Best 3d printer under 750

Best Budget 3D Printers under $250, $750, and $1000

Is it possible to buy a good, yet affordable, 3D printer quickly and with a warranty?

Here’s our pick of the best cheap 3D printers for hobbyists and professionals, for home and office, machines that support PLA, ABS, and other popular filaments. To make things easier, we divided the printers by price into the following categories: under $250, $750, and $1000. We included a line of affordable SLA printers under $800 and laser MFDs under $600 into separate categories.

We selected the best-selling 3D printers with the minimum number of warranty claims - they are simply the best 3D printers according to our clients’ feedback.

Please note that the prices indicated in this article are approximate and can vary depending on the exchange rate and the desire of the manufacturers. Click on the link provided in the product specifications to find out the exact price of a 3D printer.

- Do-It-Yourself (DIY) kits are the machines that you will need to assemble yourself.

- Most of the 3D printers are supplied semi-assembled - they come as several major components that need to be connected with each other. This usually takes less than 10 minutes.

- Ready-to-work 3D printers are tagged as fully assembled.

All 3D printers in this selection are arranged according to their price range in ascending fashion. However, several models of the same line are listed together for convenience.

Best 3D printers under $250

Wanhao Duplicator i3 mini

Fully assembled

- Technology: FDM

- Extruder type: Single

- Build volume: 120х135х100 mm

- Extruder temperature: 170-260° С

- Layer thickness: 100 microns

- Positioning accuracy: XY: 0.012 mm, Z: 0.04

- Material support: PLA, Wood

- Nozzle size, mm: 0.4

- File transfer: MicroSD, USB

- Printing speed: 10-70 mm/s

- Price: $231.

00

00

The i3 Mini is a compact, precise and the cheapest 3D printer among Wanhao products, although it prints only with PLA on a relatively small print bed, it never fails to produce high-quality objects. On top of that, it simply looks great. It is a very good option for beginners, but it will also be a reasonable solution for those enthusiasts who want to print small details with PLA without paying too much for their hobby.

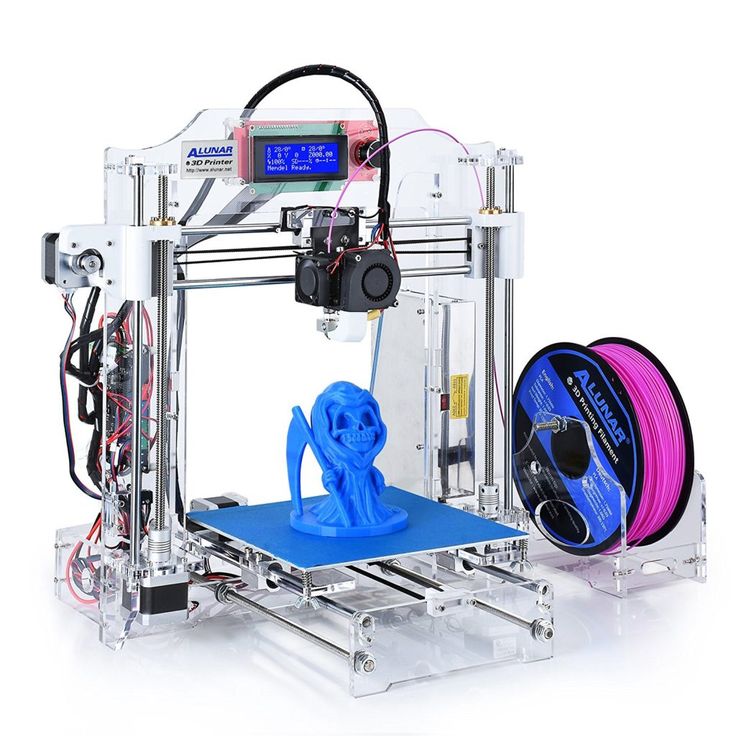

Anet A6 and A8

Do-It-Yourself

- Technology: FDM

- Extruder type: Single

- Build volume: 220х220х250(240) mm

- Max extruder temperature: 260°C

- Max print bed temperature: 100°C

- Layer thickness: 100 (120) microns

- Bed leveling: manual (automated)

- Positioning accuracy: Z: 0.

004 mm, XY: 0.012 mm

004 mm, XY: 0.012 mm - Material support: PLA, ABS, TPU, PVA, Nylon, PVA, PP, Wood

- Filament size: 1,75

- Printing speed: 40-120 mm/s

- Price: $274.99 ($179.00)

You can see the A8 specs within brackets. A more detailed comparison of these two models can be found here.

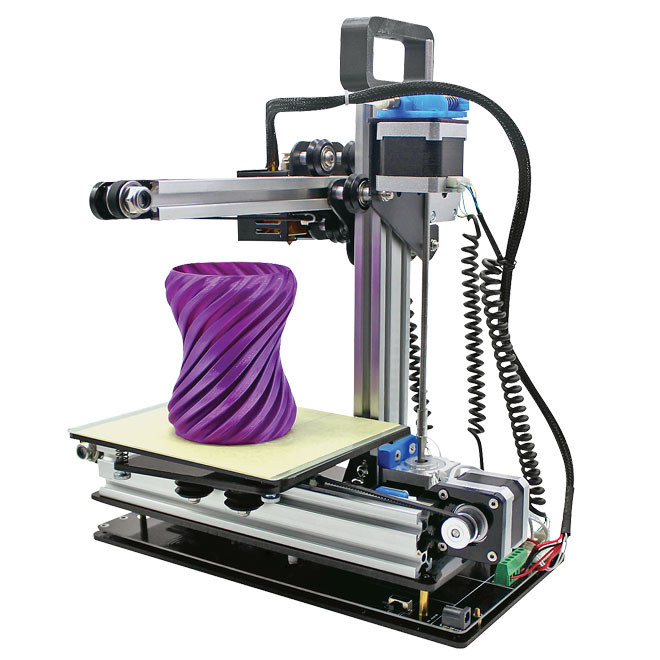

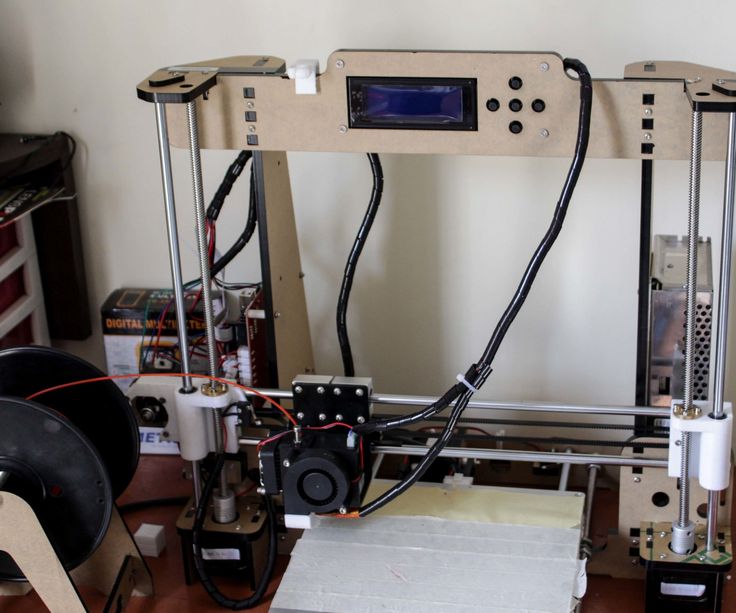

Both the Anet A6 and A8 come as DIY kits. You can assemble a very inexpensive, yet robust, 3D printer with an LCD display and supported memory cards that will allow you to print without connecting the machine to a computer. Such a printer will be great for those just trying their hands at 3D printing and want to sharpen their skills at a minimum cost.

Features: acrylic platform, 1 extruder, build volume 220 x 220 x 250(240) mm.

Despite being very cheap and having quite a simplistic construction, this machine produces surprisingly good prints.

Tevo Tarantula

Semi-assembled

- Technology: FDM

- Extruder type: Single

- Max extruder temperature: 210°C

- Build volume: 200 x 200 x 200 mm

- Print bed temperature: 60-120°C

- Layer thickness: 50 microns

- X,Y axes positioning accuracy, mm: 0.

012

012 - Material support: PLA, ABS, PETG, wood, PVA, and flexible filaments (with Pro Metal Extruder)

- Nozzle size, mm: 0.4

- Printing speed: 150 mm/s

- Price: $203.00

The frame of this 3D printer is made of aluminum profile. Features automated bed leveling. The extruder positioning accuracy is adjusted with the help of the inductive sensor.

Best 3D printers under $500

Anet A4

Do-It-Yourself

- Technology: FDM

- Extruder type: Single

- Build volume: 200х210 mm

- Extruder temperature: 260 °C

- Print bed temperature: 100℃

- Layer thickness: 100 microns

- Positioning accuracy: XY: 12 microns, Z: 4 microns

- Material support: ABS, PLA, HIPS

- Nozzle size, mm: 0.

4

4 - Printing speed: 40-120 mm/s

- Price: $277.09

A large delta 3D printer with a steel frame, metal platform, and belt tension adjustment with one screw.

Creality Ender-3

Do-It-Yourself

- Technology: FDM

- Extruder type: Single

- Build volume: 220х220х250 mm

- Extruder temperature: 255°C

- Print bed temperature: 110°C

- Material support: PLA, ABS, TPU

- Layer thickness: 100 microns

- Positioning accuracy: 100 microns

- Filament size: 1,75 mm

- Nozzle size, mm: 0.4

- Printing speed: 180 mm/s

- File transfer: USB, SD

- Price: $268.00

Features:

- Quick assembly — 10 minutes, 20 screws;

- V-slot — compatible with Prusa frames ;

- Can resume printing after power loss;

- Print bed can heat up to 110°C in 5 minutes;

- Aluminum profile frame with a rigid black coating.

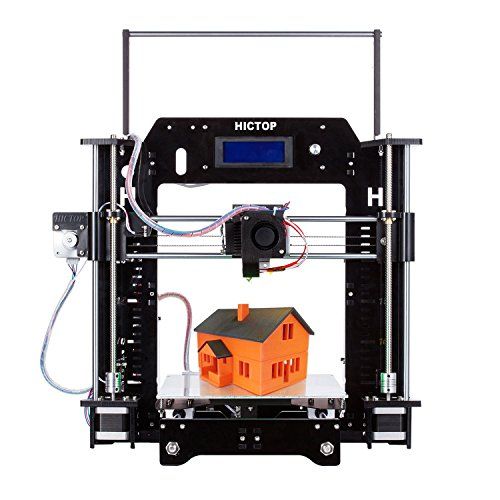

Wanhao Duplicator i3

Semi-assembled

- Technology: FDM

- Extruder type: Single

- Layer thickness: 100 microns

- Operating temperature: 190-260°С

- Build volume: 200 x 200 x 180 mm

- Positioning accuracy: Z axis – 0.004 mm (5 microns), XY axis – 0.012 mm (12 microns)

- Material support: ABS, PLA, HIPS, PVA, and others.

- Nozzle size, mm: 0.4

- File transfer: USB, SD/TF-card

- Printing speed: 100 mm/s

- Price: $358.00

Wanhao Duplicator i3 3D printer series and the i3 v2.1 version, in particular, is one of the most popular 3D printers from Wanhao.

The wide-profile steel frame is extremely rigid and will never become unstable. Considerable weight reduces vibration, while improvements made by the manufacturer following thousands of customer reviews ensure easy and smooth performance.

