How long does it take to 3d print something

How long does 3d printing take?

You're on a very tight deadline and you're probably wondering how long would it take to 3D print your 3D model.

Here's our short answer to that:

On average, 3D printing an object can take anywhere from 30 minutes up to 12 hours to print. Sometimes, it can even take several days depending on how large and detailed your 3D model is.

Why does 3D printing take so long?

First, it depends on your 3D model that you want to 3D print.

Larger and more complex designs take longer to 3D print than smaller and simpler objects. Higher quality 3D prints would also take longer to 3D print.

As you can see there are many variables that can affect the time it takes to 3D print.

The time it takes to 3D print depends on multiple factors such as the type of 3D printing technology, material, size of your 3D model, and any post-processing you wish to do.

In this article, we're going to break down each factors so you can have a better understanding of how long it really takes to 3D print an object.

Factors that affect the time it takes to 3D print an object

3D model

This one is fairly obvious. As mentioned earlier, more complex or larger 3D models would take longer to 3D print compared to much simpler designs. The time it will take to print something can be hard to predict, without a 3D model.

The volume of your 3D model is also a factor. Hollow models are faster to 3D print than models that are solid inside. This is because the 3D printer's nozzle or laser (depending on your 3D printer) would need to travel around the whole object if it's solid. The less surface area it needs to cover, the faster it takes to 3D print.

Layer height and layer thickness

The higher the layer height, the longer it will take to 3D print an object. Similarly, a print with a lower layer thickness takes longer to 3D print.

3D Printing Technology

Different 3D printing technologies also affect how fast your 3D print will finish.

Let's take this miniature figurine for example and see the different 3D printing speeds based on the technology being used.

| 3D Printing Technology | 3D Printing Time For A Miniature |

| SLA 3D Printing | ~ 5hrs |

| LCD 3D Printing | ~ 4hrs |

| FDM 3D Printing | ~ 6hrs |

LCD 3D printers tend to 3D print faster compared to SLA 3D printers. While SLA and LCD 3D printing are faster than FDM when 3D printing a complex part or a large object. When it comes to 3d printing simple objects, FDM might have a slight edge.

Again, 3D printing speed can vary and your 3D model matters.

3D printing settings

Your 3D printing settings also matter when it comes to the the time it takes to 3d print. If you want more accurate, high quality 3D prints then choosing a slower print speed might be a better option for you.

Better quality means sacrificing speed for accuracy. So if you need a high quality part, then you need to to forget about printing speed and focus on the result.

So if you need a high quality part, then you need to to forget about printing speed and focus on the result.

Post-processing

The 3D printing process doesn't end when it comes out of the 3D printer. We wish it does because it would make our lives so much easier. But in most cases, you still need to clean the resulting print to make it work.

Here's what a typical post-processing looks like:

Remove the supports

Cure the print. (For resin 3D prints)

Start polishing

Post-processing time for FDM 3D prints

Approximate time: 4-24 hrs depending on complexity

Polishing can take forever for objects printed using an FDM machine. We've experienced this first hand. It took us a full day of work just to polish a simple art sculpture and we still ended up with those annoying lines that you see on low quality ABS/PLA 3D prints. To add salt to the wound, removing supports was time consuming as well.

Post-processing time for SLA 3D prints

Approximate time: 2-8 hrs depending on complexity

Compared to FDM, the 3D prints from SLA 3D printers are easier to clean and polish. Objects that used to take us several hours to polish (by hand) would only take a 20 minutes or less with a resin 3D print.

Although 3D prints from an SLA machine requires UV curing, it's less labor-intensive as we usually leave it in a UV oven after cleaning the resin with alcohol.

Post-processing time for SLS 3D prints

Approximate time: 0-2hrs depending on requirements

One of the caveats of additive manufacturing is that supports are usually required in order to print an object. Without them, your 3D print will likely fail.

SLS 3D printers, however, do not require any supports which makes them faster and easier to work with when it comes to post-processing. This makes them popular among on-demand 3D printing companies like Shapeways or 3D Hubs because it doesn't require a ton of labor.

