3D print polishing

How to Smooth PLA to a Mirror Finish [Step-by-Step]

Need to make your prints look super smooth? Or perhaps you just want rid of those layer lines to make your print look more ‘factory finished’?

For any 3D printing materials that can’t be acetone smoothed, this quick guide is for you.

This is one of our favorite techniques when smoothing PLA prints: how to polish PLA 3D prints to a shine you won’t believe was ever 3D printed.

And we’re really talking professional grade smoothing.

The best way to smooth 3D prints vs other PLA finishing techniques

Can PLA be acetone smoothed?

It’s often said that ABS is easy to smooth (using acetone baths and similar methods), but what about PLA acetone smoothing?

Most PLAs and similar non-acetone-dissolving 3D printer filaments cannot be smoothed the same way as ABS. That’s because PLA in its pure form is not reactive to acetone.

When PLA and acetone smoothing works, it’s due to other materials added to the PLA. You’ll usually find that very cheap PLAs that have been blended with cheaper plastics to form a less pure PLA can sometimes be acetone smoothed.

Or on the other end of the scale, modified PLAs with additives can make vapor smoothing PLA possible, or at least acetone bonded.

Generally, the purer the PLA, the less acetone has an effect on it. We should maybe note here: our standard PLA won’t acetone smooth, hence us mastering this new technique!

Read on to learn how to sand 3D prints – with the right technique it’s easy.

- We also have an article on acetone smoothing ABS and ASA

Sometimes, PLA vapor smoothing can be achieved with Ethyl Acetate or even Tetrahydrofuran (THF), but we strongly advise against using either of these chemicals. They’re dangerous, the effect only works with some PLAs and you can lose a lot of detail.

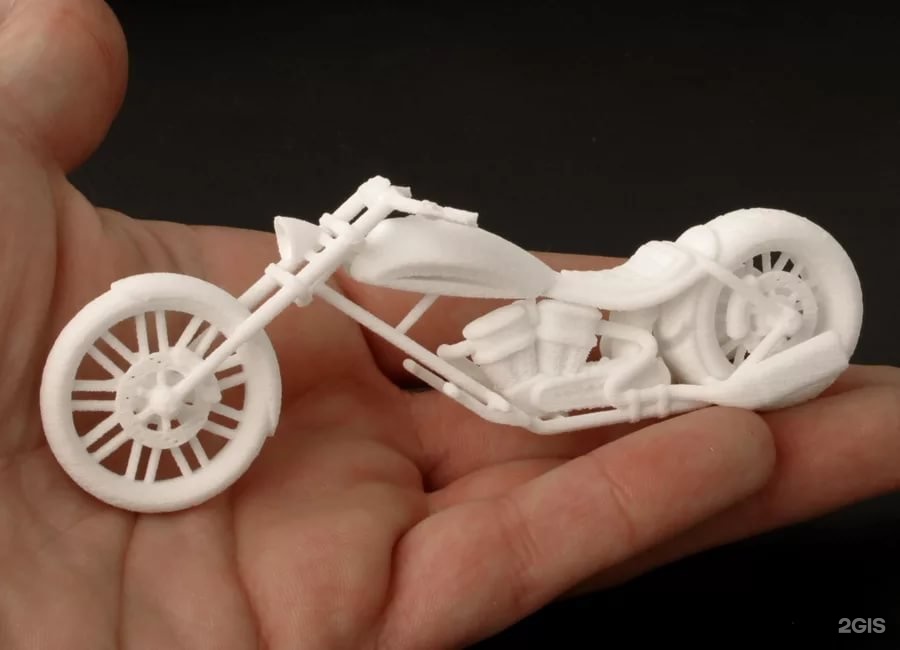

We recommend finishing PLA prints using the technique we’re describing here for your most prized prints, as it can take a little bit of time. Additionally, this technique to smooth 3D prints (with PLA filament) does not work as well on very intricate prints.

Additionally, this technique to smooth 3D prints (with PLA filament) does not work as well on very intricate prints.

Here’s a close-up of the finished effect. The gold filament is Gold/Bronze PLA. This is a 6cm long 3D Benchy for scale, and we only smoothed one side of the hull to compare. This is one smooth PLA print! Honestly, it’s like glass!

How to Smooth PLA Prints: What You’ll Need

We’re coming clean – this how to smooth PLA guide is mostly achieved from you sanding 3D printed parts.

When sanding PLA and other lower temperature materials it’s important not to be tempted to use a powered sander. The heat generated will deform the outer layers of your print.

It’s worth noting, not all PLA is created equal. Poorer quality PLA isn’t as easy to sand as higher quality. So if you are going to sand PLA, you’ll save yourself hassle printing with high-quality filament.

Now to the sanding. To start, you’re going to need a selection of fine grit sandpapers.

We suggest the following grit sizes when sanding 3D prints (and if you want a really smooth finish like above, we recommend not skipping any steps): 200, 400, 600, 800, 1000, 1200, 1500, 2000, 2500 and finally 3000.

Don’t worry: this sounds like a lot of work – but if your print has a nice finish already each layer will only take a few minutes.

It’s best if you can use ‘wet & dry’ paper when sanding 3D prints (black grit as opposed to beige effect), especially with PLA, because if you’re sanding fast, heat can build up and affect the smooth surface you’re trying to achieve.

Wetting the glass paper will lubricate and cool the surface when you’re sanding PLA prints.

This is not as necessary with smoothing higher temperature 3D printing materials, but still advisable.

1. Start with the coarsest sandpaper (approx. 200), sand and smooth the surface until you cannot feel any printing layer lines at all.

You’ve got to sand in a circular motion, as you don’t want any lines from the sandpaper affecting the surface later on.

2. Start scaling up the grit number. Once you’ve got an acceptable result with the 200 or 400, move higher up and smooth the print in increments. Don’t skimp on the time to sand them down in these early stages, it’ll save more work layer (and keep going with the circular motion).

Try to be mindful of details so you don’t lose definition as you go.

The good news is with each finer grit, you don’t need to spend as much time sanding that layer.

After using 1000 grit sandpaper it’ll start to look really smooth3. Keep working up the sizes, from 400 to 600, then to 800 and upwards. Don’t miss out steps when you get to 2000.

It’ll feel really smooth, and will polish nicely at that level – but if you want a 3D print finishing like a mirror you need to build to 3000. Here we’re at 3000 grit; you can start to see the shine before you’ve polished

4. The final (and most fun) part is when you actually get to start polishing PLA prints. Layering up those sandpaper increments doesn’t feel like you’ve made much progress, but once you polish up, the final finish looks great.

The final (and most fun) part is when you actually get to start polishing PLA prints. Layering up those sandpaper increments doesn’t feel like you’ve made much progress, but once you polish up, the final finish looks great.

How to smooth out 3D prints polished to that mirror finish? Well, we’ve found you just need any good liquid metal polish. Our favorite is the ol’ trusty Brasso.

