3D printed airplane parts

How the Aerospace Industry is Finding New 3D-Printing Use Cases for Old Aircraft Parts

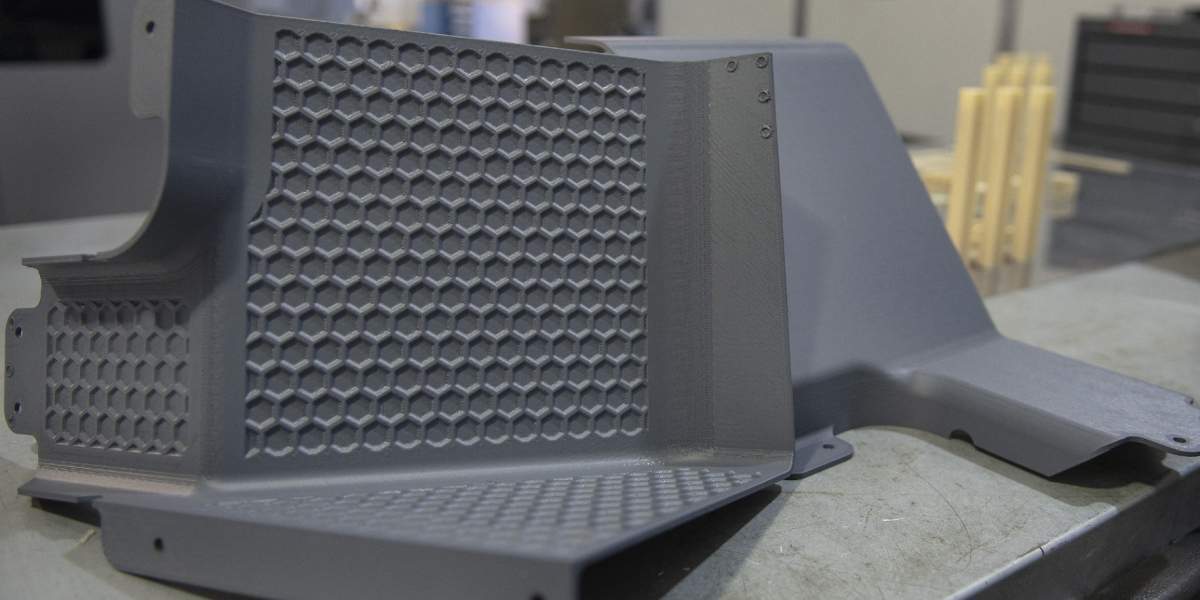

A picture of Airbus Services subsidiary Satair's tooling facility in Hamburg, where it is supplying what is believed to be the first certified additively manufactured part to fly on an in-service commercial airliner. (Satair)

3-D printing is no longer a new or innovative technology for the largest manufacturers in aerospace who have been creating solid objects from digital files for more than a decade, but what's happening across the industry now is a massive expansion in the number of use cases where additive can replace conventional methods of manufacturing commercial and military aircraft parts at lower costs, faster lead times and with more digitally flexible design and development methods.

As just one major recently highlighted example in a year that has included a number of aerospace industry additive manufacturing advancements, Airbus Services subsidiary Satair supplied what it "believes," according to an Oct. 27 press release, to be the first additively manufactured certified metal printed flying spare part to an un-disclosed U.S. airline that operates a fleet of Airbus A320 current engine option (A320ceo) aircraft.

