Orion delta 3d printer

SeeMeCNC Orion Delta 3D Printer Review: Tall and Smooth

Skip to main contentTom's Guide is supported by its audience. When you purchase through links on our site, we may earn an affiliate commission. Here’s why you can trust us.

The SeeMeCNC Orion Delta is a great pick for printing large, smooth objects in a number of materials, but it's not great for small, detailed items.

Tom's Guide Verdict

The SeeMeCNC Orion Delta is a great pick for printing large, smooth objects in a number of materials, but it's not great for small, detailed items.

Pros

- +

Solid construction and design

- +

Works both stand-alone and PC-controlled

- +

Excellent software

- +

Fine print quality for curvy and large models, like vases and sculptures

Cons

- -

Struggled with some detailed models

- -

Open construction makes it sensitive to drafts and temperature shifts, and unsafe for children

- -

On-screen controls are awkward

Today's best SeeMeCNC Orion Delta 3D Printer deals

No price information

For more information visit their website

Who it's for: Sculptors and potters experimenting in 3D printing, and those looking to do large, tall prints at low cost.

SeeMeCNC is mainly known as a supplier of kits for people who want to build their own 3D printers. The Orion is a departure for the company: It's a pre-built 3D printer that comes almost fully assembled. Priced at a reasonable (for its capabilities) $1,299, this machine offers flexible printing for objects up to about 9 inches tall, making this a good pick for those who need to regularly produce large prints.

