Biodegradable filament 3d printing

Fillamentum unveils first fully biodegradable filament NonOilen for 3D printing

0Shares

Czech 3D printing filament producer Fillamentum has launched its first 100 percent biodegradable filament for 3D printing, NonOilen.

The biobased filament is made from a blend of polylactic acid (PLA) and polyhydroxy butyrate (PHB) to yield improved toughness and temperature-resistant properties. It can be reused time and again to adhere to the principles of a circular economy.

Once an object printed with NonOilen reaches the end of its lifecycle, it can be fully degraded to biomass, water, and carbon dioxide (CO2) in compost or food waste disposal or sent back to Fillamentum for recycling. The company has also joined the DHL GoGreen program to neutralize its carbon footprint with each NonOilen parcel sent via the delivery service.

According to the company, the driving force behind creating NonOilen was to reduce the use of fossil resources, such as oil, to make its 3D printable filaments and reduce the firm’s environmental footprint on the planet.

Developing a fully biobased and biodegradable filament

Previous attempts to improve the biodegradability of plastics include the creation of oxo-bioplastics, where standard polymers were modified by adding substances that cause degradation in the presence of oxygen. However, these oxo-bioplastics can not be sufficiently degraded in compost as secondary microplastics, created as the plastic decays, can have harmful effects on the surrounding environment, such as soil or oceans.

To solve this problem, Fillamentum states that new ways to degrade such polymers need to be discovered, in addition to finding new sources to replace fossil resources in creating biodegradable polymers with high-value use and improvements in waste handling.

To this end, the company’s latest 3D printing filament, NonOilen, has emerged out of a long-term partnership with the research team of Professor Pavol Alexy from the Slovak Technical University in Bratislava, Slovakia. The filament is 100 percent biodegradable and all polymers used in its production are fully biobased.

The filament is 100 percent biodegradable and all polymers used in its production are fully biobased.

Once an object reaches the end of its lifetime, it can be placed in industrial or home food waste composters where degradation takes place around three times faster than standard PLA. The PHB in NonOilen acts as an initiator for the breakdown process, allowing bacteria to depolymerize and metabolize the polymer quicker.

Alternatively, if sent back to Fillamentum the material will be recycled and reused several more times while retaining its mechanical properties.

The principle of a circular economy. Image via Fillamentum.Mechanical properties of NonOilen

In addition to its biodegradable credentials, NonOilen also possesses improved toughness, hardness, and strength properties when compared to standard PLA, as a result of its PHB content.

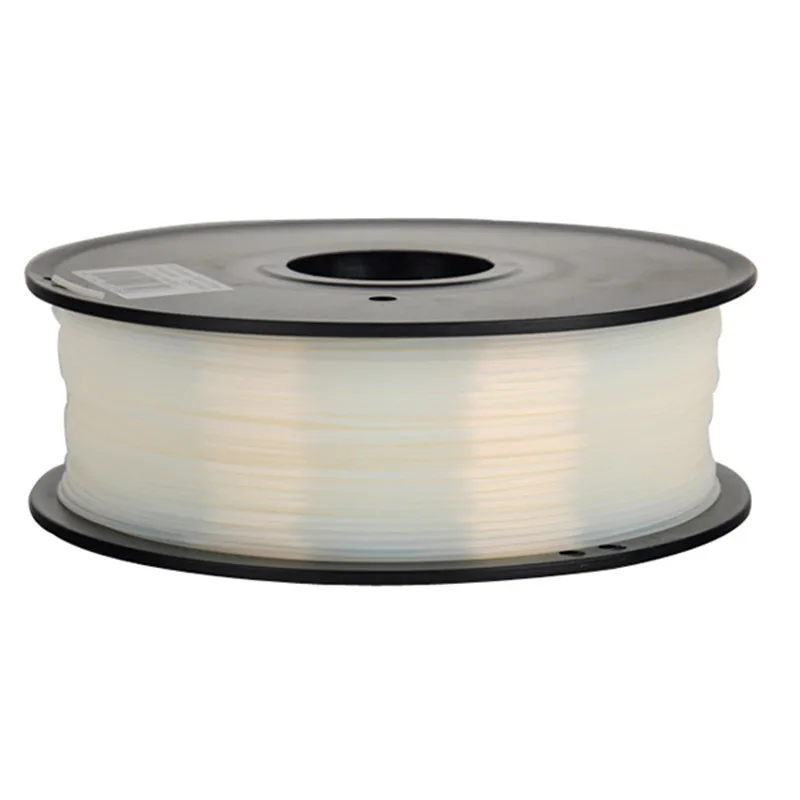

One of the main advantages of the filament is its temperature resistance up to 110 degrees celsius after 3D printing, meaning there is no need for annealing. NonOilen is easily printed, reportedly comparable to the ease of printing with standard PLA, with parts featuring a smooth surface with a natural silk look that is translucent when printed in a thin layer.