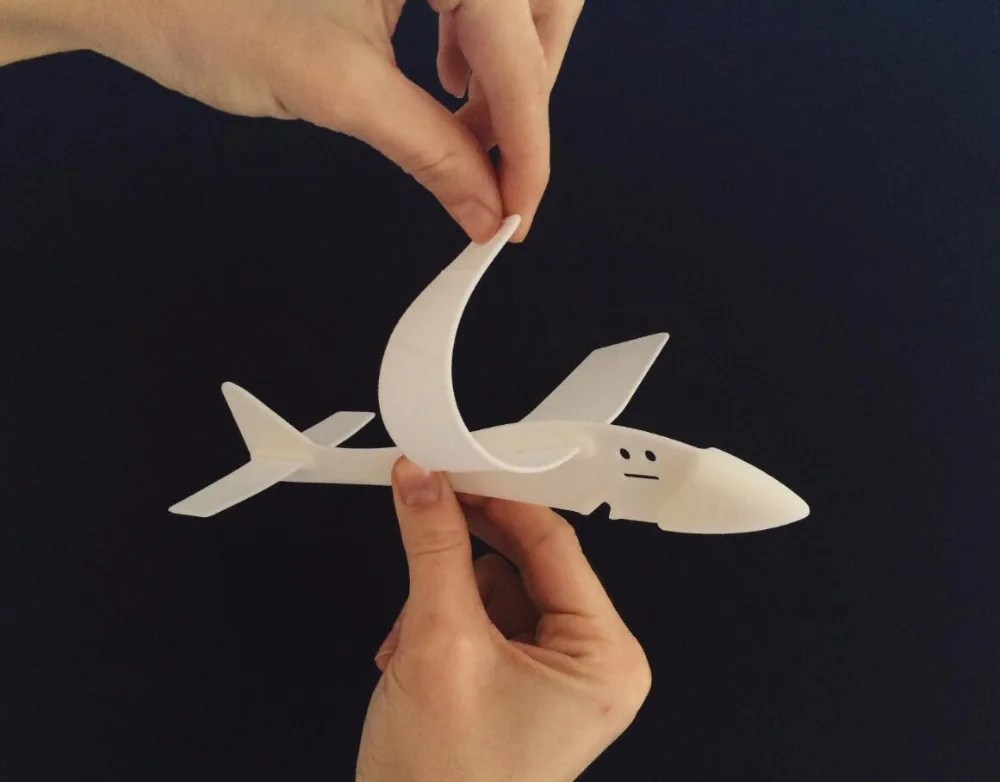

This particular advancement represents a growing trend where major OEMs like Airbus are able to 3D print older aircraft parts using new materials at lower costs and faster lead times. The first passenger-carrying A320ceo entered into service in April 1988 and 22 years later Satair has found a way to replace the aircraft’s conventionally manufactured part wingtip fences that are used as a method for addressing wingtip vortices that can develop below the wing.

According to Satair, the wingtip fences on the A320ceo are installed in four different positions – starboard, port, upper, and lower. These parts are A320ceo specific and no longer in production, and the sole spare parts supplier for the cast version of the part recently experienced difficulties supplying it which started to lead to a regular loss of the molds used to hold the wingtip fences in place by operators.

"Without the part, the aircraft cannot be operated," Felix Hammerschmidt, head of additive manufacturing solutions for Satair told Aviation Today in an emailed statement.

"As there was an issue with the conventional supplier there was a risk of a future supply shortage which could have led to the grounding of an aircraft. By switching the part to additive manufacturing the issue was solved and the supply is secured for decades to come," he added.

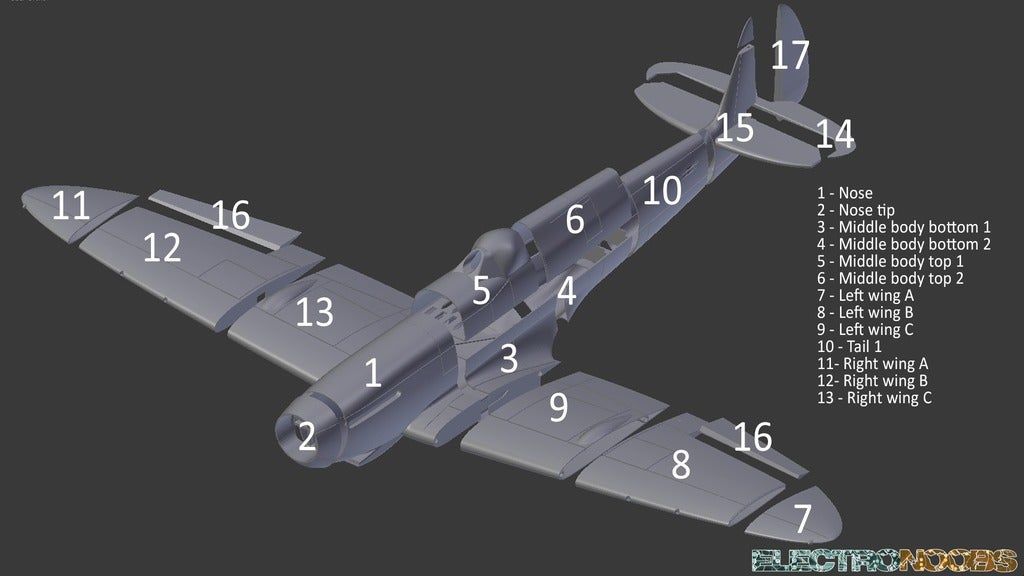

When Airbus Services received an order for the A320ceo replacement parts and their AOG procurement department was unable to find a supplier, they turned to their additive manufacturing division's RapidSpares design offices. There, a new certification process was used to re-certify the cast version of the part within five weeks, and adapt it to titanium, a commonly used additive manufacturing material that has repeatedly demonstrated the ability to meet international airworthiness certification regulations for additively manufactured aircraft materials.

Hammerschmidt said the lead time for certification of the wingtip fences could be reduced even further in the future as the technology becomes increasingly standardized.

"The part is believed to be the first metal application for after-sales reasons only – in serial production, there are already plenty of metal parts across different programs and especially engines," Hammerschmidt said. "The wingtip fences are manufactured in Titanium by the additive manufacturing process called Laser Powder Bed Fusion (L-PBF) which produces parts layer by layer from a very fine metal powder using a high-power laser to melt the material. You end up with a fully dense metal part."

By spreading the fixed costs such as the setup of their L-PBF machine and powder layup across more parts, the AM division of Airbus can drive down the cost per part of developing wingtip fences and other parts by printing a full four-part wingtip fence shipset in one run, the company's head of AM solutions said.

Airbus is one of many aerospace companies exploiting the use of additive manufacturing for different purposes, especially replacing conventional manufacturing with an additive to lower costs. Other recent examples include Honeywell Aerospace, which marked a major additive manufacturing technical milestone in August, by creating what the company described as the "first certified, flight-critical engine part using additive manufacturing, commonly known as 3D printing," in an Aug. 19 press release.

