3D print blistering

6 Ways How to Fix Bubbles & Popping on Your 3D Printer Filament – 3D Printerly

There are many issues that can happen with 3D prints due to various issues. One of those issues is a phenomenon called bubbling or popping, which negatively affects the 3D print quality of your pieces and could result in failures altogether. This article will quickly outline how to fix this problem.

The best way to fix bubbles and popping sounds on your 3D printer is to extract moisture out of your filament before printing. When filament with moisture is heated to high temperatures, the reaction causes bubbles and popping sounds. Prevent this by using high-quality filament and proper storage.

The rest of this article will go into some useful details about this issue and give you practical ways to prevent it from happening in the future.

What Causes Bubbles in Extruded Filament?

During the printing process, it is obvious that filament contains air bubbles, which is practically unstable for 3D printing.

Basically, this can mess up the whole printing process, especially your first and print quality layers.

Moreover, the bubbles in the filaments can make it look non-uniform as the filament diameter will be affected. There are many causes, and I will be discussing the major ones with you.

One of the most common causes of these bubbles is the moisture content, which can affect the first layer and lower 3D printing quality.

The best solution available for this is drying the material before extrusion. However, the possible causes are as follows:

- Moisture content of filament

- Incorrect slicer settings

- Ineffective filament cooling

- Incorrect flow rate

- Printing at height temperature

- Low-quality filament

- Nozzle quality

How to Fix 3D Printer Bubbles in Filament

- Reduce Moisture Content of Filament

- Adjust the Relevant Slicer Settings

- Fix Ineffective Filament Cooling Systems

- Adjust an Incorrect Flow Rate

- Stop Printing at Temperature Too High

- Stop Using Low-Quality Filament

Bubbles occur when air pockets get trapped in print, and this is caused by the temperature of the extruder being too high, resulting in the hot end boiling the plastic.

When it starts cooling, the air bubbles can get trapped in print, and you can notice that it will become a permanent part of the final model. So, let’s start to fix these causes.

Reduce Moisture Content of Filament

Moisture content is one of the main causes that creates bubbles in the filament, which can ultimately be seen in the 3D printing process.

This is because in the filament extrusion process, the moisture content present inside the polymer reaches its boiling temperature and turns into steam. This steam becomes the cause of bubbles, which are seen then on the 3D print model.

Drying before the extrusion process is the best solution for such a problem. It can be done using a special filament dryer or a conventional hot air oven, though ovens aren’t usually calibrated very well for lower temperature.

I’d recommend using something like the SUNLU Filament Dryer from Amazon. It has an adjustable temperature from 35-55° and timer of 0-24 hours. Many users who got this product say that it helped their 3D print quality significantly and stopped those popping and bubbling sounds.

If you get a nozzle popping sound, this could be your solution.

But remember, you must maintain the temperature according to the material you are drying. Almost all filaments absorb moisture content, so it is always a healthy practice to dry them before the extrusion process.

If you are hearing a PETG popping noise for example, you want to dry out the filament, especially because PETG is known to love moisture in the environment.

Adjust the Relevant Slicer Settings

There are a group of settings that I’d advise you adjust to get rid of these bubbles on your 3D prints. The ones that seem to work best are the following:

- Retraction settings

- Coasting setting

- Wiping settings

- Resolution settings

Once you start to adjust these settings, you can see significant differences in your print quality, improving them a lot more than you may have seen in the past.

With retraction settings, you can build up too much filament pressure in your extrusion pathway, leading to filament that actually leaks out the nozzle during movements. When you set optimal retraction settings, it can reduce these bubbles in your 3D prints.

Check out my article on How to Get the Best Retraction Length & Speed Settings, it describes in more detail about these settings and how to get it right.

My article on How to Fix Blobs and Zits on 3D Prints goes over many of these key settings also.

Stefan from CNC Kitchen did a lovely video which goes over the resolution settings, and has received praise from many 3D printer users stating how much it helped them.

Fix Ineffective Filament Cooling Systems

3D print blistering results from an ineffective filament cooling system because if you do not have a proper and fast cooling system, it will take more time to cool down.

Thus, when it takes more time to cool down, the print’s shape’s deformation is noticed, even more so with materials that have a lot of shrinkage.

Add more cooling systems in the printer so that the material is cooled in the required time when it hits the bed. This way, you can avoid any kind of bubbles and blisters.

Something like the Hero Me Fanduct from Thingiverse is a great addition for better cooling.

Adjust an Incorrect Flow Rate

If your flow rates are too slow, the filament spends more time under that hot temperature from the nozzle. It’s a good idea to adjust your flow rate, especially the ‘Outer Wall Flow’ and see whether that clears the issue of bubbles on your filament.

Small 5% increments should be enough to tell whether it helps fix the problem.

Stop Printing at Temperature Too High

Printing at too high a temperature can result in bubbles, especially first layer bubbles because the first layer is slowed down, with less cooling, which compounds the issues of high heat and time under that heat.

When you also have too much moisture in your filament, from absorbing it in the surrounding environment, these high temperatures are even worse in resulting in popping filament and bubbles in your prints.

Try to 3D print at as low heat as you possibly can while the flow of filament remains satisfactory. That is usually the best formula for the optimal printing temperature.

Using a temperature tower is a great way of finding your optimal temperature settings, and can even be done with speed as well. The video below takes you through the process.

Stop Using Low-Quality Filament

In addition to the rest of these factors, low quality filament that doesn’t have the best quality control can contribute to these bubbles and popping of your filament. You are a lot less likely to experience this from high quality filament.

You are a lot less likely to experience this from high quality filament.

I’d look for a brand that has a great reputation and top reviews for a good period of time. Many on Amazon, even though they are cheap, really are manufactured with care in mind.

You don’t want to waste time, effort and money trying to make a cheap roll of filament work for your 3D printing desires. You’ll save more money in the long run and be happier with the results by using some great filament.

You can avoid PLA or ABS popping sounds by using good filament.

Make Sure to Use a Good Nozzle Material

The material of your nozzle could also have an impact on bubbles and popping of your filament. Brass is a superb conductor of heat, allowing it to transfer the heat easier from the heating block to the nozzle.

If you are using a material such as hardened steel, it doesn’t transfer heat as well as brass, so you’d need to make adjustments in the printing temperature to compensate for that.

