3D print carbon fibre

Ultimate Materials Guide - 3D Printing with Carbon Fiber

Overview

Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. Several popular filaments can be bought with carbon fiber fill including PLA, PETG, Nylon, ABS, and Polycarbonate. These fibers are extremely strong and cause the filament to increase in strength and stiffness. This also means that the 3D printed parts will be much lighter and more dimensionally stable, as the fibers will help prevent shrinking of the part as it cools. Print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material that the fibers were added to (for example, the stock PLA settings would be a good starting point for PLA-based carbon fiber filament). However, due to the added fibers, these specialty materials are more likely to clog and can require special hardware to avoid damaging the printer.

- Increased strength and stiffness

- Very good dimensional stability

- Lightweight

- Abrasive and requires hardened steel nozzle

- Increased oozing while printing

- Increased brittleness of filament

- Higher tendency to clog

Hardware Requirements

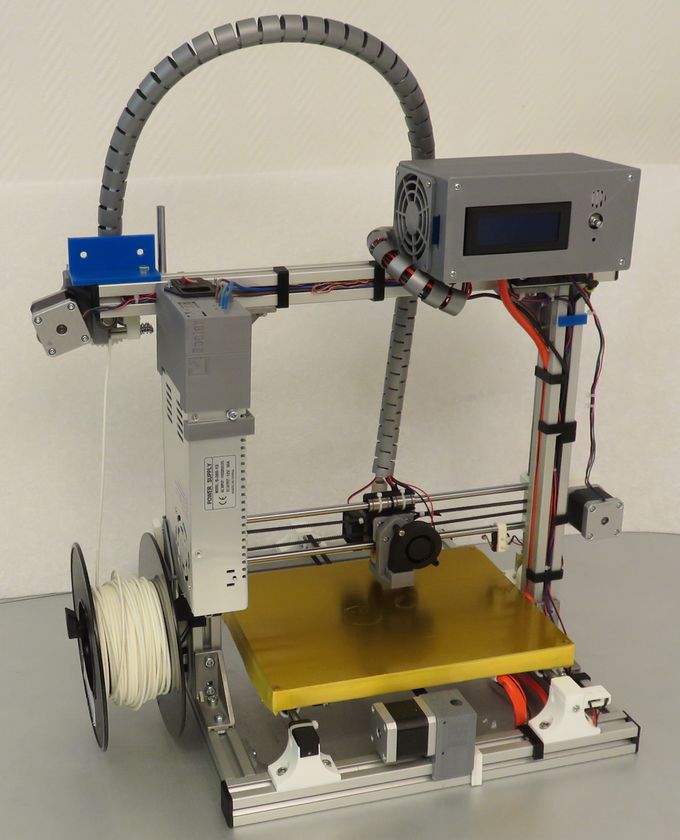

Carbon fiber filled filaments have the same requirements as the base filament it is infused with. The hardware requirements listed below are for carbon fiber filled PLA filament.

Bed

Temperature: 45-60 °C

Heated Bed Optional

Enclosure not required

Build Surface

Painter’s tape

PEI

Glass plate

Glue stick

Extruder

Temperature: 200-230 °C

Requires Wear Resistant Hardened Steel Nozzle

Cooling

Part Cooling Fan Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with carbon fiber filled filaments such as clogging and the nozzle wearing down.

Upgrade to Hardened Steel Nozzle

The carbon fibers in these filaments can be extremely abrasive. In many cases, the carbon fibers are actually harder than the brass nozzles used on most 3D printers, so trying to print these materials with a stock nozzle could damage the printer. Instead, plan on upgrading to a hardened steel hotend. These hotends can resist the added wear from the fibers, however, they also tend to be less thermally conductive than their brass counterparts. You may need to set the extruder temperature as much as 40° hotter than usual, which also helps with reducing the chance of a clog. Reducing the fan speed can also be useful to prevent thermal issues with the steel nozzles.

Adjust Retraction Settings to Avoid Clogs

Since the filament is full of small fibers that won’t melt, the chances of a nozzle clog are greatly increased over the base material. We recommend reducing your retraction distance or disabling retractions all together, as the retractions can increase the change of a buildup of fibers inside the extruder assembly. If you want to minimize the number of retractions that are performed, Simplify3D includes a very useful setting that will actually adjust the travel path of the extruder to stay within the interior of the part so that no retraction is needed. You can enable this setting by turning on the “avoid crossing outline for travel movements” option on the Advanced tab of your process settings.

