3D print drone parts

3D Printed Parts - 3D Printing

Skip to ContentFilter By:

Black (68) Blue (8) Fluorescent Yellow (1) Gold (4) Gray (1) Green (11) Orange (6) Pink (2) Purple (2) Red (14) Titanium (4) White (6) Yellow (7)

Manufacturer

AstroX (1) BETAFPV (2) Brain3D (101) Diatone (8) Ethix (1) Flywoo (11) GEPRC (1) GetFPV Affiliate (1) Great 3D (1) Happymodel (5) HOM FPV (1) iFlight (10) ImmersionRC (1) Lumenier (11) Madcase (1) PIRAT (1) RunCam (1) Shen Drones (3) SpeedyBee (4) StanFPV (2) Team BlackSheep (1) XHover (6)

Receiver Protocol

Analog (1) DJI (11)

Antenna Connector / Length

SMA (1)

Voltage / Cell Count

14. 8 Volt (4 Cell) (155)

Sort Featured New Best Sellers Most Viewed Biggest Saving Price: low to high Price: high to low Reviews Count

View as Grid List

Page

- You're currently reading page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page

Show

20 40 60 100

per page

of 174

Loyalty Program

Earn 'Crash Cash' loyalty rewards to redeem towards your next purchase!

Create An Account

Discounts & Coupons

Check out our landing hub for all GetFPV promotions, discounts, and coupons!

Learn More

Stay Connected

Enter your e-mail to get exclusive deals and stand a chance to win monthly FREE products!

Email Address

Live Chat

Check Order Status

Same Day Shipping

Customer Support

Mon - Fri: 9:00am - 6:00pm ESTsupport@getfpv.

com | +1 (941) 444-0021

com | +1 (941) 444-0021 Need Help?

- Technical Support

- Order Support

- Check Order Status

- FAQ

- Contact Us

Store & Shipping

- Loyalty Program

- Drone Brands

- Discounts and Coupons

- Reseller Catalog

- FREE SHIPPING on most orders $99+

- Local Curbside Pickup

- Shipping Tips

- Return Policy

Shop Top Categories

- Drone Bundles

- FPV Equipment

- Drone Frames

- Electronics

- Motors

- Batteries / Chargers

- Radios

- Propellers

More GetFPV

- GetFPV Learn

- GetFPV Benefits

- GetFPV Distribution

- FPV Crate

- FPV Clearance

- Career Opportunities

Connect

- Newsletter Sign-Up

- Text Message Sign-Up

- YouTube

- AUVSI

- Clubs, TSA, STEMS

© 2023 GetFPV LLC. All Rights Reserved. | Terms & Conditions | Privacy Policy | Site Map

All Rights Reserved. | Terms & Conditions | Privacy Policy | Site Map

Best 3D printed drone projects

Is a 3D printed drone as efficient as a traditional drone?

Drones and 3D printing are a perfect match! The benefits of drones are more and more attracting for numerous sectors, as it allows to go to areas which are inaccessible for humans. The problem is that a traditional drone can be very expensive if you want a high-quality device. Moreover, it may occur that the quadcopter that you chose isn’t totally adapted to your project and doesn’t have all the features you need. Or on the contrary, the drone can have too many features and you will not use all of them.

The 3D printing industry allows to create your own drone, it’s the perfect way to get a drone customized to fit your needs. It’s is cheaper and the product development process is faster with the additive manufacturing technology. It is possible to create really lightweight drones, little or bigger ones, and even faster ones. 3D printing appears to be a smart choice to develop a drone project.

3D printing appears to be a smart choice to develop a drone project.

And if you’re not planning to use 3D printing to manufacture your drone, at least, it is possible to use 3D printing for your prototyping phase.

Now, let’s see in our top the best projects developed with 3D printed drones!

Top 15 of the best 3D printed drone projects

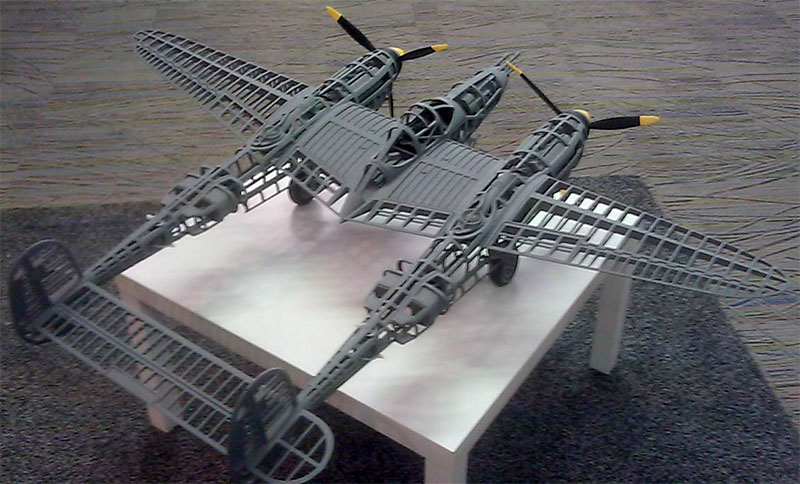

1 – The 3D printed drone project of the Marine Corp

Drones are already well-used in the military sector since they allow the troops to get real-time images of dangerous areas and situations. But the major problem with a drone is its cost. If the drone is broken, it is quite expensive to replace. And even if there’s just a broken part, the budget to fix it can be really high.

