3D print roller coaster

3D Printed Model Roller Coaster Accurately Simulates The Real Thing

- by: Robin Kearey

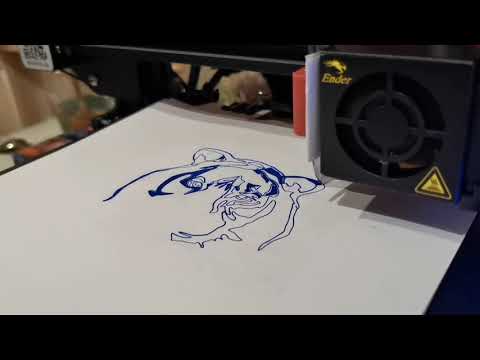

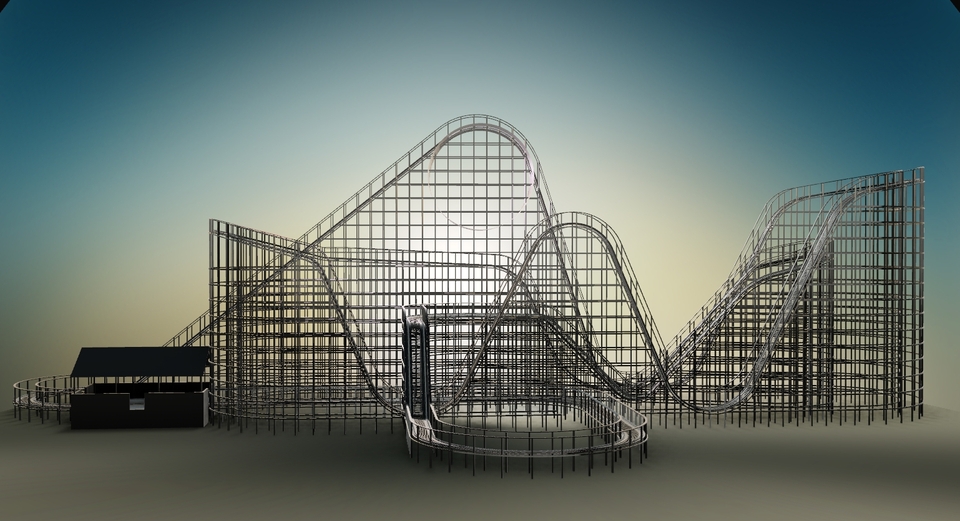

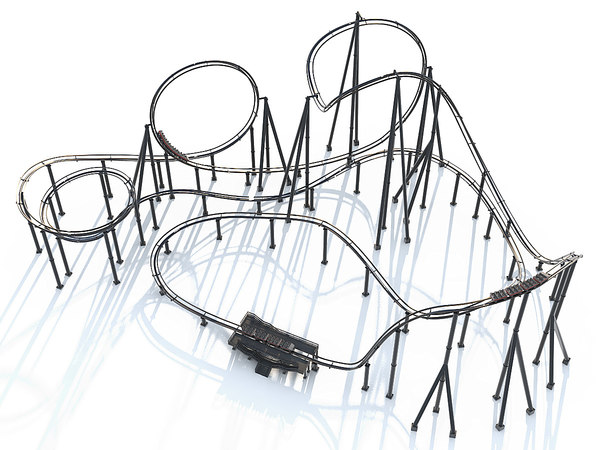

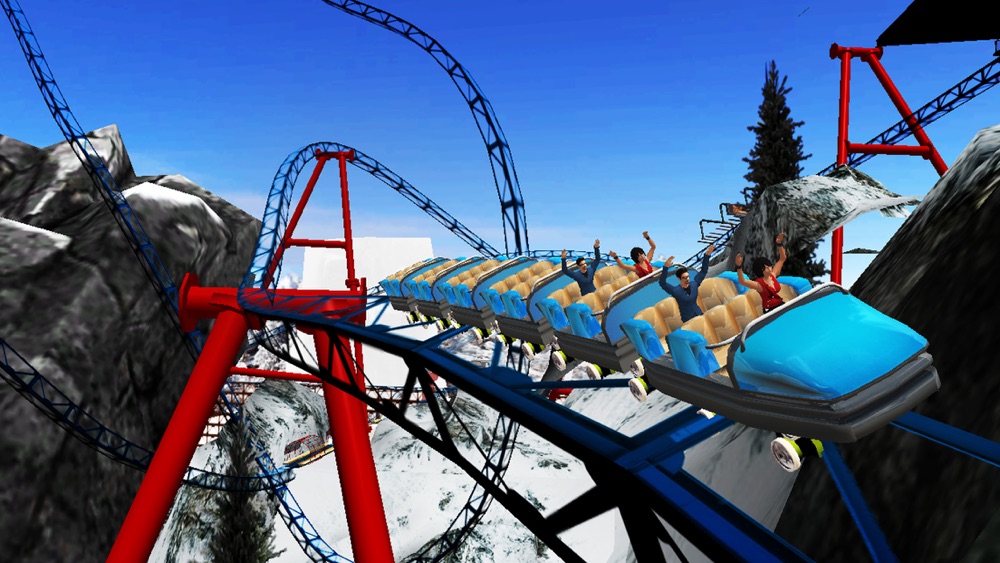

While they don’t give the physical thrill of a real one, model roller coasters are always fun to watch. However, they actually make a poor analog of a full-sized ride, as gravitational force and aerodynamic drag don’t scale down in the same way, model roller coasters usually move way faster than the same design would in the real world. [Jon Mendenhall] fixed this deficiency by designing a model roller coaster that accurately simulates a full-sized ride.

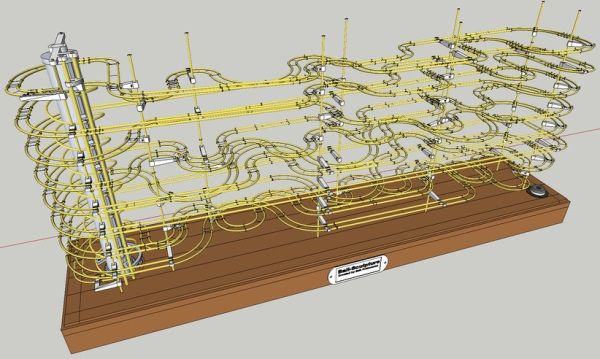

The track and cart are all made of 3D printed pieces, which altogether took about 400 hours to print. The main trick to the system’s unique motion is that the cart is motorized: a brushless DC motor moves it along the track using a rack-and-pinion system. This means that technically this model isn’t a roller coaster, since the cart never makes a gravity-powered drop; it’s actually a small rack railway, powered by a lithium-ion battery carried on board the cart. An ESP32 drives the motor, receiving its commands through WiFi, while the complete setup is controlled by a Raspberry Pi that runs the cart through a predetermined sequence.

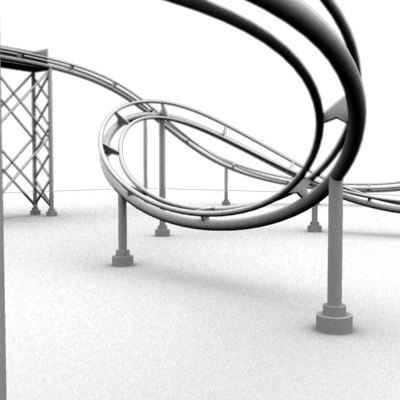