Tevo Michelangelo

Semi-assembled

- Technology: FDM

- Extruder type: Single

- Layer thickness: 100 microns

- Build volume: 150x150x150 mm

- Material support: PLA

- Nozzle size, mm: 0.4 mm

- File transfer: SD; USB

- Printing speed: 100 mm/s

- Price: $315.00

It is an FDM 3D printer with no enclosure but featuring a rigid metal structure and the Titan extruder. It also comes with a great cooling system of 2 coolers and 1 temperature sensor. The extruder positioning is dictated by the inductive sensor.

Creality CR7

Fully assembled

- Technology: FDM

- Extruder type: Single

- Build volume: 130 x 150 x 100 mm

- Extruder temperature: 250°C

- Layer thickness: 10 microns

- Positioning accuracy by axes X, Y, mm: 0.

012

012 - Material support: PLA, Wood

- Nozzle size, mm: 0.4

- File transfer: TF card

- Printing speed: 150 mm/s

- Price: $417.32

Comes fully assembled. It is basically a less heavy and more compact version of Creality Ender-2. MK10 extruder with an operating temperature of up to 250°C allows to print with the majority of popular plastics, including composites like Woodfill.

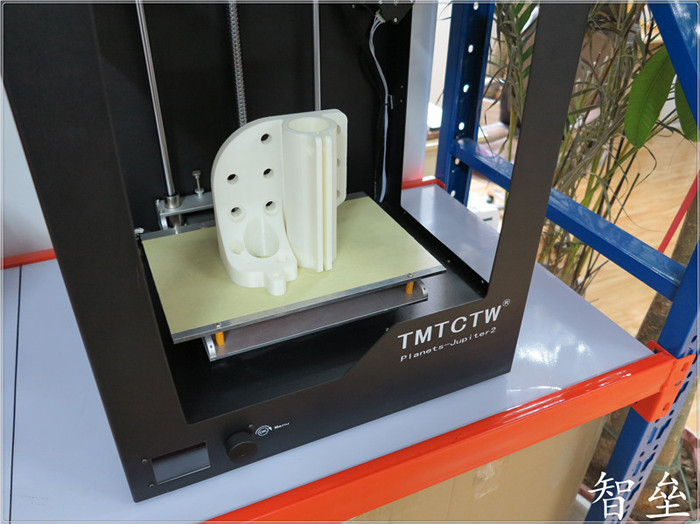

Wanhao Duplicator 10

Fully assembled

- Technology: FDM

- Extruder type: Single

- Weights, kg: 4

- Heated bed: no

- Build volume: 116 х 116 х 125 mm

- Layer thickness: 100 microns

- Printing accuracy: 100 microns

- Positioning accuracy: Z: 0.004 mm, XY: 0.012 mm

- Extruder: MK12

- Material support: PLA

- Nozzle size, mm: 0.4

- Printing speed: 70 mm/s

- Price: $499.

00

00

Small and easy-to-use, this cheap machine that prints with PLA is equally good for home and office. Extra compact, surprisingly light, with a relatively small build volume (116 х 116 х 125 mm), and looking like a toy, this printer, nevertheless, produces high quality and precise objects. It has a layer thickness of 100 microns, while printing speed is 70 mm per sec. This 3D printer is great as a present.

Flyingbear P905

Semi-assembled

- Technology: FDM

- Extruder type: Dual

- Build volume: 220 х 220 х 210 mm

- Platform temperature: 60-120°C

- Extruder temperature: up to 240°C

- Layer thickness: 50 microns

- Positioning accuracy: Z: 2 microns, XY: 10 microns

- Material support: PLA, ABS, PETG, Wood, PVA, Flex

- Nozzle size, mm: 0.4

- File transfer: SD, USB

- Printing speed: 150 mm/s

- Price: $399.

00

00

Structural features: automated bed leveling, dual Z-axis, a large printing platform, a steel frame, and easy access to components for hardware upgrade.

Anet E12

Do-It-Yourself

- Technology: FDM

- Extruder type: Single

- Layer thickness: 100 microns

- Build volume: 300 х 300 х 400 mm

- Print bed temperature: 100℃

- Extruder temperature: 260℃

- Positioning accuracy: XY 12 microns, Z 4 microns

- Material support: ABS, PLA, HIPS

- Nozzle size, mm: 0.4

- File transfer: SD

- Printing speed: 40-120 mm/s

- Price: $498.79

This robust 3D printer has a very simplistic construction, and it won’t take you more than 10 minutes to fully assemble the machine. The printer features a heated bed, and it’s capable of creating large prints.

Anet A3

Fully assembled

Technology: FDM

Extruder type: Single

Build volume: 150 х 150 х 150 mm

Material support: PLA, ABS, TPU, Wood

File transfer: SD

Price: $307. 95

95

This machine has an aluminum heatbed, and user-friendly controls. On top of everything, it is also space-effective!

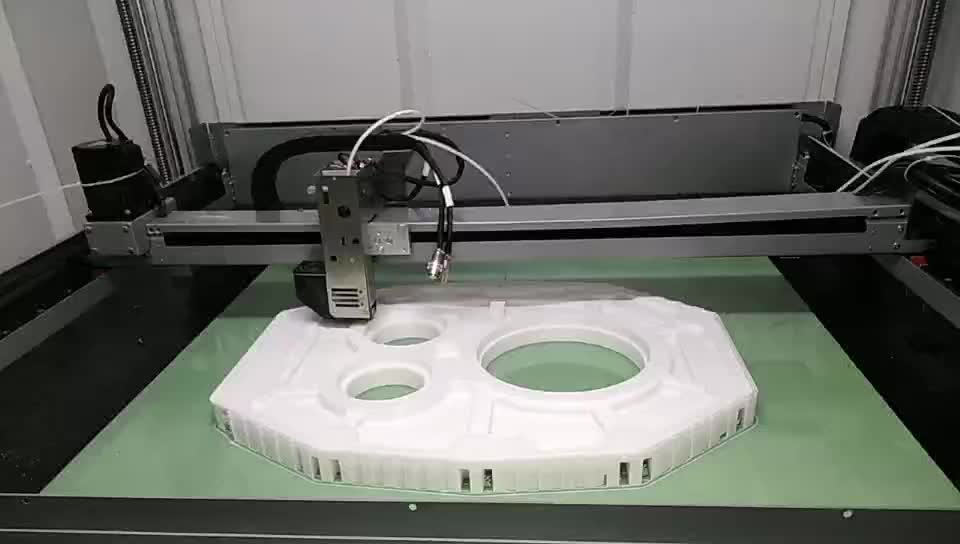

Wanhao Duplicator 9/300

Semi-assembled

- Technology: FDM

- Extruder type: Single

- Heated bed: Yes

- Build volume: 400 х 400 х 400 mm (300 х 300 х 400 mm)

- Layer thickness: 100 microns

- Positioning accuracy: XY: 0.012 mm, Z: 0.004 mm

- Material support: PLA, PVA, PEVA, PLA, Nylon

- Nozzle size, mm: 0.4

- File transfer: USB, SD

- Printing speed: 70 mm/s

- Price: $545.00

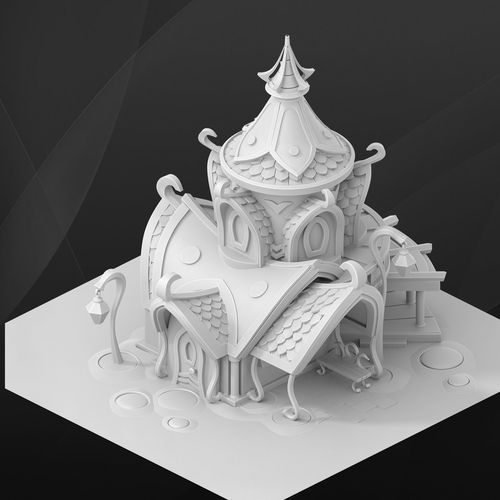

The features of this model include: a solid aluminium frame, roller bearings and the Z axis ball screw. The model also comes in multiple types. You can choose the dimensions and build volume you like most. Both models enjoy a large build volume that allows to create prints of just about any size. For example, take a look at the picture below:

For example, take a look at the picture below:

It took 28 hours to print this 30cm tall model in one go.

A heated bed and a touch screen control panel are featured by default in all Wanhao 3D printers.

Creality CR-20

Semi-assembled

- Build volume: 220 х 220 х 250 mm

- Extruder temperature: 260°C

- Print platform temperature: 100°C

- Print platform: 235 х 235 mm

- Price: $349.00

A DIY 3D printer which is essentially an alternative and peer competitor to popular Wanhao D9 3D printers.

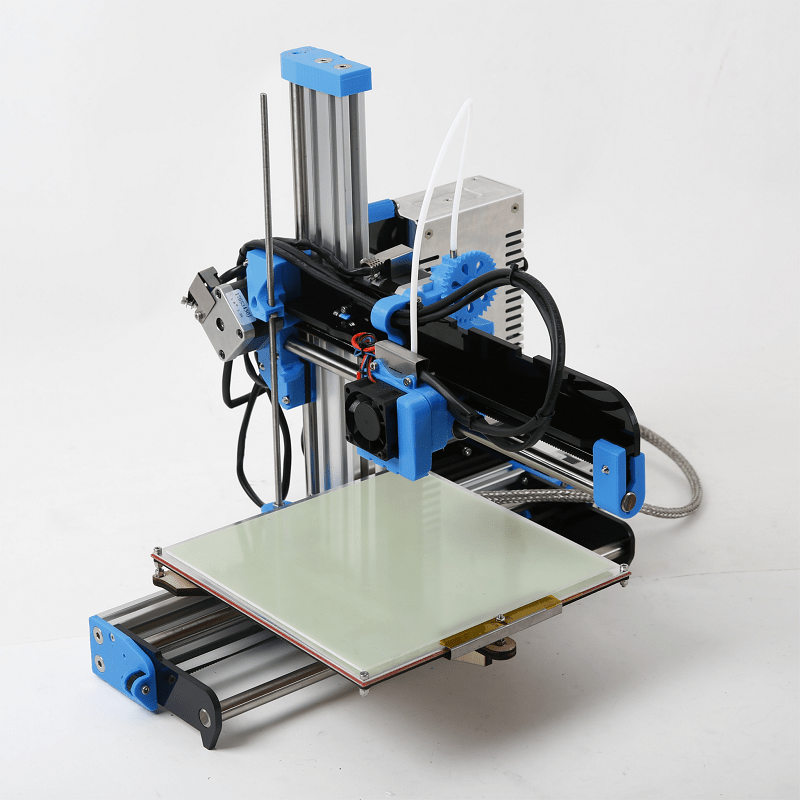

As you can see in the image below, the printer is supplied in a form of several major components, but rest assured, they are very easy and quick to assemble.

This machine has some unique features, including

- Quick and stress-free assembly

- Control elements, i.e. display and navigation knob are placed at an angle of 30 degrees for convenience.

- The platform has a flexible coating that will allow you to easily remove your prints from the platform.

- Print resume after power loss.