If you want to minimize the number of retractions that are performed, Simplify3D includes a very useful setting that will actually adjust the travel path of the extruder to stay within the interior of the part so that no retraction is needed. You can enable this setting by turning on the “avoid crossing outline for travel movements” option on the Advanced tab of your process settings.

Reduce the Print Speed for Consistent Results

Using a slower print speed can be a big benefit for carbon fiber filled materials, as the extruder will be under less stress, and has a higher chance of pushing small clogs through the nozzle if they start to form. Try reducing your print speed by 25-50% to see what value works best for your specific brand of plastic. If you still experience clogs after making these changes, we have an entire section on our Print Quality Guide dedicated to this issue that includes several other tips to help troubleshoot this issue: How to Fix a Clogged Extruder.

Use a Guided Filament Path

Carbon fiber filled filaments tend to be far more brittle than the base filament and can snap easily if they are forced through tight corners, or rub on sharp edges of the printer frame. Make sure that the entire filament path, from the spool to the nozzle, consists only of gentle curves, with no sharp turns or areas where the filament will be dragged along a surface. Using a PTFE guiding tube, or ensuring that the filament spool is in a strategic place with regards to the extruder can help reduce the chance of filament breakage.

Pro-Tips

- Nozzles with larger diameters (0.5mm or more) are far less likely to clog, as the fibers will fit through the larger nozzle hole much more easily.

- If the nozzle seems to clog right away after printing the first layer or two, try increasing the first layer height. If the nozzle is too close to the bed, this will create increased back-pressure while printing these layers that can cause the fibers to build up and clog the nozzle temporarily.

Get Started with Carbon Fiber Filled

There are many unique applications for this speciality material. We’ve compiled a few tips below to help you get started.

Common Applications

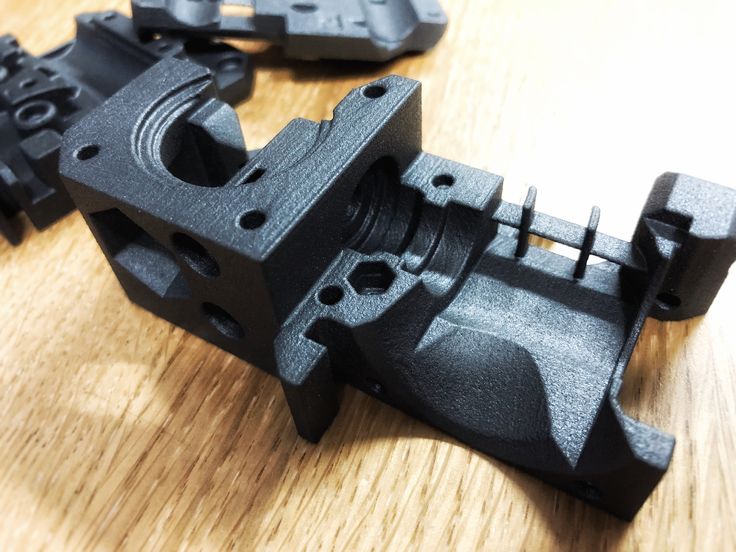

- R/C Vehicles

- Functional prototypes

- Decorative pieces

- Lightweight Props

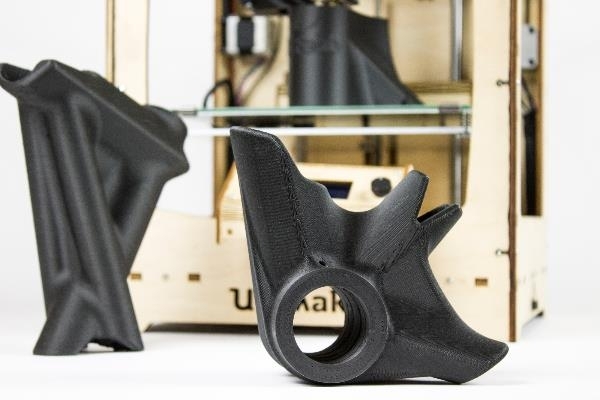

Sample Projects

- F16

- Formula 1 Car

- Quadcopter

- Darth Revan’s Mask

Popular Brands

- Proto-Pasta Carbon Fiber Reinforced PLA

- Matterhackers NylonX

- 3DXTECH

3D Printing Carbon Fiber and Other Composites

Composite materials, on the other hand, are parts made up of more than one material that, when combined, have properties different from their original materials. Materials like concrete and particleboard can be considered composites, because they are mixtures of a variety of materials. However, when we talk about composites from an engineering standpoint, we usually refer to composites with reinforcing fibers. Carbon fiber, fiberglass, and Kevlar are three of the most common fiber materials used for composites in industry. As we covered in the Physics of 3D Printing, the fibers are like spaghetti - thin, brittle, and easy to snap if bent. These fibers are almost never used by themselves - they are woven into sheets, wrapped into rods, or formed into custom molded shapes with the help of a matrix material to harden the fibers into an optimized shape. When many fibers are bound together to create larger structural elements, forces can distribute and disperse loads along the lengths of all of the fibers.

