What do you make with 3d printers

100 useful things you can make with a 3d printer

By Roborefuge

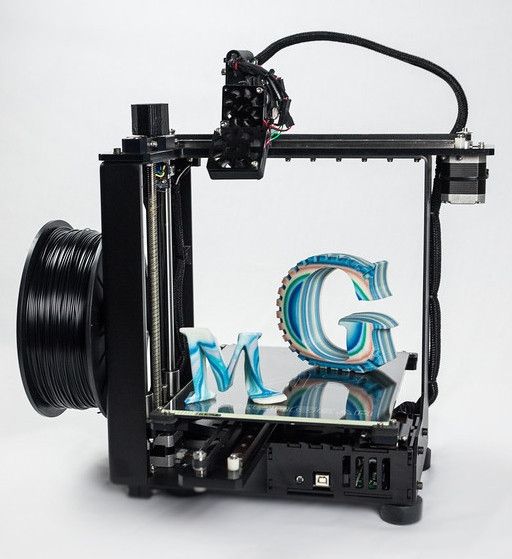

There are a lot of cool things you can make with 3d printers. I’ve seen a lot online and up close. But, wouldn’t 3d printers be more valuable if they can make things that are practical?

Well, I wrote this article for that reason. There are a lot of useful things you can make, especially for the house.

Here are 100 useful things you can make with a 3d printer. Let me know in the comments if you have any more suggestions!

Why Should You Get A 3D Printer?

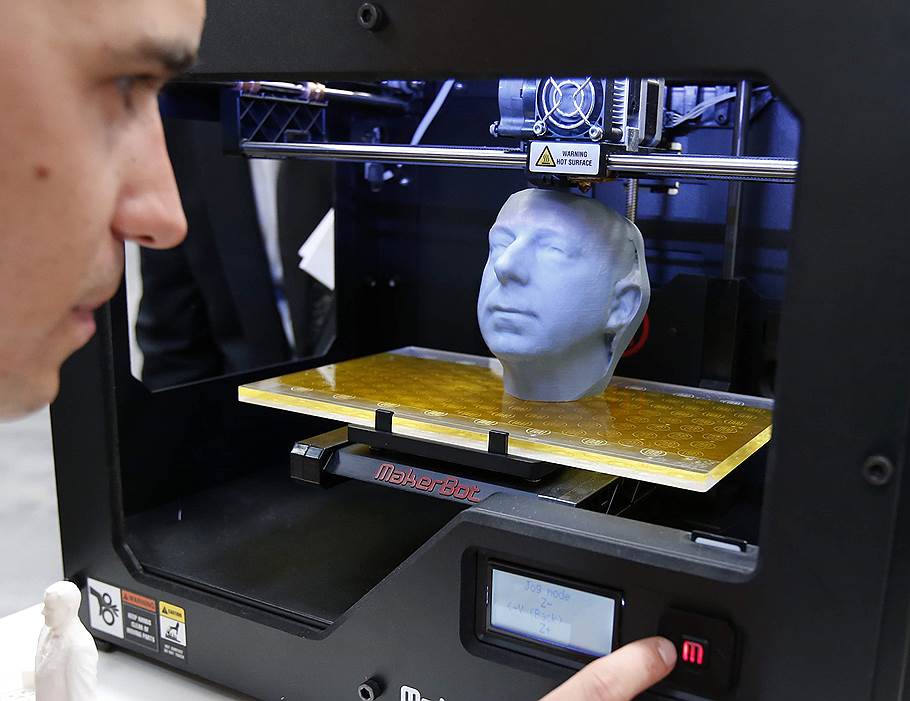

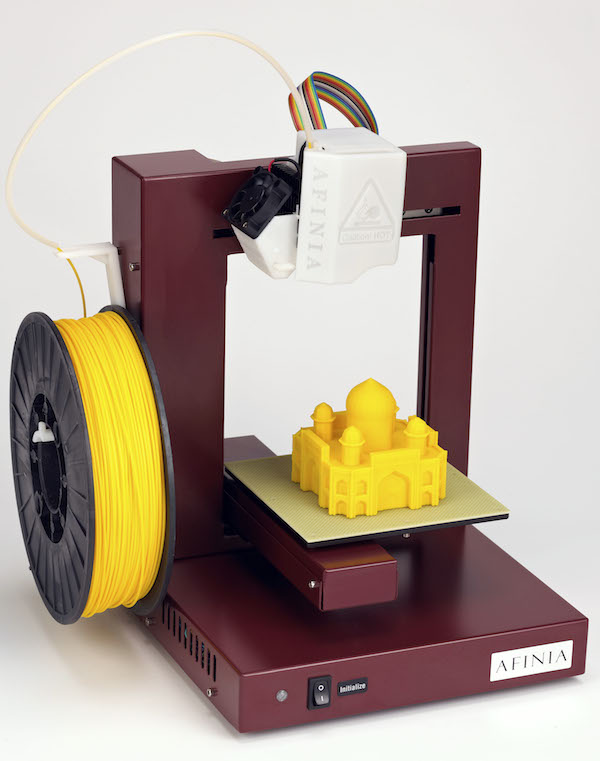

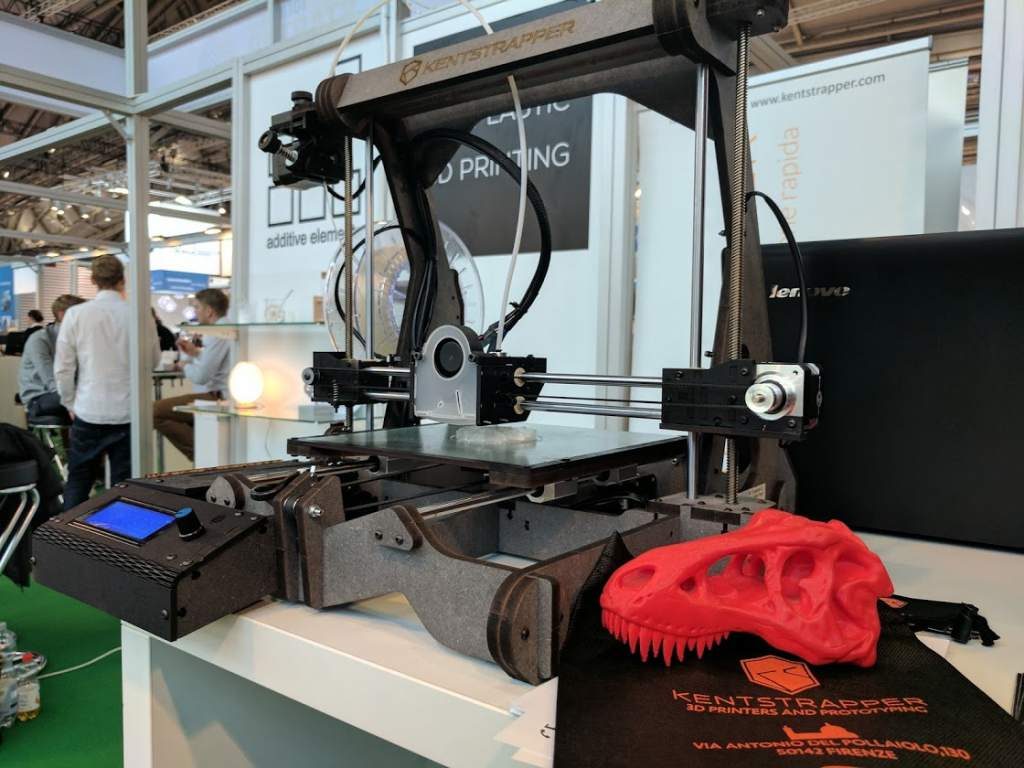

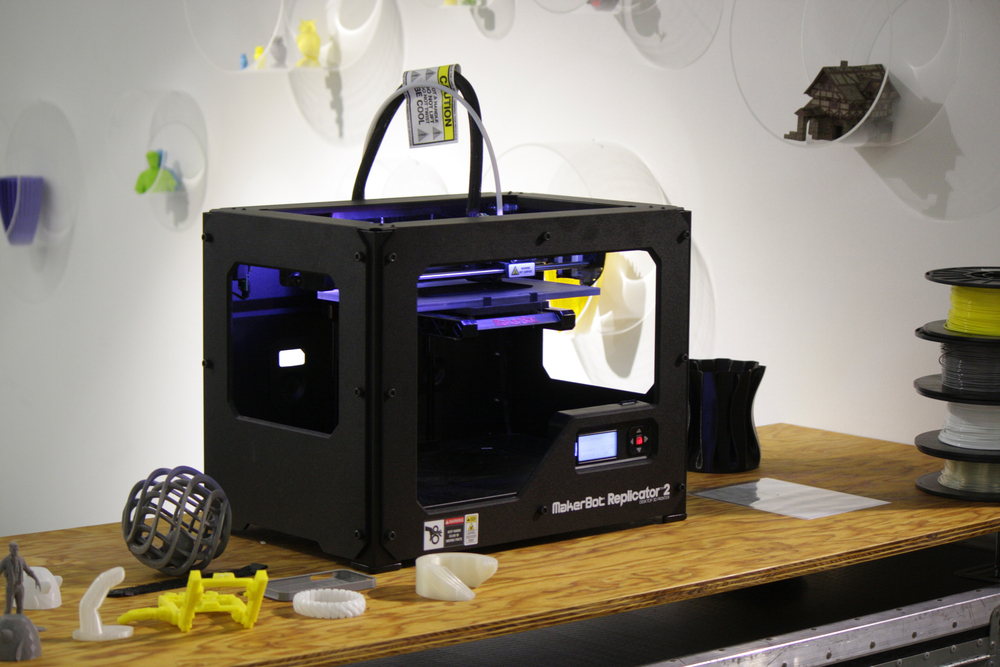

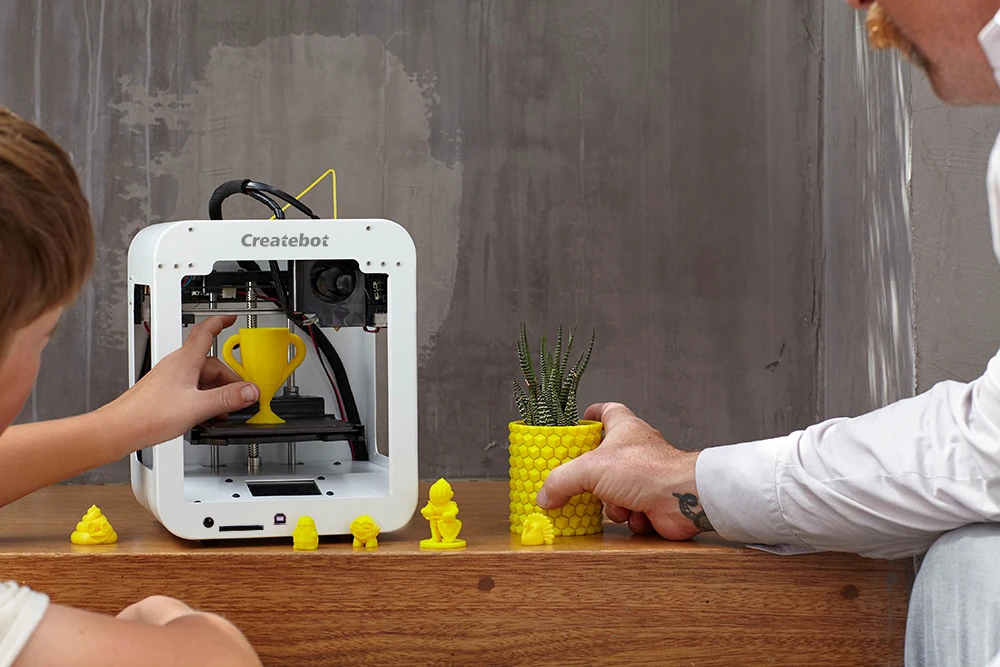

I believe 3d printers will be in every household in the future. Just like any other technology, 3d printers were originally found in institutions like colleges or labs.

Now, people who are curious about 3d printers can buy one for their homes.

3d printers are the future of manufacturing in my opinion. Getting one now helps you make things around the house. They’re also great for kids who want to get creative. There aren’t a lot of 3d printers in schools nowadays, but that will change soon.

Not only will 3d printers be in schools, but students will be using them in the future to prepare themselves for jobs in the future. But that’s not the best part, 3d printers will also help you save money in the long run.