The design of the track was inspired by the Fury 325 roller coaster and simulated in NoLimits 2. [Jon] wrote his own software to generate all the pieces to be printed based on outputs from the simulator. This included all the track pieces as well as the large A-frames holding it up; some of these were too long to fit in [Jon]’s 3D printers and had to be built from smaller pieces. The physics simulation also provided the inputs to the controller in the form of a script that contains the proper speed and acceleration at each point along the track.

The end result looks rather slow compared to other model roller coasters, but actually feels realistic if you imagine yourself inside the cart. While it’s not the first 3D printed roller coaster we’ve seen, it’s probably the only one that accurately simulates the real thing. If you’re more interested in a roller coaster’s safety systems, we’ve featured them too.

If you’re more interested in a roller coaster’s safety systems, we’ve featured them too.

How Dan Fritsche Designed and Built a 3D Printed Launch Coaster

When I was a kid growing up, I always wanted to design and build my own model roller coaster from scratch. To date myself, this was in the early days of the internet, before CoasterDynamix or LEGO roller coaster kits existed. As much as I tried, I lacked the tools and resources to do so. Flash forward to today, and those tools and resources now exist and creative engineers like Dan Fritsche have taken full advantage. Dan has fulfilled my childhood dreams of creating a working model launch coaster by using 3D printing and other tools. Once I saw the fully functioning 3D printed launch coaster, I just had to know more about how it worked so I could live vicariously through Dan’s awesome creation.

