3D print vinyl

3d Print Vinyl - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

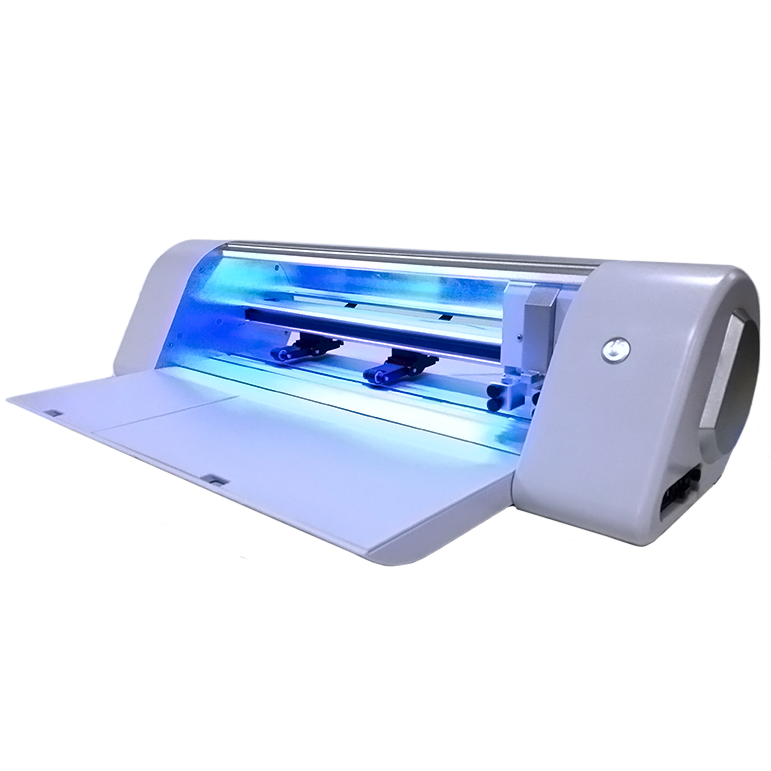

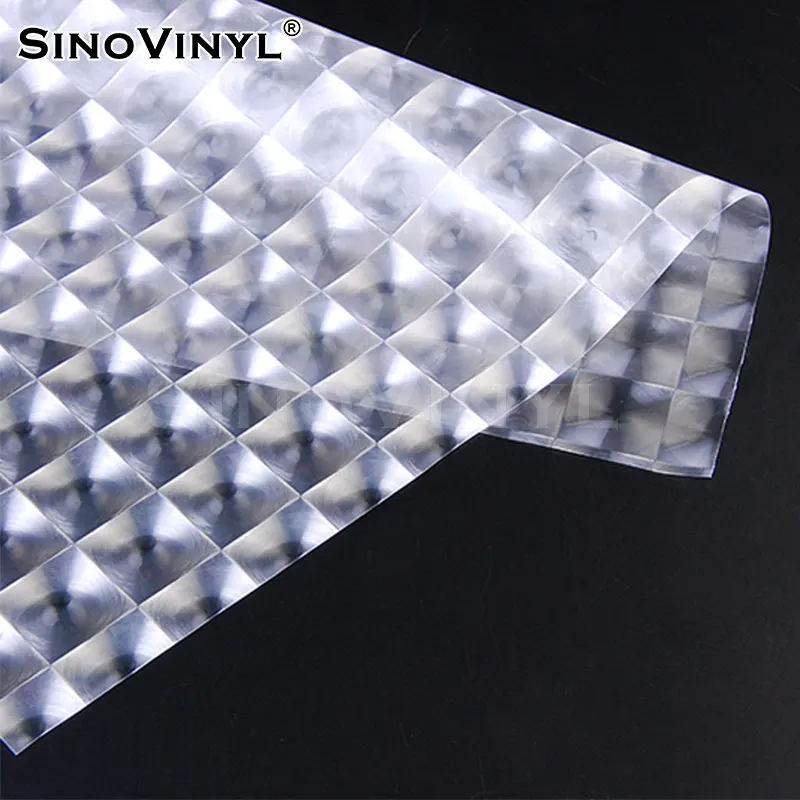

Fillamentum PVC Vinyl 3D Printing Filament

Fillamentum PVC Vinyl Filament

Fillamentum

Fillamentum ASA Series

A rugged weather-resistant material that is much more resistant to UV light.

Fillamentum ExtraFill Series

An excellent baseline PLA that prints amazingly well.

Fillamentum FlexFill Series

Flexfill is rubbery and elastic, making it impact, oil and abrasion-resistant.

Fillamentum Crystal Clear Series

An incredible line of semi-transparent, colored materials.

Fillamentum TimberFill Series

Made from a PLA base with wood particulate, Timberfill gives you 3D prints that look like they were carved from wood.