Creality Ender-5

Semi-assembled

- Technology: FDM

- Build volume: 220 х 220 х 250 mm

- Print platform temperature: 110°C

- Extruder temperature: 255°C

- Material support: PLA, ABS, TPU

- Layer thickness: 100 microns

- Printing accuracy: 100 microns

- Nozzle size, mm: 0.4

- Printing speed: 180 mm/s

- File transfer: USB, SD

- Price: $349.99

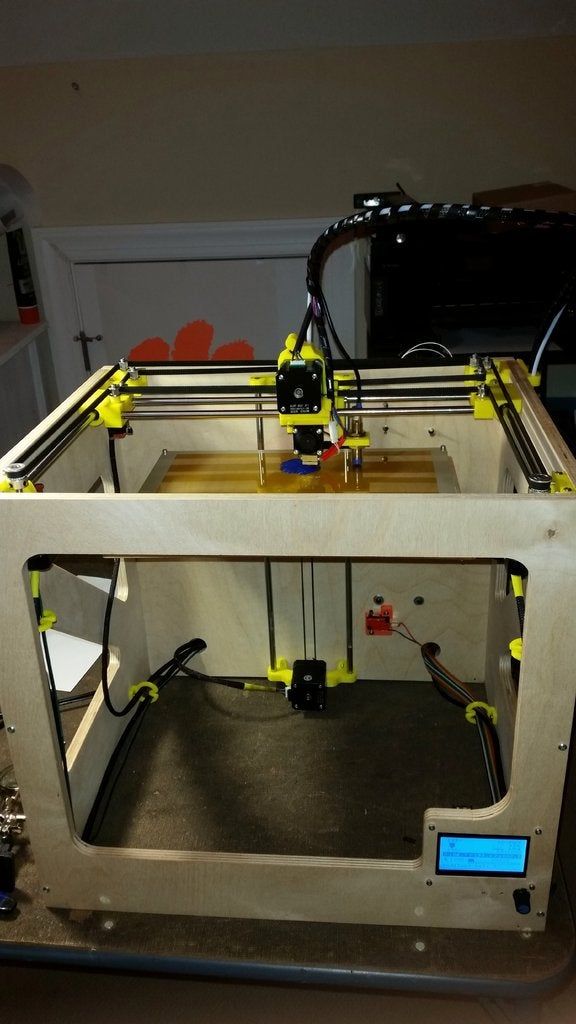

This is yet another DIY 3D printer that will not take you much time to assemble. Unlike less advanced Ender 3D printers, this machine is much bigger and features a complete and sturdy metal frame.

Creality CR-10

Semi-assembled

- Technology: FDM

- Build volume: 300 х 300 х 400 mm

- Extruder temperature: up to 250°C

- Layer thickness: 100 microns

- Material support: PLA, TPU, Wood, Copper, Rubber, etc

- Nozzle size, mm: 0.

4

4 - Printing speed: ≤200 mm/s

- Price: $379.00

A simple 3D printer with great possibilities. Depending on the version, it can print objects with dimensions up to 500 х 500 х 500 mm. This model offers the build volume of 300 х 300 х 400 mm, which is the most budget-friendly option in this line of 3D printers.

Despite having quite an ordinary, simplistic appearance, this 3D printer is well-proven and made of top-quality components.

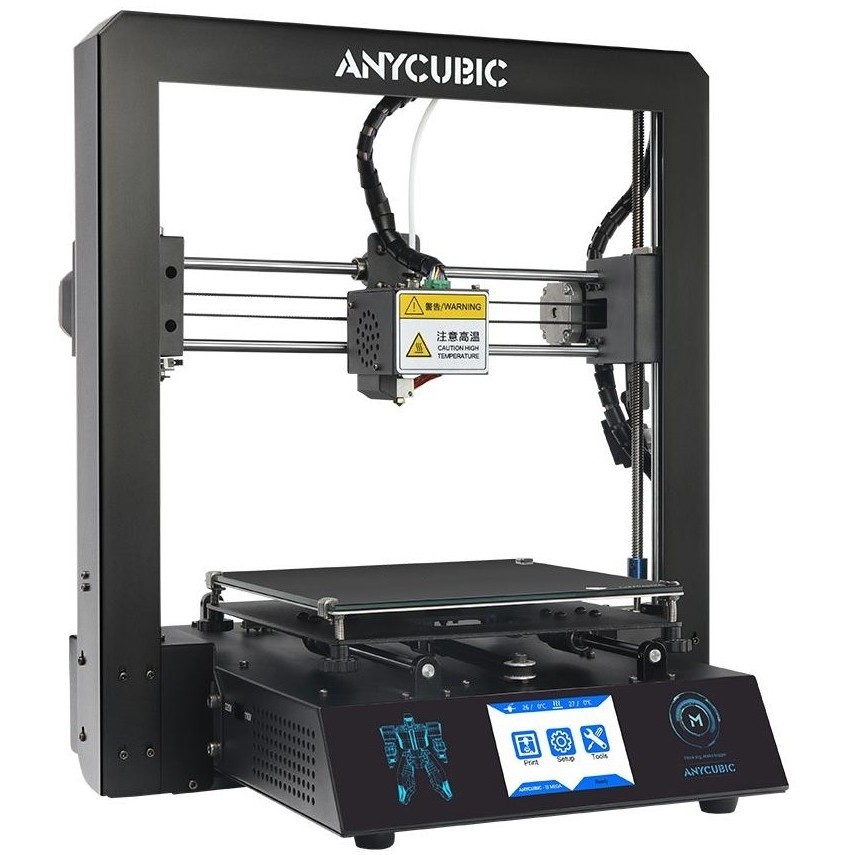

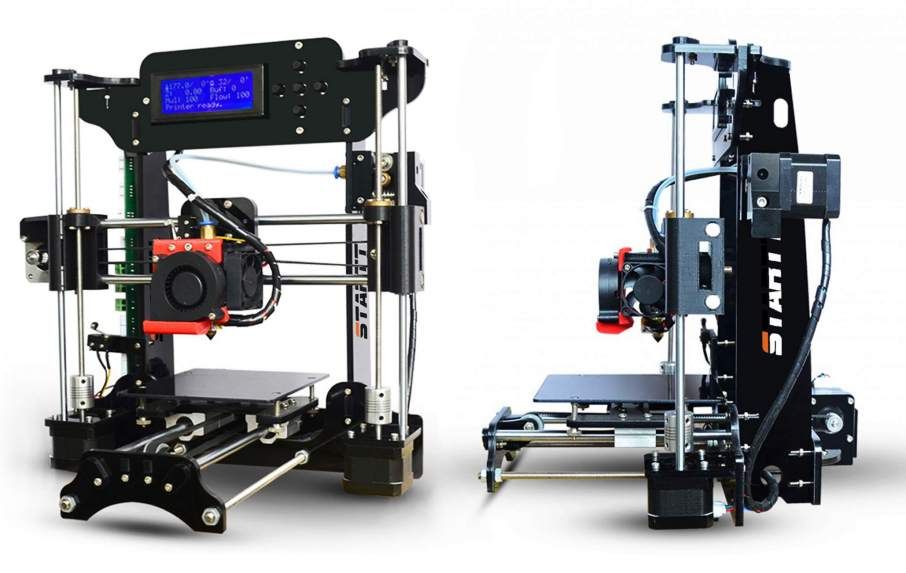

Best 3D printers under $750

Prusa i3 MK3S

Do-It-Yourself

- Technology: FDM

- Extruder type: Single

- Print bed temperature: up to 120°С

- Build volume: 200 x 200 x 220 mm

- Layer thickness: 50 microns

- Material support: ABS, PLA, HIPS, FLEX, PVA, RUBBER, RELAX, WOOD

- Nozzle size, mm: 0.

4

4 - Printing speed: 50-120 mm/s

- Price: $749.00

This DIY kit will allow you to assemble a 3D printer of a special quality with your own hands while getting familiar with its every detail: + 50 knowledge, +100 mastery, + 200 charisma.

Credit: @opermajki / Instagram

Features: rigid metal frame, every part of the kit is safely packed, easy and painless assembly, warranty of quality. You will find a detailed instruction manual inside the box.