source: https://www.popsci.com/marine-corps-3d-printed-drones

As they were beginning to be unwilling to use it, they looked for another solution. With a more affordable drone, they would be more confident to use it. And here came the solution: 3D printing. To 3D print a drone is way cheaper and fast to assemble. By using additive manufacturing, the entire system that they are planning to use only costs 615$ while an individual Raven drone costs 30 000 $.

To 3D print a drone is way cheaper and fast to assemble. By using additive manufacturing, the entire system that they are planning to use only costs 615$ while an individual Raven drone costs 30 000 $.

This 3D printed drone project is the proof that additive manufacturing can be useful in various sector: even the Marine Corp wants to 3D print their drone. It is also the proof that these kind of drones are reliable.

2 – 3D printed drone to save lives during disaster relief

This 3D printed quadcopter drone as designed by Yuki Ogasawara and Ryo Kumeda. The idea of the project emerged after the earthquake that touched Japan in 2011.

During this disaster, nearly 16 000 people were killed and 2 500 missing. The goal of this 3D printed drone is to fly in dangerous zones to find survivors, after a catastrophe, such as an earthquake. These drones could enable emergency services to see images in real time and be more efficient by saving time in the research.

Source: https://3dprint. com/181435/generative-design-x-vein-drone/

com/181435/generative-design-x-vein-drone/

3D printing allowed them to create a model that they could customize and adapt to their project. It has the perfect size and weight for these kinds of conditions, it has an extended flight time, and a reinforced frame. The drone is also capable of carrying thermographic and infrared-imaging equipment, which can be particularly useful to locate people needing help.

3 – UVify and their 3D printed racing drones using autonomous technology

UVify is an american tech company, working on racing drones, robotics, and artificial intelligence systems. Their will is to develop their drones with FPV (First Person View) in the e-sport world. This 3D printed drone is called Draco. Some of the drones created by UVify are raced by professionals in different competitions.

They are according a big importance to the drone design and the rapidity of the drones. They have to be efficient. Uvify wants to create an out of the box drone, specially made for the professional drone racing market.

“We used and are still using 3D Printing in our activity: we’re creating at least a new iteration every week thanks to 3D printing prototypes.” said Robert Cheek in one of our previous blogposts.

They are using the 3D printing technology both for prototyping and production. It allows them to get their drone with a fast lead time and get a high-quality final product.

4 – Earth observation with a 3D printed drone thanks to Svarmi

Svarmi is an Icelandic company, specialized in drones as a service, for remote sensing or earth observation. Their clients are architects, engineers, researchers, and any people wanting aerial images.

As their product development is based on their clients’ expectations, 3D printing allows them to be free and customize their drone as much as their customers need it. As this company explained to us: “Other traditional manufacturing methods are too slow and costly for our purposes since we need to be able to have something ready within a week or two. After integrating the new sensors to our drones we test them out with our customers and redefine the requirements if needed to suit the task and sometimes redo the process again by refining the design or selection of sensors.”

After integrating the new sensors to our drones we test them out with our customers and redefine the requirements if needed to suit the task and sometimes redo the process again by refining the design or selection of sensors.”

These 3D printed quadcopters are the challenging and innovative project of two mechanical engineers. They created 3D printed drones thanks to our online 3D printing service, they state that 3D printing allowed them to save 40% time on their product development process.

5 – CargoCopter 3D printed drones: the future of delivery

Delivery services are more and more requested. Recently, we’ve heard a lot in the past few years about delivery services that could be using drones in the future. This is now a reality, and it’s the goal of the CargoCopter, a fully 3D printed drone. This drone is able to transport a charge of 5 kg and reach the speed of 150 km/h. It is an efficient drone which aims to deliver goods on a long distance.

It is an efficient drone which aims to deliver goods on a long distance.

3D printing is allowing these KU Leuven researchers to do some rapid prototyping, so they can adjust the design of the drone through the years to finally create this CargoCopter. This drone project may be the future traditional way to deliver goods!