The part is further described by Honeywell as the "#4/5 bearing housing, is currently in production and was installed on an in-service engine." Dassault's Falcon 20G maritime patrol aircraft, used by the French Navy for patrol and search and rescue missions, operate ATF3-6 turbofan engines that use the additively manufactured bearing housing.

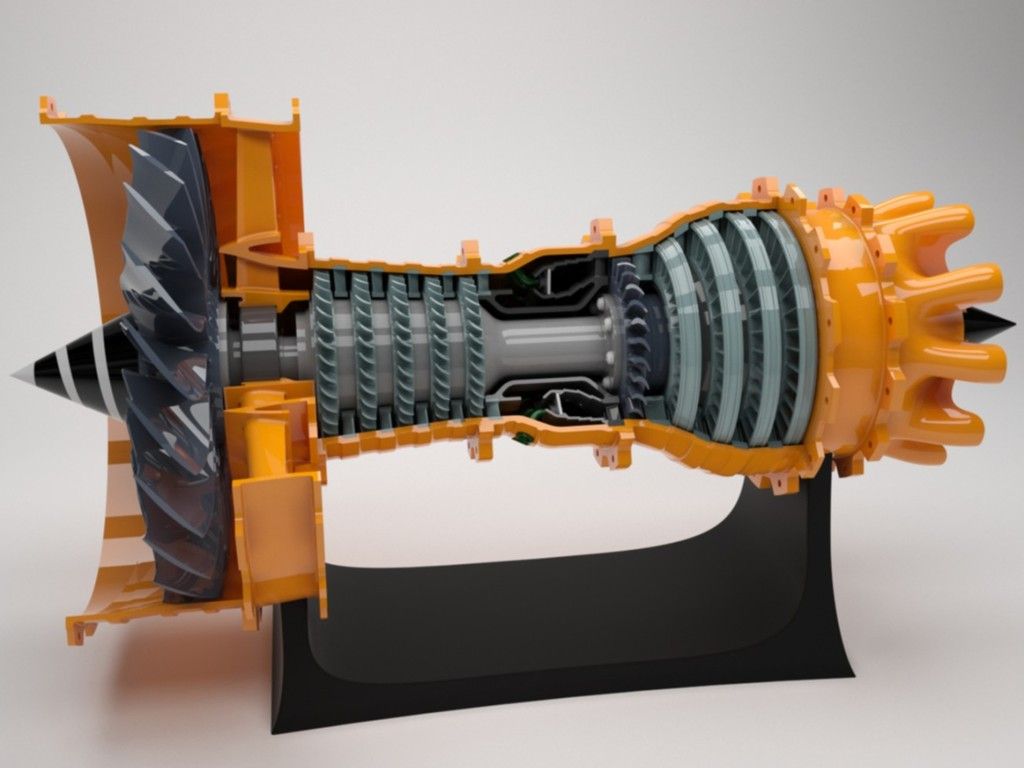

Elsewhere in the industry, Boeing’s 777X is another example of how far 3-D printing has come in the aerospace industry. The 777X, which completed its first test flight on Jan. 25 and is projected to enter into service by 2022, features two GE Aviation’s GE9X engines each with 300 3D printed parts. GE9X features 3D printed fuel nozzles, temperature sensors, heat exchanges, and low-pressure turbine blades are among the many parts made by GE Aviation’s Additive Technology Center, which added 27 Arcam electron beam melting (EBM) machines to its Ohio facility last year to titanium alumni blades for the 777X engine.

25 and is projected to enter into service by 2022, features two GE Aviation’s GE9X engines each with 300 3D printed parts. GE9X features 3D printed fuel nozzles, temperature sensors, heat exchanges, and low-pressure turbine blades are among the many parts made by GE Aviation’s Additive Technology Center, which added 27 Arcam electron beam melting (EBM) machines to its Ohio facility last year to titanium alumni blades for the 777X engine.

Low pressure turbine (LTP) blades 3D-printed from titanium aluminide (TiAl) for the GE9X engine. Of the seven components and 304 parts being additively manufactured for the GE9X, all except the LPT blades and the heat exchanger are cobalt chromium alloy parts. (GE Aviation)

Aerospace companies are also increasingly adopting new digital tools to accelerate the design and data gathering development phase when considering the use of additive manufacturing for specific parts, Aaron Frankel, Vice President of Siemens' additive manufacturing software program told Aviation Today.

Most of the 3D-printed parts actually manufactured by Siemens are for their own products used in the energy, medical, and mobility industries, according to Frankel. However, companies like Materials Solutions, Sintavia, and Morf3d that directly 3D-print parts for aerospace companies are using their additive development software.

"Our software is being used to design parts from standard brackets, to airframe components, to jet engine components and systems. When it comes to additive, aerospace companies are utilizing the technology for some very innovative solutions to complex problems. These innovations are enabled by the way that additive allows for the manufacturing of very complex geometries with the pinpoint precision necessary in the aerospace industry," Frankel said.

Siemens is mainly seeing demand for additive manufacturing software services by companies based in the U.S. and Europe, Frankel added. These companies are producing aircraft engines, satellites, space vehicles, and military equipment.

