3D printers prices in egypt

3d Printer in Egypt, Classifieds in Egypt

للبيع 3d printer 30*30*30 طابعه ثلاثيه الابعاد

EGP 11,000Negotiable

Mokattam, Cairo•12 hours ago

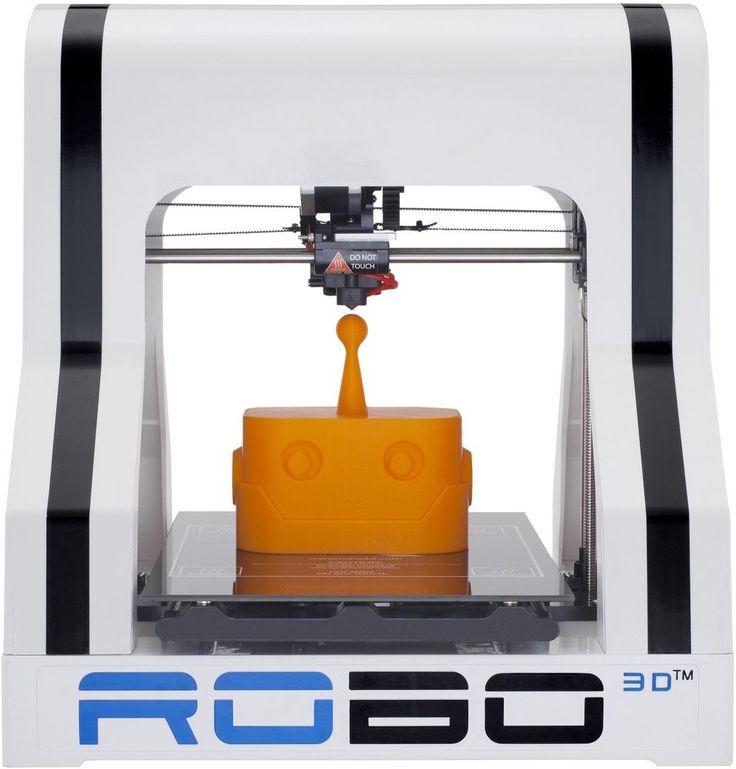

3d printer

EGP 8,500Negotiable

Menouf, Monufia•1 day ago

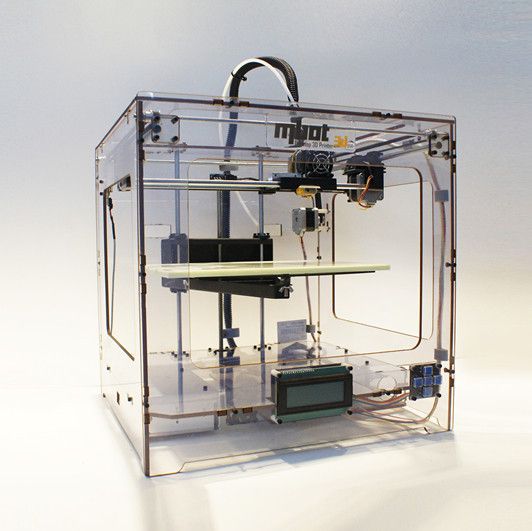

3d printer

EGP 12,000Negotiable

Abu Qir, Alexandria•3 days ago

طابعة Creality 3D CR-10

EGP 8,000

6th of October, Giza•3 days ago

طباعة ثلاثية الابعاد 3d printer سعر الجرام 1.45

EGP 2

Damanhour, Beheira•4 days ago

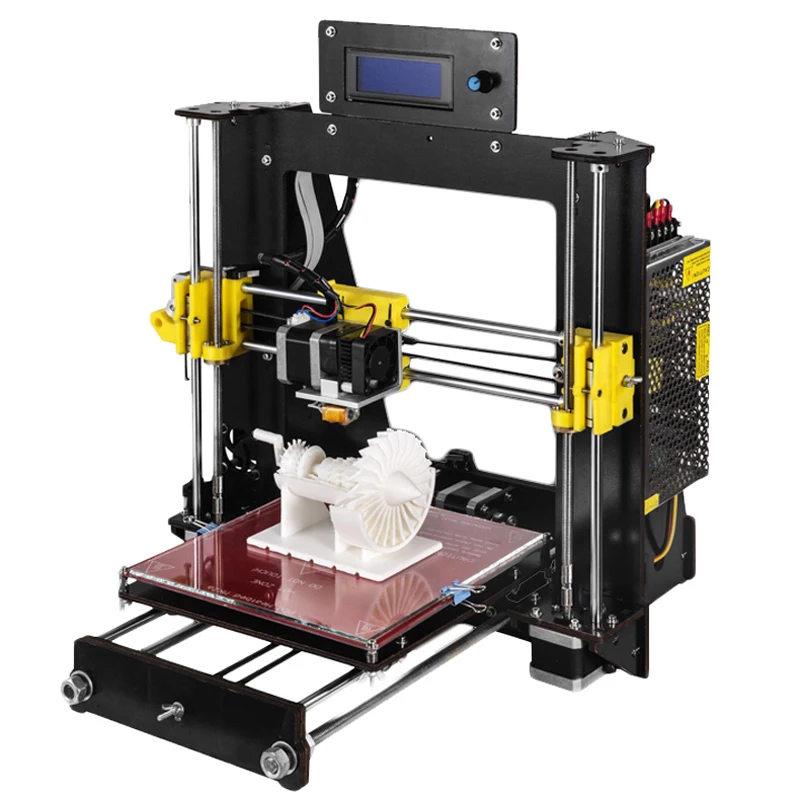

3d printer

EGP 15,000Negotiable

New Cairo - El Tagamoa, Cairo•1 week ago

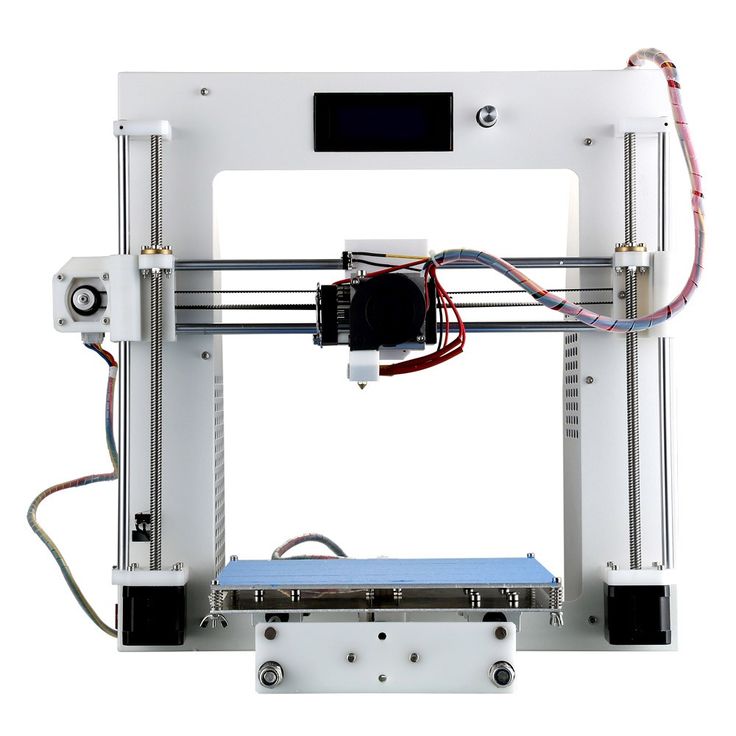

3D printer

EGP 12,500

Seyouf, Alexandria•1 week ago

طابعات ثلاثية الابعاد-3d printer

EGP 6,000

Agami, Alexandria•1 week ago

3d printer filament pla

EGP 3,500

6th of October, Giza•1 week ago

Want to see your stuff here?Gain more money through posting your ads, there is no easier and quicker way!