The technique to polish your prints is simple. Get a soft cotton cloth, and apply a small amount of liquid polish. Then apply to your 3D print surface in small circles until all the polish is rubbed into the surface.

Once you’ve finished that, the surface should look reasonably shiny. The final stage is to buff up the surface into that mirrored, polished shine.

Just get an unused area of your cloth, without any polish on, and go back over the area you’ve just worked on to buff it up to a shine. And that’s it.

Here’s a before and after reminder on the technique:

Hope you found this guide on how to smooth 3D prints useful.

Checkout our packed, comprehensive guide for even more professional grade 3D printing finishing techniques here. You’ll also find painting techniques, for making those movie-grade replicas.

Raed more:

- PLA 3D printing guide

- Best PLA filament brands

6 Ways How to Polish PLA 3D Prints – Smooth, Shiny, Glossy Finish – 3D Printerly

PLA is the most popular 3D printing material, so people wonder how they can polish their 3D prints to make them smooth, shiny, and give them a glossy finish. This article will take you through the steps to make your PLA prints look great.

Keep on reading for more information about making PLA prints polished and shiny.

Here’s how to make PLA 3D prints shiny & smooth:

- Sanding your Model

- Using Filler Primer

- Spraying Polyurethane

- Applying Glazing Putty or Airbrushing it

- Using UV Resin

- Using Rub ‘n Buff

1.

Sanding your Model

Sanding your ModelOne of the most important steps to make your PLA 3D prints shiny, smooth and looking as good as they possibly can is to sand your model. Sanding can be a lot of work but it’s worth the effort as it will hide the layer lines making it a lot better to paint and apply other finishing touches.

For that, you can use sandpapers of different grits, like the PAXCOO 42 Pcs Sandpaper Assortment from Amazon, ranging from 120-3,000 grit.

It’s a good idea to move from a low grit sandpaper, then more to finer grits as you progress.

One user recommended doing the following:

- Start with 120 grit sandpaper and sand your pieces

- Move up to 200 grit

- Then give it a finer sand with 300 grit sandpaper

You can move up to a higher grit depending on how smooth and polished you want your 3D print to be. It’s always good to have a wide variety of grits, going from course to smooth, and you can even do dry or wet sanding.

Even when you plan on using other methods to smooth and polish your PLA 3D prints, you still want to sand it first.

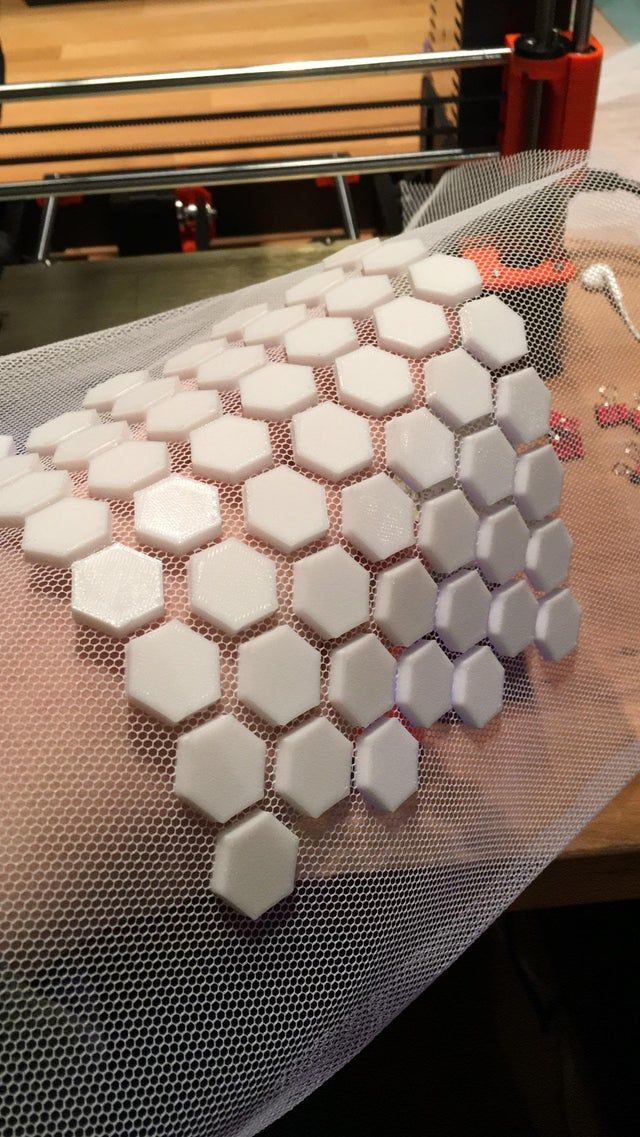

Here’s a great example of some successful sanding of a PLA model.

First attempt at sanding PLA, critiques? from 3Dprinting

If you are getting small white grooves on your PLA print after sanding, try heating them a bit with a lighter or heat gun to get rid of them. Make sure you don’t heat up the model too much or it can quickly deform, especially if the model’s walls are thin.

Sanding your PLA prints? from 3Dprinting

You can use something like the SEEKONE Heat Gun from Amazon. One user said using a heat gun is great for restoring the original color of PLA after sanding since it can get discolored easily.

If you gradually move up in sandpaper grit, that can also get rid of the white marks on your PLA.

Darkwing dad has a great video on YouTube about how to properly sand PLA printed parts, check it out below:

2. Using Filler Primer

Another great option to get your PLA prints smooth and glossy is using filler primer to smooth out the imperfections of your 3D print. Filler primer can help hiding layer lines as well as making sanding a lot easier.

There are a few different options of filler primer to choose but one of the most recommended for PLA 3D prints is automotive filler primer, such as Rust-Oleum Automotive 2-in-1 Filler, available on Amazon with great reviews.

One user started to use Rust-Oleum filler primer on his PLA pieces and found that they got a lot smoother, offering a better end-product.

Filler primer really smooths things up from 3Dprinting

Another user found that 90% of his layer lines disappeared when spraying filler primer on the printed object besides also cutting down on sanding time. Just be careful not to lose too much dimensional accuracy by using too much filler if that’s something you want.

Just be careful not to lose too much dimensional accuracy by using too much filler if that’s something you want.

Many people have been impressed with the results achieved after sanding and using filler primer on PLA objects because it allows for a very smooth and polished surface, perfect for painting afterwards.

Using a good filler is a great way to cover up imperfections and layer lines on a 3D print.

A user that has gotten good results recommended following these steps:

- Sand with low grit sandpaper like 120

- Assemble any pieces if needed

- Use filler putty in big gaps – spread a thin layer over the whole model

- Let it dry then sand with 200 grit sandpaper

- Use some filler primer and sand again with 200-300 grit sandpaper

- Paint if desired

- Apply a clear coat

FlukeyLukey has an awesome video on YouTube about spraying automotive filler primer to smooth your PLA 3D print, check it out below.