6 – Jarriquez and their 3D printed drone

As for the military or rescuing sector, using a drone is firstly a way to go where humans can’t go. It is also the goal of the 3D printed drone developed by Jarriquez

This 3D printed drone is actually able to find its way with minimal human intervention. This unmanned aerial vehicle can generate a high quality 3D map, and can go in dangerous zones. Why did they chose 3D printing to develop their project? Because it was easy to get an object from a CAD model in a few days only, and with a reasonable price.

Jarriquez Drone with its 3D mount for the LIDAR sensor

“Our solution integrated a LIDAR sensor that could have been used for many different devices. Attaching it to the body of the drone in the proper way was essential for the feature to work. 3D printing gave us the possibility to do it in a record time and at a very reasonable price” added Mathieu Agostinucci, from the Jarriquez team in our previous interview.

7 – A 3D printed drone for rescuing missions

This drone is the result of the work of a swiss-based doctoral assistant Przemyslaw Mariusz Kornatowski. This 3D printed drone is called PackDrone.

This quadcopter can be deployed in rescue missions. It is made to deliver water, food or any first aid equipment to people trapped after a catastrophe.

source: https://www.redbull.com/gb-en/packdrone-folding-drone

A lot of parts of this drone were created thanks to additive manufacturing. It has a particular design: it actually is a folding drone, created especially to be safe and easy to put in a backpack by the teams in charge of rescuing missions.

8 – Blue Robotics and their underwater 3D printed drones

The company Blue Robotics created underwater drones. This crazy project started with a crazy idea: they decided to send a GPS-guided solar-powered robotic boat from Los Angeles to Hawaii.

“The industry of Marine Robotics has stifled innovation by keeping the mechanics and technology expensive. With 3D printing people are able to prototype and final manufacture parts inexpensively and quickly. That’s why we chose Sculpteo!” – said Rusty Jehangir, the founder of Blue Robotics

Using additive manufacturing is also a way to get small batches for the parts of the final product, which isn’t possible with traditional manufacturing. This drone is quite a challenging project, as the final result has to be resistant, light, and ready for a special journey!

9- Local Motor and their 3D printed drone connected to its… 3D printed car.

This project is quite ambitious but it is above all managed to see the limits of three different technologies : autonomous cars, drones and 3D printing.

source: https://www.cnet.com/roadshow/news/local-motors-3d-printed-car-now-has-a-drone-because-autonomy/

It is an impressive challenge, driven by Local Motor. The autonomous car is able to drive by itself thanks to a dedicated software. In the meantime, the driver of the car is able to pilot the rc drone to look around with the specific view of the drone. It enables the driver to see eventual traffic jams, or just see the landscape, and explore new areas.

