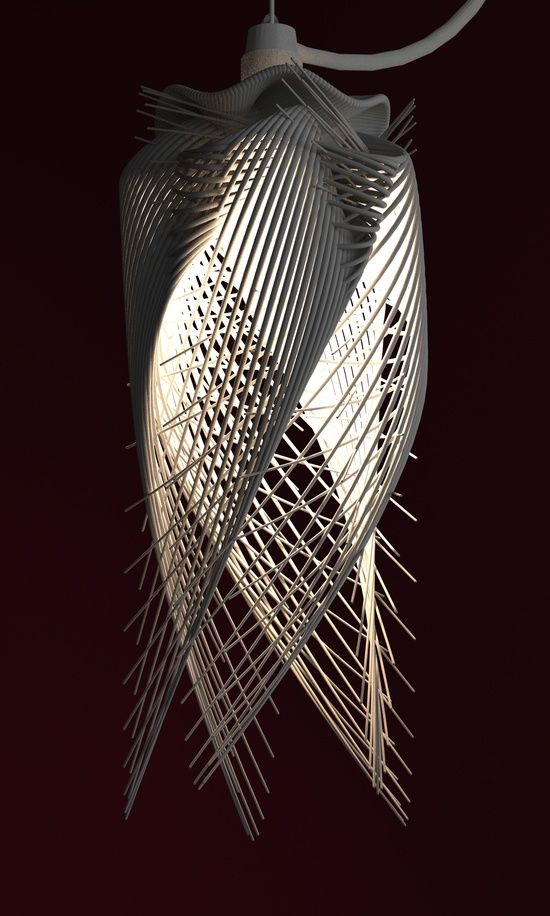

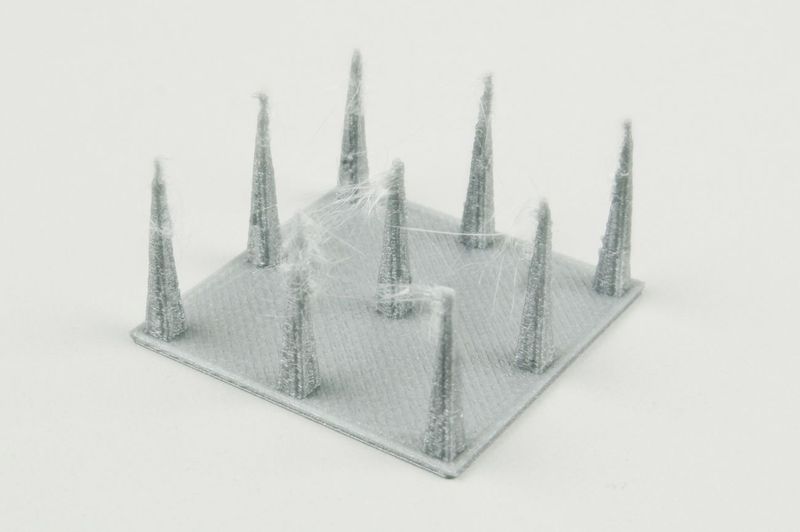

3D print string

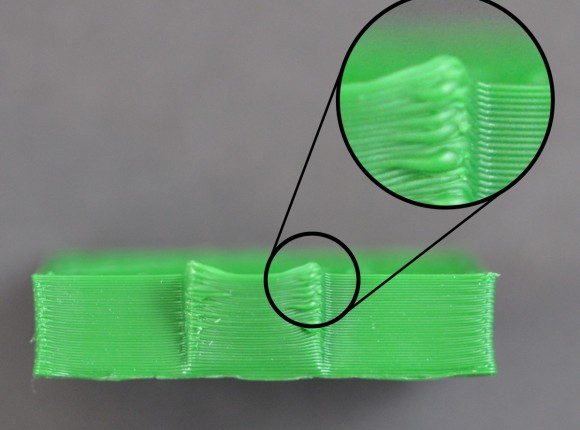

Stringing or Oozing

Stringing or Oozing

Stringing (otherwise known as oozing, whiskers, or “hairy” prints) occurs when small strings of plastic are left behind on a 3D printed model. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. Thankfully, there are several settings within Simplify3D that can help with this issue. The most common setting that is used to combat excessive stringing is something that is known as retraction. If retraction is enabled, when the extruder is done printing one section of your model, the filament will be pulled backwards into the nozzle to act as a countermeasure against oozing. When it is time to begin printing again, the filament will be pushed back into the nozzle so that plastic once again begins extruding from the tip. To ensure retraction is enabled, click “Edit Process Settings” and click on the Extruder tab. Ensure that the retraction option is enabled for each of your extruders. In the sections below, we will discuss the important retraction settings as well as several other settings that can be used to combat stringing, such as the extruder temperature settings.

