3D print nasa

NASA to explore 3D printed lunar structure possibilities with Redwire Regolith Print launch

0Shares

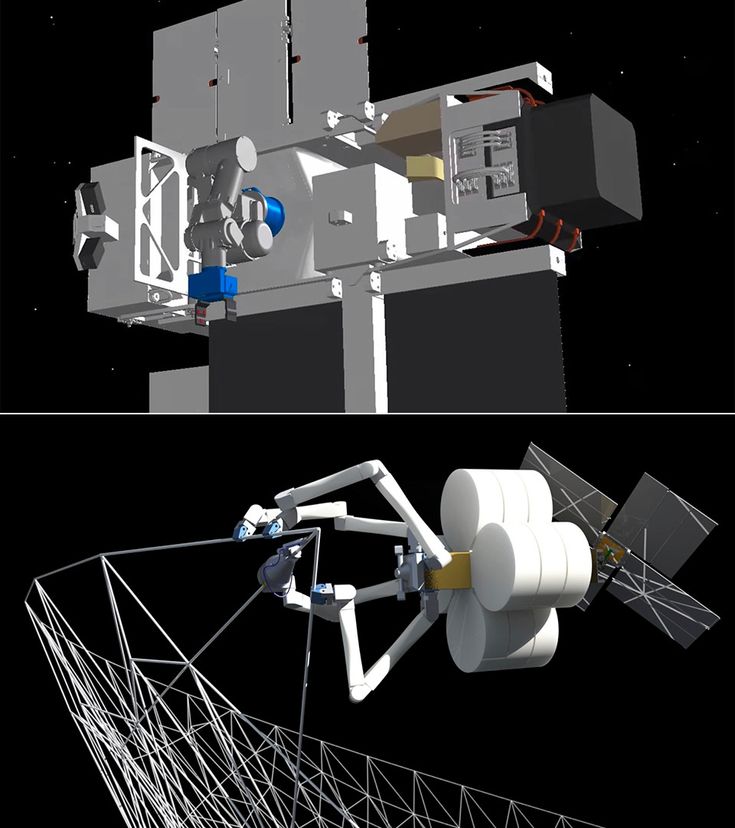

NASA is launching a new set of scientific experiments to the International Space Station (ISS), including a study from mission-critical space systems specialist Redwire that will determine the feasibility of 3D printing regolith for the on-demand construction of lunar structures.

The Redwire Regolith Print (RRP) study will head to the ISS on Northrop Grumman’s Cygnus spacecraft, targeted for launch on August 10th just before 6pm EDT. At a media teleconference hosted by NASA in the lead-up to the launch, Redwire’s Chief Technology Officer Michael Snyder explained what the firm hopes to achieve with the project, and what it could mean for future space exploration missions.

“The Redwire Regolith Print project is a tech demo of on-orbit additive manufacturing using regolith simulating feedstock material,” he said. “This represents a critical step in developing sustainable manufacturing capabilities for lunar surfaces that will ultimately establish a permanent human presence off-earth by utilizing available resources with adaptive systems. So this is really exciting for the future and hopefully, something like this gets eventually deployed to the moon.”

The Redwire Regolith Print study

National space agencies like NASA are continuing to seek a permanent presence on the moon and Mars, and using raw resources available on-site to build structures and habitats could reduce how much material future missions need to bring from Earth. As a result, this could significantly reduce the launch mass and cost of future missions and provide a more sustainable method of constructing housing and other structures on planetary bodies.

