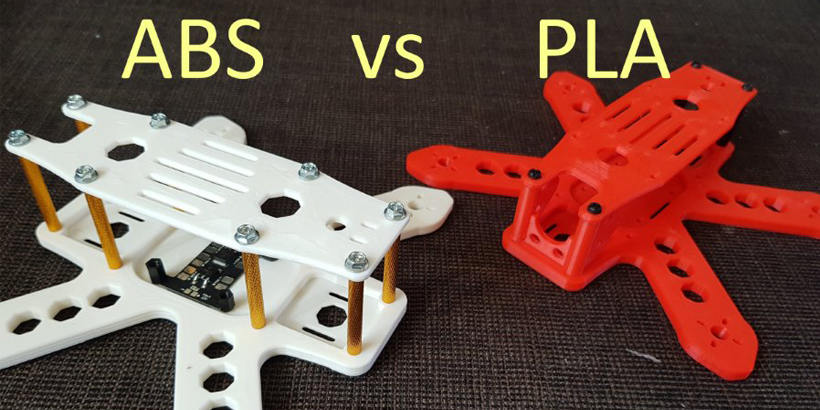

3D print pla vs abs

3D printing with PLA vs. ABS: What's the difference?

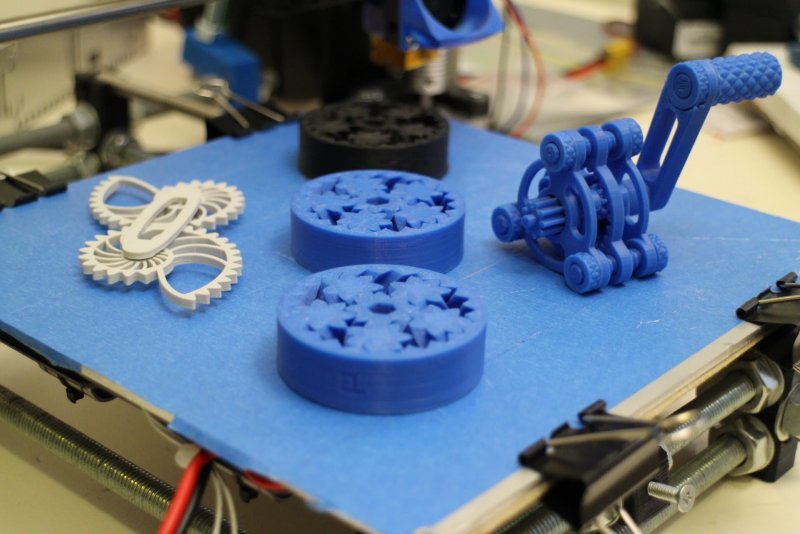

PLA and ABS are two essential materials for 3D printing with FDM. They are also two of the most popular materials on our platform. This comparison will help you choose which material to use for your 3D-printed custom parts.

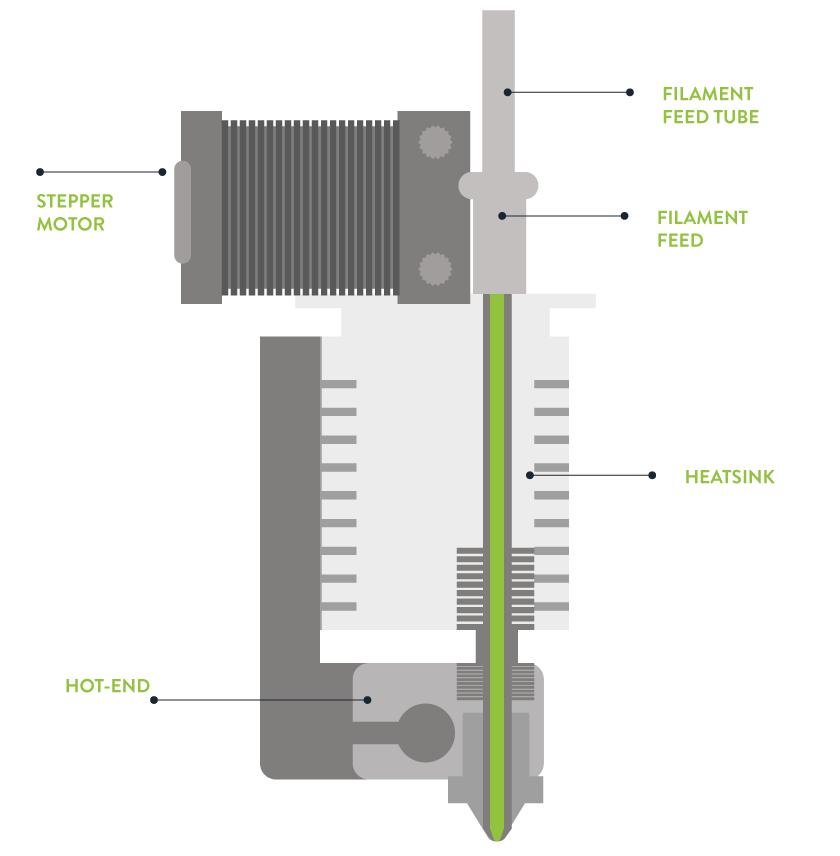

PLA and ABS are the two most common materials for prototyping (desktop) FDM 3D printing (aside from, perhaps, PETG). As thermoplastics, both filaments enter a soft and moldable state when heated, returning to a solid-state when cooled. FDM printers melt and extrude PLA and ABS filament through a nozzle to build up parts layer by layer.

