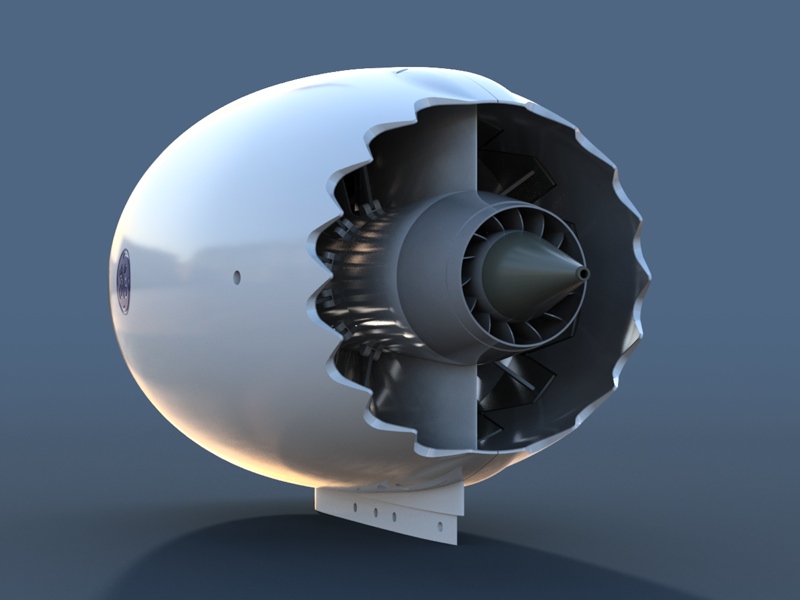

Ge jet engine 3d print

GE's 3D-Printed Airplane Engine Will Run This Year

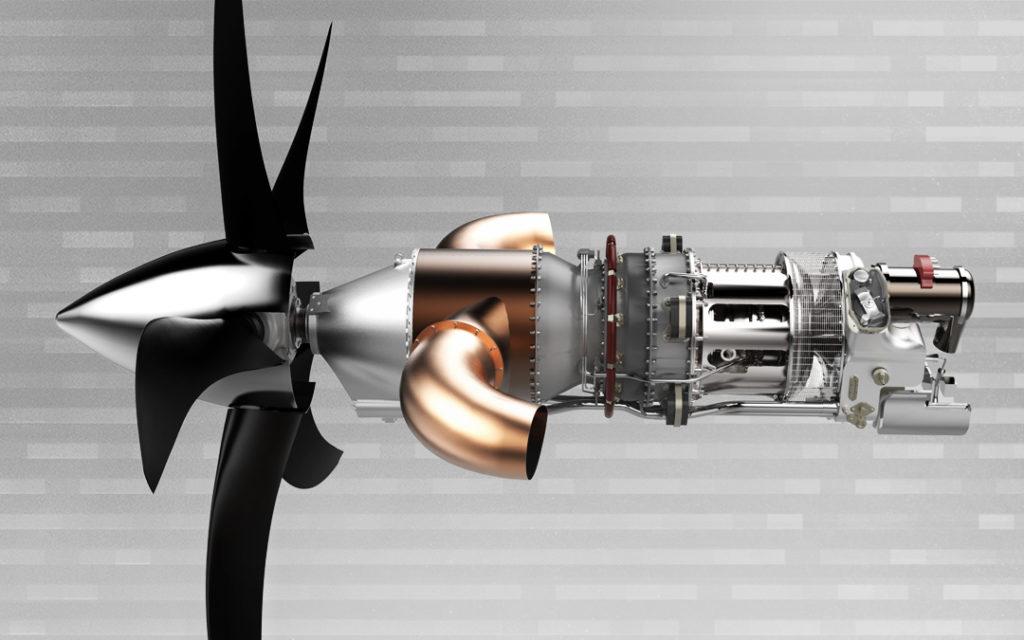

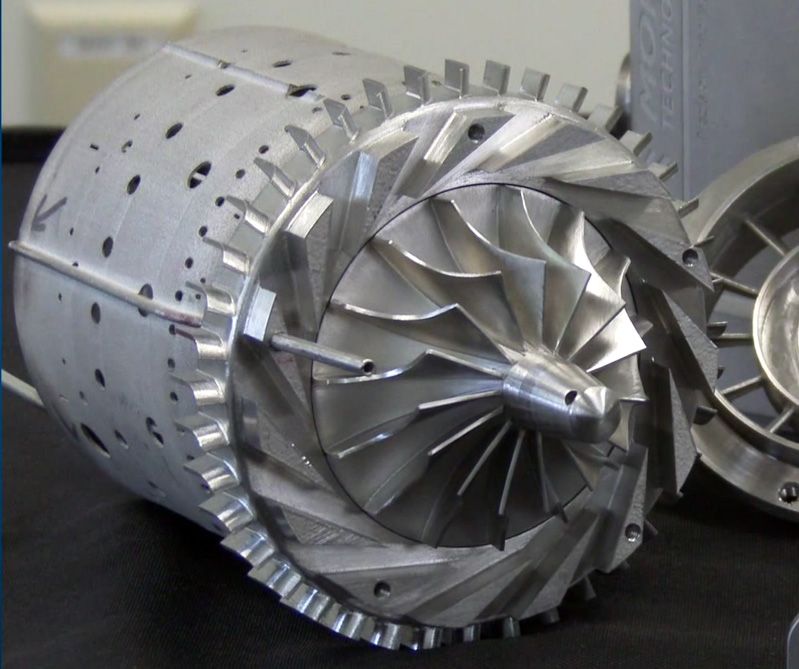

The last time engineers designed a civilian turboprop engine from scratch for mass-production, humans had not yet landed on the moon. Unlike jet engines, turboprops typically power small commercial shuttles and personal aircraft, but they still represent a multibillion-dollar market. As a result, a new machine created by a team at GE Aviation is now causing a stir.That’s because their engine, called the Advanced Turboprop (ATP), will be the first commercial aircraft engine in history with a large portion of components made by additive manufacturing methods, which include 3D printing. The designers reduced 855 separate parts down to just 12. As a result, more than a third of the engine is 3D-printed.

Engineers working on the ATP are planning to run it for the first time in a special test cell in Prague, Czech Republic, later this year. It should see its first test flight in late 2018, and full production is expected to begin in 2020. It will eventually provide the thrust for Cessna’s new single-engine, 10-person business aircraft design called Denali.

Additive manufacturing has helped the GE team bring the ATP from an idea to a working machine in record time. Announced in 2015, “the ATP is going from a dream to a reality in just two years,” says Gordie Follin, the executive manager of GE Aviation’s ATP program. The normal cycle to get to a running engine is usually twice as long, and it can take as much as 10 years to develop, Follin says. “With additive manufacturing, we’re disrupting the whole production cycle,” he says.