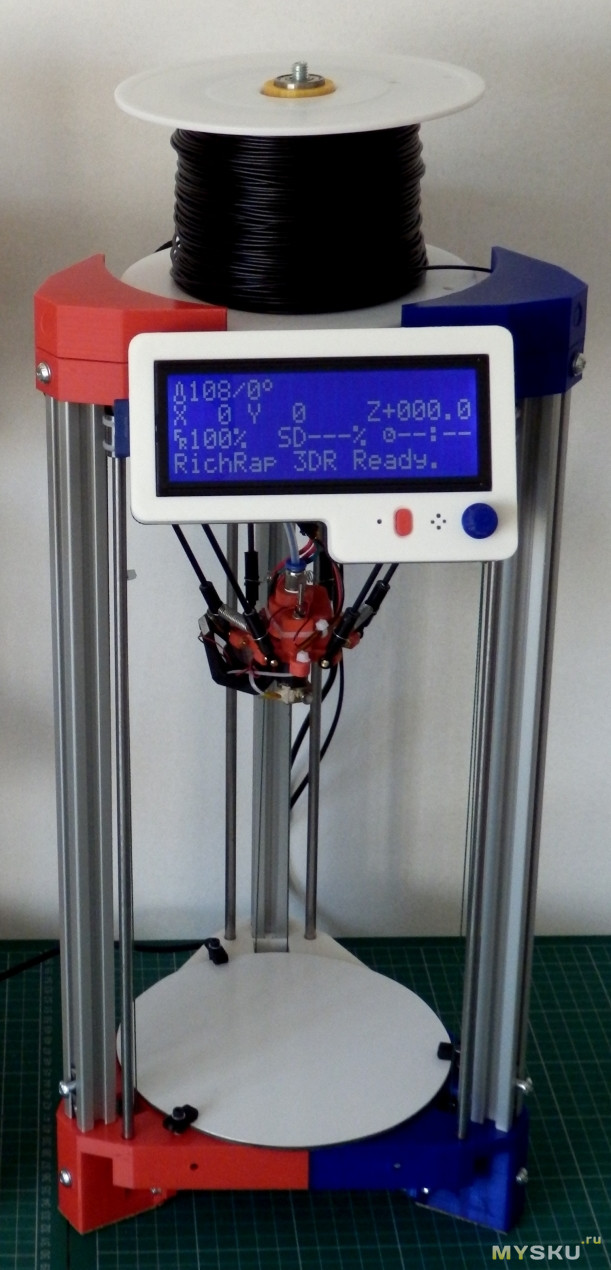

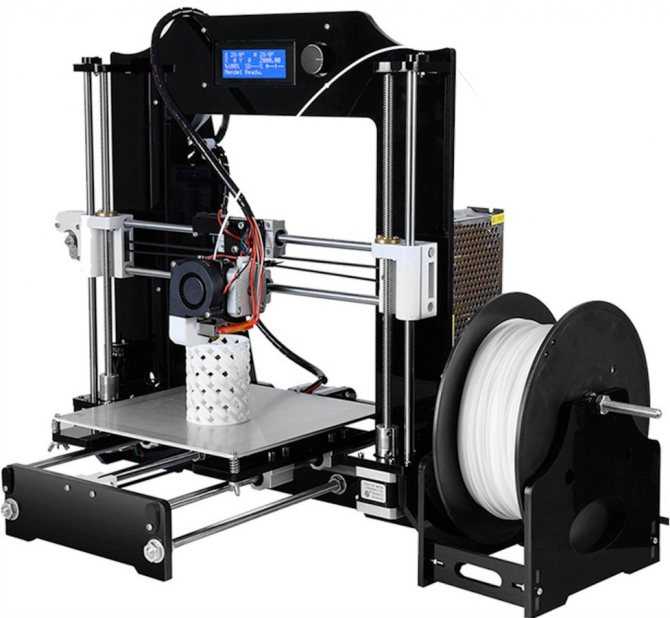

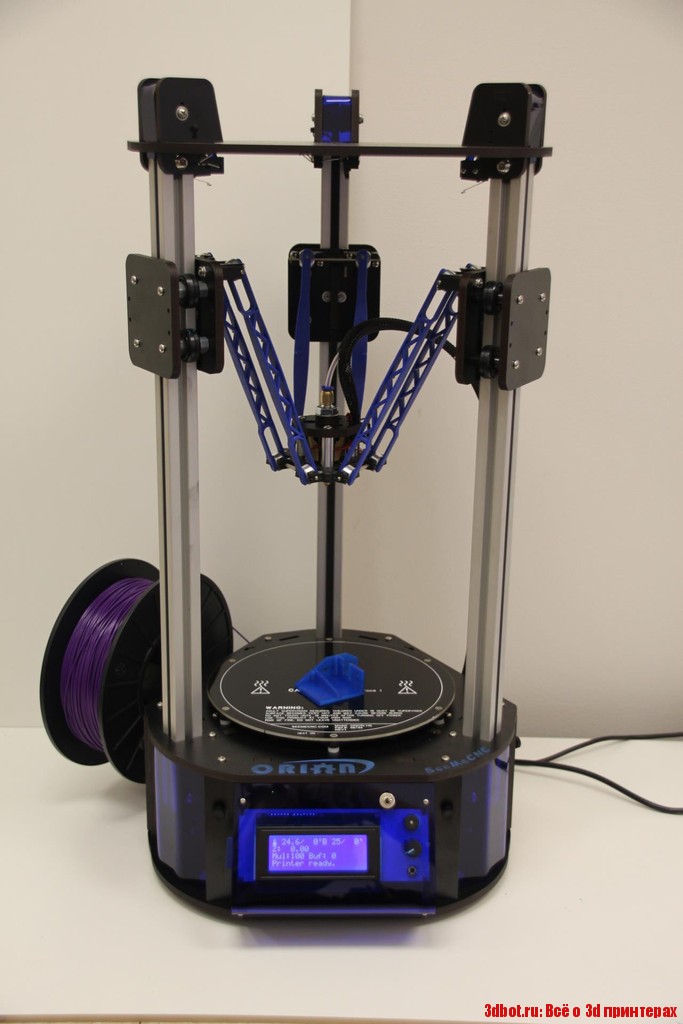

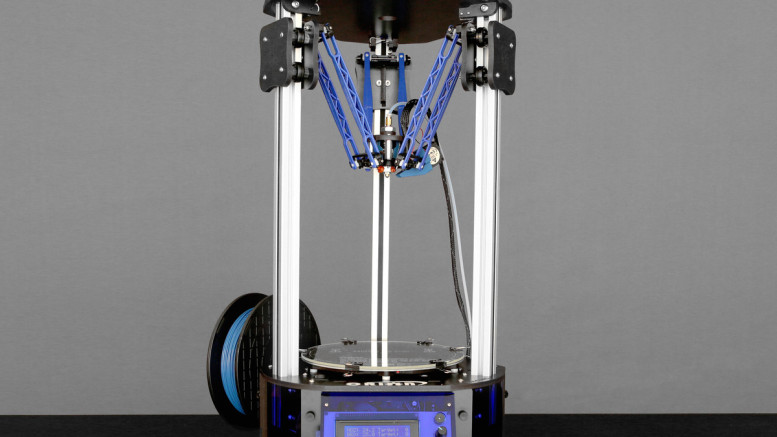

Most 3D printers are boxy and square, but as a delta-style printer, the Orion has a cylindrical design, 4 feet tall and 2 feet wide. It has three arms that are linked to platforms that slide up and down the three posts that form the printer frame. These are driven by motors in the base that, in turn, move the print head. It's a more complex design than the platform that moves left-right, up-down and front-back, such as that used in the LulzBot Mini (see review), but it has the advantage of offering a very large, tall build space. While the LulzBot Mini can build objects up to only 6 inches high, the Orion Delta goes up to a little more than 9 inches.