Keep in mind though that SLS 3D prints are rougher than SLA prints, so if you require smooth finishing then you need to take that into account as well.

Finishing touches for your 3D print

Metal finishing

Approximate time: 2 - 3 weeks

Metal finishing can also add time to your 3D printing processes. Want it gold? Chrome? It can take an additional 2-3 weeks as metal plating 3D prints requires a delicate approach as sometimes there is no room for error. A casting house would need to redo the whole process again. So if you're in a rush, getting 24k gold or other metal finishing might be out of your option.

Painting

Approximate time: 1 day - 3 weeks

Painting a 3D print requires less time than metal finishing so this might be a good alternative if your on a tight deadline. Again, it depends on the complexity of your project. If you require a very detailed, multi color painting, then that would take longer. But if you want it in one color, then that would take less time.

But if you want it in one color, then that would take less time.

With that in mind here are some ways to speed up your print time based on the factors that we mentioned.

How to speed up your 3D printing process

Keep in mind that there are tradeoffs when trying to speed up your 3D printing

Optimize your 3D printer settings for speed. You might lose quality and increase your risk of failure so be careful with this.

Scale down your 3D model. If size don't really matter then 3D printing it at a smaller scale would decrease the time it takes to print

Print all of them at the same time. If you have a large enough 3D printer, then you might be able to get away with 3D printing your parts next to each other.

Hire a professional 3D printing service to save you time. 3D printing companies like us can do 1-2 day turnaround depending on your project.

We also have large scale 3D printers that can print multiple parts at the same time.

We also have large scale 3D printers that can print multiple parts at the same time.

Frequently asked questions

These are some of the questions that our clients keep asking us, so we've summarized them for you.

How long does it take to 3D print a miniature?

It can take approximately 3-4 hrs for 28mm miniatures to 3D print. For large miniatures, it can go up to 12 hrs and sometimes, even more. It also depends on how accurate you want your 3D printer to print. More accurate prints would mean a slower 3D printing time.

How long does it take to 3D print a phone case?

Contrary to popular belief, 3D printing a phone case is not economical because they can take awhile to 3D print. A phone case can take anywhere between 3-8 hrs to 3D print depending on the complexity of your design and your chosen 3D printing technology. If you're planning to sell 3D printed phone cases, take this into account as it will affect your pricing.

In Summary

There are many factors that affect the time it takes to 3D print something, that's why how long it takes to 3D print varies on a project basis. If you're only counting the time from loading it in a machine, it can take between 30 mins up to 12 hours or even days to complete. And if you take into account the additional time it takes to make your 3D print functional or aesthetically pleasing, then 3D printing would take even longer.

If you ever need a 1-2 Day turnaround 3D printing, check out our 3D printing service to see if we're the right fit for your 3D printing needs.

How Long Does 3D Printing Take?

3D printing a part can take anywhere from 30 minutes to 7 days or more. There are a several factors that dictate how long it takes to 3d print a part. These include the overall size and geometry of the part as well as the 3D printing technology being used. The larger the part or the more complex the geometry, longer it will take to 3D print.

However, we can offer a quick and dirty answer by providing a few reference points. The parts above represent the typical size and shape of parts that we 3D print here at 3 Space and should provide you with a general idea of how long it might take to 3D print your own parts. Of course, this is just an estimation. Read on to learn more about the various factors that dictate build time for various 3D printers.

Part Size

Taller parts will usually take longer to 3D print than shorter parts, even if their volume is the same.Volume

Several factors dictate how long it takes to 3D print a part, but the volume of the part is usually the first indicator. As a general rule, the larger the part the more time it will take to print. We’ve seen small parts (about 1 cubic inch) take as little as 5 minutes to 3D print, while very large parts (100+ cubic inches) can take upwards of 200 hours.

Footprint (XY)

The part’s footprint, or the area it occupies on the build surface, plays a role in determining the time to 3D print. The larger the footprint, the farther the print head has to travel from its home position to complete each layer.

The larger the footprint, the farther the print head has to travel from its home position to complete each layer.