Creality Ender 3 Pro 3D Printer for sale

EGP 11,000

6th of October, Giza•1 week ago

3d printer طابعة ثلاثية الابعاد

EGP 11,000

Maamoura, Alexandria•2 weeks ago

طابعة ثلاثية الأبعاد 3d printer

EGP 8,500

Maamoura, Alexandria•2 weeks ago

3D Printer spare parts - قطع غيار وتجميع طابعة ثلاثية الابعاد

EGP 2,145

Al Ibrahimiyyah, Alexandria•2 weeks ago

تصنيع طباعات 3D Printer

EGP 1

Shubra al-Khaimah, Qalyubia•3 weeks ago

3d printer

EGP 100,000Negotiable

New Cairo - El Tagamoa, Cairo•3 weeks ago

3دي برنتر 3d printer

EGP 10

New Cairo - El Tagamoa, Cairo•3 weeks ago

3d printer ender 3 max

EGP 14,000

New Nozha, Cairo•3 weeks ago

5M GT2 Open Timing Belt 6mm 3D Printer Arduino CNC Projects اردوينو

EGP 110

Khosous, Qalyubia•3 weeks ago

Snapmaker 2. 0 A350 Modular 3-in-1 3D Printer

EGP 25,000

Giza District, Giza•4 weeks ago

3d printer

EGP 4,000

Asyut City, Asyut•4 weeks ago

3D Printer

EGP 17,000

Qanater al-Khairia, Qalyubia•4 weeks ago

3D printer

EGP 13,500

Qanater al-Khairia, Qalyubia•4 weeks ago

Anycubic Photon S - Photon Mono X SLA 3D Printer

EGP 15,000

Sheikh Zayed, Giza•4 weeks ago

Lead Screw Nut T8 8mm Thread 2mm Pitch 3D Printer Arduino CNC اردوينو

EGP 35

Khosous, Qalyubia•4 weeks ago

3d printer

EGP 8,500

Al Ibrahimiyyah, Alexandria•1 month ago

ثري دي برنتر - 3D PRINTER

EGP 9,500Negotiable

Shebin al-Koum, Monufia•1 month ago

Huge 3d Printer

EGP 11,000

Nasr City, Cairo•1 month ago

طابعة ثلاثية الابعاد Ender 3 pro 3d printer

EGP 17,000Negotiable

Tanta, Gharbia•1 month ago

3d printer creality ender3 v2 ماكينة طباعة ثلاثية الابعاد

EGP 11,999

Agami, Alexandria•1 month ago

3d printer طابعة ثلاثية الابعاد

EGP 5,500

Ain Shams, Cairo•1 month ago

3D Printer Prusa i3

EGP 10,000

Downtown Cairo, Cairo•1 month ago

3D Printer Photon Mono X 4K

EGP 20,000

Maadi, Cairo•1 month ago

3D PRINTER فائق الدقة للأعمال الدقيقة استعمال شهر واحد

EGP 18,000Negotiable

Azarita, Alexandria•1 month ago

Creality 3D Printer Ender-3 V2

EGP 12,500

Smoha, Alexandria•1 month ago

3d printer phrozen mini 4k

EGP 19,000

Heliopolis, Cairo•2 months ago

3d printer مع خاصية ups

EGP 9,000

Damanhour, Beheira•2 months ago

طباعة ثلاثية الابعاد سعر الجرام1. 65جنيه 3d printer

65جنيه 3d printer

EGP 1.65

Raml Station, Alexandria•2 months ago

3d printer Ender 5

EGP 10,000Negotiable

Sidi Beshr, Alexandria•2 months ago

3D printer new with 1 kg plastic. professional

EGP 8,000Negotiable

Hurghada, Red Sea•2 months ago

3d printer

EGP 4,400

New Cairo - El Tagamoa, Cairo•2 months ago

3d printer for seal

EGP 5,000

Maryotaya, Giza•2 months ago

EDME FDM 3D Printer

EGP 7,890

Obour City, Cairo•2 months ago

3d printer طابعة ثلاثية الابعاد

EGP 8,500

Maamoura, Alexandria•2 months ago

Anycubic Photon S 3D Printer

EGP 14,000Negotiable

Abasiya, Cairo•2 months ago

3D printer anycubic chiron 40X40

EGP 2,500

Dokki, Giza•2 months ago

First 3D printer for gold jewellery to be launched in Egypt: Mohamed El Hashemy

Lamina for Additive Manufacturing Technologies & 3D Printing is an Egyptian company aiming to disrupt the local gold jewellery market with 3D printing technology.

Mohamed El Hashemy, Chairperson of Lamina for Additive Manufacturing Technologies & 3D Printing, told Daily News Egypt that the design of gold and jewellery includes several stages, starting with the initial design, then the production of 3D wax models, and finally the stage of smelting and casting of gold ore turning it into gold jewelry ready to be sold in the market.

Daily News Egypt interviewed El Hashemy, to find out the company’s plans, and how would 3D printing change the local jewellery market.

When was Lamina established?

Lamina is a start-up company established in March 2017, through the Ministry of Investment’s Falak Startups, which is Egypt’s largest startup accelerator. Falak owns 4% of the company’s capital.

When did the company introduce the first 3D printer?

The company launched the first 3D printer for gold jewellery in February, intending to develop Egypt’s gold industry and shift from manual labour to technological manufacturing.

Did the company experiment with prototypes to reach the final model?

The company conducted several experiments with prototypes during the period from 2016 to 2018 to reach the best model of the 3D printer, to produce high-quality gold jewellery in addition to low economic costs to suit the requirements of SMEs.

What is the percentage of local materials in the printer?

The printer is produced in 90% local materials, aside from the projector, which is imported from a global company specialized in optical imaging. This is one of the main parts relevant to the quality and details of the preliminary wax models, which is part of the manufacturing stage.

Why didn’t you use an alternative to the projector as a light source from local materials?

The company conducted several experiments on the use of lasers as a light source, but the experience proved that the quality of wax prototypes was low in addition to the short life span of the material at only one year.

Is there a warranty on the printer?

The company gives customers a guarantee on the projector of 50,000 working hours and a one year on the printer.

Is the wax used in the manufacture of the prototype locally made?

The company is currently considering the preparation of its own new wax production line to be compatible with the printer. The printer can work with both local and imported wax.

How is the gold piece made of wax?

The idea of the printer is to build the jewellery piece inside the platform in the form of successive layers on top of one another made of liquid wax, which is dried by the shedding of a light source on it. The accuracy of showing the details depends on the severity of the light.

What is the sales volume of the company? What is the target by the end of this year?

Lamina achieved sales of EGP 500,000 during the first half of this year, selling 3D printers to produce gold and jewellery. We aim to increase the sales volume to EGP 1. 5m by the end of this year, through the marketing of its products to about 5,000 workshops that manufacture gold jewellery in the local market. We also aim to market the printers to jewellery designers and small business owners and colleges of art and design, within the framework of the development of the gold industry and transforming it from manual methods to modern methods that adopt the technology of producing gold jewellery through 3D printers.

5m by the end of this year, through the marketing of its products to about 5,000 workshops that manufacture gold jewellery in the local market. We also aim to market the printers to jewellery designers and small business owners and colleges of art and design, within the framework of the development of the gold industry and transforming it from manual methods to modern methods that adopt the technology of producing gold jewellery through 3D printers.

Do factories still rely on traditional gold production methods?

A large percentage of gold workshops and factories in the Egyptian market are still dependent on the production of prototypes made of wax using manual methods, which do not commensurate with the recent boom in the gold industry.

The use of 3D techniques in the production of gold jewellery saves time, effort and labour as well as facilitate the implementation of complex designs. It also helps workshops and factories to turn into mass production.

Why do not factories and workshops accept to rely on modern technology in production?

Many workshops and companies were unable to turn to this technology because of the high cost of purchasing 3D printers, which range in price from $5,000 to $10,000.

What are the specifications and prices of the company’s 3D printer?

