3D print temperature

3D Printing Temperatures & Printing Guidelines

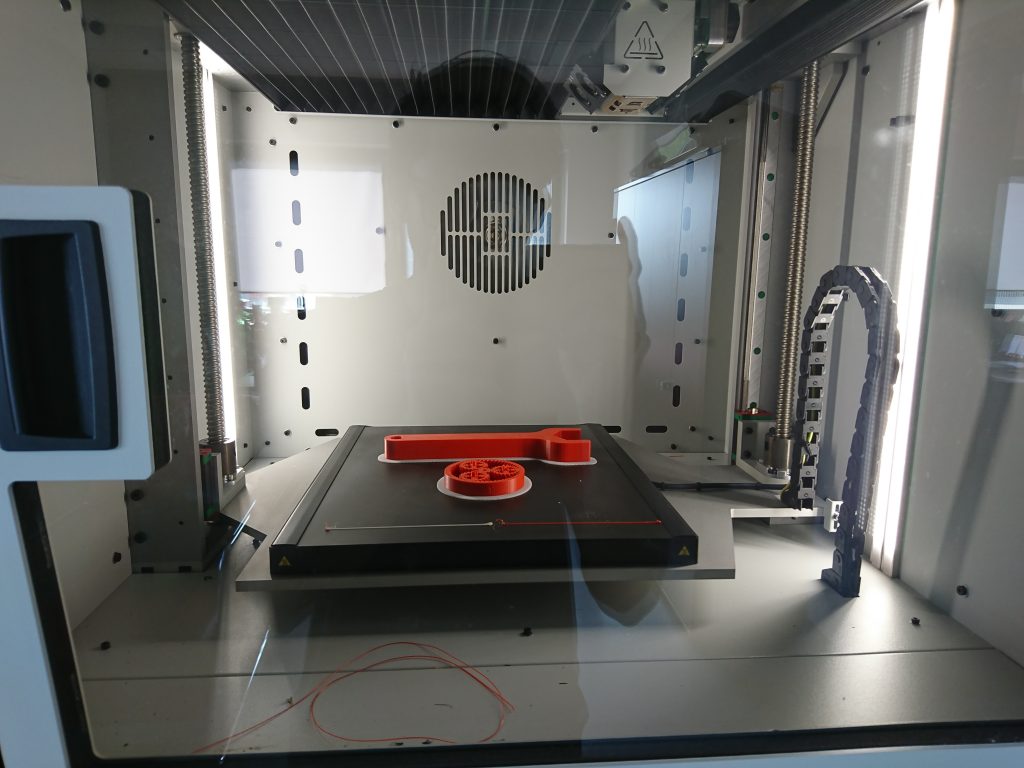

As each desktop 3D printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. To obtain optimal results for your prints you need to take into account variables like your 3D printer’s nozzle diameter, your printing speed settings, and layer height. Every printer is different, for each material/printer, make sure to take notes of what works and what doesn't.

Your print bed MUST BE LEVEL & CLEAN. You can use acetone and a towel (lint free) to clean your surface and make sure it is free from oils and dirt before printing.

If your printer is equipped with a heated print bed, make sure you turn it on, especially for ABS.

| PLA (Original Series) | PLA (Creative Series) | smart ABS |

| ABS (Original Series) | ABS (Creative Series) | Soft PLA |

| HIPS | TPU (Flexible Polyurethane) | Bendlay |

| PVA | Flame Retardant ABS | Laywood |

| Nylon PA6 | Wood | Laybrick |

| PETG | Conductive / Anti-Static ABS | Thermochrome PLA |

| Polycarbonate (PC) | EasyFil PLA | |

| PolyMax PLA | EasyFil ABS | |

| Taulman3D T-Glase | PolyFlex | EasyWood Coconut |

| Taulman3D Nylon 618 | Porolay Porous Gel | |

| Taulman3D Nylon 645 | NinjaFlex | |

| Taulman3D Bridge | Carbon Fiber PLA | |

| Taulman3D PCTPE | Polycarbonate ABS (PC-ABS) | |

| High Temperature PLA |

Material |

Temperature |

Comments |

| PLA (Original & Creative Series) | 215°C - 235°C |

|

| ABS (Original & Creative Series) | 230°C - 240°C |

|

| smartABS | Aprox. 250°C |

|

| HIPS | 230°C - 250°C |

|

| PVA | 190°C - 220°C |

|

| Soft PLA | 210°C - 220°C |

|

| NinjaFlex | 210°C - 225°C |

|

| BendLay | 215°C - 240°C |

|

| Laywoo-D3 | 165°C - 250°C |

|

| Laybrick | 165°C - 210°C |

|

| Thermochrome PLA | Aprox. 210°C |

|

| Nylon PA 6 | 240°C - 280°C |

|

| PETG | 230°C - 250°C |

|

| Taulman T-Glase | 207°C - 238°C |

|

| Taulman Nylon 618 | Aprox. 245°C |

|

| Taulman Nylon 645 | Aprox. 245°C |

|

| Taulman "Bridge" Nylon | Aprox. 245°C |

|

| Polycarbonate (PC) | 250°C - 320°C |

|

| PolyMax PLA | 180°C - 240°C |

|

| PolyFlex | 210°C - 240°C |

|

| Carbon Fiber Reinforced PLA | 190°C - 230°C |

|

| Polycarbonate ABS (PC-ABS) | 260°C - 285°C |

|

| High Temperature PLA | 190°C - 230°C |

|

| EasyFil 2.85mm PLA | 210°C - 220°C |

|

| EasyFil 2.85mm ABS | 220°C - 260°C |

|

| TPU (Flexible Polyurethane) | 195°C - 230°C |

|

| Flame Retardant/Resistant ABS | 230°C - 250°C |

|

| Wood | 200°C - 260°C |

|

| Conductive / Anti-Static ABS | 230°C - 250°C |

|

| EasyWood Coconut | 210°C - 220°C |

|

| Porolay Porous Gel | 225°C - 235°C |

|

| Taulman3D Flexible PCTPE | 225°C - 230°C |

|

| Revised: January 23, 2015 |

3D Printer Filament Temperature (+ Chart) (2022)

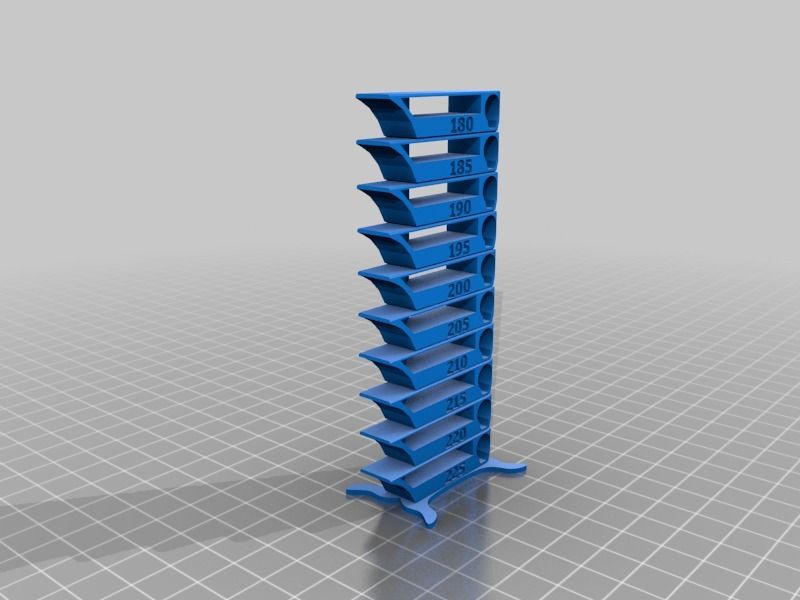

Knowing the temperature of the filament you want to use is critical in 3D printing. Read on to find the melting points of various filaments. Also, download our handy 3D printing filament chart that you can use for reference in your workshop.