Overall, the 3D-printing effort will pay off by decreasing the finished ATP engine’s weight. The engine is 5 percent lighter, which means it will take the aircraft less fuel to attain the same speed. Design changes will allow the ATP to burn 20 percent less fuel and achieve 10 percent more power than its competitors.

Design changes will allow the ATP to burn 20 percent less fuel and achieve 10 percent more power than its competitors.

Additive design, which accounts for 35 percent of the engine, is also disrupting maintenance because the ATP will have fewer assembled parts and opportunities for wear. The engine is expected to run 1,000 hours longer between overhauls compared to its competitors. “We’re no longer constrained by traditional design and engineering processes,” Follin says. “3D printing is letting us be more creative than we’ve ever been before.”

Follin’s group has already made all of the engine’s parts. They are now putting them together, adding instrumentation and getting ready to test critical sub-units.

Additive manufacturing also simplifies the supply chain and lowers the opportunities for delays. “These reductions are real,” Follin says. “We’re not putting so much effort into additive manufacturing because it’s a sexy new technology for its own sake. It’s demonstrably better. It lets us disrupt the process.”

It lets us disrupt the process.”

GE has been aggressively developing its 3D-printing capabilities in recent years, so far spending $1 billion to mature the technology for its businesses. Last year, the company acquired two manufacturers of 3D-printing machines and launched GE Additive, a new GE business dedicated to supplying 3D printers, materials and engineering consulting services.