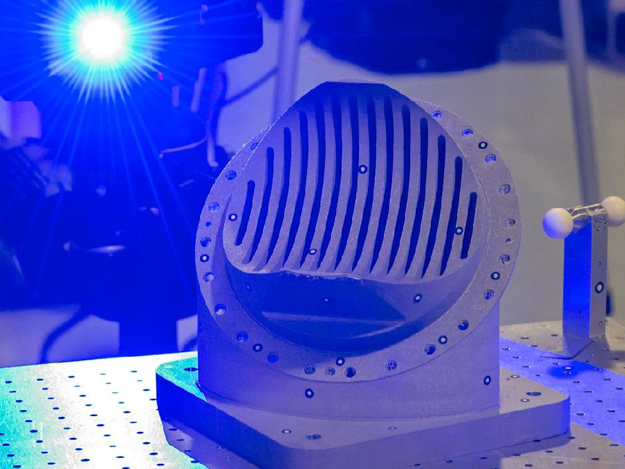

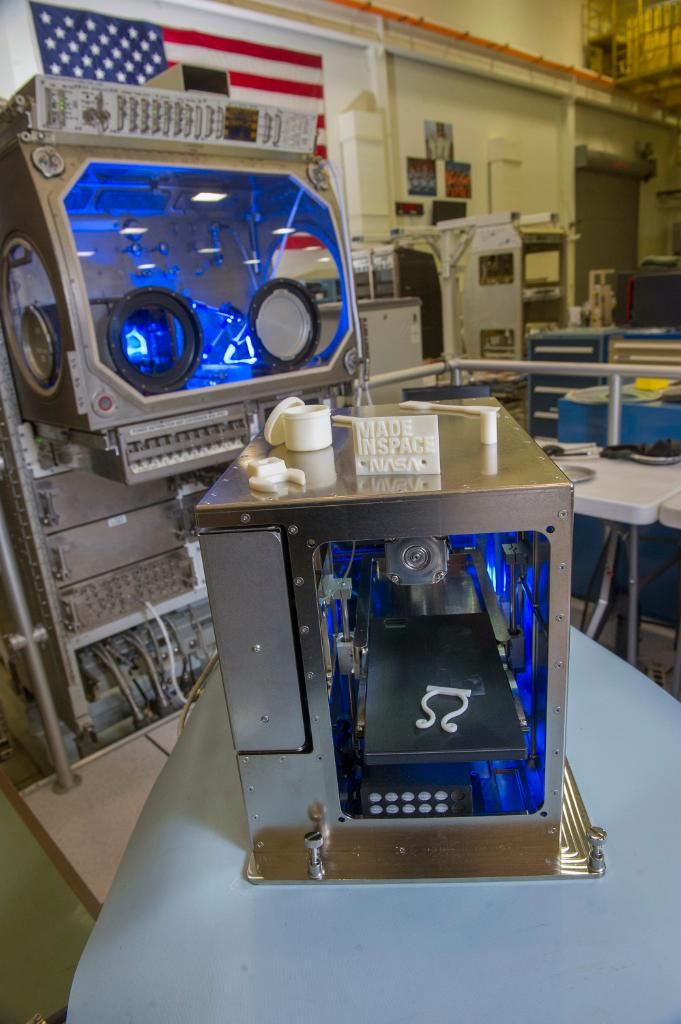

Once installed on the ISS, the RRP project will seek to demonstrate the potential for 3D printing with regolith feedstock material in microgravity using the Made In Space additive manufacturing device currently housed aboard the station. Regolith is the loose rock and soil found on the surfaces of planetary bodies such as the Moon, and the study hopes to demonstrate the feasibility of 3D printing the material to construct on-demand habitats on future space exploration missions.

During the project, Redwire will use a feedstock made up of metal oxides and a binder that simulates regolith to 3D print multiple plates that, once brought back to earth, will be formed to the exact specifications of the required test specimens. Printing the samples as plates will also enable Redwire to produce as many samples as possible for the destructive testing phase. The regolith-simulating samples will be printed using an extrusion-based 3D printing technique similar to fused deposition.

“For this demonstration, an initial set of three specimens will be produced on the ISS,” explained Snyder. “That will be done by installing newly developed manufacturing components into Redwire’s existing additive manufacturing facility. Once those components or specimens are returned, NASA will test the material properties of the prints by performing destructive tests.”