NonOilen is easily printed, reportedly comparable to the ease of printing with standard PLA, with parts featuring a smooth surface with a natural silk look that is translucent when printed in a thin layer.

Objects printed with NonOilen showcase long-term durability and are safe for food contact applications. The filament can also be used for the production of 3D printed electrical components and electronic equipment.

According to Fillamentum, NonOilen can retain its mechanical properties even after being recycled “many times”, an improvement on the firm’s other biodegradable filaments PLA Extrafill and PLA Crystal Clear, which both experience at least some loss of mechanical properties when recycled. What’s more, the material performs significantly better than the firm’s Timberfill filament which, while biodegradable, cannot be recycled.

NonOilen also has a substantially higher temperature resistance than the company’s other biodegradable filaments and boasts a considerably shorter biodegrading timeframe.

“Green prototyping” of NonOilen by Fremach

Fremach, a global supplier of complex plastic components to the automotive market, has tested Fillamentum’s NonOilen filament in the production of control gauges and gears. The firm chose the material for its ability to resist high temperatures and for its complete recyclability, which is a welcome benefit when printing large numbers of these components.

The gauges are used to check the positions of symbols on decorative parts, which then go unused once their purpose has been served. The recyclability of NonOilen is therefore a huge benefit to the company and enables Fremach to significantly reduce waste. The 3D printed gears form part of a rotating system for painting cylindrical parts, and here Fremach hails the filament’s ability to resist the high temperatures that the gears are exposed to in the pant shop furnace without deforming.

“The benefits of 3D printing are obvious and are increasingly important to our business,” said Miroslava Pribylova, Process Engineer for Fremach. “Furthermore, Fillamentum’s ecological thinking motivates us to take our own steps closer to nature.”

In cooperation with Fillamentum, Fremach will regularly collect and recycle unused parts made of NonOilen materials for use in its own production. As of today, Fillamentum is available for purchase and shipping.

NonOilen retains its mechanical properties even after being recycled many times. Photo via Fillamentum.Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Fillamentum NonOilen filament is biobased and fully biodegradable. Photo via Fillamentum.

Photo via Fillamentum.

Tags DHL GoGreen Fillamentum Fremach NonOilen PLA Crystal Clear PLA Extrafill Slovak Technical University Timberfill

Hayley Everett

Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

Eco-friendly 3D filament guide - what are the possibilities and innovations

What is eco-friendly 3D filament?

Eco-friendly 3D filament is a new alternative to the classic plastic filament. 3D printing requires a lot of energy and often uses non-biodegradable materials. For example, ABS is made from petroleum. It is one of the most common 3D printing materials when it comes to filament extrusion.

However, innovations now offer the opportunity to 3D print ecologically and responsibly at a lower cost. Many biodegradable filaments, made from recycled materials, have been developed to be environmentally friendly and have become alternatives to plastic filaments.

Many biodegradable filaments, made from recycled materials, have been developed to be environmentally friendly and have become alternatives to plastic filaments.

By incorporating a biodegradable plastic base (in the form of fibers or powders), it is possible to create filaments that include a high percentage of organic material.

3D printing from recycled plastics

How to make 3D printing materials from plastic waste

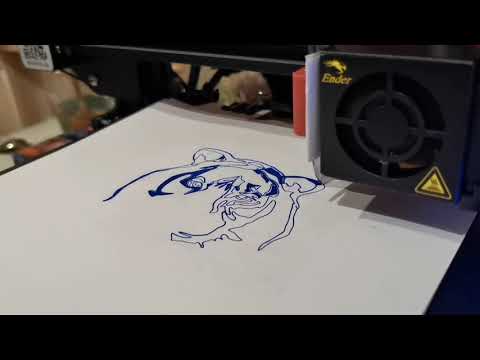

Thanks to Tyler McNaney’s Filabot, or MIT’s Recyclebot, it is possible to create ecological filament at home by recycling plastic waste. These machines turn waste into a 3D filament that a 3D printer can use.

A bottle of milk recycled by the Filabot converts into 2.5 meters of 3D filament.

First, the machine crushes recyclable plastic waste (bottles, boxes, etc.) to transform it into plastic pellets (or granules). The recycling machine then heats and extrudes these pellets into the shape of filament. The filament is then wrapped around a spool so that it can be reused again by a 3D printer.