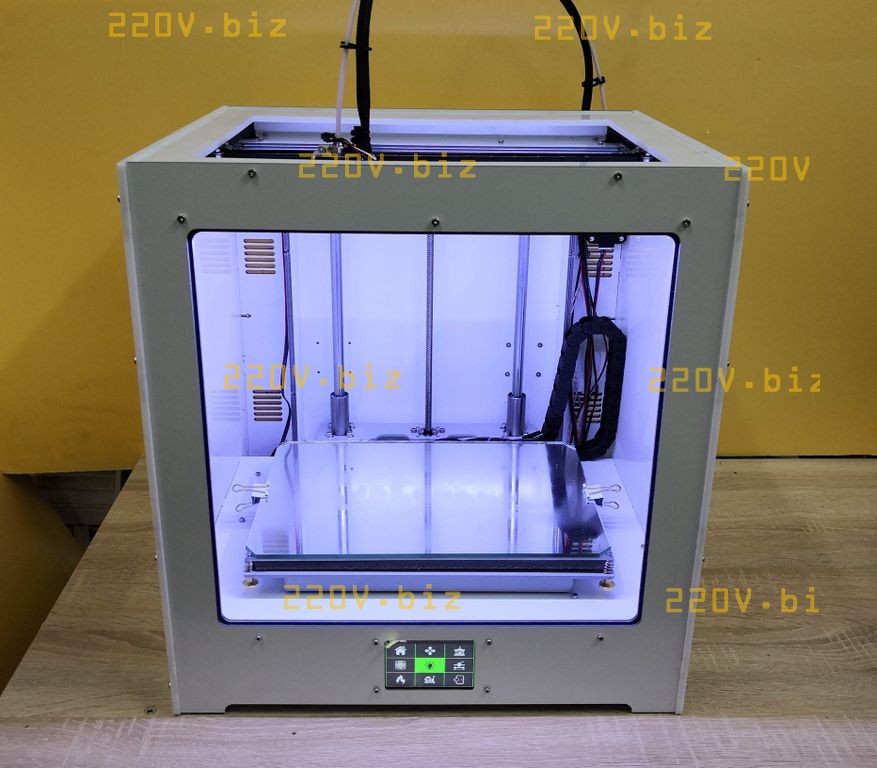

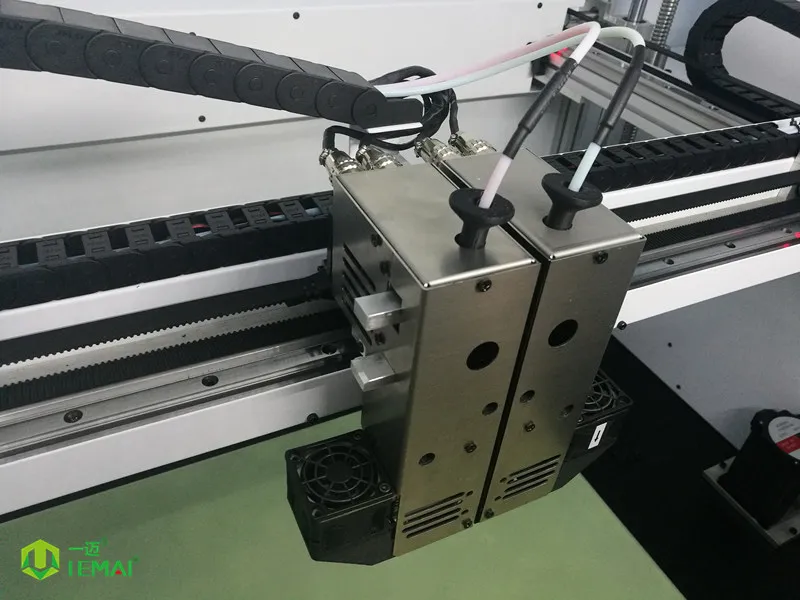

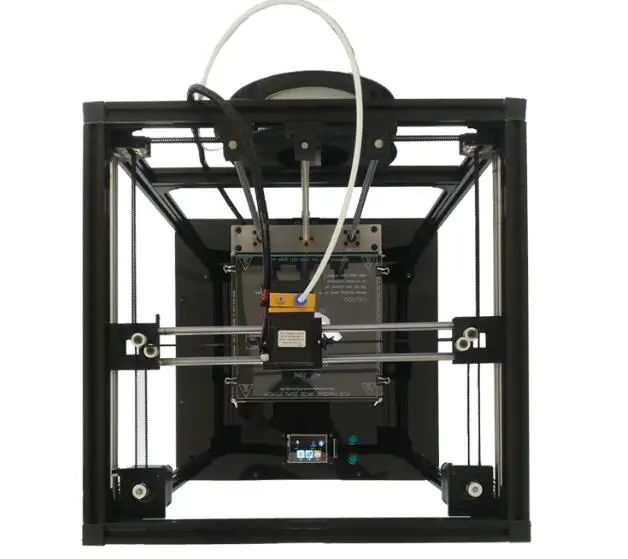

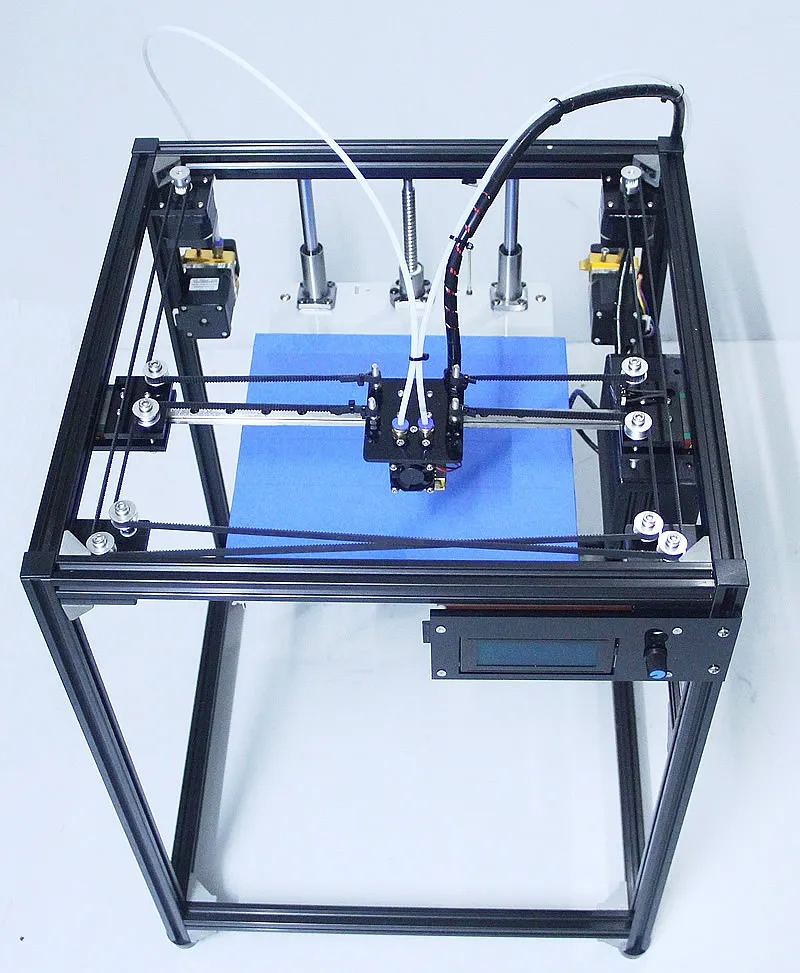

Flyingbear P905X

Semi-assembled

- Technology: FDM

- Extruder type: Dual

- Build volume: 280 х 242 х 360 mm

- Print platform temperature: 60-120°C

- Extruder temperature: up to 240°C

- Layer thickness: 50 microns

- Positioning accuracy: Z: 2 microns, XY: 10 microns

- Material support: PLA, ABS, PETG, Wood, PVA, Flex

- Nozzle size, mm: 0.

4

4 - File transfer: SD, USB

- Printing speed: 150 mm/s

- Price: $555.00

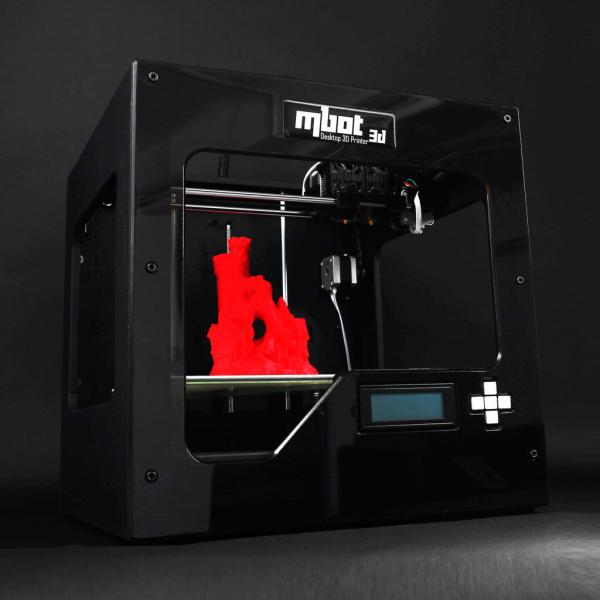

In terms of design, this 3D printer is similar to Makerbot, but it works quicker while its cost is significantly lower.

All major elements of the structure are made of metal. The printer’s controller board features its own cooling system, which increases the printing stability and the machine’s durability.

The plate metal body frame is equipped with extra installation holes, which allows you to modify the printer - you can attach side covers or add more components.

The precision is enhanced due to the Z-axis featuring guides and a drive gear on the two sides of the printing platform.

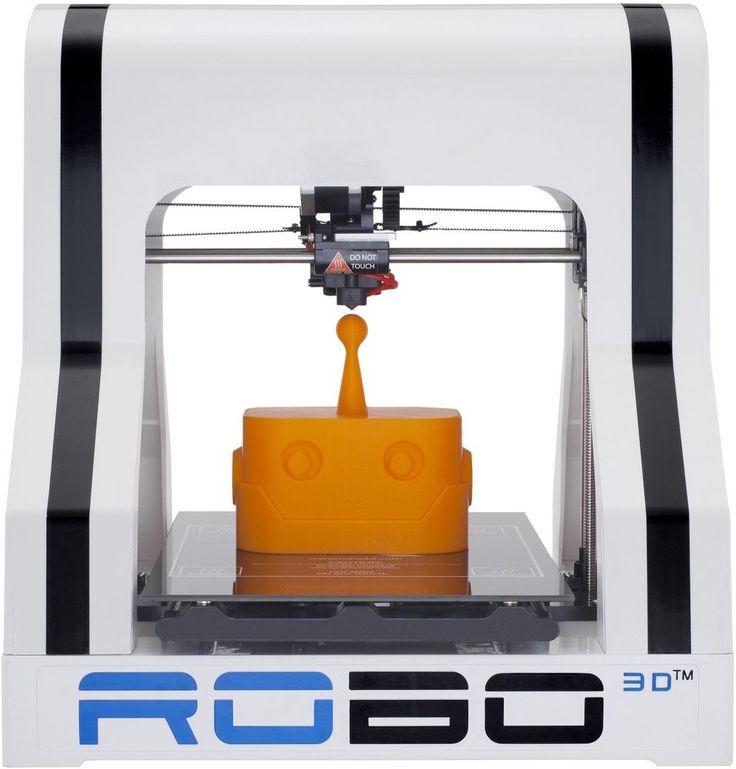

XYZPrinting da Vinci Junior 1.0 Pro

Fully assembled

- Technology: FDM

- Extruder type: Single

- Build volume: 150 x 150 x 150 mm

- Extruder temperature: 190°C ~ 230°C

- Layer thickness: 100 microns

- Material support: PLA

- Nozzle size, mm: 0.

4, optionally 0.3 (0.4) mm

4, optionally 0.3 (0.4) mm - File transfer: USB 2.0, SD (USB, SD, Wi-Fi)

- Printing speed: 100 mm/s

- Price: $490.00

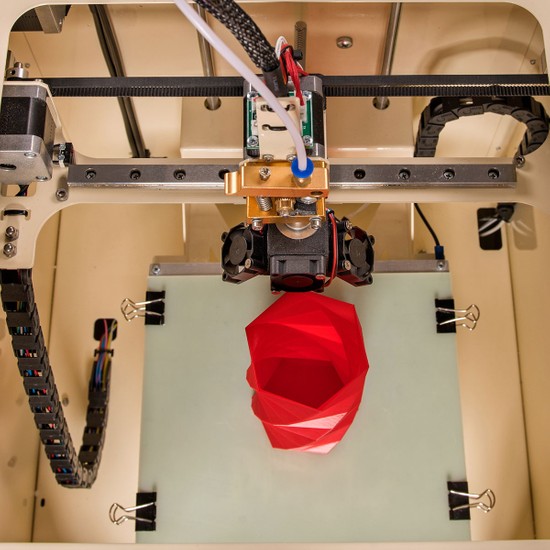

XYZPrinting da Vinci Junior is a compact 3D printer with enclosure. If you are looking for a good gift for someone, this wonderful machine is a great option to consider - in addition to being powerful, it also looks great.

On top of that, the printer is powered by sophisticated XYZware Pro software, while the optional 0.3 mm nozzle allows you to print with PLA with resolution of 50 microns and printing speed up to 100 mm per sec.

On the image below, you can see the details printed by the 0.4 mm and 0.3 mm nozzles.

Advantages of the PRO version: automated bed leveling, advanced software and the ability to install a 0.3 mm nozzle.

There is also a Wi-Fi version that offers wireless connection with a PC.