Carbon fiber, fiberglass, and Kevlar are three of the most common fiber materials used for composites in industry. As we covered in the Physics of 3D Printing, the fibers are like spaghetti - thin, brittle, and easy to snap if bent. These fibers are almost never used by themselves - they are woven into sheets, wrapped into rods, or formed into custom molded shapes with the help of a matrix material to harden the fibers into an optimized shape. When many fibers are bound together to create larger structural elements, forces can distribute and disperse loads along the lengths of all of the fibers.

Fiberglass strands being laid down in a mold and cured with a thermoset resin.

Carbon fiber has one of the highest strength-to-weight ratios out there, making it very valuable for creating lightweight, strong parts. The fibers themselves are made up of carbon atoms whose crystal structure is aligned into strands, making the strands incredibly strong in tension. Traditionally, thermoset resins are used as the bonding agent to set these fibers into a designated shape, cured around a matrix material like foam. So you can create a sandwich panel by “sandwiching” the foam between to sheets of fiber weave, and curing it all with resin. In the context of 3D printing, the fiber can take two different forms:

So you can create a sandwich panel by “sandwiching” the foam between to sheets of fiber weave, and curing it all with resin. In the context of 3D printing, the fiber can take two different forms:

Chopped Fibers are short-length fibers chopped into segments less than a millimeter in length and mixed into traditional thermoplastics to form what is called a filled plastic. These can be printed with an FDM printing process.

Continuous Fibers require a slightly different 3D printing method, in which continuous fiber strands are coated in a curing agent and laid down into a thermoplastic matrix extruded via a secondary print nozzle. This process is called Continuous Fiber Fabrication (CFF).

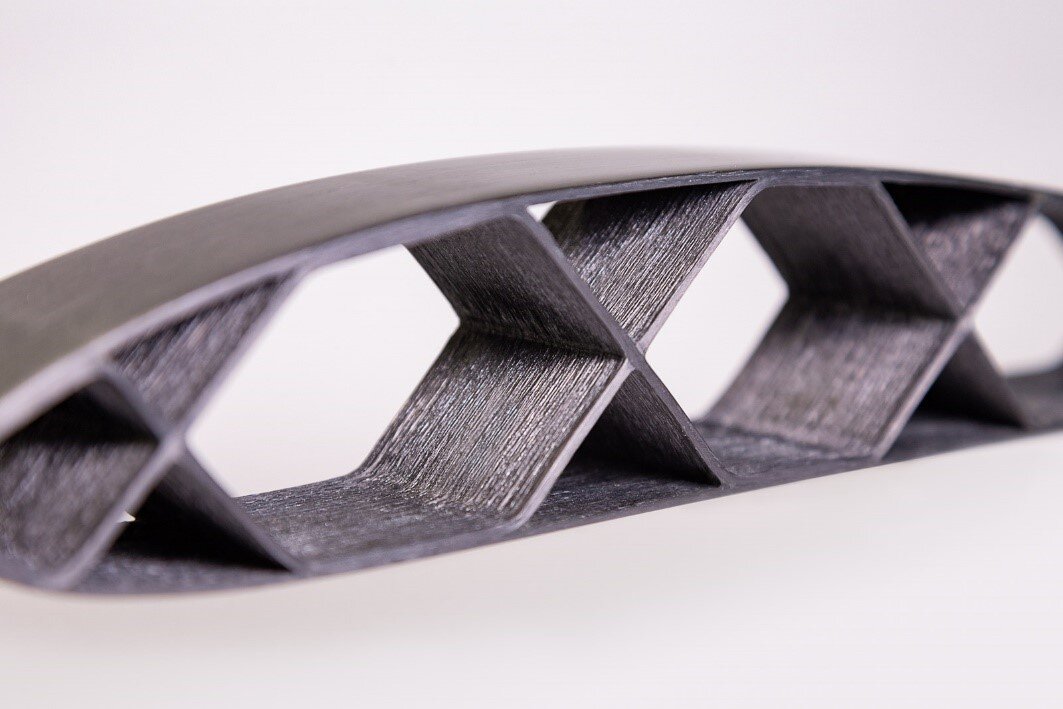

Two forms of 3D printed carbon fiber: on the top is a chopped fiber 3D printing filament, and below is a continuous strand of carbon fiber.

