3D print xbox controller holder

▷ xbox one controller holder 3d models 【 STLFinder 】

Xbox One Controller Holder

thingiverse

Xbox one controller holder, can be made with custom text on it.

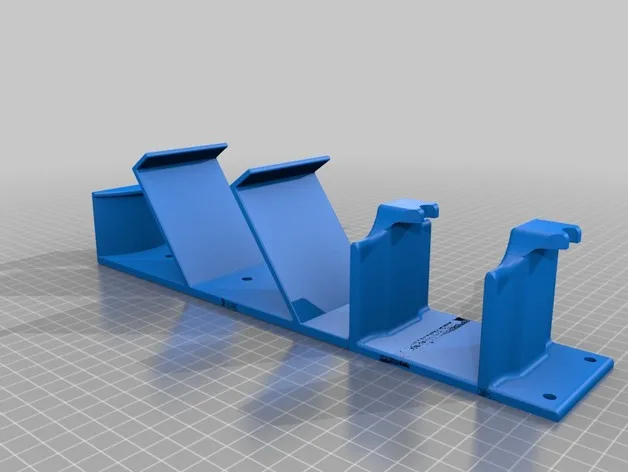

XBOX one Controller Holder

thingiverse

XBOX One Controller holder to be fixed on a 25mm shelf or steel bar

xbox one controller holder

grabcad

stand for a xbox one controller

Xbox One controller holder

pinshape

Xbox one controller hoder, three parts, can hold two controllers

Xbox One Controller Holder

thingiverse

Xbox One controller holder with enough space for wall clearance, hooks that hold surely, and saves on plastics Print standing flat on the bottom of the hooks with minimal supports for ease of support material removal

Xbox One Controller Holder

thingiverse

Holder for controller connected to PC. ...If the controler is connected to an Xbox One, the holder will push the sync button and will launch the console. I'll try to fix this in the next version (Edit: ok I still need to fix this...).

Xbox one controller holder

thingiverse

Here is a Xbox One controller holder that can hold up to 2 controller. I've designed it for a 18mm tray. I don't have other game console but, I think it can be used for other kind of controller. ... Feel free to modify it for your purpose.

Xbox One controller holder

thingiverse

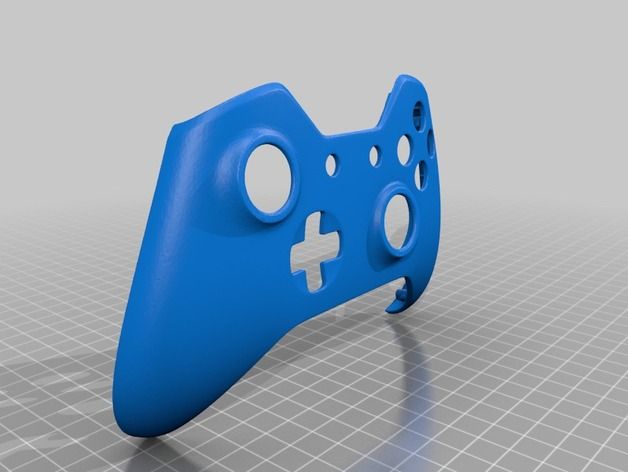

(total print time on medium speed 1h 36mins for 16mm model and a faceplate)This controller holder will only work with Xbox One controllers (the 360's protruding battery pack stops it from fitting in this design) but it can also hold a mic/headphones. ...

...

xbox one controller holder

thingiverse

THIS EXACT VERSION HAS NOT BEEN TESTED YET PLZ GIVE ME FEEDBACK - UPDATE 2017/11/21 : corrected file upload and enlarged a little bit - UPDATE 2017/11/21 : corrected radius An Xbox one controller holder design to hold a controller WITHOUT its cable,...