The printer is available in three different sizes, the first printer contains a platform area (4-6) cm with a height of 15 cm, and is suitable for low production volumes, worth EGP 115,000. The second printer has a platform area (5.5 – 9.5) cm with a height of 15 cm and suitable for medium-sized products, worth EGP 170,000. The third printer contains a platform area (7.9 – 13.5) cm with a height of 15 cm and the value of EGP 220,000.

Does the company provide other services?

The company offers integrated services for gold and jewellery production, including training courses in the management and operation of these 3D printers, in addition to the gold jewellery design software such as RhinoGold and Matrix. We are working with universities to implement graduation projects instead of only designing jewellery.

How much does a 3D printer cost?

3D printing is a one-stop solution for a wide range of applications, from high-resolution model production to rapid prototyping, rapid tooling for traditional manufacturing processes, production of aids and end-use models.

However, when you consider investing in a 3D printer, the viability of a solution usually boils down to a simple question: Is it cost-effective for your business? How much does a 3D printer cost and how much time and money can it save your business?

3D printer prices range from $200 to $500,000 depending on the printing process, materials, and complexity of the solution.

In this guide, we'll break down 3D printing costs by technology, compare outsourcing versus in-house manufacturing, list factors to consider when calculating the cost of each model, and look at what else to look for when comparing different solutions. for 3D printing and other production methods.

Interactive

This interactive ROI tool will help you find out how much time and money you can save by 3D printing with a Formlabs 3D printer.

Calculate Your Costs

The three most well-known plastic 3D printing technologies today are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Each technology has its advantages and disadvantages - take a look at the infographic:

Download this high resolution infographic here. Interested in learning more about FDM, SLA and SLS 3D printing technologies? Check out our detailed guide.

Prices for 3D printers have dropped significantly in recent years, and today all three technologies are available in compact, low cost systems.

FDM generally produces models at a lower cost if you only print relatively simple prototypes in limited quantities. SLA technology offers higher resolution and quality, as well as a wide choice of 3D printing materials at a slightly higher price. But this difference is quickly offset when you print complex designs or larger batches due to the less labor-intensive post-processing process. Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models.

Comparing the total cost of different 3D printers by price tags alone will not give you a complete picture of how the cost of a 3D printer and a printed model will compare. The cost of 3D printing materials and labor significantly affects the cost of a model, depending on the application and your production needs.

The cost of 3D printing materials and labor significantly affects the cost of a model, depending on the application and your production needs.

Let's look at the different factors and costs for each process.

FDM, also known as Fused Filament Manufacturing (FFF), is a printing method where the parts of a model are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer onto the model being made.