An example could be switching from hardened steel back to brass, and not lowering the printing temperature. This could result in you printing at a temperature which is too high, similar to the cause listed above.

Conclusion for Fixing Bubbles & Popping in Filament

The best solution to get rid of the popping and bubbles from filament is a combination of the points above, so to summarize:

- Store your filament properly and dry before using if it has been left out for a while

- Adjust your retraction, coasting, wiping & resolution settings in your slicer

- Implement an improved cooling system using something like the Petsfang Duct or Hero Me Fanduct

- Adjust your flow rates, especially for the outer wall and see if it fixes the issue

- Decrease your printing temperature and find the optimal temperature with a temperature tower

- Use higher quality filament with a good reputation

- Take note of your nozzle material, brass is recommended due to its great thermal conductivity

Print bubbling on heated bed during print - 3D Printers - Talk Manufacturing

Scott_Jenkins

#1

I have printed this base for the last 2 days now trying to get it right. I have taken the temp all the way down to 185 degrees it still does this… I am currently printing at 205 degrees I upped the temp during printing because it was doing it at 200 degrees. Any suggestions?

I have taken the temp all the way down to 185 degrees it still does this… I am currently printing at 205 degrees I upped the temp during printing because it was doing it at 200 degrees. Any suggestions?

1 Like

3dpGeek

#2

A. What type of filament

B. What type of bed? Heated glass?

C. What type of products so you use for adhesion to the bed?

I had this problem on my da vinci a couple of times when I first got it back in the day and it was because the glue I was using wasn’t strong enough to hold the print on the build surface.

1 Like

Scott_Jenkins

#3

PLA wood filament

Heated aluminumn with build tak

no adhesion products

jamesarmstrong

#4

Clean lightly with sandpaper then wipe with alcohol. Sometimes it gets a buildup and has to be refinished.

Sometimes it gets a buildup and has to be refinished.

amorton12

#5

This can also happen if you are overextruding too much. Check your filament diameter with good calipers, and check the extrusion multiplier setting in your slicer as well.

luc1dni9htmare

#6

Try to level your bed again and add more distance between your nozzle and bed. I normally use 0.15mm to get a nice first layer. Yours like its way too close to the bed.

bbogner

#7

First layer is too smooshed. The heat isn’t bubbling it, but rather the next line of filament is pushing it up. Either you are over-extruding, or your bed leveling put your nozzle too close. Both can be handled in Simplify3d if you are using that. In S3D, bump your first layer height up. For instance, if it’s set at the default(85% i believe), then set it to 95% and try again. You can go over 100% if needed. This basically tells the printer to extrude 100% filament in a space that’s 85% of normal. Check out S3D’s FAQ for more info. Might play with your first layer extrusion width as well. In the future, when bed leveling, make sure the bed is hot when you do it. Seems to work for me to help alleviate this issue.

The heat isn’t bubbling it, but rather the next line of filament is pushing it up. Either you are over-extruding, or your bed leveling put your nozzle too close. Both can be handled in Simplify3d if you are using that. In S3D, bump your first layer height up. For instance, if it’s set at the default(85% i believe), then set it to 95% and try again. You can go over 100% if needed. This basically tells the printer to extrude 100% filament in a space that’s 85% of normal. Check out S3D’s FAQ for more info. Might play with your first layer extrusion width as well. In the future, when bed leveling, make sure the bed is hot when you do it. Seems to work for me to help alleviate this issue.

gomezjj3

#8

Is that bed actually flat?

Looks almost like it has bulges.

Only seen it happen once. It was under extrusion on first layer. Either bed leveling off or profile settings on slicer. Filaments can be a pain in the butt also, they get moisture in them. Check out the same print with another Filament or even different material. They each have their own challenges. Obtaining the right temperature takes patience and lots of runs until you get the perfect one. I just ran a set of gears with Bridge Nylon on the Duplicator i3V2 and so far I have 4 sets of not so good prints until the right temp hit… Tweaking and preparation is time consuming but it pays off. Take a look at your profiles for that material, see if something doesn’t look right. Good luck.

Scott_Jenkins

#9

Thank you…I have left this filament on the printer while I used it so it could be moist. As far as the bed…it should be I’ve only had the printer for 2 weeks. I’m noticing that there are lots of tweaks…I just got a beautiful print the night before with the same filament…I’m printing a dice towed and it came out great…I have over piece left and I can’t get it to sick to the bed…It’s so frustrating

As far as the bed…it should be I’ve only had the printer for 2 weeks. I’m noticing that there are lots of tweaks…I just got a beautiful print the night before with the same filament…I’m printing a dice towed and it came out great…I have over piece left and I can’t get it to sick to the bed…It’s so frustrating

Scott_Jenkins

#10

I have never been so frustrated with a piece of equipment in my life, every time I fix one problem another crops up. This one though is going to be the death of me… Last night I couldn’t get a first layer to stick to the print bed. A problem that just started happening. I followed some advice on here and lightly sanded the bed and wiped with alcohol. Didn’t work, tried hairspray, didn’t work. I just don’t get it my last print was the best one yet but now I cant get another to print… By the time its printing the 3rd layer the bottom layer has detached and it starts sliding all over the bed and messing up. Please give me some advice as to when your leveling the bed how should the paper feel when your testing it. Should I barely feel the pull or should it be tighter? I thought I had this 2 days ago. when I printed the tower of my dice tower, (I had to press the first layer to the build plate then too, but it stuck and didnt curl up too much) Ive tried the nozzle closer Ive tried the nozzle farther away, Ive tried the bed temp up, Ive tried the bed temp low, Ive tried the nozzle tem up and Ive tried it lower nothing seems to work, Please Help.

Please give me some advice as to when your leveling the bed how should the paper feel when your testing it. Should I barely feel the pull or should it be tighter? I thought I had this 2 days ago. when I printed the tower of my dice tower, (I had to press the first layer to the build plate then too, but it stuck and didnt curl up too much) Ive tried the nozzle closer Ive tried the nozzle farther away, Ive tried the bed temp up, Ive tried the bed temp low, Ive tried the nozzle tem up and Ive tried it lower nothing seems to work, Please Help.

gomezjj3

#11

hi,

It going to be all right, don’t worry everyone goes through the same frustrations. Listen you know how when you drink coffee that is hot you tend to blow on it so that it cools right! Check that your print is not being overcooled. Example: ABS, Nylon etc needs to have the fan off when printing, because otherwise it will cool the parts too quick thus warping and non sticking. You can change those settings on the profile and inclusive on the Wanhao Duplicator i3 while printing. By turning fan On or Off. Take a look at the profile and see what it say in the Cooling section concerning your fan.