While both materials are used for FDM, they have key differences that make each more optimal for different applications. In this article, we’ll cover the main differences between these commonly used materials.

We also have this handy Youtube explainer video that covers the differences between PLA and ABS filaments.

Want to compare pricing for PLA and ABS?

Upload your CAD file to the quote builder

What is PLA? Printing with polylactic acid

PLA (Polylactic Acid) is a thermoplastic derived from renewable sources such as cornstarch or sugarcane. Biodegradable under the right conditions, PLA is one of the most popular bioplastics and is perfect for a variety of applications ranging from plastic cups to medical implants.

Compared to many other 3D printing materials, PLA is quite cost-efficient, providing good value for money in exchange for high-quality components with relatively smooth surface finishes. PLA is easy to print with and has a higher stiffness than ABS and other materials like nylon, though it doesn't handle high temperatures or significant stress so well. While PLA is stronger than ABS and nylon, it’s not very heat or chemical-resistant.

What is ABS? Printing with

Acrylonitrile Butadiene Styrene

ABS (Acrylonitrile Butadiene Styrene) is another common thermoplastic. It's a common fixture in 3D printing and quite popular in the world of injection molding. Real-world applications of ABS include toys (think LEGO bricks), housings for electronics, automotive parts, household appliances and much more.

Tough and resistant to impact to a certain point, ABS has superior mechanical properties to PLA while being lighter and more durable. However, the tradeoff is that it's harder to print with and often requires higher temperatures for effective printing. The material can deflect heat more effectively than PLA, but it's absolutely not known for total heat resistance. And for 3D printer operators, be aware that ABS can produce strong odors during the manufacturing process.

What’s the difference between PLA and ABS?

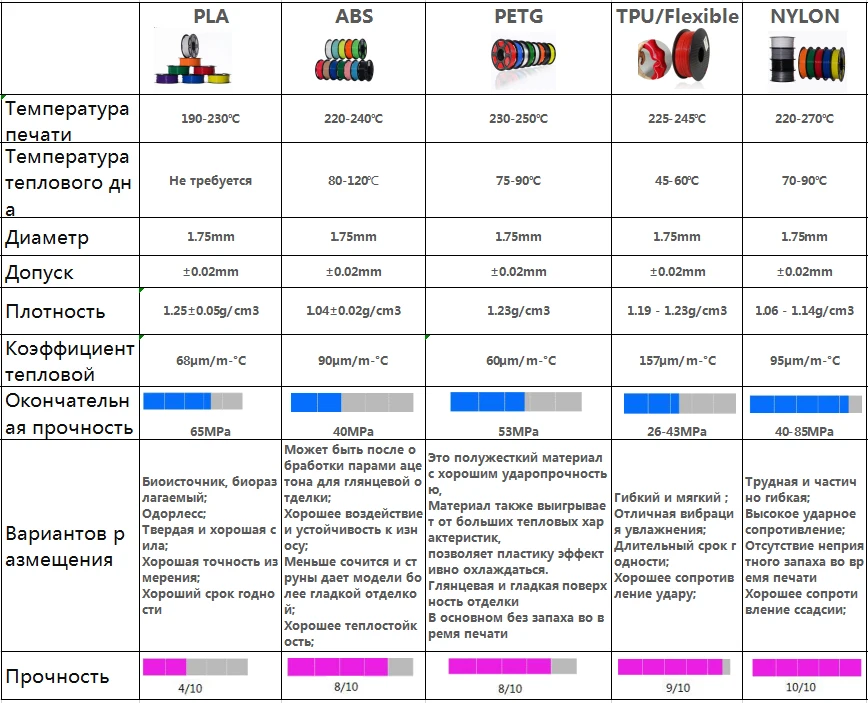

PLA and ABS differ in several ways, including their unique tensile strength, density and ideal applications. The table below compares the key material properties of PLA and ABS filaments.

The table below compares the key material properties of PLA and ABS filaments.

| Properties* | ABS | PLA |

|---|---|---|

| Tensile Strength** | 27 MPa | 37 MPa |

| Elongation | 3.5 - 50% | 6% |

| Flexural Modulus | 2.1 - 7.6 GPa | 4 GPa |

| Density | 1.0 - 1.4 g/cm3 | 1.3 g/cm3 |

| Melting Point | 200 ℃ | 173 ℃ |

| Biodegradable | No | Yes, under the correct conditions |

| Glass Transition Temperature | 105 ℃ | 60 ℃ |

Spool Price*** (1kg, 1. 75mm, black) 75mm, black) | $USD 21.99 | $USD 22.99 |

| Common Products | LEGO, electronic housings | Cups, plastic bags, cutlery |

What is the part accuracy of PLA and ABS?

In general, the tolerances and accuracy of FDM printed components depend on printer calibration and model complexity. However, you can use PLA and ABS to create dimensionally accurate parts with printing details of 0.8 mm and minimum features of 1.2 mm. For connecting or interlocking parts, we recommend a tolerance of 0.5 mm and a minimum wall thickness of 1-2 mm. This will ensure that your part has adequate strength across all wall elements.

