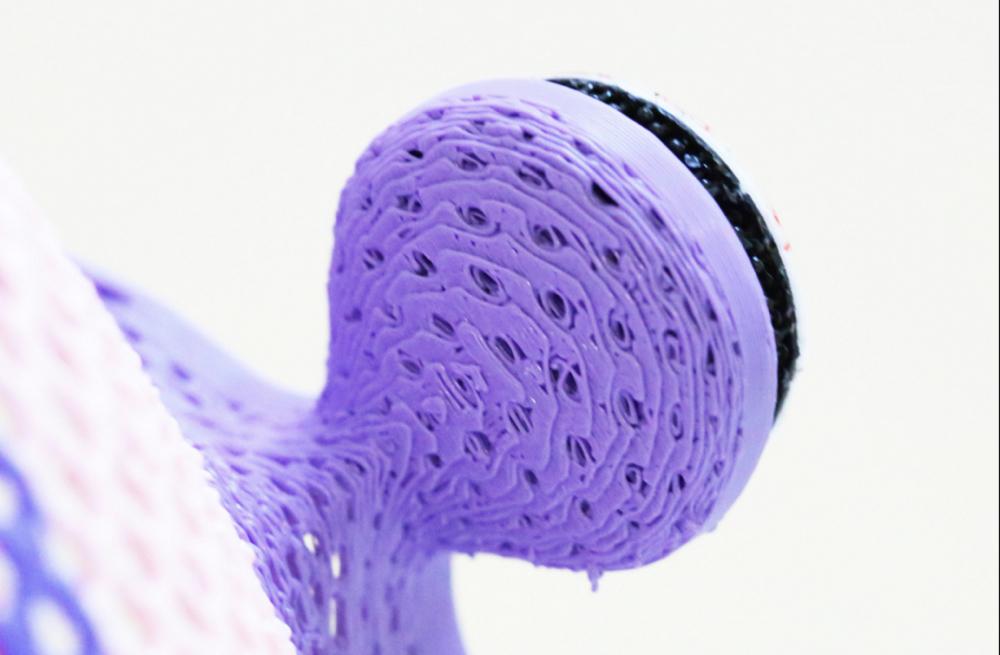

350g ABS plastic and about 20 hours of slow printing and ready to assemble

Perch for sitting around and at the same time a restriction for climbing inside

Each plate on 604 bearings (so that birds do not atrophy their foraging skills at all)

I collect everything on M4 fasteners (except for the central bolt M6 in the central bearing 606)

Long support brackets reinforced with M4 studs

And here is the complete feeder

Protruding screws leave a feeling of incompleteness. I urgently print decorative caps on them

Trial operation and state acceptance

As it turned out, the caps serve as an excellent stopper, preventing the feeder from turning into a crazy fan even in light wind

Meeting of the representative of the customer and the supervisory authority))

The customer tests the product for strength

And for the maximum load

And ergonomics

And nothing happened!

Now you can proceed to the final banquet

Well, the commissioning took place. So far, all indicators are within the design limits. The bag of seeds is open. Salo is waiting for frost in the refrigerator.

So far, all indicators are within the design limits. The bag of seeds is open. Salo is waiting for frost in the refrigerator.

If something goes wrong, the printer is always at hand. It can be corrected.

So far, only the first feathered scouts have arrived. With frosts to catch up the main forces. Last year I counted more than 3 dozen tits on the bush opposite. This is not counting sparrows and birds on other trees. And all this turned into a continuous conveyor for eating seeds and fat

Photos of past years

The first version of plastic flower pots. Of the shortcomings - snow got inside

New plate design. Grosbeak also liked

Bullfinches. Beautiful but quarrelsome birds

While the gentlemen are fighting, you can grab something

Last year's version - calculation for masses

Sparrows on the principle that I will not eat, I will bite

Duboss again. Pahan doesn't like it. The design was too mobile for him.

Pahan doesn't like it. The design was too mobile for him.