Example: ABS, Nylon etc needs to have the fan off when printing, because otherwise it will cool the parts too quick thus warping and non sticking. You can change those settings on the profile and inclusive on the Wanhao Duplicator i3 while printing. By turning fan On or Off. Take a look at the profile and see what it say in the Cooling section concerning your fan.

Adhesion to printing platform is going to be a challenge regardless. There are so many factors involved. 1st layer width, bed leveling, fan status, and so on. Keep playing with it. Once I get the temp and all is going well on a big print like the one you are doing. I usually will go in and Place blue painters tape along the edges of the Brim to help it stay in place, especially if it is a long job. Try using a Brim of about 5-6 lines or even a Raft to aid in adhesion.

As far as your bed leveling and how the paper should slide. A rule of thumb I use is I go into the gap not from the back, I dont put any pressure on the bed, so if the paper doesnt go into the gap freely, My extruder is too low. Adjust and try again. The paper slide is almost like a bite as I pull the paper away. But the bite is soft enough to allow the paper to move freely. I do this with a hot bed. after all the oozing of filament has completed. Or if you have not loaded the filament yet, Level your hot bed before loading filament. Glue, Hairspray, ABS juice, Painters tape and a few others are adhesion aides, but none of them will work if your temperature and printing profiles are not correct. Wanhao has a tips and trick site where they have some printing profiles, experiment with those and see what happens. Test with small prints that are wide, this will give you a better idea of how your prints come out before going into big jobs.

Adjust and try again. The paper slide is almost like a bite as I pull the paper away. But the bite is soft enough to allow the paper to move freely. I do this with a hot bed. after all the oozing of filament has completed. Or if you have not loaded the filament yet, Level your hot bed before loading filament. Glue, Hairspray, ABS juice, Painters tape and a few others are adhesion aides, but none of them will work if your temperature and printing profiles are not correct. Wanhao has a tips and trick site where they have some printing profiles, experiment with those and see what happens. Test with small prints that are wide, this will give you a better idea of how your prints come out before going into big jobs.

Lastly make an enclosure for your printer, this helps with wind drafts. Use PVC board it is cheap and easy to cut. The front you can make a door with Plexi glass. As far as hardware, I use duct tape, no screws. and the door open upward when done printing and lays on top of enclosure.

Keep going at it, Been there done that, and still wearing the T-shirt

gomezjj3

#12

Hi Scott, Have you printed the gcode files that came with printer? Make sure that the material used is the same for the gcode. So example if you use ABS on a gcode for PLA your print will have issues. Check temperature on gcode, particularly the bed temp. PLA is gonna have a lower temp than ABS. I don’t know what you print with, but try to keep your filament dry. If when you print you hear popping it could be moisture on filament. Yeah so check that the filament matches profiles. Key in on bed temps. If you want I can send you some example temps for filament I use and even profiles for specific filament that work for me.

Scott_Jenkins

#13

Thank you, I think I did mess with the fan settings a few prints ago because someone said to have the fan on low on the first layer, will change that.

Scott_Jenkins

#14

That would be great thank you

gomezjj3

#15

Scott,

So check it out. Make sure your bed is leveled the best you can. Take a measurement of the Z axis on both sides make sure they are even. Use a level on your bed to make sure it is even both X and Y axis orientation. Then level using the paper with a hot bed. Once all is good, give it a shot at printing. Here are some example I use for printing.

1.75mm filament on a .4 nozzle FLOW 100%

PLA

Layer Height .16

Shell Thickness 1.2

Enable Retraction True

Bottom Top Thickness 1. 2

2

Fill Density (your preference)

Print speed 40 (yeah its slow but it produces nice prints)

Printing Temp 200

Bed Temp 60

Fan speed 100%

1.75mm filament on a .4 nozzle FLOW 100%

ABS

Layer Height .32

Shell Thickness 1.2

Enable Retraction True

Bottom Top Thickness 1.2

Fill Density (your preference)

Print speed 40 (yeah its slow but it produces nice prints)

Printing Temp 240

Bed Temp 100

Fan speed OFF

1.75mm filament on a .4 nozzle FLOW 100%

HIPS

Layer Height .16

Shell Thickness 1.2

Enable Retraction True

Bottom Top Thickness 1.2

Fill Density (your preference)

Print speed 40 (yeah its slow but it produces nice prints)

Printing Temp 220

Bed Temp 105

Fan speed 40%-50%

BRIM or RAFT is user preference. If using brim it is easier to use 5-6 lines vice 15-20, it will give you same results. The bigger the project the more lines can be added. A Raft in my opinion is usually best used on smaller items. But do you really need to use these. Folks tend to say that it is a waste of filament. TRUE. But whatever works for you stick with it.

A Raft in my opinion is usually best used on smaller items. But do you really need to use these. Folks tend to say that it is a waste of filament. TRUE. But whatever works for you stick with it.

Also once you get a Profile to work save it on your desktop, Name it I3PLA for example. That way you know it works and you can open it up on the Slicer you use and it gives you a peace of mind once you start. Always stay close to the printer, On its first layers it is key to determining whether a print will work or not.

gomezjj3

#16

Scott, I forgot to tell you that I use a glass bed so your temps may be a bit lower. Use increment of 5 degrees when testing on yours.

Scott_Jenkins

#17

ok thank you, I have all the stuff to put a glass bed with PEI on but I keep procrastinating because I dont want to mess up my printer lol

Scott_Jenkins

#18

Im home Trying a new print added a raft, fiddled with a few settings leveled the printer hot and increased the bed temp to 80c looking good so far crossing my fingers

gomezjj3

#19

Awesome, let us know how the print did.