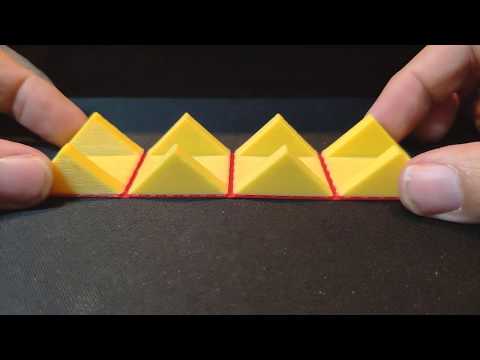

Thanks to its lower printing temperature, PLA is easier to print with and less likely to warp (when properly cooled). You can use PLA to print sharper corners and finer features than with ABS.

Want to improve your 3D printing design skills?

Download our free 3D printing design rules poster

How strong are PLA and ABS parts?

PLA and ABS have similar tensile strengths, making them solid options for many prototyping applications. Designers and engineers often prefer ABS due to its improved ductility over PLA. ABS has higher flexural strength and better elongation before breaking than PLA, which means that ABS can also be used for end-use applications. PLA, on the other hand, is more popular for rapid prototyping when the form is more critical than the function.

Designers and engineers often prefer ABS due to its improved ductility over PLA. ABS has higher flexural strength and better elongation before breaking than PLA, which means that ABS can also be used for end-use applications. PLA, on the other hand, is more popular for rapid prototyping when the form is more critical than the function.

Overall, PLA is a good option for your custom parts if you don’t plan on putting them under a lot of physical stress (or UV radiation and high temperatures). ABS is more fitting for industrial applications and can weather physical strain better than PLA.

How fast can you print with PLA and ABS?

Both PLA and ABS print at nearly identical speeds. This means that you don’t have to change speed settings on your FDM machines when switching between materials. For PLA, printing at 60 mm/s is pretty standard, though some operators have printed at over 150 mm/s, so the standard speed is by no means a limit. You can also print ABS at the same speed, but between 40-60 mm/s is a bit more accurate for this material.

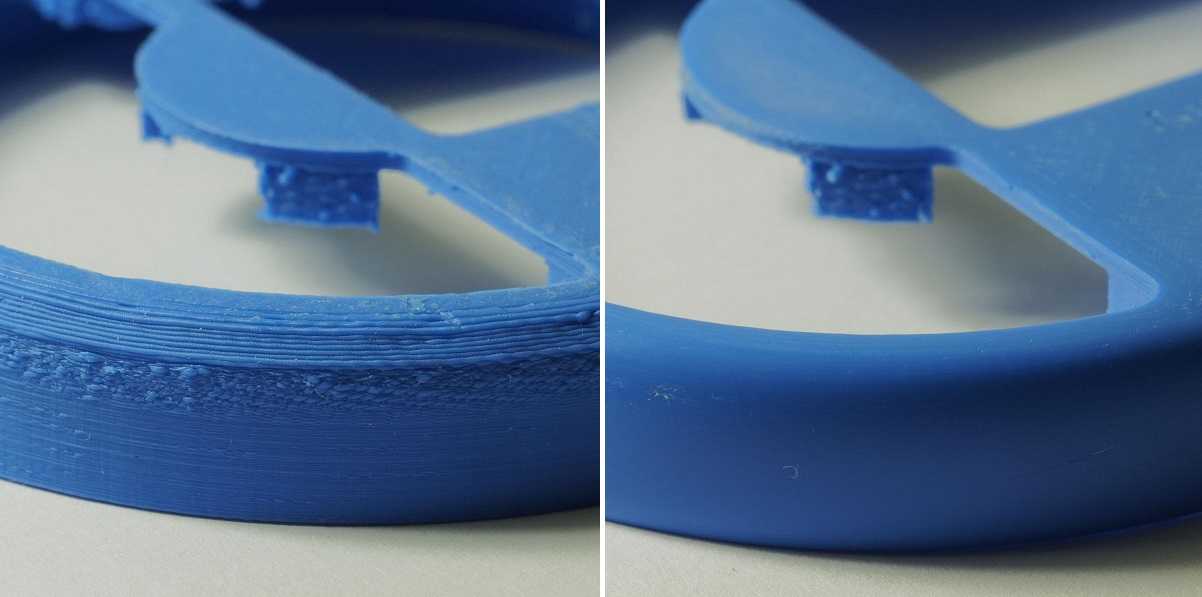

Surface finishes and post-processing for PLA and ABS

Whether you produce parts using PLA or ABS, FDM-printed components will always have visible layers. Using PLA often results in a glossier finish, while ABS typically prints in a matte finish. To smooth an ABS-printed part and give it a glossy finish, you can use acetone in post-processing. Sanding and additional machining are viable post-processing options for parts printed in ABS. You can also sand and machine PLA, though greater care is required.

If aesthetic quality is critical, then we recommend using SLA 3D printing to produce your custom parts.

Want to explore all the options for FDM post-processing?