The filament is then wrapped around a spool so that it can be reused again by a 3D printer.

Reuse 3D printed objects and plastic print waste

3D printing requires patience and involves a lot of testing to perfectly configure a 3D printer and produce quality 3D models. Many of these tests result in print fails, extra material, supports, or simply old pieces that are no longer useful.

Plastic waste extruders such as the Filabot or ProtoCycler can recycle this plastic waste. This innovation, with its ecological aspect, also represents a big cost saving for the users who can reduce their 3D filament expenses.

Various 3D-printed objects made from old plastic waste that was turned into filament by the ProtoCycler.Buy 3D filament made from recycled materials

The Dutch startup Refil sells 3D filament made from two recycled plastics, ABS and PET. These two plastics mainly come from plastic bottles and car dashboards. This award-winning innovation is called Refilament.

These two plastics mainly come from plastic bottles and car dashboards. This award-winning innovation is called Refilament.

According to Refil’s co-founder Casper van der Meer, the recycled filament (free of toxic additives), boasts the same features as ordinary filament and is available at a price between 30 and 40 dollars a spool.

Black ABS 3D filament produced by Refil from old car dashboards.3D printing with biodegradable 3D filament

PLA, a cornstarch-based 3D printing material

With ABS, PLA is the most commonly used 3D printing material when it comes to filament deposition.

PLA is made from cornstarch. It is compatible with most 3D printers using extrusion 3D printing technology.

Unlike ABS, PLA is a biodegradable material. Thanks to its non-toxicity, PLA can also be used to 3D print objects that will be in contact with food.

The main weakness of PLA is its high sensitivity to moisture and its tendency to break rather than bend. It makes it more difficult to handle than ABS.

It makes it more difficult to handle than ABS.

Sustainable 3D printing: paper, an alternative to plastic

Mcor Technologies (now CleanGreen 3D) is a 3D printer manufacturer that has successfully made 3D printing material from paper. Their Laminar 3D printing technology successively cuts sheets of paper and glues them onto each other to 3D print an object.

Paper is not as environmentally friendly as PLA, but it is a serious alternative to more toxic materials. It also costs much less: a ton of paper costs around €1,300 while a ton of PLA costs between €5,000 and €10,000.

A colorful and complex geometric figure 3D printed with paper using a Mcor 300+ printer.Plant-based 3D printing materials

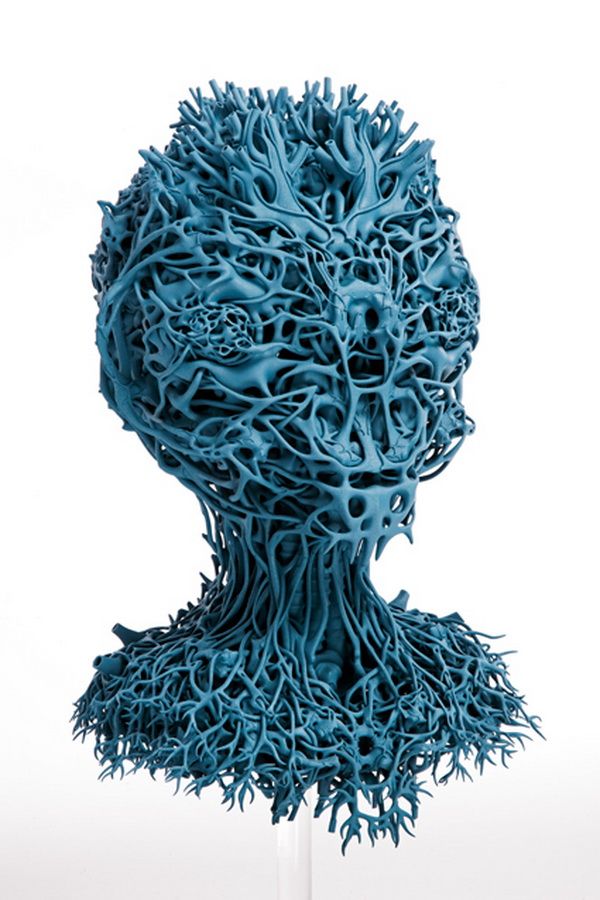

Many plant-based filaments have been developed, such as the soy-based FilaSoy or SeaWeed, a material made from seaweed. The Algix from 3DFuel is also available and is made from nuisance algae.

Wood is also a material that is used to make natural 3D filaments. For example, Laywood is made up of 40% of wood, which gives it a touch and appearance similar to wood.