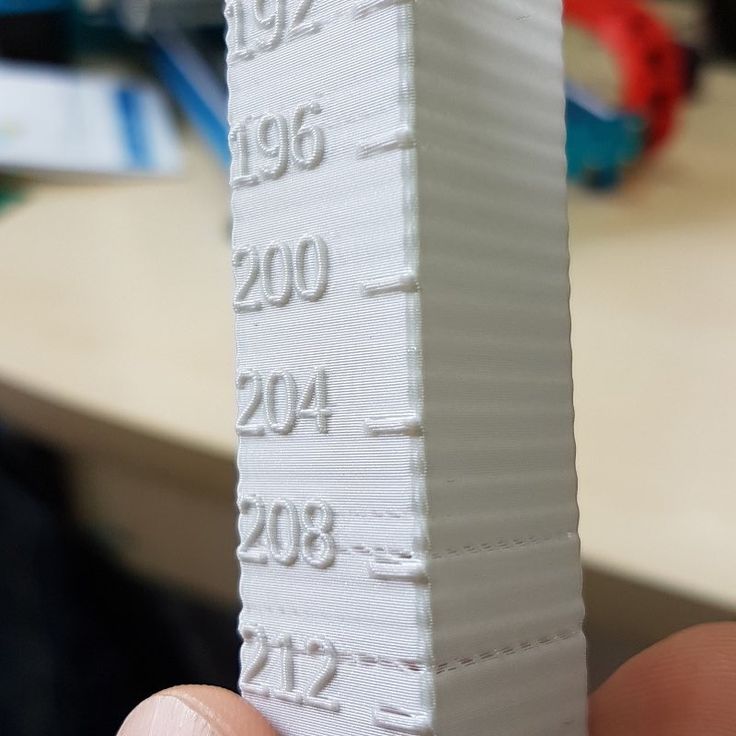

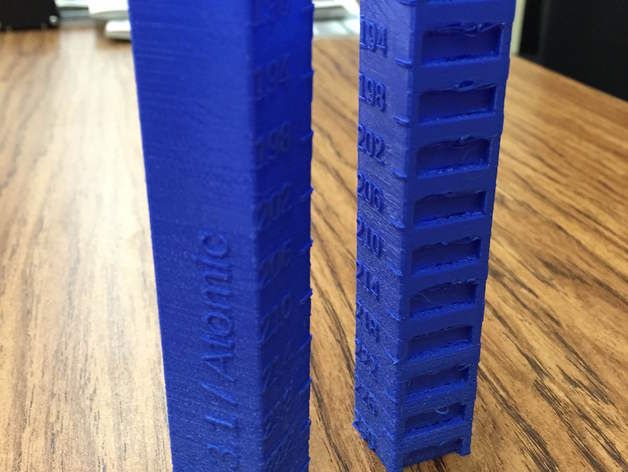

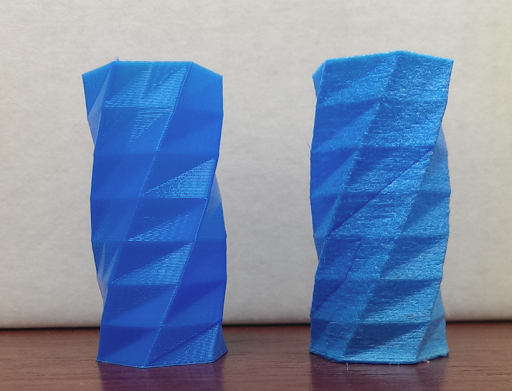

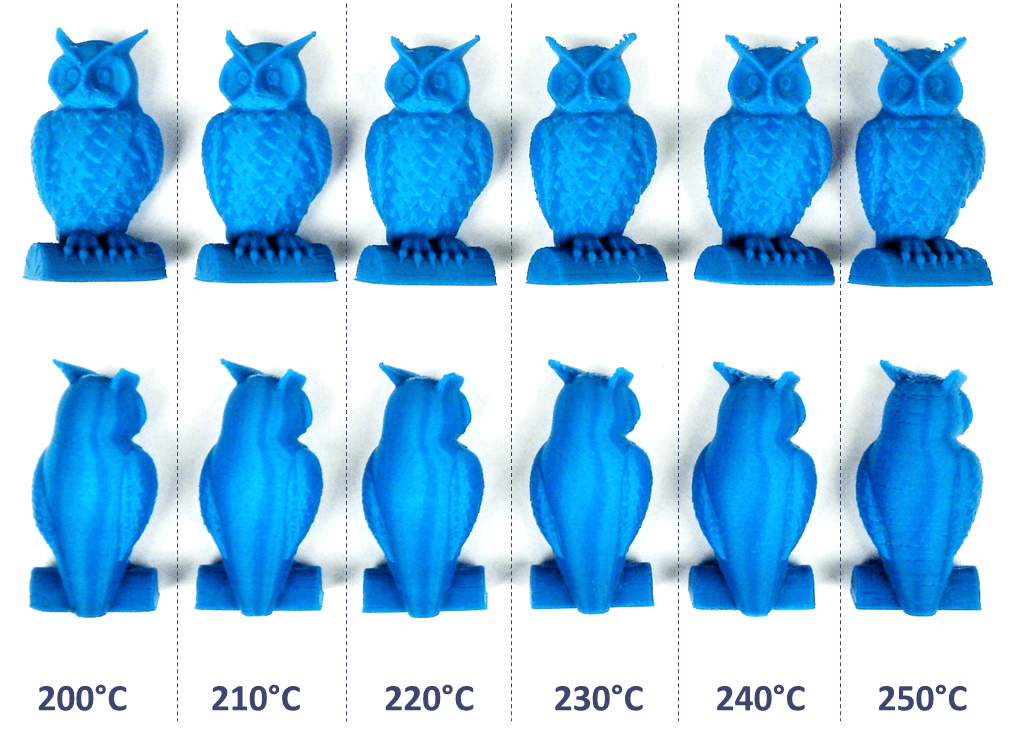

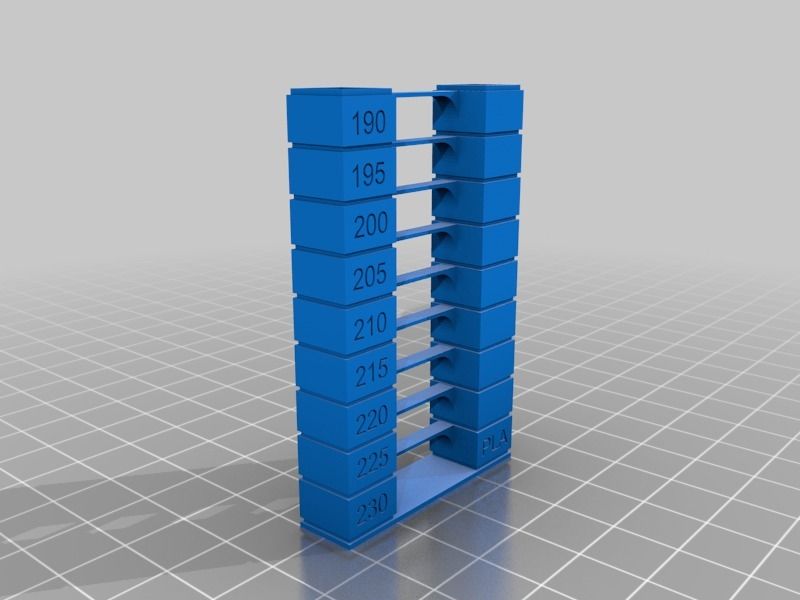

In the world of 3D printing, there are various plastics with different characteristics, including temperatures. It is important to choose the correct temperature when printing. A change of even 1°C can completely change the quality of the model it terms of appearance and strength.

A change of even 1°C can completely change the quality of the model it terms of appearance and strength.

In this Guide

3D Printing Temperature

The most important thing is the nozzle temperature. This temperature will determine how the filament will be squeezed out and adhered to the previous layers.

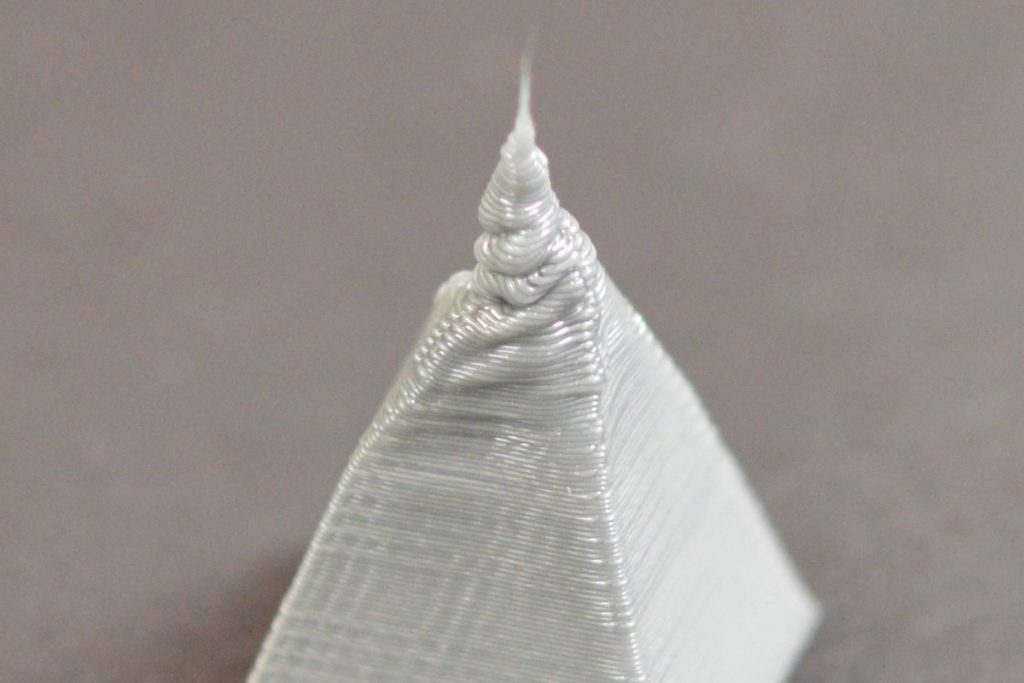

If the temperature is too high, it will cause the model to be out of shape, create cavities or even damage the printer. The model will also be affected as the plastic will not have time to solidify in the place where the printer squeezed it out. It will move a little.