Learn more

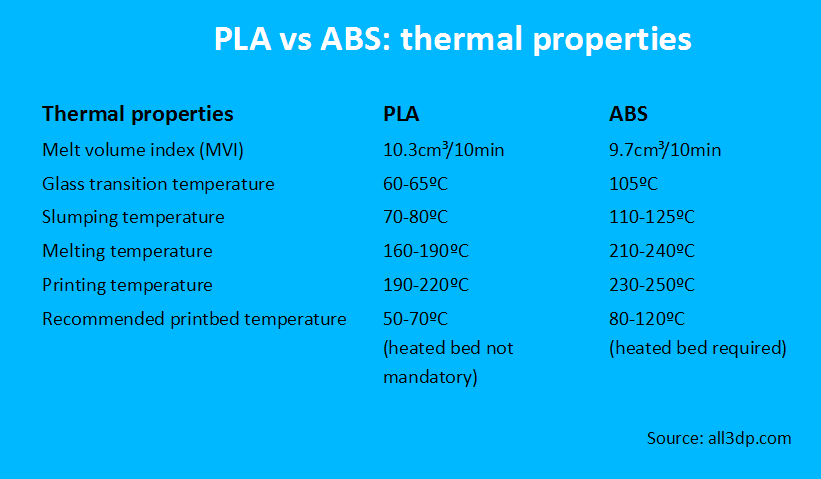

How heat resistant are PLA and ABS?

For applications requiring higher temperatures, ABS (glass transition temperature of 105°C) is preferable over PLA (glass transition temperature of 60°C). PLA can rapidly lose its structural integrity and can begin to droop and deform as it approaches 60°C, especially if it's supporting a heavier load.

Are PLA and ABs biodegradable?

PLA is stable in general atmospheric conditions, though it will biodegrade within 50 days in industrial composters and 48 months in water. While ABS is not biodegradable, you can recycle it. This being the case, manufacturers tend to use PLA to produce items related to food service, though we absolutely recommend you get safety confirmation from filament manufacturers.

Ready to transform your CAD file into a custom part? Upload your designs for a free, instant quote.

Get an instant quotePLA vs ABS - What's The Difference? [Simple Guide] (Updated 2022)

Which 3D printing filament should you use - PLA or ABS? Find out what are the differences and which material should you use for your 3D printing needs!

By Justin Evans

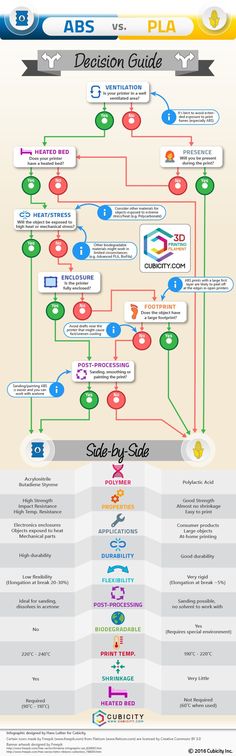

Once you’ve bought a 3D printer, you have to start thinking about what kind of filament to acquire. Most beginner’s guides recommend PLA or ABS. They’re interchangeable but the reality is there are significant differences between the two.

Most beginner’s guides recommend PLA or ABS. They’re interchangeable but the reality is there are significant differences between the two.

Do you really need to know these differences? Well, if you’re only going to be printing occasionally, probably not. However, a deeper understanding of your equipment will be a huge upside when you move onto printing larger and more complex items. Without further ado then, let’s jump right in.

Table of ContentsShow

What Is PLA?

PLA stands for polylactic acid. What makes PLA so different from most other plastics is that it’s made from renewable, organic materials like sugar cane and cornstarch. Because the production doesn’t rely on petroleum, it can be made at a much lower cost. This keeps prices down for the consumer while reducing PLA’s environmental footprint.

Further, PLA degrades a lot faster than other plastics. A standard plastic bottle can take over a hundred years to break down whereas PLA breaks down fully within two years. This doesn’t mean it’s a poor choice for printing with, though; as we’ll cover in the section below.

This doesn’t mean it’s a poor choice for printing with, though; as we’ll cover in the section below.

Characteristics Of PLA

PLA has a very low glass transition temperature. This is the temperature at which the filament becomes malleable – for PLA, it’s around 65°. The good news is that you don’t need nearly as much heat or power to print with this material. The bad news, though, is that PLA isn’t suitable for printing things that have to withstand heat for any real period of time.

Now, because PLA is made with natural sugars, it’s pretty sticky when heated. This is great because it helps your models stick to the print bed and prevents them from shrinking as you print. As a bonus, the sugars give off an almost honey-like smell that makes every print session a little bit more enjoyable.

PLA is a tad more brittle than other materials, which does limit its range of applications a little. For instance, we wouldn’t make a PLA striking hammer or anything like that. Instead, it’s better used as a general all-purpose plastic for miscellaneous items like stationary holders or figurines.

Price

We were able to find 10-meter spools of plain PLA for less than $6. Again, this is due to the material’s unique construction. Because it’s so affordable, you don’t have to worry as much about making mistakes – after all, you can always just try again. For this reason, it’s one of the simplest ways to get started in the world of 3D printing.

What is ABS?

ABS (Acrylonitrile Butadiene Styrene) is the other most commonly used 3D printing filament. While ABS doesn’t have the same biodegradability as PLA, it can be recycled very easily. In fact, one of the most common uses for old ABS is making new ABS. It’s the circle of life – cool, isn’t it?