Fillamentum Vertigo Series

Vertigo PLA series reflect light and create awesome, eye-catching prints with flecks of gold, silver and blue.

Fillamentum Extrafill ABS Filament

Premium ABS Filament with a wide variety of vibrant colors.

Fillamentum PVC Vinyl Filament

Fillamentum PVC Vinyl Filament

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

How to Succeed when 3D Printing with Polycarbonate Filament

Follow these helpful steps to start successfully printing with this extremely tough, professional grade material.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

Vinyl record filament.

Consumables

Subscribe to the author

Subscribe

Don't want

28

Hi Friends!

Remember, vinyl is not to be trifled with! If possible, you should not experiment with melting this material at all.

Today I will try to print from vinyl records. I can imagine how dissatisfied fans of vinyl records will be. I have a lot of this stuff. I will donate 5 pieces for the sake of the experiment.

I didn't expect plastics to be so flexible. The label can not be torn off the plate, pasted on the Soviet glue. It remains only to cut out this pasted circle. It was possible to shove the entire record into the grinder.

The shredder looks like it was designed to shred vinyl records. For further grinding, I will use the Chinese saucepan that you saw in past videos. I grind the material with a respirator, being afraid that small particles of the material can fly in the air.

Vinyl cured to dust, just a little check on a Chinese extruder. To begin with, I will set the temperature on the extruder to 180 degrees so that the previous test polymer comes out, after which I will lower the temperature.

It's hot! I didn't expect vinyl to be so malleable. The filament is even. I believe that the finer the material is crushed, the more stable the filament is. There are slight deviations, but it's not terrible. I have seen factory filament with much larger deviations. I thought that the filament would turn out to be brittle, but it was not there. It turned out a very elastic and durable thread.

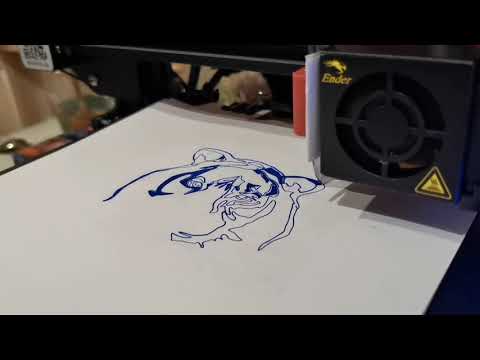

Now is the time to print the test disk. Instead of glue, I print the first layer of PLA plastic and then change the filament to the test one. It's a miracle that I started printing the first time. Nozzle temperature 245°, table 60° nozzle diameter 0.8mm., Z step 0.20mm. Of course with a nozzle diameter of 0.4mm. the tested part would have turned out much more attractive. I'm printing these discs to see if it's possible to print with the tested plastics.

It's a miracle that I started printing the first time. Nozzle temperature 245°, table 60° nozzle diameter 0.8mm., Z step 0.20mm. Of course with a nozzle diameter of 0.4mm. the tested part would have turned out much more attractive. I'm printing these discs to see if it's possible to print with the tested plastics.

Next I want to test the spiral print. It has already become a tradition. Previous samples I printed from car headlights, PVC windows, audio tape. At first, of course, I was a little upset that such a low-quality print was obtained.

I looked closely and noticed that the previous layers do not have time to cool. Most likely for printing with this polymer you need a good airflow. Unfortunately, there was no airflow on the printer on which I am testing. Will have to make from improvised materials. Blowing solved the problem.

You will not find such a filament in the store. When heated, gas vapors are poisonous. Heating above 80° is already dangerous. I read that vinyl has a sweetish taste when heated, which of course I felt myself in the workshop. I use protective equipment and I turn on the ventilation at full capacity.

I read that vinyl has a sweetish taste when heated, which of course I felt myself in the workshop. I use protective equipment and I turn on the ventilation at full capacity.

Finally, as always, you need something for yourself. Without hesitation, the idea arose to print a mount for goggles. These glasses are constantly lying around the room, more than once I broke stepping on them. We need to make sure they are in the same place.

If you want, I will upload this model for download, but I think you can easily develop such a simple detail yourself.

You can create things out of vinyl, I don't think it's necessary. Vinyl records are already valuable. And take care of your health.