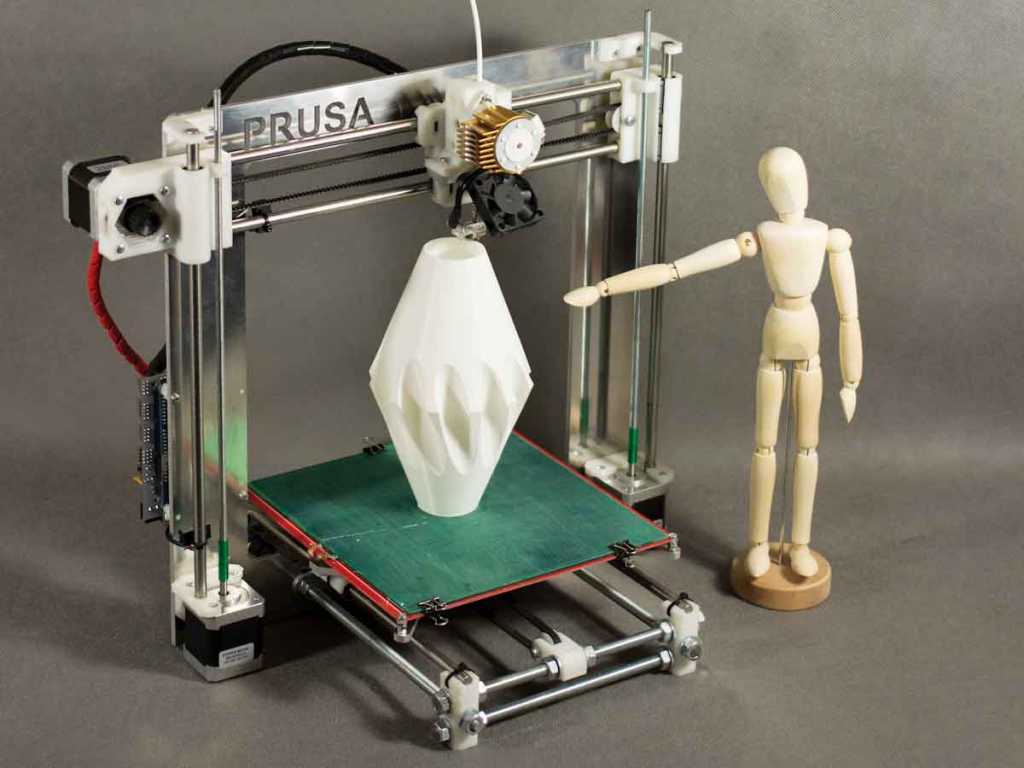

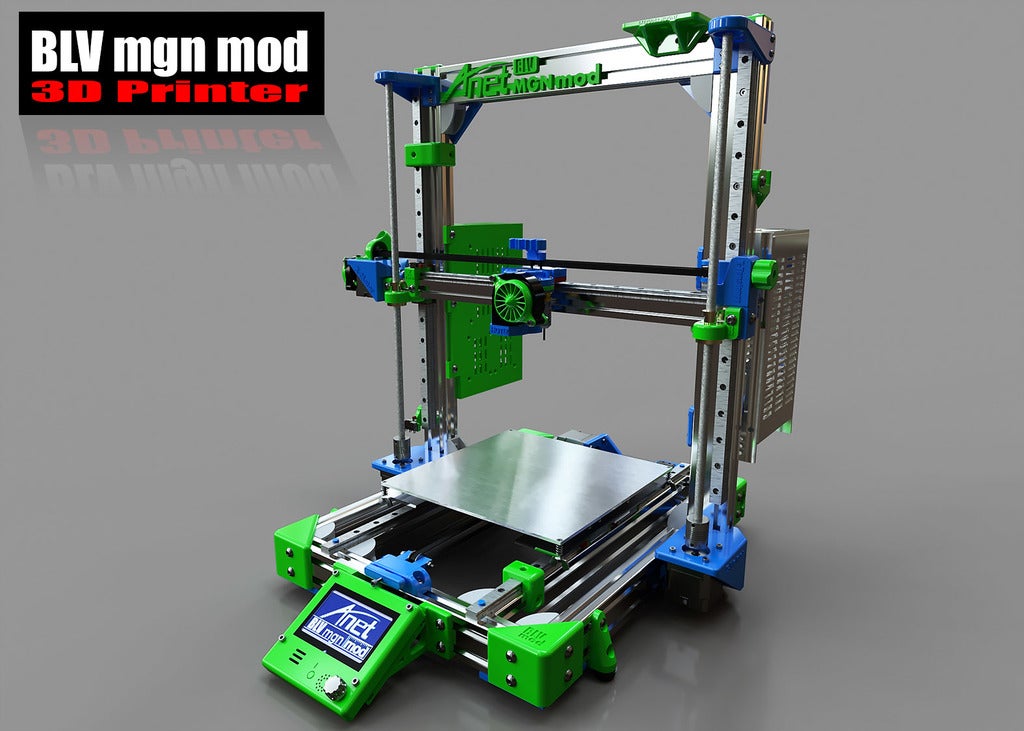

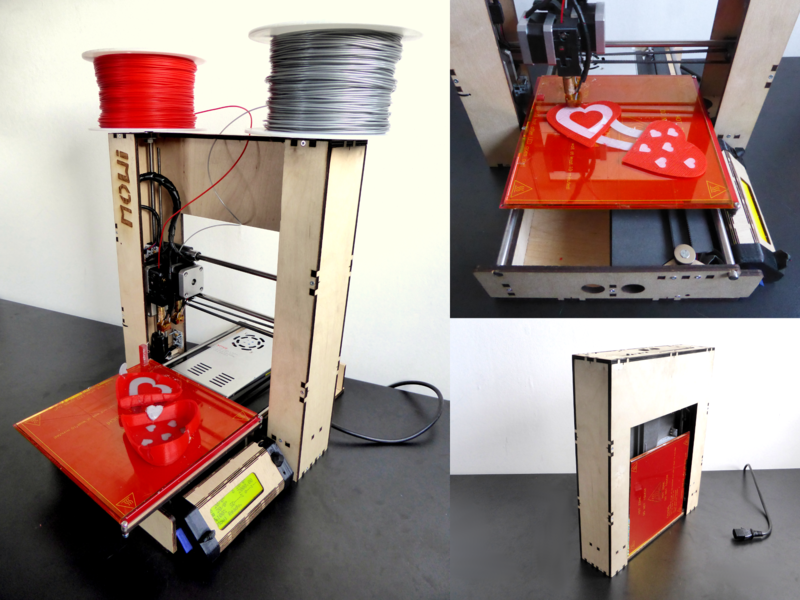

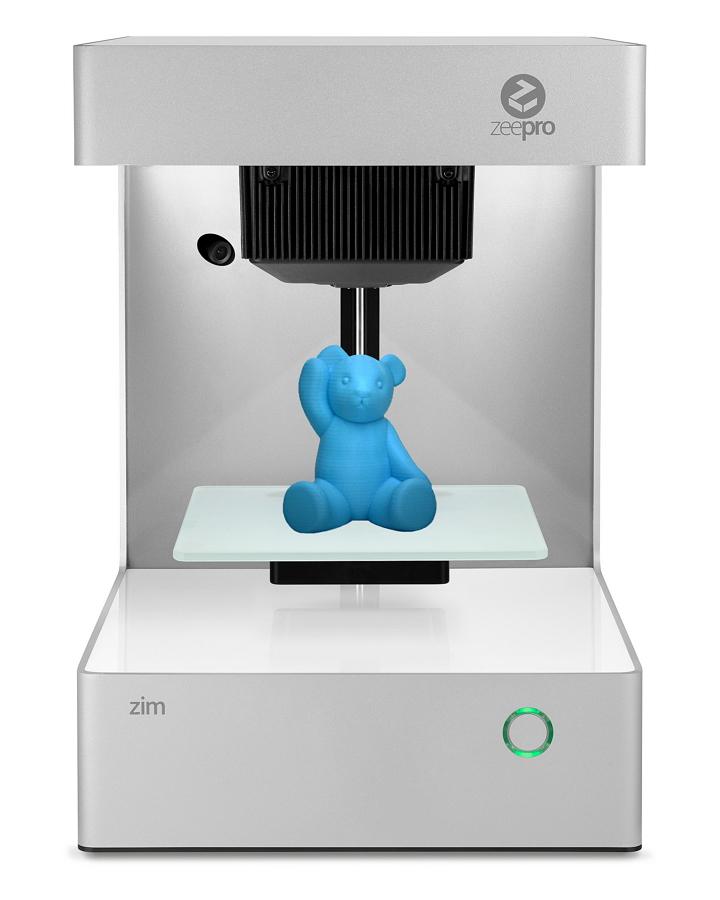

The best 3D Printer by PRUSA

See best 3d printers

How Much Money Can You Save?

The average household in the U.S pays around $2,000 for furnishings in equipment. A low-budget 3d printer costs $200-$500 and can last years. Think of all the products you can make with the 3d printer and how much those items cost. You can save thousands of dollars over the long run.

1. Covid Mask Breather

Source: Thingiverse.comI had to give the most practical item first. If this doesn’t seal the deal for you, then I don’t know what else to give you.

Mask breathers do what it says. It creates space between the mask and your mouth to filter out condensed air. This’ll help if you have musty breath, or didn’t brush your teeth that morning. And, it’s just nice to breath fresh air.

Besides wearing a mask for Covid, you can print different masks as you’ll see soon.

2. Hand-Made Camera Lens

This one blew my mind. Looking at the material for 3d printers, I didn’t think it was possible. But, here we are. Being able to make a camera lens lets you experiment with different pictures. Another thing that’s cool is how much money you save if you break the original lens.

A camera repair service can cost up to $100-$250 on average. A 3d printer can print you a new lens in hours.

This is another example of how you can save money.

3. 3D Printed Acoustic Guitar

You can also create instruments with 3d printers. Here’s a cool video of a guy playing a 3d printed guitar. 3d printed guitars look cool because you don’t usually see one around. You also have the advantage of designing it the exact way you want.

4. Flutes

I mean if you can print a guitar, you can also print some flutes. There are so many different flutes. There are different types for each culture or occasion. If you’re in middle school, you can print your own recorder flute and bring it to class.

If you’re in middle school, you can print your own recorder flute and bring it to class.

Or, you can make another flute called the “Native American Sparrow Hawk Flute”.

5. Surgical Instruments

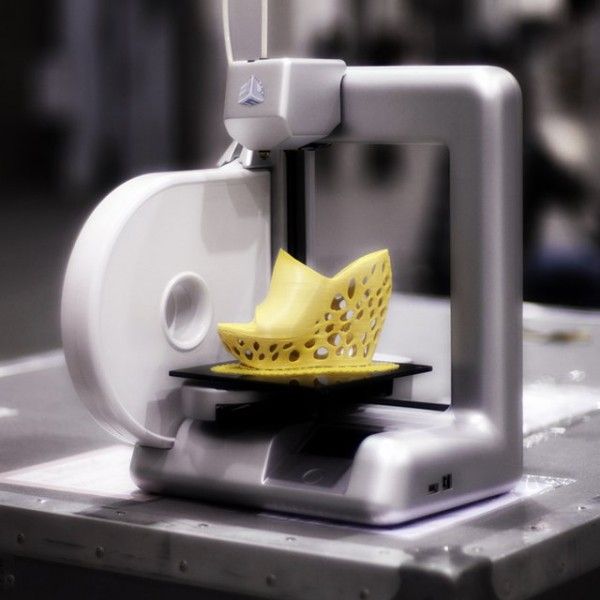

Source: 3dsystems.comIf an apocalypse breaks out and you need to perform surgery, a 3d printer can make the tools to do it. Think of all the handheld instruments in surgery. There are clamps, scalpels, forceps, and more.

Surgeons talk about having surgeon-specific tools too. If one tool doesn’t work for you, you can just print another one that’s customized for you. This level of iteration is great for us in the long run.

6. 3D Fetus

You can also make 3d fetuses. This one made me happy. And, the reason why is this type of 3d model can help visually-impaired soon-to-be parents “see” their kids.

3d printed fetuses can be the new ultrasound pic too. Having a “physical” version of your child sounds cooler than a pic to me.

7. 3D Figurines From Children’s Drawings

Once your child is born, you can also print their drawings. Creating and building is fun. Your child can create the drawing and build it with a 3d printer. Taking your ideas and making them real is fulfilling. Letting your child do this will spark their creativity.

Creating and building is fun. Your child can create the drawing and build it with a 3d printer. Taking your ideas and making them real is fulfilling. Letting your child do this will spark their creativity.

Here are some examples of 3d figurines from drawings.

8. 3D Printed Miniature Furniture

Those mini figurines your child makes will need some furniture. Making miniature furniture completes the whole set up. Creating miniature furniture also gives you prototypes for future house decor.

You would take house decor planning to a new level.

9. Iphone Case & Card Holder

The utility of this is self-explanatory. You know what you get just by looking at the title. The question is what type of case/card holder are you going to make. Personally, my case contains a card holder that holds everything snug. A better idea would be to create one that opens up like a door.

10. Electric Bike

Source: Theverge.comYou thought it couldn’t get crazier I bet. Well, this 3d printed bike sounds wild.

Well, this 3d printed bike sounds wild.

This specific bike was made in one go. There was no need for attaching support parts to complete the bike. A 3d printed bike also means less support parts to worry about. Another impressive part is this bike is more durable and stronger than regular bikes.

11. Gun

Technology also makes controversial things. However you feel about guns, just know it’s possible to build with 3d printers. Printing a working gun is another case though. There’s more science to set off the fire arm. Making the actual model is easier as all you need are the files.

Maybe one day 3d printers can print a whole working gun.

12. Camping Wraps

If you’re bringing a lot of things for camping, then you can use wraps to keep things organized. Instead of spending time untangling wires, you can spend a few hours making 3d printed wraps.

3d printing doesn’t only save money, it saves time too.

13. Cantilever Laser Engraver

Just saw this bad boy. I honestly didn’t know what a laser engraver was until the time of this article. But, now that I know of it, I can see how it could be useful. A laser engraver is exactly what it sounds like. It engraves designs through lasers.

I honestly didn’t know what a laser engraver was until the time of this article. But, now that I know of it, I can see how it could be useful. A laser engraver is exactly what it sounds like. It engraves designs through lasers.

This could be used to engrave family names onto some of your property. It can also be used to engrave the entrance of your home too.

A laser engraver isn’t something you come across everyday. But, with a 3d printer, you can get a lot closer than before.

14. Hanging Light

You can print a circular object with an opening and you’re close to having lights. All you need is the bulb and you’re good to go. This is one way you can make hanging lights. If you need light in a specific area, but don’t have all the tools, a 3d printer can help you get creative.

15. Robotic Arm

Source: Thingiverse.comI love this. An industrial robot creating another industrial robot makes me think robots will be creating themselves soon. If you know how to wire and code a robot, you might be able to create a whole army of robots starting with a 3d printer.

A robotic arm can help you with monotonous tasks. Having a bunch of robotic arms can also help you get rid of tasks you don’t like doing. This frees you up for more play time.