XBOX ONE Controller holder

thingiverse

Enjoy this BOX ONE controller holder. There are 2 versions. For one controller and for two. ...Didn't know what else to type into the summary window :)

XBOX ONE Controller holder

prusaprinters

Enjoy this BOX ONE controller holder. There are 2 versions. For one controller and for two. ...Didn't know what else to type into the summary window :)</p>

There are 2 versions. For one controller and for two. ...Didn't know what else to type into the summary window :)</p>

Xbox One Controller Holder

thingiverse

... will be needed for non-metal frames. This is a desk mounted controller holder I made to be easily removable with no adhesives or nails/screws needed. ...This holder simply slides onto your desk and attaches to a metal frame with the magnet in back.

xbox one controller holder

thingiverse

...

I have made this so it is compatible with two screw points so it will be more secure. ...

there are who files. .. one with holes 24 mm apart and the other with no holes. ...it is a very simple tinkercad edit to add the correct holes for your desk!

.. one with holes 24 mm apart and the other with no holes. ...it is a very simple tinkercad edit to add the correct holes for your desk!

SKADIS - Xbox One Controller Holder

thingiverse

Holder remix for a single Xbox One S Controller, to be hanged on Skadis pegboard.

Pegboard Xbox One Controller Holder

thingiverse

This is a Xbox One Controller holder designed to fit an 25mm pegboard.

Xbox One Controller Holder V2

thingiverse

This is an Xbox One controller holder that relies on a bistable switch to hold the controller in place. To lock the controller, push down, and the arms will latch on. To unlock it, pull back on the arms, and the controller will be pushed out.

For...

To lock the controller, push down, and the arms will latch on. To unlock it, pull back on the arms, and the controller will be pushed out.

For...

Xbox one controller holder (+ headphones)

thingiverse

150x2 mm Magnet. ...I delete logo on small holder)

xbox one controller holder for ikea table

thingiverse

Xbox one controller holder for Ikea table thats 34mm thick

IKEA Skadis Xbox One Controller Holder

thingiverse

This is a Xbox One Controller holder designed to fit an IKEA Skadis pegboard. ... There's not much else to it!

... There's not much else to it!

Under Desk Xbox One Controller Holder

thingiverse

... a few days after I printed it. ...This works very well so I am reuploading it here. Unfortunately I only downloaded the STL with mounting hole. Originally called "Under-Desk_Xbox_One_Controller_Holder_-_Sunken_Hole_Version_-_K_V_Design.stl"

hl2run's XBOX ONE Controller Holder Reversed

thingiverse

I was looking to find an XBox One S controller and hl2run's design was solid but the only issue is that with where my XBox is located in I needed the controller on the opposite side from what the design has which is the bottom/left side. So, I had...

So, I had...

Under Desk Xbox One Controller Holder

prusaprinters

... after I printed it. ...This works very well so I am reuploading it here.</p> <p>Unfortunately I only downloaded the STL with mounting hole. Originally called "Under-Desk_Xbox_One_ControllerHolder-_Sunken_HoleVersion-_K_V_Design.stl" Category: Computer

Xbox one controller holder Mk 3

thingiverse

A simple yet stylish holder for your xbox one controller Improvement list: Rounded most sharp corners for improved aesthetic looks Removed unnecessary material in base, minimizing footprint Some material removed from thicker support columns Print. ..

..

Profile Mounted Xbox One Controller Holder

thingiverse

Basically, I have my 3D printer on my table where I have my gaming systems and I needed something to keep my Xbox One controller on and I didn't want another stand, so I remixed someone else's frame clips and another's Xbox controller stand into...

IKEA Skadis Xbox One Controller Holder

prusaprinters

Xbox One controller holder for use with IKEA Skadis pegboard.Hooks are designed to be printed on the side so the layer lines are not the weak point.These holders need to be assembled with two M3x8 screws that self tap into the plastic. Made with the...

Made with the...