Height (Z)

While the overall size and footprint important, the build height of a part is probably the single most important dimension in determining how long it will take to 3D print. A part that is 4x4x8” will typically take longer to 3D print than a part that is 5x5x5” even though they are roughly the same volume. That’s because the taller part will have more layers and the print head will therefore have to make more passes to create them. Barring wildly different geometry, each layer should take roughly the same amount of time to print.

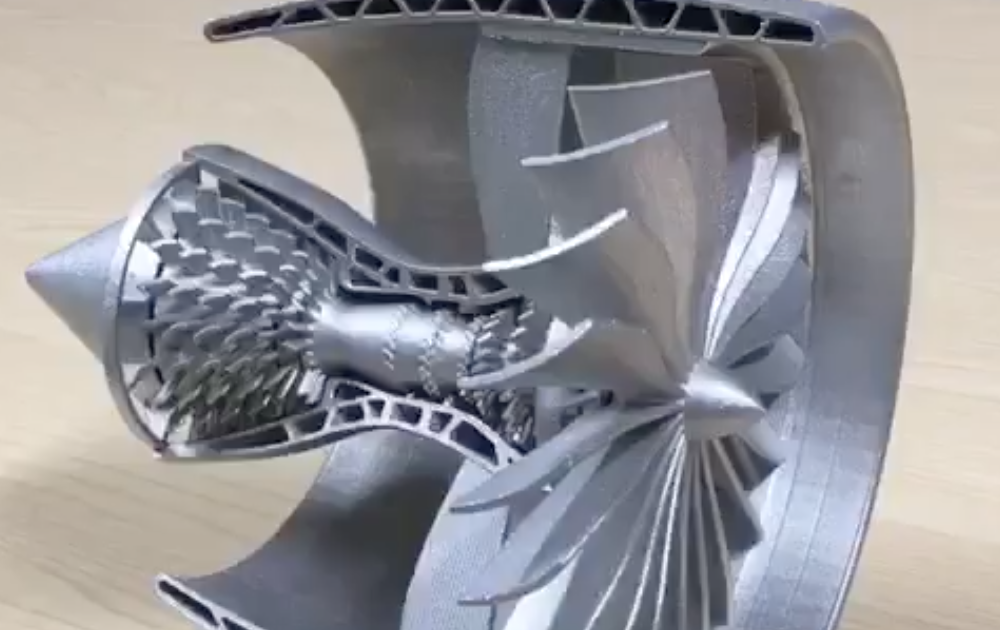

Part Geometry

3D printing is faster when parts have simple cross-sectional layers.The complexity of a part’s geometry is another important factor in determining how long it takes to 3D print. The more complex the part is, the more complex each layer will be. And the more complex the layers are, the longer it will take for the print head to replicate them.

A part with many small features will have layers that look like a group of small islands, while a simple cube or sphere will have one large island. The print head will have to draw the boundary each island and then fill it in, so more islands means more time. However, that the degree to which part geometry affects build time is highly dependent on the 3D printing technology being used.

3D Printing Technology

3D printing technologies with print heads that work like a paint roller are faster than those that work like a paint brushAt this point there are about a dozen different 3D printing technologies and they each create parts using their own unique processes. FDM melts plastic like a hot-glue gun, SLS uses lasers, PolyJet and stereolithography use UV light to solidfy liquid photopolymers and so on. But when discussing how long it takes to 3D print a part, the most important factor is the configuration of the print head. We can broadly divide print head configurations into two categories: paint brush and paint roller.

Paint Brush

These are 3D printing technologies where layers are created the same way that you would paint them on canvas with a brush. The print extrudes material (or fires a laser, as the case may be) from a single point as it moves all over the build tray, drawing out each island in the layer. These technologies include FDM, selective laser sintering and stereolithography.

Paint Roller

For these technologies the print head evenly passes back and forth across the entire build tray, the way you might paint a wall with a paint roller. Material is extruded from an array of points on the print head, rather than just a single pinpoint. These include PolyJet, MultiJet, and ColorJet 3D printers.