To date myself, this was in the early days of the internet, before CoasterDynamix or LEGO roller coaster kits existed. As much as I tried, I lacked the tools and resources to do so. Flash forward to today, and those tools and resources now exist and creative engineers like Dan Fritsche have taken full advantage. Dan has fulfilled my childhood dreams of creating a working model launch coaster by using 3D printing and other tools. Once I saw the fully functioning 3D printed launch coaster, I just had to know more about how it worked so I could live vicariously through Dan’s awesome creation.

C101: Thanks for taking the time to give us more insight for how you designed and built a working 3D printed launch coaster. But first, for those who don’t know you, please introduce yourself!

Dan: I’m Dan Fritsche, a 2019 Mechanical Engineering grad from Iowa State University. Growing up in Minnesota, the only park nearby was Valley Fair, but that and family trips to Cedar Point every summer were enough to get me hooked on coasters at a super young age. When I was 7 and finally tall enough to ride Millennium Force, I saw the “Intamin” decal on the train and realized there must be companies out there that made these things. I knew that someday I had to work for one. In 2018, I had the opportunity of a lifetime to intern at Premier Rides for 7 months. Learning the ins and outs of coaster design, I gained a whole new appreciation for these awesome machines after seeing firsthand how they were built. Going forward, I’d love to get the chance to work at a coaster manufacturer again and will continue to do whatever I can to chase the dream. But for now, designing and printing them myself is good enough until another opportunity comes along.

When I was 7 and finally tall enough to ride Millennium Force, I saw the “Intamin” decal on the train and realized there must be companies out there that made these things. I knew that someday I had to work for one. In 2018, I had the opportunity of a lifetime to intern at Premier Rides for 7 months. Learning the ins and outs of coaster design, I gained a whole new appreciation for these awesome machines after seeing firsthand how they were built. Going forward, I’d love to get the chance to work at a coaster manufacturer again and will continue to do whatever I can to chase the dream. But for now, designing and printing them myself is good enough until another opportunity comes along.

C101: What made you want to take on the challenge of designing and building your own 3D printed launch coaster?

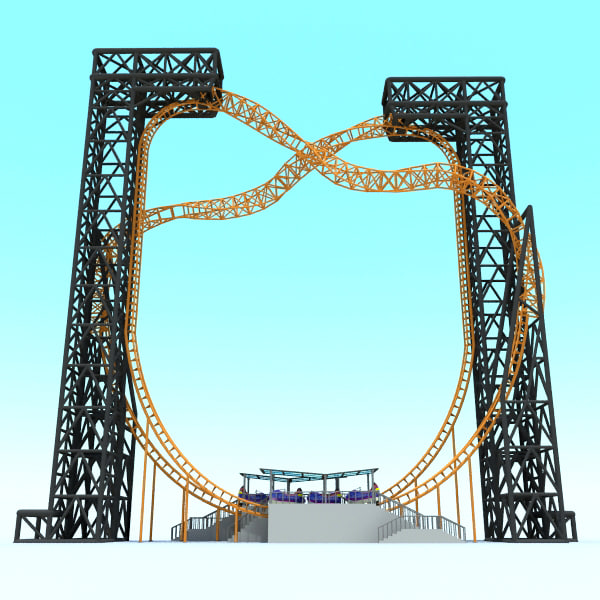

Dan: As a kid I spent hours and hours building K’nex coasters and this was just the next level. K’nex never had the realism I was after and after seeing the functional inverted boomerang model Matt (@print_my_ride) printed in 2017, I figured I could use my 3d modeling experience to do something similar eventually.

C101: Describe the overall process – what did you have to do or figure out first?