Xbox One controller holder for shelves

thingiverse

Xbox One controller holder designed to keep the device hanging from shelves. Printing the model with >15% infill is advised. The model can be printed without any supports but make sure to pay attention to your settings. My shelf thickness is about...

Xbox one controller holder/napkin dispenser

thingiverse

A simple yet stylish xbox one controller base or napkin dispenser! you decide! ...This is a work in progress,, but I liked it enough to share

Xbox One Controller Holder V1 (Outdated)

thingiverse

THIS IS OUTDATED New Version: https://www. thingiverse.com/thing:4114646 This is an Xbox One controller holder that relies on a bistable switch to hold the controller in place. To lock the controller simply push down and the arms will latch on. To...

thingiverse.com/thing:4114646 This is an Xbox One controller holder that relies on a bistable switch to hold the controller in place. To lock the controller simply push down and the arms will latch on. To...

$2.79Under-Desk Xbox One Controller Holder

myminifactory

My Under-Desk Xbox One Controller Holder stores your device in a practical yet aesthetically pleasing manner. I have also used this to store a Steam Controller to great success. I have used 3M command strips to hold this to the underside of my...

Xbox One Controller Holder (LG Monitor Mounted)

thingiverse

Snaps on to the bevel of an LG monitor (27GL83A-B) and holds an Xbox One controller. Features:

* LG logo window

* Display control/button cutout

* Cable access (e.g., a USB cable)

Note: Remix. See details for original design. This snaps on to...

Features:

* LG logo window

* Display control/button cutout

* Cable access (e.g., a USB cable)

Note: Remix. See details for original design. This snaps on to...

Xbox Controller Mount - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 284 relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Learn more. )

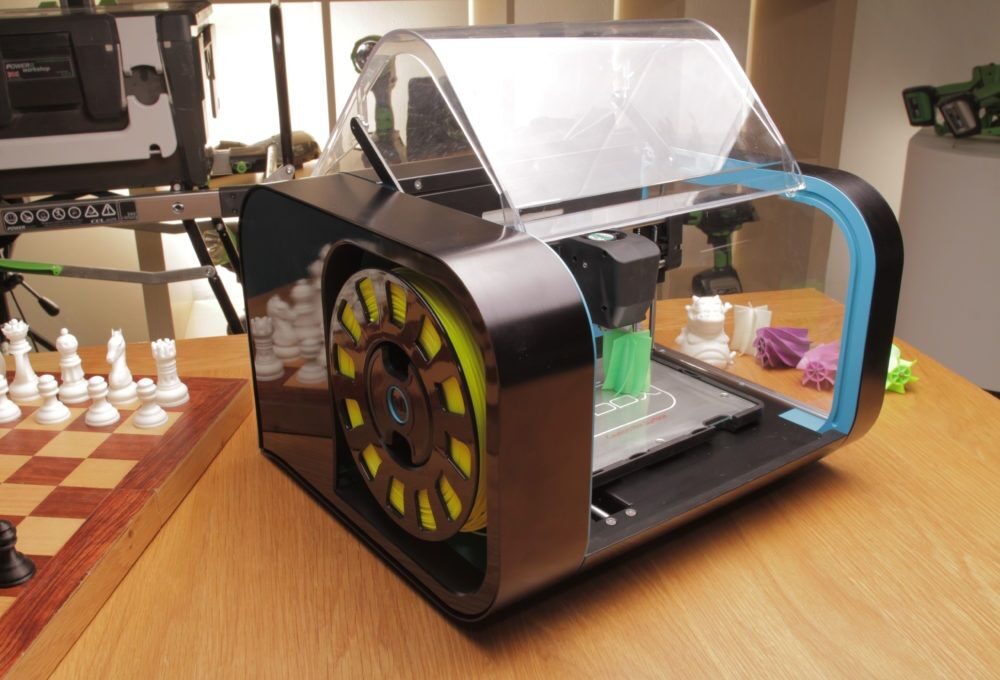

is one of the best budget models with an excellent base for improvements / 3D printers, machine tools and accessories / iXBT Live

There are a huge number of 3D printer models on the market that differ in price, functionality and print quality. But among all the abundance, only a few “folk” models stand out, which are easy to understand and use, work great out of the box, have a good element base, upgrade options, and all this at a relatively low cost. One of such models is the Flying Bear Ghost 5, which is perfect for both beginners and professionals. If you are interested, you are welcome ...