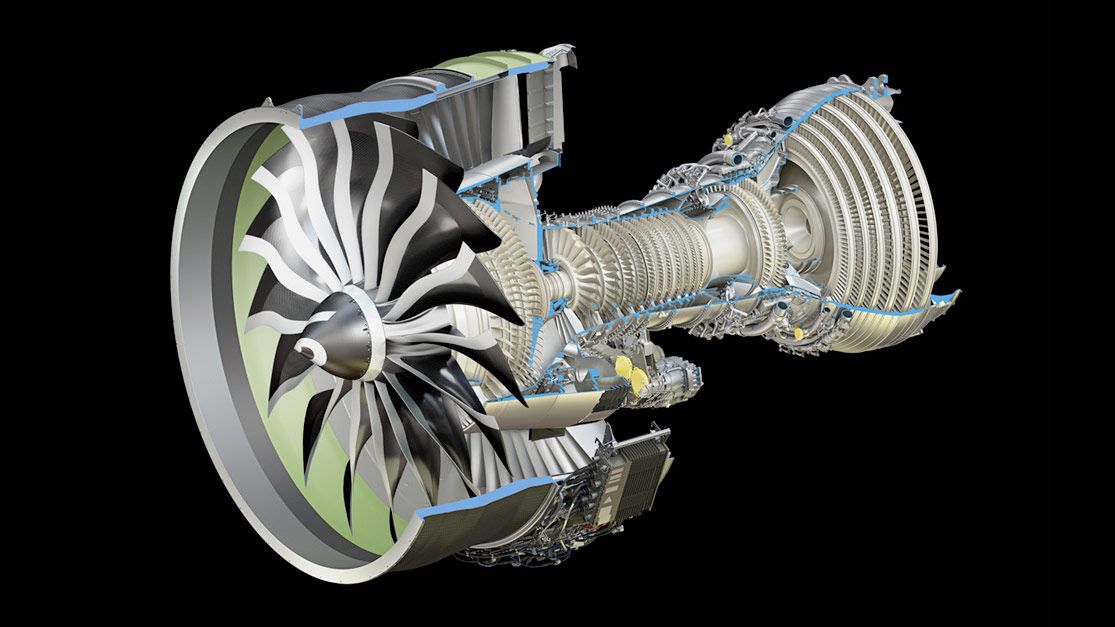

Additive manufacturing makes products stronger and more durable. In production aircraft engines, those investments have started paying dividends. CFM International, a joint venture between GE Aviation and Safran Aircraft Engines, is producing the advanced LEAP engine, which is being installed on Airbus’ and Boeing’s new fleet of narrow-body commercial airliners. Complex 3D-printed fuel nozzles on the engine contribute to LEAP’s 15 percent cut in fuel burn and emissions.

The Devil Is In The Details: How GE Found A Way To Bring 3D Printing To Mass Production

3D printing has rightfully gotten a lot of buzz because of the marvels it can do. Also known as additive manufacturing, it has opened new paths for designers to create custom shapes that were previously too expensive or downright impossible to make. The technology's potential is enormous, but GE engineer Peter Martinello offers a dose of perspective. “This is true if you have to print just one part,” he says. “But as soon as you have to print thousands of copies of the same part consistently, you are in a territory that’s both similar to traditional manufacturing, but also more complex than anything that we’ve had before.”

Also known as additive manufacturing, it has opened new paths for designers to create custom shapes that were previously too expensive or downright impossible to make. The technology's potential is enormous, but GE engineer Peter Martinello offers a dose of perspective. “This is true if you have to print just one part,” he says. “But as soon as you have to print thousands of copies of the same part consistently, you are in a territory that’s both similar to traditional manufacturing, but also more complex than anything that we’ve had before.”

