3D powder printer for sale

Top 11 Best SLS 3D Printers 2023 (For ALL Price Ranges!)

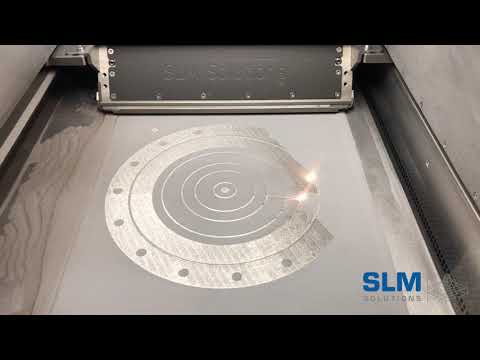

Selective Laser Sintering is one of the main plastic 3D printing technologies for creating accurate parts on demand. SLS 3D printers create accurate prototypes by sintering plastic powders using a laser. As with Fused Deposition Modeling, the part is traced layer-by-layer to gradually create the finished part.

Introduction: A Short History of SLS Printing

Closely following Stereolithography as one of the first 3D printing technologies invented, Selective Laser Sintering was theorized by Carl Deckard in 1988 who filed the patent while working at the University of Texas. Instead of using a UV light as with Stereolithography, SLS involves powder 3D printers using a laser to trace and solidify layers of powder polymers to create a finished part.

Until recently, SLS 3D printers were industrial 3D printers costing tens of thousands of dollars. However, with recent patents expiring and a renewed interest in 3D printing, several more affordable SLS 3D printers have been developed, starting at a few thousand dollars.

- You can also view our in-depth Selective Laser Sintering guide here.

SLS 3D printer materials

SLS printers have a more restricted material range than technologies like FDM, mostly restricted to Nylon Polyamide powders. Some are restricted to just black PA12, whereas some can also print powders including PA11 and PA6.

Increasingly, powder mixes are compatible with industrial and desktop SLS 3D printers. These include glass mixes, carbon fiber mixes, and even food-grade powders for niche applications. Increasing numbers of SLS printers can print TPU, a flexible rubbery material.

But what is the best SLS 3D printer on the market today?

Best Desktop / Cheap SLS 3D Printers under $15,000

Firstly, we have listed the desktop SLS 3D printers. These are defined as printers under $15,000 and are appropriate for small business rapid prototyping rather than solely industrial work.

Note: we have ordered these printers by price.

Sinterit Lisa

- SLS 3D printer price: €9,995 — Available on 3DPrima here

- Company based: Poland

- Print volume: 150 x 200 x 150 mm

Pros

Affordable SLS printer.

Precise.

Compatible with Nylon and Flexa black materials.

Cons

Not portable, weighing in at 41kg.

The Sinterit Lisa is an affordable SLS printer made by Polish manufacturer Sinterit. Compatible with the usual PA12 Nylon and Flexa black materials, the Sinterit Lisa offers a 150 x 200 x. 150 mm printing volume, enough for most single-part projects.

The Sinterit Lisa is a precise powder 3D printer, with a layer thickness of between 0.075-0.175mm. Though a desktop SLS printer, it still isn’t portable, weighing 41kg. The Sinterit Lisa can be purchased for around €9,990, and comes with a 4-inch touch screen for managing printing.

While the Lisa is already an impressive machine, Sinterit have since gone one step further and released the Sinterit Lisa Pro, a premium and upgraded SLS printer. Though it’s more expensive at over €12,000, the printer has won a slew of awards and appears to be a success.The Sinterit Lisa SLS 3D printer is one of the first desktop SLS 3D printers on the market.