But among all the abundance, only a few “folk” models stand out, which are easy to understand and use, work great out of the box, have a good element base, upgrade options, and all this at a relatively low cost. One of such models is the Flying Bear Ghost 5, which is perfect for both beginners and professionals. If you are interested, you are welcome ...

Characteristics:

- — Model name — Flying Bear Ghost 5

- — Printing technology — FDM

- — Number of extruders — 1 piece (Bowden extruder material) 90 —1 for printing plastic , FLEX, Watson, PETG (diameter 1.75mm)

- — Display — touch LCD 3.5″

- — Platform — heated

- — Printable area — 255x210x200 mm

- — Nozzle diameter — 0.4 mm

- - Layer thickness - 0.05-0.3 mm

- - Print speed - 20-150 mm / s

- - Supported format - STL, OBJ, G-Code

- - Options for downloading models - from a PC via cable, SD cards and Wi-Fi

- — Supply voltage/operating voltage — 220/24 volts

- — Dimensions — 388x337x411 mm

- — Weight — 13.

5 kg

5 kg

Packing and contents:

Flying 3D printer Bear Ghost 5 comes semi disassembled in a large cardboard box:

When ordering on the Aliexpress website, choose express delivery from the Russian warehouse. In this case, you can save about $ 20, and the parcel will be delivered to your home by a courier company in just a few days.

There are no complaints about the quality of the packaging. All components are placed separately in a kind of polyethylene foam compartments and are reliably protected from external influences:

An additional bonus is a rich set of accessories:

a set of nylon ties, a calibrated needle for cleaning the nozzle, a set of spare parts and tweezers. The kit is chic, there is everything necessary for the operation of the “box”, as well as some spare parts.

Appearance:

The Flying Bear Ghost 5 3D Printer is one of the most popular models in the budget segment:

It uses layering technology (FDM), has a solid construction and excellent printing performance.

Design:

Before us is a printer with makerbot kinematics, where the X-axis motor moves with the Y-axis. The design consists of a base (base), four steel corners (racks), a movable frame with a table (platforms) and an upper portal with a carriage and guides.

The base is quite massive and serves to accommodate all the electronics, as well as fastening the supporting elements to each other. The front part has a slight slope with a display and indicators for more convenient operation:

For good stability and to reduce all kinds of vibrations, the sole is equipped with rubberized feet:

The bottom cover is made of 3D-printed plastic and has ventilation holes.

The USB Type B connector for wired connection to a computer and a slot for microSD memory cards are removed from the right side:

Why there is no full-fledged USB socket for flash drives remains a mystery to me.

Inside the base are the control board, power supply, display module and Z-axis drive:

The assembly of the elements is neat, the soldering is smooth, the cables are tightened with bundles, and the detachable connections are fixed with hot-melt adhesive. The board uses MKS Robin Nano 1.2 running a 32-bit STM32F103VET6 controller:

The board uses MKS Robin Nano 1.2 running a 32-bit STM32F103VET6 controller:

One of the main features of the updated model is the quieter TMC2208 drivers on the XY axes with a positioning accuracy of 0.01mm, which allows you to print even during sleep.

The power supply is designed for 300W (24V/12.5A) and quiet enough in terms of noise:

If desired, it can be replaced with some branded one (MeanWell), there is plenty of space inside.

Corners deserve special respect. If in previous models they were made of thin steel and did not provide the structure with sufficient rigidity, now everything is different. The thickness of the uprights is 1.6 mm, they do not bend by hand at all:

Corners are designed to fasten the upper portal to the base, as well as the side walls. Despite the fact that the side walls are made of plastic, they provide additional rigidity and protect the work area from drafts and dust.