Common Solutions

Retraction distance

The most important retraction setting is the retraction distance. This determines how much plastic is pulled out of the nozzle. In general, the more plastic that is retracted from the nozzle, the less likely the nozzle is to ooze while moving. Most direct-drive extruders only require a retraction distance of 0.5-2.0mm, while some Bowden extruders may require a retraction distance as high as 15mm due to the longer distance between the extruder drive gear and the heated nozzle. If you encounter stringing with your prints, try increasing the retraction distance by 1mm and test again to see if the performance improves.

Retraction speed

The next retraction setting that you should check is the retraction speed. This determines how fast the filament is retracted from the nozzle. If you retract too slowly, the plastic will slowly ooze down through the nozzle and may start leaking before the extruder is done moving to its new destination. If you retract too quickly, the filament may separate from the hot plastic inside the nozzle, or the quick movement of the drive gear may even grind away pieces of your filament. There is usually a sweet spot somewhere between 1200-6000 mm/min (20-100 mm/s) where retraction performs best. Thankfully, Simplify3D has already provided many pre-configured profiles that can give you a starting point for what retraction speed works best, but the ideal value can vary depending on the material that you are using, so you may want to experiment to see if different speeds decrease the amount of stringing that you see.

If you retract too slowly, the plastic will slowly ooze down through the nozzle and may start leaking before the extruder is done moving to its new destination. If you retract too quickly, the filament may separate from the hot plastic inside the nozzle, or the quick movement of the drive gear may even grind away pieces of your filament. There is usually a sweet spot somewhere between 1200-6000 mm/min (20-100 mm/s) where retraction performs best. Thankfully, Simplify3D has already provided many pre-configured profiles that can give you a starting point for what retraction speed works best, but the ideal value can vary depending on the material that you are using, so you may want to experiment to see if different speeds decrease the amount of stringing that you see.

Temperature is too high

Once you have checked your retraction settings, the next most common cause for excessive stringing is the extruder temperature. If the temperature is too high, the plastic inside the nozzle will become less viscous and will leak out of the nozzle much more easily. However, if the temperature is too low, the plastic will still be somewhat solid and will have difficulty extruding from the nozzle. If you feel you have the correct retraction settings, but you are still encountering these issues, try decreasing your extruder temperature by 5-10 degrees. This can have a significant impact on the final print quality. You can adjust these settings by clicking “Edit Process Settings” and selecting the Temperature tab. Select your extruder from the list on the left, and then double-click on the temperature setpoint you wish to edit.

However, if the temperature is too low, the plastic will still be somewhat solid and will have difficulty extruding from the nozzle. If you feel you have the correct retraction settings, but you are still encountering these issues, try decreasing your extruder temperature by 5-10 degrees. This can have a significant impact on the final print quality. You can adjust these settings by clicking “Edit Process Settings” and selecting the Temperature tab. Select your extruder from the list on the left, and then double-click on the temperature setpoint you wish to edit.

Long movements over open spaces

As we discussed above, stringing occurs when the extruder is moving between two different locations, and during that move, plastic starts to ooze out of the nozzle. The length of this movement can have a large impact on how much oozing takes place. Short moves may be quick enough that the plastic does not have time to ooze out of the nozzle. However, long movements are much more likely to create strings. Thankfully, Simplify3D includes an extremely useful feature that can help minimize the length of these movements. The software is smart enough that it can automatically adjust the travel path to make sure that nozzle has a very short distance to travel over an open space. In fact, in many cases, the software may be able to find a travel path that avoids crossing an open space all together! This means that there is no possibility to create a string, because the nozzle will always be on top of the solid plastic and will never travel outside the part. To use this feature, click on the Advanced tab and enable the “Avoid crossing outline for travel movement” option.

Thankfully, Simplify3D includes an extremely useful feature that can help minimize the length of these movements. The software is smart enough that it can automatically adjust the travel path to make sure that nozzle has a very short distance to travel over an open space. In fact, in many cases, the software may be able to find a travel path that avoids crossing an open space all together! This means that there is no possibility to create a string, because the nozzle will always be on top of the solid plastic and will never travel outside the part. To use this feature, click on the Advanced tab and enable the “Avoid crossing outline for travel movement” option.