Scott_Jenkins

#20

I will post pictures after work but this is how it went, the Raft laid down like a dream it looked perfect, then when the print started… I curled and bubbled just like when there was no raft, it makes not sense, but the difference being, it stuck to the raft, mainly because I pushed down on the curls as it did the first layer. In the end the print came out ok and my Dice tower is finally done.

next page →

Large format 3D printing on Colossus 3D printer

3D printing

we have the necessary equipment. We are talking about Colossus, a huge additive system capable of printing plastic and composite products almost three meters long.

Colossus

This huge 3D printer was not invented by us, since our company is primarily engaged in the development and production of consumables. But we print on it when our customers require large-sized polymer or composite parts. The system comes from Belgium and is designed by the company of the same name - Colossus. The name is appropriate, because together with the auxiliary equipment, this 3D printer occupies a seven-meter shipping container.

But we print on it when our customers require large-sized polymer or composite parts. The system comes from Belgium and is designed by the company of the same name - Colossus. The name is appropriate, because together with the auxiliary equipment, this 3D printer occupies a seven-meter shipping container.

The size of the construction area of this machine reaches no less than 2.7x1.25x1.5 meters. The choice of consumables is also great: the equipment “digests” any polymers with an extrusion temperature up to 280°C, including ABS, PLA, PETG, Flex elastomers and many others.

Pure polymers are not limited, as Colossus is able to work with high-strength glass and carbon-filled composite materials from various pellet manufacturers, including proprietary materials from REC - X-Line and Clotho. Even better, this 3D printer can recycle recyclable materials, including plastic waste.

Extruder

Printing products in the meter range using conventional filaments for 3D printers is impractical, so Colossus works directly with granular materials. The granulate is dried with special equipment, and then fed into a screw extruder with a 7 mm nozzle. The material is then melted and applied layer by layer until the whole product is "grown". This scheme allows to achieve much higher productivity, reaching 15 kg / h. In practice, everything depends on the material used and the settings, so the average productivity is about three to five kilograms per hour, which in itself is a lot and orders of magnitude higher than the performance of 3D printers working with filaments.

The granulate is dried with special equipment, and then fed into a screw extruder with a 7 mm nozzle. The material is then melted and applied layer by layer until the whole product is "grown". This scheme allows to achieve much higher productivity, reaching 15 kg / h. In practice, everything depends on the material used and the settings, so the average productivity is about three to five kilograms per hour, which in itself is a lot and orders of magnitude higher than the performance of 3D printers working with filaments.

Drying and granulate supply unit (left) and heated vacuum platform (right)

All polymers are subject to heat shrinkage to some extent, in some cases quite significant. The larger the dimensions, the stronger it manifests itself, and the higher the risk of deformation or even separation of the product from the platform during 3D printing. To combat this unpleasant phenomenon, three solutions are provided at once. Firstly, printing is carried out in a closed volume, which helps to stabilize the background temperature. Secondly, a vacuum platform is used, which has a positive effect on the adhesion of the material to the working surface. Thirdly, the platform itself is heated, again helping to combat premature and uneven shrinkage.

Secondly, a vacuum platform is used, which has a positive effect on the adhesion of the material to the working surface. Thirdly, the platform itself is heated, again helping to combat premature and uneven shrinkage.

3D printed composite

Sounds good, you say, but what about examples?

With pleasure! The illustration below shows a chair "freshly printed" with our new glass-filled rPETG composite. The new composite is now undergoing final tests.

Pro self composite

This material combines good weather resistance with the inherent ease of 3D printing of PETG and high strength due to the presence of a reinforcing filler. PETG and materials based on it have a fairly low shrinkage, and therefore are excellent for large-format 3D printing. Last but not least, this composite is manufactured is made from recycled polymer and is therefore offered at a very low price for materials in this class.

If the products will not be subjected to high loads, and the main role is played by cost, you can resort to conventional plastics for 3D printing. Functional products can be made with ABS or PETG polymers, for decorative purposes such as advertising installations or interior decorations, PLA (polylactide) can be used, and for outdoor use, UV-resistant ACA is perfect.

Functional products can be made with ABS or PETG polymers, for decorative purposes such as advertising installations or interior decorations, PLA (polylactide) can be used, and for outdoor use, UV-resistant ACA is perfect.

Ask questions - we will be happy to answer.

Best regards, REC3D team.

Colossus

Follow author

Follow

Don't want

20

Loading

10/16/2022

1499

9

Follow author

Follow

Don't want to

Hello my friend! Today I decided to assemble a simple pneumohydraulic generator or Generator...

Read more

261

Subscribe to the author

Subscribe

Don't want

I continue the series of articles started with the part devoted to polymers.

This part will be devoted to...

Read more

Dima_pb

Loading

02/04/2016

74491

157

Subscribe to the author

Subscribe

Don't want to

Everyone knows about the rollback, but few people understand where to start to manage it properly....

Read more

is a 3D printer?

- 1 3D printing term

- 2 3D printing methods

- 2.1 Extrusion printing

- 2.2 Melting, sintering or gluing

- 2.3 Stereolithography

- 2.4 Lamination

- 3 Fused Deposition Printing (FDM)

- 3.1 Consumables

- 3.2 Extruder

- 3.3 Working platform

- 3.

4 Positioners

4 Positioners - 3.5 Control

- 3.6 Types of FDM printers

- 4 Laser Stereolithography (SLA)

- 4.1 Lasers and projectors

- 4.2 Cuvette and resin

- 4.3 Varieties of Stereolithography Printers

The term 3D printing

The term 3D printing has several synonyms, one of which quite briefly and accurately characterizes the essence of the process - "additive manufacturing", that is, production by adding material. The term was not coined by chance, because this is the main difference between multiple 3D printing technologies and the usual methods of industrial production, which in turn received the name "subtractive technologies", that is, "subtractive". If during milling, grinding, cutting and other similar procedures, excess material is removed from the workpiece, then in the case of additive manufacturing, material is gradually added until a solid model is obtained.

Soon 3D printing will even be tested on the International Space Station

Strictly speaking, many traditional methods could be classified as "additive" in the broad sense of the word - for example, casting or riveting. However, it should be borne in mind that in these cases, either the consumption of materials is required for the manufacture of specific tools used in the production of specific parts (as in the case of casting), or the whole process is reduced to joining ready-made parts (welding, riveting, etc.). In order for the technology to be classified as “3D printing”, the final product must be built from raw materials, not blanks, and the formation of objects must be arbitrary - that is, without the use of forms. The latter means that additive manufacturing requires a software component. Roughly speaking, additive manufacturing requires computer control so that the shape of final products can be determined by building digital models. It was this factor that delayed the widespread adoption of 3D printing until the moment when numerical control and 3D design became widely available and highly productive.