16. Coffee Cups

Coffee lovers need their mugs. There’s nothing like waking up to a fresh pot with your favorite cup. Being able to design your own mug is cool. A little morning slogan on your cup is a nice touch. You can also design your own coffee cup holder.

17. Flight Sim Joystick

Future pilots will find this more valuable than others. A flight sim joystick is similar to a practice steering wheel. Instead of buying one, you’ll save more by creating your own. Just remember that an actual flight joystick isn’t fully ready with 3d print.

You still have to finish the base so you can move back and forth mimicking real life.

18. 3D Printed Fabrics

If you want to be stylish and help the planet then 3d printed fabrics is one way. This type of fabric uses less labor, and is recyclable. Saving the planet and having people spend less time manufacturing frees them up. It turns into creating more useful things.

Saving the planet and having people spend less time manufacturing frees them up. It turns into creating more useful things.

People who want to go out the box can also create unique designs on their fabric. There’s a lot to like with 3d printed fabrics.

19. Customizable 3D Printed Bugdroids

Android fans can make their own bug model. These are usually colored green, but you can use different filaments to color them differently. Try printing some bugdroids and let me know what you think. Bugdroids are great for testing the quality of your printer.

20. Target Pen Holder

Source: Thingiverse.comMessy people like yours truly will find this useful. It seems like I’m always looking for a pen even though I rarely use one nowadays. A pen holder will keep me from embarrassing myself. These things can go from $10-$20 too. Being able to save some change with your own design is fulfilling.

A pen holder is one of the many pieces of furniture you can print.

21.

Divers Watch

Divers WatchI’ve never heard of a divers watch, but they look expensive. If you told me this is a Rolex I might believe you. The fact this is even possible with a 3d printer is hilarious. This particular watch is bigger than it looks because it’s made for the desk. It took 131 individual parts with a total of 30 hours of printing time.

22. Jesus Cross Pendant

If you come from a religious Catholic/Christian family, then you definitely have some sort of religious figure in the house. I personally come from one and they’re everywhere. There’s a Last Supper painting in my kitchen as we speak.

3d printers make it possible to print a Jesus Cross Pendant. You can make one for your desk or workspace.

23. Bikinis

A customized bikini sounds like a cost-saver. For women, this sounds like an opportunity to have a new bikini every time they hit the beach. Similar to fabrics, creating your own bikini with 3d printers means less labor, and more green efficiency.

I wouldn’t be surprised to see this in runways soon.

24. Blood Type Tags

Letting people know your blood type is important for survival. This is why some waivers ask for it. 3d printers can make you a blood type tag just in case someone needs to know your blood type.

25. LED Lamp

Source: Thingiverse.comThis is a nice lamp to set an ambience. The 3d printer can handle the build easily. The rest of the build depends on how you handle electronics.

You’re going to need to know information about batteries, and circuitry to finish this. Nonetheless, you can place this LED lamp on your desk along with other items you made.

26. Megaphone

Unlike the LED lamp, the megaphone doesn’t need electronic skills. All you need is the print files and you can make one in hours. A megaphone is useful for parties you throw around the house. There are many ways you can design this, let me know which one you go with.

27. Candy Dispenser

I hate having to open packages up continuously for snacks. A candy dispenser makes this inconvenient problem easy.

A candy dispenser makes this inconvenient problem easy.

If you have kids, you might want to place this in an area that’s hard to reach. Your dispenser will be empty in a day or two if you don’t.

28. Hamster House

It’s hard to print a whole dog house because those are huge. But, a hamster house is the next best thing. If you use the whole print bed, your hamster will be thinking it’s living in a mansion. It should be fun creating this for a pet hamster.

You can create pathways for your hamster to run through which is enjoyable in and of itself.

29. Ratchets

A ratchet is perfect for big cables. You can use this for television cables, equipment cables, and more. There are countless places in the household with cables. The cool thing about printing a ratchet is they’re quick to print. You should be able to print one in an hour or two.

30. Combination Lock

Source: Cults3d.comA combination lock is one of the most interesting products you can make. What’s cool is you don’t need much support equipment. Some glue and bolts will finish the assembly.

What’s cool is you don’t need much support equipment. Some glue and bolts will finish the assembly.

One thing you have to understand is 3d printers can’t print with metal. A combination lock, which is usually made out of metal won’t be as secure if it’s made out of plastic. Plastic is easier to break.

The lock should still prove difficult to break though. Just keep your expectations in check.

31. Collapsible Dice Holder

This one reminds me of dungeons and dragons. But, a dice holder like this prevents someone from rolling the dices off the boards. It’s also a cool way to roll the dice. If you’re a big board game person, this is a nice addition to the set.

32. Anti Gravity Planter

Perfect for mini plants. An anti-gravity planter makes a plant look like it’s hovering. Make sure you have soil and give the plant the water it needs.

33. Metric Screw Measuring Device

This is a good tool for all the things you’re going to make. Being able to make things with something you made from a 3d printer is very meta. Get yourself a screw measuring device if you plan on building a lot in the future.

Get yourself a screw measuring device if you plan on building a lot in the future.

34. Stand For Cotton Swabs

Another great storage furniture. Cotton swabs don’t get mentioned a lot when it comes to household necessities, but they need something to hold them.

You can design this stand which holds swabs and cotton. It’s especially helpful if you, or someone you know wears makeup. This stand can store all the items they need to clean up.

35. Blade Holder

Source: Thingiverse.comIt gets messy when shaving hair. It gets even messier when you place those blades in a bag. What makes having a blade holder convenient is you can find the blade you’re looking for faster.

This also doesn’t take long to make. If you’re looking for a project, then this is an idea. It’s also a great starter project for new 3d printer users.

36. Credit Card Wallet

A credit card wallet can also be the iphone case/card holder. But, if you want to print something less complex, then get this. This specific credit card wallet takes 8 hours to print.

This specific credit card wallet takes 8 hours to print.

37. Underdesk Drawer

I have a bunch of pencils, pens, and paper on my desk. A nice under desk drawer remedies that. I can just stuff everything in there to keep the illusion of cleanliness. Hanging the under desk drawer shouldn’t be too hard either.

38. Warning Signs

Place warning signs on your backyard doors with this. It’ll warn potential intruders, or first-time visitors. You can also use it for children who might not know better. A couple examples to place warning signs for children are stairs and stoves.

Just make sure to make those warning signs huge. Children can be oblivious when playing.

39. Water Diffuser

A water diffuser is great for backyards. If you don’t want to drown your plants, but need to water them routinely, try out this water diffuser design.

40. Cable Clips

Source: Thingiverse.comThis is similar to a ratchet. But, the difference is the size. Cable clips are smaller and can grasp smaller cables better. Try it on thin cords like phone or laptop chargers.

Try it on thin cords like phone or laptop chargers.

41. Photo Frames

Yes, photo frames are possible. It’s not that hard to imagine though considering the items on this list. Being able to print photo frames means you can go a little crazy taking pictures. Just make sure you have enough filament.

42. Multipurpose Apple Charging Dock

If you’re in the Apple ecosystem, then you’ll find huge value in this. Having a multipurpose Apple charging dock charges your phone, charges your Airpods, and hangs your Apple watch.

You might even be able to incorporate your laptop somewhere. It all depends on the design you go with.

43. Costumes

The options you have with costumes is crazy. You’re able to print masks, dresses, and accessories. The only limitation is your imagination. Check out this article on some ideas.

44. Rice Paddle

Rice paddles are one of my best friends when it comes to food. It feels satisfying to grab a big portion of rice and placing it on your plate. What’s great about this is it’s not complex for a printer to make. The design is straightforward.

What’s great about this is it’s not complex for a printer to make. The design is straightforward.

45. Keys

Source: 3dprint.comThis can be a combo piece to your combo lock. Similar to rice paddles, they’re not too difficult to make. I’m surprised 3d printer keys aren’t more popular. If you take the concept of keys and locks, you can create a unique lock that wouldn’t even look like a lock.

This will confuse potential thefts.

46. Towel Holder

Instead of manually rolling paper towels have a towel holder do it for you. The one I linked to is stable and durable. That specific towel holder can be used without holder caps and it can be placed on the bottom of a cupboard.

47. Laptop Case

You’ve seen the different type of laptop cases out there. Some of them look basic in a good way. This means you can print yourself one just by getting the dimensions of your laptop.

You can even go above and beyond and add a batman logo or what not.

48.

Board Game Pieces

Board Game PiecesAvid Monopoly players rejoice! You can now replace your favorite missing pieces. In fact, you can make new pieces. Add to the experience of board games by creating your own pieces.

49. Golf Ball Clip

This is another way to organize your golf balls. If you have a special golf ball, you can use a golf ball clip to hold it upright in a special place.

50. Toy Kettlebell

Source: Thingiverse.comHaving a toy kettlebell made me laugh. I’m sure this is not as heavy as a real kettlebell. But, you can still use this for exercises.

As long as the handle is right, you can perform the same exercises as if you had a real one.

51. Lunchbox

You probably can’t even tell between a lunchbox that you bought, and a 3d printed one. Furthermore, lunch boxes are usually made out of plastic which is the material most 3d printed items are made out of.

If you don’t have a lunchbox, you know what time it is.

52. Small Toys

Small soldiers, small cars, and more are on the table. While children are playing with small toys less and less, it’s still cool this is possible.

While children are playing with small toys less and less, it’s still cool this is possible.

53. Homo Erectus Skull

All my biologists would find this interesting. Shoot, I’m not one and this is interesting. Downloading some files and printing some 3d skulls sounds wild. If I got a chance I would definitely do this as it’s not only fun, it’s educational.

54. Lego Pieces

These things would hurt my feet so bad. Stepping on one is like stubbing your toe on the corner of the bed.

A 3d printer will give you the chance to step on more. In addition, they also help you finish large lego models. If you’re missing a piece, you can just print the remainder to finish it off.

55. Kitchen Utensils

Source: Thingiverse.comHaving a 3d printer make you a spoon and fork is like having plastic utensils.

This person made a spork with their printer. You can even try something new and make a kitchen utensil that combines a spoon, fork, and knife.

56.

Vase

VaseHold your flowers in a spiral shape vase. There’s no big difference between a bought vase and a 3d printed one. You can even make a mix-colored vase if you want to. Try different shaped vases too. Don’t just go with a spiral one.

57. Ventilation Cover

Try making a ventilation cover if you’ve had the same one for years. Sometimes ventilation covers are so old you’ll just be bringing in old air from the cover itself.

58. Piggy Bank

What if you use 3d printed money and put it in your 3d printed piggy bank? Another meta situation. I’m not sure if there is pink filament, but I’m sure a 3d printed piggy bank would be hard to break. Tearing plastic apart isn’t as easy as smashing metal.

59. Microphone Stand

If you have a karaoke mic you can use a microphone stand. Not many karaoke sets come with one that I know of. It’s also nice having a microphone stand because you don’t want your microphone rolling around.

60. Mini Mechanical Mouse

Source: Thingiverse. com

comBuilding a mechanical mouse is going to need electronic skills. With a 3d printer, you can print the whole case. You might need to use the insides of another mouse to get your new mouse to work though. Try something similar to what this person did.

61. Dead Blow Hammer

You can also smash things if you want. If 3d printers can make guns, what’s wrong with hammers.

In all seriousness though, the ability to make a hammer helps you make other things. A dead blow hammer helps minimize damage to the targets and is easy to control. This way you won’t bend nails out of shape.

62. Knife Holder

A knife holder is super valuable. Even though it does one thing, that one thing saves a lot of pain. You can do a combo for a 3d printer by making knives and a knife holder. Making a 3d printer knife might not come out as sharp as you need though.

63. Bookmark

A simple, but useful tool. I always lose my favorite bookmarks. Having a 3d printer is a convenient way to replace things.

One thing is a 3d printed bookmark won’t be as thin as a paper one. Other than that, a 3d printed bookmark will work just fine. Just make sure it’s dry before placing it in your book.

64. Headphone Stand

I find this one valuable. People who spend a lot of time on their computer use headphones of some kind. Having a nice headphone stand keeps your desk cleaner than usual.

65. Desk Riser

Source: Thingiverse.comThis is a nice complement to the desk you work on. If you’re starting to have neck problems, having a desk riser helps.

66. HEV Charger

This Half Life USB charger is based on the game “Half Life” and it comes with sounds from the game. This charger is used to charge your USBs. The case can be made with the 3d printer, but the full assembly requires electronic skills.

67. Watering Can

Combine your filter with this water can to grow beautiful plants. There’s nothing special about this tool, but it’s effective. I would recommend giving it multiple colors as one color can be dull.

68. Bottle Pump

There are some messy liquids out there. One of them is syrup. Having a bottle pump helps you dispense the syrup neatly. You can also use this for soap.

Try and make your bottle pump adaptable to different bottle sizes though. Another tip is to not make your pump short. This leaves room for error, and helps the pump get liquid in taller bottles.

69. Measuring Spoons

Retail measuring spoons don’t look much different compared to 3d printed measuring spoons. The set you see here can be customized sizes.

The designer here says there are 2 types of measuring spoons you can make. One that sits flatly on surfaces, and another which allows you to nest a spoon in another.

70. Children’s Chopsticks

Source: Thingiverse.comI remember trying to learn chopsticks. It wasn’t a pleasant experience. Having children’s chopsticks can be beneficial though. Think of it as training wheels. These chopsticks allow you to hold food easily by pinching the 2 sticks together with a larger surface compared to regular chopsticks.

71. Garlic Press

3d printers make a lot of useful kitchen tools. A garlic press is another example. This garlic press is made to be durable. Find the strongest filament you can find to do so.

If you plan on making this, remember to plan on making holes to the press yourself. The designer for this garlic press didn’t like the way the printer made the holes.