If the temperature is too low, the plastic may not be extruded in sufficient volume. This will impair the strength and appearance of the model. If the plastic is too hard, then the printer will not be able to extrude the required volume.

The temperature of the printbed is important for the adhesion of the first layer. Thermal chamber technology allows you to prevent cracks if the plastic shrinkage (i. e., the decrease in volume with a drop in temperature) is too high. However, this technology is rarely found in budget 3D printers.

e., the decrease in volume with a drop in temperature) is too high. However, this technology is rarely found in budget 3D printers.

Let’s look at the most popular 3D printer filaments, their printing temperatures and features.

3D Printer Filament Temperatures

1. PLA

PLA is an abbreviation for polylactide. The material is made from corn and sugarcane, and is one of the safest plastics for household use.

Due to its ease of 3D printing and low toxicity, this filament is highly recommended for newbie 3D printing enthusiasts.

Temperature Settings:

- Nozzle temperature: 190-210°C

- Printbed temperature: 60-70°C

- Fan speed: 100%

The printing temperature of PLA filament is one of the lowest among all the 3D printing materials. However, you should pay attention to the fan speed of the model as this plastic remains flexible over a wide temperature range. If the airflow is insufficient, the edges and corners of the model may be bent.

For the model to stick better to the table, set the nozzle temperature to about 210°C and the printbed temperature to about 70°C. On the second and subsequent layers, reduce the temperature so as to prevent the edges from creasing.

2. ABS

Despite the difficulties in 3D printing with ABS, it is the second most popular material as it combines cheapness and versatility. This filament is more flexible than PLA, and allows you to print springs and bendable parts.

Due to its lower strength, it is easier to process ABS models mechanically with files and sandpaper. However, the filament releases toxins when heated. Therefore, it is not recommended for use in printing kitchen utensils.

Temperature Settings:

- Nozzle temperature: 230-250°C

- Printbed temperature: 90-100°C

- Fan speed: 50-75%

ABS plastic has a large shrinkage. Therefore, avoid increasing the fan speed above 40-60%. However, if there are small parts or printing bridges, you can increase the speed to 75-80%.

Cooling down too quickly can cause the part to crack during printing.

The strength of ABS filament highly depends on the temperature set. So, if accuracy is not so important, then it is better to increase the temperature up to 250°C. If you print at the lowest temperature, then the strength of the part can be reduced by 2 times than if it were printed at the maximum allowable temperature.

Be careful: When printing with ABS plastic indoors, you may experience dizziness or headaches! Make sure you 3D print in a well-ventilated area. Also, use an enclosure to prevent the fumes from the plastic from harming you.

3. PETG

This plastic has great chemical resistance. It’s property combines the strength of PLA with the flexibility of ABS. Therefore it is used in the manufacture of dishes.

However, with the filament, it takes a long time to adjust the correct temperatures specifically for your printer in order to remove all printing defects.

Temperature Settings

- Nozzle temperature: 230-260°C

- Printbed temperature: 60-90°C

- Fan speed: 25-50%

When printing with PETG, there is often a problem with “hairs” on some parts of the model. To prevent such cases, you can increase the retract distance. Changing the temperature will hardly change the situation.

To prevent such cases, you can increase the retract distance. Changing the temperature will hardly change the situation.

Because of the low adhesion of the plastic to itself, the fan speed should not be set higher than 50%. Otherwise, the model will easily break between layers.

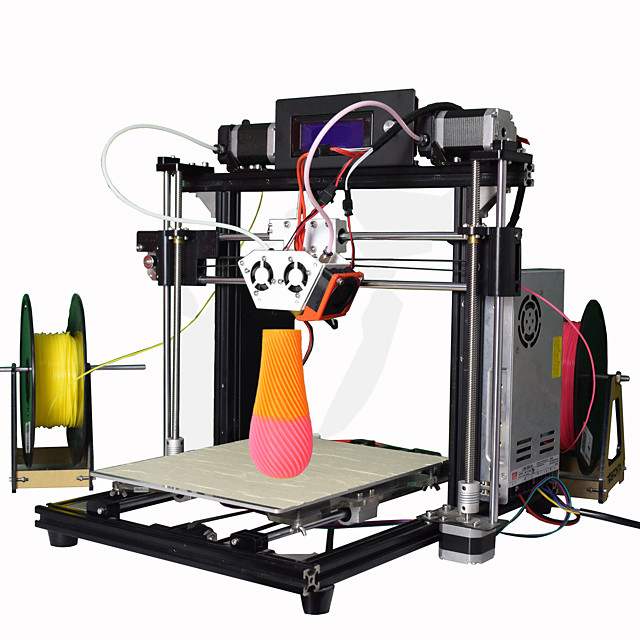

4. HIPS

This plastic is used as a support material when printing on printers with multiple extruders. Usually, the main plastic is ABS or PLA, since they are neutral to D-limonene, and HIPS is soluble in it. This allows for nearly perfect overhangs.

Temperature Settings

- Nozzle temperature: 230-240°C

- Printbed temperature: 90-100°C

- Fan speed: 0%

Since the strength and hardness of this plastic is extremely low (sometimes it can be pushed through with a fingernail), it should not be used as the main material of the model. No blowing is needed because even when using HIPS for the entire model, it hardens during the printing of the layer.

5. SBS

The main properties of this plastic are transparency and flexibility. With this filament, you can make bending parts, such as hinges, fasteners, clamps, and other. When the model is processed with a solvent, it becomes almost completely transparent as in the photo below.

With this filament, you can make bending parts, such as hinges, fasteners, clamps, and other. When the model is processed with a solvent, it becomes almost completely transparent as in the photo below.

However, when working with SBS, two rules must be followed:

- The walls should be thin walls

- The space between the walls should be completely filled

Temperature Settings

- Nozzle temperature: 220-230°C

- Printbed temperature: 60-80°C

- Fan speed: 50-100%

Tip: If you need to print a sealed part, then the flow should be increased by 1-2%. This will increase the size discrepancy relative to the model but make the model completely sealed.

6. Nylon

This filament is familiar to many in everyday life, thanks to nylon clothing. The material is used in the manufacture of gears and other moving elements due to its flexibility, strength and low coefficient of friction.

Temperature Settings

- Nozzle temperature: 240-260°C

- Printbed temperature: 70-90°C

- Fan speed: 0-25%

This filament requires a long selection of the right temperatures as it has many problems, including poor sintering capacity between layers, low adhesion, hygroscopicity (the ability to absorb moisture from the air), among otheers.

The latter characteristic is especially important since it radically changes the behavior of the plastic. Due to the presence of water particles in the plastic, the model becomes very fragile and the surface becomes rough, such as in the photo below.

Therefore, it is imperative to keep the plastic dry.

If you do not know whether the filamnet has absorbed moisture, dry it using special devices or in the oven at a temperature of 60-70°C for 2-5 hours.

7. TPU

Some people call this plastic “rubber” because it is the most flexible material for 3D printing. The filament can stretch up to 4 times its initial size. At the same time, over time, it returns to its original form.

Temperature Settings

- Nozzle temperature: 210-240°C

- Printbed temperature: 50-70°C

- Fan speed: 50-100%

Due to its flexibility, printing problems can occur. The most common problem is the filament chewing in the feeder. Printing with this plastic is recommended only in direct extruders at low speeds not exceeding 40 mm/s.

You can try to print them in bowdens, but then the speed should be no more than 20-30 mm/s. Otherwise, the filament will curl up in the tube and print will stop.

This problem is caused by the gap between the hole where the filament exits the extruder and the feed gear. To solve this problem, you can use special spacers to reduce this gap.

8. PVA

PVA is a water soluble filament used for printing supports. It has low strength, which makes it impossible to use as the main material of model.

Unlike HIPS, which has similar properties and applications, PVA is much easier to remove from the part because, even when heated and dissolved in water, it is completely harmless.

Temperature Settings

- Nozzle temperature: 220-230°C

- Printbed temperature: 65-75°C

- Fan speed: 0-50%

Since this plastic is only needed to create supports, avoid using blowing. If you need a high-quality part made entirely of PVA plastic (for example, a soluble cork or fastener), then the blowing speed should be below 50% since the adhesion of the layers of this filamnet is extremely low.

You can increase the strength of a PVA plastic model with water. To do this, carefully moisten the part, wait 5-7 minutes and dry the surface. This way, the outer walls of the part will “stick” to each other much more, thereby increasing the overall strength of the part.

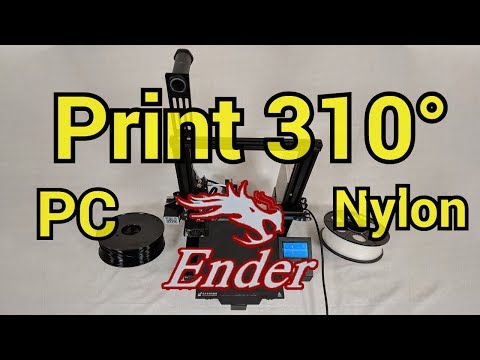

9. PC

PC stands for polycarbonate. This 3D printing filament has more strength but relatively little flexibility than PLA. Also, when lit, it tends to self-extinguish. Therefore, it is a good material to use for parts for fire safety.