"Since AM-specific geometries like lattice structures and topology optimized structures can be used for weight reduction, this leads to reduced environmental impact, and improved ROI from these activities," Frankel said. "For example, when 1 pound of weight costs as much as $10,000 to launch into space, every bit of weight saved turns into large cost savings. When you also consider the lower fuel requirements, and therefore the improved environmental impact from reducing weight, you can see how the adoption of additives can be very attractive for companies who produce products like space vehicles and satellites.

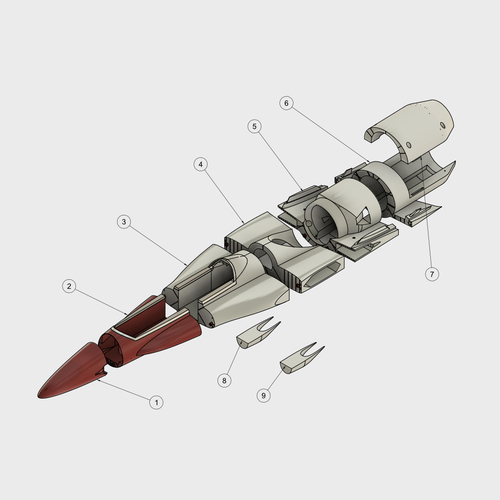

A $1 million contract issued by the U.S. Air Force to New Mexico-based additive manufacturing systems supplier Optomec on Sept. 2 represents another new use case for old aircraft parts, repairing them. Under the contract, Optomec will use a process called Directed Energy Position (DED), "in which a highly concentrated stream of metal powder is jetted into a molten pool created by the focus of a laser beam," the company said in a Sept. 2 press release.

2 press release.

By precisely controlling the melt pool and the powder flow, a high-performance metal structure is built up, either in the form of a fully printed part or as a local deposit onto an existing component to repair it. According to Optomec, their LENS technology enables the new repair method and will be used to process thousands of repairs a year.

Airlines are also looking at how they can use 3-D printing to lower the cost of replacement parts, through internal investments and partnerships. Etihad Aviation Group's maintenance, repair, and overhaul (MRO) division opened the first additive manufacturing facility with design and production approval from the European Aviation Safety Agency (EASA) in November 2019 after becoming the first Middle Eastern airline to use a certified 3D-printed aircraft interior monitor frame in 2017.

In February, the airline formed a partnership with BigRep that will install the company's BigRep Edge 3D printer at its MRO facility in Abu Dhabi to print both flying and non-flying parts on-demand. Several months prior to Etihad's 3D printer acquisition, in December 2019, British Airways began researching the use of 3D-printing for up to 10 aircraft spare parts that the airline believes could be developed using 3D-printing in the near future. These include tray tables, windows, in-flight entertainment screens and flight deck switches.

Several months prior to Etihad's 3D printer acquisition, in December 2019, British Airways began researching the use of 3D-printing for up to 10 aircraft spare parts that the airline believes could be developed using 3D-printing in the near future. These include tray tables, windows, in-flight entertainment screens and flight deck switches.

In the future, Airbus' head of AM, Hammerschmidt, believes that within the next few years there will be more opportunities to 3D-print metal technologies in the way they're using additive for the A320ceo wingtip fences.

"Applications today and in the future are widespread," Hammerschmidt said. "Additive offers the potential to reduce weight and improve part functionality, for example, the reduced pressure drop in hydraulic systems or improved efficiency of engines. The development of greener aircraft could also benefit from the possibilities that additive manufacturing offers as some technical solutions might be so complex that they cannot be manufactured by conventional machining. "

"

3D Printing in Aviation | EOS GmbH

As air traffic is steadily growing, the total volume is expected to roughly double over the next fifteen years. Even today, the industry is already under heavy load, as building and maintaining freight and passenger aircraft is a growing challenge. The CO2 emissions from operating flights also need to be reduced. And additive manufacturing paves the way for solutions.

In the aircraft construction sector, 3D printing makes faster production processes possible. Manufacturing can be performed precisely when needed. Another advantage: demand-driven additive manufacturing does not generate any of the excess or surplus that often occurs with series production. The process also allows lighter parts to be manufactured, which noticeably reduces the fuel consumption of the machines – the lower the weight, the less fuel is burned.

Additive manufacturing is perfectly suited to efficiently manufacture high-tech parts in the aviation sector that satisfy standard safety requirements.

63_lightweight_construction_solitaire_stroke_EOSGrey

By saving materials through design and engineering, you can successfully produce lightweight structures with 40-60 % less weight.

62_functional_integrationFunctionally optimized system components can be implemented in a single piece, which simplifies assembly and quality assurance processes.

28_calibrationAdditive manufacturing by EOS guarantees maximum flexibility in production planning. Modified components, upgrades and spare parts can be produced on demand, meaning that storage is not necessary.

Constructing engines and turbines means mastering challenges such as optimizing volume, performance and environmental friendliness. In these areas, 3D printing can make a significant contribution. It allows engines with sophisticated geometries, defined aerodynamic and fluid dynamic properties to be produced, as well as lightweight structures whose individual parts weigh up to 60 % less. Processing superalloys is also more cost-effective with 3D printing, since the material usage rate is lower. The results: significantly reduced environmental pollution over the lifetime of the aircraft. Parts made from a single piece are also more resilient and less susceptible to damage.

Processing superalloys is also more cost-effective with 3D printing, since the material usage rate is lower. The results: significantly reduced environmental pollution over the lifetime of the aircraft. Parts made from a single piece are also more resilient and less susceptible to damage.