ColorFabb has even developed two 100% organic filaments: the WoodFill made up of 70% PLA and 30% wood fiber, and the BambooFill, half bamboo, and half PLA.

Finally, oysters and coconuts have also been experimentally used to create new 3D filaments.

A small 3D printed elephant made with ColorFabb’s Woodfill material.3D printing with recycled building materials

3D printed houses made from recycled concrete

The Chinese company WinSun Decoration Design Engineering received attention in 2014 by 3D printing ten houses in less than 24 hours. These were 3D printed from a mix of cement, industrial waste, and recycled fiberglass. In 2015, they did it again, this time with a four-story building, and also succeeded in less than 24 hours.

In January 2018, the same company 3D printed bus stops at Fengjing Town in Shanghai.

In Amsterdam, a canal house was also 3D printed by DUS Architects in 2016. This house, designed in partnership with Henkel, is 3D printed with bioplastics. It consists of 80% ecological materials.

Examples: two innovative projects to recycle plastic waste

An eco-friendly 3D printer launched by Coca-Cola, 3D Systems, and will.i.am

will.i.am, who was previously creative director of the 3D printer manufacturer 3D Systems, had teamed up with Coca-Cola to create Ekocycle. The Ekocycle is a 3D printer that uses a 3D filament, of which 25% is made from recycled plastic bottles.

“Ekocycle’s goal is to collaborate with the world’s most influential brands and use technology, art, and fashion to change an entire culture. It’s the beginning of a more sustainable lifestyle through 3D printing. Waste is waste only if we waste it.”

will.i.am

Ekocycle will be able to 3D print objects with a build volume of one hundred cubic centimeters, with a minimum layer thickness of 70 microns.

Three 500ml Coca-Cola bottles are needed to make one Ekocycle cartridge. The available colors Coca-Cola’s emblematic colors: red, black, and white.

will.i.am, a founding member of the Black Eyed Peas and 3D Systems’ previous artistic director, presenting the Ekocycle eco-friendly 3D printer.Clean beaches and 3D printed souvenirs of the sea

In 2014, two Swiss entrepreneurs, Jennifer Gadient and Fabian Wyss, launched the Seafood Project. This project aimed to clean the beaches of France, Spain, and Morocco by recycling all plastic waste into 3D printed objects.

The couple left France in October 2014 and drove down to Morocco in their van, in which they had all the necessary equipment for 3D printing.

On the beaches, they recovered plugs, bottles, and other plastic waste. With the help of an extruder and a shredder, they transformed this waste into 3D filament. They then 3D printed objects with an Ultimaker 3D printer and sold them on their website.

Picture of Jennifer Gadient and Fabian Wyss in front of their van, equipped with a 3D printer to recycle plastic waste from beaches.Biodegradable thread. In search of the best eco-friendly thread.

There are still many unclear points in 3D printing. One of them - it will happen when everyone starts printing kilos of harmful ABS plastic without any control. Faced with this terrible future, many companies who started search of biodegradable thread is perfect. The holy grail of 3D printing.

In this article, we will look at market options for if we want our 3D prints to be environmentally friendly. in various chemicals included in its composition in natural environmental conditions .

This does not mean that everything that is biodegradable is good for the planet. There is glass, but in order for nature to assimilate the bottle, 4000 years must pass.

To define acceptable and unacceptable times, ISO 14885 (also called EN 13432). This standard specifies Biodegradability under controlled composting conditions . Decomposition level must be greater than 90% and this must be achieved within a period of time not exceeding 6 months .

Biodegradable Thread

Now that we have a clear idea of what biodegradable thread should be, we are going to look at the most common options in this sector for purchasing sustainable thread.

PLA

The main material used in 3D printing is PLA. is a polymer composed of lactic acid molecules which are usually obtained by processing corn starch, cassava or sugar cane. Time decomposition of is approximately 2 years .

The approximate cost of this thread is 20 euros per 1 kg coil.

ALGIKS3D

ALGIKS has several on the market fibers made from algae as raw material . They claim to use only harmful algae, so using their fibers is doubly good for the planet. To give the filament consistency, they have to mix this seafood with PLA. Unfortunately, they don't indicate how much they use of each material.

They guarantee that all material produced is 100% American product . They are also very focused on making their audience American and sell them affinity for the raw material.

They guarantee that the production of your thread will continue. the strictest quality control of and that the accuracy tolerance for thread thickness is maximum. All this to ensure that your filament does not clog the nozzles and other delicate parts of our printers.

the strictest quality control of and that the accuracy tolerance for thread thickness is maximum. All this to ensure that your filament does not clog the nozzles and other delicate parts of our printers.