ABS is a favorite among hobbyists because of its versatility. It can be easily painted and even reheated several times without burning. If there’s an edge that isn’t quite right, no problem. Just heat it up again and you can fix it. So, what else sets it apart from other materials?

It can be easily painted and even reheated several times without burning. If there’s an edge that isn’t quite right, no problem. Just heat it up again and you can fix it. So, what else sets it apart from other materials?

Characteristics Of ABS

ABS has a higher glass transition point than PLA, at about 105°C. This means that it’s a better choice for printing objects that will be impacted by heat. For instance, you could make a gearshift knob that won’t melt in your car on a hot day.

There’s another factor that makes ABS the go-to material for many printers. It’s very resilient. ABS is far more likely to stretch than shatter and it’s resistant to corrosion too. Its tensile strength makes it an amazing choice for people looking to sand, buff, or glue the finished product.

There is one thing you should be aware of, though. ABS has a tendency to shrink pretty aggressively when cooling. For this reason, it’s crucial you ensure there’s adequate heating in your printing area, lest the product shrink too much and crack.

Unlike PLA, ABS has a smell that can only be described as unhealthy. Guess what? This is because the fumes are bad for you. Make sure to print in a well-ventilated room. We know, we know: a well-ventilated, yet warm room? Unfortunately, this balancing act is the price to pay for a stronger, more durable print.

Price

Generic ABS is roughly the same price as PLA, if not a little cheaper. We managed to find a 10-meter tester spool for as little as $5 but you’ll likely want to buy in higher volumes to drive the price down even farther.

Conclusion

Both ABS and PLA are good choices for beginners but which is best for you? Well, this really depends on what you’d like to create. PLA is better for basic, everyday printing whereas ABS excels at building sturdy, shock-resistant pieces that can be further modified afterward. Since both are relatively affordable, there’s no reason not to try them both, assuming your printer allows it.

Now that you know the basic differences between two of the most commonly used filaments, there’s nothing to stop you from printing whatever you like. Remember to research your filament provider beforehand to ensure you get the best product available, though. That said, have fun and happy printing!

Remember to research your filament provider beforehand to ensure you get the best product available, though. That said, have fun and happy printing!

3D Printer Materials Guide

Comparison of 3D printing technologies: FDM, SLA and SLS

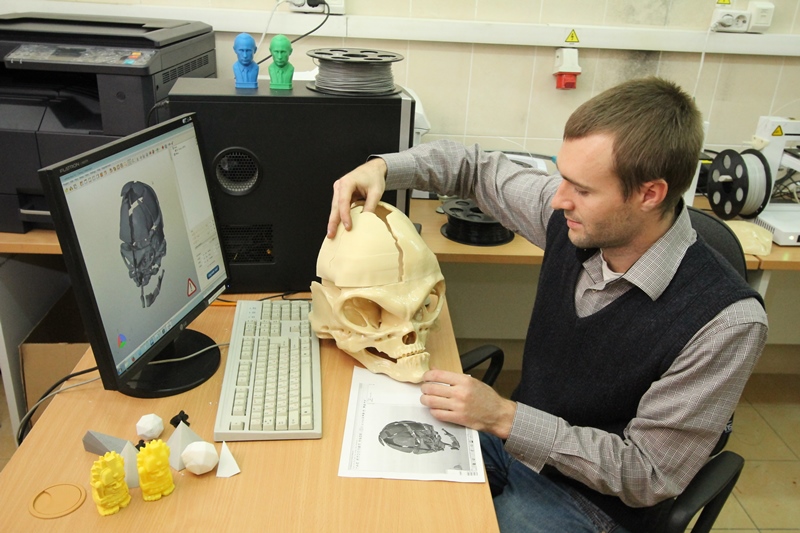

Additive manufacturing or 3D printing reduces costs, saves time and expands the technological possibilities in product development. 3D printing technologies offer versatile solutions for applications ranging from rapid concept and functional prototypes in the field of prototyping to fixtures and clamps or even final parts in manufacturing.

Over the past few years, high resolution 3D printers have become more affordable, more reliable and easier to use. As a result, more companies have been able to use 3D printing technology, but choosing between different competing 3D printing solutions can be difficult. nine0003

Which technology is right for your needs? What materials are available for her? What equipment and training is needed to get started? What are the costs and payback?

In this article, we take a closer look at three of today's most well-known plastic 3D printing technologies: Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Choosing between FDM and SLA 3D printer? Check out our detailed comparison of FDM and SLA technologies. nine0012

Download this high resolution infographic here.

VIDEO MANUAL

Can't find the 3D printing technology that best suits your needs? In this video tutorial, we compare Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) technologies in terms of the top factors to consider when purchasing.

Watch Video

Fused Deposition Modeling (FDM), also known as Fused Filament Manufacturing (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the rise of consumer 3D printers. On FDM printers, models are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer to the model being built. nine0003

The FDM method uses a range of standard plastics such as ABS, PLA and their various blends. It is well suited for making basic experimental models, as well as for quickly and inexpensively prototyping simple parts, such as parts that are usually machined.

It is well suited for making basic experimental models, as well as for quickly and inexpensively prototyping simple parts, such as parts that are usually machined.