The top gantry is a 1.2mm thick square steel frame with carriage motor, extruder and guides:

The quality of the bearings is very good. Due to the large diameter of the guides and fine adjustment, the backlash during operation is minimal, and this, in turn, has a positive effect on the print quality:

Due to the large diameter of the guides and fine adjustment, the backlash during operation is minimal, and this, in turn, has a positive effect on the print quality:

special changes. And judging by the reviews, this is one of the strengths of this model. In the fifth version of the printer, the manufacturer installed a lightweight molded plastic carriage together with a lightweight body of the hot part of the extruder (“hot-end”), which reduced the overall weight of the bundle and had a positive effect on positioning speed and print quality:

Size 5015 Cooling Turbine sends air directly to the printable area:

It is much more efficient than the one in the fourth model and blows the printed part well.

Filament is fed using a Bowden extruder in a transparent housing, which allows you to control the feeding process if necessary. The feed mechanism (“cold-end”) is fixed on the rear wall and has a filament end sensor:

The filament is fed through a special Teflon tube into the hot part of the extruder (“hot-end”), which combines a plastic heating unit and a special print head ( nozzle) located directly on the movable carriage:

ABS, HIPS and PLA plastics with a diameter of 1. 75mm are supported without additional manipulations, you need to experiment with other types.

75mm are supported without additional manipulations, you need to experiment with other types.

The moving frame includes a steel plate with adjusting screws and flange bearings, and a worktable consisting of an aluminum plate with a heating element and tempered glass with a Magnetic Mat coating for better adhesion (sticking) of the printed part. It loses a little to UltraBase, but performs its functions perfectly. I do not recommend removing the protective sticker until the printer is fully assembled, since there is a possibility of glass damage during assembly:

At the bottom of the table there is a thermal insulation pad that minimizes all kinds of heat leakage and promotes rapid heating to operating temperature:

The height of the movable frame is adjusted by a lead screw with trapezoidal thread, which is attached to the motor through a split coupling:

The dimensions of the table are 275mm * 215mm , a small comparison with a thousandth banknote:

The model building area is 255x210x200mm, which is enough for most tasks:

The side walls are made of plastic by 3D printing and to some extent protect the model from drafts and dust:

Assembly:

A special advantage of this model is that the printer is already assembled and configured from the outset. All belts are tensioned, most helical and cylindrical guides are installed and lubricated. Despite this, some elements will have to be connected and configured manually. I will not fully describe the assembly process, since there should not be any difficulties, but I will focus only on the main stages. To facilitate assembly, the manufacturer made a visual video instruction.

All belts are tensioned, most helical and cylindrical guides are installed and lubricated. Despite this, some elements will have to be connected and configured manually. I will not fully describe the assembly process, since there should not be any difficulties, but I will focus only on the main stages. To facilitate assembly, the manufacturer made a visual video instruction.

The short sequence is as follows:

1) fasten the 4 corners to the base. It is not necessary to tighten the screws too much, so that later on the upper portal will be set exactly

2) fasten the side walls. The screws of the rear wall can only be screwed in, because it will need to be removed

3) install the flange bearings on the movable frame with screws. Install two matching shafts from the kit into the holes in the base. Install the movable frame on these shafts. If necessary, you can loosen the rails at the bottom of the base:

4) Fasten the top portal with the appropriate screws. If all the mounting holes are aligned, tighten the screws of the posts, portal and side walls. Remove the rear wall

If all the mounting holes are aligned, tighten the screws of the posts, portal and side walls. Remove the rear wall

5) put some block under the movable frame for convenience. Place a spacer or key on the Z-axis shaft and assemble the coupling according to the scheme:

Screw the shaft so that it reaches the coupling, fix it with a screw:

based)