This thread can be found at an approximate cost of 19euro per spool 300 gr.

Willowflex

Manufacturer Bioinspiration He tells us about this material without telling us where it came from, although in many cases many of its characteristics are compared with those of wood.

They explain to us that their material es is flexible and resistant to cold and heat. To demonstrate the quality of their manufacturing process, they mention a third company that actually manufactures the product to their specifications.

A very important detail is that we are told that your material impression complies with EN 13432 . That is, in less than 6 months, it degrades by 90%. They also confirmed that the produced compost does not contain heavy metals and is suitable for use in growing plants. Under less ideal conditions than those encountered during ISO certification, they have proven that it decomposes in a couple of years, just like wood.

They also confirmed that the produced compost does not contain heavy metals and is suitable for use in growing plants. Under less ideal conditions than those encountered during ISO certification, they have proven that it decomposes in a couple of years, just like wood.

And just like with wood, they assure us that we can use it in our facilities without fear that we will come in one morning and rot.

El Costa approximate value of this thread 29 € for 300 grams.

hummed

This is the first of several threads created by American 3D Fuel.

Este filamento made with waste resulting from brewing . The filament has a curious gold color and the print temperature is slightly lower than PLA. Ambient at 190ºC. The company also talks about a local product. The thread is produced in North Dakota with the strictest quality control. A 500gr reel can be found for 45 euros.

Biom3D

biome company it also has eco-friendly thread. In this case, it is from vegetable starches and oils . Thus, they assure us that the resulting filament is a high quality material with an exceptional finish and can print faster than PLA . However, we could not find the thread in stock in any store.

Enviro ABS

This is the only ABS thread what you will find in comparison. Yes, we said that ABS is not biodegradable. However, 3DPrintlife ha reformulated the chemical properties of the material to make it possible for to be consumed by some bacteria when is discarded. Being an ABS plastic, it retains the impressive characteristics of that material. And as the icing on the cake, they assure us that a share of the income from each reel It will be used plant a tree in one of the most emblematic forests in the US

HempBioPastic

This unique Italian project, which received the necessary donations on Kickstarter to make it a reality, offers plant-based filament . The raised project was completed in September of this year, and they are ready to be sent to patrons. We are assured that 100% of the material is made from waste industrial hemp . This characteristic gives printed objects of curious with veins . Kanesis also assures us that your product in is 20% lighter and 30% stronger than PLA . We can even print at a lower temperature than is required for PLA printing.

The raised project was completed in September of this year, and they are ready to be sent to patrons. We are assured that 100% of the material is made from waste industrial hemp . This characteristic gives printed objects of curious with veins . Kanesis also assures us that your product in is 20% lighter and 30% stronger than PLA . We can even print at a lower temperature than is required for PLA printing.

Filament is currently only being produced for delivery to KickStarter members. We will keep you posted when it finally becomes public.

The already named 3DFuels also has hemp-based thread since 2016.

Wound up

Another EcoFriendly thread developed by 3DFuel. With nice brown color and using coffee as raw material . Unfortunately, in this case, they were not able to create 100% coffee thread, and had to resort to using PLA as the basis of the resulting polymer. In this regard, they warn us that objects printed in this way cannot come into contact with very hot liquids or foodstuffs . A 500gr reel can be found for 45 euros.

In this regard, they warn us that objects printed in this way cannot come into contact with very hot liquids or foodstuffs . A 500gr reel can be found for 45 euros.

Conclusion

We can appreciate this producers of they make a great effort to produce filamentos with individuality and at the same time Respect for the environment . Some have even better performance than PLA. However, PLA is still more affordable

We hope you enjoyed this biodegradable thread article and encouraged you to be more environmentally friendly in your experience. If we ever have access to any of these curious threads, take it for granted that we will analyze it in the blog.

Do you know of any biodegradable filaments that we haven't listed here?

3D Printer Filament Buyer's Guide

- home

- 3D printing technologies

- Weld FDM, FFF and FGF material

- 3D Printer Plastic Filament Buyer's Guide - Part 4

19 — Wood (Wooden)

WHAT IS A WOODEN FILAMENT?

Thinking of printing an object that looks and feels like wood? And you can make it happen! But of course it won't be wood - it's PLA filled with wood fiber.-black-kupit-v-soin-store.ru-2.jpg)

USER NOTE

There are many Wood-PLA 3D printer filaments on the market today. These include standard woods such as pine, birch, cedar, ebony and willow, but the range also extends to less common bamboo, cherry, coconut, cork and olive.