3D printing techniques

3D printing technologies are numerous, and there are even more names for them due to patent restrictions. However, you can try to divide technologies into main areas:

Extrusion printing

This includes methods such as deposition fusion (FDM) and multi-jet printing (MJM). This method is based on the extrusion (extrusion) of consumables with the sequential formation of the finished product. As a rule, consumables consist of thermoplastics or composite materials based on them.

Melting, sintering or bonding

This approach is based on bonding powdered material together. Formation is done in different ways. The simplest is gluing, as is the case with 3D inkjet printing (3DP). Such printers deposit thin layers of powder onto the build platform, which are then selectively bonded with a binder. Powders can be made up of virtually any material that can be ground to a powder—plastic, wood, metal.

This model of James Bond's Aston Martin was successfully printed on Voxeljet's SLS printer and just as successfully blown up during the filming of Skyfall instead of the expensive original

sintering (SLS and DMLS) and smelting (SLM), which allow you to create all-metal parts. As with 3D inkjet printing, these devices apply thin layers of powder, but the material is not glued together, but sintered or melted using a laser. Laser sintering (SLS) is used to work with both plastic and metal powders, although metal pellets usually have a more fusible shell, and after printing they are additionally sintered in special ovens. DMLS is a variant of SLS installations with more powerful lasers that allow sintering metal powders directly without additives. SLM printers provide not just sintering of particles, but their complete melting, which allows you to create monolithic models that do not suffer from the relative fragility caused by the porosity of the structure. As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium.

As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium.

Stereolithography

How an SLA printer works

Stereolithography printers use special liquid materials called "photopolymer resins". The term "photopolymerization" refers to the ability of a material to harden when exposed to light. As a rule, such materials react to ultraviolet irradiation.

Resin is poured into a special container with a movable platform, which is installed in a position near the surface of the liquid. The layer of resin covering the platform corresponds to one layer of the digital model. Then a thin layer of resin is processed by a laser beam, hardening at the points of contact. At the end of illumination, the platform together with the finished layer is immersed to the thickness of the next layer, and illumination is performed again.

Lamination

Laminating (LOM) 3D printers workflow

Some 3D printers build models using sheet materials - paper, foil, plastic film.

Layers of material are glued on top of each other and cut along the contours of the digital model using a laser or a blade.

These machines are well suited for prototyping and can use very cheap consumables, including regular office paper. However, the complexity and noise of these printers, coupled with the limitations of the models they produce, limit their popularity.

Fused deposition modeling (FDM) and laser stereolithography (SLA) have become the most popular 3D printing methods used in the home and office.

Let's take a closer look at these technologies.

Fused Deposition Printing (FDM)

FDM is perhaps the simplest and most affordable 3D construction method, which is the reason for its high popularity.

High demand for FDM printers is driving device and consumable prices down rapidly, along with technology advances towards ease of use and improved reliability.

Consumables

ABS filament spool and finished model

FDM printers are designed to print with thermoplastics, which are usually supplied as thin filaments wound on spools. The range of "clean" plastics is very wide. One of the most popular materials is polylactide or "PLA plastic". This material is made from corn or sugar cane, which makes it non-toxic and environmentally friendly, but makes it relatively short-lived. ABS plastic, on the other hand, is very durable and wear-resistant, although it is susceptible to direct sunlight and can release small amounts of harmful fumes when heated. Many plastic items that we use on a daily basis are made from this material: housings for household appliances, plumbing fixtures, plastic cards, toys, etc.

In addition to PLA and ABS, printing is possible with nylon, polycarbonate, polyethylene and many other thermoplastics that are widely used in modern industry. More exotic materials are also possible, such as polyvinyl alcohol, known as "PVA plastic". This material dissolves in water, which makes it very useful for printing complex geometric patterns. But more on that below.

More exotic materials are also possible, such as polyvinyl alcohol, known as "PVA plastic". This material dissolves in water, which makes it very useful for printing complex geometric patterns. But more on that below.

Model made from Laywoo-D3. Changing the extrusion temperature allows you to achieve different shades and simulate annual rings

It is not necessary to print with homogeneous plastics. It is also possible to use composite materials imitating wood, metals, stone. Such materials use all the same thermoplastics, but with impurities of non-plastic materials.

So, Laywoo-D3 consists partly of natural wood dust, which allows you to print "wooden" products, including furniture.

The material called BronzeFill is filled with real bronze, and models made from it can be ground and polished, achieving a high similarity to products made from pure bronze.

One has only to remember that thermoplastics serve as a binding element in composite materials - they determine the thresholds of strength, thermal stability and other physical and chemical properties of finished models.

Extruder

Extruder - FDM print head. Strictly speaking, this is not entirely true, because the head consists of several parts, of which only the feed mechanism is directly "extruder". However, by tradition, the term "extruder" is commonly used as a synonym for the entire print assembly.

FDM extruder general design

The extruder is designed for melting and applying thermoplastic thread. The first component is the thread feed mechanism, which consists of rollers and gears driven by an electric motor. The mechanism feeds the thread into a special heated metal tube with a small diameter nozzle, called a "hot end" or simply a "nozzle". The same mechanism is used to remove the thread if a change of material is needed.

The hot end is used to heat and melt the thread fed by the puller. As a rule, nozzles are made from brass or aluminum, although more heat-resistant, but also more expensive materials can be used. For printing with the most popular plastics, a brass nozzle is quite enough. The “nozzle” itself is attached to the end of the tube with a threaded connection and can be replaced with a new one in case of wear or if a change in diameter is necessary. The nozzle diameter determines the thickness of the molten filament and, as a result, affects the print resolution. The heating of the hot end is controlled by a thermistor. Temperature control is very important, because when the material is overheated, pyrolysis can occur, that is, the decomposition of plastic, which contributes both to the loss of the properties of the material itself and to clogging of the nozzle.