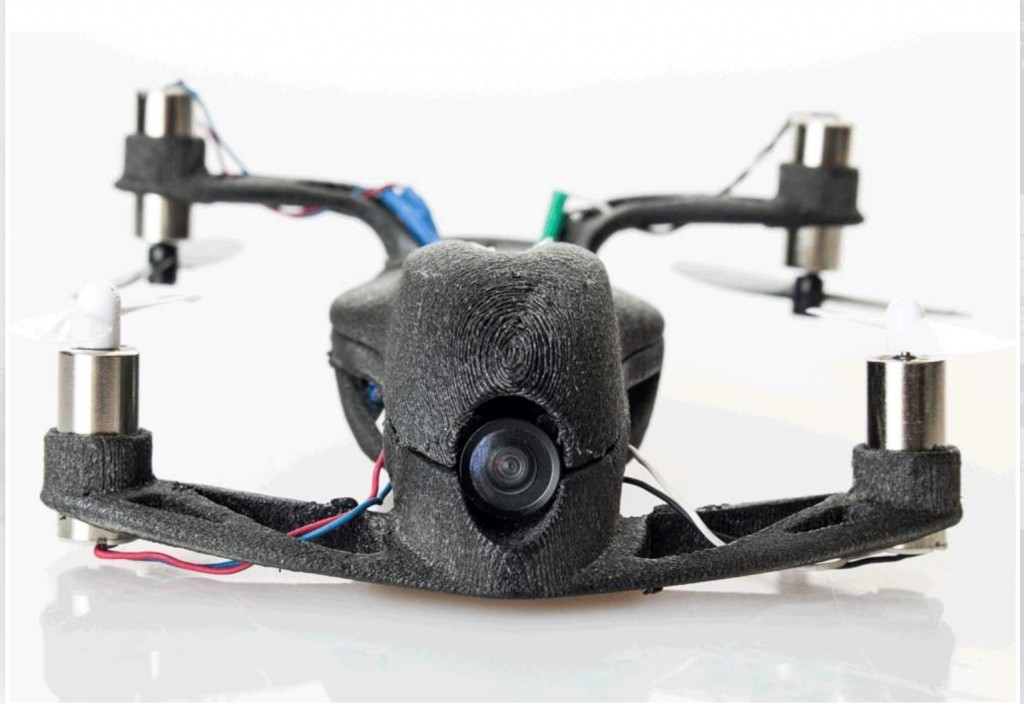

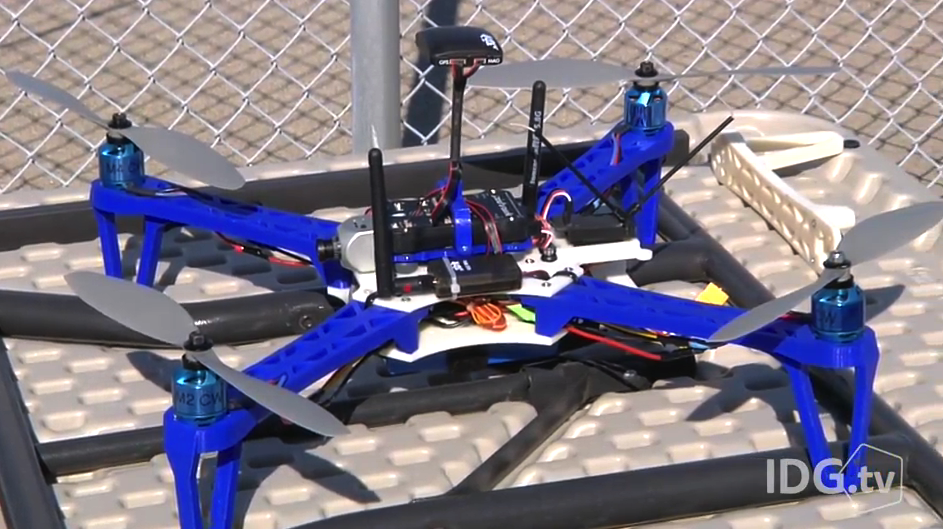

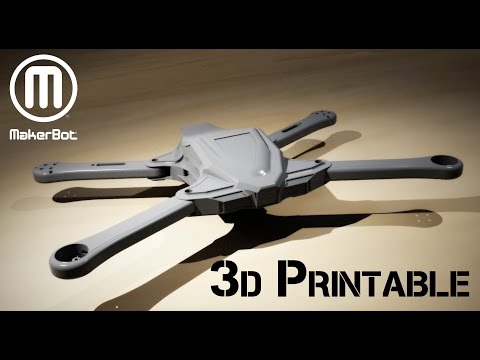

10 – 3D printed drone, created only using 3D printing and laser cutting technology

Most of the time, 3D printed drone projects are using additive manufacturing to create prototypes, and some parts of the finished product.

Here, the project was to create a traditional quadrotor drone, using exclusively 3D printing and laser cutting. They 3D printed the arms, the motor mounts, and every parts of the drone. It was a success, showing that it is possible to create anything with 3D printers. This drone is extremely light and it is the proof that everything is 3D printable, thanks to all of our 3D printing materials and technologies. Moreover, this project shows the capacity and accuracy of the laser cutting technology.

Moreover, this project shows the capacity and accuracy of the laser cutting technology.

11 – A 3D printed drone to capture professional images with Hexadrone

Hexadrone is a company based in France, building drones and offering their service to film for TV shows, advertisements or movies. As they are creating high quality filming, they need a stable drone.

As there is actually a weight limitation for drones, Hexadrone needed to use a light material. And that is where 3D printing shows to be a helpful solution. They used our plastic material, and the SLS technology enables them to get resistant and complex parts, perfectly fitting their needs.

“Thanks to 3D printing, parts are really quickly available, which means we can test them within a few days, and make changes reactively” said Alexandre Labesse, CEO at Hexadrone.

12 – 3D robotics and My Mini Factory create 3D printed drones

3D robotics and My Mini Factory collaborated on the development of drones and the model Iris+ is one of them. You can then download all the technical STL files with great 3D details, and you can then 3D print at home using your 3D printer, or a 3D printing service such as Sculpteo.

You can then download all the technical STL files with great 3D details, and you can then 3D print at home using your 3D printer, or a 3D printing service such as Sculpteo.

13 – The Dark Matter, by Clogworks

The Dark Matter is a drone developed by Clogworks, based on a modularity concept.

This drone is not fully 3D printed, but is manufactured using CNC Machining, Carbon fibre and 3D printing. The goal of this Dark Matter project, was to create a drone with a bigger flexibility and a great ease of maintenance. The performances of the drone are quite impressive, all about precision.

14 – The smallest drone, by UPenn

The 3D printed mini drone made by UPenn, Piccolissimo just has one motor and two rigid bodies. Researchers at the University of Pennsylvania’s School of Engineering and Applied Science developed the smallest flying vehicle. In order to make a really light device, this tiny drone has been 3D printed with really light plastic.