As with other types of 3D printer filament, wood filaments also have a reverse side. In this case, aesthetic and tactile appeal is achieved by reducing flexibility and strength.

Be careful with the temperature at which you print the wood, as too much heat can result in a charred or caramelized appearance. On the other hand, the look of your wooden creations can be greatly improved with a little post-printing treatment. Wood filament can also wear out your 3D printer's nozzle, so use steel or reinforced nozzles.

WHEN SHOULD WOOD FILAMENT BE USED?

Wood is popular for printing items that are valued not for their functionality, but more for their natural appearance. When printing interior and decor items, wood filament for a 3D printer is often used, for example, for printing bowls, figurines and awards. One really creative use of wood as a 3D printer filament is to create scale models used in architectural models.

One really creative use of wood as a 3D printer filament is to create scale models used in architectural models.

Resume

-

Plus: aesthetically, ideal for visual models

-

Minutes: Non -consumed mechanical properties, requires an increased nozzle with an increased diameter (from 0.5 mm)

WHAT IS A METAL FILATION?

Maybe you're looking for a different type of aesthetic in your prints - something more voluminous and shiny. To do this, you can use "live" metal. Like wood 3D printer filament, metal filament is not entirely made of metal. It is actually a mixture of metal powder and PLA or ABS. But this does not prevent the results from having the appearance of metal.

Even the weight is metal-like as blends tend to be several times denser than pure PLA or ABS.

USER NOTES

Bronze, brass, copper, aluminum and even stainless steel filaments are just some of the "metallic" 3D printer filaments available on the market. And if you need to get a special look for your product, don't be afraid to polish, tumble or matt products after printing with these filaments - even a little post-processing can have a huge visual impact.

And if you need to get a special look for your product, don't be afraid to polish, tumble or matt products after printing with these filaments - even a little post-processing can have a huge visual impact.

However, please note that you will need to replace the nozzle sooner after printing with "metal", as the metal powder in such filaments is highly abrasive and will cause increased nozzle wear.

The most common metal-filled 3D printer filaments typically contain around 50% metal powder and 50% PLA or ABS, but there are also composites containing up to 85% metal.

WHEN SHOULD METAL FILAMENT BE USED?

Metal-filled filament is used to solve a wide range of tasks: both for aesthetics and to achieve certain functionality. Figurines, models, toys, and dog tags can all look great with metal 3D printing. And as long as the printed objects don't have to deal with undue stress, feel free to use metallic 3D printer filament to create functional prints such as tools, grills, or finishing components.

SUMMARY

-

Pros: mimics a metallic look, ideal for both aesthetic and functional models mm)

21 — BIOFILA (Biodegradable)

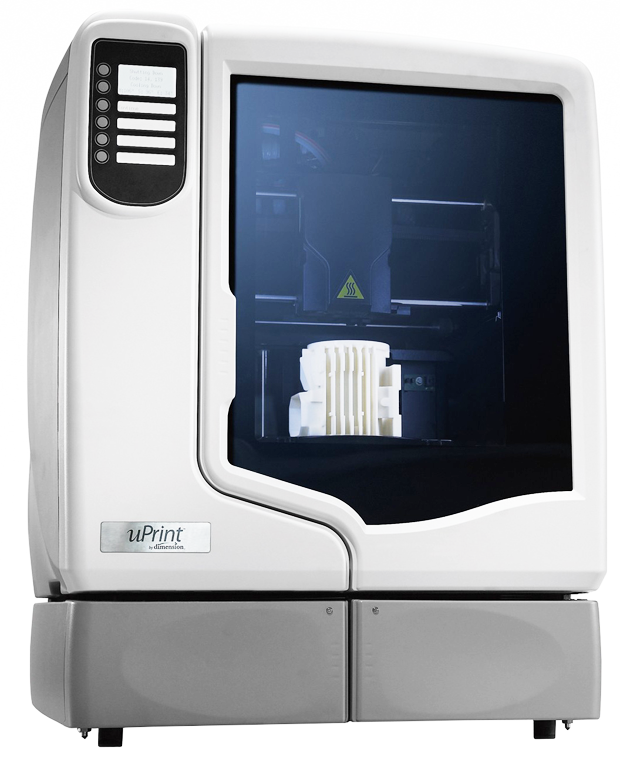

WHAT IS A BIODEGRADABLE FILAMENT?

Biodegradable 3D printer filaments constitute a unique category because their most valuable characteristics are independent of their technical parameters. As most 3D printing enthusiasts can attest, not every print comes out the way you intended, and that results in a lot of plastic being thrown away. Biodegradable threads seek to negate the negative environmental impact that plastic waste has.