Best 3D printers under $1000

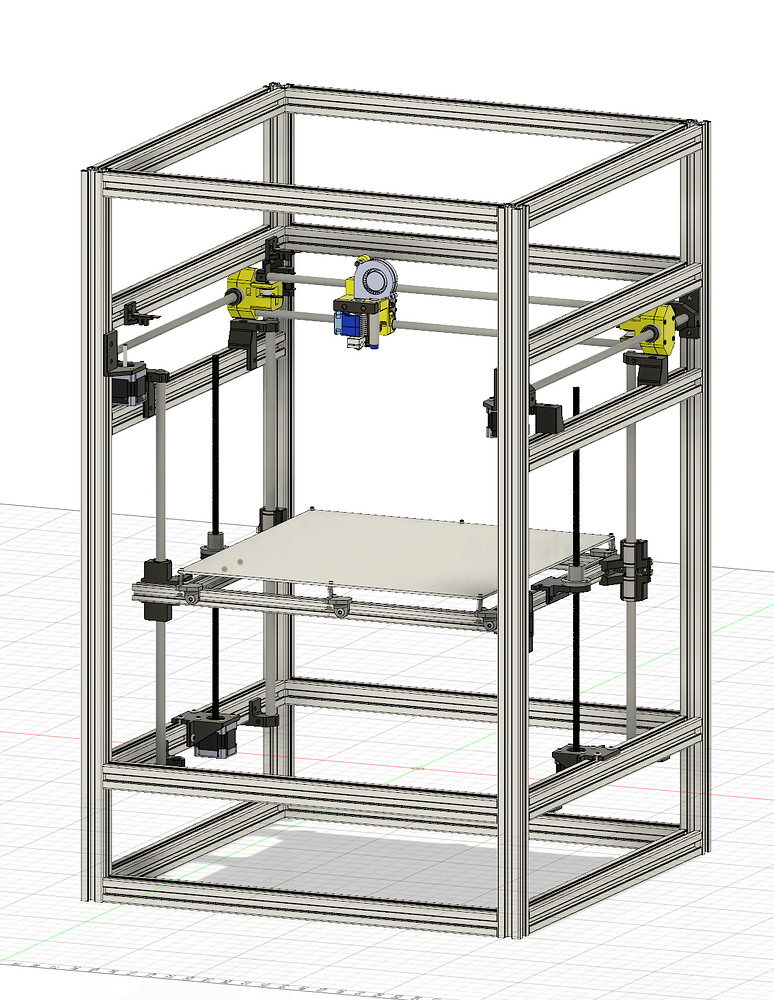

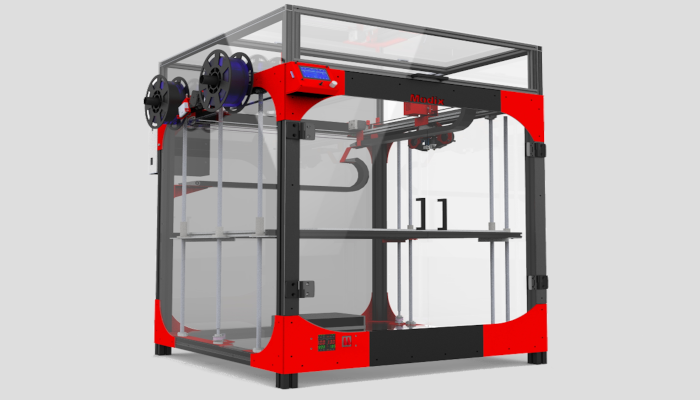

Flyingbear Tornado

Semi-assembled

- Technology: FDM

- Extruder type: Dual

- Build volume: 350 х 300 х 300 mm

- Extruder temperature: up to 240 °C

- Print platform temperature: 60-120°C

- Layer thickness: 50 microns

- Positioning accuracy: Z: 2 microns, XY: 10 microns

- Material support: PLA, ABS, PETG, Wood, PVA, Flex

- Nozzle size, mm: 0.

4 (optionally 0.2, 0.3 mm)

4 (optionally 0.2, 0.3 mm) - File transfer: SD, USB

- Printing speed: 150 mm/s

- Price: $799.00

Printer Features: metal frame, large build volume, big belts, silent-running stepper motors, large touch-screen control panel and a big cooler attached to the system unit.

High-quality prints.

Wanhao Duplicator 4S

Fully assembled

- Technology: FDM

- Extruder type: Dual

- Build volume: 225 х 150 х 145 mm

- Extruder temperature: 260°C

- Material support: ABS, PVA

- Nozzle size, mm: 0.4

- File transfer: USB, SD

- Printing speed: 40 mm/s

- Laser power: 220 W

- Price: $999,99

This 3D printer features a metal frame and acrylic body panels. Though it does not offer the highest printing speed, it always produces awesome prints. The machine can also print with two materials at once, which allows you to create bicolored models or print with soluble support materials.

The machine can also print with two materials at once, which allows you to create bicolored models or print with soluble support materials.

Wanhao Duplicator 6

Fully assembled

- Technology: FDM

- Extruder type: Single

- Build volume: 200 х 200 х 200 mm

- Extruder temperature: 260°C

- Layer thickness: 20 microns

- Material support: PLA, PVA, HIPS, ABS

- Nozzle size, mm: 0.4

- File transfer: USB, SD

- Printing speed: 30-150 mm/s

- Price: $675.00

This model features: advanced design of the metal frame, high printing speed, reliable industrial-grade components, open-source software, and the ability to use any suitable program.

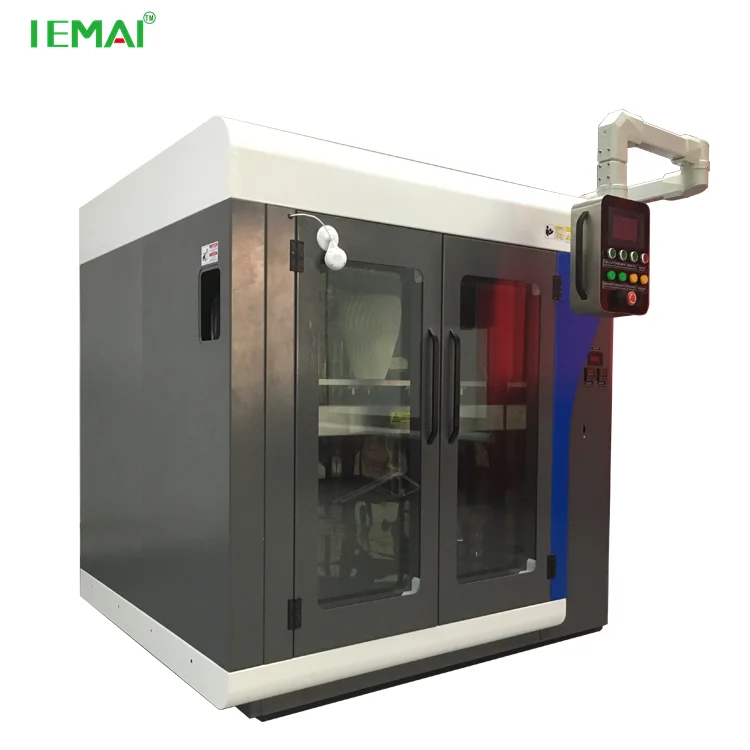

Best MFDs under $1000

Snapmaker

Fully assembled

- Technology: FDM

- Extruder type: Single

- Build volume: 125 х 125 х 125 mm

- Extruder temperature: 250°C

- Layer thickness: 50 microns

- Material support: PLA, ABS, Wood, Flex

- Nozzle size, mm: 0.

4

4 - File transfer: USB, Wi-Fi

- Printing speed: 100 mm/s

- Price: $799.00

Besides 3D printing this machine is also capable of CNC milling and laser engraving. This is achieved with 3 interchangeable modules that can be set via the X-axis rail. The wide variety of functions made this device popular among 3D printing enthusiasts all over the world.

Resin 3D printers under $800

Wanhao Duplicator 7

Resin 3D Printer, Fully assembled

- Technology: LCD/DLP

- Laser: 405 Nm

- Build volume: 120 х 68 х 200 mm

- Layer thickness: 35 microns

- Printing accuracy: 0.04 mm

- Resolution: 2560 х 1440 pixels

- File transfer: USB

- Printing speed: 30 mm/h

- Price: $449.00

Wanhao Duplicator 7 (D7 1.5) 3D printer is one of the cheapest on the market of resin 3D printers with the stable printing quality. The device also features a rigid metal frame.

The device also features a rigid metal frame.

Given the price, the device provides a very high quality of prints.

The machine can be used in jewelry manufacturing to print full molds for casting. In the picture below, you can see casts made with the D7 molds without post processing.

One significant disadvantage of this machine is that in order to be able to print, it requires a continuous transmission of images from a computer while being connected to the PC as the second monitor. It means that you will need a separate computer without third-party programs. It’s imperative that you disable auto updates and sleep mode if you want to work with D7.

However, this drawback is eliminated in the next model — D7 Plus.

Wanhao Duplicator 7 Plus

Resin 3D Printer, Fully assembled

- Technology: LCD/DLP

- Laser: 405 Nm

- Build volume: 120 х 68 х 200 mm

- Layer thickness: 35 microns

- Printing accuracy: 0.

04 mm

04 mm - Print definition: 2560 х 1440 pixels

- File transfer: USB

- Printing speed: 30 mm/h

- Price: $468.99

This device is the modified and enhanced version of the D7 and comes with touch-screen control panel. The machine can print pre-loaded models without a computer.

Anycubic Photon S

Resin 3D Printer, Fully assembled

- Technology: DLP

- Laser: 405 Nm

- Build volume: 115 х 65 х 165 mm

- Layer thickness: 25 microns

- Printing accuracy: XY- 47 microns, Z-1.25 microns

- Resolution: 2560 х 1440 pixels

- File transfer: USB

- Printing speed: 20 mm/h

- Price: $459.99

It’s a bit more advanced machine similar to the D7 Plus but from another manufacturer. Its main features include:

- Layer thickness: 25 microns (compared to Wanhao’s 35 ), which is a remarkable advantage;

- Proprietary software, which works faster and supported by the manufacturer.

However, it won’t be pretty if the manufacturer stops the support. Therefore, it’s for you to decide whether it’s a drawback or an advantage.

However, it won’t be pretty if the manufacturer stops the support. Therefore, it’s for you to decide whether it’s a drawback or an advantage. - Transparent door instead of a completely removable top cover typical for the D7. On the one hand, it is, surely, much more convenient. On the other hand, it results in less secure isolation of the print from the outer light.

We can’t tell you which one is better. It’s up to you to decide.

Final thoughts

Today’s market has plenty of affordable 3D printers. Whether you are an entry-level enthusiast looking for a cheap machine to use at home, a professional with solid 3D printing experience looking for a sophisticated machine for high quality production or just trying to find an unusual gift for someone who matters, all the 3D printers mentioned above will easily fulfill any of these tasks.

make the most of your budget!

What is the best 3D printer for under $1,000?

With a $1,000 budget, you’re bound to find a good FDM 3D printer.

Low-cost 3D printer manufacturers– mostly Chinese– have been driving prices down over the past two or three years, all while putting more and more effort into quality.

We’ve gone from complex, DIY 3D printer kits that required hours or days to be assembled, to more user-friendly, pre-assembled machines that you can almost use right out of the box.

New standards have arisen, too. Features that used to be considered rare are now pretty common on the top 3D printers under $1,000: filament detection, heated beds, touchscreens, closed frames, and more.

Without further ado, let’s move on to the next section to check out which FDM 3D printers pack in the best performance for under $1K!