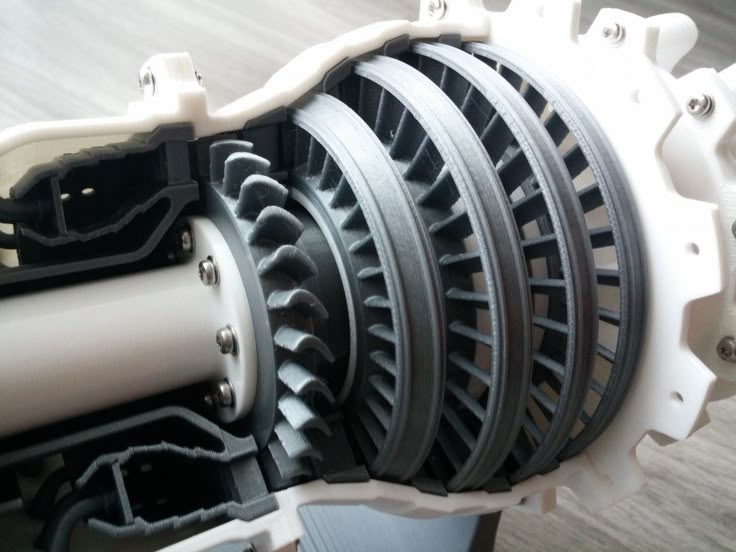

Martinello knows this as well as anyone. As a senior engineer for additive design at GE Aviation’s Additive Technology Center (ATC) in Cincinnati, in 2016 he helped bring to mass production a 3D-printed fuel nozzle that efficiently sprays fuel inside the LEAP jet engine. The size of a walnut, this wickedly complex metal part was previously made from 20 components. GE now prints 600 of them per week as a single piece.

But Martinello and his colleagues have just taken that feat to a new level. Over the last 10 months, they've developed a new process to mass-print a much larger part for a version of the GEnx jet engine that powers the latest generation of Boeing 747s. To do so, the team also had to “production-proof” the new line of printers for the part.

Over the last 10 months, they've developed a new process to mass-print a much larger part for a version of the GEnx jet engine that powers the latest generation of Boeing 747s. To do so, the team also had to “production-proof” the new line of printers for the part.

This is the first time GE has designed a mass-production process for a line of its own printers made by Concept Laser, a German engineering company it acquired in 2016. “Minor tweaks here and there are OK in the development phase, but when you get into production, everything has to be locked down," says Danny Brandel, a lead manufacturing engineer at the ATC and a member of the team. He says this is especially important in aviation because of tight FAA regulations due to the importance of safety and quality in air travel.

GE Aviation plans to begin mass-producing the GEnx parts this month at its factory in Auburn, Alabama. “The reason we did this project was because it represented several firsts for us,” says Eric Gatlin, a general manager for GE Aviation’s additive integrated product team. “It’s our first program we certified on a Concept Laser machine, and it’s also the first project we’ve taken from design to production in less than 10 months.”

“It’s our first program we certified on a Concept Laser machine, and it’s also the first project we’ve taken from design to production in less than 10 months.”

Top: Brandel (left) and Martinello (right) hold in their hands 3D-printed brackets for the GEnx-2B engine. GE Aviation plans to mass-produce them on Concept Laser 3D printers. Image credit: Tomas Kellner for GE Reports. Above: GE Aviation's Additive Technology Center in Cincinnati might easily be the world’s largest and most advanced 3D-printing and development center. “It’s not hard to walk into this building every morning and go to work,” says Eric Gatlin, a general manager for GE Aviation focusing on additive manufacturing. “A lot of the things we do here, we are doing for the very first time. I think that breeds a certain amount of excitement, a certain amount of energy, and requires a certain culture.” Image credit: GE Aviation.

But the part for the GEnx, a simple bracket the size of a human rib that holds open the engine cover during servicing, had few of these qualities. It already was a single piece of metal, and because it’s already inside a working engine, the GEnx first flew in 2010, the designers had to stay close to drawings approved by the FAA.

It already was a single piece of metal, and because it’s already inside a working engine, the GEnx first flew in 2010, the designers had to stay close to drawings approved by the FAA.

That created some hand-wringing. First, members of the Additive Global Management team, who decide what to print, had to agree on whether they even wanted to make the part. Every two weeks, engineers pitch their ideas to this diverse body, which includes employees from GE Aviation’s supply chain, engineering and engine product lines. “When the project first came to us, we said, ‘This is an oddball, this is an outlier,'” Gatlin says. “It took time for it to sink in, before we realized that this is exactly what additive can be used for, to demonstrate its speed and low cost.”