The EOS technology is characterized by its great design freedom and the significantly shortened development, production and delivery times. In addition, development and production costs are drastically reduced. Components of lighter weight and greater complexity can be made a reality and production requires less material and minimal tools.

Dr. Karl-Heinz Dusel

|

MTU

The 3D printed valve block has proven that additive manufacturing with EOS technology is feasible for building critical primary flight components.

Alexander Altmann

|

Liebherr-Aerospace Lindenberg

Considering ecology and design taken together, optimized structures can also result in reduced CO2 emissions due to weight reduction. I see tremendous potential in DMLS technology for future aircraft generations, when it comes to both development and manufacturing.

I see tremendous potential in DMLS technology for future aircraft generations, when it comes to both development and manufacturing.

Jon Meyer

|

EADS

Our team has many years of experience in fluid-dynamic development as well as in the industry. We are driven by an entrepreneurial spirit that results in the continuous improvement and expansion of our product range, with innovative production methods playing a key role. We are absolutely convinced by EOS technology. It is revolutionary.

Katharina Kreitz

|

Vectoflow

Airbus is a global leader in the aerospace industry and related services. 3D printing technology by EOS helps Airbus to build a more cost- and resource-efficient aircraft. Additively manufacturing a locking shaft for aircraft doors achieved remarkable results:

Additively manufacturing a locking shaft for aircraft doors achieved remarkable results:

- 45 % weight reduction of the additively manufactured part, while keeping the same robustness

- 25 % savings in production costs by reducing material usage and assembly times

- Number of parts reduced from 10 to 1

- Weight reduction of more than 4 kg across 16 door shafts installed in an A350 aircraft

The component was made from titanium on the EOS system EOS M 400-4.

MTU Aero Engines, Germany’s leading engine manufacturer, has optimized its EOS machines to manufacture safe and cost-efficient parts in series. Using additive manufacturing, MTU builds borescope bosses for the geared turbofans of the new generation of PurePower® PW1100G-JM engines by Airbus A320neo. The low-pressure turbine in the A320neo turbofan is the first turbine ever to be equipped with additively manufactured borescope bosses by default. The cost benefits of EOS technology were one of the decisive factors for both production and development.

Fast: development, manufacturing and delivery times are significantly reduced

06_design_freedomFlexible: very high design freedom

03_cost_reductionCost-efficient: low material and tool usage, drastically reduce development and manufacturing costs

48_trusted_companyThe EOS system supports comprehensive quality assurance, including online monitoring and optical tomography.

Source: MTU | EOS

Additive manufacturing of borescope eyes for the geared turbofans of the new PurePower® PW1100G-JM engine generation of the Airbus A320neo.

download case study

The high safety requirements for approval are a major challenge in the aviation sector. Every part destined to fly has to be monitored continuously from raw material to end product, and there cannot be any defects. In collaboration with EOS, MTU Aero Engines developed an optical tomography technique for the build process into a serial product called EOSTATE Exposure OT. The parameterizable software allows detailed conclusions to be drawn about the quality of parts at every layer. In this way, optical tomography enables reproducibility to be verified, improves comparability between parts, build jobs and printing systems and creates the right conditions for cost-efficient quality assurance in series production applications.

In collaboration with EOS, MTU Aero Engines developed an optical tomography technique for the build process into a serial product called EOSTATE Exposure OT. The parameterizable software allows detailed conclusions to be drawn about the quality of parts at every layer. In this way, optical tomography enables reproducibility to be verified, improves comparability between parts, build jobs and printing systems and creates the right conditions for cost-efficient quality assurance in series production applications.

more about EOSTATE Exposure OT

Reduce cost drivers – a key factor to manufacture structural parts for the aviation sector more efficiently. Digitalized manufacturing processes offer wide-ranging opportunities. Thanks to additive manufacturing, multiple parts can be combined into a single component, eliminating production steps such as assembly. The process of storing spare parts, which currently ties up a lot of capital, is also becoming obsolete. Production only ever occurs when a part is needed, without requiring any preliminary processes. Additionally, additively manufactured structural parts are comparatively lighter, which helps to balance the CO2 footprint of aircraft.

Production only ever occurs when a part is needed, without requiring any preliminary processes. Additionally, additively manufactured structural parts are comparatively lighter, which helps to balance the CO2 footprint of aircraft.

Liebherr Aerospace is a leading supplier of systems for the aviation industry. With more than fifty years of experience, the company develops, manufactures and maintains a variety of aircraft instruments, including flight control and actuation systems, landing gears, air management systems and gearboxes.