72. Bottle Opener

Get yourself a bottle opener if you want to be a hero at the next party. You’re going to need extra equipment to complete this project though. Those items include bolts and rubber bands. At least that’s what the designer of this bottle opener did.

73. Bag Clip

I have a couple bag clips at my place right now. These are great if you need a way to close your chip bags reliably. Nobody likes stale chips. Bag clips are a great first model for printing too. They can print in one piece and are easy to remove from the print bed.

74. Customizable Vacuum Nozzles

Some nozzles reach areas better than others. This is why you need to have customizable vacuum nozzles. You can print a set of vacuum tools, or print one that’s usable for most vacuums.

This is why you need to have customizable vacuum nozzles. You can print a set of vacuum tools, or print one that’s usable for most vacuums.

75. Soap Holder

Source: Thingiverse.comA soap holder is a must. If you’ve ever tried grasping soap in the shower then you feel my pain. Creating a soap holder with a 3d printer isn’t hard either. You can make one in hours.

Some designers use support parts to complete the holder. Most designers use one piece to create soap holders though.

76. Car Trash Bag Hooks

Perfect for long road trips. Once you’re done with your snacks, just place them in the bag which is hanging thanks to these trash bag hooks.

77. Sketch Frames

A sketch frame makes drawing super easy. It’s almost a cheat code. A sketch frame is easy to build too. You don’t need support parts, or any other extra outside parts.

78. Prosthetics

The gun printing can be viewed as bad. Being able to print prosthetics should be looked at as positive though. I’m not even going to get into details of how people get it to work because I have no clue.

I’m not even going to get into details of how people get it to work because I have no clue.

But, what I do know is this is a great step for people who need them.

79. Door Stop

Dog stops require detailed layer height. You need to make the ridges good so the stop is stable. This piece can be done in one go.

80. Dog Treat Holder

Source: Thingiverse.comYou can create a simple dog snack container. You’ll need to print 2 times to complete this holder though. This model requires multiple parts. The good news is both pieces aren’t hard to print.

81. Toothbrush Case

Toothbrush cases aren’t hard to print. The thing with toothbrush cases are they accumulate gunk quick. They should be routinely replaced. A 3d printer can print you one easily.

82. 3D Printer Scraper

Filaments can be hard to get off the print bed. Doing so the wrong way causes damage to the bed. A 3d printer scraper makes it easier to remove models from the bed. You can make one using 100% filament, or make one with a real blade at the edge.

83. Bag Holder

Now you can have a place for those shopping bags. Every household accumulates bags. We all know that one place we have.

Creating a bag holder keeps things nice and tidy.

84. Power Card Wall Mount

Create this if you hate those pesky cables on the floor. You might have to manually create the smaller holes yourself. It’s a nice addition to the office, or any place crowded with cables.

85. Napkin Holder

Source: Thingiverse.comThe design of a napkin holder can get fancy. The best ones are simple though. This napkin holder might have overhangs due to the design. You can also do a simple design. Besides, most napkin holders aren’t fancy anyway.

86. 3D Speaker Enclosure

Speaker enclosures can get elaborate. This one looks elaborate, but it’s only 2 pieces created by the 3d printer. It covers the top and bottom.

87. Hose Clamp

This model doesn’t require support. It’s a model that can be done quickly. Another thing I noticed about this hose clamp is it doesn’t require anything too detailed. Similar to the bottle opener, this is a useful yet simple design to help you around the house.

Similar to the bottle opener, this is a useful yet simple design to help you around the house.

88. Door Lock

You’ve seen 3d printers make utensils, drawers, and now door locks. This piece can be done with 3 separate prints. You have the pin with the pin holder, then the connector on the other side.

89. Dropper Bottle Flat Rack

This rack is useful for artists. You can keep your colors in this rack in an organized fashion. It can also be used for medication. Get yourself a flat rack. You can organize a bunch of items with this.

90. Candle Case

Source: Cults3d.comCandle cases are similar to vases. You can print them in different colors and designs to match the ambience of the room you’re in.

You can get a Christmas candle holder for the holidays, or a single candle case. I would opt for the single case for the first print as it’s easier to make.

91. Chess Set

Printing a chess set takes awhile. You have to print individual pieces and the whole board. Chess is one of those games that make it worth it though. A good set will last you years and bring you more joy if you give it a chance. I highly recommend this for people who want to exercise their brains in their free time.

Chess is one of those games that make it worth it though. A good set will last you years and bring you more joy if you give it a chance. I highly recommend this for people who want to exercise their brains in their free time.

92. Wall Socket

Wall sockets can be done in one print. What’s great about 3d printers is you can use different material for each product.

Find the material which works best as a protective barrier.

93. Pulley System

My cousin literally built his own pulley system a couple weeks ago. They’re great for pulling heavy things with leverage. Instead of lifting something from dead weight, use a pulley to make moving things easier. You just need 3 parts and some rope to make one.

Those 3 parts include the pulley wheel, pinwheel, and pulley housing. Here’s a pulley system model to get started.

94. Origami Inspired Forceps

This tool is something I haven’t seen. The designer says you can use this for surgery, space tools, and more.

Forceps like this make me excited for the future of 3d printers. Customizable tools are optimal for unique situations.

95. Center Finder

Source: Thingiverse.comThe more tools you make, the more products you can produce overall. A center finder is applicable for a lot of projects. This tool also helps you save a lot of time.

96. Dial Caliper

A dial caliper is a measurement tool. It measures length, height, and diameter of a specific part. The markings on this tool need to be detailed though or else it’s useless.

If you print this, make sure your printer has great precision.

97. Precision Screwdriver Racks

If you print a lot of screwdrivers, you’ll need screwdriver racks. You don’t need support parts for this either. It’s easy to make. A design like this is common for screwdriver racks.

98. Finger Wrench

You will get in awkward positions building things. A finger wrench can help you when you need to attach a nut to a bolt. Other times you’ll use it for tight corners.

Other times you’ll use it for tight corners.

99. Wrist Rest

3d printers can also make comfortable furniture. A wrist rest is essential for modern life. Think of how many times we’re needed in front of a computer. This wrist rest is made with PLA filament. Use material that are soft so your wrists are comfortable.

100. Small Windmill

Source: Thingiverse.comWindmills provide clean energy. They can get noisy, but impactful. It’ll take awhile to print one though.

Wind energy is used for electricity. Print a lot of these and you can help the whole neighborhood.

Summary

There are a lot of things you can make with a 3d printer. Please don’t think of this as the limit to what a 3d printer can do. We’re in the early stages of the 3d printer revolution. Soon, printers will be faster, and will be able to do more. The room for home manufacturing looks bright.

By Roborefuge

20 Amazing Stuff You Can Make With 3D Printers

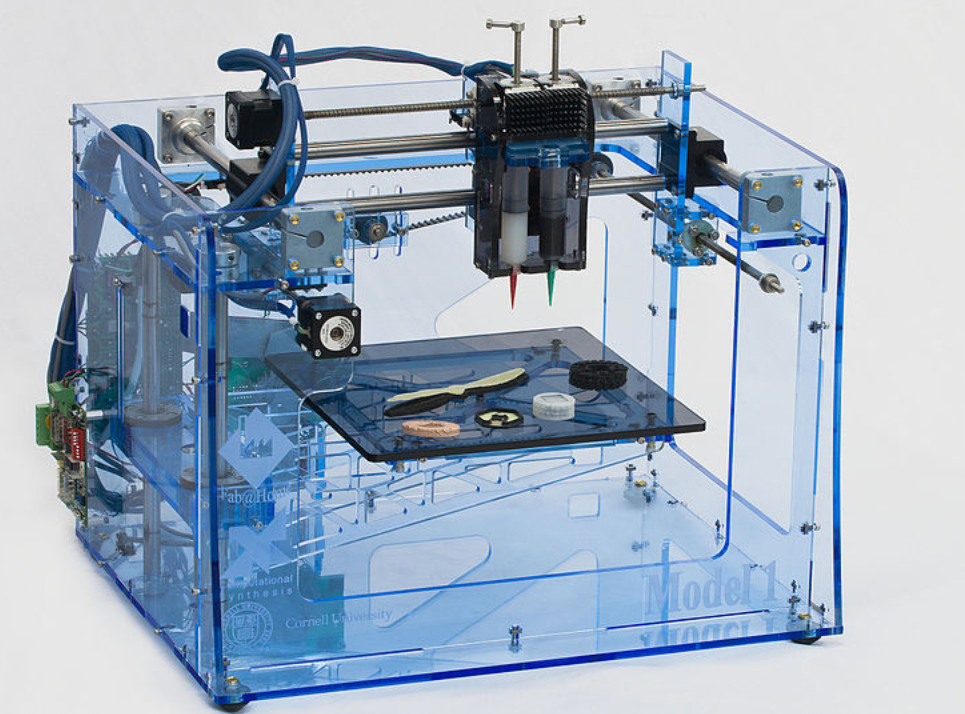

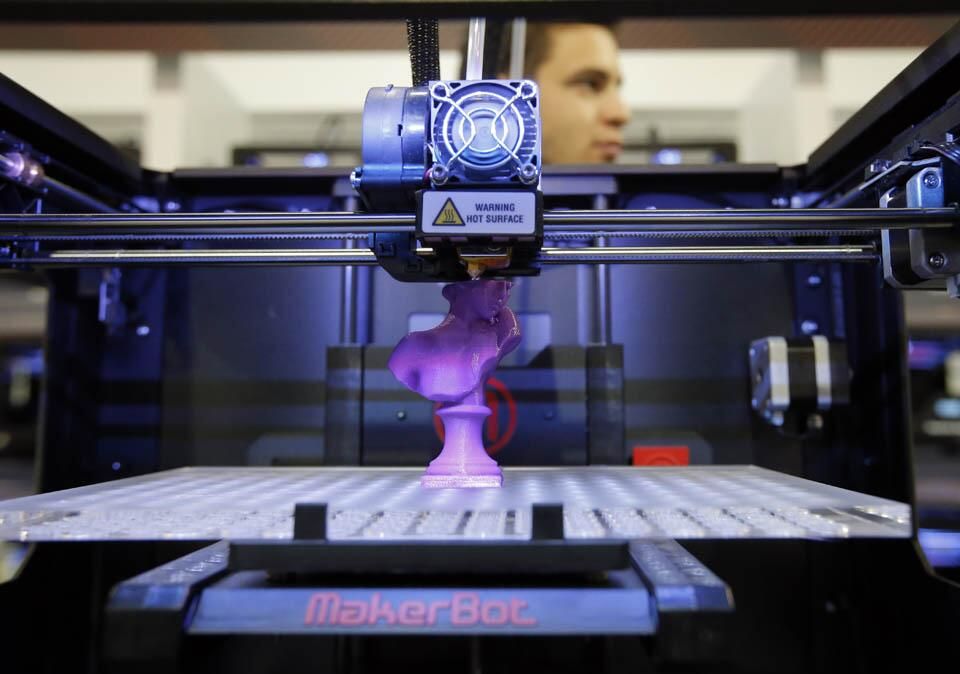

If you can print in 2D, can you print in 3D? Well, the technology is already here. You can print out 3-dimensional objects based on a working template, and they aren’t just for show. They actually work! Manufacturers can provide you with a template where you can print a broken part of a machinery, let’s say, a screw, rather than order then wait for a replacement to come in.

You can print out 3-dimensional objects based on a working template, and they aren’t just for show. They actually work! Manufacturers can provide you with a template where you can print a broken part of a machinery, let’s say, a screw, rather than order then wait for a replacement to come in.

Alternatively, you can make a model replica of an expensive car, like a 1960 Aston Martin DB5 in a 1:3 scale then crash and burn it for entertainment, like how the makers of the James Bond flick, Skyfall did.

3D printing is made possible by fusing layers upon layers of materials made from durable plastics and metals based on a template, designed with a 3D Computer-Aided Design (CAD) software. Each layer is about 0.1 mm thick and consist of liquid, powder and sheet materials.

With this technology and a 3D printer, you can create designs or print 3D models of just about anything under the sun, provided you have the templates. Just to give you a taste of what 3D printing can do, here are 20 amazing masterpieces made from 3D printing.

10 Cheap and Affordable 3D Printers to Buy

10 Cheap and Affordable 3D Printers to Buy

There was a time when 3D printers were a novelty - but not anymore. You see hundreds of... Read more

1. A Working Gun

In the past, 3D printed firearms easily break after firing a few rounds. However today, non-profit corporation Defense Distributed offers users to download the necessary files to print your own firearms provided you have a 3D printer at home.

Here’s a video of one of their creations firing at semi-auto and full-auto modes.

2. 3D Printed Acoustic Guitar

Scott Summi created the world’s first 3D printed acoustic guitar, which means the rest of us now know it can be done.

With 3D printing, guitars can be made with plastic, complete with the metal soundhole cover and heel joint. Apart from making working musical instruments, avid guitarists can also make a 3D replica of the guitars of their favorite musicians or idols.

3. Hand-made Camera Lens

A camera lens is complex to create, but with 3D printing you can make your own lens and even stumble upon some creative and unique results.

The creator of this camera lens used acrylic to replace the glass on the lens and other tools and machines to combine the many small parts together. And best of all, the lens works! Check out these few pictures taken with 3D printed lens.

4. Shakuhachi Flute

This is a beautiful Japanese flute made out of stainless steel, 3D printed. It comes with a few different finishes such as gold plated matte or glossy and antique bronze matte (pictured below). The flute is 9.4 inches long and has a tiny dragon design if you look closely enough.

You can buy this beautiful music instrument for $239.95. Can you imagine what this means for fans of fantasy movies?

5. Rigid Heddle Loom

If you’re into weaving fabric then you could create this rigid heddle loom with a 3D printer and some raw plastic material; the whole thing held together by screws. The creator used a 3D modeller program called openSCAD to design this.