The Redwire Regolith Print facility suite, consisting of Redwire’s Additive Manufacturing Facility, and the print heads, plates and lunar regolith simulant feedstock that will be launching to the International Space Station. Photo via Redwire.

Photo via Redwire.The hardware for the Made In Space additive manufacturing device was developed in partnership with NASA’s Marshall Space Flight Center and was created to identify and test the methodology for regular manufacturing in the US on a lunar surface to support NASA’s Artemis program. A key phase of NASA’s Artemis plan is to create lunar infrastructures for future exploration missions to the surface, that will be critical to humanity’s sustainable presence on the moon and beyond, Snyder said.

“The payload is practically a manufacturing head that is inserted into our existing additive manufacturing facility on the ISS,” he added. “Since 2016, we have produced over 200 tools for it so this is basically a new deposition head and a new deposition plate that we will be printing on. We’re really excited about this because it’s the first time testing a new manufacturing technique in microgravity.”

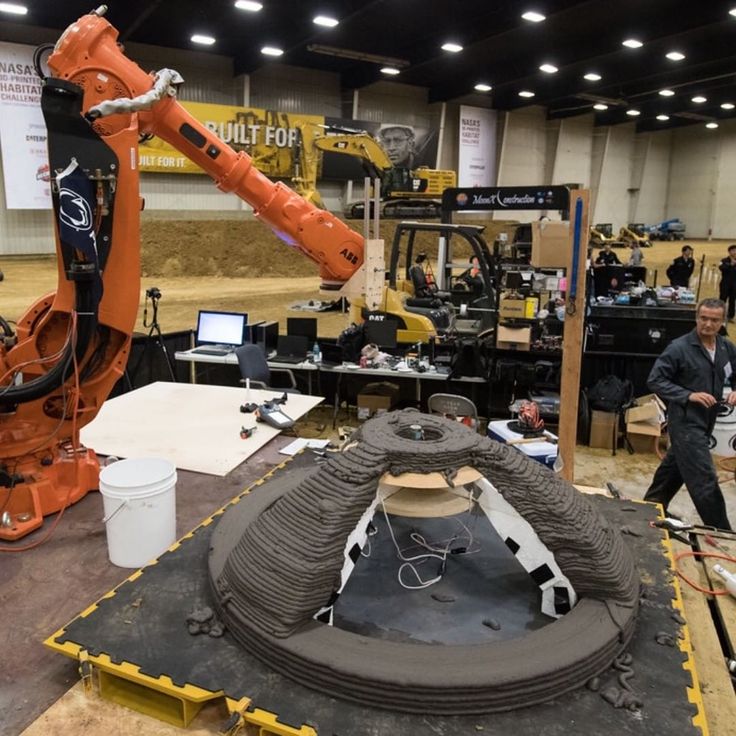

Redwire has been working with NASA’s Marshall Space Flight Center for some time on the project, having taken part in the first round of the 3D Printed Habitat Centennial Challenge. The multi-phase challenge was aimed to advance the construction technology needed to create sustainable housing solutions for Earth and beyond, and was the origin of Redwire’s regolith-simulating material.

The multi-phase challenge was aimed to advance the construction technology needed to create sustainable housing solutions for Earth and beyond, and was the origin of Redwire’s regolith-simulating material.

Once the 3D printed regolith samples are returned to Earth, they will be analyzed and compared with samples produced in a ground facility prior to launch. Comparing the samples will help Redwire to validate that the printing process works at levels of gravity lower than that on Earth.

“The capability has already been proven on Earth, but requires further validation in the space environment,” said Snyder. “Operating both on the ground and in microgravity will increase the competence in the process for use on planetary bodies with gravity fields, including the Moon and Mars. The regolith print demonstration will be the first-ever test of manufacturing regolith simulate feedstock in space.”

The RRP study will launch on Northrop Grumman’s 16th commercial resupply services mission on August 10th from NASA’s Wallops Flight Facility in Virginia. Other experiments and supplies also being launched to the ISS include engineered tissue to study muscle loss, slime mold, a flow boiling and condensation experiment, and thermal protection systems, among other things.