Temperature Settings

- Nozzle temperature: 290-310°C

- Printbed temperature: 90-120°C

- Fan speed: 0-25%

Like PETG, this plastic is very hygroscopic. Therefore, it should be stored in a dry space or in a bag with silica gel. Due to the need to maintain high temperatures and storage characteristics, polycarbonate is not widely used in 3D printing.

10. PEEK

This plastic is difficult to 3D print but has outstanding mechanical properties. Therefore, parts are made from it are designed to work with high loads and friction. The filament is also neutral to various chemicals.

Therefore, parts are made from it are designed to work with high loads and friction. The filament is also neutral to various chemicals.

Temperature Settings

- Nozzle temperature: 350-410°C

- Printbed temperature: 120-150°C

- Fan speed: 0-25%

To print PEEK, you must use professional 3D printers. If you use a 3D printer intended for home use, there is a possibility of burning the extruder and the heating element in it.

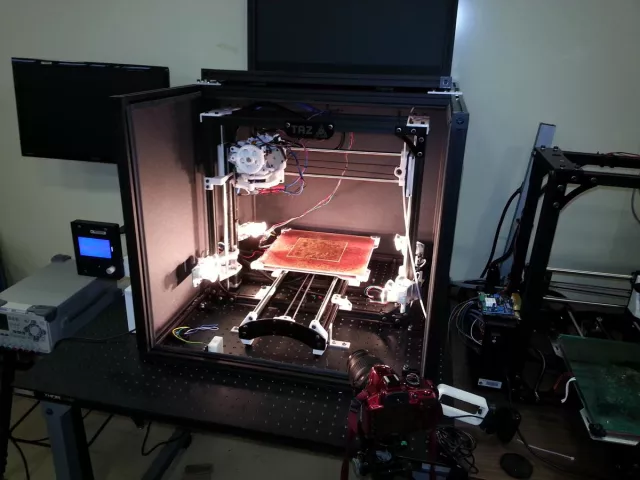

A heated heat chamber is also required.

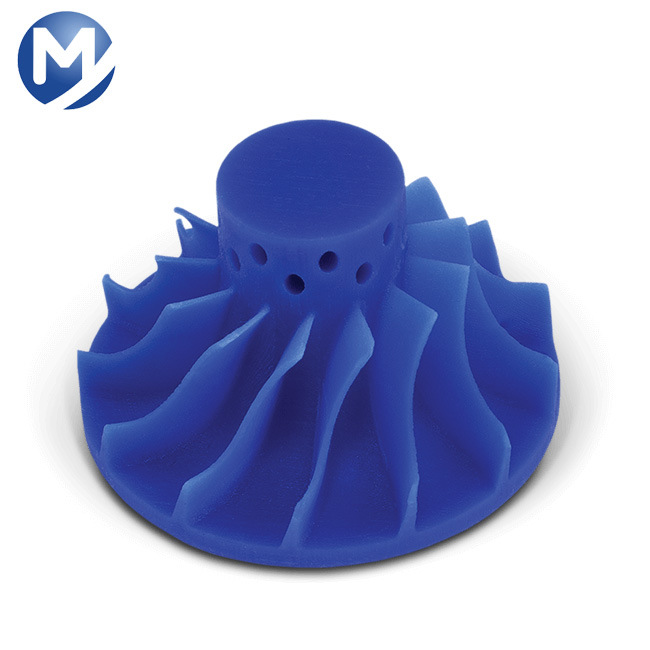

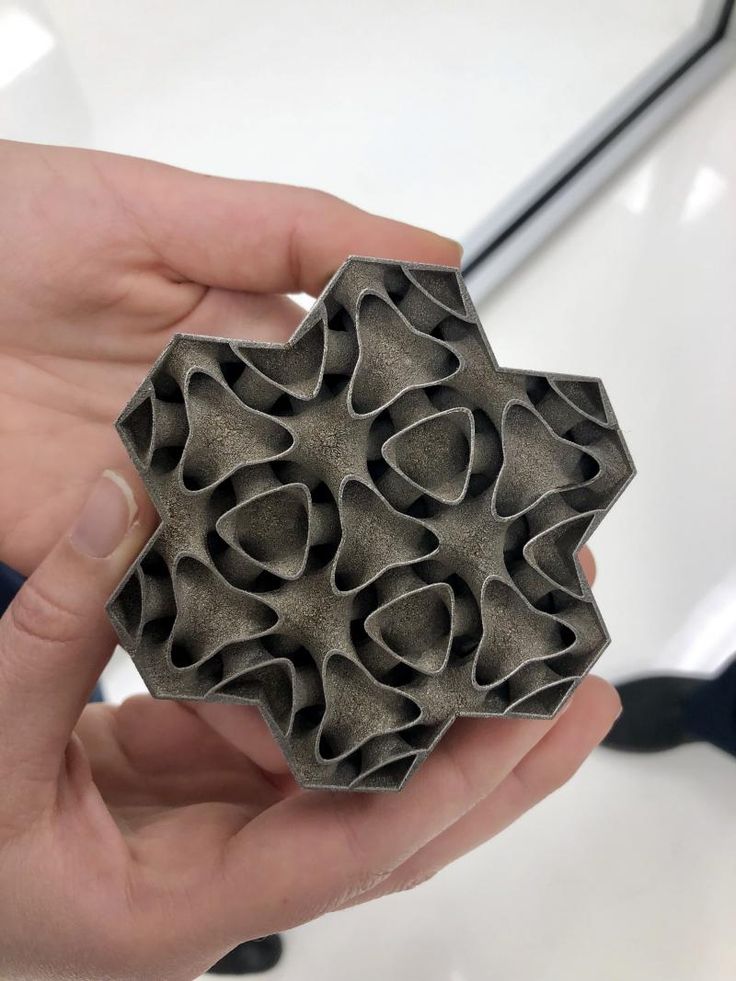

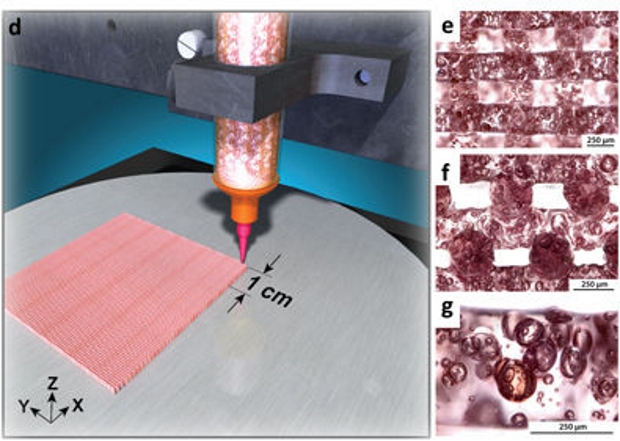

Composite Plastics

This category includes filaments containing particles of any material. This material consists of two parts: the base (usually PLA, ABS or other plastic) and the added component (wood, metal, ceramic or carbon fibers).

These plastics differ not only by the type of added component, but also by the percentage. Typically, the higher the content of the additional component, the more the properties of the plastic differ from those of the base.

The temperature depends on the base of the filament. All temperature settings must be obtained from the manufacturer.

All temperature settings must be obtained from the manufacturer.

A common feature of all filaments in this category is the need to use a nozzle with a large outlet diameter (from 0.5mm). Otherwise, the nozzle will quickly become clogged with the added component.

The material of the nozzle is also important as normal brass nozzles will wear off quickly. Hardened steel nozzles are usually sufficient.

Setting the Printer Temperature

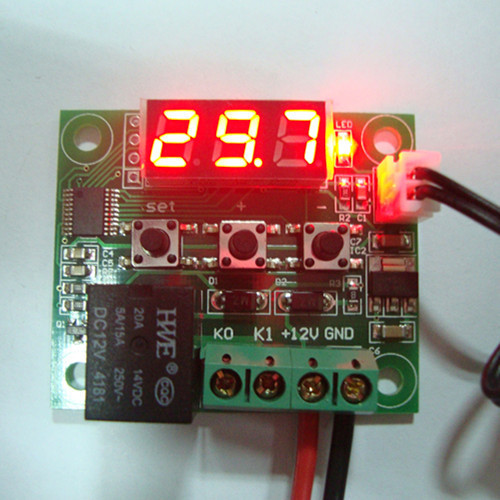

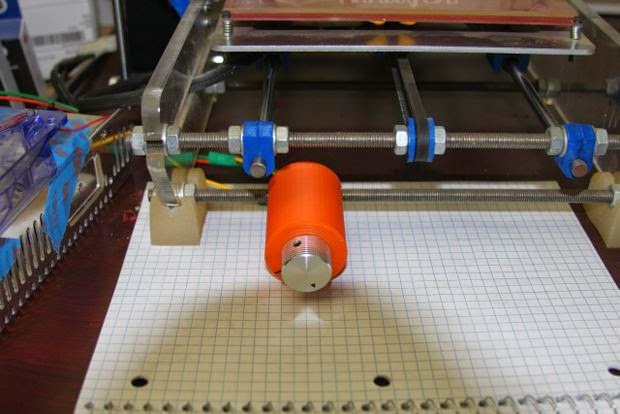

Ensure that the printer is heating the nozzle to the correct temperature before printing, and that it does so without jumps. To do this, confirm that the printer’s firmware is configured and that the thermocouple is installed correctly.