The result of this difference is that “paint brush” printers typically take longer to 3D print than “paint roller” printers. While the FDM print head has to go spiraling all around the build chamber, drawing out and filling in each shape in the layer, the PolyJet print head makes a few quick and even passes across the entire bed, regardless of the geometry it’s printing.

Layer Height

We’ve discusses how important the height of the overall part is, but the height of the individual layers also determines how long 3D printing takes. Our FDM machines, for example, can build parts with layer heights of 0.005”, 0.007”, 0.010” or 0.013”. Using different layer heights allows you to prioritize speed or detail, depending on your part’s requirements.

Shorter layer typically mean smaller features, higher detail and a smoother surface finish. But shorter layers also mean that there will be more layers and therefore a longer build time. For example, FDM parts with 0.005” layers can take up to 5-10 times longer to 3D print as parts with 0.013” layers.

Quantity

All of the above factors that determine how long 3d printing takes are compounded when you are printing more than one copy of the same object. You will always reduce your per-part time when printing multiple copies, but the more factors you already have in your favor, the more time you will save.

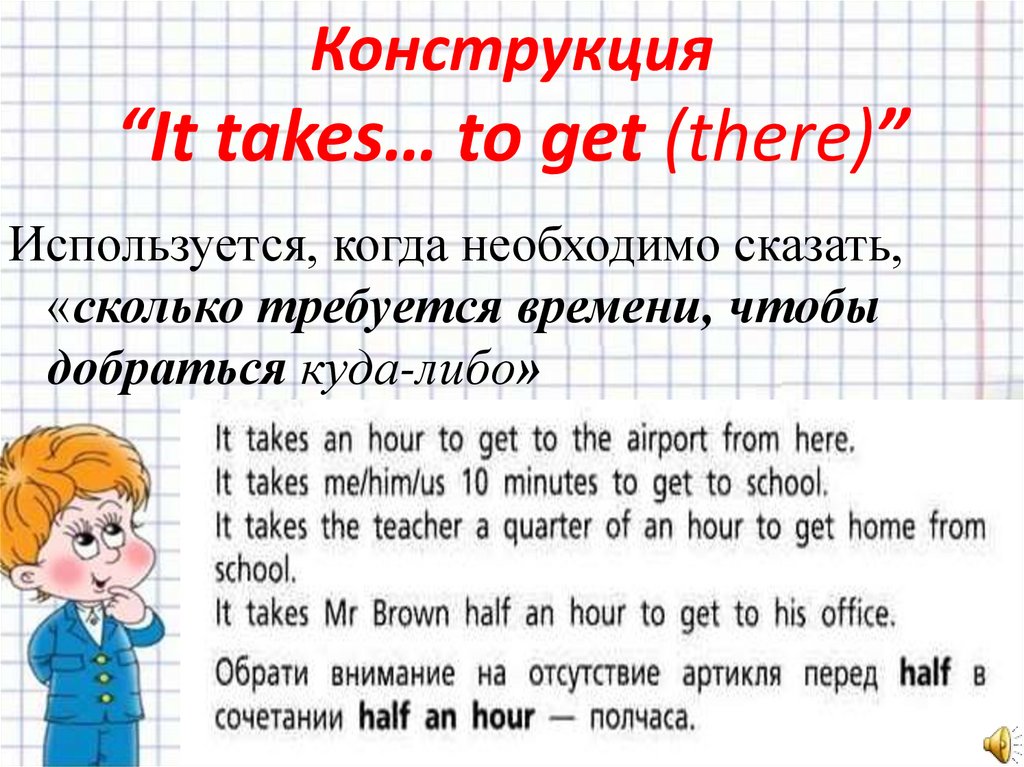

For example, it takes about an hour to 3D print one copy of a 1” cube on PolyJet, but it only takes two hours to print 25 copies. Meanwhile, printing two copies of a large FDM part with short layers will generally take about twice as long as printing one.