USER NOTE

As mentioned earlier in this article, PLA is actually a biodegradable filament, but also includes the BioFila lines from TwoBears and Biome3D from Biome Bioplastics.

WHEN SHOULD BIODEGRADABLE FILAMENT BE USED?

Regardless of their primary purpose of being environmentally friendly, biodegradable filaments can still be printed with good physical properties.-green-kupit-v-soin-store.ru-3.jpg) Use them when you do not have high requirements for strength, flexibility or wear resistance of the printed product. And if you really want to take advantage of the waste-free printing of biodegradable filaments, try using them in your prototyping projects.

Use them when you do not have high requirements for strength, flexibility or wear resistance of the printed product. And if you really want to take advantage of the waste-free printing of biodegradable filaments, try using them in your prototyping projects.

Resume

-

Plus: Ecological safety

-

disadvantages: meager mechanical properties, limited choice and usually increased cost on the market

22 - decorative types of PLA - marble, marble sparkling, silk and colored glass

It would seem that all the advantages of the ease of use and variety of types of PLA filament have already been described earlier in this article in the first section. Does it make sense to allocate decorative grades of PLA to a special additional section? Yes, it does, and more than that. All the variety of colors and additives that increase strength and elasticity will not convey the advantages of specialized decorative grades of PLA. These wonderful filaments allow you to create great visual effects in the professional field for creating special ways of decorating interiors and furniture or imitating handicrafts at no significant cost. They can also be useful for personal use, such as printing colorful children's toys. Many decorative varieties of various materials already exist and will still be created. As an example, we will consider marble, Marble, sparkling, Twinkling, and colored glass, Transparent Glass, which are already widely represented on the market thanks to enthusiastic manufacturers from the Celestial Empire.

These wonderful filaments allow you to create great visual effects in the professional field for creating special ways of decorating interiors and furniture or imitating handicrafts at no significant cost. They can also be useful for personal use, such as printing colorful children's toys. Many decorative varieties of various materials already exist and will still be created. As an example, we will consider marble, Marble, sparkling, Twinkling, and colored glass, Transparent Glass, which are already widely represented on the market thanks to enthusiastic manufacturers from the Celestial Empire.

USER NOTE

eMarble Marble Filament

Based on PLA with the addition of colored particles that visually imitate a stone surface. Of course, about any properties of stone strength or density, heat capacity, etc. there is no question - the imitation is only visual. However, with proper use, this material will reveal its full potential and allow you to imitate from sculptures to elements of marble decoration of furniture and / or interiors. Remarkable Feature Marble is low shrinkage due to the base used. This will help you immediately get into the dimensions laid down when modeling "stone" prototypes and easily mount the printed decorative element into the main product or interior.

Remarkable Feature Marble is low shrinkage due to the base used. This will help you immediately get into the dimensions laid down when modeling "stone" prototypes and easily mount the printed decorative element into the main product or interior.

Twinkling eTwinkling

Able to delight both the child and the professional graphic designer. Multi-colored bright colors and splashes of sparkles create the illusion of complex painting with tinsel on the printed product. The biggest misconception is to classify this material as "only for children's toys." This filament is indispensable for creating prototypes, bright indoor signs (but not for outdoor use!), advertising structures, Christmas decorations and anything that is designed to attract attention with a strong visual effect, especially in the case of backlighting (most materials are translucent).

Silk thread (eSilk)

Features a high-gloss bright surface, visually reminiscent of silk fabric. Of course, this plastic does not have any properties of real silk, only a visual effect. However, its use in prototyping furniture finishing elements, decor items, Christmas toys and other decorative accessories can give a significant gain both in the cost and speed of manufacturing a prototype, and in the ability to reproduce a product of a very complex shape. Try silk upholstering a model of the Eiffel Tower or a wicker chair? A 3D printer using eSilk can do this in exactly the same time as printing these prototypes with regular PLA filament. Agree - this is a unique opportunity that, if used skillfully, can become a strong competitive advantage.

Of course, this plastic does not have any properties of real silk, only a visual effect. However, its use in prototyping furniture finishing elements, decor items, Christmas toys and other decorative accessories can give a significant gain both in the cost and speed of manufacturing a prototype, and in the ability to reproduce a product of a very complex shape. Try silk upholstering a model of the Eiffel Tower or a wicker chair? A 3D printer using eSilk can do this in exactly the same time as printing these prototypes with regular PLA filament. Agree - this is a unique opportunity that, if used skillfully, can become a strong competitive advantage.