MORE: Best 3D Printers

These objects can have a maximum diameter of 6 inches (for a total 261 cubic inches) if they are circular, or a side length of just over 4 inches (for 148 cubic inches) otherwise. That compares well with the 76 cubic inches of the MakerBot Mini, or the 223 cubic inches of the LulzBot Mini, both of which are similarly priced. But print volume isn't the whole story: The circular print bed and tall print height make delta printers like the Orion especially suited to large, tall objects. The open design does mean, however, that any drafts or sudden temperature changes could cause failed prints, so you need to pick a location with care. If you are looking to print meditating Buddhas, flower vases or 3D scans of yourself in heroic poses, this is the device for you.

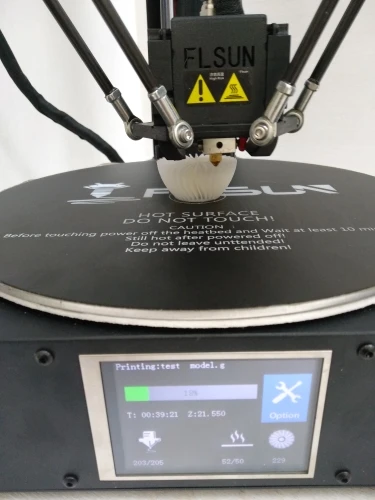

The base of the printer contains the electronics, motors and controls, with a single 4-line LCD panel providing status updates. A single rotary dial and button form the controls, and an SD Card slot is located on the left side of the display panel. The Orion can print from an SD Card inserted into its slot or from a computer connected to its USB port.

The Orion can print from an SD Card inserted into its slot or from a computer connected to its USB port.

On top of the base is the round, glass, heated print bed, measuring a little more than 6 inches in diameter. This is held onto the heater and platform by a rather low-tech solution: a series of binder clips. One nice touch is a small, red LED that illuminates when the print bed is heating.

Print Materials: Support for a wide range

The Orion can use a wide range of materials, with PLA, ABS and Ninjaflex plastic supported right out of the box. The temperatures supported by the print bed (up to 120 degrees Celsius) and print head (up to 245 degrees C) should allow the Orion to use nylon and transparent materials like T-Glase. The Orion forum on the SeeMeCNC site features a thriving community of users who are experimenting with materials.

Print Quality: Smooth curves but rough details

The quality of the Orion's 3D prints varied. The device did an excellent job printing larger models with smooth surfaces, but it struggled with the fine details on models that required more precision in sharp edges and more intricate shapes.

Our Thinker statue came out with clean, smooth curves around the shoulders. We did have some issues with visible layering, though, on the Standard and Coarse presets that the Matter Control software offers: Some layers seemed to have slipped slightly, producing a vertical stripe in the final print. These issues were much less pronounced when using the Fine preset, though, so it's a trade-off between detail and speed. We did notice some whiskers of filament, though, where the melted plastic had continued to flow as the print head pulled away. You can see some of these filaments in the photo below, printed in PLA using the Standard preset in MatterControl. Below are close-up examples of part of this print using the Coarse, Standard and Fine presets.

The Orion also did a decent job with our test model of a set of gears. After printing at the standard preset, these gears fit together with only a small amount of trimming to widen some of the holes that other parts have to fit through. That's not unusual, though: Most filament deposition model (FDM) printers that we test require some finishing work, as the prints tend to slump a little as new layers are added. I also had to clean off a few small bits of filament that stuck to the threads of the screws and other parts. The gears from the Orion looked somewhat rougher than those we've produced on other FDM printers like the LulzBot Mini, but the gear mechanism fit together quite easily and worked well.

That's not unusual, though: Most filament deposition model (FDM) printers that we test require some finishing work, as the prints tend to slump a little as new layers are added. I also had to clean off a few small bits of filament that stuck to the threads of the screws and other parts. The gears from the Orion looked somewhat rougher than those we've produced on other FDM printers like the LulzBot Mini, but the gear mechanism fit together quite easily and worked well.

Our hardest test model — a geometric sculpture — proved to be a bit much for the Orion: The device produced a print that was complete, but with rough edges and a lot of stray filaments hanging off. At one spot near the top, a printed layer seems to have slipped (see the second close-up photo below). At the very least, this piece would require a lot of trimming and cleaning to make it look nice.

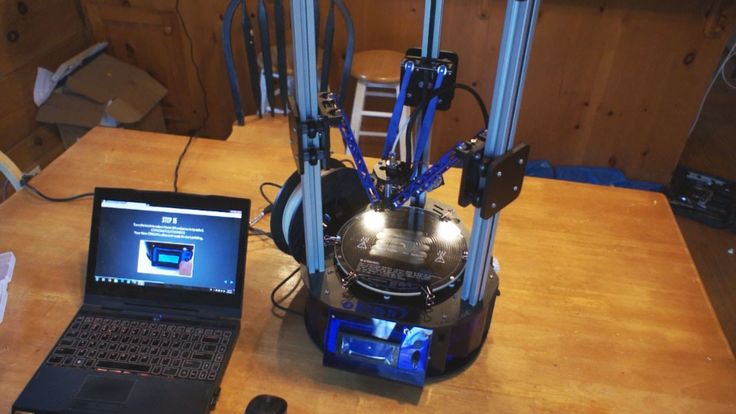

Setup: Minimal assembly required

The Orion requires minimal assembly before you can start printing — mainly removing packing materials and plugging in a few cables to connect the display. No tools are required, and the process is well illustrated in the downloadable manual. I was up and running about 30 minutes after I opened the box.