The creator used a 3D modeller program called openSCAD to design this.

History class would be a whole lot more interesting when you can see actual tools of the trades from a period in time.

6. 3D Figurines From Children’s Drawings

Ever wanted to turn one of your child’s drawings into something ‘real’, from a drawing to maybe a sculpture? Well now you can, for 99 Euros. Your child’s colorful drawing can be turned into a work of art thanks to 3D printing.

The object is about 4 inches in length and can be used to decorate your work desk or home or be used as a trophy for your kid’s artistic talents.

7. 3D Fetus

"3D scans" of your unborn child is taking on a whole new meaning. Instead of a picture of your ultrasound, a Japanese company is now giving you a ‘Shape of an Angel’, a 3D print of your foetus for $1275. The 3D model is created by 3D processed image data with BioTexture.

8. 3D Printed Medical Models

When it comes to tech, science has to have a dab in it. With 3D printing, doctors would have a cheaper alternative to learn about the human anatomy and also be able to inject realism into surgery practice without the use of cadavers.

With 3D printing, doctors would have a cheaper alternative to learn about the human anatomy and also be able to inject realism into surgery practice without the use of cadavers.

Since the printing of these medical models is so accurate, surgeons can also plan a surgery on a printed model like this before the real patient goes under the knife.

9. Electric Light Shoe

This shoe filled with intricate detail and lights is 1 meter long and not a pair of shoes you can wear. It was used as an Onitsuka Tiger commercial and created with a 3D printer. The link says you can purchase it for 5879.83 Euros and keep it as a modern sculpture in your home.

10. iPhone Case & Card Holder

This creation by Janne Kyttanen might look like a well designed iPhone 5 case, but it’s really more functional than that. It can also hold two cards too.

It’s named the Mondriaan Case which is derived from the painter, Piet Mondrian, who liked the design of multiple horizontal and vertical lines. There are 3 colors to choose from for a price of $34.99.

There are 3 colors to choose from for a price of $34.99.

11. Gear Wraps

If you like to bring your gear around with you and want it to be organized neatly, then you could buy this 3D printed Gear Wraps that can save you the hassle and time of untangling your many cables.

It can be printed in a wide variety of different colors and ranges from a price of 10 to 20 Euros depending on the color you choose.

12. Infinite Sisu – iPad Stand

This stand is inspired by a Finnish concept of determination; the little muscular ‘man’ holding up the iPad is pretty hard to miss. This is definitely a work of art which you can purchase at a price of $161.

It might seem pricey for an over-glorified smartphone or tablet stand, but it’s the hefty price you pay for any kind of beautiful art.

13. Customizable 3D Printed Bugdroids

Android enthusiasts would love an Android figurine to display on their desks, but what’s awesome about these 3D printed ones is that they have custom themes to describe your personality.

There are 25 designs to choose from for a price of $21.99; if you don’t find something that describes you, there is the option to customize your own Bugdroid at a starting price of $29.99.

14. Hanging Light

From the same person who created the iPhone 5 case above, here is the Palm Lamp. Janne Kyttanen created this eye-catching work of art which comes in a variety of sizes. Use it as part of your decor, as a standing lamp, a table or ceiling light fixture.

15. Kaleidoscope Clock

Here is a two-piece 3D-printed clock, which comes in two parts, Part A and Part B. The clock is split into 2 ‘faces’, the purple numbered face and the design face behind it.

With a few instructions, you can put the two together and have it up and running in no time. The white Kaleidoscope Clock kit is available for a total of $51 or a black one for $61.

16. 3D Anatomica di Revolutis Sculptural

This work of art is the creation of one of the most recognized 3D printing designer Joshua Harker. It’s printed with polyamide, a combination of nylon and glass fused together with a laser. Check the link out for more close-up photos of this fascinating and intricate creation.

It’s printed with polyamide, a combination of nylon and glass fused together with a laser. Check the link out for more close-up photos of this fascinating and intricate creation.

17. Coffee Cups

These are espresso coffee cups printed out of Glazed Ceramics. The printing process takes almost a full day, and the One Cup a Day project aims to design and create 30 unique cups in 30 days. You can purchase their creations from this website where prices range from $36 to $77.

19. 3D-Printed Fabrics

Designer Jiri Evenhuise worked together with Janne Kyttanen to make the needle and thread obsolete by using a software that collects a person’s body data to instantly create perfect fitting clothing.

This type of technology is recyclable, requires less labor, shortens production time and ultimately lowers the carbon footprint for a greener way to create clothing. Plus, you can be sure that clothing you buy online can fit you like a glove.

20. 3D Printed Bikini – N21

This high-tech bikini is made from Nylon 12, a strong, flexible and 0. 7 mm thin material that is waterproof. Because of this, the creators said it’s ideal for swimwear and actually becomes more comfortable when exposed to water. This futuristic 3D clothing costs $200-300 and can be ordered from this website.

7 mm thin material that is waterproof. Because of this, the creators said it’s ideal for swimwear and actually becomes more comfortable when exposed to water. This futuristic 3D clothing costs $200-300 and can be ordered from this website.

What is 3D printing in 2021

3D printing technology has changed the manufacturing process of everything that surrounds us. From children's toys and clothes to prostheses, implants, etc.

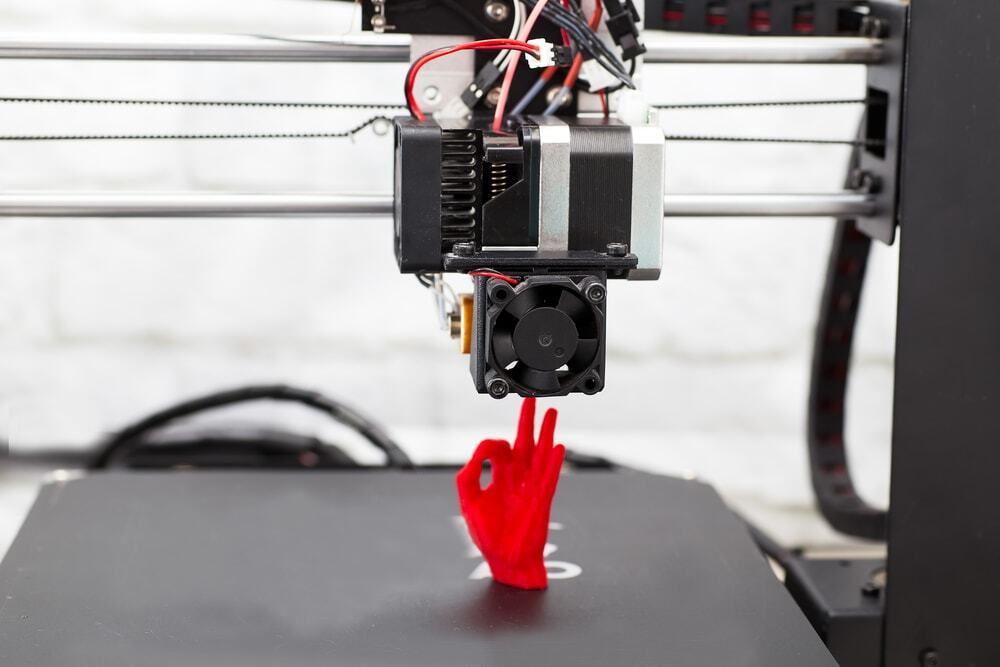

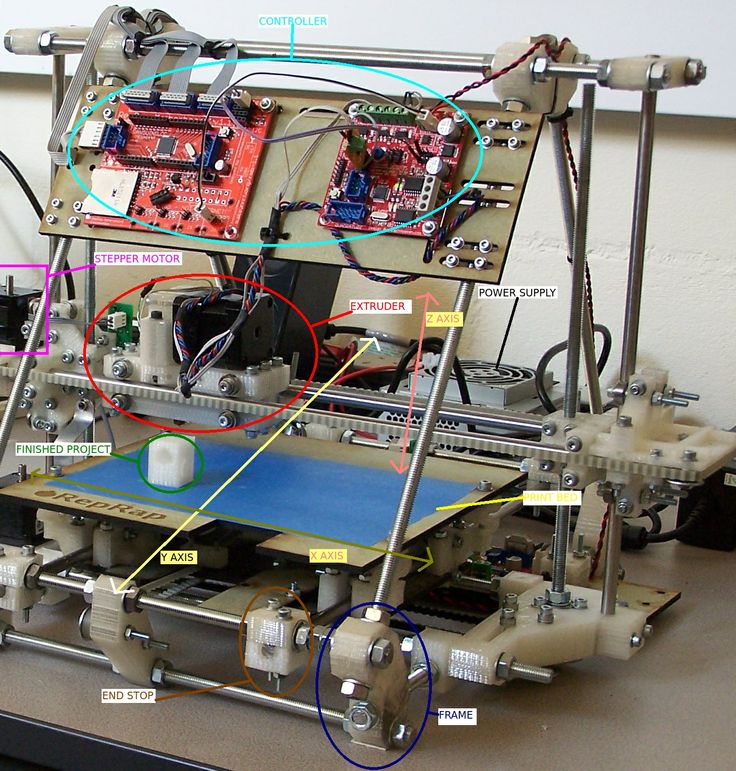

The 3D printing process is also known as additive manufacturing. In simple terms, a computer program tells the printer where to lay thin layers of material that gradually turn into a solid object.

Types and processes of 3D printing technologies

The first mention of 3D printing technology appeared in the late 1980s. They were called rapid prototyping technologies. The name refers to a process that was conceived as a faster and more cost-effective method of prototyping in product development. The very first patent application for this technology was filed by Dr. Hideo Kodama in May 1980. But, unfortunately for the inventor, the full patent specification was not submitted until one year after the application was filed. Kodama used ultraviolet light to cure plastic and create an AM object.

The very first patent application for this technology was filed by Dr. Hideo Kodama in May 1980. But, unfortunately for the inventor, the full patent specification was not submitted until one year after the application was filed. Kodama used ultraviolet light to cure plastic and create an AM object.

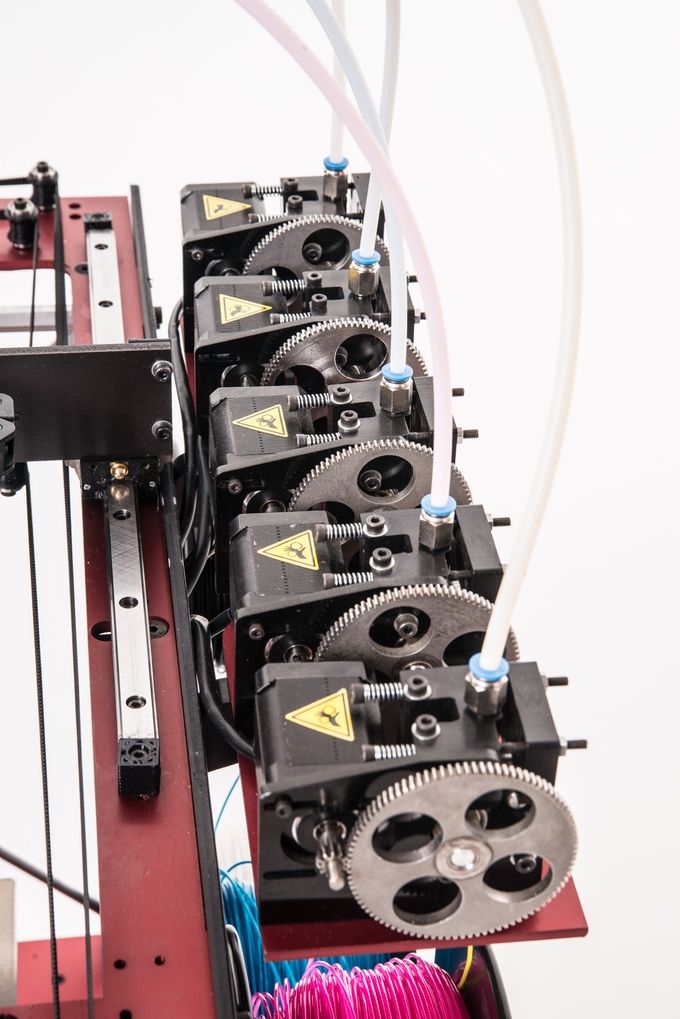

Years later, the American Scott Crumb developed the most common type of 3D printing today - FDM (Fused deposition modeling). This technology stands for deposition modeling. This type is characterized by the fact that the thermoplastic material is heated to a liquid state and extruded through the nozzle layer by layer.

Charles Hull, co-founder of 3D Systems, was one of the inventors of the 3D printing technology known as stereolithography. The technology is based on photochemical processes.

But Kodama, Crump, and Hull weren't the only ones to develop 3D printing techniques.