Using their metal 3D printer, the EOS M 400-4, Liebherr produced an innovative high-pressure hydraulic block for the Airbus A380. The new additively manufactured valve block achieves the same performance as the conventionally made part but is much lighter and contains fewer individual components. The part is made from a titanium alloy and satisfies all of the certification requirements needed for flight operations.

weight reduction

functional integration

find out more

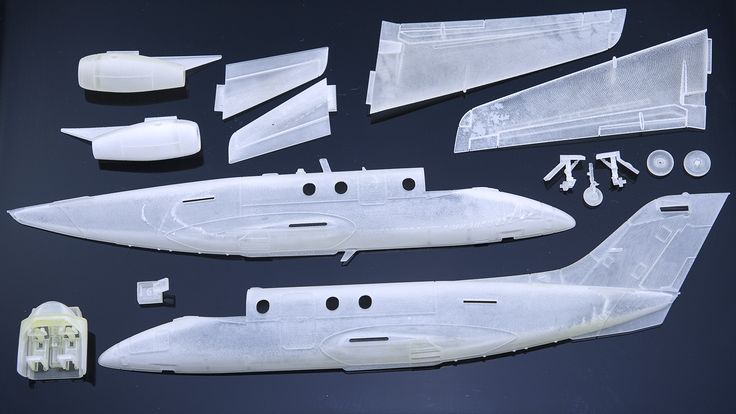

Additive manufacturing with polymer technology is also becoming increasingly important for cabin interiors. There are several reasons: in this type of environment, high customization and flexible tool-free production are crucial. Materials used in the cabin also have to satisfy very strict requirements, e.g. in terms of flammability. The technology needs to be capable of processing these materials, especially when complex designs such as twisted strands are required. Finally, a consistent build process is necessary, with minimally complex post-processing, as well as a digital spare parts strategy and digital spare parts, with virtual inventories. Polymer technology for industrial 3D printing meets all of these criteria.

There are several reasons: in this type of environment, high customization and flexible tool-free production are crucial. Materials used in the cabin also have to satisfy very strict requirements, e.g. in terms of flammability. The technology needs to be capable of processing these materials, especially when complex designs such as twisted strands are required. Finally, a consistent build process is necessary, with minimally complex post-processing, as well as a digital spare parts strategy and digital spare parts, with virtual inventories. Polymer technology for industrial 3D printing meets all of these criteria.

Etihad Engineering is the largest service provider for aircraft maintenance, repair and operations (MRO) in the Middle East. As a subsidiary of the Etihad Aviation Group, the company offers around-the-clock maintenance services, including design, composite material repairs, cabin refitting and part-related services, in its modern facilities at Abu Dhabi International Airport.

Together with EOS, Etihad opened the first 3D printing manufacturing facility in the Middle East approved by the European Aviation Safety Agency (EASA) to design and manufacture aircraft parts.

Source: Etihad | EOS

Etihad Technicians at Work on an EOS P 396

The EOS P 396 system allows parts to be manufactured from polymer materials such as PA 2241 FR and can therefore be used to manufacture cabin parts that are replaced during the aircraft inspection process known as C-checks. Defects can also be remedied quickly by manufacturing any needed parts while performing maintenance during regular aircraft downtime (line maintenance).

Etihad and EOS are known for high-quality solutions and technological innovations and share the same mindset: “Together, we want to take the design and production of parts for aircraft interiors to the next level,” says Markus Glasser, Senior Vice President for the EMEA Region at EOS. “Additively manufactured cabin interior parts offer significant added value thanks to the simplified repairs, lightweight design, shorter lead times and flexible customization options. This tackles some of the key challenges of the aerospace industry.”

“Additively manufactured cabin interior parts offer significant added value thanks to the simplified repairs, lightweight design, shorter lead times and flexible customization options. This tackles some of the key challenges of the aerospace industry.”

Markus Glasser | Senior Vice President for the EMEA Region | EOS GmbH

Want to certify and scale your production? We can give you the know-how you need.

Our Additive Minds Consulting team makes it easier for you to implement robust processes that guarantee all-round stable industrial 3D printing production. In this way, you can generate detailed documentation to demonstrate that your production facilities and methods will operate smoothly, even in series production. We support you with certification for the standards you need.

more about Additive Minds

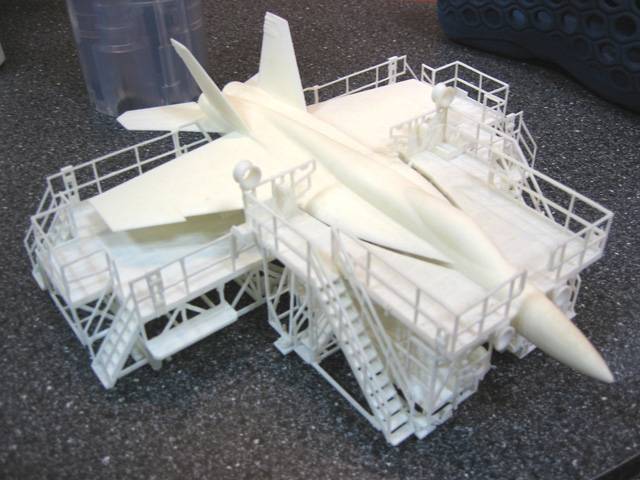

Aircraft 3D Printing: An Engineer's Story Boeing

Each Boeing 787 passenger aircraft has about 30 3D printed parts. Combined, Boeing Commercial Airplanes (jet airliners and business jets) contain 25,000 printed parts. And military aircraft F-15 and F / A-18 - about 40,000. Most of the components are components of air ducts, but there are engine parts and parts of the interior of the cabins.

Combined, Boeing Commercial Airplanes (jet airliners and business jets) contain 25,000 printed parts. And military aircraft F-15 and F / A-18 - about 40,000. Most of the components are components of air ducts, but there are engine parts and parts of the interior of the cabins.