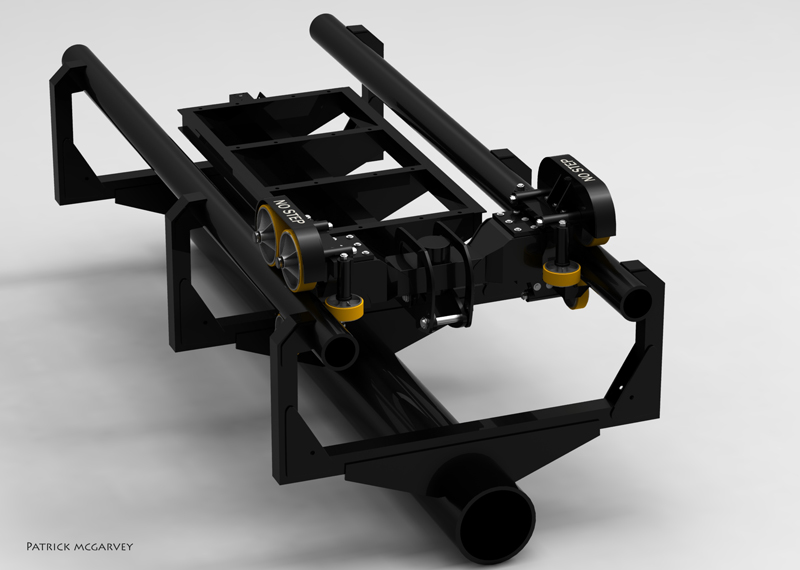

Dan: First off, I had to start by prototyping the train. My biggest goal was to make the model functional and the key to that was making a functional ride vehicle. It took 3 iterations and slight redesigns to get there, but over that time, I was able to figure out the best way to scale down a full-sized train’s construction and maintain all the degrees of freedom and clearances that were needed.

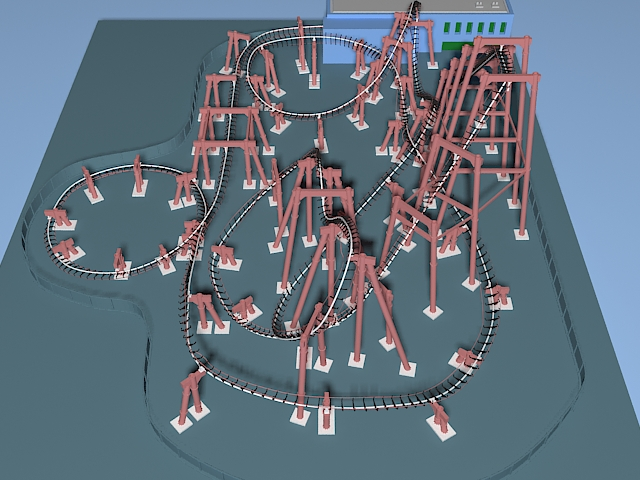

The next thing was coming up with a layout. It had to be short and simple since this whole thing was basically just a proof of concept that I could make a functional coaster in the first place. Once I designed and settled on a layout in NoLimits2 (NL2), I exported the spline coordinates and imported them into Fusion 360 where I hand modeled everything from there. This was all relatively straightforward, but extremely time consuming — around 600 hours for the train, track, columns, station, launch, brake run, etc.

I had already prototyped the launch mechanism about a year before starting this project so most of the R&D there was done thankfully. I just streamlined the design a bit and made it more compact so it could fit inside the station. The only other moving components on the layout were the brake run and station gates, which used simple mechanical assemblies (a four-bar linkage and a linear rotation mechanism).

View this post on Instagram

A post shared by Dan Fritsche (@3d_coasters)

Throughout the whole process of 3D modeling, I was printing parts as I went so I could verify the design within a few minutes to hours. My poor printer didn’t turn off for a week straight while I was printing all of the track and supports. The relatively fast turnaround time between design and actually being able to assemble the parts was super handy to ensure everything fit together like I wanted them to. Only a handful of parts had to be redesigned throughout the whole process, which I’m pretty proud of.

My poor printer didn’t turn off for a week straight while I was printing all of the track and supports. The relatively fast turnaround time between design and actually being able to assemble the parts was super handy to ensure everything fit together like I wanted them to. Only a handful of parts had to be redesigned throughout the whole process, which I’m pretty proud of.

The last thing was to automate it all, so I put micro servo motors in wherever motion was needed. Then, with the help of one of my friends, wrote a simple code to run the launch mechanism, brakes, station gates, and drive tires.

C101: What was the most challenging part of making your 3D printed launch coaster?

Dan: Definitely the coding — I’m a big mechanical guy and really struggle grasping how to code well. Shout out to Ryan O’Neill for basically writing the code for me.

C101: You’ve name a couple of them already, but what tools did you use?