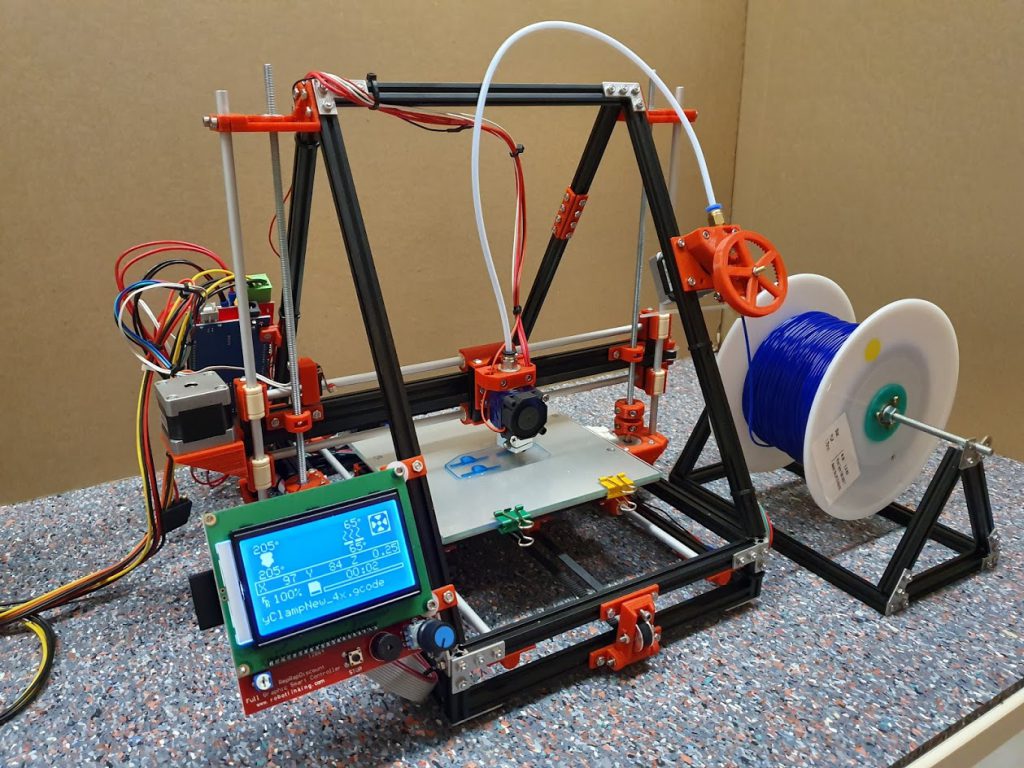

WINBO 3D printer at Art-Up Design Studio

Here are some other types of 3D printing in use today:

- FDM (Fused Deposition Modeling) is by far the most common method for producing thermoplastic parts and prototypes today.

Based on the melting of the filament in the nozzle with its subsequent laying in layers. It is also the most economical way of 3D printing due to the availability of a wide range of thermoplastic materials with different technical characteristics, which allow generating both functional parts of mechanism prototypes and volumetric cases, as well as any free spatial decorative forms.

Based on the melting of the filament in the nozzle with its subsequent laying in layers. It is also the most economical way of 3D printing due to the availability of a wide range of thermoplastic materials with different technical characteristics, which allow generating both functional parts of mechanism prototypes and volumetric cases, as well as any free spatial decorative forms. - SLA (Stereo Lithography Apparatus) is based on the layer-by-layer curing of a liquid photopolymer material under the influence of UV study. Can print objects in multiple colors and materials with different physical properties, including rubber-like parts. The high printing accuracy of this method makes it more expensive and not optimal for simple plastic structures.

- DLP (Digital Light Processing) cures polymers using a light projector rather than an ultraviolet laser. This allows you to create a whole layer in one exposure, thus increasing the speed of production.

Metals too have their own 3D printing techniques. The type of technology is selected depending on the features of the object.

The type of technology is selected depending on the features of the object.

- SLS (Selective Laser Sintering) is based on layer-by-layer sintering of polymer powder particles using laser radiation. The nylon powder melts into a strong, hard plastic. Due to the peculiarity of the technology, the surface of the part is not ideal, but very functional for use in prototypes with hinges and latches.

- SLM (Selective Laser Melting) is based on layer-by-layer sintering of metal powder under the action of a laser beam. Used in the manufacture of decorative items. Therefore, it is useful for applications in medicine and lightweight structures. Often this method is used in conjunction with traditional metal casting technology to create prototypes or final products.

- EBM (Electron Beam Melting) is based on layer-by-layer melting using an electron beam. The printing uses electromagnetic coils to superheat the metal powder in a vacuum.

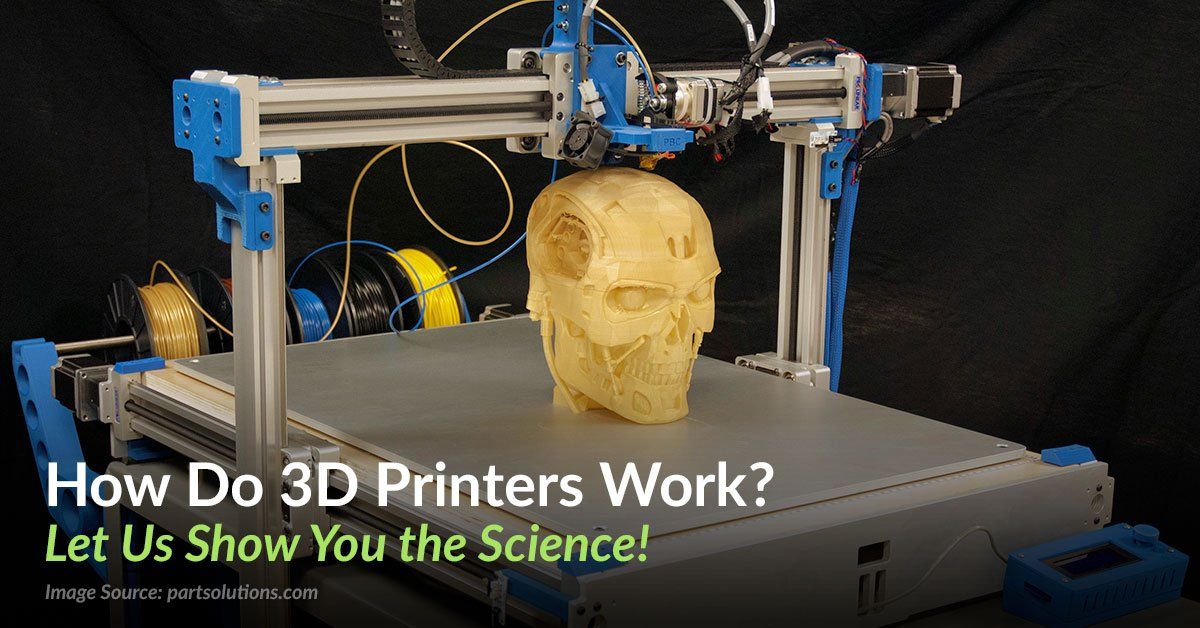

How 3D printing works

3D printing is the process of layering one on top of another. Every 3D printed object starts life as a 3D model in a computer program.

Every 3D printed object starts life as a 3D model in a computer program.

You can create your own design in programs such as Maya, Blender, ZBrush, CATIA, Solidworks. In addition, ready-made 3D models of parts can be downloaded from sites such as Thingiverse or CGTrader.

When you have a 3D model obtained in one way or another, you “run” it through the “slicer” program (from the English word “to slice”), which converts the original 3D model in STL format into print layers. The information received is eventually converted into a special data format called G-code for further printing on a 3D printer.

Such programs usually come with the 3D printer, or they can be freely downloaded, such as the Cura program. What these softwares have in common is that they create thousands of lines of code for layers. This code tells the printer how to print.

Next, you need to set up your 3D printer, select the print quality and the correct material settings. To start printing, you load your "sliced" part into the printer via a USB stick, SD card, or send directly from your computer. And the printer starts a slow additive layering process.

And the printer starts a slow additive layering process.

Photograph of Christian Rail from Pixabay

Materials used in 3D printing

The materials available for 3D printing have come a long way. Currently, there is a wide range of materials that differ both in properties, types, and in the states supplied (powder, threads, granules, resins, etc.).

Some materials are developed for specific applications to perform special tasks. For example, the medical sector, where special photopolymer resins (SLA 3D printing technology) are used, the properties of which make it possible to print implants, casts, and so on.

Some of the most commonly used materials:

- Plastics. Sintering (SLS) typically uses polyamides or nylon supplied in powder form. It is a strong, flexible and durable material. It is white in color, so it needs to be tinted before or after printing. The most common 3D printing technology today is FDM, which uses ABS or PLA plastic filaments.

These plastics are available in a wide range of colors. Compared to PLA, ABS plastic has higher strength characteristics. But PLA is biodegradable, so it's as widespread as ABS.

These plastics are available in a wide range of colors. Compared to PLA, ABS plastic has higher strength characteristics. But PLA is biodegradable, so it's as widespread as ABS. - Metals. More and more metals and metal composites are finding their way into industrial 3D printing. The most common of them are derivatives of aluminum and cobalt. Due to its strength characteristics, stainless steel is often used in powder form in 3D printing technologies such as sintering, melting, EBM. In the last couple of years, silver and gold have been added to the list of metals suitable for printing. This made it possible to significantly expand the possibilities of jewelry production.

- Ceramics. A relatively new group of materials used in 3D printing. The peculiarity of printing with these materials is that the printed ceramic parts must go through the same processes as ceramic products made by traditional methods - firing and glazing.

- Biomaterials. Currently, a large number of studies are being conducted aimed at exploring the possibility of 3D printing from biomaterials for the needs of medicine.

This includes the printing of human organs for transplantation, external tissues for replacement of body parts. To do this, leading institutions research living tissues.

This includes the printing of human organs for transplantation, external tissues for replacement of body parts. To do this, leading institutions research living tissues. - Food. Over the past few years, there has been an increase in experimentation with food 3D printing extruders. Chocolate printing is the most widely used. There are 3D printers that use sugar, pasta, meat, dough.

Photo of mebner1 from Pixabay

What 3D printing is used for

If you can think of an item, then most likely you can print it. Children's toys, jewelry, phone cases and much more are already being printed by enthusiasts on 3D printers. Some use 3D printing for fun. Fun projects already exist: a printed guitar, a loom, and an intricate sculpture created from a combination of laser-fused glass and nylon. 3D printing has already moved beyond its origins in plastic printing and has moved into the use of metal, rubber, wood, synthetic fabrics, and ceramic resins. Functional 3D-printed human organs have not yet been created, but scientists say that this is a matter of the near future.

Functional 3D-printed human organs have not yet been created, but scientists say that this is a matter of the near future.

Because additive manufacturing of complex objects is faster and cheaper than traditional molding and casting methods, it has found its way into industry and the arts. The possibilities of this technology are almost limitless, but 3D printers are not perfect machines. In addition to all the advantages, there are also reasons for concern.

Ethical issues in 3D printers

3D printers consume a lot of energy and emit ultra-light plastic particles into the air, which are then inhaled by humans. These harmful emissions can be compared to a cigarette lit indoors.

While humanity is trying to reduce the use and consumption of plastic, 3D printers are another technology heavily dependent on it. This presents a problem for all ecosystems, in particular for the already suffering oceans with their floating islands of plastic.

A few years ago, the news of the first 3D printed firearm caused a media frenzy. The creation of untraceable weapons by a private individual remains a modern security problem.

From a legal point of view, there is no clear answer to the question of who is liable in the event of harm to health caused by a printed object. Indeed, in most cases, the developer of a 3D model, the manufacturer of a 3D printer, and the one who printed it are different people or organizations. Determining liability for potential injury and death is a new challenge.

At the same time, the use of 3D printing technology in the medical field to print tissue raises a number of ethical and moral questions. These issues are similar to the talk of stem cell research and gene editing that has been going on for decades.

On the other hand, we have a powerful tool in our hands that is changing the way we create and produce things. We still don't fully understand what this means for our future.

Potential effect on the global economy

If 3D printing continues to develop at the same pace as it is now, then its use could potentially affect the global economy. The transition of production and distribution from the current model to localized custom manufacturing can reduce the imbalance between exporting and importing countries.

3D printing is creating new industries and new professions. Professions related to the production of 3D printers or, for example, a vacancy for a rapid prototyping technician at the Cartier jewelry house. New professional services are emerging, such as supply of materials, printer operator, legal services in dispute resolution and intellectual property issues. With the development of 3D printing technology, the issue of "piracy" becomes an urgent problem.

The impact of 3D printing on developing countries is a double-edged sword. The positive effect for such countries is the reduction in the cost of production through the use of recycled and other local materials. But the loss of manufacturing jobs could hit these economies hard, and it will take time to find a balance.

But the loss of manufacturing jobs could hit these economies hard, and it will take time to find a balance.

Where can I use a 3D printer

Owning a 3D printer with the necessary software and materials can still be expensive for individual needs, so public 3D printers are becoming more common.

There are places like labs and 3D printing shops. You can send your design and pick up the finished part in a couple of days. Some companies, such as ART AP Design Studio, also do 3D printing.

If you are a student or student, 3D printing services may be available at your school.

Printed products in Art-Up Design Studio

Where can I learn how to use a 3D printer

For those who already have the specialty of an engineer, there are advanced training programs (Additional education) from the Russian Academy of Crafts, designed for 36 or 72 academic hours.

The training course in an accessible lecture form reveals the theoretical and practical foundations of design, three-dimensional modeling, design of plastic products. It provides for the performance of work and tests within the framework of the design tasks of the course and the final exam.

As a result of mastering the program, the trainee receives a certificate "Specialist in Additive Technologies". Profession Code 15.02.09

If you are just starting out, you can find vocational training programs with 144 academic hours.

It is important to understand that the basic knowledge is obtained in practical exercises on real equipment. For example, you can get up-to-date skills using modern equipment at the SKOLKOVO Technopark at the production base of the CUC OOO Design Studio ART AP, which is the anchor partner of this educational program.

As a result of training, the student of the course "Specialist in additive technologies" independently solves the following professional tasks:

- modeling and design of plastic parts,

- fundamentals of aesthetics in the design of industrial products,

- features and types of 3D printing equipment,

- preparation of the model for 3D printing,

- setting up and launching a 3D printer,

- features of printing from various materials,

- post-processing of 3D printing results,

- Product assembly.

Investing in yourself is the most profitable and rewarding investment.