Boeing spokesman Bernardo Malfitano spoke at the EAA AirVenture Oshkosh forum of aviation enthusiasts and spoke about how 3D printing is being used in the aircraft industry today.

Mechanic, tester, aircraft builder and pilot

Bernardo Malfitano has been with Boeing since 2007. In his career, he was engaged in the repair and maintenance of the air fleet, analyzed the wear and tear of aircraft. Now he is involved in the development of new aircraft.

According to the expert, all popular 3D printing methods are now used in the aerospace industry: laser stereolithography (SLA), deposition deposition method (FDM), selective laser sintering (SLS) and direct metal deposition (DMD). Unlike traditional techniques, in which the cost of a part depends on the circulation (the higher it is, the lower the price for each spare part), 3D printed products cost the same: it doesn’t matter if you ordered 10 or 1000 pieces. Therefore, it is advantageous to use this technology for small circulations.

Unlike traditional techniques, in which the cost of a part depends on the circulation (the higher it is, the lower the price for each spare part), 3D printed products cost the same: it doesn’t matter if you ordered 10 or 1000 pieces. Therefore, it is advantageous to use this technology for small circulations.

Where are printed parts on airplanes?

Air ducts are the part of the aircraft where 3D printed parts are most widely used today. In modern aircraft, circulating air maintains a comfortable temperature for a person and a safe pressure. 3D printed air duct connections are used in the Boeing 787, F/A-18 and F-35 fighter jets, and Bell 429 helicopters.

There are also 3D printed parts in the systems that propel the aircraft. As a rule, these are metal products made by laser sintering or metal deposition. So, in the Boeing 777, the compressor is connected to the temperature sensor using a 3D-printed adapter. And in the F-15K Slam Eagle military aircraft, casings for turbines were made using volumetric printing. This reduced the cost of the part from $34,000 to $2,550 and halved its production time.

This reduced the cost of the part from $34,000 to $2,550 and halved its production time.

Interior details . Shelves, brackets and various fixtures in passenger aircraft cabins are often printed in plastic. For example, the popular Boeing A350 has over 500 of these parts on board.

Small parts. End caps, parts of seats and instrument cases - all this can also be made using the 3D printing method. In the Boeing A300 passenger ship, brackets and seat belt buckles for crew seats are produced in this way.

Advantages of 3D printing for aircraft construction

Additive technologies attract aircraft designers not only because they are economical. They make it possible to optimize the shape at the model stage and significantly reduce the weight of the product. So, by replacing the cast metal bracket with a plastic one printed on a 3D printer, the designers managed to reduce its weight from 918 grams to 326. Of course, there is more than one bracket on the plane, so the total gain in weight is several kilograms. For passenger aircraft, lightening the design means reducing fuel consumption, which reduces not only the costs of the airline, but also environmental damage.

Of course, there is more than one bracket on the plane, so the total gain in weight is several kilograms. For passenger aircraft, lightening the design means reducing fuel consumption, which reduces not only the costs of the airline, but also environmental damage.

Parts with a mesh and cellular structure are lighter than monolithic ones, but at the same time they do not lose strength. Each new sample introduced in the aircraft industry undergoes multi-stage tests, especially if it is a functional part.

Is it possible to print the entire aircraft?

If additive technologies are so good for 3D printing, is it possible to print an entire airplane? Bernardo Malfitano is sure that now it is impossible.