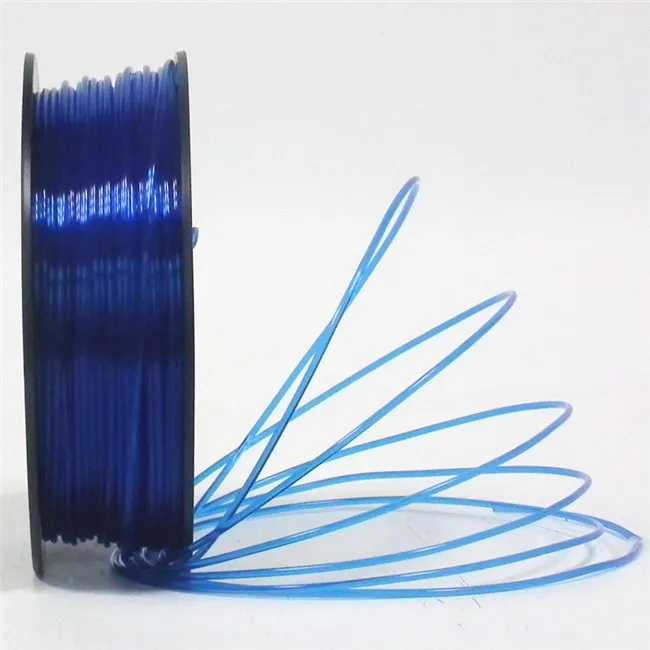

Colored glass (Transparent Glass)

The filament, unlike the basic grades of PLA, is transparent in mass - as if made of tinted glass due to the high degree of purification of raw materials and additional chemical processing.

The product printed with it can be visually confused with the PETG product, but transparent PLA is easier to print and is much cheaper on the market. Orange, yellow, red, blue and green colors, which are often used in household appliances and radio engineering, are chosen as the main tints, which immediately outlines the scope of application - backlight indicators, translucent tinted buttons, prototypes of backlight elements, automotive parts, and, of course, lighting elements. advertising structures.

Orange, yellow, red, blue and green colors, which are often used in household appliances and radio engineering, are chosen as the main tints, which immediately outlines the scope of application - backlight indicators, translucent tinted buttons, prototypes of backlight elements, automotive parts, and, of course, lighting elements. advertising structures.

WHEN TO USE PLA DECORATIVE FILAMENT?

Decorative PLA is indispensable for the tasks of quickly and accurately creating design elements for decorative elements, advertising structures and backlit product prototypes. Very much in demand for the development of children's creativity.

SUMMARY

-

Pros: ease of printing and post-processing, low cost, visual impact

-

Cons: increased abrasiveness of filaments with additives due to the effect of the filler on the nozzle. PLA-based materials are not suitable for outdoor use due to the biodegradable base

23 - Fluorescent Glow in the Dark

Fluorescent Glow in the Dark 3D Printing Filament - very impressive! Leave your imprint in the light for a while, then flip the switch and there's this ominous green light.

Of course, it doesn't have to be green. There are also other colors of the luminescent thread: blue, red, pink, yellow or orange. But green is perhaps the most popular and echoes the classic night glow style.

NOTE TO THE USER

So how does it work? It all comes down to phosphorescent materials mixed with a PLA or ABS base. Thanks to these added materials, the 3D printer filament is able to absorb in the light and then emit photons in the dark, which resemble tiny particles of light. This is why your prints will only glow when exposed to light - they must store energy before they can release it.

For best results, we recommend printing with thick walls and little infill. The thicker your walls, the stronger the glow!

WHEN SHOULD I USE LUMINESCENT FILAMENT?

Mostly PLA or ABS based luminescent materials are used in decorative applications such as Halloween installations, lanterns, window decorations. You can print wearable items (jewelry), toys, and figurines.

SUMMARY

-

Pros: visually bright (we mean it glows in the dark!)

-

Cons: limited mechanical properties, larger diameter 5 mm)

24 — Color-changing

Remember those 80s T-shirts that changed color depending on body temperature? Or what about chameleon rings? Well, it's the same idea here, because color-changing 3D printer filaments also change color based on changes in temperature or UV light.

USER NOTE

Threads in this category have a gradient between two colors, such as purple to pink, blue to green, or yellow to green.

As with other exotic 3D printer filaments, the color changing filament is based on PLA or ABS.

WHEN SHOULD COLOR-CHANGING FILATION BE USED?

This type of 3D printer filament has no special physical, tactile or functional characteristics and is intended solely for aesthetic purposes.