6) Install the Y-axis motor with the angle bracket and screws on the appropriate stand. Do not tighten the four motor mounting screws, this is necessary for the correct tension of the belt. If necessary, loosen the gear on the shaft and align it with the gear on the motor shaft. Then tighten the belt and tighten 4 screws:

7) install the rear wall, and on it the fastening of the extruder feed part and the reel holder. Do not forget about the spacer for the upper screw of the wall, as well as about the tube clamp, which must be inserted all the way into the feed mechanism:

8) connect cables, use cable ties to fasten them to the case. All loops are signed, it is impossible to make a mistake. Install the cable on the carriage in such a way that the red wire is closer to the turbine:

All loops are signed, it is impossible to make a mistake. Install the cable on the carriage in such a way that the red wire is closer to the turbine:

The fasteners of the Y-axis motor buckles must be on the side of the printer wall, otherwise they will interfere with the carriage:

cables

9) After turning on the printer, adjust the screw of the moving platform limit switch and adjust the platform with the adjusting screws. Adjustment can be made with a regular piece of paper

This completes the assembly operations and you can try to print test models.

Management and preparation for printing:

All control is concentrated in the front and is carried out using a 3.5-inch touch screen:

Firmware version 5.8, if desired, you can change the interface language to Russian:

The menu is very simple, so difficulties with it should not occur. Before starting printing, you need to prepare the printer:

1) calibrate the desktop using four adjustment screws from the bottom side. It is necessary for each assembly / disassembly, as well as various mechanical effects on the body. Then it is necessary to achieve the same minimum gap at all points of the table using a regular sheet of paper, after setting the nozzle to the zero point along all axes (“Move” menu):

It is necessary for each assembly / disassembly, as well as various mechanical effects on the body. Then it is necessary to achieve the same minimum gap at all points of the table using a regular sheet of paper, after setting the nozzle to the zero point along all axes (“Move” menu):

2) degrease the table with isopropyl alcohol or wet wipes so that the printed model adheres to it securely. For more reliable fixation, you can use adhesives (BF glue with alcohol)

3) heat the extruder (“hot-end”) to the required temperature and load the filament. For PLA plastic it is 190-200°C, for ABS and PETG 220-230°C. This model has a built-in function for heating PLA and ABS plastic (“Preheat” menu):

There is a “Filament” menu for loading plastic:

Down arrow loads plastic and up arrow unloads. Loading/unloading operations will start after the nozzle has warmed up. While the filament is moving through the tube, a high speed can be used to speed up the process. Before the nozzle, be sure to switch the speed to low, as its section is not enough to extrude the plastic at this speed.

You can then try to print. There is a test model on the memory card for printing, located in the "Printing" menu:

To print any other models of interest, you must first download them on specialized sites. This printer model supports "STL" (for single color models), "OBJ", "DAE" and "AMF" formats. These formats represent a part diagram with all dimensions, polygons and other information. The printer uses layering technology (FDM), so in order for it to understand the scope of work, it is necessary to cut the model into layers in a form that it understands: how much to make a layer, how quickly and how much to fill, and so on. This is done by special slicer programs. One of the most popular and free CURA programs:

It allows you to slice an object into layers and convert data into a printer-friendly G-CODE format. It has many settings, including typing speed, padding, support, and more. The test cube turned out to be of quite good quality:

Operating features:

The Flying Bear Ghost 5 3D printer is assembled quite simply in a couple of hours. It has a simple and clear design and is easy to operate, so it is perfect for beginners as a first printer. During the operation of special problems, I have not identified. Some write about insufficient cooling of the model. In my opinion, the turbine 5015 is quite enough. The second most common complaint is the extruder. This is a Bowden extruder with a separate hot and cold section. The feeding part sometimes turns and does not feed the thread, and sometimes it breaks off completely. A more precise adjustment of the screw seems to solve the problem. I’ll add on my own that the Teflon tube is very poorly removed from the fittings, so you have to completely unscrew them. Otherwise, there are no complaints: it is easy to manage and configure, the mechanics fit perfectly and do not play, it prints quietly. In addition, it has a huge user base with recommendations and improvements, as well as a responsible manufacturer who is trying to eliminate possible shortcomings in the new firmware or new version.