The first GEnx engines used brackets made with traditional methods such as milling. “When the GEnx program kicked off, they just hogged the brackets out of a big block of metal,” Martinello says. “By the time you had the finished product, you cut away more than half of it. ” The team realized that by 3D-printing the part, they would be able to reduce as much as 90 percent of the waste. “We just had to machine some bolt holes and some clevis pins and we were done,” he says.

” The team realized that by 3D-printing the part, they would be able to reduce as much as 90 percent of the waste. “We just had to machine some bolt holes and some clevis pins and we were done,” he says.

The new approach would not only allow GE to produce the part in-house, but also to reduce supplier expenses. “We were being charged a significant amount for these parts,” Gatlin says. The team also implemented small design tweaks that reduced the bracket’s weight by 10 percent. When it comes to flying, he says, every ounce counts.

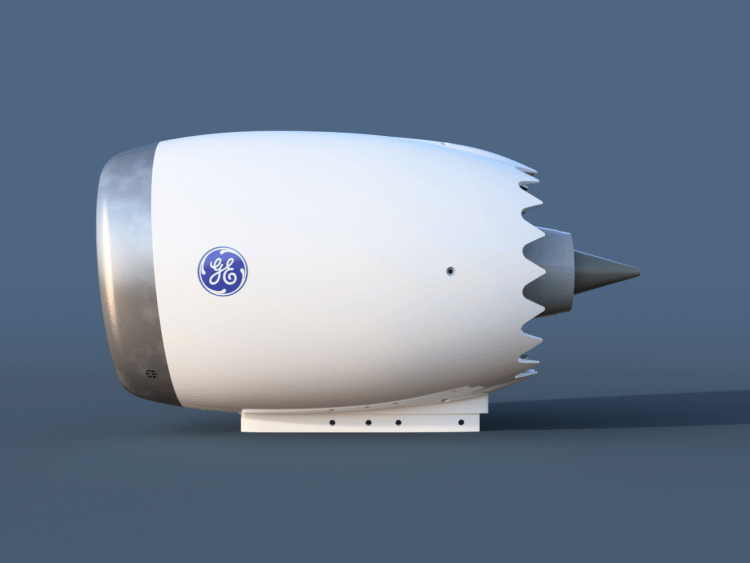

A GEnx engine on a test stand in Peebles, Ohio. Image credit: GE Aviation.

But the project was only half done. Working in a parallel track, a team of engineers was readying the Concept Laser machine for mass production. The group, based in the U.S. and also in Germany, would get together every day on a 7:30 a.m. conference call to track their progress and lay out their next steps. “It’s a highly collaborative process,” Martinello says.

They selected Concept Laser’s M2 printer, a fast, midsize machine that uses a pair of lasers to print four brackets at a time. One of the team’s tasks early on was making sure that brackets coming out of the machines were of identical quality. For example, they took a system designed to air out the smoke produced when the powerful lasers hit and melt the layers of powder into the desired shape, and gave it more power. If left untreated, smoke could deposit soot into the tiny pools of molten metal created by the lasers and alter the density of the part — but also disperse the laser beam and make it less sharp, like sun rays filtering through morning fog. “Air flow is pretty critical in terms of getting parts with good internal and external quality,” Brandel says.

Brandel and his colleagues spent several months making sure the machines were ready for prime time. “I like to get my hands dirty and get to understand the inner working of the machine, rather than just churning out hardware,” he says.

To keep an eye on the conditions inside the machines, the engineers installed sensors and high-resolution cameras to monitor the power and stability of the laser, the oxygen levels in the printing chamber and other factors. They started by focusing on individual machines, but in the future, they will feed the data into the cloud, monitor the parameters across a whole fleet of printers and look for patterns that will allow them to spot potential problems early. “We want to have everything quantified and take variation out of the process,” Martinello says.

Getting the part ready for printing was another riddle. To move faster, the team decided to print the bracket from a cobalt-chrome alloy — rather than the original nickel-based superalloy, Inconel 625 — because the FAA already certified it for use inside engines. But in order to make the approach economical, they had to print four brackets at a time. That’s when a group of designers working at the ATC came up with a clever solution: fitting all the parts like interlocking fingers onto a single “build plate” the size of an average computer screen. “It looks like one of those woodblock puzzles, where all the pieces fit together,” Gatlin says. “When you are printing it, it’s hard to tell whether it’s one part or four parts, but when you cut them off the plate, they separate and you have an aircraft’s worth of brackets in one build.”