Post-processing

Post-processing activities include support removal processes to ultimately clean, rinse, and/or dry 3D printed parts. Each technology requires different methods of post-processing. Of course, average times vary depending on factors such as size and geometry of the parts. A small part may only take 20 minutes to clean, while a larger part could take several hours. The most important part of the post-processing activities is to be careful not to break or damage the parts as they can often be fragile depending on their design.

3D Printing at 3 Space

At 3 Space we offer a variety of 3D printing technologies and dozens of materials. Whether you need rapid prototyping or end-use parts, 3D printing is almost always time-sensitive. We strive to maintain short lead times for all of our 3D printing services. Click here to learn more about our services.

We strive to maintain short lead times for all of our 3D printing services. Click here to learn more about our services.

90,000 at what speed are the FDM 3D printers

with what resolution 3D printers are printed

threaded parts of the printed parts

6 safe ways to remove 3D scribes

9000 3D-spent at home gives us the opportunity to give us the opportunity to produce given objects at a very low cost. However, the time it takes to turn a 3D model into a physical object is not as short as one might think. The size and quality of the print has a decisive influence on the speed of printing, and it can take many hours to get the final result. In fact, various tests show that printer speed has a much smaller effect on print time than size and quality settings.Desktop printers

3D print speed settings

In general, there are currently three blocks of speed settings supported by 3D printers. The first block includes speeds from about 40 to 50 mm / s, the second - 80-100 mm / s, the fastest printing is carried out at about 150 mm / s. Some printers can even print at speeds over 150mm/s.

Some printers can even print at speeds over 150mm/s.

Usually, though, faster 3D printing means lower quality. At speeds above 150 mm/s, the quality drops significantly, and problems can arise, since the filament is prone to slip at such speeds.

How to set the print speed

Typically, the 3D print speed is set in the slicer software used to prepare the 3D model for printing. In Cura, for example, you just need to enter the desired print speed in the Print speed field in the Basic tab (in previous versions, you first had to switch to the Advanced mode and open the Speed tab).

Cura calculates the duration of the print process based on print speed and quality settings.

As soon as the print speed ( Print speed ) or other setting is changed, Cura recalculates the print time and displays it (see arrow). Cura's calculations turn out to be very close to real-time printing.

How long does 3D printing take in practice?

To find out how fast 3D printers actually print, two popular desktop printers, the Ultimaker 2 and the Wanhao Duplicator 6, were tested on two more or less complex objects.

These two models were printed:

3DBenchy. This 3D model is designed to test and measure the speed of 3D printers; it is quite complex and requires attention. The boat is 6 cm long, 4.8 cm high and 3.1 cm wide. Here you can get the 3DBenchy STL file for testing for free.

3DBenchy's 3D printing speed is relatively slow, the model is quite difficult to print (Photo: 3DBenchy.com).

Universal tablet stand (up to 1.2 cm thick). The stand is 14 cm long, 4.2 cm high and 9.8 cm wide. The STL file is available for free on Thingiverse.

The stand is quite large and difficult to print (Photo: Thingiverse).

These objects were printed at two speeds, 100 mm/s and 50 mm/s, at similar settings. Here are the results:

Here are the results:

Printer

Model

50 mm/sec

100 mm/sec

Ultimaker 2

3DBENCHY

h 09 min 9 min.0003

1 h 55 min

Wanhao Duplicator 6

3dbenchy

2 h 13 min

1 h 51 min

Ultimaker 2

Stand

9000 H 23 min4 h 36 min 9000 min

Wanhao duplicator 6

Stand

6hrs 27mins

4hrs 45mins

- For the smaller models, the difference between slow and fast printing is not particularly striking: almost 2.25 hours versus less than 2 hours. Unless you're insanely short on time, choose a slower speed for better print quality.

- For large models, the print speed varies more significantly: 6.5 hours versus 4.75 hours.

Cunning. If you don't have your own 3D printer, download the free Cura software from the Ultimaker website. Cura has profiles for most desktop printers (FDM), so you can check how long it takes to print a specific 3D model on a particular device - just import the STL file and play with Cura settings. To try another 3D printer, select Machine > Add new machine.

To try another 3D printer, select Machine > Add new machine.