3. Spraying Polyurethane

If you’re looking to leave your PLA prints smooth and shiny then you should consider the method of spraying polyurethane on the printed model as it is thick enough and dries fast enough to fill in the layer lines, helping to create a better look to the finished object.

I’d recommend going with something like the Minwax Fast Drying Polyurethane Spray from Amazon. It’s a popular choice with the 3D printing community for smoothing PLA prints to a polished finish.

Be careful not to apply too much polyurethane because it is really thick and can remove a lot of detail, as it happened to one user who was trying to smooth out a blue PLA print. He still thinks the polyurethane added a lot of shimmer to his object.

Another user really recommends using this Minwax Polyurethane Spray as it makes adding it much easier than using a brush, he suggests doing a couple of coats in satin, high-gloss or semi-gloss to really add some shine to your object.

He also thinks it is extremely useful for clear PLA as it removes the “haze” present on surfaces and allows the print to become really transparent.

Spraying polyurethane helps to seal PLA 3D prints and even slows down the process of absorbing moisture and degrading, making the models last longer. It’s great for waterproofing PLA prints, even one coat getting the job done.

Even food safe objects can be created by using a coat of food safe polyurethane.

3DSage has a really cool video about spraying polyurethane to help smooth out PLA prints that you can check below.

4. Applying Glazing Putty or Airbrushing It

There is another great method you can try in order to polish and properly smooth out your PLA 3D prints and make them as shiny as possible. It consists of airbrushing glazing putty on your object to help hide layer lines and give it a nice smooth finish.

It consists of airbrushing glazing putty on your object to help hide layer lines and give it a nice smooth finish.

You will need to reduce the glazing putty in acetone so be aware that you will need to take the adequate safety measures, using proper gloves and a mask/respirator to handle toxic materials.

If you don’t have an airbrush setup you can still use glazing putty normally and just not reduce it in acetone. The most popular glazing putty in the market seems to be Bondo Glazing and Spot Putty, which is available on Amazon with great reviews.

One user really likes Bondo Glazing and Spot Putty to smooth out his PLA prints, he doesn’t use the airbrush method, he just applies it normally but he does recommend you to sand the piece after applying the putty.

A reviewer said he uses this putty to fill in print lines on his 3D printed cosplay pieces. He mentioned that plenty of people recommend it and there are many video tutorials that show people how to use it. It’s easy to apply and sands easily.

It’s easy to apply and sands easily.

It’s a good idea to sand the object before the putty fully dries out since it’s easier to sand before that.

Another user said he uses the Bondo Putty to smooth out his 3D printed Mandalorian armor models and gets amazing results. You can use it to fill in any gaps in your final 3D prints.

Check out the video below by Darkwing Dad who shows you how to airbrush Bondo Putty on your 3D print.

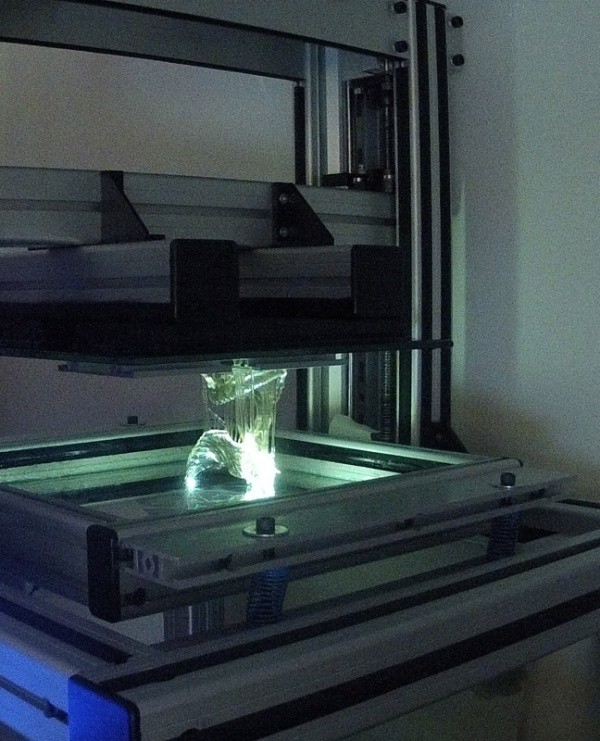

5. Using UV Resin

Another method of smoothing and polishing your PLA 3D prints is to use UV resin.

It consists of applying standard clear 3D printer resin to the model like some Siraya Tech Clear Resin with a brush then curing it with a UV light.

When you do this method, you want to brush the resin along the layer lines to avoid creating bubbles. Also, you don’t want to dip your whole model in the resin since it’s not very thick and you don’t need to apply much of it.

It can be done with just one thin coat, especially if you don’t want to decrease the detail in the model too much.

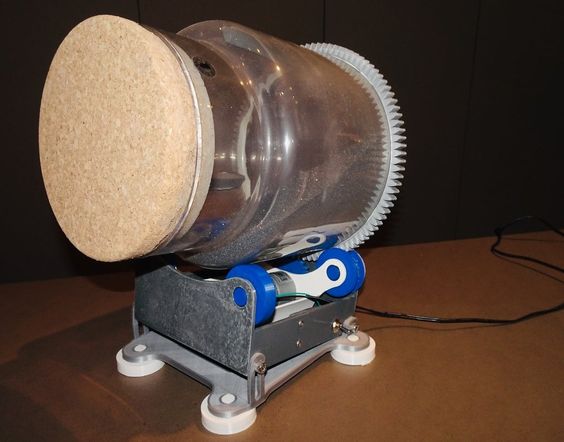

After the coat of resin is on, use a UV light and a rotating turntable to cure the model. It could be a good idea to tie some string to a part of the model so you can elevate it, then coat and cure it in one go.

You can use something like this Black Light UV Flashlight from Amazon. Many users have said they used it for their resin 3D prints to cure them.

Some users recommend that you pour some of the clear resin on a paper towel, then dry it on a UV light to use it as a curing time reference so you know how long to cure it for.

Using this technique can really get you a smooth polished surface and hide your layer lines in PLA models.

One user who has an Ender 3 said he achieved great results by filling out the layer lines and smoothing it out using the UV resin technique. He said the UV resin immediately got rid of the layer lines and help make sanding easier.

You can watch the video below by Panda Pros & Costumes on how to use the UV resin method.

6. Using Rub ‘n Buff

Rub ‘n Buff (Amazon) is one of the easiest options when making PLA prints smooth and shiny. It is a paste you can apply by rubbing it on the object’s surface to leave it more shiny and give it a unique look. Just remember to use rubber gloves to avoid any skin irritation.

It comes in a variety of different colors and metallic tones and it can give your object a unique finishing touch.

One user who put this product on their 3D prints said it worked great for making objects look like metallic silver. He uses it for post-processing 3D printed replicas successfully.

Another user said he uses it to add elegance to some lightsabers he 3D printed with black carbon fiber PLA. It works great and lasts a long time as one person put it. You can apply it with a small brush for better accuracy, then rub it with a clean cotton cloth.