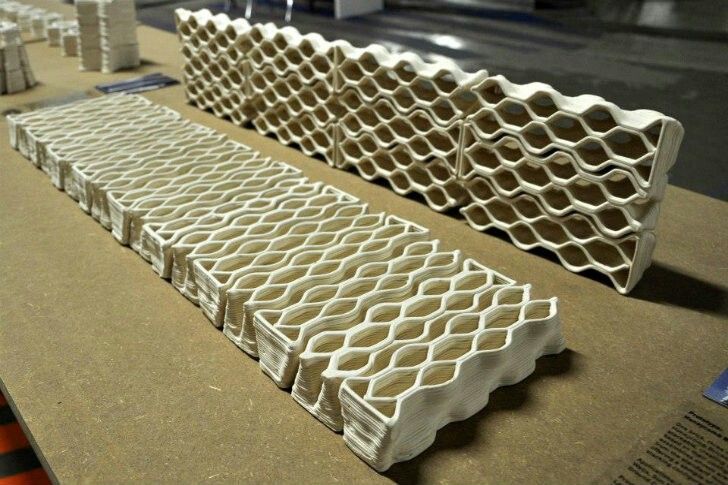

15 – Skeleton x14 quadcopter

The Skeleton x14 quadcopter can be printed by any desktop 3D printers, as its STL files are available online. The design of this drone is quite interesting as it is based on an intricate design mesh. It is totally possible to customize it once you have the 3D files of the drone!

The design of this drone is quite interesting as it is based on an intricate design mesh. It is totally possible to customize it once you have the 3D files of the drone!

DIY: build your own drone!

You have an idea for a drone project ? Keep in mind that your ideas are 3D printable, and that we can totally help you with this, thanks to the 3D printers of our online 3D printing service. Here, at Sculpteo, an intern created a 3D printed drone from scratch and we are sure that you could do it as well.

As we just saw, it is possible to create a drone using 3D printing and laser cutting you don’t need traditional manufacturing, just 3D printers. First, you will have to use a 3D printing software. If you don’t know which software to use check out our blogpost to choose the perfect free 3D modeling software, adapted to your level of expertise. Some of them are pretty easy to use.

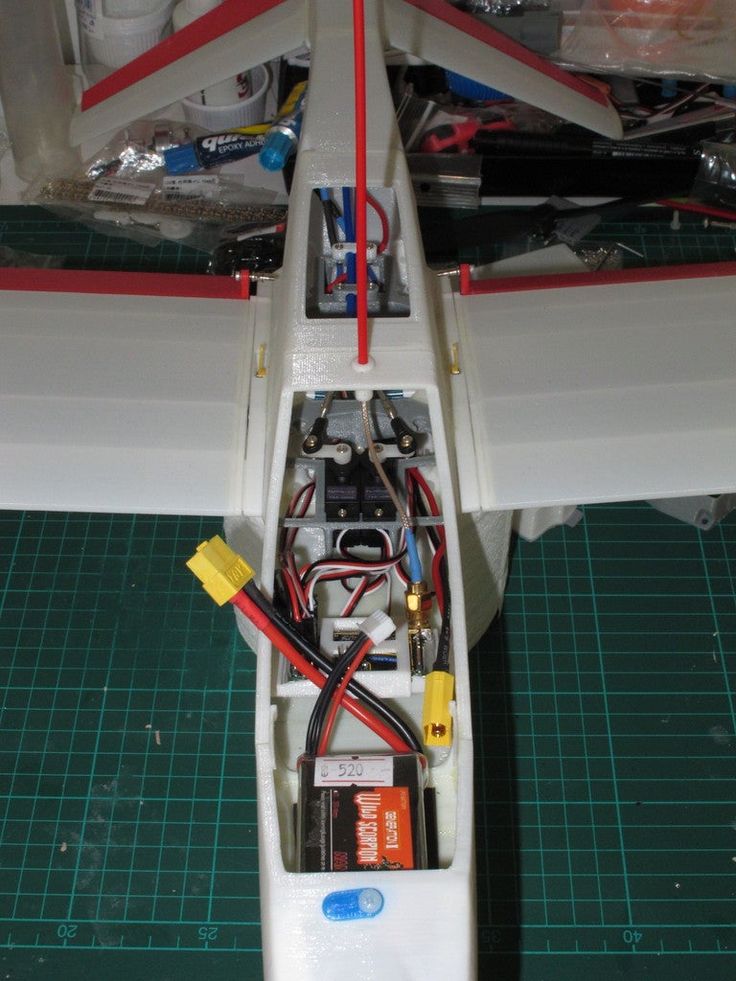

Once your drone is 3D designed, you can choose the 3D printing materials to print your parts. Then, you have to complete your order, and you’ll receive your 3D printed models in a few days. Obviously, you’ll have to assemble the different parts. If you are a little bit crafty and determined, ready to deal with electronic components, motor mounting and camera mounting, you can achieve a great 3D printed drone project.