Movement Speed

Finally, you may also find that increasing the movement speed of your machine can also reduce the amount of time that the extruder can ooze when moving between parts. You can verify what movement speeds your machine is using by clicking on the Speeds tab of your process settings. The X/Y Axis Movement Speed represents the side-to-side travel speed, and is frequently directly related to the amount of time your extruder spends moving over open air. If your machine can handle moving at higher speeds, you may find that increasing this settings can also reduce stringing between parts.

If your machine can handle moving at higher speeds, you may find that increasing this settings can also reduce stringing between parts.

Related Topics

5 Ways How to Fix Stringing & Oozing in Your 3D Prints – 3D Printerly

If you’re in the field of 3D printing, you might have come across an issue of strings of melted plastic or plastic oozing from your 3D prints. This is called stringing and oozing, which fits perfectly.

Fixing stringing and oozing is best done by having good retraction settings, where a good retraction length is 3mm and a good retraction speed is 50mm/s. You can also decrease your printing temperature to help filament be less runny, which reduces the instance of stringing and oozing.

It’s a fairly common problem that people experience which leads to poor quality prints, so you definitely want to get this fixed.

There are more details to know about so keep on reading the article to find out why this happens in the first place, and how to fix it once and for all.

What Causes 3D Prints to Have Stringing & Oozing?

Sometimes users try to print an object in which the nozzle has to move through an open area to reach the next point.

Stringing and oozing is the problem in which the nozzle extrudes the melted plastic while moving from an open space.

The melted plastic sticks between two points and look like attached strings or threads. To prevent or solve the problem, the first step is to find out the actual cause of the issue.

Some of the major causes behind the stringing and oozing problem include:

- Retraction settings not being used

- Retraction speed or distance too low

- Printing with a temperature too high

- Using filament which has absorbed too much moisture

- Using a clogged or jammed nozzle without cleaning

Knowing the causes is a good way to start before getting into the solutions. The section below will take you through a number of ways how to fix stringing & oozing in your 3D prints.

Once you’ve gone through the list and tried them out, your problem should hopefully be solved.

How to Fix Stringing and Oozing in 3D Prints

Just like there are various reasons that cause stringing and oozing problems, there are also plenty of solutions that can help you fix and avoid it.

Most of the time this type of problem can be fixed just by changing some settings in the 3D printer such as extruder speed, temperature, distance, etc. It’s not ideal when your 3D prints are stringy so you want to get this sorted out quickly.

Below are some of the simplest and easiest solutions that can be implemented without requiring any major tools or techniques.

The methods that will help you to get rid of the problem for once and for all includes:

1. Print at a Lower Temperature

The chances of stringing and oozing increase if you are printing at a high temperature. The very first thing that you should do is to reduce the temperature and check for the results.

The very first thing that you should do is to reduce the temperature and check for the results.

Reducing the temperature will help you because it will extrude less liquid material reducing the chances of stinging and oozing.

Those higher temperature materials are more prone to stringing because of the effects of higher heat on the viscosity or liquidity of filament.

Although PLA is a relatively low temperature material, it doesn’t mean it’s safe from stringing and oozing.

- Reduce the temperature step by step and check if there are any improvements.

- Make sure that the temperature is within the range required for the type of filament being used (should be on the filament packaging)

- Try to use a filament that melts at lower temperatures efficiently like PLA

- While reducing the printing temperature, you may have to lower down the extrusion speed because the filament material will take time to melt at low temperatures.

- Do test prints of little objects to get an idea about the perfect temperature because different materials print well on different temperatures.

- Some people will print their first layer 10°C hotter for good adhesion, then lower the printing temperature for the rest of the print.

2. Activate or Increase Retraction Settings

3D printers include a mechanism that works as a pullback gear called retraction, as explained in the video above. Enable retraction settings to pull back the semi-solid filament that is pushing the liquid to extrude from the nozzle.

According to experts, activating the retraction settings usually work to fix the stringing problems. What it does is relieve the pressure of the melted filament so it will not drip while moving from one point to another.

What it does is relieve the pressure of the melted filament so it will not drip while moving from one point to another.

- Retraction settings are activated by default but check for the settings if you are experiencing stringing or oozing.

- Enable the retraction settings so that the filament can be pulled back every time the nozzle reaches an open space where printing is not designed or required.

- A good retraction setting start-point is a retraction speed of 50mm/s (adjust in 5-10mm/s adjustments until good) and retraction distance of 3mm (1mm adjustments until good).

- You can also implement a setting called ‘Combing Mode’ so it only travels where you have already printed, rather than in the middle of your 3D print.