Other experiments and supplies also being launched to the ISS include engineered tissue to study muscle loss, slime mold, a flow boiling and condensation experiment, and thermal protection systems, among other things.

3D printing for off-world structures

Additive manufacturing is garnering increasing interest from multiple national space agencies as they seek to establish a permanent presence on the moon.

For instance, Texas-based construction firm ICON has gained a NASA contract for the development of a full-scale prototype off-world 3D printer. As part of the project, the team is working on fabricating space-faring structures using only lunar regolith.

3D printing with lunar regolith in zero gravity has also been explored by scientists from the Technical University of Braunschweig and Laser Zentrum Hannover, in a project titled ‘MOONRISE’. The scientists devised a customized laser that, with further R&D, could form the basis of a flight-ready lunar rover enabling astronauts to create economical long-term structures on the moon.

The scientists devised a customized laser that, with further R&D, could form the basis of a flight-ready lunar rover enabling astronauts to create economical long-term structures on the moon.

Elsewhere, Russian space agency Roscosmos has confirmed its support for long-term missions by 3D printing structures made from on-site material, and China’s National Space Administration has revealed its own plans to 3D print a base on the Moon.

Redwire’s Howie Schulman, project lead, packs the Redwire Regolith Print printing plate ahead of delivery to NASA for launch. Photo via Redwire.Nominations for the 2021 3D Printing Industry Awards are now open, have your say who is leading the industry now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows the Redwire Regolith Print facility suite, consisting of Redwire’s Additive Manufacturing Facility, and the print heads, plates and lunar regolith simulant feedstock that will be launching to the International Space Station. Photo via Redwire.

Tags China National Space Administration Cygnus spacecraft icon International Space Station Laser Zentrum Hannover Made in Space Michael Snyder MOONRISE Nasa Nasa Artemis NASA centennial challenge NASA Marshall Space Flight Center Northrop Grumman Redwire Redwire Regolith Print Roscosmos Technical University of Braunschweig

Hayley Everett

Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

ICON 3D Prints the First Simulated Mars Surface Habitat for NASA Designed by Renowned Architecture Firm BIG-Bjarke Ingels Group

Mars Dune Alpha, the 3D-printed Habitat Located at Johnson Space Center in Houston, Texas, Will Aid in Long-duration Science Missions