“It looks like one of those woodblock puzzles, where all the pieces fit together,” Gatlin says. “When you are printing it, it’s hard to tell whether it’s one part or four parts, but when you cut them off the plate, they separate and you have an aircraft’s worth of brackets in one build.”

The engineers from ATC and Auburn spent the spring collaborating and comparing notes so that Auburn will be ready to start cranking out the brackets. The list includes printing parameters, but also heat treatment and inspection steps. “There’s no part that just comes off a printer and goes straight into the engine,” Gatlin says.

Back in Cincinnati, Gatlin, Martinello, Brandel and their colleagues are already working on their next projects. They’ve identified more than 100 components that could be printed. Of those, one-third are new products like the Catalyst engine, but the rest involve redesigning existing parts like the bracket — a huge new market for additive manufacturing. For example, they are working on significant cost- and weight-reduction projects across their other engine lines like the LEAP, the GE9X engine for Boeing’s new 777X widebody jet, and military programs.

For example, they are working on significant cost- and weight-reduction projects across their other engine lines like the LEAP, the GE9X engine for Boeing’s new 777X widebody jet, and military programs.

3D printing is still so new that Martinello, who is 37, is often learning on the job. “I’ve been doing this for three years now, but I still have to take a step back and remind myself what it is we are trying to do and why,” he says. “Fundamental engineering principles still apply. It’s just a new tool that you have at your disposal. It’s about understanding what it can do, and how it can improve your designs.”

https://www.facebook.com/GE/videos/10160864544500422/

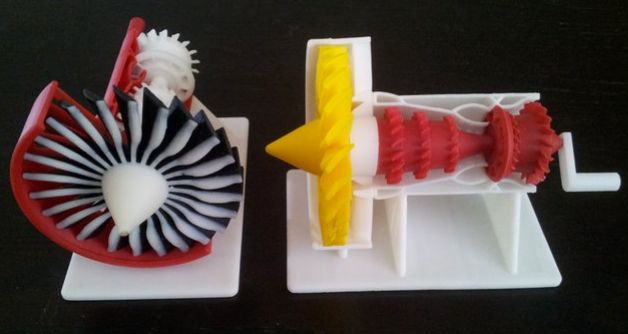

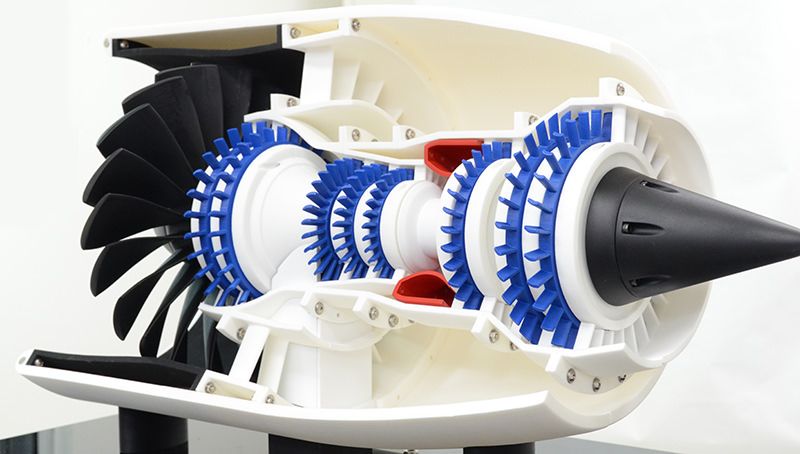

Win a GE 3D printed jet engine... or print your own today!

Archive

Subscribe author

Subscribe

Don't want

One of GE's 12 3D printed jet engines

General Electric is known as one of the largest 3D corporations in the world today -Printing not only for the manufacture of prototypes, but also in the production of final products. They use various forms of additive manufacturing to create jet engines, as well as parts for a range of other machines.

They use various forms of additive manufacturing to create jet engines, as well as parts for a range of other machines.

The 3D printing (additive manufacturing) technology most commonly used by GE is DMLM (Direct Laser Metal Melting Technology), in which the printer progressively melts metal powder to create three-dimensional objects. GE Aviation purchases metal powder in bulk, in 15lb and 30lb bags. They use this technology for various aspects within the production of jet engine components.