I’d advise you to download and use this Retraction Test on Thingiverse, created by deltapenguin. It’s a great way to quickly test out how well in-tune your retraction settings are dialed in.

It really is hit or miss, high retraction settings of 70mm/s retraction speed and 7mm retraction distance works well, while others get good results with much lower.

3. Adjust Print Speed

Adjusting the print speed is a common factor to fix stringing, especially if you have reduced the printing temperature.

Reducing speed is necessary because with the reduced temperature the nozzle can start under extruding. After all, the filament will take more time to melt and become ready to extrude since it’s less runny.

If the nozzle is moving at a high speed, with a high temperature, and no retraction settings, you can bet you’ll experience stringing and oozing at the end of your 3D print.

- Reduce the printing speed because this will mitigate the chances of leaking filament and causing stringing.

- A good starting speed ranges from 40-60mm/s

- A good travel speed setting is anywhere from 150-200mm/s

- As different filaments take different time periods to melt, you should test the material by reducing the speed before starting your printing process.

- Make sure that the printing speed is optimal because both too fast and too slow speed can cause problems.

4. Prevent your Filament from Moisture

Most 3D printer users knows that moisture affects the filament badly. Filaments absorb moisture in the open air and this moisture turns into bubbles when heated.

The bubbles usually keep on bursting and this process forces the dripping of the filament from the nozzle causing stringing and oozing problems.

The moisture can also become steam and will increase the chances of the stringing problems when mixed with the plastic material.

Some filaments are worse than others such as Nylon and HIPS.

- Keep your filament stored and protected in a box or something that is totally airtight, with desiccant and has the ability to stop moisture from reaching the filament.

- If suitable, try to use a filament which absorbs less moisture like PLA

I’d recommend going for something like the SUNLU Upgraded Filament Dryer from Amazon. You can even dry filament while you’re 3D printing since it has a hole that can feed through. It has an adjustable temperature range of 35-55°C and a timer that goes up to 24 hours.

It has an adjustable temperature range of 35-55°C and a timer that goes up to 24 hours.

5. Clean the Printing Nozzle

Whenever you print an object some particles of the plastic are left behind in the nozzle and with time get stuck in it.

This happens more so when you print with a high temperature material, then switch to a lower temperature material like from ABS to PLA.

You don’t want any kind of blockage in the way of your nozzle, since this is a very significant area for creating successful prints without imperfections.

- Clean your nozzle thoroughly before printing to make it free from the residues and dirt particles.

- Use a brush with metal wires to clean the nozzle, sometimes the common brush can also work well.

- It will be better if you clean the nozzle every time you complete a print because it becomes easier to remove the heated liquid residues.

- Clean your nozzle using acetone if you are printing after a long time.

- Keep in mind that cleaning the nozzle is considered essential whenever you switch from one material to another.

After going through the above solutions, you should be in the clear for getting rid of that stringing and oozing problem that you have been experiencing.

It may be a quick fix, or it can require some trial and testing, but at the end of it, you know you’ll come out with some print quality you can be proud of.

Happy printing!