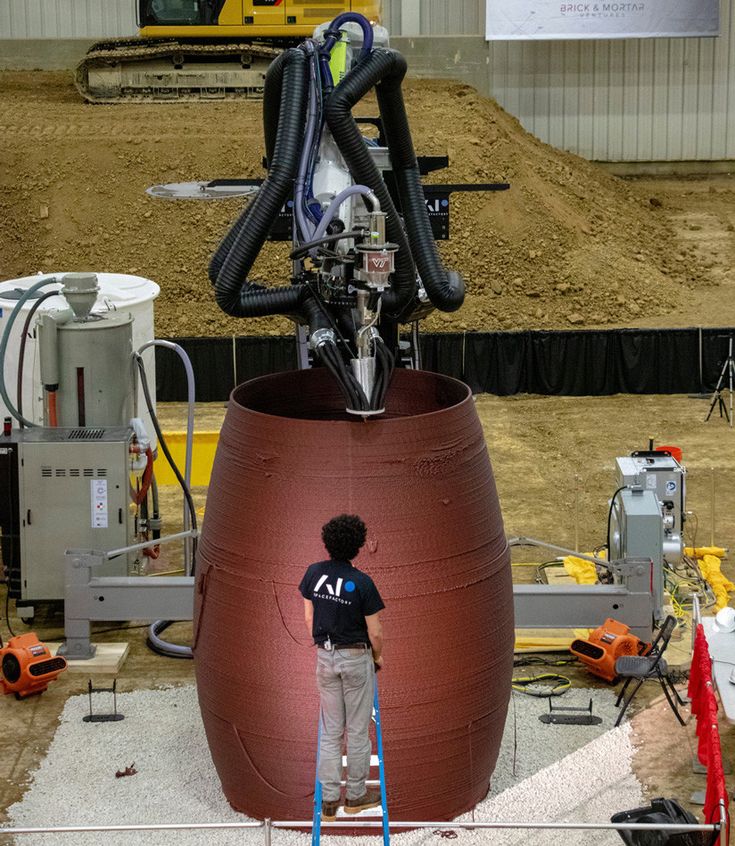

AUSTIN, TX, AUGUST 6, 2021 – ICON, developer of advanced construction technologies including robotics, software, and building materials, today announced it has been awarded a subcontract through Jacobs supporting NASA’s The Crew Health and Performance Exploration Analog (CHAPEA) to deliver a 3D-printed habitat, known as Mars Dune Alpha, at NASA’s Johnson Space Center. ICON’s next-gen Vulcan construction system will complete a 1,700 square-foot structure, designed by world-renowned architecture firm BIG-Bjarke Ingels Group, that will simulate a realistic Mars habitat to support long-duration, exploration-class space missions.

CHAPEA, is a sequence of three one-year Mars surface mission simulations at the NASA Johnson Space Center in Houston. The analog missions will provide valuable insights and information to assess NASA’s space food system, as well as physical and behavioral health and performance outcomes for future space missions. NASA will use research from the Mars Dune Alpha simulations to inform risk and resource trades to support crew health and performance for future missions to Mars when astronauts would live and work on the Red planet for long periods of time.

Future space exploration habitats have the potential to be 3D printed with additive construction technology to eliminate the need to launch large quantities of building materials on multiple flights, which is cost prohibitive.

“This is the highest-fidelity simulated habitat ever constructed by humans,” said Jason Ballard, co-founder and CEO, ICON. “Mars Dune Alpha is intended to serve a very specific purpose--to prepare humans to live on another planet. We wanted to develop the most faithful analog possible to aid in humanity's dream to expand into the stars. 3D printing the habitat has further illustrated to us that construction-scale 3D printing is an essential part of humanity's toolkit on Earth and to go to the Moon and Mars to stay. ”

We wanted to develop the most faithful analog possible to aid in humanity's dream to expand into the stars. 3D printing the habitat has further illustrated to us that construction-scale 3D printing is an essential part of humanity's toolkit on Earth and to go to the Moon and Mars to stay. ”

Life in Mars Dune Alpha will resemble the expected experience for those living in a future Mars surface habitat. Designed by BIG-Bjarke Ingels Group, the layout of the innovative structure is organized in a gradient of privacy. Four private crew quarters will be located on one end of the habitat; dedicated workstations, medical stations and food-growing stations are located on the opposite end, with shared living spaces found in between. Varying ceiling heights vertically segmented by an arching shell structure accentuate the unique experience of each area to avoid spatial monotony and crew member fatigue. A mix of fixed and movable furniture will allow crew members to reorganize the habitat according to their daily needs, as will the customizable lighting, temperature, and sound control – helping regulate the daily routine, circadian rhythm, and overall well being of the crew.

“Together with NASA and ICON, we are investigating what humanity’s home on another planet will entail from the human experience,” says Bjarke Ingels, Founder and Creative Director, BIG-Bjarke Ingels Group. “The data gained from this habitat research will directly inform NASA’s standards for long-duration exploration missions, and as such will potentially lay the foundation for a new Martian vernacular. Mars Dune Alpha will take us one step closer to becoming a multiplanetary species.”

Ballard continued, “Bjarke Ingels and the team at BIG are incredible thought leaders in the architecture space. It was important to have a partner who believed in this transformative role of the future of construction and who could help us imagine pioneering new frontiers -- both materially, technologically and environmentally. ”

”

Today, NASA has begun its recruitment for the long-duration Mars mission analog study inside the 3D-printed habitat. Applications to participate as crew are being accepted through mid-September 2021 for the one-year analog mission that starts in Fall 2022. To learn more or to apply, visit www.nasa.gov/chapea/participate.