For printing with the most popular plastics, a brass nozzle is quite enough. The “nozzle” itself is attached to the end of the tube with a threaded connection and can be replaced with a new one in case of wear or if a change in diameter is necessary. The nozzle diameter determines the thickness of the molten filament and, as a result, affects the print resolution. The heating of the hot end is controlled by a thermistor. Temperature control is very important, because when the material is overheated, pyrolysis can occur, that is, the decomposition of plastic, which contributes both to the loss of the properties of the material itself and to clogging of the nozzle.

PrintBox3D One FDM Printer Extruder

In order to prevent the filament from melting too early, the top of the hot end is cooled by heatsinks and fans. This point is of great importance, since thermoplastics that pass the glass transition temperature significantly expand in volume and increase the friction of the material with the walls of the hot end. If the length of such a section is too long, the pulling mechanism may not have enough strength to push the thread.

If the length of such a section is too long, the pulling mechanism may not have enough strength to push the thread.

The number of extruders may vary depending on the purpose of the 3D printer. The simplest options use a single printhead. The dual extruder greatly expands the capabilities of the device, allowing you to print one model in two different colors, as well as using different materials. The last point is important when building complex models with overhanging structural elements: FDM printers cannot print “over the air”, since the applied layers require support. In the case of hinged elements, temporary support structures have to be printed, which are removed after printing is completed. The removal process is fraught with damage to the model itself and requires accuracy. In addition, if the model has a complex structure with internal cavities that are difficult to access, building conventional supports may not be practical due to the difficulty in removing excess material.

Finished model with PVA supports (white) before and after washing

In such cases, water-soluble polyvinyl alcohol (PVA) comes in very handy. Using a dual extruder, you can build a model from waterproof thermoplastic using PVA to create supports.

After printing, PVA can simply be dissolved in water and a complex product of perfect quality can be obtained.

Some FDM printers can use three or even four extruders.

Work platform

Heated platform covered with removable glass work table

Models are built on a special platform, often equipped with heating elements. Preheating is required for a wide range of plastics, including the popular ABS, which are subject to a high degree of shrinkage when cooled. The rapid loss of volume by cold coats compared to freshly applied material can lead to model distortion or delamination. The heating of the platform makes it possible to significantly equalize the temperature gradient between the upper and lower layers.

Heating is not recommended for some materials. A typical example is PLA plastic, which requires a fairly long time to harden. Heating PLA can lead to deformation of the lower layers under the weight of the upper ones. When working with PLA, measures are usually taken not to heat up, but to cool the model. Such printers have characteristic open cases and additional fans blowing fresh layers of the model.

Calibration screw for work platform covered with blue masking tape

The platform needs to be calibrated before printing to ensure that the nozzle does not hit the applied layers and move too far causing air-to-air printing resulting in plastic vermicelli. The calibration process can be either manual or automatic. In manual mode, calibration is performed by positioning the nozzle at different points on the platform and adjusting the platform inclination using the support screws to achieve the optimal distance between the surface and the nozzle.

As a rule, platforms are equipped with an additional element - a removable table. This design simplifies the cleaning of the working surface and facilitates the removal of the finished model. Stages are made from various materials, including aluminum, acrylic, glass, etc. The choice of material for the manufacture of the stage depends on the presence of heating and consumables for which the printer is optimized.

For a better adhesion of the first layer of the model to the surface of the table, additional tools are often used, including polyimide film, glue and even hairspray! But the most popular tool is inexpensive, but effective masking tape. Some manufacturers make perforated tables that hold the model well but are difficult to clean. In general, the expediency of applying additional funds to the table depends on the consumable material and the material of the table itself.

Positioning mechanisms

Scheme of operation of positioning mechanisms

Of course, the print head must move relative to the working platform, and unlike conventional office printers, positioning must be carried out not in two, but in three planes, including height adjustment.

Positioning pattern may vary. The simplest and most common option involves mounting the print head on perpendicular guides driven by stepper motors and providing positioning along the X and Y axes.

Vertical positioning is carried out by moving the working platform.

On the other hand, it is possible to move the extruder in one plane and the platforms in two.

SeemeCNC ORION Delta Printer

One option that is gaining popularity is the delta coordinate system.

Such devices are called "delta robots" in the industry.

In delta printers, the print head is suspended on three manipulators, each of which moves along a vertical rail.

The synchronous symmetrical movement of the manipulators allows you to change the height of the extruder above the platform, and the asymmetric movement causes the head to move in the horizontal plane.

A variant of this system is the reverse delta design, where the extruder is fixed to the ceiling of the working chamber, and the platform moves on three support arms.

Delta printers have a cylindrical build area, and their design makes it easy to increase the height of the working area with minimal design changes by lengthening the rails.

In the end, everything depends on the decision of the designers, but the fundamental principle does not change.

Control

Typical Arduino-based controller with add-on modules

FDM printer operation, including nozzle and platform temperature, filament feed rate, and stepper motors for positioning the extruder, is controlled by fairly simple electronic controllers. Most controllers are based on the Arduino platform, which has an open architecture.

The programming language used by printers is called G-code (G-Code) and consists of a list of commands executed in turn by the 3D printer systems. G-code is compiled by programs called "slicers" - standard 3D printer software that combines some of the features of graphics editors with the ability to set print options through a graphical interface. The choice of slicer depends on the printer model. RepRap printers use open source slicers such as Skeinforge, Replicator G and Repetier-Host. Some companies make printers that require proprietary software.

The choice of slicer depends on the printer model. RepRap printers use open source slicers such as Skeinforge, Replicator G and Repetier-Host. Some companies make printers that require proprietary software.

Program code for printing is generated using slicers

As an example, we can mention Cube printers from 3D Systems. There are companies that offer proprietary software but allow third-party software, as is the case with the latest generation of MakerBot 3D printers.

Slicers are not designed for 3D design per se. This task is done with CAD editors and requires some 3D design skills. Although beginners should not despair: digital models of a wide variety of designs are offered on many sites, often even for free. Finally, some companies and individuals offer 3D design services for custom printing.

Finally, 3D printers can be used in conjunction with 3D scanners to automate the process of digitizing objects. Many of these devices are designed specifically to work with 3D printers. Notable examples include the 3D Systems Sense handheld scanner and the MakerBot Digitizer handheld desktop scanner.