Then, you have to complete your order, and you’ll receive your 3D printed models in a few days. Obviously, you’ll have to assemble the different parts. If you are a little bit crafty and determined, ready to deal with electronic components, motor mounting and camera mounting, you can achieve a great 3D printed drone project.

You want to give it a try ? Upload your 3D model now and 3D print your own unmanned aerial vehicle!

If you want more informations to 3D print your drone, don’t hesitate to contact us.

3D plastic printing for the development of quadrocopters

3D plastic printing for the development of quadrocopters

Konstantin Innokentiev

3D scanning engineer, metrology expert

Aerialtronics is a Dutch company that designs and manufactures civilian drones. It employs 35 people. The company specializes in the production of the most customized drones, made according to the requirements of the customer. This is a piece production, which requires an individual approach to the manufacture of parts. nine0003

nine0003

Aerialtronics is a Dutch company that designs and manufactures civilian drones. It employs 35 people. The company specializes in the production of the most customized drones, made according to the requirements of the customer. This is a piece production, which requires an individual approach to the manufacture of parts.

Challenge: How to accelerate the development of new drones

The company has developed a concept model that combines the basic platform and a set of elements that can change depending on the customer's tasks. This drone was named Altura Zenith. In addition to the basic characteristics, customers were offered various options to choose from: the number of motors and power, payload, flight time, supported software. nine0003

To implement all these options, the company's engineers needed to make unique parts of the drone's body. Even minor changes in technical specifications required redesigning and changing individual parts of the device. The solution of such issues by traditional methods required large financial and time costs.

The solution of such issues by traditional methods required large financial and time costs.