ICON also received funding from NASA and launched “Project Olympus” to begin research and development of a space-based construction system to support future exploration of the Moon. As part of a government Small Business Innovation Research (SBIR) contract, “Project Olympus” brought ICON and BIG together again to imagine humanity’s first home on another world.

Known for its advanced 3D printing technology for homebuilding on Earth, ICON delivered the first, permitted 3D-printed home in the U.S. in 2018. Since then, the team delivered the world’s first 3D-printed community of homes in Mexico in partnership with housing nonprofit New Story (as seen on Apple TV+ docuseries, “HOME”), completed a series of homes serving the chronically homeless in Austin, TX with nonprofit Mobile Loaves & Fishes at Community First! Village and forged a partnership with the Defense Innovation Unit and United States Marine Corps. In 2021, ICON entered mainstream American housing by printing the first 3D-printed homes sold in the U.S. and launched its Exploration Series of homes pushing the boundaries of architecture and design in 3D-printed home construction. The Austin-based technology company continues to break ground on additional projects spanning mainstream developments, social/affordable housing, disaster-relief housing along with continued work with the Department of Defense and military forces.

In 2021, ICON entered mainstream American housing by printing the first 3D-printed homes sold in the U.S. and launched its Exploration Series of homes pushing the boundaries of architecture and design in 3D-printed home construction. The Austin-based technology company continues to break ground on additional projects spanning mainstream developments, social/affordable housing, disaster-relief housing along with continued work with the Department of Defense and military forces.

For more information visit www.iconbuild.com.

About ICON

ICON develops advanced construction technologies that advance humanity. Using proprietary 3D printing robotics, software and advanced materials, ICON is shifting the paradigm of homebuilding on Earth and beyond. For more information visit www.iconbuild.com or follow the conversation on Instagram, Twitter, Facebook, YouTube (@ICON3DTech).

About BIG

BIG-Bjarke Ingels Group is a Copenhagen, New York, London and Barcelona based group of architects, designers, urbanists, landscape professionals, interior and product designers, researchers and inventors. The office is currently involved in a large number of projects throughout Europe, North America, Asia and the Middle East. BIG’s architecture emerges out of a careful analysis of how contemporary life constantly evolves and changes. By hitting the fertile overlap between pragmatic and utopia, we architects once again find the freedom to change the surface of our planet, to better fit contemporary life forms.

The office is currently involved in a large number of projects throughout Europe, North America, Asia and the Middle East. BIG’s architecture emerges out of a careful analysis of how contemporary life constantly evolves and changes. By hitting the fertile overlap between pragmatic and utopia, we architects once again find the freedom to change the surface of our planet, to better fit contemporary life forms.

NASA begins testing a 3D printer that works in the conditions of the Moon

Trends

TV channel

Newspaper

Pro

Investments

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating Club

Research

Credit ratings

Franchises

Conferences

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Politics

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: Redwire

NASA delivered to the ISS a 3D printer capable of printing from regolith in microgravity on the Moon

What's happening

- As part of the latest ISS resupply mission, the Northrop Grumman Cygnus spacecraft delivered to the station a machine designed to 3D print regolith on the Moon and other extraterrestrial surfaces.

- The unit, called Redwire Regolith Print (RRP), will work in tandem with the ManD printer system installed on the ISS. The RRP is reported to be comprised of several extruders and printing platforms specifically designed to work with regolith.

- If the experiment is successful, the ISS crew will measure the strength of the resulting material based on ASTM (Additive Manufacturing Technology Standards) standards to see if it can withstand harsh conditions off Earth.

- Successful implementation of the RRP project could bring researchers closer to astronauts printing the items they need on space bodies, which will reduce the amount of materials that NASA delivers to the Moon and Mars.

- The project is part of NASA's Artemis lunar program, which also plans to land humans on the moon in 2024. It is assumed that the astronauts will stay on its surface for about a week.