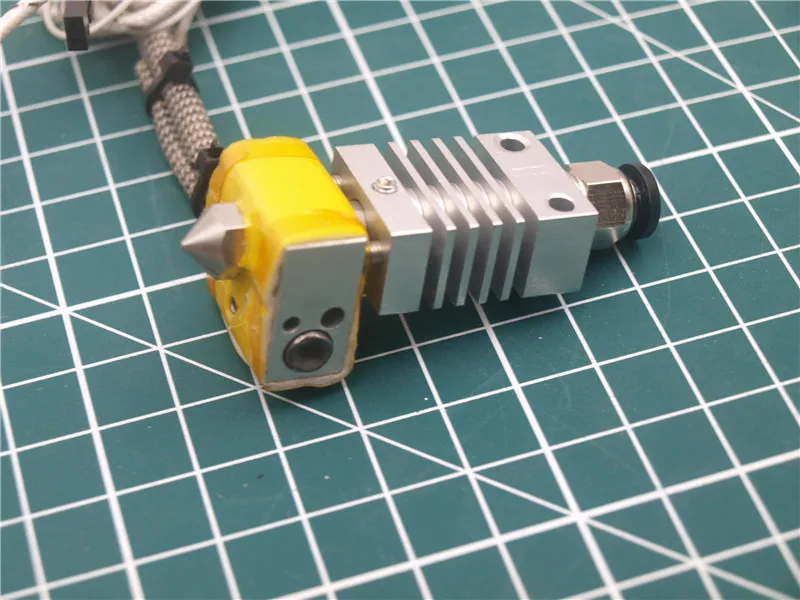

Correct Installation of the Thermocouple in the Hotend

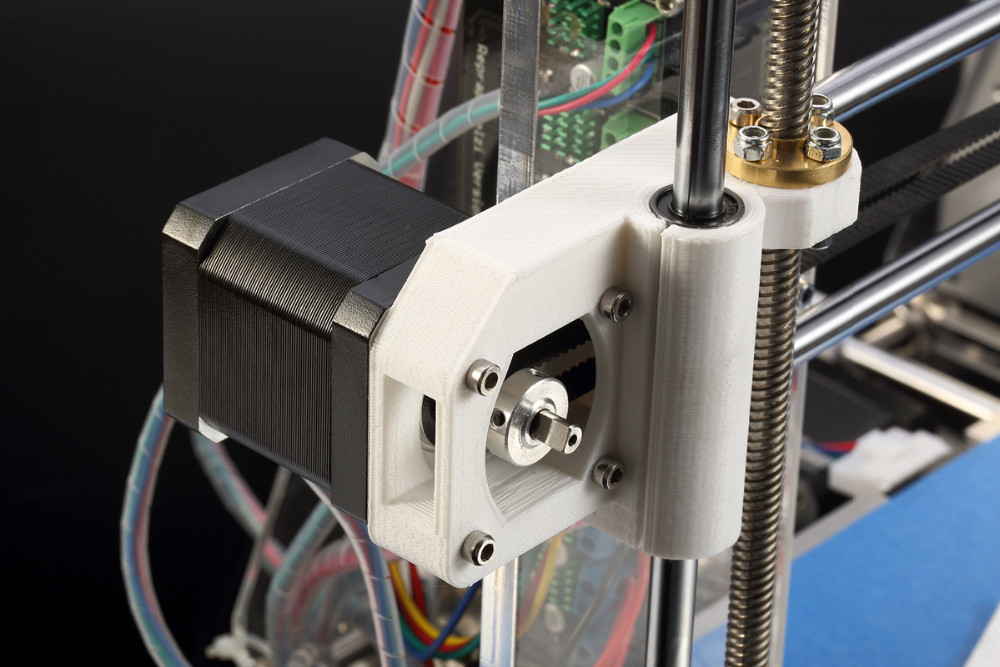

The printer receives data on the temperature of the hotend using a thermocouple installed in the hotend. Usually, there is a special hole for this. You need to insert the thermocouple into it as deep as possible and secure its wire.

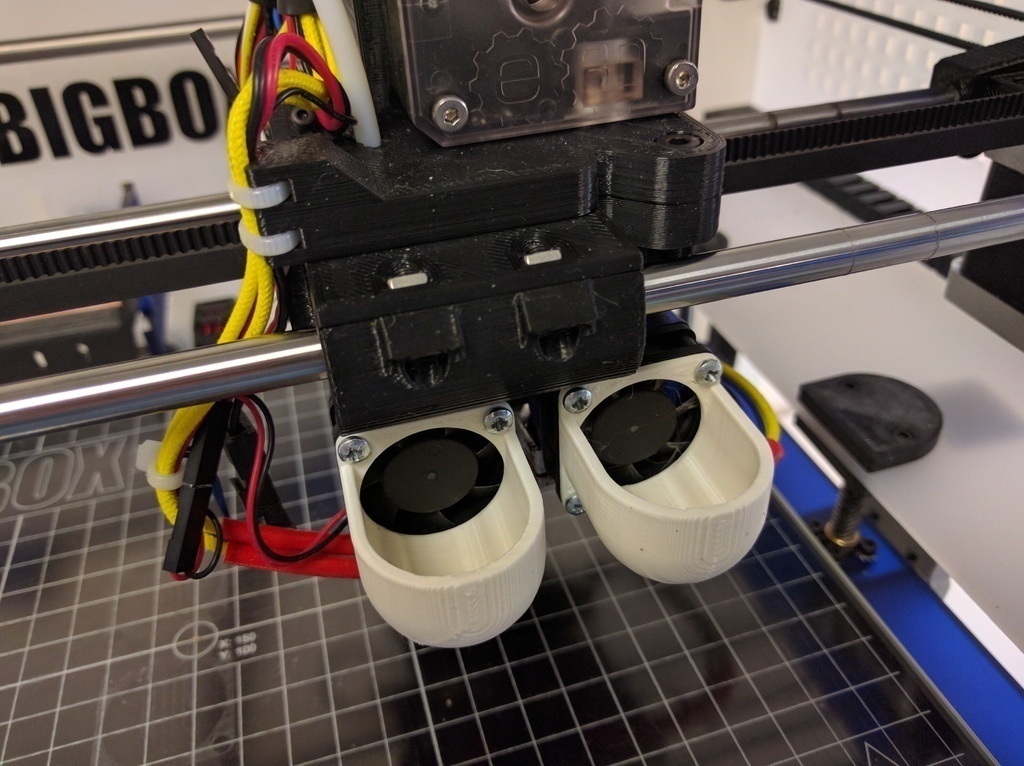

Most printers have a hole in the hotend where the screw is screwed in. Run two wires on opposite sides of the center of the screw to securely fix the thermocouple in the hotend. If no thermocouple attachment is provided, fix the thermocouple wire to the heating element wire. See the photo below for an example on how to do it.

Run two wires on opposite sides of the center of the screw to securely fix the thermocouple in the hotend. If no thermocouple attachment is provided, fix the thermocouple wire to the heating element wire. See the photo below for an example on how to do it.

Attention: a loose thermocouple can fall out of the hotend, thereby creating a fire hazard!

Configuring the Firmware

If the printer is going to be assembled on its own, select the type of thermocouple in the firmware. If you are going to use the Marlin firmware, go to the Configuration.h file, and find the line:

#define TEMP_SENSOR_0 0

In place of the last digit, there may not be a zero but another digit. In most cases, if your printer has a thermistor in the form of a “droplet”, then instead of the last digit, put 1. As a result, you should have the line:

#define TEMP_SENSOR_0 1

If the printer detects the temperature incorrectly, trying changing the last digit to a different one. A list of numbers and the thermocouples they represent is written above this setting.

The table has the same setting, it can be found by the line:

#define TEMP_SENSOR_BED 0

Here you should also change 0 to 1.

PID setting

This abbreviation hides a complex name: proportional-integral-differential regulator. In simple terms, this is a function that allows you to more accurately keep the temperature within the specified limits.

Since the printer can only turn on and off the heating element, the only way to control the temperature is to turn off the heating element when the required temperature is reached, and turn it on if the temperature has dropped below the set value. But in this case, the temperature will “jump” strongly due to the inertness of the heater. This is precisely why the PID function exists – to compensate for the inertness of the heater.

However, each printer needs its own PID setting since the inertia can vary greatly depending on many parameters.