Either way you add fiber, the addition of the fibers boosts part strength and other material properties, but the amount it helps differs depending on the way that fiber is used, and what fiber it is. Generally speaking, a continuous carbon fiber 3D print is stronger than chopped carbon fiber 3D because the continuity distributes any applied loads.

Generally speaking, a continuous carbon fiber 3D print is stronger than chopped carbon fiber 3D because the continuity distributes any applied loads.

Chopped Fiber 3D Printing Materials

Chopped fiber filled plastics are the most common type of composite 3D printed plastics. The most widely used chopped composite 3D printing material is chopped carbon fiber - where carbon fiber pieces are mixed with traditional 3D printing plastics like nylon, ABS, or PLA. Adding this “filling” to thermoplastics is a material booster pack. The fibers take on some of the stresses of the part, like how concrete is added to cement to boost its strength. The fibers handle some of the applied stresses on the part, boosting the properties of typically lower-grade materials. The addition of carbon fiber also improves the thermal stability of mechanical properties, which widens the range of operating temperatures and improves predictability of material behavior in both high and low temperatures.

A close-up of chopped carbon fibers used in 3D printing, taken on an SEM.

These fibers are chopped up into fine pieces and mixed into the plastic before it gets extruded into a spool for use with material deposition-based 3D printers. In this case, the 3D printing process remains the same, because the fibers are just suspended in the thermoplastic - so it gets heated, extruded, and cooled into the part just like any other FFF style 3D printed. Chopped composite 3D printing materials take normal plastic that may be lacking in certain properties and boost it. In the case of carbon fiber, the fibers boost the strength, stiffness, and dimensional stability of the part to make it higher-performing than its base plastic.

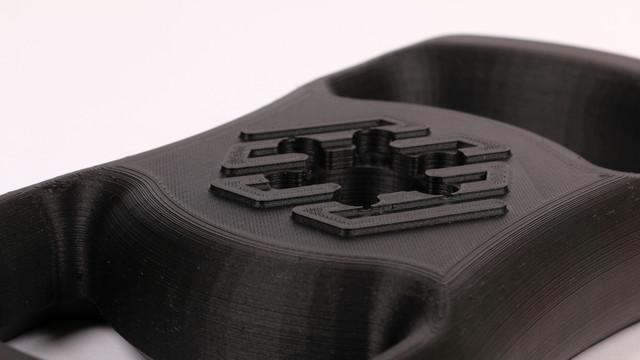

Chopped carbon fiber 3D printing materials can be used like normal 3D printing plastics, boosting some material properties.

The quantity of fibers and the length of chopped segments impacts the strength and quality of the part. Different vendors blend different amounts of fiber into their plastic, yielding materials with different strengths. Below a certain threshold, and the fibers boost surface finish, print quality. Above that threshold, mixing in a large quantity of longer fibers, and you get a stronger material, but you sacrifice surface finish and part accuracy because there is a smaller percentage of plastic in the material overall. The thermoplastic is essential to the mixture because it makes the printing process work well, so your parts can only get so strong.

Below a certain threshold, and the fibers boost surface finish, print quality. Above that threshold, mixing in a large quantity of longer fibers, and you get a stronger material, but you sacrifice surface finish and part accuracy because there is a smaller percentage of plastic in the material overall. The thermoplastic is essential to the mixture because it makes the printing process work well, so your parts can only get so strong.

Continuous Fiber 3D Printing

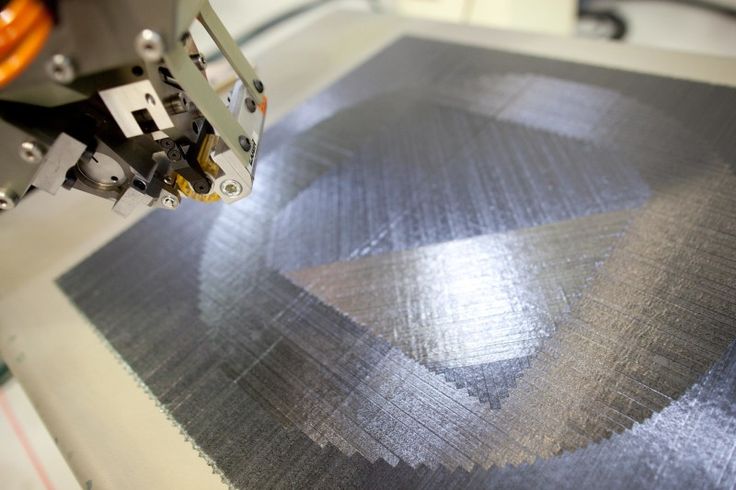

Continuous fiber 3D printing adds continuous strands of fiber reinforcement to the part (think back to fiber strands), to achieve metal-strength properties at a fraction of the weight. Using two print nozzles, the printer builds the matrix material out of a thermoplastic, and irons down continuous strands of continuous fibers into the part. This process is called Continuous Fiber Fabrication (CFF).