Notable examples include the 3D Systems Sense handheld scanner and the MakerBot Digitizer handheld desktop scanner.

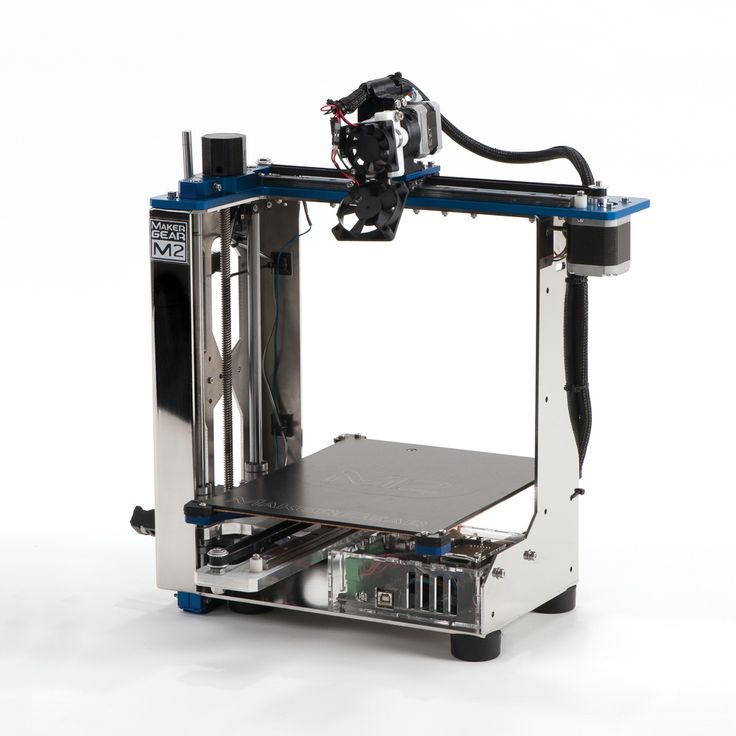

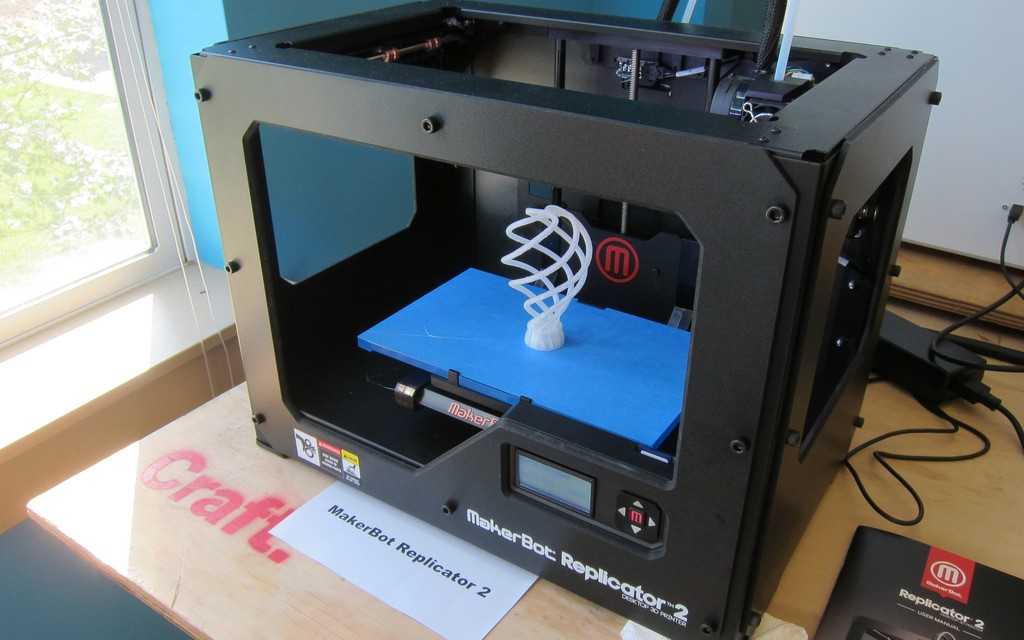

MakerBot Replicator 5th Generation FDM Printer with built-in control module on the top of the frame

The user interface of a 3D printer can consist of a simple USB port for connecting to a personal computer. In such cases, the device is actually controlled by the slicer.

The disadvantage of this simplification is a rather high probability of printing failure when the computer freezes or slows down.

A more advanced option includes an internal memory or memory card interface to make the process standalone.

These models are equipped with control modules that allow you to adjust many print parameters (such as print speed or extrusion temperature). The module may include a small LCD display or even a mini-tablet.

Varieties of FDM printers

Professional Stratasys Fortus 360mc FDM printer that allows printing with nylon

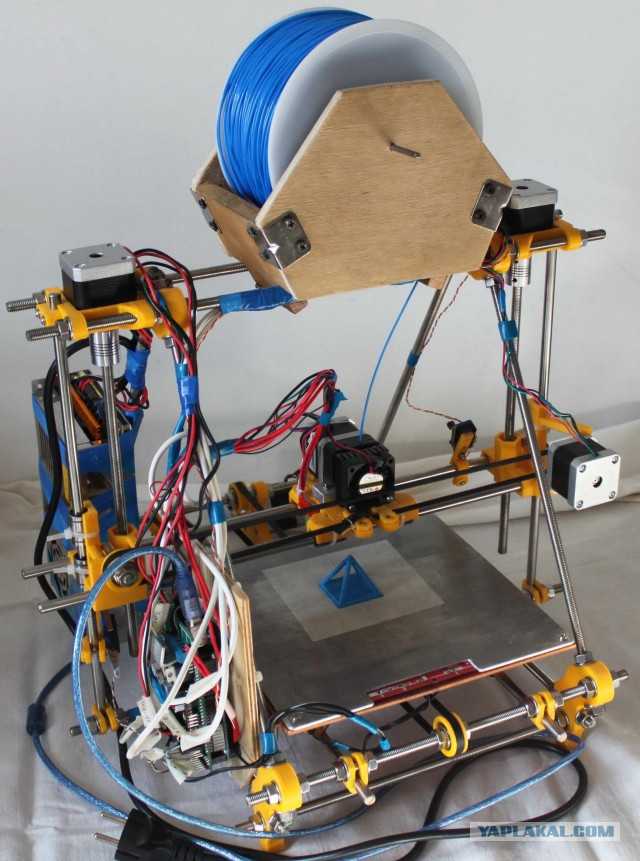

FDM printers are very, very diverse, ranging from the simplest home-made RepRap printers to industrial installations capable of printing large-sized objects.