Wouldn't each of us want to own our own 3D printed jet engine? Now we have such an opportunity. GE Aviation is holding a raffle called "Build Your Own Jet Engine" to give away a dozen 3D printed jet engines to winners.

3D printed jet engine assembly from GE

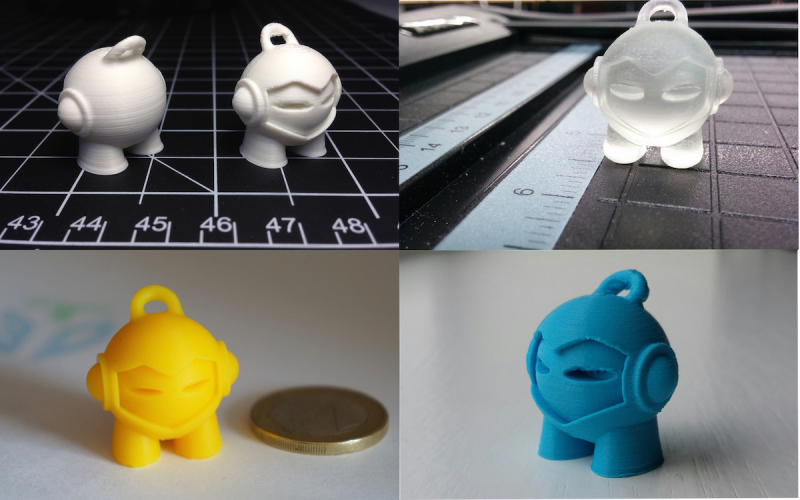

But it's probably worth clarifying that these are not real jet engines, but plastic 3D printed models. However, they still look mesmerizing and would look great on any table, fireplace or coffee table.

In total, 12 winners will be selected at the end of the competition, each of whom will receive one of these unique 3D printed jet engine replicas. The contest kicked off tonight and will run until 4:00 pm on July 21st or until all 12 winners are announced. You can read more about the rules of participation on the competition website.

But even if you don't win, there's absolutely no reason to be upset. As you will still be able to download the design files for this jet engine model from the Thingiverse website. If you choose to print your own engine, this design is made up of 13 individual 3D printed parts that will then need to be assembled. Detailed assembly instructions can be found here.

3D printed jet engine from GE

What do you think about this? Would you like to participate in the competition? Or do you just download the model and print it at home? We'd love to see what you've got. Share photos of finished engines and what you think of this GE idea.

Individual printed parts to be assembled after 3D printing at home.

Article prepared for 3DToday.ru

Subscribe to the author

Subscribe

Don't want to

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

So, you are thinking about the possibility of making money on 3D printing. How realistic is this? Quite, although the way...

Read more

four

Subscribe to the author

Subscribe

Don't want

3D printing has progressed so rapidly in recent years that we will soon stop...

Read more

3

Subscribe to author

Subscribe

Don't want to

We recently reported on an interesting engineering and architectural project directly related to the application of. ..

..