Continuous Kevlar strands are ironed into this part to increase its impact resistance with a composite fiber printing nozzle.

A thermoplastic matrix material forms the skin and core of the part.

A thermoplastic matrix material forms the skin and core of the part.The power of CFF comes from the continuity of the strands. Unlike chopped fibers, continuous strands can absorb and distribute loads across their entire length. When placed within a thermoplastic matrix, the part can handle higher loads and absorb larger impacts. This allows these parts to achieve the strength of metal at a fraction of the weight.

Continuous fibers form the backbone of a 3D printed part, because the loads distribute along their length, rather than into the plastic.

The CFF 3D printing process consists of two steps per layer - first, a thermoplastic is extruded to form the infill and shells of the part - this serves as the “matrix” material of the composite. Next, the continuous fiber is ironed into that matrix, fusing with the thermoplastic by use of a compatible resin coating. This process repeats layer by layer, forming the fibers into the backbone of the 3D printed part, while the thermoplastic acts as a skin. This process is also similar to how rebar can be laid down inside concrete to reinforce it.

This process is also similar to how rebar can be laid down inside concrete to reinforce it.

The fibers form the "backbone" of the part and can be laid down in specific patterns to optimize a part’s strength for its weight and material consumption. You can place fiber in specific areas based on how the part will experience load, putting the strength exactly where you need it. This is very different from standard deposition-based 3D printers, including with chopped fibers, because these methods have an even distribution of properties throughout the entire part. Different fiber reinforcement options can be used for different loading conditions and behaviors. You can learn more about the different reinforcement strategies in Fiber Reinforcement Strategies.

A variety of different fibers can be used for reinforcement as well, depending upon what material properties your part needs to have. Markforged 3D printers offer a few different fiber materials so that you can choose the strength behavior of the reinforcement:

Carbon Fiber is a stiff and strong fiber that behaves like 6061 Aluminum, so it can be used for lightweight components that support heavy loads.

This 3D printed carbon fiber can match the strength of aluminum when continuous. Both are supporting a 27.5 lb load.

Fiberglass is a sturdy, cost-effective reinforcing material with some compliance to it. It boosts part strength above that of plastics and is a good starting point for printing with reinforcement.

Fiberglass is a robust 3D printing fiber option, exceeding the strength of chopped fiber, ABS, and PLA when supporting a 7.5 lb weight.

Kevlar has high toughness and shock resistance, making it ideal for shock-loading and high-impact conditions. It bends instead of breaking.

PLA, ABS, and Kevlar reinforced 3D printed parts getting shock-loaded with some big hammer hits!

High Strength High Temperature (HSHT) Fiberglass maintains its strength and stiffness at high temperatures because of its high heat-deflection temperature. Its heat resistance allows it to hold up in more extreme environments.

This test was performed after heating each beam to 300 degrees Fahrenheit in an oven. HSHT does not lose strength at high temperatures, so it still supports the 5 lb load.

So between selecting different fiber types for certain material needs, and controlling where the fiber can be placed layer by layer, you can control the behavior and performance of your parts. This is one of the primary advantages continuous 3D printed composites have over chopped fiber materials. Not only do you get stronger parts, but you also can produce parts optimized for their application.

Everything you need to know about 3D printing carbon fiber

First produced by Joseph Swan in 1860, carbon fiber is made up of a long chain of carbon atoms bonded together. The chain is typically 5 to 10 micrometers in diameter and varies in length depending on the application. Over the years, carbon fiber has become popular in many sectors because it offers interesting properties, including high stiffness, high tensile strength, light weight, high chemical resistance, high temperature resistance, and low thermal expansion. Pure carbon fiber is actually five times stronger than steel and twice as stiff but lighter. As you can imagine, these characteristics make carbon fibers suitable for applications in sectors such as aerospace, automotive, military or civil engineering.

Pure carbon fiber is actually five times stronger than steel and twice as stiff but lighter. As you can imagine, these characteristics make carbon fibers suitable for applications in sectors such as aerospace, automotive, military or civil engineering.