No tools are required, and the process is well illustrated in the downloadable manual. I was up and running about 30 minutes after I opened the box.

The other bit of setup required is to adjust the Z height, allowing the print head to hover just above the print bed. You use a piece of paper to set the small gap between print bed and print head by adjusting a screw on the arm connected to the post. Some printers (such as the LulzBot Mini) now do this automatically, using a sensor to detect the print head. Once this was done, the printer ran the included test print of the SeeMeCNC mascot, Blinky that stuck to the print bed nicely using the included roll of PLA filament.

Interface: Simple controls, sophisticated software

The onboard controls of the Orion are simple: The 4-line LCD, control dial and single button provide access to an on-screen menu that allows you to set up and control the printer, and set prints going from the SD Card. This is a little awkward, though, with a lack of indicators to let you know that you have selected an option. When you set the printer to preheat, for instance, there is no visual indication that it is preheating except the red light on the print base. You don't get any indication on the LCD screen until you go back up the menu structure to the initial page that shows the print-head and print-bed temperature. Similarly, there is no indication when the printer has finished preheating. This makes it rather too easy to set the printer preheating and forget about it, as it takes between 10 and 20 minutes to heat the bed (depending on the temperature).

When you set the printer to preheat, for instance, there is no visual indication that it is preheating except the red light on the print base. You don't get any indication on the LCD screen until you go back up the menu structure to the initial page that shows the print-head and print-bed temperature. Similarly, there is no indication when the printer has finished preheating. This makes it rather too easy to set the printer preheating and forget about it, as it takes between 10 and 20 minutes to heat the bed (depending on the temperature).

The Orion has one control that I wish were present on more 3D printers: a stop button, located below the control dial. If you spot a problem in a print, hit this, and the Orion stops and moves the print head back to the home position at the top of the printer. That's much quicker than using an on-screen or in-program menu. All 3D printers fail sometimes, but at least this one can be quickly stopped when that happens.

The Orion can be controlled from a variety of 3D printing programs (such as Cura or Repetier), but SeeMeCNC recommends a program called MatterControl, available as a free download for PC or Mac on SeeMeCNC's website. I found MatterControl to be straightforward and simple to use for loading and processing all of our test models. It offers better visualization of the 3D model than the rival program, Cura, providing a 3D view of the print layer by layer. This can help you spot possible problem layers, and help you track how a print is progressing. MatterControl is also better at queuing up multiple print jobs, a definite plus for high-volume print setups where you need to produce multiple copies of the same print.

I found MatterControl to be straightforward and simple to use for loading and processing all of our test models. It offers better visualization of the 3D model than the rival program, Cura, providing a 3D view of the print layer by layer. This can help you spot possible problem layers, and help you track how a print is progressing. MatterControl is also better at queuing up multiple print jobs, a definite plus for high-volume print setups where you need to produce multiple copies of the same print.

MatterControl is also available as an Android app, and SeeMeCNC offers a version of the Orion with the software pre-installed on a 7-inch Android tablet for an extra $266 ($1,565 in total). That's an attractive option for those who want to avoid the complications of a PC, but also keep the additional features that MatterControl offers.

Print Process: Rather noisy and lots of movement

The open delta design of the Orion involves a lot of movement: The shifting platforms and arms are clearly on display. That and the open, heated print bed mean that this isn't a printer to use around children without a separate enclosure: There are too many components that could crush or burn curious fingers.

That and the open, heated print bed mean that this isn't a printer to use around children without a separate enclosure: There are too many components that could crush or burn curious fingers.

The Orion is a little noisy while printing, with a continual low-frequency buzz sounding like a hive of angry bees, and an occasional clonk and thump as the print head shifts. There's also an occasional note of honking geese in there, producing a combination of noises that is noticeable rather than unpleasant, but which is definitely audible in the next room.

Print Speed: Rather slow

3D printing is still a rather slow business, and the Orion Delta doesn't do a lot to change that. Printing our 4.5-inch statue of The Thinker takes between 6 hours, 22 minutes using the Coarse preset and a 0.3mm layer height, and 17 hours, 32 minutes using the Fine preset, with a 0.1mm layer height. That's a little on the slow side; the Ultimaker 2 (see review) managed the same print in 3.5 hours for coarse quality and 14. 5 hours for fine quality.