SOFTWARE

- NoLimits 2 – layout design

- Fusion 360 – solid modeling

- Cura – solid slicing to prepare for printing

- Arduino – coding software for motor control

HARDWARE

- Arduino Uno

- 5 Micro servo motors

- 1 DC motor

PRINTER

- Creality CR-10

TOOLS

- Plotter – printing footer locations

- Electric drill – drilling footer locations

- Skill saw – cutting base shape

- Router – finishing base edges

- Lots and lots (and lots) of sandpaper

C101: Wow, that’s a great list for anyone interested in getting started with designing and 3D printing their own roller coaster model. What advice would you give to a beginner? Where do they even start?

What advice would you give to a beginner? Where do they even start?

Dan: Definitely recommend taking it slow and not immediately tackling a functional model. Start small and work your way up with a static train and track design after having a solid base of 3d modeling knowledge. Even modeling individual components like bogies will do wonders in building your confidence and teaching you important lessons in what you can and can’t get away with when designing at the scale you’re working at. The most important advice I can give though is to not give up — it’s not going to happen overnight. It’s easy to get frustrated when the model or print isn’t turning out the way you want it to but take a break and come back to it later. Sticking with it is the only way you can get better at this or anything else for that matter.

Finally, I started a Discord with a few other coaster modelers and anyone who’s interested can join. It’s a great resource to help each other out if you’re stuck, get cool ideas for projects, and just share your progress with other likeminded coaster nerds. DM me on Instagram @3d_coasters for an invite link or any questions. I’m more than happy to give my best answer!

DM me on Instagram @3d_coasters for an invite link or any questions. I’m more than happy to give my best answer!

C101: And we always wrap up our interviews with this question: what’s your favorite real-life coaster?

Dan: Yikes favorite coaster… what an impossible question. I have a soft spot for Wildfire at Kolmärden and Helix at Liseberg, but I’m going to say the trim-less rides on Steel Vengeance I got in 2018 were some of the best rides I’ve ever had. As a guy who loves airtime, there’s no other way to go than with 27.2 seconds of it on Steve.

C101: Where can people go to follow your projects or learn more about you?

Dan: I’m working on a Weebly website where I’ll have a more in-depth look at the process behind everything, but for now Instagram is my go-to for general project updates. Anyone can feel free to connect with me on LinkedIn too.

Thanks again to Dan for taking the time to answer our questions. We look forward to seeing what future 3D printed coasters you come up with!

We look forward to seeing what future 3D printed coasters you come up with!

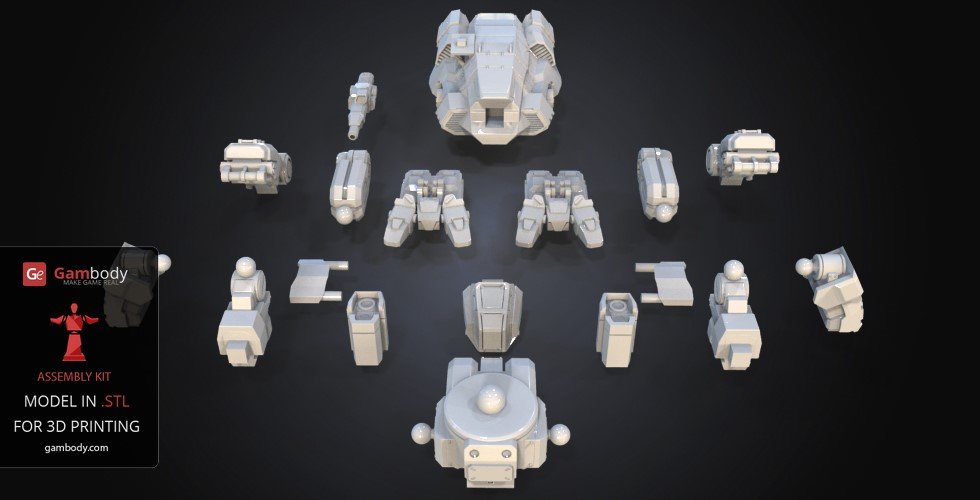

roller coaster model by Dan Fritsche

News

Subscribe author

Subscribe

Don't want

12

American engineer Dan Fritsche built a functional 3D-36 scale model of a roller coaster using Fusion 3-35 printer , spending approximately six hundred hours on design and 3D modeling, plus another eight hundred on 3D printing, not counting post-processing and assembly. But it was worth it!