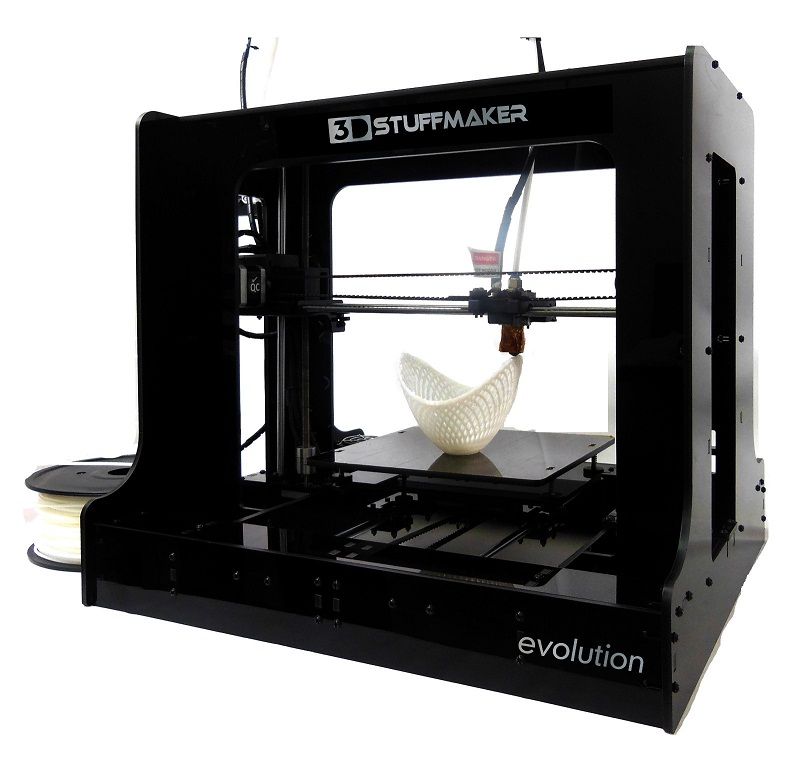

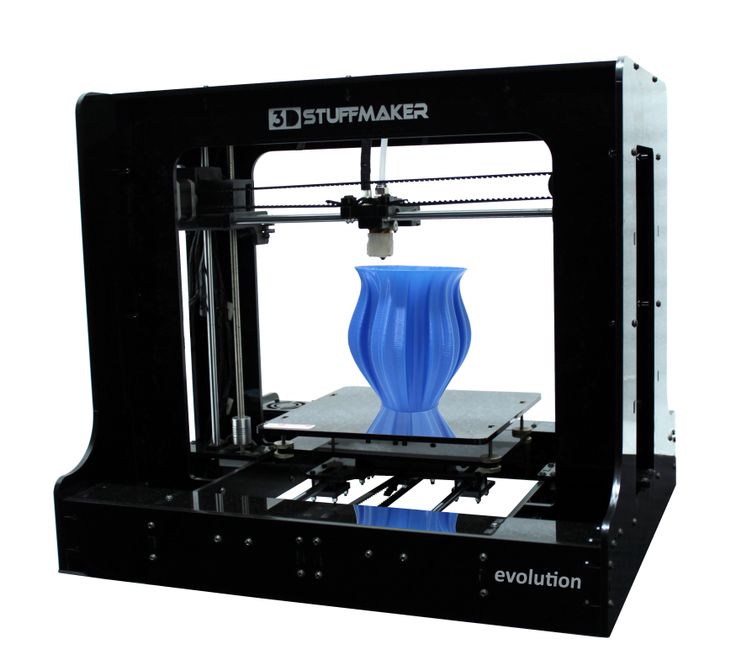

FDM is the most popular form of consumer grade 3D printing, fueled by the proliferation of hobbyist 3D printers. However, professional and industrial FDM printers are also popular among professionals.