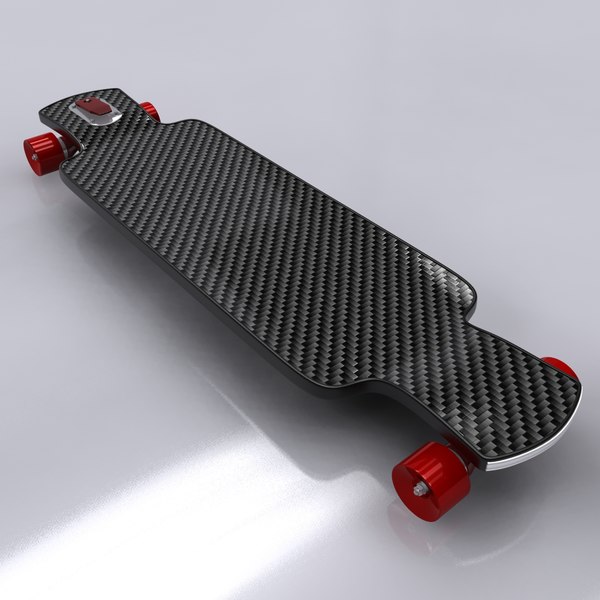

As some of you may already know, carbon fibers are rarely used on their own. They are usually combined with other materials to form what we call a composite material - in this particular case, these are materials reinforced with carbon fiber. These composites are made from a matrix material, usually a polymer, although it is possible to use non-polymer materials such as ceramics to which carbon fibers are added. The main advantage is that you end up with a stronger but lighter plastic with a higher level of stiffness.

The body of this bike frame is made of carbon fiber | Source: Arevo

Traditionally, carbon fiber composites have been used for structural design, where added weight results in increased life cycle costs or unsatisfactory performance. Carbon fiber composites can be used to create many products such as bicycle frames, aircraft fenders, propeller blades, automotive components, etc. As you can imagine, given the many benefits of carbon fiber, it is already being used by more than just traditional manufacturing systems. In recent years, more and more 3D printing companies are offering carbon fiber reinforced materials or technologies. They are designed to work with this composite to provide better performance. So how is carbon fiber being used in additive manufacturing?

Carbon fiber composites can be used to create many products such as bicycle frames, aircraft fenders, propeller blades, automotive components, etc. As you can imagine, given the many benefits of carbon fiber, it is already being used by more than just traditional manufacturing systems. In recent years, more and more 3D printing companies are offering carbon fiber reinforced materials or technologies. They are designed to work with this composite to provide better performance. So how is carbon fiber being used in additive manufacturing?

3D Printing Applications

In its 3D Printing Composites 2020 - 2030 report, IDTechEx reports that the global market for 3D printing composites will reach $1.7 billion by 2030. This figure also includes other composite materials, such as materials reinforced with fiberglass or plastic. However, this trend clearly demonstrates that the 3D printing industry is increasingly using all composites, including carbon, in their manufacturing activities. There are essentially two ways to use carbon fiber in 3D printing, the first is carbon fiber reinforced filaments and the second is continuous carbon fiber reinforcement.

There are essentially two ways to use carbon fiber in 3D printing, the first is carbon fiber reinforced filaments and the second is continuous carbon fiber reinforcement.

Carbon fiber filament

Carbon fiber filament uses short carbon fibers composed of segments less than one millimeter long, which are mixed with a thermoplastic known as a base material. There are a number of popular filaments available with carbon fiber fill, including PLA, PETG, nylon, ABS, and polycarbonate. These fibers, being extremely strong, cause an increase in the strength and stiffness of the thread, and also reduce its overall weight. The requirements for 3D printing carbon fiber filaments should be the same as for the base material they were added to. The main difference is that fibers can clog 3D printer nozzles, so experts recommend using a hardened steel nozzle. In addition, when a certain threshold of fibers is exceeded, the part printed on a 3D printer loses its surface quality.

Carbon fiber segments embedded in thread for reinforcement | Source: Markforged

Some companies have developed carbon fiber fibers for more technical applications. These yarns use high performance polymers (HPPs) such as PEEK or PEKK as the base material. Consequently, they not only offer the benefits of HPPs such as durability and high mechanical and chemical performance, but also an improved strength to weight ratio. Print settings need to be adjusted as HPPs require extruders that can heat up to 400°C and systems that have heated chambers and build plates. Some of the carbon fiber filament manufacturers are: Roboze, 3DXTech, ColorFabb, Markforged, Kimya, Intamsys, Zortrax, etc.