The 10 best 3D printers under $1,000 in 2022

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. | |

|---|---|---|---|---|---|

| FlashForge | Creator Pro (2016) This product has been reviewed by our team. | 227 × 148 × 150 mm8.94 × 5.83 × 5.91 in | China | $ 399406 €354 £59,473 ¥ | Contact |

| FlashForge | Dreamer | 230 × 150 × 140 mm9.06 × 5.91 × 5.51 in | China | $ 419426 €372 £62,454 ¥ | Contact |

| Creality | CR-10 V2 | 300 × 300 × 400 mm11.81 × 11.81 × 15.75 in | – | $ 519528 €460 £77,360 ¥ | Contact |

| Tiertime | UP Mini 2 ES This product has been reviewed by our team. | 120 × 120 × 120 mm4.72 × 4.72 × 4.72 in | – | $ 599609 €531 £89,285 ¥ | Contact |

| Creality | Ender 5 Plus | 350 × 350 × 400 mm13.78 × 13.78 × 15.75 in | – | $ 599609 €531 £89,285 ¥ | Contact |

| Dremel | DigiLab 3D20 | 230 × 150 × 140 mm9. 06 × 5.91 × 5.51 in 06 × 5.91 × 5.51 in | United States | $ 679690 €602 £101,209 ¥ | Contact |

| Creality | CR-10 S5 | 500 × 500 × 500 mm19.69 × 19.69 × 19.69 in | – | $ 759772 €673 £113,134 ¥ | Contact |

| Qidi Tech | X-Plus | 270 × 200 × 200 mm10.63 × 7.87 × 7.87 in | – | $ 899914 €797 £134,001 ¥ | Contact |

| Prusa Research | Original Prusa i3 MK3S This product has been reviewed by our team. | 250 × 210 × 210 mm9.84 × 8.27 × 8.27 in | Czech Republic | $ 9991 015 €886 £148,907 ¥ | Buy |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Product | Brand | Build size | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|

| Creator Pro (2016) This product has been reviewed by our team. | FlashForge | 227 × 148 × 150 mm8.94 × 5.83 × 5.91 in | $ 399406 €354 £59,473 ¥ | Contact manufacturer |

| Dreamer | FlashForge | 230 × 150 × 140 mm9.06 × 5.91 × 5.51 in | $ 419426 €372 £62,454 ¥ | Contact manufacturer |

| CR-10 V2 | Creality | 300 × 300 × 400 mm11.81 × 11.81 × 15.75 in | $ 519528 €460 £77,360 ¥ | Contact manufacturer |

| UP Mini 2 ES This product has been reviewed by our team. | Tiertime | 120 × 120 × 120 mm4.72 × 4.72 × 4.72 in | $ 599609 €531 £89,285 ¥ | Contact manufacturer |

| Ender 5 Plus | Creality | 350 × 350 × 400 mm13.78 × 13.78 × 15.75 in | $ 599609 €531 £89,285 ¥ | Contact manufacturer |

| DigiLab 3D20 | Dremel | 230 × 150 × 140 mm9.06 × 5.91 × 5.51 in | $ 679690 €602 £101,209 ¥ | Contact manufacturer |

| CR-10 S5 | Creality | 500 × 500 × 500 mm19. 69 × 19.69 × 19.69 in 69 × 19.69 × 19.69 in | $ 759772 €673 £113,134 ¥ | Contact manufacturer |

| X-Plus | Qidi Tech | 270 × 200 × 200 mm10.63 × 7.87 × 7.87 in | $ 899914 €797 £134,001 ¥ | Contact manufacturer |

| Original Prusa i3 MK3S This product has been reviewed by our team. | Prusa Research | 250 × 210 × 210 mm9.84 × 8.27 × 8.27 in | $ 9991 015 €886 £148,907 ¥ | Buy on Prusa |

3D printer comparison engine

Overview of the best budget 3D printers under $1,000

This desktop 3D printer offers a pretty good performance for the price. It has dual Z-axis rails to provide more stability and avoid wobbling issues, and it’s versatile in terms of material compatibility.

Indeed, Qidi Tech includes two interchangeable extruders with the printer. One for common types of filament such as PLA or ABS, and one that’s tougher and can reach higher temperatures for Nylon, Carbon-fiber filled, and even Polycarbonate.

The printer’s flexible, removable build plate is two-sided, too. All you need to do is flip it over to switch between easy materials and tougher materials. Additionally, there are two different spool holders, outside or inside the printer if you need a completely closed frame.

Contact manufacturer Add to comparison

The Original Prusa i3 series has been a best-seller worldwide for years. Prusa Research focuses on quality and support, and their award-winning open source printers have been thoroughly praised by the community.

The MK3S was released early 2019 and is the most up-to-date version of the Original Prusa i3. It’s equipped with numerous features, including a magnetic print bed with swappable sheets, a range of sensors (filament, shifted layers, skipped steps, temperature drifts, etc.), and high-quality components.

A multi-material upgrade is available to allow 3D printing with up to 5 different filaments at a time. It isn’t full-color 3D printing, but it can definitely spice prints up.

Buy on Prusa Add to comparison

For a $599 3D printer, the UP mini 2 ES is a very capable machine with plenty of user-friendly perks. It offers automatic leveling and material detection, and its interchangeable build plates make it easy to remove finished prints.

Although its build volume is a bit small compared to current standards, it does provide a great performance, especially with ABS prints. Its frame is closed to maintain a warm interior environment and its air filter helps reduce the amount of particles released in the air.

Also, you can open it from the front or back doors, and there are two magnetic lids on top as well.

Contact manufacturer Add to comparison

The award-winning Dremel DigiLab 3D20 (Idea Builder series) has been on the market since 2014 and remains to this day a staple educational 3D printer. It is a reliable, plug-n-play workhorse that will last you several years.

The Dremel 3D20’s closed frame and non-heated print bed make it safe enough to use in the classroom. That also means that it’s only able to print PLA-based filaments.

That also means that it’s only able to print PLA-based filaments.

Hence, although it’s an excellent 3D printer for beginners, it may not be versatile enough for more advanced users who will quickly outgrow it.

Contact manufacturer Add to comparison

If you’re in the market for a 3D printer with a large build area, the CR-10 V2 may be just what you’re looking for. In addition to providing a large print size, it’s equipped with a number of user-friendly features that make it easy to use (even if it isn’t exactly a plug and play machine).

Those features include a filament sensor, a pause and resume function that works in case of a power failure, and optional automatic bed leveling that you can order separately and install yourself.

The printer also boasts dual cooling fans and a quiet, modern mainboard and power supply.

Contact manufacturer Add to comparison

The Creator Pro, another well-established and award-winning classic, is one of the few 3D printers in this price range to offer dual extrusion. It’s capable of printing a wide range of materials, from PLA to ABS and flexible filaments.

It’s capable of printing a wide range of materials, from PLA to ABS and flexible filaments.

Aside from its dual extruder, the FlashForge Creator Pro is pretty basic with a heated print bed and a regular LCD screen. The relative lack of features– which is mainly due to the fact that the printer was released in 2016– doesn’t stop it from providing a reliable performance.

It’s easy to use, comes fully assembled, and FlashForge provides great customer service.

Contact manufacturer Add to comparison

Creality is a Chinese manufacturer that finds a place in many of our rankings and product selections. Their Ender 3 is in our selection of 3D printers under $300, and their standard Ender 5 printer is part of our “3D printers under $500” guide.

This particular Creality 3D printer offers a super-sized build volume, so you can print huge objects or various smaller models in one go. It comes as a semi-kit which means you’ll have a few assembly steps to follow before being able to use it.

The Ender 5 Plus boasts auto-leveling, filament detection, and a large touchscreen.

Contact manufacturer Add to comparison

You may be thinking that this printer looks pretty similar to the Dremel 3D20, and you’re right. The 3D20 is actually a kind of rebranded version of the FlashForge Dreamer. However, the latter provides a bit more functionality.

FlashForge’s printer offers Wi-Fi connectivity, a heated build plate (120°C) and, more importantly, a dual extruder. This explains the price gap between both models.

The FlashForge Dreamer is compatible with PLA filaments and ABS filaments.

Contact manufacturer Add to comparison

The CR-10 S5 is currently the largest 3D printer you can find for under $1,000. It doesn’t have a touchscreen or automatic bed leveling like higher-end printers do, but it’s a fair deal considering the huge build volume it provides at this price.

This 3D printer does have other cards up its sleeve, like a heated and removable bed, an auto-resume feature, and a filament detector.

It comes as a semi-kit to be assembled in a few quick steps.

Contact manufacturer Add to comparison

Buying guide for 3D printers under $1,000

These are some of the things you should take into account when deciding on which 3D printer to buy.

Build volume

Your printer’s maximum build size will, obviously, determine how big your prints can be. Keep in mind that the bigger your prints are, the longer they’ll take. Even small prints can require a few hours, so for a big 3D model, you may be looking at a few days worth of printing.

For an idea of what can be printed, take a look at some of these sites where you can download STL files for free. Note that if your build volume is too small, it’s possible to “cut” models into separate 3D printable files and glue them together after.

Materials

PLA is the most common kind of plastic you’ll find to 3D print. There’s an incredibly wide range of colors and types available, from glittery rainbow gradients to glow-in-the-dark filaments. This material is also the cheapest and doesn’t require a heated bed (even if it does help for first layer adhesion).

There’s an incredibly wide range of colors and types available, from glittery rainbow gradients to glow-in-the-dark filaments. This material is also the cheapest and doesn’t require a heated bed (even if it does help for first layer adhesion).

If you want to go beyond PLA filament, for example, if you want to print flexible TPU or strong ABS, you’ll need a heated print bed. Ideally, it’s also best to have a closed frame for these materials, to protect your prints from room drafts. You can still go for an open printer though and make a frame yourself. Even cardboard can do the trick!

For abrasive materials like Carbon-fiber-filled Nylon, your nozzle must be reinforced. A brass nozzle can be damaged with just one abrasive print. It’s possible to order new, suitable nozzles online if your printer doesn’t come with one.

Layer thickness and speed

Almost all 3D printers under $1,000 boast similar specs. Minimum layer thicknesses are typically around 0. 1mm, or 0.05mm for some. The thinner your layers, the better your prints will look, and the longer they’ll take to print, too.

1mm, or 0.05mm for some. The thinner your layers, the better your prints will look, and the longer they’ll take to print, too.

Users tend to print thicker layers anyways to get their prints done more quickly, as the difference isn’t too noticeable. In slicing software, you can see various layer profiles; “draft quality” is around 0.2mm, for example.

Maximum print speeds are also quite similar from one printer to another in the sub-1000 price range. They’re generally between 120 mm/s and 180 mm/s, but at those speeds, you’re losing precision and print quality.

Recommended speeds for most prints are around 60 mm/s, or slower for highly detailed prints. If you want small, detailed prints with excellent surface quality, you should look into resin 3D printers. There are cheap options, too, with some resin 3D printers under $1,000.

3D printing still has a long way to go before it’s truly plug-n-play, even with professional or industrial 3D printers.

However, there have been many advances in the past years. Here are a few key features that can make printers more user-friendly:

- Automatic bed leveling: it’s recommended to level your print bed before each print. Some printers have sensors that allow them to level the bed automatically, so all you need to do is press a button. Otherwise, you have to do this manually, and it can take a while depending on how off it is.

- Assisted bed leveling: with this feature, the touchscreen interface lets you choose different points of the print bed (e.g. corners, the center of the build plate). The print head moves automatically where you tell it to, instead of you having to move it by hand. You still have to tighten or loosen the print bed screws manually.

- Dual extruder: this functionality is relatively rare in this price range. It allows you to 3D print with two different materials at the same time.

- Filament sensor or filament run-out detection: many printers have this feature.

With a filament sensor, the print head can detect if there’s a jam, breakage, or if you run out of filament. If that’s the case, the printer pauses immediately.

With a filament sensor, the print head can detect if there’s a jam, breakage, or if you run out of filament. If that’s the case, the printer pauses immediately. - Print resume: enables you to pause and resume your prints. Often, it works automatically in case of an unexpected power cut. If your print has been going on for several hours and you get a power failure, you’ll really appreciate being able to easily pick up where you left off.

- Swappable build plates: this makes it easier for you to remove your prints, and to do so without un-leveling your print bed (sometimes tugging on your part can throw off your bed level).

Assembly

Some printers come fully assembled, or only require you to plug in the print head, for example. However, the majority of affordable 3D printers come as kits that you need to assemble yourself.

Kits used to be complex and time-consuming to assemble for beginners (shoutout to the Anet A8 kit), but today they mainly come as semi-assembled kits. That means that most of the complicated parts are already assembled and you only have to put together the frame. This shouldn’t take more than an hour of your time.