Read more

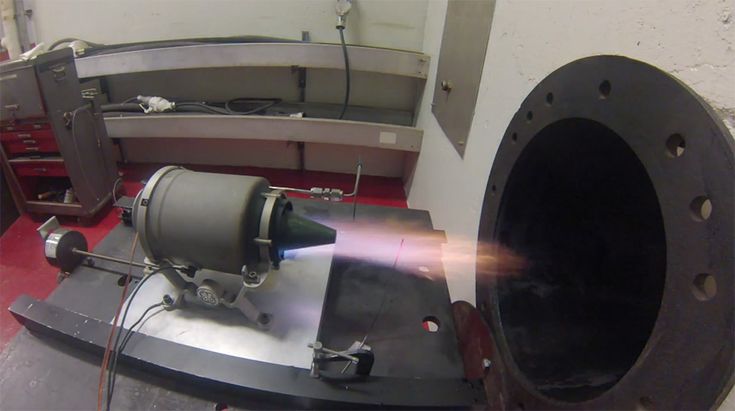

GE tested a three-circuit jet engine with 3D printed components

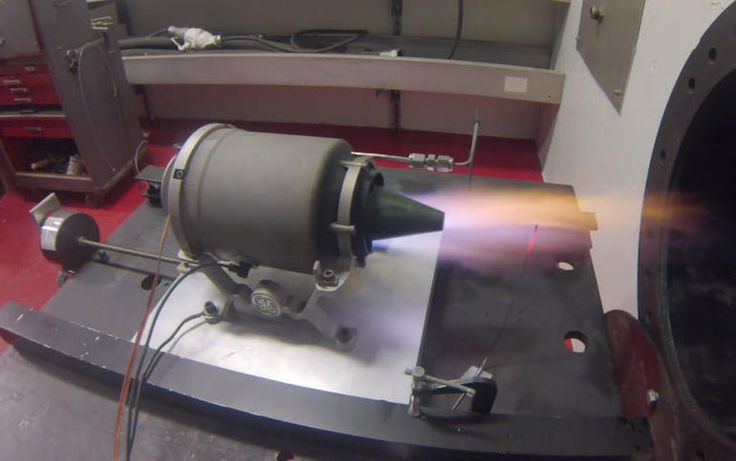

General Electric Corporation has completed testing of a prototype XA100-GE-100 adaptive three-circuit turbofan engine built using 3D printing technologies. The three-circuit scheme allows you to choose between modes of increased efficiency and power.

The XA100-GE-100 competes with the XA-101 from Pratt & Whitney. The project provides for the development of a new generation power plant, which is characterized by increased efficiency, power and stealth in the infrared spectrum while maintaining weight and size characteristics. It was possible to achieve all the goals at once by adding another, “adaptive” contour.

Depending on the mode, the engine either operates similarly to a conventional bypass turbofan engine, or redirects some of the flow to an additional external circuit, essentially increasing the bypass ratio. In the three-circuit mode, higher fuel economy is achieved, as well as a decrease in exhaust temperature, which favorably affects stealth, but at the cost of a decrease in acceleration performance. In other words, the three-circuit mode is planned to be used in flight at cruising speed to increase the range and reduce visibility, especially at low altitudes.

In other words, the three-circuit mode is planned to be used in flight at cruising speed to increase the range and reduce visibility, especially at low altitudes.

Since we are talking about stealth, it should be clear that the new power plants are designed primarily for military aircraft. The fifth generation Lockheed Martin F-35 Lightning II fighter-bombers are considered as the first and main potential recipient. These machines are currently equipped with F135-PW-100 engines, on the basis of which the first competitive bid from Pratt & Whitney was created with the same gas generator, that is, the first circuit. Later, the company decided to offer the third circuit for the F135-PW-100 as an upgrade, and to develop a new gas generator for the XA-101 project. Potentially, adapted versions of the new engines could also find application in advanced sixth-generation fighters, fifth-generation F-22 fighters, and fourth-generation aircraft, in particular the F-15 and F-16.

Referring to the General Electric application, the XA100-GE-100 prototype showed a 10% increase in power with a 25% increase in fuel economy. Ceramic matrix composites, polymer composite materials and parts made using 3D printing technologies are widely used in the design of the new power plant. Bench tests of an experimental engine began in December last year and ended the other day.

Ceramic matrix composites, polymer composite materials and parts made using 3D printing technologies are widely used in the design of the new power plant. Bench tests of an experimental engine began in December last year and ended the other day.

General Electric is equally active in applying new technologies and materials in the civil aircraft industry. There is a separate GE Additive division in the structure of the corporation, which is responsible for the introduction of 3D printing technologies and serial additive manufacturing. The aviation division of GE Aviation operates an entire additive manufacturing facility in Auburn, Alabama, equipped with dozens of industrial 3D printers using Selective Laser and Electron Beam Fusion (SLM and EBM) technologies for metal powder compositions.

In the fall of 2016, General Electric reached agreements to acquire German SLM 3D printer manufacturer Concept Laser and Swedish EBM 3D printer manufacturer Arcam. The additive systems of these companies are not only offered for sale, but also used in their own needs, including in the serial production of low-pressure turbine blades made of titanium aluminide, injectors, temperature sensors, swirlers, heat exchangers and circuit separators for GE9X engines installed on the latest airliners Boeing-777X.