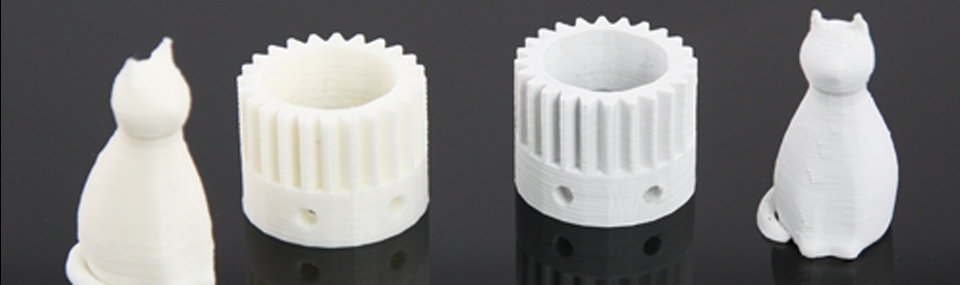

FDM models often show layer lines and may have inaccuracies around complex features. This sample was printed on a Stratasys uPrint FDM industrial 3D printer with soluble support structures (printer price starting at $15,900).

FDM printers have the lowest resolution and accuracy of SLA or SLS and are not the best option for printing complex designs or parts with complex features. Surface quality can be improved by chemical and mechanical polishing processes. To address these issues, industrial FDM 3D printers use soluble support structures and offer a wider range of engineering thermoplastics, but they are also expensive. nine0003

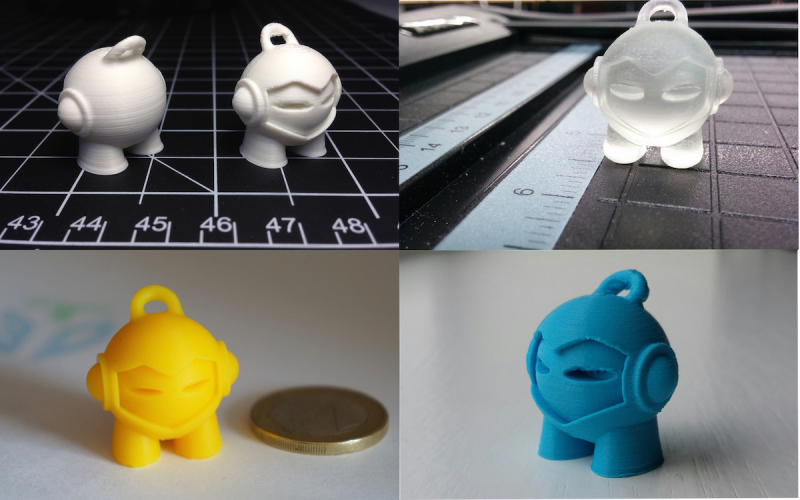

FDM printers do not handle complex designs or parts with complex features well (left) compared to SLA printers (right).

Invented in the 1980s, stereolithography is the world's first 3D printing technology and is still one of the most popular technologies among professionals today. SLA printers use a process called photopolymerization, which is the conversion of liquid polymers into hardened plastic using a laser.

SLA printers use a process called photopolymerization, which is the conversion of liquid polymers into hardened plastic using a laser.

See stereolithography in action.

Models printed on SLA printers have the highest resolution and accuracy, the sharpest detail and the smoothest surface of all plastic 3D printing technologies, but the main advantage of the SLA method is its versatility. Materials manufacturers have developed innovative formulas for SLA polymers with a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics. nine0003

Models created using SLA technology have sharp edges, a smooth surface and almost invisible layer lines. This sample was printed on a Formlabs Form 3 Desktop Stereolithographic 3D Printer (price starting at $3499).

SLA is an excellent option for making highly detailed prototypes that require tight tolerances and smooth surfaces such as molds, templates and functional parts. SLA technology is widely used in industries ranging from engineering and design to manufacturing, dentistry, jewelry, modeling, and education. nine0003

SLA technology is widely used in industries ranging from engineering and design to manufacturing, dentistry, jewelry, modeling, and education. nine0003

White Paper

Download our in-depth white paper to learn how SLA printing works, why thousands of professionals use it today, and how this 3D printing technology can be useful in your work.

Download white paper

free sample

Experience Formlabs print quality firsthand. We will send a free 3D printing sample directly to your office.

Request a free sample

Selective laser sintering is the most common additive manufacturing technology used in industry.

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper. Models produced using SLS printing have excellent mechanical characteristics: their strength can be compared with the strength of injection molded parts. nine0003

This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper. Models produced using SLS printing have excellent mechanical characteristics: their strength can be compared with the strength of injection molded parts. nine0003

Models created with SLS technology have a slightly rough surface, but almost no visible layer lines. This sample was printed on the Formlabs Fuse 1 SLS workshop 3D printer (price starting at $18,500).

The most common selective laser sintering material is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is light, strong and flexible, resistant to impact, heat, chemicals, UV radiation, water and dirt. nine0003

The combination of low part cost, high productivity, and widely used materials makes SLS a popular method for engineering functional prototyping and a cost-effective alternative to injection molding in cases where production runs are limited.