5 hours for fine quality.

There's a lot to like about the SeeMeCNC Orion Delta: It offers a large print volume for the cost and size, and it usually produces fine-quality prints, especially with smooth, clean curves. This will make the Orion especially appealing to people who want to produce tall objects like statues or vases. The Orion struggled with fine details, though, and objects with very sharp edges didn't come out as well. This would not be a printer for engineering models or small, detailed prints. For those objects, you would do better the similarly priced LulzBot Mini.

- Best All-In-One Printers

- Best 3D Printing Service

- How to Buy a 3D Printer

Today's best SeeMeCNC Orion Delta 3D Printer deals

No price information

For more information visit their website

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

Tom's Guide is part of Future US Inc, an international media group and leading digital publisher. Visit our corporate site .

© Future US, Inc. Full 7th Floor, 130 West 42nd Street, New York, NY 10036.

See-Me-CNC - Orion Delta Printer | Adafruit Desktop 3D Printer Buyers Guide

See-Me-CNC - Orion Delta Printer

Save Subscribe

Please sign in to subscribe to this guide.

You will be redirected back to this guide once you sign in, and can then subscribe to this guide.

Download Profiles

CURA Orion Delta Profiles

Our preferred software for slicing parts is CURA from Ultimaker. Below is our profiles for CURA slicer settings. You can import the .ini file by using the “Open Profile…” option in the File menu.

Download Orion CURA Profile

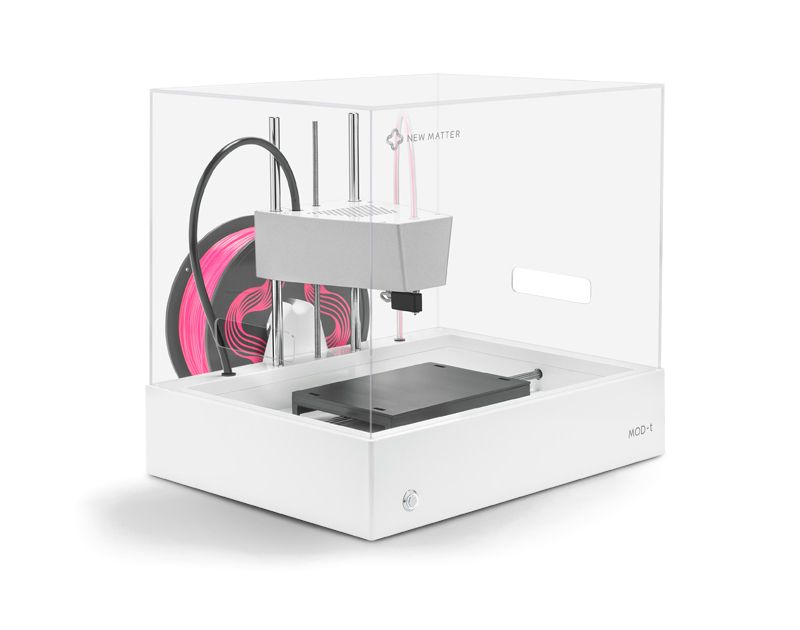

The ORION™ Delta 3D Printer is an exciting and attractive new 3D printer from the folks at SeeMe CNC that's designed to print ABS, PLA, and other materials from the very beginning. There's no need to refine or do anything to your printer - so you really have a ton more options for material than you usually do with an unmodified 3D printer.

There's no need to refine or do anything to your printer - so you really have a ton more options for material than you usually do with an unmodified 3D printer.

There's also an up-front LCD panel so you can see your printing status and an on-board SD card to store up to 4GB of files. The printer runs with high speed positioning (up to 300mm/s) with high precision at 50 micron accuracy.

This printer doesn't require much set up or configuration and you can basically start printing right out of the box. Comes with a 0.5mm nozzle and includes a 1lb spool of PLA filament. And if you need more, we carry a wide variety of filament here.

For the technical specs, accessories, and other details for the latest model version we are shipping, please visit the product page here.

- Excellent resolution for small prints at 100 microns

-

The small foot print is very welcoming in cramped spaces, enclosing it for printing in ABS will also save on space.

-

The drive gear is on the back, so it’s also more faster due to less weight on the extruder.

- Great value for a pre-assembled Delta with professionally manufactured parts such as injection molded Delta arms and Universal Joint brackets.

- Aluminum extrusions provide sturdy vertical tracks for the carriages.

- Print completely untethered with an onboard LCD interface allowing for printing from SD card *and* printer calibration.

- It is really fun watching this delta printing!

- Adjusting the endstop trigger screws at the top of each carriage is crucial to good printing, but time consuming to dial in accurately. It's worth doing this carefully!