What does it mean

It is believed that the colonization of the Moon and Mars is the next stage of space exploration. The technologies that will make this possible are being developed not only by public but also by private space companies. For example, the conquest and colonization of extraterrestrial space attract the founder of SpaceX, Elon Musk. The entrepreneur plans to take a man to Mars for the first time in six years, and the company's long-term plans include sending 1 million people to the planet by 2050.

The technologies that will make this possible are being developed not only by public but also by private space companies. For example, the conquest and colonization of extraterrestrial space attract the founder of SpaceX, Elon Musk. The entrepreneur plans to take a man to Mars for the first time in six years, and the company's long-term plans include sending 1 million people to the planet by 2050.

In this context, the development of 3D printing technologies on extraterrestrial surfaces seems to be an extremely topical issue — the future of human colonies on the Moon and Mars depends on it.

Earlier, the American architectural bureau AI SpaceFactory presented a project of buildings for construction on Mars as part of the NASA 3D-Printed Habitat Challenge. Despite the fact that architects currently use basalt fiber and bioplastics as materials, if the RRP project is successful, Martian soil could be used in construction.

Video: AI SpaceFactory

Updated on 08/17/2021

Text

Ksenia Yanushkevich

Top of the trend

Related materials

NASA builds a training simulator of a Martian colony using a 3D printer

News

Follow the author

0003

Don't want to

2

ICON, a Texas-based company, is building an experimental "Martian" building for NASA using a 3D construction printer of its own design. The Mars Dune Alpha project provides for the development of 3D printing technologies for future Martian structures using improvised materials and the study of the habitability of such structures.

The Mars Dune Alpha project provides for the development of 3D printing technologies for future Martian structures using improvised materials and the study of the habitability of such structures.

The first task is to build a building with an area of about 160 square meters. The building will then be used in the Crew Health and Performance Exploration Analog (CHAPEA) experiment, during which a team of imaginary colonists will live and work in conditions as close to Martian as possible. The experiment will last for twelve months, starting next autumn. In total, NASA plans to conduct three such experiments to study the impact of long-term expeditions on the physical, mental health and performance of astronauts. Not only people will be tested, but also equipment, such as systems for storing and preparing food.

We use the construction 3D printer Vulcan II developed by the Texas company ICON. This enterprise has already appeared in our news more than once with various projects - from the construction of affordable housing in Mexico and native Austin ( in the illustration above ) to the training of US Marines and experimental 3D printing of caponiers. Designed by BIG-Bjarke Ingels Group, the Martian House is being built in one of the hangars at the Lyndon Johnson Space Center in Houston, Texas.

Designed by BIG-Bjarke Ingels Group, the Martian House is being built in one of the hangars at the Lyndon Johnson Space Center in Houston, Texas.

In the long term, NASA is considering 3D printing already real Martian buildings, as it would be easier and cheaper in terms of logistics: it is easier to deliver relatively compact additive construction equipment and use Martian soil than to transport huge volumes of building materials from Earth. This side of the matter is also being investigated: as we reported yesterday, additional equipment and consumables have already been sent to the ISS for experiments on 3D printing of artificial regolith in microgravity conditions.

The design of the supposedly Martian house includes four bedrooms at one end of the building. At the other end there will be office space, including an infirmary. The central part will be occupied by common areas and a hydroponic garden.

ICON also received funding from NASA and launched Project Olympus, a research and development effort aimed at building additive space building equipment to support the Moon and later Mars exploration program.

construction NASA icon Mars Dune Alpha Mars

Subscribe author

Subscribe

Don't want

2

Article comments

More interesting articles

5

Subscribe to the author

Subscribe

Don't want

Children's City Multidisciplinary Clinical Specialized Center for High Medical Technologies

Read more

5

Subscribe to the author

Subscribe

Don't want

The name of the new brand will only change one letter from lowercase to uppercase - UltiMaker together with.