Even a tiny blob of this stuff can cover large areas. Check out the example below of Rub ‘n Buff on black PLA.

Another user really liked how Rub ‘n Buff performed on PLA 3D printed objects. Even without any other finishing touch, the final result looked very shiny and smooth, being a perfect option for those that lack the painting abilities.

Rub n buff on black PLA from 3Dprinting

Check out this other example also.

Having some fun with Rub n Buff. Predator mugs that perfectly fit beer/pop cans.

Design by HEX3D from 3Dprinting

Check out this awesome video about applying Rub ‘n Buff to your 3D printed parts.

3D printed plastic post-processing, mechanical and chemical

The most popular finishing methods for 3D printed objects are sanding, sandblasting and solvent vapor treatment.

It is a misconception that 3D printing cannot produce objects that are as smooth and polished as traditional industrial technologies. Such claims can be countered with simple sandpaper, and this finishing technique is very common.

Which finishing technique is used depends largely on the geometry and material of the part. These factors determine both the level of aesthetics that can be achieved and its functionality, because different methods allow you to achieve different textures and appearances. Some methods are better suited for prototypes and exhibition models, while others are better for machine parts. nine0003

Some methods are better suited for prototypes and exhibition models, while others are better for machine parts. nine0003

Sanding

Although fusing systems are designed to produce high-quality parts directly from the printer, layer connection lines remain visible and the end user does not need this at all, especially when it comes to a solution in which the aesthetic appearance is priority. Sanding eliminates these shortcomings and can be used for models, sales samples or concepts, fully functional prototypes and end-level assemblies and mechanisms. nine0003

Many high-quality 3D-printed objects can be smoothed with sandpaper to get rid of lines where layers overlap.

Everyone knows the process of sanding. Plastic parts are processed by hand or on a grinding machine, as is done with wooden or metal elements. Sanding is inexpensive and effective, and it is a proven method by which a quality finish can be achieved. In fact, this is the most common way to refine 3D printed objects. nine0003

nine0003

All but the smallest details can be sanded with sandpaper. And they can be large as much as you like, although it can be difficult to manually get to small defects and irregularities. In typical situations, the process is relatively fast. In layer-by-layer welding, we are usually talking about the fight against stepped surfaces. Steps on a part the size of a remote control take about 15 minutes to clean, while painting the same part takes 2 hours due to additional steps such as preparation and drying. nine0003

When a part must be precise and durable in the first place, it is very important to consider how much material will be removed by sanding. If a lot of it is removed, it is necessary to make changes to the design before printing, to make the walls thicker. The requirements for the part also determine which sanding technique will be used, manual or mechanical, and which tool will be used.

Sandblasting

The second most common finishing method is sandblasting. In this case, the operator controls the nozzle, from which a finely dispersed material is sprayed under pressure onto the part in order to hide traces of layers on it. The process is fast, takes 5-10 minutes, the result looks whole. nine0003

In this case, the operator controls the nozzle, from which a finely dispersed material is sprayed under pressure onto the part in order to hide traces of layers on it. The process is fast, takes 5-10 minutes, the result looks whole. nine0003

During sandblasting, a stream of small plastic particles is sent to the part placed in a closed chamber, as a result of which the surface becomes smooth after 5-10 minutes.

This technology is easily modified and can be used with most materials. It is also used during the development and manufacture of a part, at any stage - from prototyping to production. This kind of flexibility is due to the fact that processing is usually done with fine particles of finely processed thermoplastic. It is this "sand", the abrasive characteristics of which, when sprayed, are in the range from medium to high. Baking soda works very well as it is not too harsh. However, it is somewhat more difficult to work with than with plastic. nine0003

One of the limitations of sandblasting is the size of the object. Since the process is carried out in a closed chamber of limited volume, it is usually up to about 60 x 80 x 80 cm.

Since the process is carried out in a closed chamber of limited volume, it is usually up to about 60 x 80 x 80 cm.

Steaming

The third most popular finishing method is called steaming or steaming. In this case, the part is in an atmosphere of evaporation of a substance brought to the boiling point. The particles of the evaporating substance are fused into the treated surface to a depth of approximately 2 microns, making it smooth and shiny in just a few seconds. Those who prefer a matte finish can sandblast the part after steam blasting, when the part has already been smoothed and mechanical contact stress has been removed. nine0003

Acetone vapor treatment of ABS plastic makes the surface smooth and glossy, the only drawback of this technology is that corners and small parts are folded

Since the surface is very smooth, vapor treatment is widely used for consumer goods, prototypes and medical applications. The method does not significantly affect the accuracy of the part. After sandblasting, the object is ready for applying a film, protective or decorative layer. Such coatings are usually applied to more durable materials, which are subject to high requirements. nine0003

After sandblasting, the object is ready for applying a film, protective or decorative layer. Such coatings are usually applied to more durable materials, which are subject to high requirements. nine0003

Unfortunately, like sandblasting, steam blasting has limitations on part sizes. Unlike sanding and sandblasting, steam blasting also has material limitations. Acetone is used to process ABS plastic. When processing PLA plastic, tetrahydrofuran or dichloromethane is used. Processed materials are quite practical and durable, created products retain their original strength and flexibility.

Plastic processing for 3D printer. Plastic post-processing after 3D printing ABS, PLA, Nylon, Petg

Contents:

- Post-processing of FDM parts

- Remove supports

- Removing Soluble Supports When Printing With Dual Extruder 3D Printer

- Sanding plastic 3D printed products

- Use of Acetone in ABS Plastic

- Filling irregularities in ABS plastics

- Polishing ABS/PLA nine0053 Priming and painting 3D printed products

- Acetone Baths for ABS Products

- Chemical solvent baths

- Using epoxy to finish prints

Hello everyone, Friends! With you 3DTool!