Nikita Pelevin, Alexey Kutyaev for the Russian Academy of Crafts

On the cover of the article ZMorph4D photo from Pixabay

13 notes about 3D printing, after 3 years of owning a 3D printer / Habr

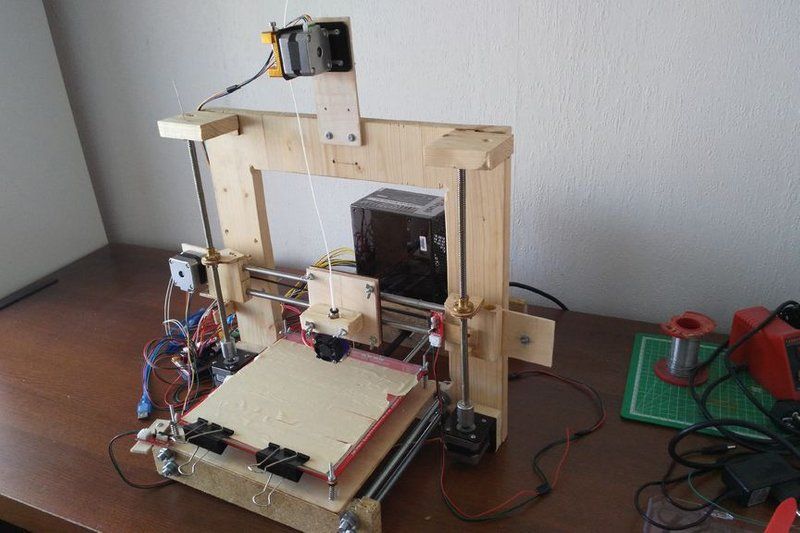

This article will be, first of all, of interest both to those who have directly dealt with 3D printing, that is, who owns a 3D printer, but also to those who are just about to join the ranks of 3D printers and are thinking about buying their own printer. As part of this article, I would like to share my observations, as a direct owner of a 3D printer, for more than 3 years.

Despite the fact that 3D printers have been known for a long time and, in my memory, have become widely used, judging by the information on various resources, starting around 2010 (I may be wrong, these are my subjective observations), for a long time I ignored this area, it’s hard to say why…

Probably, he considered it some kind of “childish pampering”, another hype topic, for which there is simply not enough time…

The break happened when one of the wheels on my travel suitcase wore out. You know, a big plastic suitcase, with four spinning wheels on the bottom. Unfortunately, it is a “rather disposable thing”, due to the lack of bearings on the wheels, which is why the wear of the friction point of the axle and wheel allows the suitcase to last no more than one or two seasons.

You know, a big plastic suitcase, with four spinning wheels on the bottom. Unfortunately, it is a “rather disposable thing”, due to the lack of bearings on the wheels, which is why the wear of the friction point of the axle and wheel allows the suitcase to last no more than one or two seasons.

And it’s like “lightning flashed in the middle of the day: 3D printer!” It is with his help that I can fix this problem! Looking ahead, I’ll say that I didn’t succeed in fixing the suitcase in this way, so I had to use a different approach ...

As a result, I "upped" him - by installing wheels from unnecessary roller skates. Thanks to this “up”, the suitcase has become a real all-terrain vehicle and, even being very loaded, it rides easily - pushed forward even with “one finger”. And even in the snow, 5-6 cm thick. A tank, not a suitcase turned out! By the way - I took spinning wheeled "units" in Leroy. Then he took off and threw out his native plastic wheels from there, inserting from roller skates:

But this thought itself became a kind of trigger that allowed me to finally join the world of printers and buy my first 3D printer.

Like many, before buying it, I studied various forums and sites for a long time, delving into all the subtleties. And for some reason, I immediately liked the type of printer called the delta printer. Probably because during operation it looks like some kind of "alien device".

If at your leisure you like to sit “looking into the carpet”, then with the advent of such a printer you will have a much more interesting activity, even, one might say, hypnotizing :-))

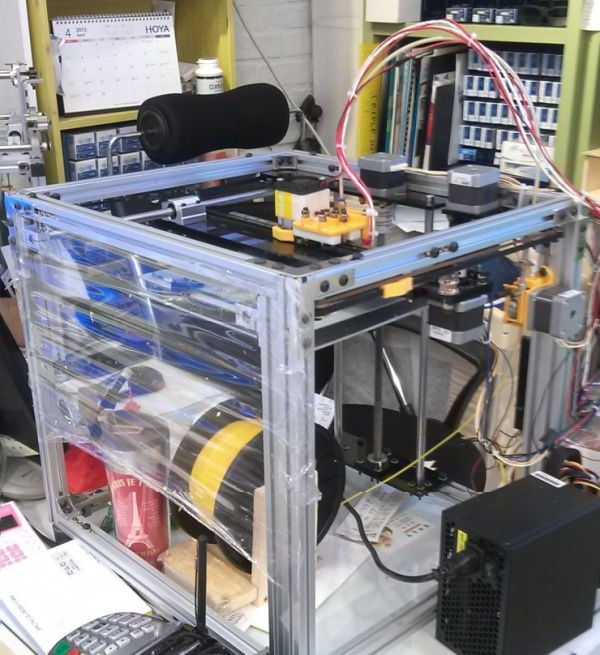

And this, in fact, is my delta (if anyone interesting), which went, let's say, "ultimate up": all the electronics were placed upstairs, on a self-made welded frame, covered with polyethylene and a magnetic door was made. The coil with a bar is installed at the top, on the frame. The axis on which the coil is put on is machined on a lathe from aluminum and a bearing from the VAZ timing is inserted into it. As a result, the coil - "rotates even from the passage of a fly nearby":

Well, yes, I won’t argue for a long time, let’s start reviewing the main facts that I have accumulated as a result of owning this car . .. The facts are purely subjective and may differ from your vision. In any case, I will be glad to comments, clarifications, etc.

.. The facts are purely subjective and may differ from your vision. In any case, I will be glad to comments, clarifications, etc.

▍ NOTE 1. Delta is good, but...

Here I should give a number of my observations regarding the delta printer:

- It contains a completely finished frame of the future box, which makes it easy to form a heat chamber. I understand that many printers are made in the form factor of a “certain box” (but this point cannot be ignored), which greatly facilitates the process of wrapping this box with heat-insulating material. In my case, as such a material, I used a plastic film.

- Already thanks to its design, delta allows you to work at much higher speeds than XY printers. By the way, it is on the delta principle that many modern high-speed industrial robots are built to sort various parts directly on the conveyor belt:

However, this plus does not allow to fully realize the occurrence of parasitic vibrations, even despite their suppressors:

Thus, accurate printing is possible, only at speeds (at least that was the case for me), no more than 60 mm per second. A complex procedure for aligning the movement of the head parallel to the table, which is why, for many, the so-called "lens" appears. People struggle with it with varying degrees of success, but I have not encountered this on my printer and for me, therefore, the “lens” has never been a problem. At the same point, it is worth noting the calibration of the table, which was initially absent on the first deltas, and I had to use an external third-party solution from one American do-it-yourselfer called EZBED. This solution was a hardware-software complex that allows you to quickly and easily calibrate the printing table, that is, to let the printer understand its geometry. Modern printers do not have this issue as they come with a built-in calibration solution. It is worth noting that I solved this problem by attaching a limit switch to the print head, and using the Marlin-1.1.9 firmware.

A complex procedure for aligning the movement of the head parallel to the table, which is why, for many, the so-called "lens" appears. People struggle with it with varying degrees of success, but I have not encountered this on my printer and for me, therefore, the “lens” has never been a problem. At the same point, it is worth noting the calibration of the table, which was initially absent on the first deltas, and I had to use an external third-party solution from one American do-it-yourselfer called EZBED. This solution was a hardware-software complex that allows you to quickly and easily calibrate the printing table, that is, to let the printer understand its geometry. Modern printers do not have this issue as they come with a built-in calibration solution. It is worth noting that I solved this problem by attaching a limit switch to the print head, and using the Marlin-1.1.9 firmware.

▍ NOTE 2. "Size is not the main thing..." :-)

When I got the printer, I was impressed by the possibility of huge printouts, a la the handguards of some futuristic rifles, huge body parts, etc.

However, if you try to analyze the results of your many years of practice, it turns out that in most cases, rather small objects were printed that easily fit in the palm of your hand, a maximum of two palms. Despite such a seemingly small size, the printing of these details took a significant amount of time. Of course, this very much depends on which nozzle you print with. But, despite this, it is difficult to disagree with the fact that most of the printed parts will be quite utilitarian and small in size.

Therefore, to be honest, the need for a printer that allows you to print "Venus de Milo in life size" is not obvious.

Of course, you can object to me that “I’m going to buy a printer, I’ll get used to it a little and I’ll get started!!!”

One simple point must be taken into account here: there are no universal things. And in order to understand how much 3D printing in general and your printer, in particular, you will need to solve your problems, and how much it will be able to solve such problems, you just need to first try the 3D printing method personally and then a lot will become clear to you .

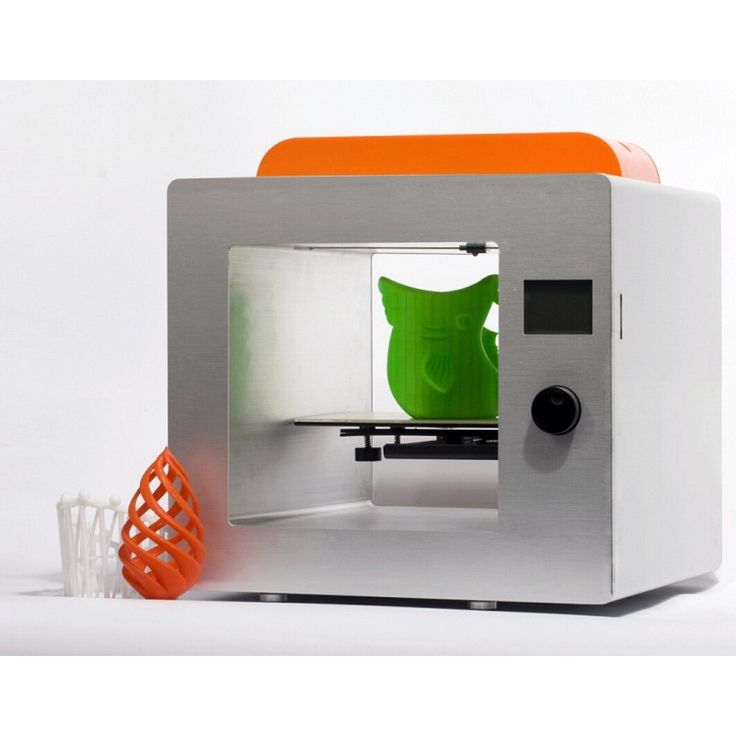

Therefore, for a beginner, I recommend taking a small printer that allows you to print extremely small items that fit in the palm of two. With such a device, you will definitely never lose, as it will always be needed. In addition, with its help you will be able to get used to the printing process and, if necessary, purchase a larger device, already clearly understanding its capabilities and ability to solve your set of tasks.

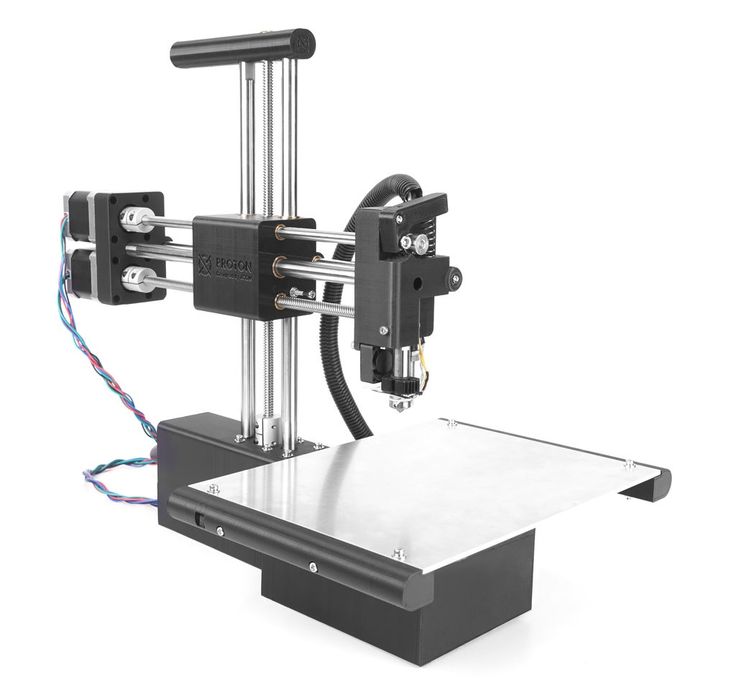

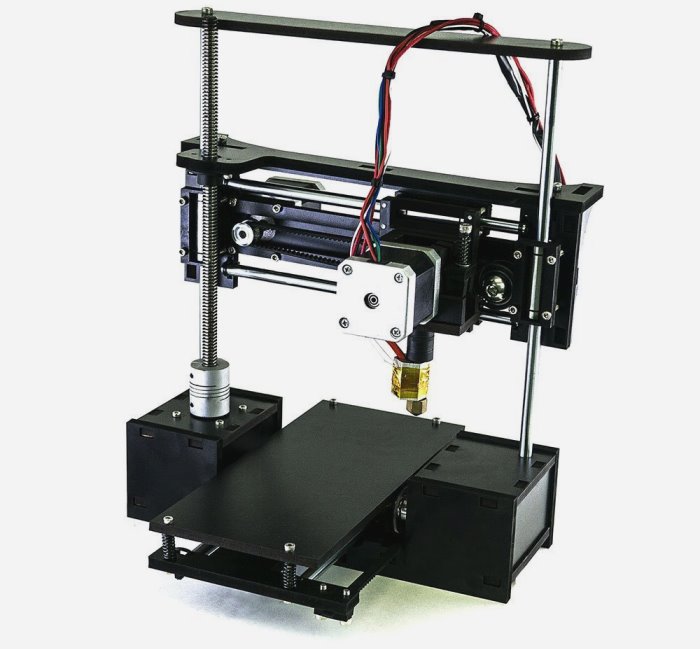

▍ NOTE 3. "What type of printer to get."