Continuous carbon fiber reinforcement

Carbon fiber thread is definitely stronger than thread that has not been reinforced. However, to get an even stronger part, another method called continuous carbon fiber reinforcement can be used. Since carbon fiber is not cut into smaller pieces, it retains much more strength. In fact, continuous printing on carbon fiber is strong enough to be half the weight of aluminium. 3D printer manufacturers claim that they can replace metal 3D printing for some applications. And the main advantage is that it is cheaper than metal. Finally, by placing carbon fiber according to DfAM techniques, it is possible to increase the strength of the part while reducing material consumption.

In fact, continuous printing on carbon fiber is strong enough to be half the weight of aluminium. 3D printer manufacturers claim that they can replace metal 3D printing for some applications. And the main advantage is that it is cheaper than metal. Finally, by placing carbon fiber according to DfAM techniques, it is possible to increase the strength of the part while reducing material consumption.

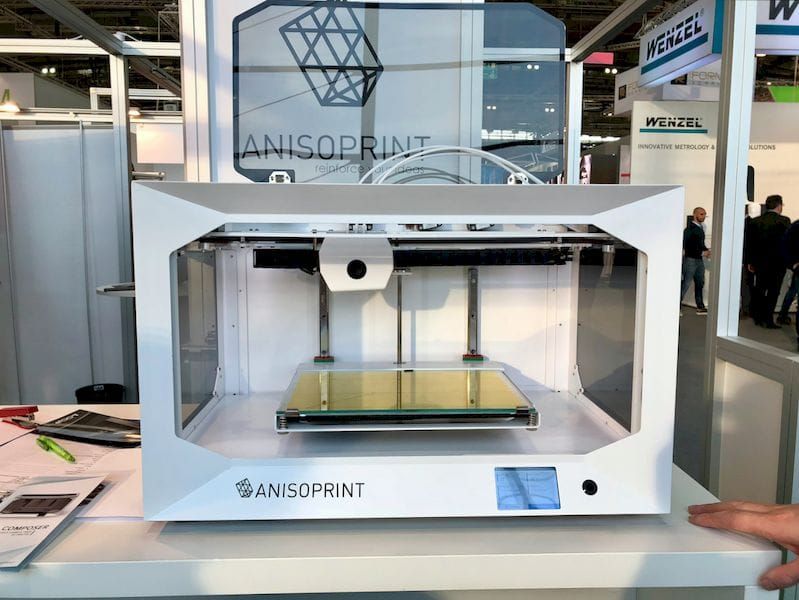

Using DfAM methods, it is possible to strengthen a part using carbon fiber | Source: Anisoprint

There are several players on the market that offer technologies that can continuously print carbon fibers. They can be divided into two main types, depending on when the carbon fiber is added (it can be added before the 3D printing process or during). When added earlier, continuous fiber 3D printing is known as backing prepreg, while when added during extrusion, it is called co-extrusion. In the prepeg technique, you also get a composite thread (or tape), but the carbon fibers have not been cut, instead they have been impregnated with a polymer through a pultrusion process.

Members offering continuous fiber 3D printing include Markforged, Anisoprint, CEAD, etc. More recently, Desktop Metal has also joined the race with a new system called Fiber. Fiber uses Micro Automated Fiber Placement (µAFP). In addition, 9T Labs has developed additive synthesis technology (AFT) to mass-produce carbon composites at a lower cost.

Carbon 3D printing: other technologies

A departure from the better known extrusion process, an interesting technology is the patented AREVO process, based on directed energy deposition technology, in which a laser is used to heat filament and carbon fiber simultaneously as a roller presses them together. Impossible Objects and EnvisionTEC have also added carbon fiber 3D printing systems to their machines, but the technology is slightly different. They weave sheets of carbon fiber using a lamination process. Last but not least, Continuous Composites uses a hybrid technology where a strand of fiber is impregnated with resin and then cured with UV light, similar to SLA 3D printing.

This part demonstrates how continuous carbon fiber 3D printing can increase the strength of a plastic part | Source: Markforged

Source

carbon fiber, composite materials, 3D printing, carbon fiber composites. additive manufacturing, PLA, ABS, polycarbonate, nylon, 3D printing filament, 3D printer, Anisoprint, additive synthesis, 9T Labs, carbon 3d printing, 3D SLA

ALL YOU NEED TO KNOW ABOUT CARBON FIBER 3D PRINTING

ALL YOU NEED TO KNOW ABOUT CARBON FIBER 3D PRINTING

Before you get started with carbon fiber 3D printing, here are some basic information we've put together just for you. Read on and learn about the advantages, disadvantages, history and applications of carbon fiber 3D printing.