The PID setting requires a wired connection to the printer. The best way to send commands is to use Repetier-Host . As soon as you connect to the printer, send this command to it:

As soon as you connect to the printer, send this command to it:

M303 C3 S210

Here, the number after C is responsible for the number of heating-cooling cycles the printer will go through. The number after S defines the temperature for which the PID is adjusted. Although the printer will be set at a certain temperature, these settings will work for higher temperatures as well.

After some time, the printer will send the values of three PID parameters to the console: Kp, Ki and Kd. These parameters are responsible for setting the PID. To enter these numbers in the printer settings, you need to send the command:

M301 P14.82 I0.8 D68.25

Here, the letters P, I, and D are followed by the corresponding Kp, Ki, and Kd values from the previous step. If you enter this command, the PID setting will only be saved until you turn off the printer.

You can add this command to the starting GCODE for each model you will be printing. In some printers, you can change these settings through the menu on the printer itself.

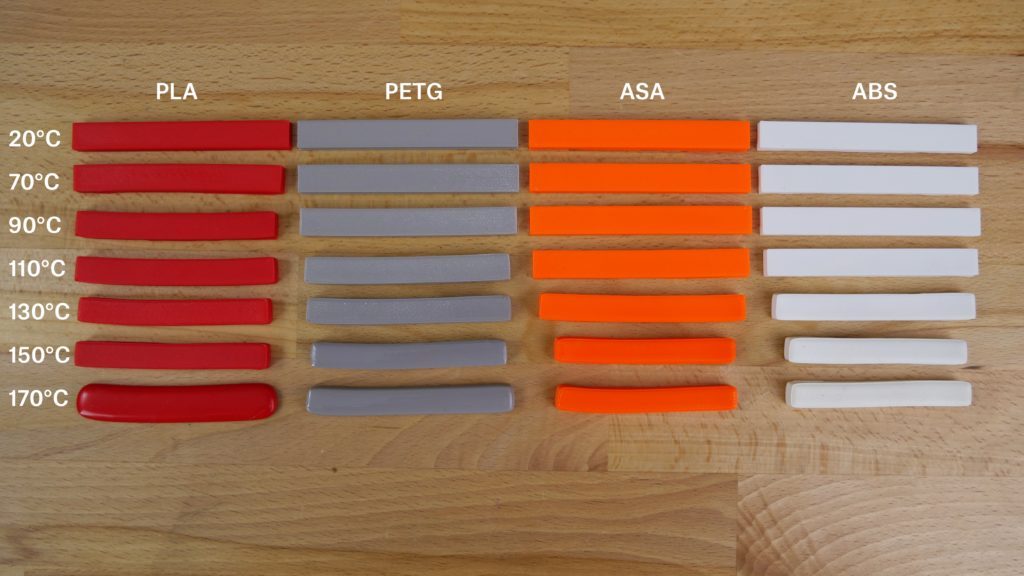

Softening Point and Post-processing

After 3D printing, you can process the part using heat to increase its strength or even change its geometry. At home, you can use the oven for these purposes.

However, be careful: some plastics emit hazardous substances when heated. Therefore, it is better to use other methods. For example, a steam bath, hot water, or hair dryer can be an alternative.

The main parameter of such processing is temperature. You need a sufficiently high temperature for the material of the model to begin to pass from a solid state to a sluggish-flowing one, but not exceed a certain temperature threshold, after which the part can change its geometry uncontrollably.

Here is a list of filaments and their softening points:

- PLA – 70°C

- ABS – 105°C

- PETG – 80°C

- HIPS – 85°C

- Nylon – 125°C

- TPU – 95°C

- PC – 145°C

- PEEK – 255°C

The data is relatively inaccurate, since filaments do not have a specific temperature when they completely go from one state to another.

3D Printer Filament Temperature Chart

If you often use different filaments, we have prepared a chart with all the information you need to set the temperature of your 3D printer on the fly.

| Plastic | Nozzle temperature (° C) | Printbed temperature (°C) | Blowing speed (%) | Peculiarities |

| PLA | 190 – 210 | 60 – 70 | 100 | Security Strength |

| ABS | 230 – 250 | 90 – 100 | 50 – 75 | Flexibility |

| PETG | 230 – 260 | 60 – 90 | 25 – 50 | Chemically neutral Abrasion resistant |

| HIPS | 230 – 240 | 90 – 100 | 0 | Soluble support |

| SBS | 220 – 230 | 60 – 80 | 50 – 100 | Transparency, great flexibility |

| Nylon | 240 – 260 | 70 – 90 | 0 – 25 | Chemically neutral Heat resistance |

| TPU | 210 – 240 | 50 – 70 | 50 – 100 | Great flexibility Frost resistance |

| PVA | 220 – 230 | 65 – 75 | 0 – 50 | Water solubility |

| PC | 290 – 310 | 90 – 120 | 0 – 25 | Strength Heat resistance |

| PEEK | 350 – 410 | 120 – 150 | 0 – 25 | Durability Heat / frost resistance |

The melting temperature of plastic on a 3D printer and the subtleties of its choice

- Correct setting of the thermocouple in the hotend

- Firmware setting

- PID setting

It is very important to choose the right temperature when printing, as a change of even 1 degree can completely change the quality of the model: its appearance and strength.

It is very important to choose the right temperature when printing, as a change of even 1 degree can completely change the quality of the model: its appearance and strength. Types of plastics and their melting points

The most important is the choice of nozzle temperature, because it determines how exactly the plastic will extrude and stick to the previous layers.

Too high will result in model geometry distortion, cavities, or even printer failure. This will also affect the model: the plastic will not have time to harden in the place where the printer squeezed it out and move a little. Also, with a slight cooling of the throat, traffic jams will appear in it, completely stopping the seal.

And at too low a temperature, the plastic can be squeezed out in insufficient volume, thereby deteriorating the strength and appearance of the model. If the plastic is too hard, then the printer will not be able to push through the required volume.

The temperature of the table is important for the adhesion (adhesion) of the first layer. Rarely seen in budget printers, but still fairly well known, thermal chamber technology helps prevent cracking if the shrinkage of the plastic (i.e. reduction in volume with a drop in temperature) is too high. Next, we look at the most popular plastics, their print temperatures and features.

PLA

This abbreviation stands for polylactide. Made from corn and sugar cane, PLA is one of the safest plastics for home use. Due to its ease of 3D printing and low toxicity, this plastic is the most popular for beginning 3D printers.

Temperature settings:

-

Nozzle temperature: 190-210°C

-

Table temperature: 60-70°C

-

Fan speed: 100%

The printing temperature of PLA plastic is one of the lowest among all the variety of materials, but it is worth paying attention to the fan speed of the model, as this plastic remains flexible over a wide range of temperatures. With insufficient airflow, the edges and corners of the model may be bent. In order for the model to adhere better to the table, it is necessary to set the temperature of the nozzle to about 210°C, and the temperature of the table to about 70°C. On the second and subsequent layers, it is better to reduce the temperature in order to prevent the above problems with curling edges.

With insufficient airflow, the edges and corners of the model may be bent. In order for the model to adhere better to the table, it is necessary to set the temperature of the nozzle to about 210°C, and the temperature of the table to about 70°C. On the second and subsequent layers, it is better to reduce the temperature in order to prevent the above problems with curling edges.

ABS

Despite the difficulties in 3D printing with this plastic, it is the second most popular, as it combines cheapness and versatility. Much more flexible than PLA plastic, allowing springs and bendable parts to be printed. Due to its lower strength, it is easier to process it mechanically: with needle files and sandpaper. But due to the release of toxins when heated, this plastic is best not used when printing dishes or kitchen appliances.

Temperature settings:

-

Nozzle temperature: 230-250°C

-

Table temperature: 90-100°C

-

Fan speed: 50-75%

ABS plastic shrinks a lot, so it is better not to increase the fan speed above 40-60%, but if there are small parts or printing of bridges, then the speed can be increased to 75-80%. If the part cools too quickly, it may crack right during printing.

If the part cools too quickly, it may crack right during printing.

The strength of this plastic is highly dependent on temperature, so if accuracy is not so important, then it is better to increase the temperature up to 250 ° C. If you print at the lowest temperature, then the strength of the part may decrease by 2 times, relative to the same model printed at the maximum allowable temperature.

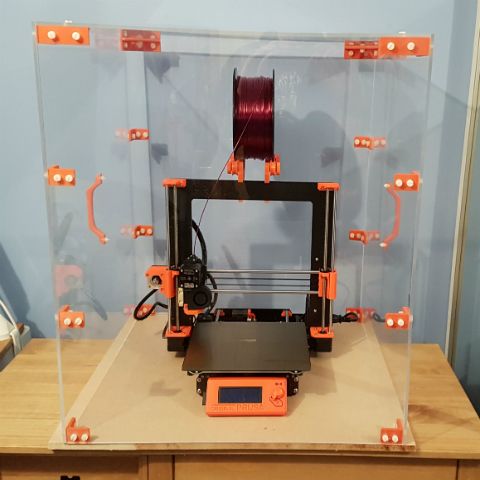

Be careful when printing with ABS indoors, you may experience dizziness or headache! Printing on a 3D printer should be carried out in well-ventilated areas, covering the 3D printer from direct drafts so that the fumes from the plastic do not harm you.