That means that most of the complicated parts are already assembled and you only have to put together the frame. This shouldn’t take more than an hour of your time.

FAQ

What’s the best 3D printer kit under $1,000?

One of the best 3D printer kits under $1,000 is the Creality CR-10 V2.

Best large 3D printer under $1,000?

The best large 3D printer under $1,000 is the Creality CR-10 S5 which offers an impressive build volume of 500 x 500 x 500 mm.

What are the best SLA 3D printers under $1,000?

Most entry-level resin 3D printers use DLP or LCD technology. Some popular and cheap resin 3D printer brands include Elegoo, Longer3D, Phrozen, and ANYCUBIC.

Consumables for FDM printing Plastic filaments

No matter how high-tech 3D printing is, 3D modeling is impossible without such an inexpensive component as consumables. Each 3D prototyping technology has its own pool of consumables - they are developed taking into account compatibility with printers, cost efficiency and quality of output 3D objects. Thus, industrial installations use powder materials, medical 3D printers are biocompatible and neutral, culinary ones work with a wide range of paste-like and viscous food compositions, and the most common in the segment of personal and semi-professional 3D equipment - with plastic thread and photopolymer resins. And since this segment is the most massive, it is on it that we will focus in the first place.

Each 3D prototyping technology has its own pool of consumables - they are developed taking into account compatibility with printers, cost efficiency and quality of output 3D objects. Thus, industrial installations use powder materials, medical 3D printers are biocompatible and neutral, culinary ones work with a wide range of paste-like and viscous food compositions, and the most common in the segment of personal and semi-professional 3D equipment - with plastic thread and photopolymer resins. And since this segment is the most massive, it is on it that we will focus in the first place.

Of course, you have already studied our range of consumables - in the 3DMall online store it is rightfully considered one of the most worthy and affordable in the whole country. Here you can buy consumables for FDM and other types of printers inexpensively with delivery in Moscow and Russia, including the possibility of picking up at one of the many points of issue. And our Knowledge Base and prompt free consultations with our experts on all issues related to 3D printing will help you make the right choice.

FDM consumables

Most modern personal printers are FDM units, which, like their consumables, are more than affordable. Today, such printers are available not only in offices, design and engineering offices, but also in the homes of many fans of maker and 3D technologies.

There are many varieties of plastics for 3D printing - a far from exhaustive list of materials includes PLA, ABS, PVA, Nylon, PC, HDPE, PP, PCL, PPSU, Acrylic, PET, HIPS, imitation wood, sandstone or metals, the characteristics of which we consider in more detail.

PLA - polyaktide

The undisputed leader of the modern market of consumables for FDM printers - an environmentally friendly, biocompatible, thermoplastic composition. Its production is based on corn and sugar cane, thanks to which products from this type of plastic are successfully used in everyday life. It is used for the manufacture of toys, dishes, souvenirs, housing elements for household appliances, designer models, food packaging, medicines, surgical thread, and due to its affordability, it is also used for education and hobbies.

Despite the high quality of the surface of PLA products, it is a stretch to call them practical - the material is quite soft and short-lived. The melting temperature is 170-180 about C, the glass transition process begins when cooled to 50 about C.

PLA has proven to be the best type of material for 3D printers with an open build chamber and a heated worktable.

Benefits include low shrinkage so finished objects do not deform during curing, ease of handling and versatility.

ABS

ABS, or acrylonitrile butadiene styrene, is the most popular heat-resistant plastic in the field of 3D prototyping, which, however, cannot be considered one of the most popular due to the fact that printing with its use is quite problematic.

Advantages - durability, mechanical strength, resistance to moisture, oils, a wide range of acids and elevated temperatures (it withstands heat up to 100-110 about C, responds well to staining). At the same time, some varieties are destroyed by prolonged contact with direct sunlight, and the melting point is about 180 about C - considered low for industrial use. When cooling, the object is subject to significant shrinkage - the first layers can twist, deform and crack. To avoid such problems, the use of ABS is recommended for printing on 3D printers with a heated desktop and a closed body. For a more reliable grip on the work surface, you should also use adhesive tape.

At the same time, some varieties are destroyed by prolonged contact with direct sunlight, and the melting point is about 180 about C - considered low for industrial use. When cooling, the object is subject to significant shrinkage - the first layers can twist, deform and crack. To avoid such problems, the use of ABS is recommended for printing on 3D printers with a heated desktop and a closed body. For a more reliable grip on the work surface, you should also use adhesive tape.

ABS products are absolutely safe at normal air temperatures, however, heat releases toxic acrylonitrile fumes, so it should not be used for printing toys, household items, dishes and food storage containers.

PVA - polyvinyl alcohol

A truly unique material for special applications. Its main feature is the ability to dissolve in water, which allows it to be used to build support structures (support for particularly filigree elements of the main object) when printing on printers with 2 extruders. The finished model after separation of the support does not require mechanical post-processing - its surface is smooth and of high quality.

The finished model after separation of the support does not require mechanical post-processing - its surface is smooth and of high quality.

The mechanical properties of this type of plastic are also interesting - in conditions of low humidity it has amazing strength, and with increasing humidity it becomes elastic, however, with a loss of strength. The melting temperature is 165-175 about C, which allows it to be used in combination with PLA and ABS plastics.

Before using PVA, it is recommended to dry it additionally (for example, in an oven) at a temperature not exceeding 80 C for 6-8 hours, even if it was stored in an absolutely sealed dry container.

Nylon

The main advantage of this material is its resistance to wear due to friction, which makes it very popular in various industries, in particular for coating parts as an alternative to lubrication.

Nylon thread is represented by a fairly large assortment, each variety has its own advantages and disadvantages. The most popular and practical are traditionally considered the nylon-66 created by DuPont in 1935 and its later analogue produced by BASF nylon-6. Their melting points are respectively 265 and 220 about C, which determines the features of their application.

The most popular and practical are traditionally considered the nylon-66 created by DuPont in 1935 and its later analogue produced by BASF nylon-6. Their melting points are respectively 265 and 220 about C, which determines the features of their application.

Key features - easily absorbs moisture, fuses with polyimide, which requires special care when choosing a printer, for a more secure fixation to the desktop, use wax-impregnated adhesive tape. Recommended for refilling printers with studded traction mechanisms as part of extruders, as well as for printing solid models, since nylon parts stick together very poorly.

PC - polycarbonate

The main advantages of polycarbonate plastic filament are its high strength and temperature resistance, it can be cooled and heated without the risk of deformation of the finished object, which cannot be said about the printing process itself. The melting temperature of the material is 265 about C, the safety requirements and risks of deformation during model building will help to optimize equipment with a closed print chamber and a heated platform. You should immediately pay attention to the risks - printing these materials is harmful to health, since bisphenol A, a potentially carcinogenic and toxic substance, is used in the process of its production.

You should immediately pay attention to the risks - printing these materials is harmful to health, since bisphenol A, a potentially carcinogenic and toxic substance, is used in the process of its production.

Due to its high hygroscopicity, RS should be stored in dry and fully sealed containers.

HDPE - High Density Polyethylene

This is one of the world's most sought after plastics for 3D printing. The material melts very easily and hardens in record time - the temperature difference between these processes is only 20-25 degrees, the average melting point is 130-145 about C. (hardening too fast), high shrinkage and deformation activity. The optimal solution for high quality HDPE printing results is high speed prototyping and careful temperature control of the build chamber and work platform to slow down the process of layer curing. However, HDPE is in the category of the cheapest consumables. It is used for the production of plastic bottles and containers, disposable tableware.

An interesting fact is that this type of plastic thread can also be made from plastic waste, there are even 2 professional installations that can cope with this task (universal processing machines FilaBot and RecycleBot.

PP - polypropylene

A versatile and inexpensive material used for production a wide range of plastic products - from dishes and packaging to pipes and fittings.The advantages of PP include low specific gravity, chemical resistance, non-toxicity, moisture resistance, wear resistance and low cost.Unstable with constant contact with direct sunlight and temperatures below -5 o C.

Print shrinkage is as high as 2.4%, 3 times greater than with ABS. Molten material adheres well even to a cold surface, but for high quality printing it is recommended to use equipment with a heated bed.

More popular than the original polypropylene is its imitation, developed by the world famous company Stratasys - Endur.

PCL - polyaprolactone

This is a low temperature biodegradable polyester that melts already at 60 about C, which requires a careful approach when choosing equipment for PLC printing - not all 3D printer models support this mode. Non-toxic - used in the field of medicine, has excellent plasticity, so it can be used an unlimited number of times.

Non-toxic - used in the field of medicine, has excellent plasticity, so it can be used an unlimited number of times.

High viscosity and low temperature resistance make this material unsuitable for functional prototypes and objects, but it is ideal for printing food containers and various layouts.

PPSU - polyphenylsulfone

Thermoplastic material with outstanding strength characteristics, in demand in the aviation industry. Chemically and thermally resistant, does not burn, does not deform in a wide temperature range (-50 o C ... +180 o C). It is used in the production of food containers, dishes, household items. Resistant to corrosion from solvents and household chemicals.

With all the advantages, it is used infrequently, since the melting point is 370 o C.

Acrylic - Plexiglas

Durable, environmentally friendly, moisture resistant material, characterized by excellent bonding quality of layers in the prototyping process. The objects have a homogeneous flat surface and excellent performance properties. It is rarely used for FDM printing, as it is difficult to store and requires the highest precision of construction, which is very, very difficult to achieve on a classic personal printer.

The objects have a homogeneous flat surface and excellent performance properties. It is rarely used for FDM printing, as it is difficult to store and requires the highest precision of construction, which is very, very difficult to achieve on a classic personal printer.

Stratasys' VeroClear imitator, which is printed on Objet Eden printers, is in much greater demand.

PET - polyethylene terephthalate

Food and medical containers are mainly made from this material with a very complex name. Its main advantage is its high chemical resistance, it is not subject to the damaging effects of a wide range of acids and alkalis, it is resistant to wear and a wide temperature range (-40 about C ... +75 about C). Shrinkage on cooling is about 2%, which, combined with a high melting point, reaching 260 about C, makes the printing process somewhat problematic. The transparency of the product is achieved by rapid cooling of the model to the glass transition threshold (+70-80 about C). In general, to obtain a consistently high-quality result, it is enough to create the same conditions as when printing ABS.

In general, to obtain a consistently high-quality result, it is enough to create the same conditions as when printing ABS.

HIPS Soluble Support Material

This is a polystyrene with amazing durability, used to produce real parts and components used in various industries in real use. It is also used for the manufacture of toys, disposable tableware, a number of building materials. In terms of physical properties (strength and durability), it is similar to ABS plastic, but it dissolves easily in limonene. This feature allows it to be used as a support material for printing ABS plastic products, in comparison with PVA it has a much lower cost and absolute insensitivity to water.

Printing is recommended in well-ventilated rooms, as toxic volatile substances may be released during melting.

Wood imitators

This category of consumables includes LAYWOO-D3 and BambooFill, products from which both visually and functionally are in no way inferior to analogues made of natural wood - the products even have a characteristic woody aroma. They do not deform and do not require the use of a heated platform. LAYWOO-D3, for example, is made from dusted sawdust and a non-toxic binder polymer, making it safe and highly post-processable.