God bless you! See you!

vinyl

Subscribe author

Subscribe

Don't want

28

More interesting articles

eleven

Subscribe to the author

Subscribe

Don't want

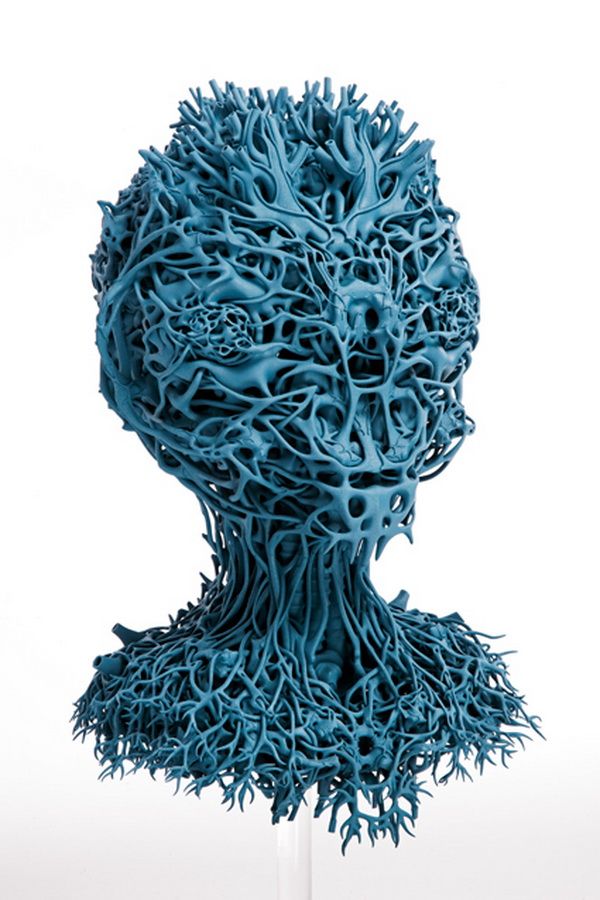

Hairy glass and children's billiards

As you can see from the previous article, me. ..

..

Read more

four

Subscribe to the author

Subscribe

Don't want

About two weeks ago I received new items - three-color PLA plastic from Eryone....

Read more

86

Subscribe to the author

Subscribe

Don't want

Greetings to all who intentionally or accidentally ended up on this page!

Considering...

Read more

3D printed vinyl and the eternal dispute

?

|

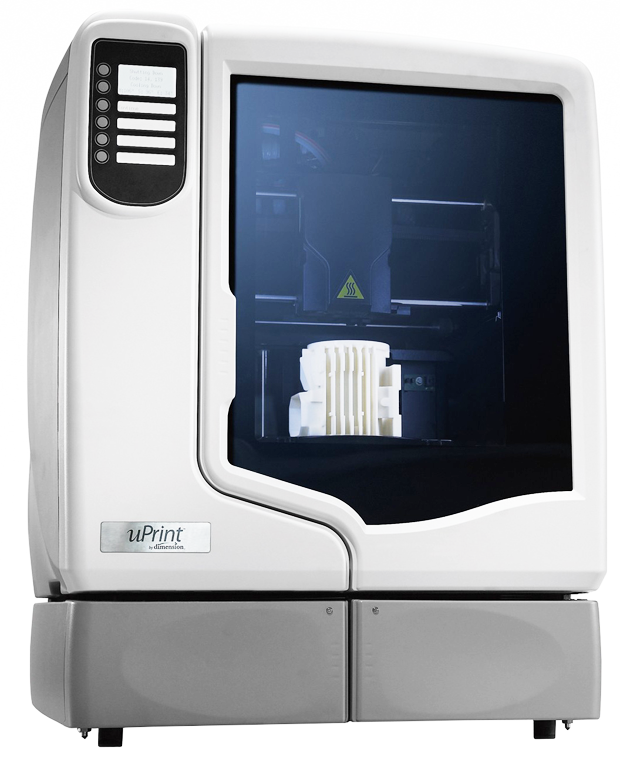

It turns out that it is possible, although it is still very bad, to print records on a printer. Not for the records, but for the idea. But I wanted a little about something else.

It turns out that it is possible, although it is still very bad, to print records on a printer. Not for the records, but for the idea. But I wanted a little about something else.  For example, any room distorts the sound due to reflections from walls and objects, but we hardly notice this. There are many more nuances associated with the production process, but here each format has its pros and cons. Usually, the bad or good sound quality of a particular recording is not due to the format, but to a bad or good production process. There are great and bad sounding vinyl, there are great and bad sounding CDs. But one of the unique properties of vinyl is the ability to record sound almost directly from a microphone to a master disc. Physically, this is the shortest path of a sound wave from the performer to the ear of the listener, separated by years and decades.

For example, any room distorts the sound due to reflections from walls and objects, but we hardly notice this. There are many more nuances associated with the production process, but here each format has its pros and cons. Usually, the bad or good sound quality of a particular recording is not due to the format, but to a bad or good production process. There are great and bad sounding vinyl, there are great and bad sounding CDs. But one of the unique properties of vinyl is the ability to record sound almost directly from a microphone to a master disc. Physically, this is the shortest path of a sound wave from the performer to the ear of the listener, separated by years and decades.