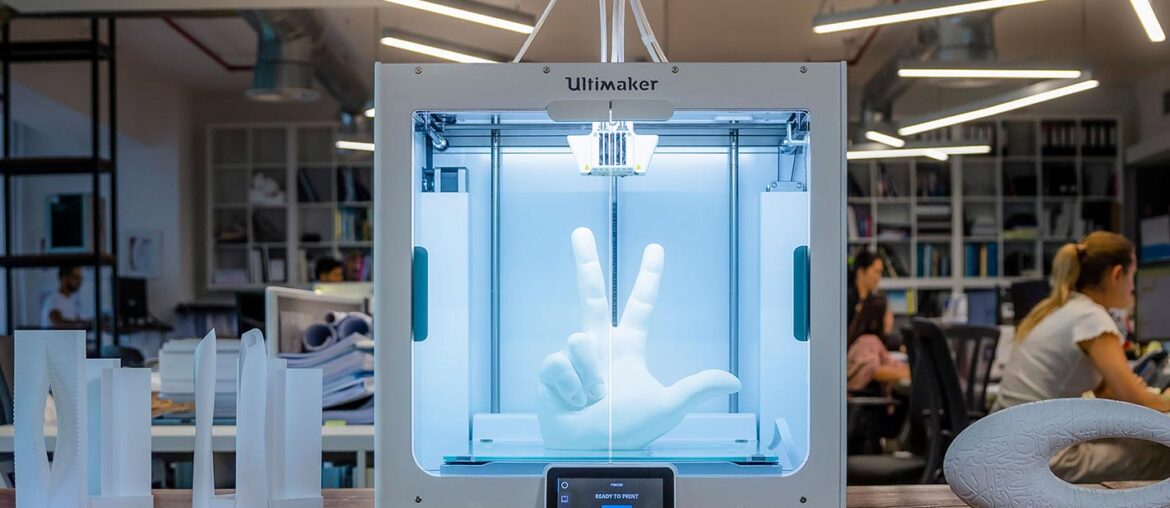

With the FDM 3D printing , plastic parts of any geometric shape can be quickly and economically produced. Finished parts show visually the lines of the layers they were printed on, making post-processing an important consideration if a smooth surface is required. Some post-processing techniques can also increase the strength of finished products by helping to reduce their anisotropic properties. nine0081 This article will discuss the most common post-processing techniques in FDM 3D printing .

Finished parts show visually the lines of the layers they were printed on, making post-processing an important consideration if a smooth surface is required. Some post-processing techniques can also increase the strength of finished products by helping to reduce their anisotropic properties. nine0081 This article will discuss the most common post-processing techniques in FDM 3D printing .

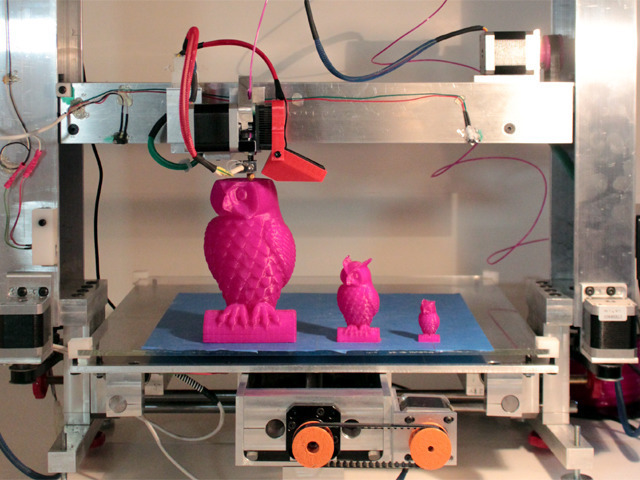

Catalog of FDM 3D printers

Post-processing of FDM parts

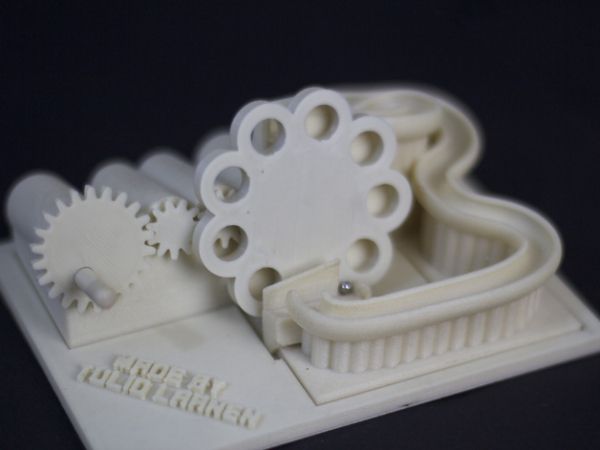

This picture above (from left to right) shows the post-processed parts FDM :

- gap filling

- raw

- sanded

- polished

- painted

- epoxy coated

Remove supports

Support removal is typically the first step in post-processing for any 3D printing technologies if the part requires support for precision manufacturing. Supports can usually be divided into 2 categories: standard and instant .

Supports can usually be divided into 2 categories: standard and instant .

Unlike other post-processing methods discussed in this article, support removal is a requirement and does not result in improved surface quality.

Removing supports mechanically is necessary when printing with a 3D printer with a single extruder (for example, PICASO Designer X, Hercules 2018, Zenit, Prusa i3 Steel Bizon) When using 3D printers with two extruders, as a rule, the supporting part of the product is made of special soluble materials. nine0003

Catalog of 3D printers with two extruders

Left to right. Original printing with support, poor support removal and quality support removal.

Tools and materials you will need for this job:

- Pliers

- Set with small tools (eg watchmaker's set).

nine0137 Support Removal Process: The support material can usually be removed from the finished model without much effort. Cleaning of the substrate material in hard-to-reach places (for example, in holes) can be done using an awl and pliers. Properly positioned support structures and proper print orientation can greatly reduce the impact of the support material on the aesthetics of the final result.

Cleaning of the substrate material in hard-to-reach places (for example, in holes) can be done using an awl and pliers. Properly positioned support structures and proper print orientation can greatly reduce the impact of the support material on the aesthetics of the final result.

Pluses

- The overall geometry of the part does not change

- Fast on time

Cons

- Does not remove visible layer lines, streaks or spots on print surface

- If support structures leave excess material or marks behind, the accuracy and appearance of the part will be reduced

Removal of soluble supports when printing with a 3D printer with two extruders

As we said earlier, the removal of supports printed from soluble materials is done differently than manually, mechanically, so the use of 2 or more extruder printers is preferable. (e.g. PICASO Designer X PRO, Raise3D PRO2) nine0003

Catalog of 3D printers with two extruders

Tools and materials you will need for this job:

- Solvent safe container

- Thinner

- Ultrasonic cleaner (optional)

Process : the final model is placed in a bath with the appropriate solvent (for example, for PVA plastic it will be ordinary water, for material HIPS will be D-Limonene ) until the support material dissolves. Support is usually printed with:

Support is usually printed with:

- HIPS (in conjunction with ABS )

- PVA (in conjunction with PLA )

Glass storage containers such as jars are excellent receptacles for diluting limonene. For dissolution in water, any non-porous container will do. For prints using HIPS/ABS bath with 1:1 ratio of limonene and isopropyl alcohol works very well for fast support removal. Many other support materials such as PVA (used with PLA ) are water soluble.

Helpful Hint: Speed up the dissolution time of the support material by using an ultrasonic bath and changing the solution as soon as it becomes saturated with plastic dissolved in itself. Using a warm (not hot) solvent will also speed up the dissolution time if you don't have an ultrasonic cleaner available. nine0081

Catalog of ultrasonic baths

Pros

- Great for complex geometries where standard support removal would be impossible without damaging the base model.

- This results in a smooth surface where the support structure is in contact with the base piece.