They do not deform and do not require the use of a heated platform. LAYWOO-D3, for example, is made from dusted sawdust and a non-toxic binder polymer, making it safe and highly post-processable.

An interesting detail is that the use of nozzles with different heating parameters can achieve different decorative effects. For example, as the extrusion temperature increases, this type of material acquires a richer, darker hue.

The only negative is the high cost, which exceeds the price of PLA or ABS by almost 4 times.

Laybrick – sandstone simulant

We owe the appearance of this composite material with high aesthetic and performance characteristics to the inventor Kai Parti. By the way, LAYWOO-D3 is also his creation. The binder used as the basis for creating this type of material is mixed with a mineral filler - this explains the original texture of the resulting products.

Depending on the selected melting temperature, the surface of the products can be smoother or rougher (the higher it is, the greater the roughness).

One of the easiest materials to work with - it does not need a heated platform, it practically does not shrink or deform. The only drawback is the high cost compared to other filaments.

BronzeFill - metal simulant

Metal is the foundation of additive manufacturing, its use in 3D printing opens up almost unlimited possibilities for mankind. If not for the high cost, of course. Therefore, it is not surprising that a high-quality imitator, BronzeFill, has also been created for the followers of FDM printing. Products printed from it are not inferior to metal ones either visually or operationally.

This is an almost transparent PLA-based plastic, which also contains a bronze filler. Finished 3D objects respond well to post-processing - grinding, polishing - and visually look like all-metal, but you should not forget that thermoplastic is based on it.

How to choose printing plastic?

The choice of filament for printing should be determined by the following several parameters:

- the capabilities of the 3D printer at your disposal;

- requirements for surface quality, detailing accuracy and performance of finished products;

- color;

- scope.

We offer you a small comparison table on the key characteristics of the most popular types of plastic in personal 3D printing, which will help you choose the best option.

layer, °С

threads, mm

The idea of the invention belongs to the American Charles Hull, he received a patent for it only two years after development. The printer was a rather massive industrial installation and, despite many inaccuracies and shortcomings in operation, the technology was used.

The idea of the invention belongs to the American Charles Hull, he received a patent for it only two years after development. The printer was a rather massive industrial installation and, despite many inaccuracies and shortcomings in operation, the technology was used. Hal co-founded 3dsystems, a leader in industrial 3D printers. However, this material is not dedicated to these large machines. 3D printing is becoming more and more part of everyday life. Thus, the technology is used to create unique toys, various models, figurines, packaging, clothes, shoes and jewelry. For these purposes, it is not at all necessary to purchase a large-sized printer. You can get by with a small device. It has a compact size, and its technology is completely identical to the industrial one. Heated plastic is fed through the nozzle (spout) of the device, which is laid out on the surface in accordance with the drawing specified in the program. And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone.

Top 10 rating according to KP

1. Creality3D Ender 3

Creality3D Ender 3. Photo: market-yandex.ruOur rating opens with a model from the world's largest manufacturer of 3D printers. The Ender 3 features an elegant and thoughtful design, excellent print quality and a wide build area. Manufacturers have provided a good arrangement of wires that do not get confused during operation. The small control unit of the device is located to the right of the work surface. The gadget prints perfectly with various types of plastic. In particular, we are talking about varieties of ABS, PLA, TPU and PETG. The scope of this printer is quite wide. It can be used to produce minifigures, do artistic modeling, and make small prototypes of parts and functional elements.

Pros and cons

Ability to use various types of plastic, high quality parts, reliable design

A small display that displays only basic information

2.

FlashForge Adventurer 3 FlashForge Adventurer 3. Photo: market-yandex.ru

FlashForge Adventurer 3 FlashForge Adventurer 3. Photo: market-yandex.ru The model from the Chinese developer FlashForge took the second position in our rating. The device is equipped with a Wi-Fi receiver, a removable heated pad for printing. In addition, manufacturers have provided a built-in webcam, a closed case and a color touch-screen display. The latter, although it does not support the Russian language, is intuitively understandable. The ergonomics of the device is provided by the filament sensor: if the printer runs out of plastic, it automatically goes into standby mode and does not idle.

Despite the rather wide functionality, this model is hardly suitable for an experienced printer or a small production due to the small area of the working space, high price

3. FlyingBear Ghost 5

FlyingBear Ghost 5. Photo: market-yandex.ru from FlyingBear is ideal for semi-professional use. Uniform supply of filament (plastic) provides good opportunities for creating three-dimensional figures with a fairly high resolution. High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display.

High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display. Pros and cons

Short power cord, inaccuracies in the Russian-language menu, weak airflow system.

4. Anet N4

Anet N4. Photo: market-yandex.ru The budget model from the Chinese manufacturer Anet N4 is equipped with all the necessary functions for a small domestic production. The base of the device is made of cast aluminum alloy. The weight of the gadget does not exceed 9kg. A transparent tinted hood protects the work surface from external sources of ultraviolet radiation. It can be removed to remove the finished product and clean the printer. Also, manufacturers have provided a removable resin bath and a working platform, which greatly facilitates the use of the device.

It can be removed to remove the finished product and clean the printer. Also, manufacturers have provided a removable resin bath and a working platform, which greatly facilitates the use of the device.

Key Features

| Print Technology | LCD | |

| Application | Home/DIY Professional | 30 mm/h |

Pros and cons

Ability to use photopolymer resins from any manufacturer, high polymer curing speed

Small work surface, slightly inferior to competitors in some parameters

Photon Scu0bic0 Anycu0bic0 5. S. Photo: market-yandex.ru In the middle of our rating is the Anycubic Photon S model. It is equipped with an advanced optical system and a large working camera. The device has a matrix light source that provides a uniform luminous flux over the entire plane of the desktop. This allows a very high curing speed of the layers to be achieved. In addition, the printer has an original function that allows you to simultaneously print eight identical models. According to the developers, the target audience for this device are orthodontists and jewelers. Most parts of the device are made of plastic. This factor significantly reduces the weight of the device and makes it convenient to transport.

According to the developers, the target audience for this device are orthodontists and jewelers. Most parts of the device are made of plastic. This factor significantly reduces the weight of the device and makes it convenient to transport.

6. ELEGOO Mars Pro

ELEGOO Mars Pro. Photo: market-yandex.ru This model is significantly different from its predecessor Elegoo Mars. Thanks to the advanced Z-axis mechanics and directional UV light from the diode array, it is suitable not only for hobbies, but also for fields of activity such as dentistry and jewelry. In addition, the developers moved the USB connector to the front of the device. Now there is no need to constantly rotate the gadget in the process. The weight of the device is only 7.5 kg, which makes it very convenient for transportation. A translucent plastic cover will reliably protect against extraneous radiation and will allow you to monitor the production process.

A translucent plastic cover will reliably protect against extraneous radiation and will allow you to monitor the production process.

Pluses and downsides

Comfortable construction, low utenstin, good-low-term 7. Two Trees Bluer Two Trees Bluer. Photo: market-yandex.ru

This is one of the most popular home models of 3D printers. It is ideal for getting acquainted with technology, various experiments, training and prototyping. Distinctive features of Two Trees Bluer are: "quiet" drivers, which are the engine of the device, a heated table, two-way airflow and a thread break sensor. The mechanics of the printer is quite simple, and at the same time very effective. The open type case will be very convenient when cleaning the work surface. The firmware of the device provides the functions of auto-calibration and automatic resumption of printing in case the power was accidentally turned off.

Pros and cons

Low price, easy and convenient to use

No protection for the work surface, poor quality of spare parts

Photo: market-yandex.ru

Miniature 3D printer does not look like other devices. However, this feature does not affect its technical characteristics. The plastic spool is located on the right side of the bracket. Wanhao branded coating is pasted over the table. There is no platform heating, so it is recommended to use PLA plastic for printing. The manufacturer clearly states in the manual that the printer is designed to work only with PLA material and nothing else. The body of the gadget is made of sheet steel. The memory card slot and all printer control elements - a monochrome liquid crystal display, a universal knob-button and a Reset micro-button - are placed on the front panel of the printer.

Pros and downsides

Good price

Lack of heating and protecting the working surface, high probability of problems with a working coat

9000.

000.000.000.000.000.000.000.000. Artillery Genius. Photo: market-yandex.ru

000.000.000.000.000.000.000.000. Artillery Genius. Photo: market-yandex.ru The base of the device consists of an aluminum case, in which all the electronics are hidden. An aluminum portal is also attached to it. The latter is also a guide for the moving parts of the printer. At the top of the portal is a plastic jumper to which the spool holder and filament sensor are attached. As for the control screen, its functionality is seriously curtailed. However, it is sufficient for simple tasks, but it is impossible to configure the printer.

Pros and cons

Spacious work surface, robust housing

Little functionality for a rather high price, lack of work surface protection, few functions on the control screen.

10. Tianfour Sparkmaker

Tianfour Sparkmaker. Photo: market-yandex.ru This model is ideal for beginners, as it does not require additional settings at all before starting work. Externally, the printer has the shape of a cylinder with a height of 27.5 cm and a diameter of 17 cm. The realistic contours and smooth curves of the figures are ensured by LCD technology. The printer works with any photopolymer resins for 3D printing with a flash length of 405nm.

Externally, the printer has the shape of a cylinder with a height of 27.5 cm and a diameter of 17 cm. The realistic contours and smooth curves of the figures are ensured by LCD technology. The printer works with any photopolymer resins for 3D printing with a flash length of 405nm.

How to choose a 3D printer

Choosing a 3D printer is not such a difficult task as it might seem at first glance. Despite the relentless interest in 3D printing and the incredible number of devices on the market, the basic requirements for models remain unchanged. Komsomolskaya Pravda turned to Svyatoslav Vulf, a blogger and host of a YouTube channel about modern technologies and experiments, for help in this matter. He regularly monitors new products on the 3D technology market and tests them at home.

Product size

Initially, you should decide what size of products you expect to receive in the end. The required area of the working surface depends on this. Note that the price of the device also depends on the size of the latter. For work at home, there will be enough indicators: 200 × 250 × 200 (WxHxD).

For work at home, there will be enough indicators: 200 × 250 × 200 (WxHxD).

Technology

Today, there are several technologies for printing on a 3D printer. They differ significantly from each other. Let's consider some of them.

SLA-technology — works on the basis of a liquid photopolymer, which under the influence of laser light changes its physical properties and hardens. It allows you to create figurines with the highest precision of microforms.

DLP technology is an alternative SLA method. However, instead of laser systems, LED projectors are used here, which significantly reduce the cost of 3D printers. When using this technology, the future prototype is formed layer by layer.

The FDM method is ideal when prototypes are required that will be actively used and not just sitting on a shelf. Here, high-strength industrial plastics will be used for production. Please note that there are other technologies, but they are very similar to the above.

Material

Before buying a printer, you should also pay attention to what materials it works with, as they have significant differences from each other. For example, ABS can take many different polymeric forms. This is a very durable plastic. It is easily sanded and processed. PLA plastic is considered more environmentally friendly. It is made from agricultural products - corn, potatoes, beets and others. In its original form, it is transparent and can be colored. PLA is just as strong but tougher than ABS. The ductility and heat resistance of SBS make it the material of choice in engineering and mechanical applications.

Noise level and drivers

An important factor when choosing a 3D printer are drivers - device engines (not to be confused with software). They affect the overall noise level of the device. For example, if you buy a printer with cheap A4988, then even neighbors will hear its work. In this case, you should pay a little more and purchase a gadget with more expensive drivers.

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).