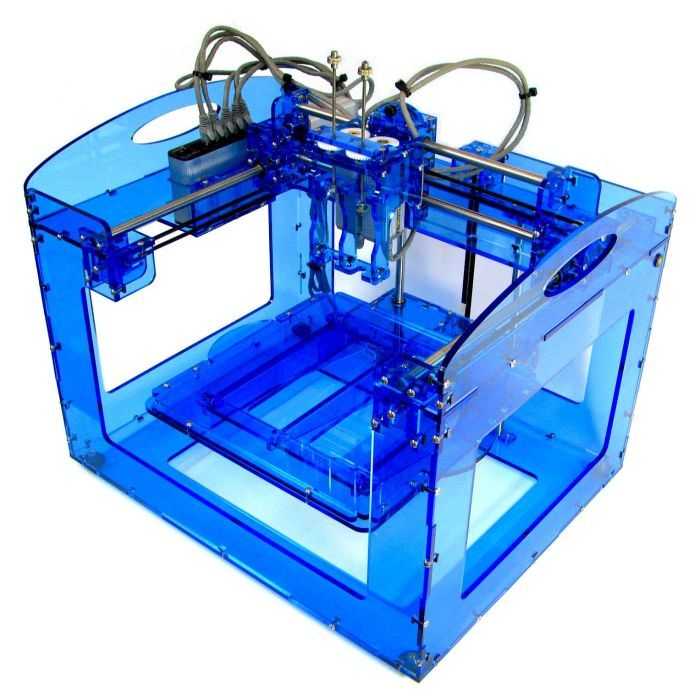

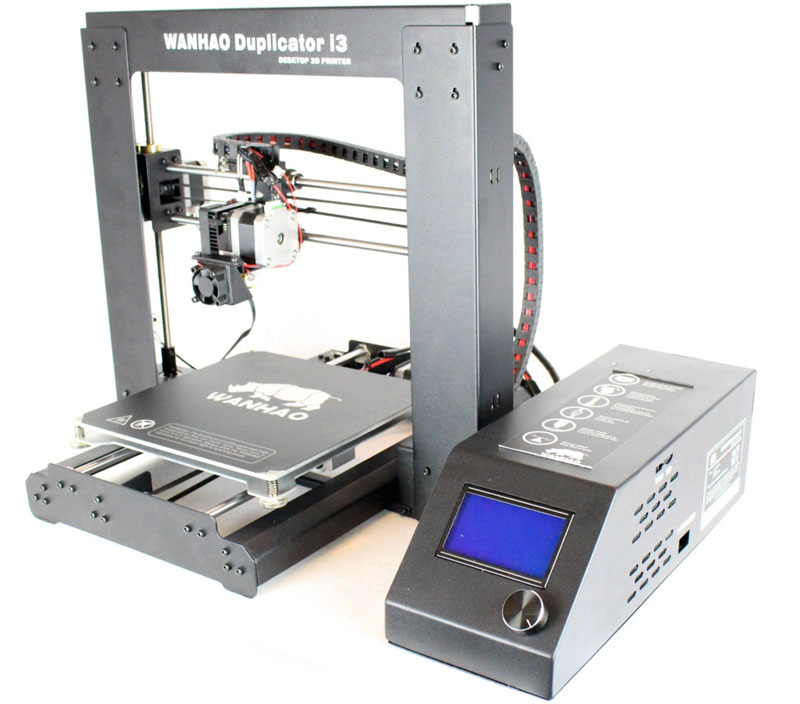

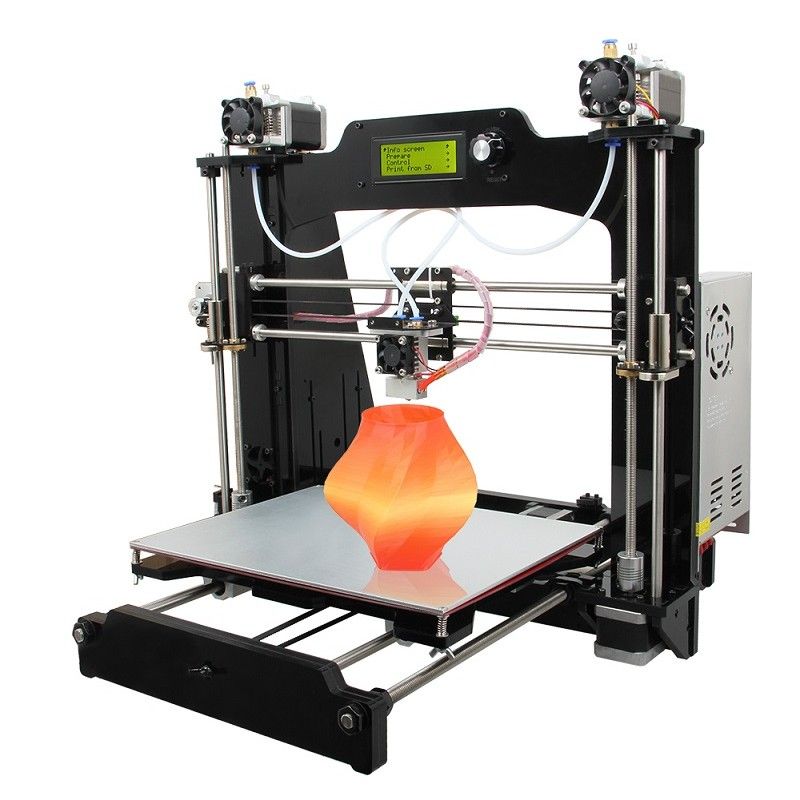

The cheapest 3D printers are FDM printers. DIY kits for FDM 3D printers start at $200. However, most of these models are more like toys or DIY projects that require a significant amount of time to build, set up and calibrate. The quality of the print largely depends on the success of these operations. In addition, machines require repairs and regular maintenance to keep them working, so they are more suitable for people with a higher engineering education who have a lot of time and patience.

Hobbyist FDM 3D printers cost between $500 and $1,500, come pre-assembled or unassembled, require less setup, but have the same disadvantages as the cheapest 3D printers. More expensive models are capable of large print volumes and work with a wide variety of materials besides low temperature ones such as PLA.

Professional 3D FDM printers start at $2,500 and large format professional FDM printers are available from $4,000. The cost of the most modern industrial FDM printers can exceed 10,000 US dollars. Most of these printers come pre-assembled and calibrated in the box, or they can be automatically calibrated. Printers in this category offer better print quality, a wider range of media, higher print volumes, improved reliability, and ease of use and maintenance. In addition, professional 3D printer manufacturers offer customer support services for troubleshooting.