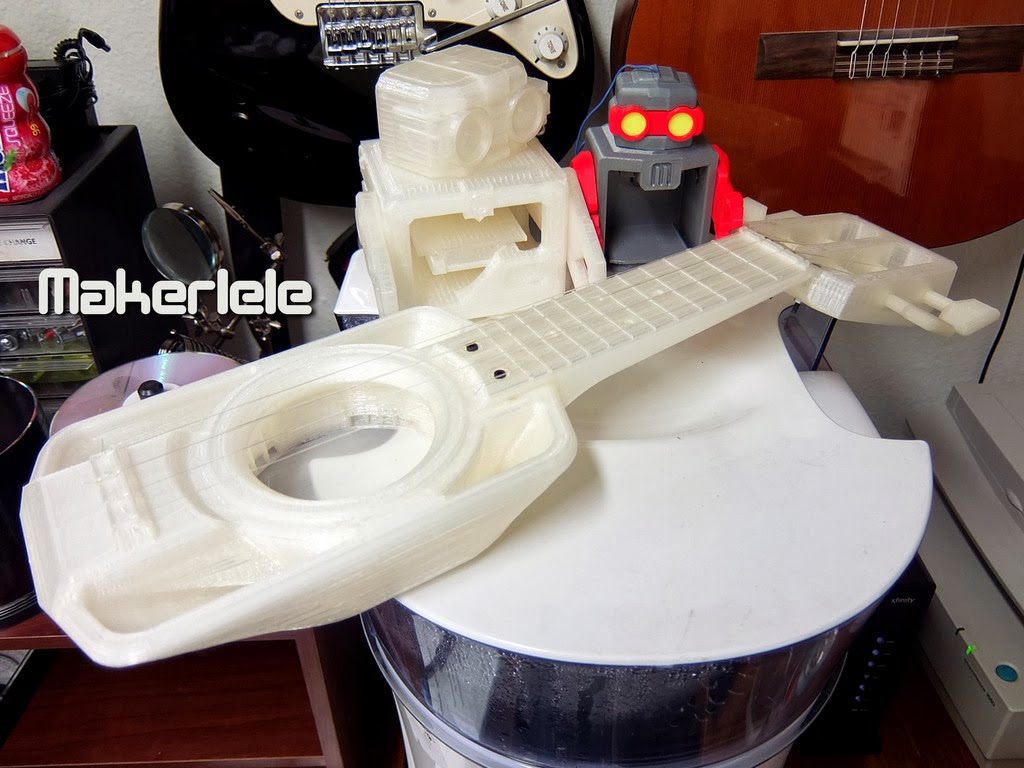

50 3D Printing Ideas

It looks like we'll soon be drowning in useless stuff made for 3D printing projects. But you can do something that will really be useful! If you're running out of ideas, here's a list of 50 3D printable items you're unlikely to throw away.

Bag clip with screw cap

Now the bag clip will have a new feature - a hole with a lid for quick access, as in the photo. This clip is easy to print and convenient to use. Strange that no one thought of this before.

Author: Minkix

Download: Thingiverse

Modular Furniture Connector

This connector allows you to quickly assemble modular furniture. The default model is designed for 17×17 mm wood, but the size and material can be changed to suit your needs using a parametric file for customization.

The default model is designed for 17×17 mm wood, but the size and material can be changed to suit your needs using a parametric file for customization.

Author: LeFabShop

Where to download: Cults

Sealant cap

No more throwing open sealant tubes away. The screw cap for the nozzle presses the o-ring tightly against the body of the tube and closes the access of air to the solvents inside.

Author: The-Mechanic

Where to download: Thingiverse

Laptop niche

Now the laptop will always be at hand, but hidden from prying eyes in a special niche that is attached to the bottom of any coffee table.

Author: Too Snide

Download: Thingiverse

Phone holder - Candice

Elegant and simple, perhaps the easiest thing you can print on a 3D printer.

Author: Clem.C2

Where to download: Cults

Polypanels

The idea for Polypanels came from Devin Montes. A polypanel is a series of three-dimensional building blocks. The individual elements of a Polypanel look simple, but if you print a lot of them and different types, you can create all sorts of complex designs. Something like LEGO where you can design each brick.

A polypanel is a series of three-dimensional building blocks. The individual elements of a Polypanel look simple, but if you print a lot of them and different types, you can create all sorts of complex designs. Something like LEGO where you can design each brick.

Author: MakeAnything

Where to download: MyMiniFactory

Coat Hook

This coat hook is designed as an E3D attachment and can be printed multiple times to fit all your clothes.

Author: Filar3D

Where to download: Cults

Plant Pot

This anatomical brain flower pot is easier to print than it looks, creator DrFemPop says. For assembly, it is only necessary to glue the parts after printing. It turns out an original house for plants.

Author: DrFemPop

Where to download: Cults

Door Holder

This is a simple solution for holding a door. Double-sided adhesive tape is sufficient for surface mounting.

Author: Akiraraiser

Where to download: Thingiverse

Piggy bank

A simple piggy bank for beginners, no complicated settings.

Author: lecaramel

Where to download: Thingiverse

Cable ties

This tie is perhaps the simplest and most ingenious of all devices. Clips are printed as a whole sheet at once, and then the required amount can be cut off from it.

Author: Sunshine

Where to download: Cults

Roller ruler

An indispensable device if you need to measure the length of something non-linear: a piece of rope, a curved line, a perimeter with bends, etc. The ruler is called Geneva and has step 5 mm.

Author: MechEngineerMike

Where to download: Thingiverse

Pliers

This small, solid piece of plastic can easily replace your pliers / pliers. These forceps take the force to the handles and redistribute it at the end of the grip. It's definitely pliers. Just smarter.

Author: BYU CMR

Where to download: Thingiverse

Cylindrical textured box

Beautiful tube from Syboulette decorated with hexagons. Well suited as a kitchen utensil for storing oatmeal, rice and other crumbly substances.

Well suited as a kitchen utensil for storing oatmeal, rice and other crumbly substances.