And for the cat it turned out to be a TV with a funny series

cat feeder, project for a 3d printer

If you have a cat or a cat, you probably know the situation when you wake up early in the morning and are urgently asked to feed. Or you can not always come home on time, and the pet has to stay hungry. This has happened to us, and more than once, so we came up with the idea to design an automatic pet feeder that can be controlled via the Internet.

Step 1: Design and Drawing

I needed to design a device that could be 3D printed and that could, of course, feed my cat. The device must also be controlled via the Internet, so that my mother can also feed a hungry animal, wherever she is. Therefore, the idea arose to use the WIFI Arduino with a servo for this project.

Fusion 360 selected for design; you can work, for example, in Auto CAD, 123D Sketch or OpenSCAD

However, if you are a little CAD specialist, you can simply download the drawings from the following link:

http://www. thingiverse.com/thing:1855459

thingiverse.com/thing:1855459

Please note that the pictures are given in the sequence as described below steps.

Base 1

Draw the outer and inner circles and the servo tray holder according to the size and dimensions of the servo motor you require. You can choose any diameter.

Base 2

Extrude the round part and the tray holder separately, i.e. create 3D objects.

Tray 1

The tray must hold food inside the device.

Here, as shown in the figure, we need two drawings - for the top and bottom. The dimensions must match the dimensions of the base.

Cunning. Create a drawing based on the base drawing.

Tray 2

Now extrude the top part to access the bottom. Make the edges smooth using liquid plastic.

Cover 1

Draw the cover according to the previous dimensions. We will also need to draw two lines on the lid to divide it into quarters, three of which will cover the trays. Now add two circles under the servo sprocket.

Lid 2

Extrude outer and inner contours separately, assemble the lid. One quarter must be open.

Cover 3

Smooth out the circular path connecting the surface of the cover (largest, top surface) and the surface that will hold the drive sprocket (smallest, topmost). Get a fairly smooth surface, use liquid plastic.

Step 2: Tools and Materials

3D Print Parts

All parts are drawn in Fusion 360. You can download them from Thingiverse.

http://www.thingiverse.com/thing:1855459

Electronics

Adafruit Feather HUZZAH and ESP8266 WiFi will drive the device, and Continuous Rotation Micro Servo - FS90R will drive the mechanism. We will also need a micro USB cable, preferably a flat one.

Tools

Here is a list of the tools you will need:

Cross screwdriver

Passatigi

Pleshots

pinch

adhesive thermal pistol

Computer

File

Squirrel

Tool for cleaning wires

Step 3: Assembly

9000 9000 9000 Wipe the hole in plastic. Smooth out the corners.

Smooth out the corners.

Lid

Using a hot glue gun, carefully attach the sprocket to the lid, making sure it sits exactly in the center.

Step 4: Electronics

Cut the wires

Install the motor and board first to determine the correct cable length; cut the wires.

Soldering

Solder three wires to the board. Be sure to tin the wires before soldering.

RED = USB

BROWN = GND

ORANGE = 5

Step 5: Further Assembly

Mounting the Electronics

Mount the servo and PCB on the base.

Arduino > Preferences

Install ESP8266 Package

Go to Tools > Board > Board manager and add ESP8266 package. Restart your computer.

Board Selection

Go to Tools > Board and select the Adafruit HUZZAH ESP8266.

Processor speed

Set the processor frequency to 80 MHz: Tools > CPU Frequency.

Upload Speed

Set Upload Speed to 115200 baud.

Port selection

Select a port for your FTDI or USB-to-Serial cable.

Code

Go to GitHub and download the code.

https://github.com/ntrobot2/IOT-Pet-Feeder-ino/blob/master/v1.ino

Enter your Wi-Fi SSID and password, but don't send them to the board first.

Application setup 1

As you may have guessed, we will use Blynk to communicate with the Arduino. In this case, we do not have to write an application from scratch.

Download Blynk to your phone: http://www.blynk.cc/

Application setup 2

Create a project inside the Blynk application.

Application setup 3

Email yourself an AUTH TOKEN and copy it into code: char auth[] = "AUTH TOKEN";

Now upload it to the board.

Application Setting 4

Click to create a widget icon.