White Paper

Looking for a 3D printer to create durable, functional models? Download our white paper to learn how selective laser sintering (SLS) technology works and why it is popular in 3D printing for functional prototypes and end-use products. nine0003

nine0003

Download white paper

Each 3D printing technology has its strengths, weaknesses, limitations and applications. The following table summarizes the key characteristics and factors.

| Modeling method (FDM) | Stereolithography (SLA) | Selective laser sintering (SLS) | |

|---|---|---|---|

| ★★★★☆ | |||

| accuracy | ★cle ★cle \ ★★★★★ | ||

| Easy to use | ★★★★★ | ★★★★★ | ★★★★★★★★★★★★★0104 |

| Benefits | Speed Inexpensive custom machines and materials | High cost efficiency High accuracy Smooth surface Wide range of functional applications | Robust functional parts Design flexibility No need for supporting structures |

| Disadvantages | Poor accuracy low detail Limited Compliance with Design Design | Susceptibility to prolonged UV exposure | Uneven surface Material Limitations |

| Applications | Inexpensive Rapid Prototyping Basic experimental models | Functional prototyping Templates, forms and tools Dental products Prototyping jewelry and molds Model building | Functional prototyping Small-scale and custom manufacturing |

| Print volume | Up to ~300 x 300 x 600 mm (desktop 3D printers) | Up to ~300 x 335 x 200 mm (Desktop and Workshop 3D printers) | Up to 165 x 165 x 300 mm (Workshop 3D printers) |

| Materials | ABS plastic, PLA and their various mixtures. | Various polymers (thermosets). Standard, engineering (with properties of ABS plastic, polypropylene, flexible, heat-resistant), molding, dental and medical (biocompatible). | Engineering thermoplastics. Nylon 11, Nylon 12 and their composites. nine0104 |

| Training | Minimum training in equipment setup, machine operation and surface treatment; short maintenance training. | Plug and play concept. Minimal training in equipment setup, maintenance, machine operation and surface treatment. | Short training in equipment setup, maintenance, machine operation and surface treatment. |

| Room requirements | Air-conditioned environment or preferably individual ventilation for desktop machines. | Desktop machines suitable for office use. | Workshop systems have moderate space requirements and can be installed in a production environment. |

| Accessories | Support removal system for machines with soluble support structures (optionally automated), finishing tools. nine0104 nine0104 | Finishing station, washing station (optionally automated), finishing tools. | Post-processing station for cleaning models and restoring materials. |

Either way, you should choose the technology that best suits your business. Prices have dropped significantly in recent years, and today all three technologies are offered in compact and affordable systems.

3D printing costing doesn't end with initial equipment costs. Material and labor costs have a significant impact on the cost of each part, depending on the application and production needs. nine0003

Below is a detailed breakdown by technology.

| Modeling method (FDM) | Stereolithography (SLA) | Selective laser sintering (SLS) | Equipment costs and sets for 3D-dimensions for 3Ds and sets several hundred dollars. Offering higher quality, mid-range desktop printers start at $2,000, while industrial systems start at $15,000. | Professional desktop printers start at $3,500, large-format workshop printers start at $10,000, industrial systems for large-scale production start at $80,000. |

|---|---|---|---|

| Material cost | $50-$150/kg for most standard and engineering yarns and $100-$200/kg for auxiliary materials. | $50-$150/L for most standard and engineering polymers. | $100/kg for nylon. SLS does not require supporting structures and unused powder can be reused, reducing material costs. |

| Labor | Manual removal of support structures (may be automated for industrial systems with dissolvable supports). Long post-processing is required to obtain a high quality surface. | Washing and final polymerization (both can be automated). Simple post-processing to remove supporting structures. nine0104 | Easy cleaning to remove excess powder. |

INTERACTIVE MATERIAL

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate savings

FDM, SLA and SLS printed prototype ski goggle frames (left to right).

We hope this article has helped you narrow down your search for the 3D printing technology best suited to your needs. nine0003

Take advantage of our additional resources to learn the ins and outs of 3D printing, learn more about each technology and learn more about specific 3D printing systems.

Learn more about 3D printing technologies

DragonFly 3D Printer - a revolution in the manufacture of multilayer printed circuit boards, articles on electronics

, into which you load the material, and in a few hours it issues finished printed circuit boards? Five years ago, when they approached me with such a question, I said “no”, and I myself thought that the person seemed to be completely unaware of the technology of printed circuit board production. What was my surprise when I learned that such a technology appeared on the market. nine0012

nine0012

And already now, 3D printing of multilayer PCBs is successfully working in many enterprises around the world, and it is safe to say that this is a revolution in the field of prototyping and PCB manufacturing.

Prototype PCBs are received differently at different plants:

-

Someone orders them on the side and often has to wait a long time, coordinate orders for orders and even hold competitions for the manufacture of printed circuit boards. The waiting time in this case can stretch up to several months. And then, when it will be necessary to correct the mistakes made or introduce constructive changes, you need to repeat everything again. nine0003

-

Someone can afford to have their own site (mini-workshop) for the manufacture of prototypes. In this case, it must be serviced: supply water, exhaust and compressed air, install treatment facilities and have mechanics, chemists and photo printing specialists on staff.

In addition, in order to obtain precision prototypes, it is necessary to have expensive precision equipment.

In addition, in order to obtain precision prototypes, it is necessary to have expensive precision equipment.