Material costs for FDM 3D printing range from $50 to $150/kg for most standard and engineering filaments, and $100 to $200/kg for auxiliary materials. There are also cheaper alternatives, but they are of lower quality.

There are also cheaper alternatives, but they are of lower quality.

In addition, FDM printing can be very labor intensive. Successful printing of complex models requires support structures that must be removed manually or dissolved in water. To obtain a high quality surface and remove layer lines, lengthy manual post-processing of models, such as sanding, is necessary.

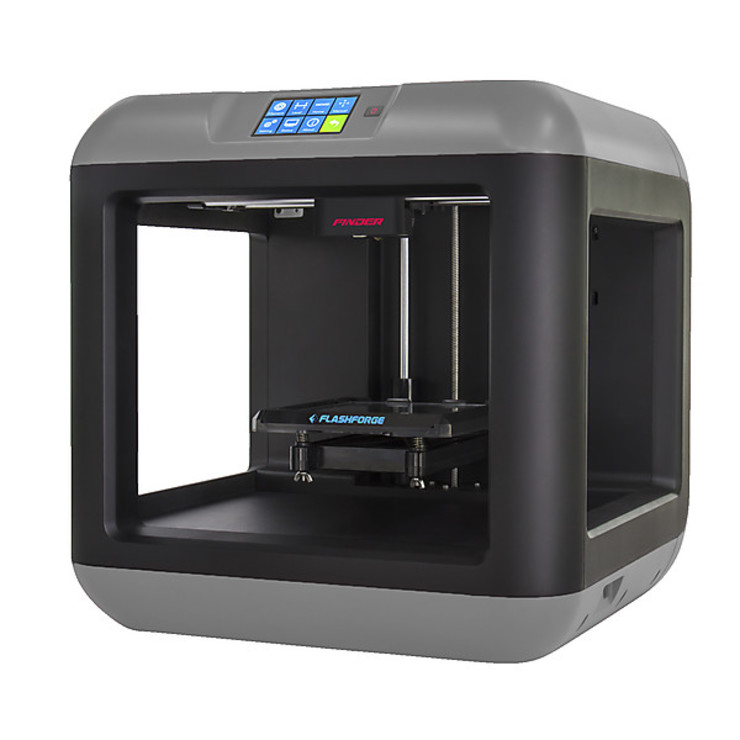

SLA 3D printers use the process of photopolymerization, that is, the conversion of liquid polymers into hardened plastic using a laser. SLA is one of the most popular processes among professionals due to its high resolution, accuracy and material versatility.

Models printed on SLA printers have the highest precision, sharpest detail and smoothest surface possible of any plastic 3D printing technology. But the main advantage of the SLA method is its versatility. SLA polymers have a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics.

SLA 3D printers can handle a wide range of resin materials for a wide variety of applications.

SLA used to be used only in large and complex industrial 3D printers costing over $200,000, but the process is now much more affordable. With the Formlabs Form 3+ Printer, businesses can now use industrial quality SLA printing for as little as $3,750. With Form 3L, large format SLA printing starts at just $11,000.