Cons

- Improper dissolution of the material can lead to discoloration and deformation of the entire part. nine0054

- Does not remove visible layer lines, streaks, or spots on part surface

- May cause small spots or holes in the final print if soluble material gets on the object during printing

-

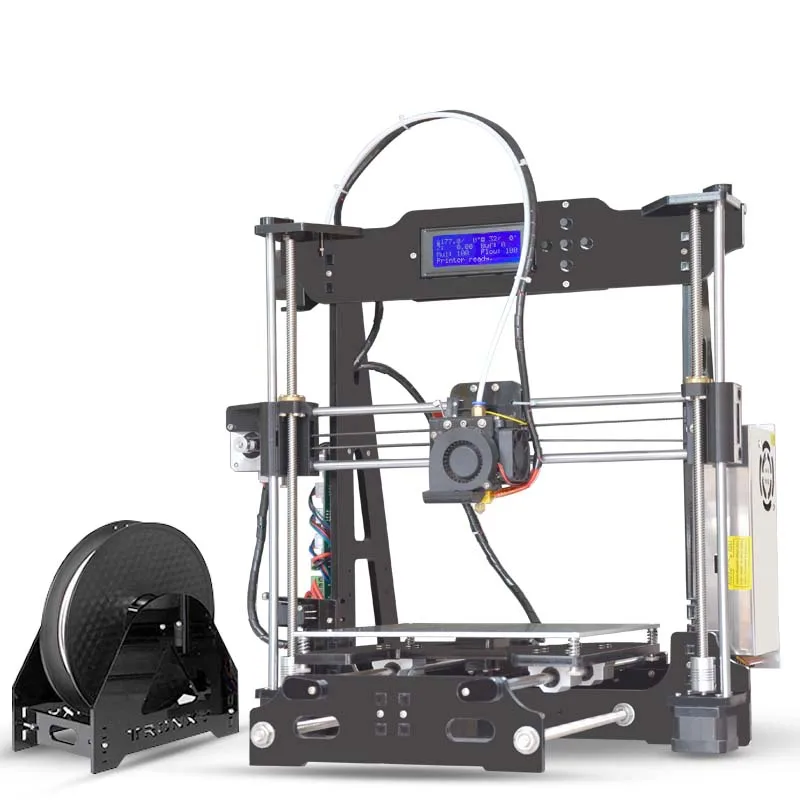

3D plastic sanding

Sanded brown ABS plastic part

Tools and materials you will need for this job:

- Sandpaper up to 1000

- Rags

- Toothbrush

- Soap

- Face mask

Sanding Process: After the supports have been removed or dissolved, sanding can be performed to smooth the part and remove any visible stains or traces of the supports. The initial grit size of the sandpaper depends on the layer height and print quality.

The initial grit size of the sandpaper depends on the layer height and print quality.

For layers with a height of 0.2 mm or less, or if there are no spots left on the part after printing, sanding can be started with a paper grain of - 150.

If there are visible spots or the object was printed at a layer height of 0.3 mm or more, start sanding with 100 grit paper.

purity. The print should be cleaned with a toothbrush in soapy water and then with a rag, between sanding gradations to prevent accumulation of dust and " sintering ". Your FDM parts can be sanded down to 5000 grit to achieve a shiny part surface. nine0003

Helpful Hint:

Always sand in small circular motions evenly over the entire surface of the part. Of course, it is more convenient to sand perpendicular or even parallel to the print layers, but this can lead to indentations in the model. If the part becomes discolored or if there are many small scratches after sanding, you can use a blow dryer. With it, you gently heat the part, thereby softening the surface a little and visible unnecessary defects will weaken or disappear altogether. nine0003

With it, you gently heat the part, thereby softening the surface a little and visible unnecessary defects will weaken or disappear altogether. nine0003

Pros

- With this method, you get an extremely smooth surface

- This method facilitates additional post-processing (such as painting, polishing, or epoxy coating)

Cons

- Not recommended for thin wall prints as this may damage part

- Difficult for surfaces with difficult geometries and fine details

- Can affect overall print accuracy if sanding is too aggressive and too much material is removed

Acetone for ABS plastics

Two printed white halves of ABS bonded with acetone and diluted plastic.

Tools and materials you will need for this job:

- Acetone

- Cotton buds or brush

Machining process: When the size of the finished part exceeds the maximum size of the 3D printer's camera, the model often has to be broken into smaller parts and reassembled later by gluing. For PLA and other materials, bonding can be done using the appropriate adhesive (selection of adhesive will depend on the plastic) . For ABS plastic, multi-piece assemblies can be glued with acetone. The mating surfaces should be lightly moistened with acetone and held firmly together or, if possible, clamped until most of the acetone has evaporated. At this point, the two parts of your model will stick together. nine0003

For PLA and other materials, bonding can be done using the appropriate adhesive (selection of adhesive will depend on the plastic) . For ABS plastic, multi-piece assemblies can be glued with acetone. The mating surfaces should be lightly moistened with acetone and held firmly together or, if possible, clamped until most of the acetone has evaporated. At this point, the two parts of your model will stick together. nine0003

Helpful Hint: increasing the contact area with acetone will increase the strength of the joint. This can be done by including block connections in the design.

Pros

- Acetone will not discolor the surface of the part like other adhesives

- After drying, the seam will exhibit ABS properties, making further processing easier and more uniform

Cons

- The joint formed by this cold welding is not as strong as a solid impression

- Excessive use of acetone can lead to aggressive dissolution of the part and adversely affect the final result and tolerances

-

Filling irregularities in ABS plastics

The gray ABS model had voids after sanding. The surface became smooth. nine0003

The surface became smooth. nine0003

Tools and materials you will need:

- Epoxy (for small voids only)

- Automotive Putty (large voids and joints)

- ABS plastic and acetone (for small voids only and for ABS parts only)

Process: After sanding or removing soluble backings, gaps often appear in the print. During printing, gaps are sometimes formed, and often this pattern is unavoidable. Small gaps and voids can be easily filled with epoxy and no further treatment is required. Large gaps, or gouges, left from attaching model assembly parts can be successfully filled with automotive putty, which will require additional sanding after drying. nine0081 The putty gives excellent results and can be easily sanded and painted after it has fully cured. The connection will be strong, and will not weaken the plastic. Conversely, autofiller parts tend to be stronger than native plastic.

Gaps in an ABS print can also be filled by making a slurry of ABS filament and acetone ( ABS juice or ABS juice ) that chemically reacts with the part and penetrates any surface voids. A ratio of 1 to 2 between ABS and acetone is recommended. This method will not significantly affect the cleanliness of the surface around the gap if properly applied. nine0003

Help Tip : If gaps are visible on FDM parts before sanding, fill them with epoxy and then sand once until dry. This will greatly reduce the overall time required to achieve a smooth surface.