But both of them want to get a solution, the implementation of which will take minimal time and minimal space, and will not require the supply of serious power communications and treatment facilities. nine0003

And it exists: additive manufacturing technology for multilayer printed circuit boards - a 3D printer from the Israeli company NanoDimension, DragonFly model fig. 1 (English: dragonfly). We can say that this decision is the door to a new era of prototyping and production of electronic products.

Fig. 1 Israeli company NanoDimension 3D printer DragonFly model

Additive manufacturing technology for multilayer printed circuit boards is a symbiosis of three components: the world's first 3D printer designed for printed circuit boards with two print heads; conductive and non-conductive ink; special software that allows the printer to accept standard files from the production of Gerber and Excellon printed circuit boards and set the thickness of the printed layer. nine0003

nine0003

Let's take a closer look at each of these components.

Fig. Fig. 2 Working area of DragonFly 3D printer

3 Four-layer PCB with conductor/gap: 100/100 µm

Fig. 4 Non-planar parts made on a DragonFly

3D printer The main elements of the printer are two printheads and two curing systems (Fig. 2). The print head for applying conductive ink is complemented by an infrared sintering system, and a UV curing system is used to cure non-conductive ink. The diameter of the dielectric drop is 3 µm, and that of the conductive ink is 0.3 µm, which makes it possible to manufacture precision boards up to the 5th accuracy class with a conductor/gap parameter of 100/100 µm (Fig. 3). The minimum layer thickness is 10 microns, and the maximum is 3 mm, so the number of layers can be said to be unlimited. DragonFly can print PCBs containing plated through holes with diameters of 0.4 mm and above, and holes filled with conductive paste have a diameter of 0. 2 mm and above. nine0003

2 mm and above. nine0003

Also, the printer can make through plated, through non-plated, blind and even hidden holes, enabling developers to quickly and easily test prototypes of layer-by-layer build-up boards, which in traditional technology is time-consuming and extremely costly. The maximum overall size of the printed circuit board produced on the printer is 200*200*3 mm, and the board does not have to be flat. The use of additive technology makes it possible to manufacture multilayer 3D-MID products (Fig. 4), opening up new opportunities for designers. nine0003

In the modern world, the technology of manufacturing printed circuit boards with embedded components is gaining momentum (Fig. 5). The technology makes it possible to reduce the weight and size characteristics of boards, reduce the length of communication lines, provide efficient heat dissipation and protection against moisture, solve electromagnetic shielding issues, and increase the mechanical strength of boards.

Fig. 5 Board with built-in discrete components

5 Board with built-in discrete components

Prototyping PCBs with embedded components using conventional technology is not an easy task. Discrete components require an additional laser cutting of windows for the components in the interfacing fiberglass (prepreg). You can, of course, try to do it manually, but in this case you should not count on a serious result. This complex problem is easily solved on the DragonFly 3D printer: during printing, the printer leaves windows in the layer, then the user installs the components, and on the next passes of the printer they are sealed with new layers. nine0003

Multilayer PCB printing time can vary from 3 to 20 hours depending on the thickness of the board and the amount of conductive ink, but on average, a 100*100*1.6mm PCB can be printed in 8 hours. This means that in the evening the developer can put the printer to print, and in the morning, having come to work, remove the finished board from the table. The printer is absolutely autonomous and does not require the presence of an operator during operation.

Fig. 6 Software layout DragonFly 3D Printer

The software (Fig. 6) that the printer is equipped with, in addition to controlling the hardware, has the ability to convert 2D Gerber and Excellon files, traditional for printed circuit boards, into 3D by simply specifying the thickness. Support for the Odb++ format is also planned. When the printer runs out of ink, the software automatically informs the operator of this.

Fig. 7 Flexible-rigid MPPs made on the DragonFly 9 3D printer0003

The used dielectric is close to FR-4 in terms of electrical parameters and basic mechanical characteristics, and the conductivity of conductive ink is currently slightly more than twice as low as copper. The dielectric constant (Dk) of the polymer used is 3.2 at 1 MHz and 2.9 at 1 GHz. The main current limitation of the material is the maximum soldering temperature, which is 140 degrees.

If the material is printed thinly, then it acquires conditionally flexible properties (Fig. 7), i.e. it cannot withstand a multiple number of folds, but it is suitable for testing installation in a product with a single fold. nine0003

7), i.e. it cannot withstand a multiple number of folds, but it is suitable for testing installation in a product with a single fold. nine0003

Fig. 8 Example of assembled printed circuit boards. From the moment of idea to implementation - a few hours.

Of course, they have not yet learned how to print foil fiberglass on a 3D printer, but such tasks were not set before him. The main application of this technology is testing the circuit, ideas (Fig. 8). Electronics is moving towards miniaturization, and the world is accelerating more and more, presenting new serious requirements for designers: even faster product design and faster results. In the era of modern additive technologies, developers have the opportunity to put in a small room a printer for printing cases, a DragonFly printer for PCB prototyping and a component installer. Thus, it is possible to completely prototype a product in one room in one day - these are ideal conditions to create new breakthrough products and bring them to the market as quickly as possible! nine0003

The DragonFly 3D printer, using additive manufacturing technology for multilayer printed circuit boards, has become a new milestone in the prototyping and manufacturing of electronic products.

Learn more