Author: Syboulette

Where to download: Cults

Door stopper

This stopper is modeled after the Guyer Anderson cat statue in the British Museum. The design is hollow, which allows you to fill the limiter with something for additional weight.

Author: Duaneindeed

Where to download: Cults

Plague Doctor Mask

Not exactly the most useful item on the list since bubonic plague is a thing of the past. But a mask can come in handy, for example, when you need to clean up after your pet. And you can also go to the carnival in it.

Author: Odrivious

Download: Cults

Universal Spool Holder

This adjustable spool holder uses a spring and an adjustable rewind clutch. It's the perfect place to store those pesky wires.

Who made it: Vincent Goenhuis

Where to download: Thingiverse

Sturdy waterproof box

This tight-fitting box will keep things from getting wet. Print it in PLA or PETG, add a flexible TPU seal and M3 screws for the spring hinge, and you're done.

Print it in PLA or PETG, add a flexible TPU seal and M3 screws for the spring hinge, and you're done.

Author: ZX82

Where to download: Cults

Dice

This dice is suitable for flat 3D printing and has a face size of 16mm.

Author: Devin Montes (MakeAnything)

Where to download: MyMiniFactory

Collapsible Coat Rack

Really cool coat rack. That's all there is to say about her.

Author: Komaru

Where to download: Thingiverse

Business Card Holder

Great for showing off your new business cards to your Wall Street friends. What could be more delightful than this Zippo card holder with flip-top lid.

Author: PentlandDesigns

Where to download: Cults

Pencil and pen holder

Iceberg or melting beehive? Be that as it may, this is a handy pen and pencil holder that is cheaper to print than to buy.

Author: BeeVeryCreative

Where to download: Cults

Groovi Monster Audio Amplifier

This is a passive smartphone audio amplifier that looks stylish and does the job well. It's called Groovi Monster for a reason.

It's called Groovi Monster for a reason.

Author: 3DShook

Where to download: Cults

Cup holder

Can be used not only as a cup holder, but also as a coaster for hot dishes. The dimensions of the template are easily adjusted to suit any size cookware.

Author: jmdbcool

Where to download: Thingiverse

Clamp

Designed for fixing various materials, including the ends of the wire in the coil. Also great as a clothespin replacement.

Author: Med

Where to download: Cults

Pencil Box

Suitable for storing all your desk trivia and trinkets (memory cards, rubber bands, pencils, paper clips, etc.).

Author: Monkey3D

Where to download: Cults

Headphone holder

This is a duck. Yes, you can hang headphones on it.

Author: Toshi_TNE

Download: Thingiverse

Polyhedral Succulent Pot

Unusual geometric pots for your growing succulent collection. These small pots can be configured to be connected together.

These small pots can be configured to be connected together.

Author: PrintFutura

Download: Cults

Survival Whistle

This is a survival whistle with original design. It is durable, easy to make and very loud (118 dB is more than enough to be heard in an emergency).

Author: Joe Zisa

Where to download: Thingiverse

Measuring Cube

Simple and original measuring cube for the kitchen. On each side there are recesses for measuring the volume of ingredients (in cups - according to the American system, and in metric units for everyone else). It is best to print with PETG material, it is the safest for products.

Author: iomaa

Download: Thingiverse

Hinge

This is a parametric hinge that can be sized to fit your needs.

Written by Rohin Gosling

Download: Thingiverse

Car Eyeglass Holder

Attaches to your car's sun visor. Glasses will always be at hand.

Glasses will always be at hand.

Author: Trevor Long

Download: Thingiverse

Opener

The simplest things are usually the most useful. Convenient and easy to print opener. Covers the sharp edges of the cork as much as possible, protecting you from injury.

Author: Jeremy Peterson

Download: Thingiverse

Superhero Keychains

Sometimes you need to remind yourself of your hidden superpowers. Stylish and cool keyrings are well suited as a small gift.

Author: Formbyte

Where to download: Cults

Headphone stand

It will be useful for music lovers and gamers who use headphones a lot and often. After all, now they will no longer roll around anywhere.

Author: MakerBot

Where to download: Thingiverse

Bag Clip

The model consists of two printed parts. Allows you to keep packages closed and keep food fresh longer.

Author: Walter Hsiao

Download: Thingiverse

Plastic wrench

Handy wrench, but don't choose soft plastic to make it.

Author: Daniel Noree

Where to download: Cults

Sliding Decal

No more worrying about whether cups are clean or dirty right now in the dishwasher! With the help of a special mechanism, the slider easily changes the inscription on the plate.