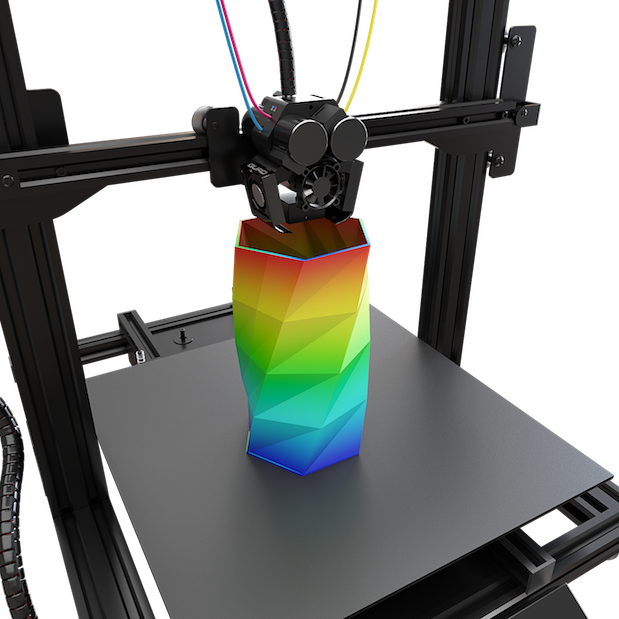

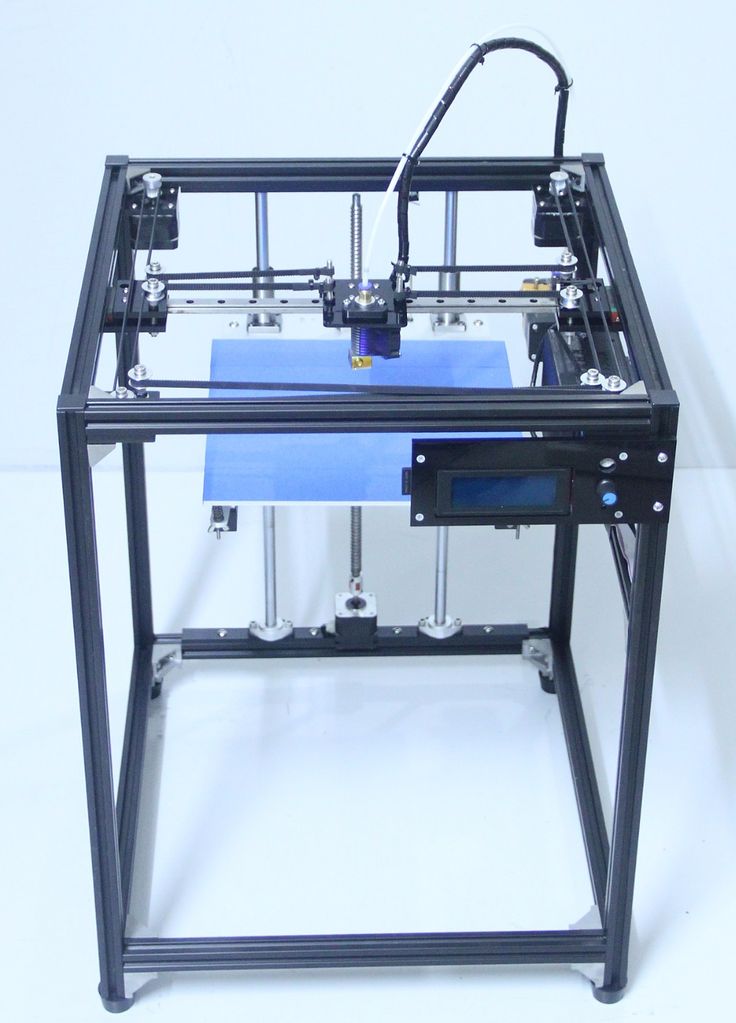

Solution: uPrint SE Plus 3D Printer

To save time and money when developing new drone models, Aerialtronics decided to use plastic 3D printing. The choice fell on the Stratasys uPrint SE Plus 3D printer. nine0003

Faster

Our engineers are thrilled with how quickly a CAD model is now turning into a physical prototype. The ABS plastic we use for printing provides excellent strength – and is ideal for the weight of flying prototypes. For example, our motors can get hot during operation, but this material easily withstands such loads and remains durable. The 3D printer has helped us take a step forward in design, reduce the overall cost and time of new product development. Compared to traditional methods, this is a real breakthrough in work. nine0026 Joost Hisimans, Chief Designer, Aerialtronics

Challenge: How to accelerate the development of new drones

The company has developed a concept model that combines the basic platform and a set of elements that can change depending on the needs of the customer. This drone was named Altura Zenith. In addition to the basic characteristics, customers were offered various options to choose from: the number of motors and power, payload, flight time, supported software. nine0003

This drone was named Altura Zenith. In addition to the basic characteristics, customers were offered various options to choose from: the number of motors and power, payload, flight time, supported software. nine0003

To implement all these options, the company's engineers needed to make unique parts of the drone's body. Even minor changes in technical specifications required redesigning and changing individual parts of the device. The solution of such issues by traditional methods required large financial and time costs.

Solution: uPrint SE Plus 3D Printer

To save time and money when developing new drone models, Aerialtronics decided to use plastic 3D printing. The choice fell on the Stratasys uPrint SE Plus 3D printer. nine0003

Faster

Our engineers are thrilled with how quickly a CAD model is now turning into a physical prototype. The ABS plastic we use for printing provides excellent strength – and is ideal for the weight of flying prototypes.

For example, our motors can get hot during operation, but this material easily withstands such loads and remains durable. The 3D printer has helped us take a step forward in design, reduce the overall cost and time of new product development. Compared to traditional methods, this is a real breakthrough in work. nine0026 Joost Hisimans, Chief Designer, Aerialtronics

Altura Zenith main frame is made of carbon. But the rest of the parts, the installation of which depends on the configuration of the drone, are created using the uPrint SE Plus 3D printer. These include: different-sized cases for sensors, video cameras, GPS systems, various tubes and containers for electronics, wires and other auxiliary elements.

Better

3D printing has allowed Aerialtronics designers and engineers to spend more time improving individual components. nine0003

They spend all day developing and rendering designs and construction, and turn on printing at night. With uPrint SE Plus, they have a finished physical sample of the part they need the very next morning. The part is tested, finalized and printed again. 3D printing allows you to try 8-10 different designs in a few days. The result is a product devoid of shortcomings and shortcomings.

With uPrint SE Plus, they have a finished physical sample of the part they need the very next morning. The part is tested, finalized and printed again. 3D printing allows you to try 8-10 different designs in a few days. The result is a product devoid of shortcomings and shortcomings.

Cheaper than

Using 3D printing, the Altura Zenith project was completed well ahead of schedule. In addition, it cost much less than it was planned. nine0003

3D printing and technology business

Aerialtronics believes that 3D printing is a great opportunity for small businesses to break new ground, reduce costs and offer customers a great product at an attractive price. The use of the uPrint SE Plus 3D printer allowed Aerialtronics to expand production, today their products are used not only by private customers, but also by the police, army, emergency services and other organizations.

Altura Zenith main frame is made of carbon. But the rest of the parts, the installation of which depends on the configuration of the drone, are created using the uPrint SE Plus 3D printer. These include: different-sized cases for sensors, video cameras, GPS systems, various tubes and containers for electronics, wires and other auxiliary elements. nine0003

These include: different-sized cases for sensors, video cameras, GPS systems, various tubes and containers for electronics, wires and other auxiliary elements. nine0003

Better

3D printing has allowed Aerialtronics designers and engineers to spend more time improving individual components.