- If the carriages are not tightened appropriately to the tracks, backlash can produce radial deformation, more difficult to identify and troubleshoot than backlash on a Cartesian machine. Adjust the "eccentric cams" to dial in the right grip on the rails, and you are back in business!

- Many of the best prints we have seen with these printers are using custom configurations for Cura, MatterSlice, or Simply3D rather than the original Slic3R profiles -- reach out to the active See-Me-CNC community and support resources for the latest slicing suggestions.

(They will be sharing more resources for us to link to here as well!)

(They will be sharing more resources for us to link to here as well!)

Who's the Machine For?

- Educators and students.

- Shop-owners, hackerspaces, and entrepreneurs looking to mesmerize onlookers.

- Those looking to print tall narrow objects such as 3D portraits.

- 3D Hobbyists eager to try a Delta -- who have been scared off by high price tag and steep learning curve of earlier Delta kits.

Bottom Line

Easy to setup and operate -- and half the cost of many of the Delta printers available on the market -- the Orion is the first Delta suitable for first-time 3D printing hobbyists, teachers and students. Expert users who spend extra effort dialing in this machine and building their own custom slicing profiles using tools such as Cura and Simplify3D will raise the baseline of the print quality from good up to excellent.

Printrbot Models

This guide was first published on Jul 31, 2014. It was last updated on Jul 31, 2014.

This page (See-Me-CNC - Orion Delta Printer) was last updated on Oct 04, 2022.

Text editor powered by tinymce.

Found a way to resist an attack on 3D printers / Sudo Null IT News

In 2016, Geektimes published an article about hacking 3D printers in order to make changes that lead to the destruction of the created object during its operation. In short, we are talking about an attack on enterprises that use 3D printers to create parts or parts of them in order to change the configuration of the manufactured elements. For example, it can be a propeller of a copter, parts of a car body, parts of a machine tool, and much more. The scientists' study was named “dr0wned – Cyber-Physical Attack with Additive Manufacturing” . During it, the specialists got access to the files of models of drone propeller parts, changed the model parameters, made the parts and launched the drone. As a result, the propeller collapsed in flight and the copter fell from a great height.

It is clear that this was only a demonstration of the possibility of an attack, which could be much larger if we were talking about real production. Only now, almost a year later, experts from another team have found a way to help counter the theoretical 3D printer hack. The results of this project were presented in Vancouver at the USENIX Security Symposium.

Other methods for tracking possible damage to parts that are printed on a 3D printer include analyzing the sounds of the device, tracking the movement of the manipulator, plus injecting gold microparticles into the source material in order to make sure everything goes according to plan.

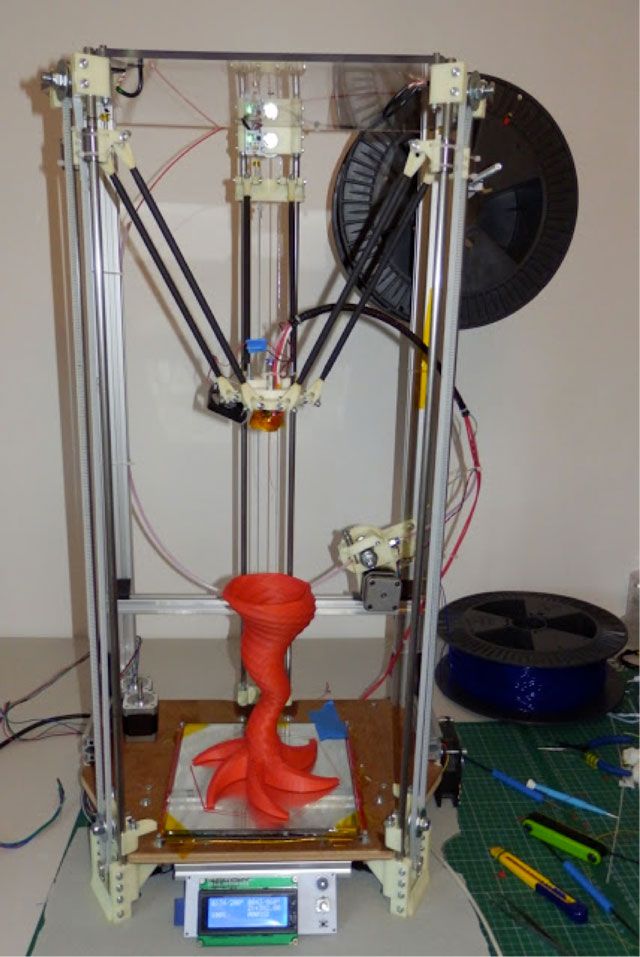

The paper describes how the researchers tested their assumptions in practice. Initially, three printers were purchased - Lulzbot Taz 6, Lulzbot Mini and Orion Delta. After that, the “hackers” changed the firmware of the systems, forcing the devices to print parts with defects. In some cases (and what's there - in the majority), it was difficult to judge the quality of the part and its compliance with the original drawing. But all these parts were defective and would deteriorate very quickly during operation.