Stratasys, founded by Scott Crump, the inventor of FDM technology, is a leader in the production of industrial installations.

You can build the simplest FDM printers yourself. Such devices are called RepRap, where "Rep" indicates the possibility of "replication", that is, self-reproduction.

RepRap printers can be used to print custom built plastic parts.

Controller, rails, belts, motors and other components can be easily purchased separately.

Of course, assembling such a device on your own requires serious technical and even engineering skills.

Some manufacturers make it easy by selling DIY kits, but these kits still require a good understanding of the technology. RepRap Printers

And, despite their "homemade nature", RepRap printers are quite capable of producing models with quality at the level of expensive branded counterparts.

Ordinary users who do not want to delve into the intricacies of the process, but require only a convenient device for household use, can purchase a ready-made FDM printer.

Many companies are focusing on the development of the consumer market segment, offering 3D printers for sale that are ready to print “straight out of the box” and do not require serious computer skills.

3D Systems Cube consumer 3D printer

The most famous example of a consumer 3D printer is the 3D Systems Cube.

While it doesn't boast a huge build area, ultra-fast print speed, or superb model build quality, it's easy to use, affordable, and safe: This printer has received the necessary certification to be used even by children.

Mankati FDM printer demonstration: http://youtu.be/51rypJIK4y0

Laser Stereolithography (SLA)

Stereolithographic 3D printers are widely used in dental prosthetics

Stereolithographic printers are the second most popular and widespread after FDM printers.

These units deliver exceptional print quality.

The resolution of some SLA printers is measured in a matter of microns - it is not surprising that these devices quickly won the love of jewelers and dentists.

The software side of laser stereolithography is almost identical to FDM printing, so we will not repeat ourselves and will only touch on the distinctive features of the technology.

Lasers and projectors

Projector illumination of a photopolymer model using Kudo3D Titan DLP printer as an example

The cost of stereolithographic printers is rapidly declining due to growing competition due to high demand and the use of new technologies that reduce the cost of construction.

Although the technology is collectively referred to as "laser" stereolithography, most recent developments use UV LED projectors for the most part.

Projectors are cheaper and more reliable than lasers, do not require the use of delicate mirrors to deflect the laser beam, and have higher performance. The latter is explained by the fact that the contour of the whole layer is illuminated as a whole, and not sequentially, point by point, as is the case with laser options. This variant of the technology is called projection stereolithography, "DLP-SLA" or simply "DLP". However, both options are currently common - both laser and projector versions.

This variant of the technology is called projection stereolithography, "DLP-SLA" or simply "DLP". However, both options are currently common - both laser and projector versions.

Cuvette and resin

Photopolymer resin is poured into a cuvette

A photopolymer resin that looks like epoxy is used as consumables for stereolithographic printers. Resins can have a variety of characteristics, but they all share one key feature for 3D printing applications: these materials harden when exposed to ultraviolet light. Hence, in fact, the name "photopolymer".

When polymerized, resins can have a wide variety of physical characteristics. Some resins are like rubber, others are hard plastics like ABS. You can choose different colors and degrees of transparency. The main disadvantage of resins and SLA printing in general is the cost of consumables, which significantly exceeds the cost of thermoplastics.

On the other hand, stereolithographic printers are mainly used by jewelers and dentists who do not need to build large parts but appreciate the savings from fast and accurate prototyping. Thus, SLA printers and consumables pay for themselves very quickly.

Thus, SLA printers and consumables pay for themselves very quickly.

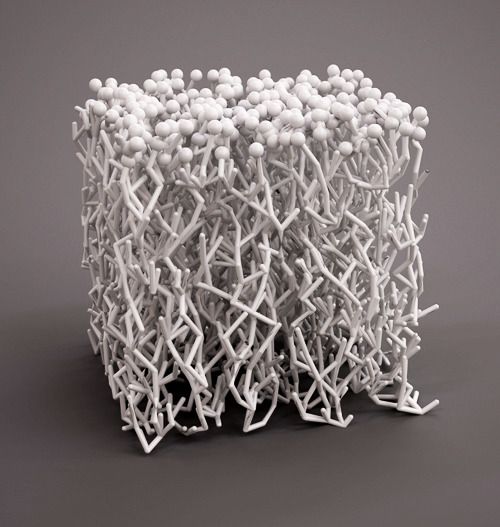

An example of a model printed on a laser stereolithographic 3D printer

Resin is poured into a cuvette, which can be equipped with a lowering platform. In this case, the printer uses a leveling device to flatten the thin layer of resin covering the platform just prior to irradiation. As the model is being made, the platform, together with the finished layers, is “embedded” in the resin. Upon completion of printing, the model is removed from the cuvette, treated with a special solution to remove liquid resin residues and placed in an ultraviolet oven, where the final illumination of the model is performed.

Some SLA and DLP printers work in an "inverted" scheme: the model is not immersed in the consumable, but "pulled" out of it, while the laser or projector is placed under the cuvette, and not above it. This approach eliminates the need to level the surface after each exposure, but requires the use of a cuvette made of a material transparent to ultraviolet light, such as quartz glass.

The accuracy of stereolithographic printers is extremely high. For comparison, the standard for vertical resolution for FDM printers is considered to be 100 microns, and some variants of SLA printers allow you to apply layers as thin as 15 microns. But this is not the limit. The problem, rather, is not so much in the accuracy of lasers, but in the speed of the process: the higher the resolution, the lower the print speed. The use of digital projectors allows you to significantly speed up the process, because each layer is illuminated entirely. As a result, some DLP printer manufacturers claim to be able to print with a vertical resolution of one micron!

Video from CES 2013 showing Formlabs Form1 stereolithography 3D printer in action: http://youtu.be/IjaUasw64VE

Stereolithography Printer Options

Formlabs Form1 Desktop Stereolithography Printer

As with FDM printers, SLA printers come in a wide range in terms of size, features and cost.