Based on the foregoing, I do not recommend taking a delta printer and this can be said right away.

Not because it is bad, in fact, it prints quite accurately, its main problem (in my opinion) is the inability to print rectangular flat, fairly large case components, as well as the inability to fully realize high-speed work, since the quality drops critically. Here it turns out to be a rather offensive situation - the printer can work quickly, but this cannot be done, since the quality will be “nothing”.

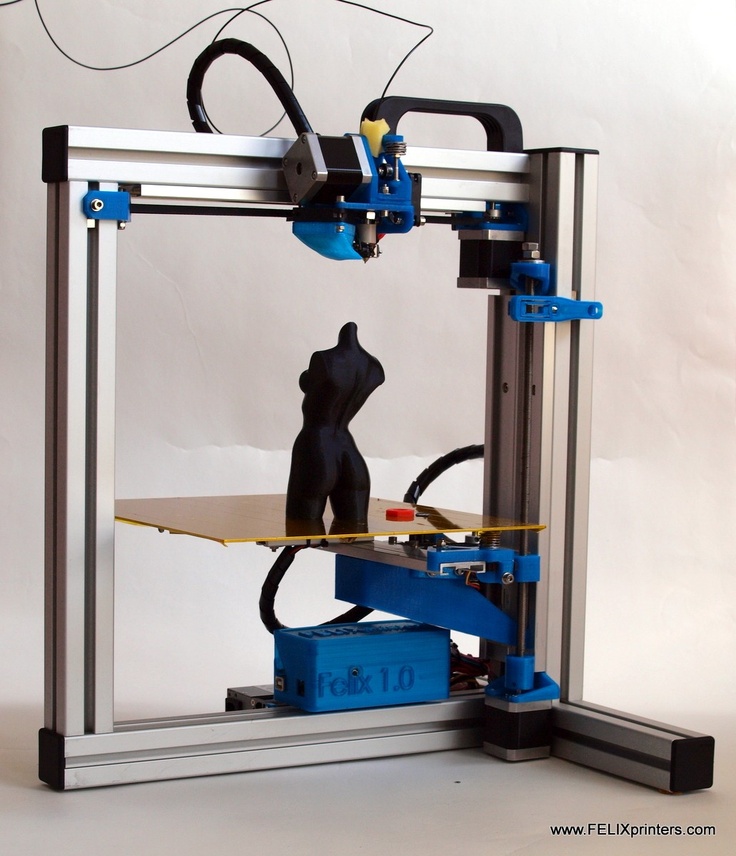

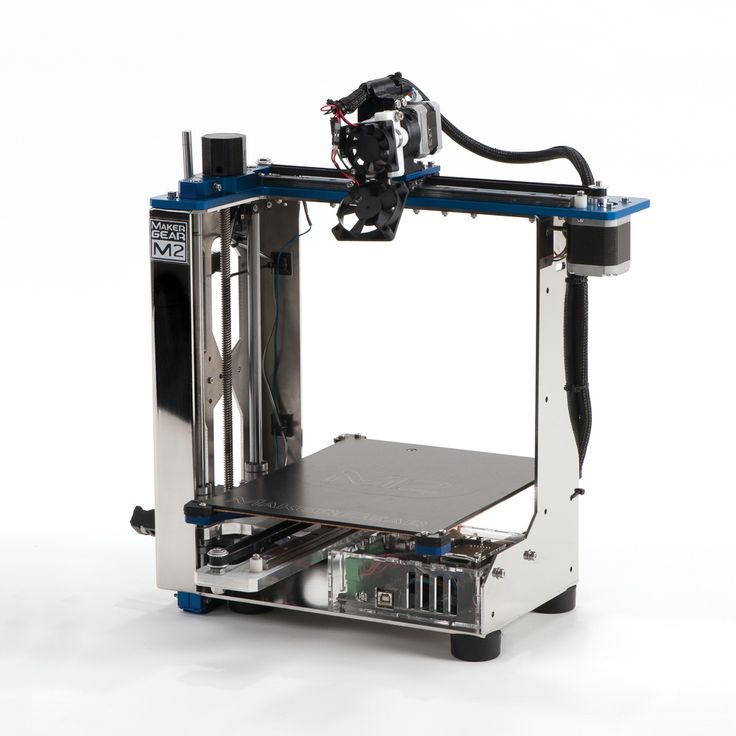

And then what kind to take? Depending on the budget and capabilities, I recommend taking any cube printer, for example, the same Core XY (the head moves, and the table goes down as the model “grows”, from top to bottom):

Image source: thingiverse.com

Such a printer allows you to easily print fairly large flat parts of cases, has good speed and accuracy. In addition, the presence of a rigid box-shaped frame allows it to be easily covered with polyethylene to create a sealed heat chamber. In addition, the very fact that the table does not move while working reduces the number of problems with model peeling.

However, the advantages of this printer will not be fully revealed if it has a direct extruder. On the one hand, it will allow printing with rubber-like materials, on the other -

large inertia and head weight. And these are parasitic vibrations, wear of the fur. parts, etc. (like everything in life, “we treat one thing and cripple another” :-))

At the initial stages, this may not be necessary, but in the future it may be necessary to print, for example, tires for your homemade car. And with this, the Bowden extruder has obvious problems. Although, in fairness, printing with such a rubber-like material is far from a daily need. However, whoever seeks will always find: over time, I found a way to “upgrade” my printer with a Bowden extruder to print with flexible materials. "Crutches" of course. But even so.

And with this, the Bowden extruder has obvious problems. Although, in fairness, printing with such a rubber-like material is far from a daily need. However, whoever seeks will always find: over time, I found a way to “upgrade” my printer with a Bowden extruder to print with flexible materials. "Crutches" of course. But even so.

By the way, there are printers of a cheaper type, the so-called "drygostol", printing by moving the table and head:

They are inexpensive, moderately accurate, but they require a sufficiently high-quality gluing of the printed model to the table, because the table moves, and the model can come off when the table is jerked sharply. When printing large models, this can be a problem.

▍ NOTE 4. What to print with?

It's only a matter of taste and purpose. That is, if your printout will only stand on a shelf and should differ in some kind of aesthetic appearance, these are some requirements, if the printout is an engineering part that will be operated under conditions of increased mechanical load, these are different requirements. That is, in the first case, you can use any PLA, SBS plastics, and others with similar properties.

That is, in the first case, you can use any PLA, SBS plastics, and others with similar properties.

For engineering parts, for example, I only use ABS. It combines high hardness, strength and low price. Although I understand that now this last statement will cause a storm of comments in the style of “no! - there is even stronger, even better, the same PETG, etc. ":-)

Just here I wanted to say that thanks to the low price and the practical experiments that I conducted with ABS plastic, I realized that it is completely meets all my requirements.

However, the fact that ABS plastic releases carcinogenic substances when heated is quite annoying and forces you to take measures to prevent poisoning. For this, my printer prints completely closed and on an open balcony. After printing, the printer chamber opens, and it remains open in this form until it is completely ventilated and cools down.

▍ NOTE 5. "ABS is difficult to type on, it separates, peels off the table, and in general.

.."

.." With a properly configured printer (in my case, at a print temperature of 205 degrees, a thermal chamber and a desktop temperature of 100 degrees), the use of auxiliary techniques, for example, among which, one can name the so-called ABS juice (which is ABS- plastic dissolved in acetone), you can create wear-resistant and durable things, without any hypothetical problems.

For example, my printer has been printing for many hours at temperatures well below freezing. And this happened more than once, not twice, not three! And the quality of the printouts was excellent:

12-hour ABS printing at -4 C

▍ NOTE 6. Acetone for post-processing and ABS juicing

At one time, I wrote a fairly detailed article on this topic and I will try to give the main excerpts from it. The essence of the issue here is as follows: due to the fact that different GOSTs are used for the production of acetone, acetone differs in quality. Despite the fact that it would seem that “acetone is also acetone in Africa,” nevertheless, one type of acetone can differ significantly from each other. For example, ordinary acetone, which can be bought at any hardware store, such as "1000 little things", "store near the house" and the like, is very low quality acetone, smells disgusting (although someone like it, maybe someone likes its pleasant building aroma and "aftertaste" :-))).

Despite the fact that it would seem that “acetone is also acetone in Africa,” nevertheless, one type of acetone can differ significantly from each other. For example, ordinary acetone, which can be bought at any hardware store, such as "1000 little things", "store near the house" and the like, is very low quality acetone, smells disgusting (although someone like it, maybe someone likes its pleasant building aroma and "aftertaste" :-))).

In contrast to it, there is a much higher quality acetone, which, however, is not found at all in any household stores, even large chain stores, such as Auchan or Leroy Merlin.

This type of acetone is found exclusively in shops that sell varnishes and paints for automotive work, i.e. these are highly specialized shops for car workshops:

Acetone, which can be purchased there, is of excellent quality, smells almost like alcohol, quickly disappears,

:-) - this is a joke, of course, don't even try it.

However, its main advantage, compared to household type acetone, is that it perfectly dissolves ABS plastic and does not allow it to precipitate. For me personally, it was a very surprising observation when the same ABS plastic was perfectly dissolved with acetone from an auto shop, and completely precipitated when I tried to use household acetone (I just ran out of good acetone, and I had to use "what is ").

Therefore, if you want your results to always be excellent, then here is the right acetone. It should be labeled "for professional use":

▍ NOTE 7. What about ABS juice?

"ABS juice" is what printers call a mixture of acetone and pieces of ABS plastic dissolved in it. This mixture is smeared on the surface of the desktop before printing and allowed to dry. Thanks to this spread, the model easily sticks to the desktop and does not peel off during the printing process. After printing is completed and the platen has cooled down, the model can be easily separated.

All that needs to be said here is that, after trying different approaches over time, I settled on using flexible metal spatulas, also called "Japanese type spatulas":

According to the results of many tests, this method of spreading turned out to be one of the most convenient options, such spatulas can be cleaned very quickly and easily after work. In other words, highly recommended!

▍ NOTE 8. "Yes, nothing sensible can be done on it, I indulged a little and decided to sell it - you can't use it for anything good anyway"

I absolutely disagree with the statement above, which is periodically heard from newcomers to 3D printing. You can even say more: at the moment I can’t even imagine how I used to live without a 3D printer! Since it is he who makes it possible for any do-it-yourselfer to significantly expand their capabilities and make piece products, almost of factory quality! Of course, for this, appropriate hands must be applied to the 3D printer, but that’s another question… and take on things that I would never have thought to take on before!

For example, among my homemade products, the following can be listed:

- Heated sole for shoes, which is a hose integrated into the insole (and filled with household silicone from a household store), through which water flows, heated with a catalytic type hand warmer.

Water is pumped using a small peristaltic pump. The engine with a metal gearbox, which is used in the creation of this pump, allows you to develop a force of 3 kg, which is even redundant for this homemade product. The engine is powered by Peltier elements mounted next to the catalytic heater. The project is currently in progress.

Water is pumped using a small peristaltic pump. The engine with a metal gearbox, which is used in the creation of this pump, allows you to develop a force of 3 kg, which is even redundant for this homemade product. The engine is powered by Peltier elements mounted next to the catalytic heater. The project is currently in progress.

- Centrifugal water pump mounted on the shaft of an internal combustion engine that drives a high pressure wearable air compressor with a pressure of 500 bar. The pump pumps coolant through the casing of the high pressure pump, or rather its second stage. Despite the fact that the pump is 3D printed and runs at over 6000 rpm, nothing “fell apart, fell apart, didn’t break.” As you can see in the photo, the pump is installed instead of the “starter”, that is, the armstarter. The compressor scheme as a whole is as follows: 2 engines. Connected by clutch. One is heavy duty. The second is modified and turned into a high pressure compressor:

Yes, before assembling this, I also did not believe that this was possible. Moreover, even when I collected it, I did not believe my eyes :-))). However, it is a fact…

Moreover, even when I collected it, I did not believe my eyes :-))). However, it is a fact…

- I printed a number of Rank-Hilsch test tubes, the essence of which I have described in detail in this article.

- Printed mass of parts, more than 100 pieces, to create 10 web-controlled robots. There was also a detailed article about this here.

Well, and a bunch of all sorts of useful and not very crafts. As you can see from my crafts above, I have a special passion for creating some useful things, a utilitarian direction. That is, so that the printout is useful, and does not belong to the type “yyy breathe, Mikola, what am I doing here” :-), and then put it on the shelf and that's it. Although, engineers are also not alien to beauties, and this will be my next fact below.

▍ NOTE 9 Proper placement of the model when printing is half the battle

It would seem an obvious fact, but many underestimate it. Here I mean the following: by experience, I accidentally discovered that when printing various statues (in which I, completely unexpectedly for myself, discovered another passion of mine), it is advisable to place the statues at an angle to the printing table.

Here I mean the following: by experience, I accidentally discovered that when printing various statues (in which I, completely unexpectedly for myself, discovered another passion of mine), it is advisable to place the statues at an angle to the printing table.

This allows the layers in the printout to run at an angle of approximately 45-50 degrees to the model. The result of this is that the printed model is almost completely invisible layers and the model looks like it has been post-processed, but at the same time retains a deep matte color, which, to my personal taste, is more like a marble than a glossy result of processing in an acetone bath :

An additional advantage of this method is that the layers going at an angle of 45-50 ° to the model give it additional strength. This is especially true for printing statues, which contain many thin elements that are easily chipped when the statue is accidentally dropped from a table or shelf (learned from bitter experience, this happened to me many times, and ruined some fairly decent prints).