But all these parts were defective and would deteriorate very quickly during operation.

Scientists have thought about the possibility of using software such as firewalls and antiviruses. But it is not a panacea either, since no one has canceled zero-day vulnerabilities and other surprises. Therefore, it was decided to develop a different way to protect devices and the parts they create.

This method consists of three steps. At the first stage, the printer produces the part according to the correct drawing. The sounds of the device are recorded and stored as a reference. Subsequently, the sounds of other printers of the same model that are working on the creation of the same part will be recorded. If there is a significant discrepancy in any case, the part and the printer are carefully checked.

The second stage is similar to the first - in this case, the movements of the reference printer are monitored. If the movements of other printers of the same model differ from the standard in the manufacture of the same part, then everything is carefully checked.

Finally, during the third stage of the work described in the document, gold microparticles are introduced into the starting material during the manufacturing process of the part. They are introduced not randomly, but at a certain time, so that the particle occupies a certain place in the part. In the future, all details are checked for the correct location of the gold. If everything is within the normal range - ok, the part can be used. But to be sure, the computer analyzes the recording of the sound of the printer and its movement. Are all three stages tested? The part is sent to the place of use.

It is clear that the danger of hacking 3D printers is most relevant to industrial systems, not home devices. Yes, if the home system is hacked, it will be unpleasant for the owner, but the problem can be solved relatively quickly. But with the hacking of industrial devices, everything is not so simple. As mentioned above, complex and expensive devices that are made using printers, not to mention people, can suffer.

“Imagine that a whole factory of 3D printers is working on the production of a certain kind of objects. They have no way of knowing if there are defects in the parts, defects that cannot be seen with the naked eye. The result can be deplorable, and no one will understand where the problem came from, ”the authors of the project say in a statement.

The method proposed by scientists can also be used to determine a possible marriage, unprovoked by a person.

| 3DNews Analytics Exhibitions Mini-report from mini-exhibition 3D Print Exp... The most interesting news 3D Print Expo took place last week. This is almost one of the first events in Russia dedicated exclusively to 3D printing and 3D scanning. Let's try to tell at least some of those interesting devices that were shown at this exhibition Well, first, let's see who came to the exhibition. You approach one stand and ask: “What is this thing? What can he do? And they answer you: “This is not for us. Ask your neighbors." Honestly, I don’t want to swear at all, since there are not very many such specialized exhibitions dedicated to some relatively young, popular and high-tech industry. In this case, most of the participants did not come to promote new technologies, but simply to sell them. At least that's the impression we got. gal-3dp Assorted 3D printers It’s also boring because many people demonstrated the “novelties” we already know well, that is, products from MakerBot, Ultimaker, RepRap, Cubify, PP3DP (UP!) and other companies, or their clones. In general, everything that everyone has already heard or even seen a thousand times. There were, of course, stands with professional or semi-professional equipment, but for the layman they are not so interesting. On the other hand, over the past 10 years, although nothing fundamentally new has been invented, already known technologies have become more accessible. No, before the slogan "3D printer in every home!" far, but both small companies and enthusiasts can buy a decent model. If you just want to play around or do a little work with your hands, then you can choose some inexpensive model from this list. You can also order some standard solution in Russia, because the number of suppliers has recently become noticeably larger. ORION Delta 3D Printer Actually, there was something interesting at 3D Print Expo. Take at least the ORION Delta printer. Instead of the usual similarity of a coordinate table, he has a different principle for positioning the print head. It is attached by means of hinges to three carriages moving along three equally spaced vertical axes. Of course, everything can be printed on it, but the best thing, probably, will be various vases. It is also worth noting the products of two Russian companies involved in the creation of 3D printers. Firstly, this is Picaso 3D Designer, a pretty nice printer from Zelenograd. Secondly, this is the PrintBox3D One printer from another young company - RTG. The creators especially emphasize the high accuracy of printing and the reliability of the device. One of the representatives at the company's booth even spoke with slight contempt about other products in the sense that they are all “toys, and we, in fact, have a real CNC machine. Chocolate 3D Printer And for the first time we managed to see a 3D printer that prints chocolate figures. It was created in Yekaterinburg club MakeItLab. The thing is simple, but fun. This is not a serial product, but rather a prototype that still needs to be brought to mind. In any case, it is gratifying that we are engaged in the creation of such unusual devices. However, the demonstration of the 3Doodler “3D pen” aroused the greatest interest at the exhibition. In fact, this is just an extruder that extrudes a thread of molten plastic, but in a very compact package. Yes, this is also more of a toy, only for adults. Like many other 3D printing projects, 3Doodler grew out of Kickstarter. It is curious that official deliveries have not yet begun, and the guys from the Russian Madrobots store, which is close in spirit to the famous Thinkgeek, were not too lazy to get the first samples and show them to the public. Handheld 3D printer 3Doodler So, we will finish with 3D printers, because almost half of the stands were occupied not by them, but by various 3D scanning systems. And sometimes they cost almost more than the printers themselves. The principle of operation also does not change over the years - most often an object on a turntable is irradiated (not necessarily in the visible range) with a laser or a projector, which form a grid or other structure on its surface, and it, in turn, is read by one or more cameras. In the future, images from several angles are analyzed and a finished three-dimensional model is “stitched” from them. gal-3ds Equally assorted 3D scanners Of the domestic solutions presented at the 3D Print Expo, perhaps the most interesting product seems to be VT ATOM by Volumetric Technologies. The design is simple: projector and camera on one tripod + turntable + tricky software. The developers promise that this scanner will be relatively inexpensive, but of high quality. True, the concept of "inexpensive 3D scanner" is quite loose. The site says that it will cost about €2,000, and the exhibition called almost twice as much. 3D scanner VT ATOM 3D scanner prototype based on PrimeSense sensor In general, the impressions from visiting 3D Print Expo turned out to be very ambiguous. It seems that the topic is fashionable and relevant, and there have never been such events before. However, in reality, all this turned out to be not at all as bright as it could be. The same models of printers, which differ little from each other. All the same technologies known a long time ago. Yes, there is definitely progress in this area, but . |