PETG

This plastic has a high chemical resistance, so it is used in the manufacture of dishes. At the same time, it combines the strength of PLA plastic and the flexibility of ABS. But it takes a long time to set the correct temperatures for your printer in order to remove all print defects.

Temperature settings:

-

Nozzle temperature: 230-260°C

-

Table temperature: 60-90°C

-

Fan speed: 25-50%

Often there is a problem with “hairs” in some parts of the model. In such cases, the retract distance can be increased. Changing the temperature does little to change the situation. Due to the low adhesion of plastic to itself, the fan speed should not be adjusted above 50%, otherwise the model will easily break apart between layers.

HIPS

This plastic is used as a backing material for printers with multiple extruders. Usually the main plastic is ABS or PLA, since they are neutral to D-limonene, and HIPS is completely soluble in it. This allows you to get an almost perfect quality of overhanging elements.

Temperature settings:

-

Nozzle temperature: 230-240°C

-

Table temperature: 90-100°C

-

Fan speed: 0%

Since the strength and hardness of this plastic is extremely low (sometimes it can be pushed through with a fingernail), it should not be used as the main material of the model. Airflow is not needed, because even when using HIPS for the entire model, it has time to harden during the printing of the layer.

Airflow is not needed, because even when using HIPS for the entire model, it has time to harden during the printing of the layer.

Add to Compare

Product added to comparison Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun

SBS

The main property of this plastic is transparency and flexibility. This allows you to make bending parts: loops, fasteners, clamps. When processing the model with a solvent, the model becomes almost completely transparent, as in the photo below. But two simple rules must be observed: thin walls and complete filling of the space between them.

Temperature settings:

-

Nozzle temperature: 220-230°C

-

Table temperature: 60-80°C

-

Fan speed: 50-100%

Tip: If you want to print a sealed part, then the flow should be increased by 1-2%. This will increase the dimensional discrepancy with respect to the model, but will make the model completely airtight.

Nylon

This plastic is familiar to many in everyday life thanks to nylon clothing. It is used in the manufacture of gears and other moving parts due to its flexibility, strength and low coefficient of friction.

Temperature settings:

-

Nozzle temperature: 240-260°C

-

Table temperature: 70-90°C

-

Fan speed: 0-25%

Plastic requires a long time to choose the right temperatures, as it has many problems: poor sintering between layers, low adhesion, hygroscopicity (the ability to absorb moisture from the air). The last characteristic is extremely important, since it radically changes the behavior of plastic. Due to the presence of water particles in the plastic, the model becomes very fragile, and the surface is rough, for example, as in the photo below.

The last characteristic is extremely important, since it radically changes the behavior of plastic. Due to the presence of water particles in the plastic, the model becomes very fragile, and the surface is rough, for example, as in the photo below.

Therefore, it is extremely important to keep the plastic dry. And if it is not known whether the plastic has gained moisture, then it is better to dry it using special devices or in an oven at a temperature of 60-70 ° C for 2-5 hours.

TPU

Some call this plastic “rubber”. And this name suits it, because it is the most plastic material for 3D printing, capable of stretching up to 4 times, relative to its initial size. However, over time, it returns to its original form.

Temperature settings:

-

Nozzle temperature: 210-240°C

-

Table temperature: 50-70°C

-

Fan speed: 50-100%

Due to its flexibility, printing problems can occur, namely plastic jamming in the feed mechanism. It is recommended to print with this plastic only in direct extruders at low speeds, not exceeding 40 mm/s. You can try to print them in bowdens, but then the speed should be no more than 20-30 mm / s, otherwise the filament will curl up in the tube and the printing will stop.

It is recommended to print with this plastic only in direct extruders at low speeds, not exceeding 40 mm/s. You can try to print them in bowdens, but then the speed should be no more than 20-30 mm / s, otherwise the filament will curl up in the tube and the printing will stop.

The cause of this problem is the gap between the hole where the filament exits the extruder and the feed gear. Special spacers that reduce this gap will help solve this problem.

PVA

Water soluble plastic used for printing supports. It has low strength, which makes it impossible to use as the main material of the part. Unlike HIPS, which has similar properties and applications, PVA is much easier to remove from the part, since even when heated and dissolved in water, it remains absolutely harmless.

Temperature settings:

-

Nozzle temperature: 220-230°C

-

Table temperature: 65-75°C

-

Fan speed: 0-50%

Since this plastic is only needed to create supports, it is better not to use airflow. If a high-quality part is required, consisting entirely of PVA plastic (for example, a soluble cork or fastener), then the blowing speed should be below 50%, since the adhesion of the layers of this plastic is extremely low. You can increase the strength of the PVA plastic model with water: you need to gently moisten the part, wait 5-7 minutes and dry the surface. Thus, the outer walls of the part will “stick” to each other much more strongly, thereby increasing the overall strength of the part.

If a high-quality part is required, consisting entirely of PVA plastic (for example, a soluble cork or fastener), then the blowing speed should be below 50%, since the adhesion of the layers of this plastic is extremely low. You can increase the strength of the PVA plastic model with water: you need to gently moisten the part, wait 5-7 minutes and dry the surface. Thus, the outer walls of the part will “stick” to each other much more strongly, thereby increasing the overall strength of the part.

Add to compare

Product added to compare Go

| Manufacturer | Esun

Add to compare

Product added to compare Go

| Manufacturer | Esun

Add to compare

Product added to compare Go

| Manufacturer | Esun

Add to compare

Product added to compare Go

| Manufacturer | Bestfilament |

PC

This name stands for polycarbonate. It has great strength, but has relatively little flexibility, less than that of PLA. Also, when tanning, it tends to self-extinguishing, which increases fire safety.

It has great strength, but has relatively little flexibility, less than that of PLA. Also, when tanning, it tends to self-extinguishing, which increases fire safety.

Temperature settings:

-

Nozzle temperature: 290-310°C

-

Table temperature: 90-120°C

-

Fan speed: 0-25%

Like PETG, this plastic is very hygroscopic, so it needs to be stored in a dry space, preferably in a silica gel bag. Due to the need to maintain high temperatures and storage characteristics, polycarbonate is not widely used in 3D printing.

PEEK

This plastic is difficult to 3D print, but it has outstanding mechanical characteristics. Therefore, parts are made from it, designed to work with high loads and friction. It is also neutral to various chemicals.

Temperature settings:

-

Nozzle temperature: 350-410°C

-

Table temperature: 120-150°C

-

Fan speed: 0-25%

To print PEEK, you need to have professional 3D printers. If you use a 3D printer designed for home use, then there is a chance of burning the extruder and the heating element in it. A heated chamber is also required.

If you use a 3D printer designed for home use, then there is a chance of burning the extruder and the heating element in it. A heated chamber is also required.

Composite plastics

This category includes filaments containing particles of any material. Such a material consists of two parts: a base (usually PLA, ABS or other plastic) and an added component (wood, metal, ceramic or carbon fibers). These plastics differ not only in the type of added component, but also in percentage. Usually, the higher the content of the additional component, the more the properties of the plastic differ from those of the base.

The temperature depends on the basis of which the filament is composed. All necessary parameters must be obtained from the manufacturer.

A common feature of all plastics in this category is the need to use a nozzle with a large outlet diameter (from 0.5 mm). Otherwise, the nozzle will quickly become clogged with the added component. The material of the nozzle is also extremely important, as conventional brass nozzles will wear out quickly. Hardened steel nozzles are usually sufficient.

Hardened steel nozzles are usually sufficient.

Temperature setting on printer

Before you start printing, it is very important to be sure that the printer heats the nozzle to the correct temperature and does it without jumps. To do this, you need to make sure that the printer firmware is configured and that the thermocouple is installed correctly.

Correct placement of thermocouple in hot end

The printer receives data on the temperature of the hotend using a thermocouple, which is installed in the hotend. Usually there is a special hole for this, you need to insert a thermocouple as deep as possible into it. It is important to secure the thermocouple wire. Often, for this purpose, there is a hole in the hot end where the screw is screwed. It is best to run two wires on opposite sides of the center of the screw. This will securely fix the thermocouple in the hotend. If there is no provision for mounting the thermocouple, then it is necessary to fix the thermocouple wire on the wire of the heating element. An example of how to do this is in the photo below.

An example of how to do this is in the photo below.

Attention: a poorly fixed thermocouple may fall out of the hot end, thereby creating a fire hazard!

Firmware setting

If the printer is assembled on its own, then it is important to select the type of thermocouple in the firmware. If you are going to use the Marlin firmware, then you need to go into the Configuration.h file and find the line:

#define TEMP_SENSOR_0 0

In place of the last digit, there may not be a zero, but another digit. In most cases, if your printer has a thermistor in the form of a “droplet”, then instead of the last digit you need to put 1. As a result, you should get a line:

#define TEMP_SENSOR_0 1

If the printer determines the temperature incorrectly, then you should try changing the last digit to a different one. A list of numbers and the thermocouples they represent is written above this setting.

The table has the same setting, it can be found by the line:

#define TEMP_SENSOR_BED 0

Here you should also change 0 to 1.