CARBON FIBER AS A MATERIAL

Carbon fiber comes in many shapes. Can be used together with resin and molds; it can be combined with polymers in composite form. It has been used for everything from light bulbs to high-performance racing cars - and has even been tested on rockets flying to Mars. Despite its wide range of applications, the most obvious advantage of carbon fiber is its high strength to weight ratio.

Despite its wide range of applications, the most obvious advantage of carbon fiber is its high strength to weight ratio.

History

Carbon fibers were first discovered by Thomas Edison in the late 19th century for use as the filament in early light bulbs. In the late 1950s, the Union Carbide Corporation first recognized the strength advantages that could be achieved with additional processing methods. Over the next 50 years, manufacturing technology advanced further, and today carbon fiber has become a ubiquitous high performance product, from racing cars to airplanes.

Production

Generally, all carbon fiber is produced using a six step process. PAN (polyacrylonitrile) is obtained as a by-product of petroleum and is generally the material of choice for carbon fiber production. PAN is mixed with other ingredients and converted into fibers up to 10% of the thickness of a human hair. The fibers are then oxidized to stabilize the bond before undergoing carbonization, during which the fibers are heated to 1000°C to remove impurities. The surface is then treated to improve adhesion before the final sizing step, in which the fibers are coated and spun into threads of varying thicknesses.

The surface is then treated to improve adhesion before the final sizing step, in which the fibers are coated and spun into threads of varying thicknesses.

These yarns can then be further processed in a variety of ways, depending on the end use. The yarn can be woven into sheets or, in the case of 3D printing, it can be cut into short fibers, mixed with a base polymer, and then extruded into a filament for a 3D printer.

Pre-cut carbon fiber for 3D printing resin

3D PRINTING WITH CARBON FIBER

3D printing with carbon fiber means choosing the right composites. The base polymer can determine the final properties of the part, as well as considerations that need to be taken into account when 3D printing. Below you will see various carbon fiber 3D printer composites and some of their strengths and weaknesses.

Nylon Carbon Fiber PA CF

Nylon Carbon Fiber is one of the most popular composites when it comes to 3D printer. This is because nylon already has desirable properties for engineering applications. It has a high degree of strength and high temperature resistance. It also has a high degree of strength that balances out the brittleness of the carbon fiber itself. A potential disadvantage of nylon is its hygroscopicity, which makes it even more important to have a protected environment for nylon carbon fiber spools such as a mylar bag and a sealed material compartment.

This is because nylon already has desirable properties for engineering applications. It has a high degree of strength and high temperature resistance. It also has a high degree of strength that balances out the brittleness of the carbon fiber itself. A potential disadvantage of nylon is its hygroscopicity, which makes it even more important to have a protected environment for nylon carbon fiber spools such as a mylar bag and a sealed material compartment.

Carbon fiber ABS. ABS CF

ABS is a well known material due to its wide application in injection molded consumer products. In carbon fiber 3D printing, ABS works as a solid base polymer due to its properties. ABS carbon fiber also tends to have a very nice surface finish, which is almost always welcome whether the application is a prototype or part of a final product. One disadvantage of this connection is that it requires a heated 3D printer chamber, which is usually only found in higher end 3D printers.

Carbon fiber PETG CF

PETG is a material known for its resistance to chemicals and moisture in general, making it a good composite resin for 3D printers under exposure conditions. Examples of such applications include parts that may come into contact with coolants or simply products that will be used outdoors in rainy climates.

Carbon fiber PEEK CF

PEEK is one of the most efficient thermoplastics ever invented.

PEEK-CF thread includes carbon fibers for added strength. Chopped carbon fiber gives printed parts high rigidity and dimensional stability. This material provides long term performance up to 240°C including exceptional chemical resistance. These properties make it particularly suitable for metal replacement in critical end-use applications such as oil and gas, aerospace and automotive. The flammability of PEEK-CF is low, as well as the emission of smoke and toxic gases.

Due to its high mechanical properties, PEEK-CF is used for critical applications, in some cases even allowing the replacement of metal parts of the structure.

(Alternative) Fiberglass

Carbon is not the only filler for 3D printer composites. Fiberglass is an alternative to carbon fiber 3D printing when a more flexible end product is required. It can be combined with many materials of the same type and can provide high strength in the same way as carbon fiber.

BENEFITS

➜ Strong and lightweight: Carbon fiber's best known property is its strength to weight ratio, so it is often used in high performance products. This is due to the low density.

➜ Temperature Resistance: is able to withstand higher temperatures than many polymers and even increase the HDT of these polymers when mixed to form a composite.