Here is a grandmother-teacher and entrepreneur rolled into one. Here are schoolchildren joyfully shoving free pens and booklets into their pockets, carefully laid out even before entering the main room. But snippets of conversation can be heard from the neighboring stand: “Well, I’ll take this one right away, but when can you put up the second one?” There are not so many visitors in general, but the crowd effect is perfectly created due to the fact that the exhibition is not really very large and all the participants are placed quite tightly.

Here is a grandmother-teacher and entrepreneur rolled into one. Here are schoolchildren joyfully shoving free pens and booklets into their pockets, carefully laid out even before entering the main room. But snippets of conversation can be heard from the neighboring stand: “Well, I’ll take this one right away, but when can you put up the second one?” There are not so many visitors in general, but the crowd effect is perfectly created due to the fact that the exhibition is not really very large and all the participants are placed quite tightly.  It's okay, but… boring.

It's okay, but… boring.  Of course, it will come out more expensive, but it will be calmer - there will be fewer problems with delivery, warranty service, spare parts and consumables will be more affordable.

Of course, it will come out more expensive, but it will be calmer - there will be fewer problems with delivery, warranty service, spare parts and consumables will be more affordable.  ” One of the "chips" of PrintBox3D One is printing models with parts hanging in the air without creating intermediate supporting elements.

” One of the "chips" of PrintBox3D One is printing models with parts hanging in the air without creating intermediate supporting elements.  And they are, perhaps, the only ones who really talked about 3Doodler and printing in general with enthusiasm. However, colleagues who visited CES 2014 say that some Russian IT distributors are seriously considering the start of deliveries of a number of 3D printers to Russia, which is interesting in itself.

And they are, perhaps, the only ones who really talked about 3Doodler and printing in general with enthusiasm. However, colleagues who visited CES 2014 say that some Russian IT distributors are seriously considering the start of deliveries of a number of 3D printers to Russia, which is interesting in itself.  In some cases, a combination of several methods is used at once to obtain better "scans". Even we once told you how to make a simple 3D laser scanner at home. It is not so much hardware as software that plays a big role here. Naturally, there are Russian developments in this area, and in general, life goes on as usual - fashionable startups are being made somewhere, someone has already managed to quarrel with partners and leave with their heads held high, and someone has been bought out by more cunning competitors.

In some cases, a combination of several methods is used at once to obtain better "scans". Even we once told you how to make a simple 3D laser scanner at home. It is not so much hardware as software that plays a big role here. Naturally, there are Russian developments in this area, and in general, life goes on as usual - fashionable startups are being made somewhere, someone has already managed to quarrel with partners and leave with their heads held high, and someone has been bought out by more cunning competitors.  However, ordinary visitors were more attracted to another stand, where everyone was offered to get a free three-dimensional color model of their own bust. But here a slightly different approach is used - the data is read using the PrimeSense sensor. In short, this is the same Kinect or ASUS Xtion. The model turns out, perhaps not the highest quality, but scanning is very fast.

However, ordinary visitors were more attracted to another stand, where everyone was offered to get a free three-dimensional color model of their own bust. But here a slightly different approach is used - the data is read using the PrimeSense sensor. In short, this is the same Kinect or ASUS Xtion. The model turns out, perhaps not the highest quality, but scanning is very fast.