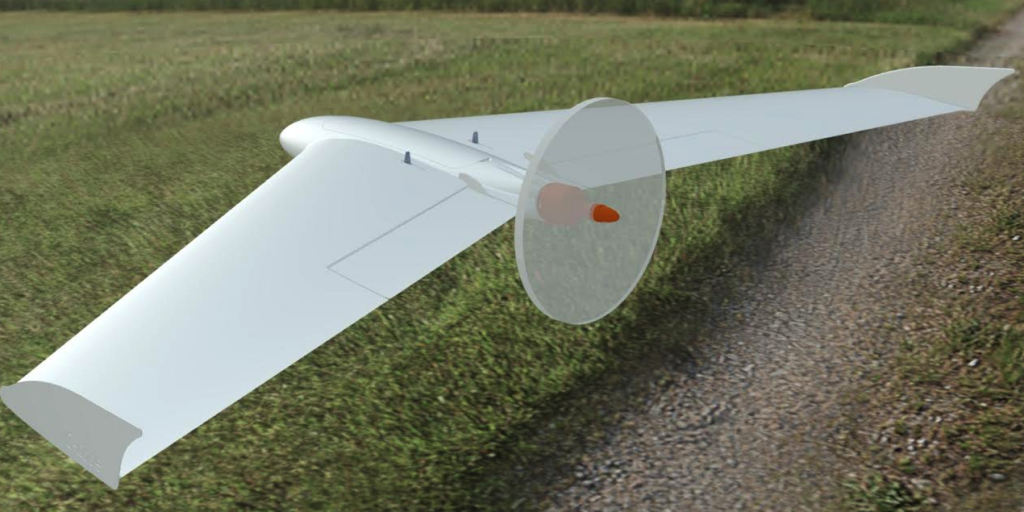

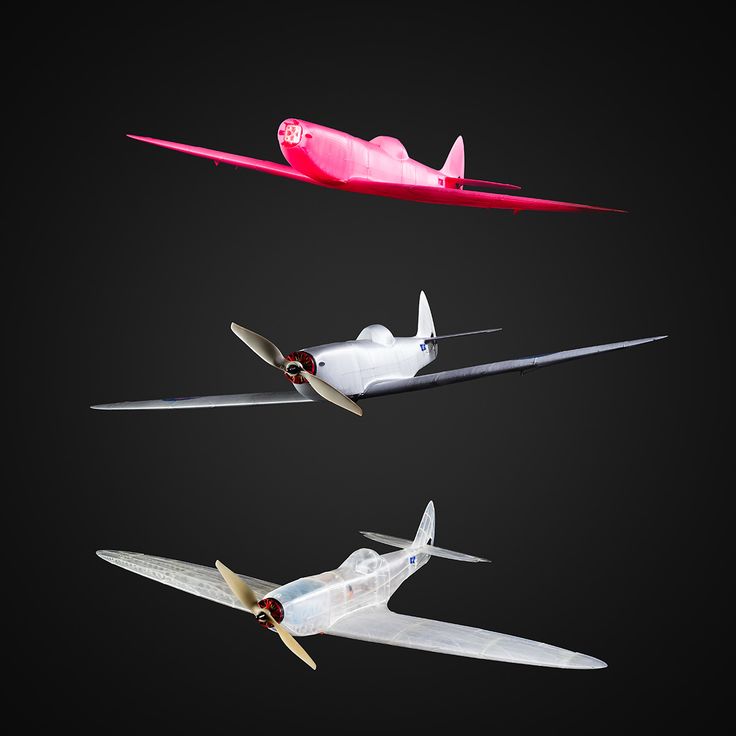

Today, 3D printing is successfully used to make drone bodies and working models of aircraft. At the Berlin Air Show in 2016, visitors saw the Airbus Thor, a remote-controlled aircraft about 2 meters long. All of its parts were 3D printed.

But to create the hulls of large aircraft - passenger liners, cargo planes, fighter jets - modern 3D printing technologies are not reliable enough.

Malfitano explained that the US has statutory manufacturing standards. The aircraft industry is governed by 14 CFR Part 25 (“Airworthiness Standards: Transport Category Aircraft”). It says that the structure of the materials must be strong, and the details must be reliable, which must be confirmed by certain tests. Meanwhile, testing parts created by 3D printing often reveals defects and inhomogeneities.

The second factor is the price. Aircraft manufacturing is mass production, so it is now more profitable to use traditional techniques at most nodes.

Bernardo Malfitano's entire presentation can be viewed on here.

Learn more about the possibilities of today's 3D printers at the 3D Print Expo. You will see flagship models from well-known companies and a gallery of amazing art objects created using 3D technologies.

Source: © robo-hunter.com

Aircraft 3D printing, Boeing 787 aircraft, 3D printer, Boeing Representative Bernardo Malfitano, EAA Aviation Enthusiasts Forum AirVenture, OshkoDash air ducts 3D printing for aircraft construction, 3D printing

3D printing in the creation of the Boeing 777 aircraftX has more than three hundred 3D printed parts, of which about 80% are titanium-aluminum engine blades. These parts were manufactured by teams from General Electric (GE) at the aerospace company Avio Aero in Cameri, Italy, and the GE Additive Technology Center (ATC) in West Chester, Ohio.

Each motor has about 300 3D printed parts. Photo: frequentflyers.ru

The first flight of an aircraft with 3D printed parts was broadcast live on a special website. The joint development between Boeing and GE confirms the effectiveness and feasibility of using additive manufacturing technologies in the aerospace industry.

Additive Manufacturing in action: Boeing 777X makes first flight with GE9X 3D printed engines

David Joyce, GE Aviation President and CEO: both companies to their cause. We are proud of our brainchild and make every conceivable and unthinkable effort to provide this aircraft with the latest GE technologies.”

Latest technology refers to the most advanced materials such as ceramic matrix composites and manufacturing methods, including 3D printing, which together make the GE9X the most fuel efficient engine in its class GE has ever produced.

Each GE9X engine is made up of over 300 parts, including a fuel injector tip that precisely atomizes the mixture of fuel and air into the combustion chamber, low-pressure turbine blades, and a heat exchanger.

Another printed element, the inductor, helps remove dust, sand and other debris that enters the motor, greatly extending its life. Parts of this type are so complex to manufacture that they have never before been used inside a GE commercial jet engine.

Zach Studt, Senior Process Engineer GE Aviation:

“The inductor cannot be made in any other way than by 3D printing. Thus, additive manufacturing improves the quality of the engine. As is often the case, implementing a better manufacturing process results in a better product. In the future, most motors will likely come with some version of this 3D printed inductor.”

Based on the most commercially successful Boeing 777, which first entered service in 1994, and incorporating advanced technology from the Boeing 787 Dreamliner, the 777X will be the largest and most fuel-efficient twin-engine jet in the world .

With revolutionary advances in aerodynamics and engine technology, the Airbus 777X will deliver up to 10% reduction in fuel consumption and emissions and a 10% reduction in operating costs compared to the competition.

The GE9X engine promises industry-leading performance and seamless integration with the 777 and 787 Dreamliner aircraft lines.