Stereolithographic 3D printers will be shipped in a box assembled and calibrated. These are professional tools that are highly reliable and require virtually no maintenance. Technical support is also always available. It provides troubleshooting in a critical situation (but its probability is extremely small).

Most standard and engineered polymers for SLA technology cost between $149 and $200 per liter.

SLA printers are easy to use and many workflow steps such as rinsing and final curing can be automated to reduce labor costs. Printed models have a high quality surface immediately after printing and require only simple post-processing to remove supporting structures.

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper.

Models produced using SLS printing have excellent mechanical characteristics - their strength can be compared with the strength of injection molded parts. As a result, SLS technology is the most popular plastic 3D printing process for industrial applications.

SLS printed nylon models are ideal for a range of functional applications, from consumer product design to healthcare applications.

Like SLA, SLS was previously only available in large format, complex 3D printing systems costing $200,000 or more. With the Formlabs Fuse 1 stereolithography printer, businesses can now solve industrial-scale tasks with SLS technology starting at $18,500. The complete kit, which includes the post-processing and powder recovery system, costs $31,845.

The complete kit, which includes the post-processing and powder recovery system, costs $31,845.

As with SLA printers, stereolithographic printers are shipped assembled and calibrated in the box. They are reliable and can operate 24/7. The package includes in-depth training and fast technical support.

SLS nylon print materials cost about US$100/kg. SLS does not require supporting structures and unused powder can be reused, reducing material costs.

SLS is the least labor-intensive plastic 3D printing process in the production environment, because the printed models are of high quality right away, and to remove excess powder, they simply need to be cleaned.

There are several processes for 3D printing not only plastics but also metals.

Metal FDM printers are similar in design to traditional FDM printers, but use extruded metal rods held together by a resin binder. The finished parts of the model are sintered in an oven to remove the binder.

SLM and DMLS printers are similar to SLS printers, but instead of polymer powders, they fuse metal powder particles layer by layer using a laser. 3D printers based on SLM and DMLS technologies can create strong, precise and complex metal products, making this process ideal for the aerospace, automotive and medical industries.

3D printers based on SLM and DMLS technologies can create strong, precise and complex metal products, making this process ideal for the aerospace, automotive and medical industries.

Prices for metal 3D printers have also begun to decline, ranging from $100,000 to $1 million today. However, these systems are still out of reach for most businesses.

SLA 3D printing is available as an alternative for casting workflows that allow metal models to be produced cheaper and faster than traditional methods and provide greater design freedom.

Technical report

Get design guides for 3D printing samples, see the step-by-step direct investment casting process, and study guides for indirect investment casting and sand casting.

Download white paper

Different plastic and metal 3D printing processes have unique qualities that make them suitable for different applications. Below is a comparison of different printing technologies.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | Metal FDM Printing | Selective Laser Melting (SLM) and Direct Metal Sintering (19008) 9008 | |

|---|---|---|---|---|---|

| Permission | ★☆ | ★ opa ★ ution | ★ opa | ★ opa | ★ opa ventary | Surgery | ★ opa ☆ | 1111111 ☆☆☆ | 1 ☆ | ★ opa |

| Ease of use | x 300 x 600 mm (Desktop and Workshop 3D printers) | Up to ~300 x 335 x 200 mm (Desktop and Workshop 3D printers) | Up to 165 x 165 x 300 mm (3D - workshop printers) | Up to 300 x 200 x 200 mm | Up to 400 x 400 x 400 mm |

| Price range | DIY kits for 3D printers start at $200 and hobby printers cost $500-1500. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. | Professional desktop printers start at $3,750 and high-volume large format desktop printers are available from $11,000. | Workshop industrial printers start at $18,500 and traditional industrial printers start at $100,000. | Metal FDM printers start at $100,000, but complete solutions including an oven are much more expensive. | DMLS/SLM solutions start at around $200,000. These printers require special infrastructure conditions, which can further increase costs. |

| Cost of materials | US$50-150/kg for most standard and engineering yarns and US$100-200/kg for auxiliary materials. | US$50-150/L for most standard and engineering polymers. | US$100/kg for nylon. SLS does not require supporting structures and unused powder can be reused, reducing material costs. | Depends on material and technology. Significantly higher than plastic. | Depends on material and technology. Significantly higher than plastic. |

| Labor | Manual removal of support structures (soluble support structures may be used in some cases). Long post-processing is required to obtain a high quality surface. | Washing and final polymerization (both can be automated). Simple post-processing to remove supporting structures. | Easy cleaning to remove excess powder. | Washing and sintering (both can be automated). It is possible to use mechanical processing and other types of surface treatment. | Stress relief, support structure removal, heat treatment, and mechanical and other surface treatments. |

| Materials | Standard thermoplastics such as ABS, PLA and their various blends. | Various polymers (thermosetting plastics). Standard, engineering (similar to ABS and PP, similar to silicone, flexible, heat resistant, rigid), injection molding, dental and medical (biocompatible). | Engineering thermoplastics - typically nylon and its composites (nylon 12 biocompatible + sterilizable). | Stainless steel, tool steel, inconel, copper, titanium. | Stainless steel, tool steel, titanium, cobalt-chromium, copper, aluminium, nickel alloys. |

| Applications | Basic experimental models, low cost rapid prototyping of simple parts. | Prototypes with a high level of detail requiring close tolerances and smooth surfaces: molds, tooling, templates, medical models and functional parts. | Complex geometries, functional prototypes, low volume production or limited trial production. | Strong and durable models, tools and production aids. | Strong and durable models with complex geometries; ideal for the aerospace, automotive and medical industries. |

When calculating the cost of one model, the cost of ownership of equipment, material costs and labor costs are usually taken into account. It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs.