Pros

- Epoxies are easy to sand and prime, making the surface easy to paint

- ABS juice will be the same color as your part, as long as you use the same filament by color and manufacturer. Therefore, there will be no discoloration of the surface

Cons

- Auto putty or other polyester epoxy will dry opaque resulting in discolored spots on the print

- Requires additional sanding to achieve uniform coverage

- Can affect overall print accuracy if sanding is too aggressive and too much material is removed

ABS and PLA polishing

nine0444 Catalog of ABS plastics

Catalog of PLA plastics

Tools and supplies you will need

- Polish

- Sandpaper

- Nonwoven wipe

- Toothbrush

- Microfibre cloth or polishing pad

Process: Plastic polish can be applied after sanding to give standard filaments such as ABS and PLA a glossy finish. After the part has been sanded to 1000 grit, wipe off any excess dust from the Non-woven » cloth, then clean it in a bath of warm water with a toothbrush.

After the part has been sanded to 1000 grit, wipe off any excess dust from the Non-woven » cloth, then clean it in a bath of warm water with a toothbrush.

Allow the piece to dry completely and buff it with a buffing pad, or by hand with a microfiber cloth and a jewelry polish designed specifically for plastic and synthetics that provides a long lasting shine.

Other plastic polishes, such as car headlight polishes, work on the same principle, but some may contain chemicals that can damage the original material. nine0003

Helpful Hint: For polishing small parts, attach the polishing pad to the Variable Speed Drill (or other rotating tool such as a drill) . Bench grinders equipped with a polishing wheel can be used for larger, stronger prints, but don't polish too long in the same place. This can cause the plastic to melt due to friction.

Pros

- Polishing is applied without the use of any solvents that can deform the part and change the precision tolerances.

- When properly ground and polished, the part will give the impression of a mirror finish, imitating plastic injection molding

- Plastic polish and cleaner are very economical, making this method quite profitable for a quality finish

Cons

- The part must be carefully sanded before polishing if a mirror finish is required. This may affect tolerances

- Primer/paint may not adhere to surface after polishing and you will need additional products

Priming and painting 3D printed products

White PLA part spray painted gray

Tools and materials you will need:

- Nonwoven wipe

- Toothbrush

- Sandpaper

- Aerosol Acrylic Primer

- Polishing agents

- Masking tape (only if using multiple colors)

- Gloves and petal mask

Finishing process: after the part is properly sanded (up to 500 grit sandpaper is required at this stage) , the print can be primed. The primer should be applied in two coats using an aerosol can.

The primer should be applied in two coats using an aerosol can.

An aerosol primer designed for painting models will provide an even coverage and be thin enough not to darken the part before painting.

A thick primer, such as one available at the hardware store, may stick together and require more sanding.

Apply the first coat in short, quick strokes at a distance of about 15 - 20 cm from the part to avoid the formation of a thick layer of primer. Let the primer dry and sand down any imperfections with 9 grit sandpaper.0079 500. Apply the final coat of primer with light, quick strokes.

Once the primer is complete, painting can begin. Painting can be done with acrylic paints and artist's brushes, but using an airbrush or spray can give a smoother surface.

Hardware store spray paint tends to be thicker and harder to control, so it's best to use paints made specifically for painting models. nine0081 The primed surface should be sanded and polished (sanding and polishing sticks used in nail salons are ideal for this application) and then cleaned with a non-woven cloth.

Paint over the model using very light layers; the first few layers will look translucent. Once the paint has formed an opaque layer of (usually after 2-4 coats) , allow the model to dry for 30 minutes to allow the paint to set. Carefully polish the paint layer with nail sticks. nine0003

Multi-colour models can be painted with masking tape. Once all layers of paint are ready, remove the tape and buff the paint using polish paper. Polishing paper such as 3M or Zona can be purchased in a variety of grit sizes. You can buy it in a pack in many online stores. It will give the paint a shine that cannot be achieved in any other way.

Helpful Hint: Do not shake the can when using spray paint! The goal is to mix the pigment or primer, shaking the propellants will cause bubbles to form in the aerosol. Instead, rotate the jar for 2-3 minutes. The stirring ball should roll, not rattle. nine0003

Pros

- Professional results with attention to detail

- Excellent appearance of the final product, regardless of the material/color in which the object was originally printed

Cons

- Paint and primer will increase the volume of the model, which will change the tolerances and can cause problems if the part is part of the assembly

- Buying a high quality spray paint or airbrush is not cheap

Acetone baths for ABS products

Smoothed black model of a petal with a spherical surface made of ABS plastic after an acetone bath.

Tools and materials you will need:

- Non-woven cloth

- Sealed container

- Thinner

- Paper towels nine0053 Aluminum foil (or other solvent resistant material)

- Face mask and chemical resistant gloves

Process: Line the chosen container with paper towels along the bottom and, if possible, up the sides. It is very important that the steam does not disturb the chamber itself. The chamber may be sealed.

It is recommended to use glass and metal containers.

Pour in enough solvent to dampen but not drown the paper towels. This will also help them stick to the side walls of the container. nine0081 Acetone is well known for its ability to smooth out ABS parts. For PLA, smoothing is possible with various solvents, they work well, but as a rule, with PLA, it is more difficult to get a smooth surface, unlike ABS.

IMPORTANT! When working with any solvent, please follow the safety regulations for the chemical and always follow the appropriate safety precautions !

A small "raft" of aluminum foil or other solvent-resistant material should be placed in the middle of a lined paper towel container. nine0081 Next, place your part on this raft (either side selected as the bottom on the raft) and close the lid of the container.

nine0081 Next, place your part on this raft (either side selected as the bottom on the raft) and close the lid of the container.

Steam polishing can vary in duration, so check the print periodically. Heat can be used to increase polishing speed, but care must be taken to prevent the buildup of potentially explosive fumes.

When removing the part from the chamber, try not to touch it at all, leaving it on the raft and removing it from the container. Any points of contact with the part will generate surface defects because the outer shell will be half dissolved. Allow parts to dry completely before use. nine0003

NOTE . Many aerosol and/or spray solvents are flammable/explosive and solvent vapors can be harmful to human health. Be especially careful when heating solvents and always work in a well ventilated area.

Pros

- Smooths out many small spots and reduces layer lines present in the print without any additional work nine0053 Creates a very smooth "shell" around part

- A very fast method that can be implemented with improvised means

Cons

- Doesn't "heal" gaps or completely mask layer height

- The dithering process "dissolves" the outer shell of the print, and therefore this greatly affects tolerances

- Negatively affects print strength due to changes in material properties nine0162

- Solvent safe container

- Thinner

- Hook or small screw

- Wire

- Drying rod or stand

- Face mask and chemical resistant gloves

- Print surface smoothes much faster than steam polishing

- Produces much less fumes than other solvent polishing methods and is safer

- Very aggressively smoothes the surface of the part, so the tolerances deviate greatly from the specified

- Immersion too long can lead to complete deformation of the part and a significant change in material properties

- Two-component epoxy (e.g. XTC-3D)

- Foam applicator

- Brushes

- Mixing container

- Sandpaper 1000 grit or higher

- A very thin coat of epoxy will not significantly affect part tolerances (unless the part has been sanded first)

- Resin provides an outer protective sheath around the part

- The layer lines will still be visible, they are under the "smooth" shell

- Using too much epoxy can cause surface dripping and over-smoothing of print details

- Electroplating solution. It can be prepared by mixing a metal salt with acid and water, but if the proportions are not accurate, it will be difficult to get a professional result.