It has a simple and clear design and is easy to operate, so it is perfect for beginners as a first printer. During the operation of special problems, I have not identified. Some write about insufficient cooling of the model. In my opinion, the turbine 5015 is quite enough. The second most common complaint is the extruder. This is a Bowden extruder with a separate hot and cold section. The feeding part sometimes turns and does not feed the thread, and sometimes it breaks off completely. A more precise adjustment of the screw seems to solve the problem. I’ll add on my own that the Teflon tube is very poorly removed from the fittings, so you have to completely unscrew them. Otherwise, there are no complaints: it is easy to manage and configure, the mechanics fit perfectly and do not play, it prints quietly. In addition, it has a huge user base with recommendations and improvements, as well as a responsible manufacturer who is trying to eliminate possible shortcomings in the new firmware or new version.

From myself I will add a few key rules:

- close the printer with a large bag or container. Since the guides are lubricated, dust sticks to them very well. After a week of inactivity, there will already be a layer of dust and this will not lead to anything good. The first problem can be solved with alcohol, but it is better not to abuse it. Immediately after printing, do not try to tear off the part, otherwise the glass may break. Wait 10 minutes and always use a spatula if possible

Where to buy:

You can buy it HERE

Conclusions:

The Flying Bear Ghost 5 3D printer performed well. At a relatively low cost, it has a rigid construction, excellent fitting parts and good print quality. A large number of assembly, upgrade and refinement guides will allow even beginners with minimal experience to delve into 3D printing, as well as get a higher-class printer with minimal investment. I can safely recommend to buy.

3D printing

3D printing

3D printing

https://masterkit. ru/blog/articles/3d?blogviewmode=1

ru/blog/articles/3d?blogviewmode=1

DIY PCB holder

3D printed outlet design. We make a printed circuit board holder in 1 hour.

Developing spatial thinking: 3D drawing

3D pens are getting more and more popular! They allow you to create almost any three-dimensional figures!

More interesting than drawing, cooler than construction kits

Our creativity with Dajet 3D pen and a bright ten-color palette of PLA-plastic for it.

How I discovered 3D drawing

I first heard about a 3D pen a few years ago. I remember being surprised then at what technology had come to.

3D Simo Mini Multi-Tool Pen for Creativity

A small overview of the unusual and innovative 3D Multi-Tool Pen.

A new era of drawing

The world is changing. New technologies break into our lives so rapidly that they break the usual order of things.

Equipping the MC7 3D printer with the RepRapDiscount Full Graphic Smart Controller display and creating your own logo

We continue our series of MC7 3D printer upgrades: installing the RepRapDiscount Full Graphic Smart Controller module, which has a graphic LCD display, an SD card reader and an encoder to manage the printer.

Safe 3D printer - the latest revision of the MC7 printer

To almost completely eliminate touching the hot part of the extruder, we have developed a protective cap for the E3D V6 extruder used in the printer, which prevents the fingers from contacting the extruder hot end. And in order to eliminate the possibility of touching hot parts and forcibly cool them, an air-cooled housing was developed for the electronics unit.

How We Decided to Make a Modular 3D Printer

What if we pre-assemble the printer components and put them assembled in the same box? How many of these nodes will there be, and how easy is it to connect them into a finished printer? Will the parts fit in the box provided?

Wake up in comfort - we make a light alarm clock with our own hands

The solution, that is, the light alarm clock is called, but the price of this thing is from 5000 And what if you build something like this on the basis of improvised means?