They spend all day developing and rendering design and construction, and turn on printing at night. With uPrint SE Plus, they have a finished physical sample of the part they need the very next morning. The part is tested, finalized and printed again. 3D printing allows you to try 8-10 different designs in a few days. The result is a product devoid of shortcomings and shortcomings. nine0003

Cheaper

Using 3D printing, the Altura Zenith project was completed well ahead of schedule. In addition, it cost much less than it was planned.

3D printing and the technology business

Aerialtronics believes that 3D printing is a great opportunity for small businesses to break new ground, reduce costs and offer customers a great product at an attractive price. The use of the uPrint SE Plus 3D printer allowed Aerialtronics to expand production, today their products are used not only by private customers, but also by the police, army, emergency services and other organizations. nine0003

The use of the uPrint SE Plus 3D printer allowed Aerialtronics to expand production, today their products are used not only by private customers, but also by the police, army, emergency services and other organizations. nine0003

Subscribe to the newsletter

Once a month we will send you a selection of fresh articles about professional 3D printers and 3D scanners

I confirm the accuracy of the information I entered and agree to the processing of my personal data in accordance with the privacy policy and user agreement.

3D Printer Drone and Quadcopter Models

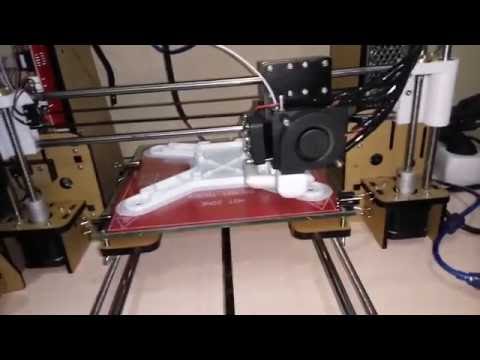

This article is an introduction to 3D Printing your own quadcopter drone. You will get acquainted with some basic principles of drone building, and we will describe some points step by step. The task will be relatively simple, since the description will be detailed. nine0003

What we need to get started

In addition to the 3D printer, we will need some non-printable parts such as a motor, batteries or accumulators, some electronics, sensors, a remote control and a knack to put it all together.

Why print a drone?

Actually, we will be printing the frame and body structure. Sometimes propellers can be printed. Why is it important? Because drones fall and break. Especially if you are a beginner pilot. Everything is clearly visible in this picture:

If we 3D print parts, we will have an almost infinite supply of spare parts, making it easier to survive pilot training and regular plane crashes. Apart from the fact that the quadcopter will be easier to repair, a homemade drone will allow you to get a better feel for its inner workings and mechanics.

And one more important point: 3D printing allows you to quickly develop parts according to your own design. Let's say you have purchased a new camera and want to install it on your quadcopter. Then you just open up your favorite 3D modeling program and end up printing out the part and testing it. Make changes, print again, etc. nine0003

What is a quadcopter drone?

A quadcopter is a multi-rotor helicopter that rises and moves with four main rotors and does not have a tail rotor. This is the most common type of amateur radio-controlled drones.

This is the most common type of amateur radio-controlled drones.

With its small size and high maneuverability, these quadcopter drones can fly both indoors and outdoors. In addition, at this size, quadcopter drones are cheaper than conventional helicopters and more reliable due to their simple design. nine0003

Here is a detailed overview of the details of a commercially available high-end quadcopter drone used for aerial photography.

Almost all parts that are not motor or electronics can be 3D printed. The printed version of the drone looks a little different.

3D printed Crossfire quadcopter. Link to project: http://www.thingiverse.com/thing:32281

In addition to the visual and aesthetic differences, the printed version has the advantage of being easy to update and modular. In the next video, Dennis Baldwin talks in detail about his quadcopter. nine0003

How to Print a Quadcopter Drone

If you want to build your own drone, we offer several entry points to the project. Here is a detailed guide for 3D printed quadcopter:

Here is a detailed guide for 3D printed quadcopter:

http://www.instructables.com/id/3D-Printed-Quadcopter-with-Arduino/?ALLSTEPS

Titch Micro Drone

https: /www.myminifactory.com/object/38967

Brushed Y6 Micro Quad

https://www.myminifactory.com/object/brushed-y6-micro-quad-31348

Millennium Falcon Drone Shell

https://www.minifactory/ millennium-falcon-drone-shell-10144

Micro 105 FPV Quadcopter

https://www.myminifactory.com/object/micro-105-fpv-quadcopter-21362

Micro 105 FPV Quadcopter

https://www.myminifactory.com/object/3drobotics-iris-19615

Hexacopter drone

https://www.myminifactory.com/

3

00 And this is the instructions for building an H-shaped drone:

http://www.