Hardware ownership costs are fixed costs: 3D printer price, service contracts, installation and maintenance. These amounts must be paid whether your printer is idle or produces dozens of models per week.

Add up all projected fixed costs over the lifetime of the equipment, then divide by the number of models you plan to make. As a rule, the higher the performance and efficiency of your 3D printer, the lower the cost of ownership of equipment per model.

In recent years, desktop 3D printers have shown excellent results in reducing the cost of ownership of equipment. With a price 10 to 100 times lower than traditional industrial 3D printers and the ability to produce thousands of models over a lifetime, the cost of ownership can be negligible.

Questions:

-

Are there installation, training or additional initial costs other than the cost of the machine itself?

-

Do I need to sign a (mandatory) service contract? What does it include?

-

What accessories and tools are needed to make the final models?

-

What kind of maintenance is required for the machine to function properly? What is the expected annual maintenance cost? Will it change with an increase in production volumes?

The 3D printing raw materials and consumables you need to create models at an affordable price. These costs largely depend on the number of models you produce.

These costs largely depend on the number of models you produce.

When calculating the cost of materials, determine how much material is required to create one model, and multiply this figure by the cost of the material. Count the amount of waste and any other consumables. As production grows, the cost of ownership of equipment decreases, and the cost of 3D printing materials tends to become more balanced.

Be sure to check what materials you need to create specific models, as the cost of 3D printing consumables can vary greatly. Please note that some 3D printers only work with their proprietary materials and thus limit your ability to use third party materials.

Questions:

-

What is the cost of each type of 3D printing material?

-

How much material is required to create one particular model, including waste?

-

What is the shelf life of the materials?

-

Do I need other consumables to create models?

-

Can the machine work with third-party materials?

While 3D printing can replace complex traditional manufacturing methods and provide significant time savings, depending on the 3D printing technology, it can still be quite labor intensive.

Professional desktop 3D printers are generally optimized for ease of use. DIY kits for 3D printers and hobby printers often require additional effort to adjust settings, while regular maintenance or material changes on traditional industrial machines can involve time-consuming tasks that require the assistance of a skilled operator.

Post-processing workflows vary depending on the 3D printing process, but in most cases include cleaning up models and removing support structures or excess material. However, there are solutions to automate some specific tasks. For example, Formlabs Form Wash and Form Cure simplify the wash and finish process for Formlabs SLA 3D printers, while Fuse Sift offers a turnkey post-processing and powder recovery system for the Fuse 1 SLS printer.

More complex processes such as SLA and SLS do not take long to achieve high quality models, while FDM models require lengthy manual post-processing to improve quality and remove layer lines.

Questions:

-

What is the whole model production workflow? What specific steps are required to set up printing, change materials, and post-process models?

-

How long does it take to post-process one specific model?

-

Are there any tools or devices available to automate some of these tasks?

Outsource production orders to 3rd party service bureaus or labs when you use 3D printing only occasionally or to produce large models in non-standard materials. Typically, the bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes.

Typically, the bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes.

The main disadvantages of outsourcing are the high cost and duration of production. One of the main advantages of 3D printing is its speed compared to traditional production methods. But it is noticeably reduced if the delivery of the model produced by the involved organization takes several days or even weeks. And as demand and capacity grow, the costs of outsourcing are rising rapidly.

Desktop 3D printers are the perfect solution for fast model production. Depending on the number of parts needed and the volume of prints, the investment in a professional 3D printer can pay for itself in just a few months.

With desktop and workshop printers, you can pay for the capacity that matches your business needs and scale your production by adding more devices as demand grows, without the heavy investment of a large format 3D printer. Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Investment, material and labor costs are relatively easy to calculate. But what about indirect costs and hard-to-calculate factors that affect your business? Let's look at some of the main considerations when comparing a desktop 3D printer to outsourcing or other manufacturing methods.

Save time: What if you could get products to market a few months faster? Or reduce the delivery time of your products by a few days or weeks? 3D printing simplifies traditional prototyping and manufacturing workflows, helping you save time and stay ahead of the competition.

Top results: 3D printing allows you to create more iterations, overcome failures faster, and produce better end products. Troubleshooting a design early on also helps avoid costly redesign and the use of additional tools.

Interaction: Having high-quality prototypes and models allows you to communicate more effectively with customers, clients, suppliers and other stakeholders. Avoid misunderstandings and costly mistakes.

Intellectual Property Protection: Do you work with confidential information? Making your own models means you don't have to transfer intellectual property (IP) to third parties, reducing the risk of IP leakage or theft.

Usually, calculating cost per part, lead time, and comparing alternatives to see if a solution is right for your business is a tedious task of creating a complex spreadsheet in an attempt to collect all of the often hidden information from a manufacturer.

Use our simple online tool to calculate cost per model and order lead time when printing with a Formlabs stereolithographic 3D printer and compare time and cost savings with other manufacturing methods.

Calculate your cost and time

Lenovo Legion 5 15ACH6H 15.