Refinement of the 3D printer MC7 Prime mini from Master Kit - installing a heated table with your own hands

As you know, equipping a 3D printer with a heated table significantly expands the capabilities of the printer and improves print quality. The print quality is improved due to the fact that the plastic extruded from the extruder remains warm.

The print quality is improved due to the fact that the plastic extruded from the extruder remains warm.

Modification of 3D printer MC7 Prime mini from Master Kit

We offer you the modification of 3D printer MC7, as a result of which it becomes possible to equip it with a popular set of electronics: Arduino Mega + shield RAMPS1.4 + 3D Smart Controller. It turns your printer into a standalone device and does not need to be connected to a computer to print.

We make a heated table for the MC2 3D printer with our own hands

In one of the previous articles, the technology for printing with ABS plastic on the cold table of the MC2 3D printer from Master Kit was presented. And what if we make this table heated and adjustable, eliminating the AUTO_BED_LEVELING function?

Printing with ABS on a cold table 3D printer MC2

Learn how to print with ABS on a cold table. After experimenting with blue tape, stationery glue, hairspray and other materials, I found a method acceptable for my tasks and printer.

3D printer as a home tool

I note with satisfaction that over time the 3D printer has become the same home tool as a hammer or soldering iron, and has firmly taken its place on the desktop. The settings got used, and the printer, being turned on at any time, prints stably and confidently. Thinking about what tool to cut and grind with, smoothly flowed into thinking about how to draw this or that surface in SketchUP. Spatial thinking develops perfectly!

Continuation of the article about improvements to the MC2 3D printer, part 2. Calibration, refinement of the cooling system

In my first article, I wrote about the pleasant assembly process, the beginning of operation and minor improvements to the MC2 3D printer from Master Kit. It's been a month and a half. I won’t say that I fiddled with the assembled animal every day, but there were many approaches, and, accordingly, a lot of interesting and useful things were learned from this.

How I modified the MC2 3D printer from Master Kit

I am by nature an enthusiastic person. And above all all sorts of electronic-iron stuff. It is clear that against the background of the growing general enthusiasm for 3D printing, I could not pass by this direction. The choice, after a short search, settled on the most affordable option (which I could find), but in which case it would be where to poke for help, that is, the local Moscow one. My choice fell on the designer of the 3D printer MS2.

And above all all sorts of electronic-iron stuff. It is clear that against the background of the growing general enthusiasm for 3D printing, I could not pass by this direction. The choice, after a short search, settled on the most affordable option (which I could find), but in which case it would be where to poke for help, that is, the local Moscow one. My choice fell on the designer of the 3D printer MS2.

Housing for MP700 with 3D printer

Due to numerous requests from users of our products, and in particular the MP700 tester (R/L/C, N/P/M, ESR), we have prepared STL files for printing on a 3D printer. If someone does not have a 3D printer, then you can order the printing of the case in the Master Kit.

Proven quality

For almost 20 years we have been making electronic devices for anyone who can assemble and install them by hand

Wide range

From beginners to sophisticated technical devices! Separate directions for teaching electronics and 3D printing! Ready-made kits - for a simple solution to your problems!

Manufacturer's Warranty

Although our products are technically sophisticated electronic devices, we give them a 6 month manufacturer's warranty.

Unique product

A significant part of our products are unique developments of Russian engineers, for which consumer demand has been confirmed. All positions are carefully selected and tested.

Import substitution

We are proud that the vast majority of our goods are produced in our own production in Russia

Technical support

We provide comprehensive technical support to our customers: by phone, by e-mail and on our Forum. Our competent and experienced product managers will help you realize your wildest DIY ideas!

Ease of payment

You can pay for Master Kit goods in any way convenient for you: in cash upon receipt or online, at the time of placing an order, by bank card or electronic money.

A lot of delivery methods

You can receive Master Kit goods in any way convenient for you: by courier to the door, pick up on your own in more than 120 self-delivery points throughout Russia, or receive by mail.

.jpg)