Who made it: MiddleFingerBoss

Where to download: Thingiverse

Collapsible basket

Cool picnic item. A folding square basket with five sections is printed from several parts and then glued together. For product safety, it is recommended to use PETG plastic.

Author: PatternToPrint

Where to download: Cults

Self-watering plant pot

Houseplants are dying from your forgetfulness? This will not happen again! This pot will water them by itself, and your conscience will be clear.

Author: Parallel Goods

Where to download: Cults

Maze Gift Box

Cash is not the most original gift. But if you present them in such a gift box, your friend will surely like it. The lucky recipient will have to work hard to get to the prize, because there is only one right way.

The lucky recipient will have to work hard to get to the prize, because there is only one right way.

Author: Robert

Download: Thingiverse

Wired headphone holder

The headphones will now be protected from tangling and breakage.

Author: Robert

Where to download: Thingiverse

Tube Squeezer

Will help squeeze out the contents of the tube to the last drop. Wide enough to fit most tubes on the market. Printed in three separate parts.

Author: Justin Otten

Where to download: Thingiverse

Webcam Shutter

The best thing for the paranoid and just for those who are uncomfortable being under the gun of a webcam. Instead of sticking tape or sticky tape over the lens, attach a slider shutter to the body and open it when you need a video call.

Author: Horizon Lab

Where to download: Cults

Hexagonal Prefabricated Drawers

Useful to free your desk from the noodles of cables, wires and just every little thing. The design can be easily expanded if necessary.

The design can be easily expanded if necessary.

Created by Dan O'Connell

Where to download: Cults

Wall Phone Shelf

Attach the shelf to a power outlet and place your phone on it while charging. The model also has a corner slot that holds your smartphone or tablet upright for watching videos.

Author: Tosh Sayama

Where to download: Cults

Card Shuffle Machine

Awesome item for poker lovers. This device will help to shuffle the cards and deal them during the game.

Author: LarsRb

Where to download: MyMiniFactory

Box with a secret lock

Box for storing things in a place inaccessible to prying eyes with a secret multi-stage opening mechanism.

Author: 3DPrintingWorld

Where to download: Thingiverse

Digital Sundial

Yes, your eyes don't deceive you. This is a digital sundial and it really works. They are designed to pass only the right beams at the right time and at the right angle to display the actual time in 20-minute intervals. Only works during daylight hours, of course.

Only works during daylight hours, of course.

Author: Mojoptix

Where to download: Thingiverse

Keyring

Designed in the shape of a stylish Swiss Army knife, it looks amazing. Printed from two plates and the keys are held in place with standard hex nuts and bolts.

Author: Craig Blanchette

Download: Thingiverse

50 Cool Things to 3D Print in June 2019 prints appear regularly. Materials on this topic are also available on the portal, but I think everyone will only be in favor of unity of causes, consequences, 'who is to blame', 'what to do' and 'do they eat chicken with their hands'. But the main task is to be able to later give a link to this post, and not look in the bookmarks for the most suitable for a particular case.

So we have a printer that prints and prints, and then for some reason shaitanama happens. As a result, we received an underprinted part. The reasons are a power failure, a disconnection with the computer, mysterious electrical processes in the brains of the printer, a plug in the extruder (either the roller has gnawed through the filament, or the bar has run out, in general, the printer is buzzing idle). And we need a single piece.

And we need a single piece.

Three options are possible. The first is to spit and reprint. Least labor intensive. If time allows and you do not feel sorry for the spent plastic, it is better to resort to it. But if this is not our method, then there are two more. The second is to remove the printed from the table, peel off the missing, print, glue. Third - Jedi, continue printing.

Determination of height

Regardless of which decision (second or third) we come to, the fundamental question arises - at what height printing stopped. The quality (and volumes of post-processing) of the seam largely depends on the accuracy of the determination. And here, again, there are options. The most free - if you can determine exactly where the print ended. For example, if the printer electronics freezes (or the connection is interrupted), and the treasured numbers 'Z-something-there' remain on the display. Or there is an opportunity to look at the terminal log before the break. The ideal case is when there is a last XY move command (G1 Xxxx Yyyy Eeee) and you can scroll the log up to the nearest layer start (G1 Zzzz). This allows you to accurately determine not even the height but the point!

The ideal case is when there is a last XY move command (G1 Xxxx Yyyy Eeee) and you can scroll the log up to the nearest layer start (G1 Zzzz). This allows you to accurately determine not even the height but the point!