PID tuning

This abbreviation hides a complex name: proportional-integral-differential controller. In simple terms, this is a function that allows you to more accurately keep the temperature within the specified limits. Since the printer can only turn the heating element on and off, the only way to control the temperature is to turn off the heating element when the desired temperature is reached, and turn it on if the temperature falls below the set temperature. But in this case, the temperature will “jump” strongly due to the inertia of the heater. This is what the PID function is for - to compensate for the inertia of the heater. But each printer needs its own PID setting, as the inertia can vary greatly depending on many parameters.

PID tuning requires a wired connection to the printer. The best way to send commands is to use Repetier-Host. As soon as you connect to the printer, you need to send a command to it:

M303 C3 S210

Here, the number after C is the number of heat-up cycles the printer will go through, and the number after S is the temperature for which the PID is being tuned. Although the printer will be set at a certain temperature, these settings will work for higher temperatures.

Although the printer will be set at a certain temperature, these settings will work for higher temperatures.

After some time, the printer will send to the console the values of three PID parameters: Kp, Ki and Kd. These parameters are responsible for tuning the PID. To enter these numbers into the printer settings, you need to send a command:

M301 P14.82 I0.8 D68.25

Here, the letters P, I, and D are followed by the corresponding Kp, Ki, and Kd values from the previous step. If you enter this command, then the PID setting will be saved only until the printer is turned off. You can add this command to the start GCODE for each model you will be printing. For some printers, you can change these settings through the printer's menu.

Softening temperature and post-processing

After 3D printing, you can process the part using high temperature. This allows you to increase its strength and change the geometry of the part. At home, you can use the oven for these purposes. But you should be careful: some plastics release hazardous substances when heated, so it is better to use other methods. For example, a steam bath, hot water, or a hair dryer can serve as an alternative. The main parameter of such processing is temperature. It is necessary to have a sufficiently high temperature so that the material of the model begins to change from a solid to a sluggish state, but not to exceed a certain temperature threshold, after which the part can change its geometry uncontrollably.

But you should be careful: some plastics release hazardous substances when heated, so it is better to use other methods. For example, a steam bath, hot water, or a hair dryer can serve as an alternative. The main parameter of such processing is temperature. It is necessary to have a sufficiently high temperature so that the material of the model begins to change from a solid to a sluggish state, but not to exceed a certain temperature threshold, after which the part can change its geometry uncontrollably.

List of plastics and their softening points:

-

PLA - 70°C

-

ABS - 105°C

-

PETG - 80°C

-

HIPS - 85°C

-

Nylon - 125°C

-

TPU - 95°C

-

PC - 145°C

-

PEEK - 255°C

The data is relatively inaccurate because plastics don't have a specific temperature when they fully transition from one state to another.

Universal table

For those who often use various plastics, we have prepared a table containing all the necessary information for adjusting the temperature of a 3D printer on the fly.

| Plastic | Nozzle temperature, °C | Table temperature, °C | Blowing speed, % | Peculiarities |

| PLA | 190 - 210 | 60 - 70 | 100 | Safety Strength |

| ABS | 230 - 250 | 90 - 100 | 50 - 75 | Flexibility |

| PETG | 230 - 260 | 60 - 90 | 25 - 50 | Chemically neutral Friction resistance |

| HIPS | 230 - 240 | 90 - 100 | 0 | Soluble Supports |

| SBS | 220 - 230 | 60 - 80 | 50 - 100 | Transparency, great flexibility |

| Nylon | 240 - 260 | 70 - 90 | 0 - 25 | Chemically neutral Heat resistance |

| TPU | 210 - 240 | 50 - 70 | 50 - 100 | Huge flexibility Frost resistance |

| PVA | 220 - 230 | 65 - 75 | 0 - 50 | Water solubility |

| PC | 290 - 310 | 90 - 120 | 0 - 25 | Strength Heat resistance |

| PEEK | 350 - 410 | 120 - 150 | 0 - 25 | Strength |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun

Add to compare

Product added to compare Go

| Manufacturer | Esun

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

Do you have any questions?

Our specialists will help you with the choice of 3D equipment or accessories, consult on any questions.

Optimum temperatures for 3D printing PLA, PETG, Nylon and TPU plastics

3DPrintStory 3D printing process Optimal temperatures for 3D printing with PLA, PETG, Nylon and TPU plastics

Although almost all 3D printing materials are thermoplastics, each has its own temperature requirements. The specificity arises from the fact that individual fibers differ greatly from each other in chemical composition. Some, like PLA, are made from starches, while others, like ABS, are oil-based.

The chemical composition of a thermoplastic directly affects its glass transition temperature, the temperature at which the material changes from a brittle filament to an extrudable elastic substance. It is this temperature that must be maintained for high-quality 3D printing. And since each material has a different glass transition temperature, each plastic must be used for 3D printing at a different extruder temperature.

It is this temperature that must be maintained for high-quality 3D printing. And since each material has a different glass transition temperature, each plastic must be used for 3D printing at a different extruder temperature.

In addition to a specific extrusion temperature, some materials require a specific hot bed temperature. When some fibers cool, they shrink and deform. The heated bed allows these plastics to cool more slowly during extrusion so that bending is minimized.

The heated bed also provides additional adhesion, ensuring that the first layer adheres well and the part does not separate from the base during 3D printing.

So the temperature of 3D printing is a very important parameter, which differs depending on the material that is used.

Recommended temperature for 3D printing with PLA plastic

PLA is the most popular plastic in the world today. One of the reasons is undemanding to the conditions of 3D printing.

PLA prints best around 210°C, although it is very versatile and can work at temperatures from 180 to 230°C. It does not require a heated bed to print, but if your 3D printer has one, set the bed temperature somewhere between 20 and 60°C.

It does not require a heated bed to print, but if your 3D printer has one, set the bed temperature somewhere between 20 and 60°C.

When printing with PLA, make sure the cooling fans are turned on. PLA produces the best results when cooled properly.

Overall, PLA is very easy to use and doesn't require much tambourine dancing to be successful.

Recommended temperature for 3D printing with ABS

Until recently, ABS was the most widely used material for 3D printing. Then ABS lost to PLA in the battle for the lead. The main reason is the great difficulty during 3D printing.

ABS requires a slightly higher temperature to print successfully. Recommended nozzle temperature is 210 to 250°C. Requires a heated bed set to 80 to 110°C.

In addition, ABS should be printed on a closed 3D printer so that the plastic cools down more slowly. This is because the ABS shrinks as it cools, and if the model cools too quickly, it deforms. For the same reason, the cooling fans must be turned off when printing ABS.

Recommended temperature for 3D printing PETG plastic

PETG is a relative newcomer to the 3D printing media market, combining many aspects of PLA and ABS.

It requires very high nozzle temperatures of 220 to 250°C. However, unlike ABS, PETG does not require a heated bed.

PETG prints best with blue masking tape on the table. Without it, the table must be heated to 50-75°C so that the extruded material will adhere well to the table on the first layer. And because this material doesn't flex like ABS, cooling fans can be turned on during 3D printing.

Although PETG is not as easy to use as PLA, it is far less demanding than ABS and is now the top of the list in popularity.

Recommended temperature for 3D printing Nylon with plastic

Nylon is another popular and interesting material, although it is more difficult to work with.

It requires a higher temperature than any of the other materials on the current list: 240 to 260° C is recommended. Required table temperature is 70 to 100° C. However, the glue stick layer is very important as Nylon suffers from adhesion quality problems first layer.

Required table temperature is 70 to 100° C. However, the glue stick layer is very important as Nylon suffers from adhesion quality problems first layer.

Nylon should not be printed with cooling fans as this will cause layer adhesion problems.

This material is also very hygroscopic, meaning it absorbs moisture from the air very actively. This significantly reduces the quality of 3D printing, so the nylon must be dried before printing or a quality thermal box must be used.

Nylon can be problematic at first, but once you learn how to print properly with this material, it will cover many of your questions and needs.

Recommended temperature for 3D printing TPU plastic

The flexible materials known as TPU are an unusual and sometimes very useful material, but very difficult to work with.

TPU is used at the same temperatures as PLA. Works best between 210 and 230°C with table temperatures between 30 and 60°C.

Because this material is very flexible, it can bend and stretch from the extruder gear to the nozzle itself.

Also, the extruder must support the filament between the exit of the drive gear and the entrance to the melt chamber.

Also, the extruder must support the filament between the exit of the drive gear and the entrance to the melt chamber.

Best results achieved on Garolite. Other/cheaper alternatives include poplar wood or PVA/UHU Glue.

Best results achieved on Garolite. Other/cheaper alternatives include poplar wood or PVA/UHU Glue. (if the print bed is not heated, consider using brim instead, 5 or more mm wide.)

(if the print bed is not heated, consider using brim instead, 5 or more mm wide.)

75mm, the recommended printing temperature is 185°C - 200°C with a heated print bed OR 200°C - 230°C without a heated print bed.

75mm, the recommended printing temperature is 185°C - 200°C with a heated print bed OR 200°C - 230°C without a heated print bed.