Does high-speed sintering promise the fastest 3D printing?

On an industrial scale, even more impressive prospects dawn on the horizon. The University of Sheffield has announced that its scientists have built a £1m-funded 3D printer that can produce plastic parts as quickly as traditional mass-production methods such as injection molding.

The process is called high-speed sintering (HSS), which melts the polymer layer by layer (similar to the additive printing process), but instead of using lasers, HSS prints on a powder substrate with infrared-absorbing inks. After the layer is printed, it is exposed to infrared radiation, the ink-coated powder is heated, resulting in melting, while the non-irradiated powder remains cold.

A team led by Prof. Neil Hopkinson claims that their machine is capable of producing parts up to 1 m³, i. e. with a washing machine, which is three times more than existing printers can. The print speed is dependent on the size of the object, however, Hopkinson estimates that small components will be created at speeds of less than one second per part.

e. with a washing machine, which is three times more than existing printers can. The print speed is dependent on the size of the object, however, Hopkinson estimates that small components will be created at speeds of less than one second per part.

What use is this to us? The good news is that HSS technology has been licensed to industrial 3D printer manufacturers on a non-exclusive basis, and new machines are expected to hit the market in 2017. This means that in the near future we can expect the transition of this industrial technology to the "home" level.

How long does 3D printing take (and why)?

Last updated: September 10, 2022 / author Sandeep Bhandari / Fact verified / 4 minutes

Exact answer: 30 minutes to 12 hours to print

3D printing is the creation of a three-dimensional object from a digital model. The model is first cut into thin layers, and then the printer prints these layers one on top of the other, using glue to bind them together.

This technology has been around for about 25 years, but only in the last few years has it become widely available and affordable. As a result, 3D printers are now being used to create everything from prosthetics to food.

More complex items such as cars may take a few days. However, the total time it takes to complete a 3D print is between 30 minutes and 12 hours.

In addition, the time required to obtain a 3D model depends on the size and structure of the object, the number of layers used in the printing process, and the type of printer used.

Complex projects can take longer than easy ones to 3D print, but this largely depends on how much detail you want in the final product. The more complex and realistic the design, the longer it will take to create it, because more details need to be assembled before printing.

The time it takes to print an item depends on several factors, including:

- The size and complexity of the model you are trying to print

- The capabilities and settings of the 3D printer

- Regardless of whether any special technologies are used additive manufacturing

The size of the 3D model also matters. Hollow construction takes less time to 3D print than solid construction. This is because the nozzle or laser of the 3D printer must travel over a solid object. As a result, it takes less time to cover the entire area.

Hollow construction takes less time to 3D print than solid construction. This is because the nozzle or laser of the 3D printer must travel over a solid object. As a result, it takes less time to cover the entire area.

Why does 3D printing take so long?

3D printing is the process of creating three-dimensional objects from a digital model. The total time it takes to 3D print an object depends on the size and size of the object.

Huge objects take longer to print because they require more printer and filament time. More complex objects also take longer to print, as it takes more time to create the necessary layers.

Some printers can print faster than others, but the average print time for a small, simple object is about an hour. Larger or more complex objects can take days or weeks to print.

Another reason is that 3D printers print objects layer by layer, and each layer takes time to print, and they often have to pause to cool down between layers. Otherwise, the object may deform or melt.

Otherwise, the object may deform or melt.

While the size and shape of a part are important factors, its build height is likely the most important indicator of how long it will take to 3D print. For example, even though they contain roughly the same material, it usually takes longer to 4D print a 4x8x3 inch component than a 5x5x5 inch.

A design with many tiny elements will look like a set of small islands, while a basic shape or sphere will have one giant island. Because the printhead has to draw a border for each island and then fill it in, larger islands mean more time.

Conclusion

In general, 3D printing is not a slow process, but what it takes to create an object depends on many factors.

The size of a 3D printed object affects how long it takes the machine to print one object. The larger the piece, the longer it will take to create that single object on that particular 3D printer.

Similarly, suppose that several people are using the same 3D printer at the same time.