Little trick number one. If you print from Repetier-Host , the program writes a log of interactions with the printer. It is cleared when the program is started or printing is successfully completed. That is. If your Repetier-Host computer crashes, DO NOT RUN the program. Instead, follow a route like C:UsersAppDataLocalRepetierHost and find repetier.log there. The log file is simple, but it saves great messages like '

Little trick number two. If you are printing from Pronterface , configure log output to a file (Settings - Options - User interface - Log path). In this case, the program will duplicate what you see in the terminal window into a text file. Which, again, will allow you to determine the height of the cessation of printing.

Where is the Pronterface log setting hidden? We'll have to determine the position in some magical way. For those who are especially diligent and print in a relatively thick layer, you can take a needle and count the layers. It can be a little easier (but also requires care).

For those who are especially diligent and print in a relatively thick layer, you can take a needle and count the layers. It can be a little easier (but also requires care).

We are wondering if we can park the printer in Z at some point on the table. If yes, then we park in XY (if the nozzle is stuck to the model, you must first heat it up and then raise it a little Z!), bring it to the safe parking point Z and we execute it. For those who have 'home' in the maximum Z position, beauty - you can park fearlessly. If Z cannot be parked, see below.

Now we raise Z above the model, bring it to XY, and slowly lower it. This is how the touch will be, the position is found.

In the following, I will refer to the G92 code more than once. I'll explain how it works with an example: G92 X100 makes the printer think that its current X coordinate is 100, and then it will dance from this setting.

If it is impossible to park

If we print the upper part of the part separately, then we remove the existing one from the table and measure it with a caliper. And if you want to stand and in a hammock, then there is a solution here. Raise Z and park XY as described above. We bring to the model (until it touches, preferably with a cold clean nozzle) and give the printer a G9 command2 Z0. Now he thinks that Z is parked, therefore, it will be necessary to prepare for printing the upper part of the part, as if it were being printed on a table. Well, more on that later.

And if you want to stand and in a hammock, then there is a solution here. Raise Z and park XY as described above. We bring to the model (until it touches, preferably with a cold clean nozzle) and give the printer a G9 command2 Z0. Now he thinks that Z is parked, therefore, it will be necessary to prepare for printing the upper part of the part, as if it were being printed on a table. Well, more on that later.

Preparing a new G-code

If we choose the option with separate reprinting, then we need to peel the model from a certain height. In Cura, on the Advanced tab, in the Quality section, there is an item called Cut off object bottom. That is, cut off the bottom of the model. In Slic3r, you need to cut (Cut) the model in Z and leave only the top part. In Simplify3D (I don’t use it, so I won’t tell you for sure) it’s a little different, there you can print exactly from a given height, and not from scratch. There will be a small gap in the story. Finally, the model can be cut in netfabb and sliced.

So we have a new G-code for the top half of the model. We print.

If we want to print on the existing lower part, here are the options again. You can prepare a G-code as in the paragraph above, discard all preparatory operations (parking) from it, park XY manually, set the desired Z, give G92 Z0, warm up the heaters and start printing. We can take the existing G-code of the model, discard everything from it up to G1 Zzzz, where zzz is our print start height. This is fine if we can park Z. Park at an accessible Z point, raise the model higher, warm up the heaters, run the trimmed G-code.

Looking for what we need

Beginning of code 'trimming' with absolute feed. You can simply execute G92 in the terminal, just not to forget.

There is a nuance with cutting off the G-code. If we have a G-code generated with a relative feed (lines like G1 Xxxx Yyyy E;), then there is no need to be weird. And if the feed is absolute (the E coordinate is constantly growing), you need to give the printer a G92 Eeee command before starting the 'cut' print, where eee is the last E coordinate in the deleted part of the G-code.

By the way, the cropped G-code can also be used for a separate reprint of the upper half of the part. To do this, manually park all the axes, give G92 Zzzz (where zzz is the height of the existing bottom), and you can start 'cutting'. Do not forget to warm up the hotend and the table to the required temperatures, or leave the appropriate commands in the G-code.

Thinness

Let's say we have a printed part height of 10.0 mm. For layer 0.2, this means that 50 layers have been printed (if the first layer is also 0.2) Not sure that the last one is completed. It would be good to guess. If the layer is completed, or close to that, then it is better to continue printing from 10.2. And if the layer has just begun, then it is better to print it again. In general, depending on the degree of the Jedi, we will either have an extruded layer (which can be cut or sanded), or a gap that is more difficult to close. In my opinion, extruded is preferable because of the greater ease of elimination (although it depends on the part) and better bond strength.