Dan is familiar with roller coasters. He fell in love with these rides at the age of seven, when he finally grew to the minimum level and received permission to ride the Millennium Force in Ohio - the first so-called "giga-hills", reaching a height of three hundred feet or about ninety meters. At the same time, the logo of the Intamin company was imprinted in his memory: the boy realized that there were special enterprises involved in the production of attractions. Dan graduated from Iowa State University of Science and Technology with a degree in mechanical engineering in 2019 and completed a seven-month internship with Premier Rides, a company that also designs and manufactures roller coaster equipment.

Dan graduated from Iowa State University of Science and Technology with a degree in mechanical engineering in 2019 and completed a seven-month internship with Premier Rides, a company that also designs and manufactures roller coaster equipment.

Now the hero of our story dreams of a full-fledged career in such a company. Someday such an opportunity will turn up, but for now, Dan decided to start creating his own functional model, since the existing toy designers, with which he played enough as a child, are not realistic enough. Something tells us that the result will complement the resume of a young engineer well.

This model is not intended to represent any particular attraction and is my own design. Dan started learning about additive technologies under the influence of Matt Schmotzer's roller coaster model, which clearly revealed the potential of 3D printing to an aspiring designer.

The design of the track began after Dan managed to create a satisfactory train model in terms of functionality - on the third attempt, as he had to experiment with tolerances and train flexibility. Then the design and 3D modeling of the track began in Fusion 360. As the author explains, the process is quite simple, but time-consuming: in total, it took about six hundred hours to model the tracks, train, supports, platform, trigger and other elements.

Then the design and 3D modeling of the track began in Fusion 360. As the author explains, the process is quite simple, but time-consuming: in total, it took about six hundred hours to model the tracks, train, supports, platform, trigger and other elements.

Refurbished trolleys made with the Original Prusa i3 MK3S+ 3D printer

3D printing took even longer, with over eight hundred machine hours and seven spools of filament to produce 2,983 individual components using a Creality CR-10 3D printer. But that's not all: add thirty-five hours for post-processing and fitting parts, plus twenty hours for the assembly of the rolling stock alone, another ten for troubleshooting and troubleshooting. Apparently, an improved and even more detailed version of the attraction with components printed on the Original Prusa i3 MK3S+ will be ready soon.

The inside of the model attraction consists of an Arduino Uno board, five miniature servos and one DC motor responsible for the launcher, brakes and even a neatly reproduced moving gate. Perhaps the only thing missing is no less detailed testers, and we even know who could help.

Perhaps the only thing missing is no less detailed testers, and we even know who could help.

The result of the efforts and a brief demonstration of the design and production process can be seen in the video below. Now Dan is preparing his own website in order to have a more convenient platform for presenting projects, but for now, you can chat with him on Instagram.

More interesting articles

eleven

Subscribe to the author

Subscribe

Don't want to

It used to be that in cases of revocation of airworthiness certificates for storks and poor harvest of cabbage, children came ...

Read more

5

Subscribe to the author

Subscribe

Don't want

New systems are initially tailored for the extended functionality of the Klipper firmware and equipped with 32-bit e. ..

..

Read more

59

Subscribe to the author

Subscribe

Don't want

3Dtoday portal with the support of Creality and Bestfilament invites everyone to participate in the contest...

Read more

you come across such an exciting project that you want to share it with the whole world. Such is the case with Dan Fritsche's miniature 3D printed roller coaster. The project took almost 3,000 parts and 900 hours and Fritsche told us exactly how he did it.

He started by building a prototype train, the goal of which was to make it functional from the start, but this strategy had its drawbacks, as he will explain later. It took him three iterations and minor design changes, but in the end, “I was able to come up with a better way to reduce the design of a full-size train and keep all the necessary degrees of freedom and clearances,” Fritsche told IE. .

.

The next step for him was to come up with a short and simple layout. He had to keep it short and simple, because at this stage it was still a proof of concept that he could turn into something complete.

He explains: “After I designed and settled on the layout in NL2, I exported the spline coordinates and imported them into Fusion 360, where I modeled everything by hand. train, way, columns, station, start, brake run, etc. »

Fritsche added that he had already prototyped the launch mechanism about a year before starting his project and that throughout the 3D modeling process he was printing parts on the go so he could test the design in minutes or hours.

“The last thing was to automate it all, so I put micro servos where movement was needed.