Buying a ready-made solution guarantees that there are no problems with plating. nine0054

Buying a ready-made solution guarantees that there are no problems with plating. nine0054 - Sacrificial anode. The anode material must match the metal of the plating solution, so if copper sulfate is used in the solution, then a copper anode should be used. You can use any item made of metal plating (copper wire, for example), or you can purchase a thin strip of metal plating that is made specifically for electroplating.

- Conductive paint or acetone and graphite. The print surface must be conductive for coating, which can be achieved with conductive paint or a 1:1 solution of graphite and acetone. Conductive ink will work on any printed material, but a solution of acetone and graphite will only work on ABS. nine0054

- Power Rectifier - A battery can be used instead of a rectifier, but a battery is not as efficient and will not deliver results as quickly and consistently as a rectifier. A rectifier is also a safer option. It can simply be turned off to stop the current flow during electroplating.

- Conductive screw or eyelet

- Non-conductive vessel

- Lead set

- Non-conductive gloves and goggles. nine0054

- The metal shell increases the strength of the plastic part, which greatly expands the possibilities of its application and use

- The outer metal coating is very thin, so if properly applied, tolerances of 9 can be held tightly0054

- Creates a beautiful surface that, if done correctly, will not look like a 3D printed object

- It is usually very expensive to do this at a professional level, and home plating requires a fair amount of professional processing equipment

- Home electroplating can cause electric shock if not followed

- Email: Sales@3dtool.

Learn more

Chemical solvent baths

Tools and supplies you will need:

Process: Make sure the container you are using is wide enough and deep enough to hold the part and solvent. Fill the container with the appropriate amount of solvent, taking care to minimize splashing. As with steam smoothing, acetone should be used to dip the ABS. nine0081 PLA is sufficiently resistant to solvents, so it may take several passes to achieve the desired result.

Fill the container with the appropriate amount of solvent, taking care to minimize splashing. As with steam smoothing, acetone should be used to dip the ABS. nine0081 PLA is sufficiently resistant to solvents, so it may take several passes to achieve the desired result.

Prepare the part for dipping by screwing an eye hook or small screw into an inconspicuous surface of the imprint. Pass the wire through the eye of the hook or around the screw so you can lower your piece into the wire bath. If the wire is too thin, you won't be able to submerge the part in the solvent.

Once the part is prepared, quickly immerse the entire object in the solvent for no more than a few seconds using wire. Pull out the print and attach it to a wire over a dryer rod or rack to allow the solvent to completely evaporate from the surface. The part should be gently shaken after you remove it to facilitate drying and avoid solvent build-up in depressions on the surface. nine0003

Helpful Hint: If the part has an opaque whitish color after drying, it can be hung over a solvent bath for a while so that the evaporating vapors slightly dissolve the surface. This will restore the color of the print and provide a glossy outer layer.

This will restore the color of the print and provide a glossy outer layer.

Pros

Cons

Using epoxy to finish prints

The part is sanded and coated with epoxy resin.

Tools and supplies you will need:

Process : After the print has been sanded (sanding first will give better end results) , completely clean it with a non-woven cloth. nine0081 Mix the correct ratio of resin and hardener as directed in the resin instructions. Make no mistake about the proportions. Epoxies are exothermic when mixed, so glass containers and containers composed of low melting point materials should be avoided.

nine0081 Mix the correct ratio of resin and hardener as directed in the resin instructions. Make no mistake about the proportions. Epoxies are exothermic when mixed, so glass containers and containers composed of low melting point materials should be avoided.

Containers specifically designed for mixing epoxy resins are recommended. The wrong ratio will lengthen the drying time and the epoxy may never be able to fully cure, resulting in a disastrous and sticky part. nine0003

Mix resin and hardener thoroughly according to instructions. Stir gently to minimize air bubbles. The faster the epoxy dries, the better. Most epoxies have a working dry time of only 10-15 minutes, so do your post-processing in the proper order.

Apply the first coat of epoxy using a foam applicator and try to minimize resin buildup on recessed surfaces or other details of the print. Once your part is sufficiently covered with resin, allow it to fully cure according to the manufacturer's instructions. One coat may be enough to smooth the detail, but for optimum appearance, the print should be lightly sanded with fine sandpaper (1 000 grit or higher) . Remove dust with a non-woven cloth and apply a second coat of epoxy in the same manner.

One coat may be enough to smooth the detail, but for optimum appearance, the print should be lightly sanded with fine sandpaper (1 000 grit or higher) . Remove dust with a non-woven cloth and apply a second coat of epoxy in the same manner.

Pros

Cons

Tools and supplies you will need:

Electrophoresis solutions are acids and can cause eye damage if splashed, so appropriate goggles are required. Also, these solutions can irritate the skin and conduct a charge when used. Therefore, non-conductive gloves should always be used.

Process: metal plating can be electroplated at home or in a professional workshop. Proper plating requires a deep knowledge of materials, and what you can do at home has certain limitations compared to what can be done in a professional workshop. nine0081 For a better finish and a wider range of plating options, including chrome plating, a workshop would be the best option. For clarity, the copper plating process will be described below.

At home, galvanization can be done using copper or nickel plate. It is imperative that the surface of the print to be processed is as smooth as possible before coating; any unevenness and visible lines of the layers will start to stand out after coating.

Prepare a cleaned and sanded print. By coating the plastic with a thin layer of high quality conductive paint or a solution of acetone and graphite (if made of ABS) . Allow the conductive coating to dry completely and sand if necessary to ensure a smooth finish. It is extremely important to minimize contact with the print or wear gloves as the sebum on your fingers will interfere with the coating process.

Insert a screw or hook with an eye into an inconspicuous surface of the part, similar to dipping in solvent.

Attach to one of the rectifier leads. This will serve as the cathode. The connection must be made to the negative terminal of the rectifier. Connect the copper anode to the positive terminal of the rectifier using the second power wire and fill the container with enough electroplating solution so that the imprint and the copper anode are completely hidden. Turn on the power rectifier. After the rectifier is turned on, make sure that the part does not touch the anode in any way. nine0003

nine0003

IMPORTANT! Be very careful at this stage. After the part is lowered into the bath and the system is energized, any contact with the solution, anode or cathode may result in personal injury !

Set the power supply rectifier to 1-3 volts. After that, the metallization process will begin until the part is completely covered with metal. Voltage may be increased to reduce coating time, but should not exceed 5 volts. Simply turn off the straightener and remove the print after a satisfactory finish has been applied. Dry the print with microfiber towels. Coat the part with a special varnish for metal after drying. This will protect it from corrosion.

Pros

Cons

Well, that's all we have! We hope this article was useful for you!

Order 3D printer or FDM consumables , you can