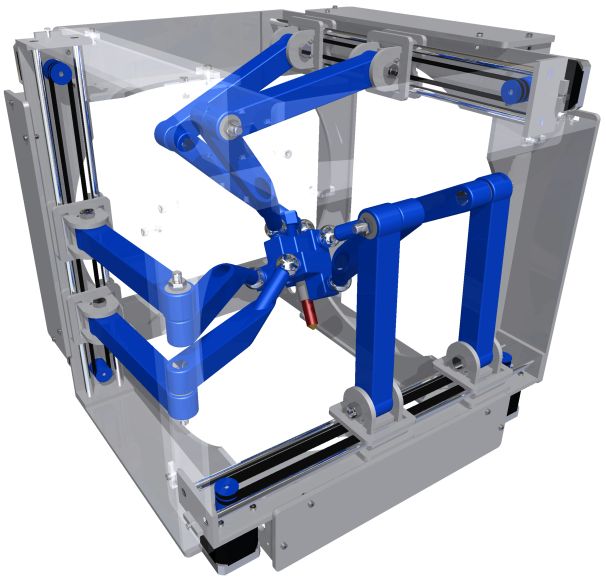

Sintratec Kit — DIY SLS 3D printer

- Cost: €4,999

- Company based: Switzerland

- Print volume: 110 x 110 x 110 mm

Pros

Only DIY SLS 3D printer on sale in the world.

No specialist technical knowledge is required.

Cheapest SLS 3D printer out there.

Cons

Cannot print many parts simultaneously.

Takes 4 days to assemble.

The Sintratec Kit is the only DIY 3D printer kit on this list, and is currently the only DIY SLS 3D printer for sale in the world! Creating an SLS 3D printer kit is a huge achievement considering how much more complex SLS is compared to fused deposition modeling, though the Sintratec takes far longer than a standard kit printer to assemble.

After successfully crowdfunding this SLS 3D printer back in 2014 — raising $213,337, more than their original $175K goal — the Sintratec DIY SLS printer kit has since been released worldwide.

With a modest 110 x 110 x 110 mm print volume, medium-sized parts can be printed without issue. For printing many parts simultaneously however, this may not be the machine for you. The Kit takes around 4 days to assemble, though Sintratec say no specialist technical knowledge is required. You can easily connect to the printer via USB to print, and Sintratec sell their own plastic powders.

For printing many parts simultaneously however, this may not be the machine for you. The Kit takes around 4 days to assemble, though Sintratec say no specialist technical knowledge is required. You can easily connect to the printer via USB to print, and Sintratec sell their own plastic powders.

If you want to try Selective Laser Sintering and don’t want to break the bank, the Sintratec Kit is also the cheapest SLS 3D printer out there, at just €4,999 — if you don’t mind building it yourself.

The only DIY kit SLS 3D printer on our list, the Sintratec Kit.Formlabs Fuse 1

- Price: $9,999

- Company based: USA

- Print volume: 165 x 165 x 320 mm

Pros

Good all-around powder printing solution.

Decent printing volume.

Can be connected via ethernet or WiFi.

Cons

Very heavy at 88kg.

Might be too expensive for some.

American 3D printer company Formlabs have grown astronomically since founding in 2011. Since taking over desktop resin 3D printing with their Form range, the Fuse 1 is Formlabs’ first foray into the SLS 3D printer market. Offering a speed of 10mm/s and a layer thickness of 100µm, the Fuse 1 is a good all-around powder printing solution.

Offering a speed of 10mm/s and a layer thickness of 100µm, the Fuse 1 is a good all-around powder printing solution.

The Fuse 1 can be connected via ethernet or WiFi, and has a very decent printing volume of 165 x 165 x 320 mm. The Fuse 1 is heavy however, weighing in at 88kg, so it’s not exactly easy to move around on a whim. Moreover, the Fuse 1 retails at around $9,999, more expensive than some printers on this list.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

The Fuse 1 is Formlabs’ first SLS 3D printer, having previously made SLA machines.Sinterit Lisa Pro

- Price: $15,000 for the base model — Available on 3DPrima here

- Company based: Poland

- Print volume: 150 x 200 x 260 mm (may be smaller maximum limit for some materials)

Pros

Great precision.

Large build area.

Smooth and accurate powder parts.

Cons

Very expensive.

The Sinterit Lisa Pro is the upgraded version of Sinterit’s original desktop SLS printer, the Lisa. The Lisa Pro comes with a number of improvements, such as better precision: 0.05 mm vs 0.175-0.75 mm. The results are noticeably smoother and more accurate powder parts — very important in industrial applications like prototype testing.

The Lisa Pro comes with a number of improvements, such as better precision: 0.05 mm vs 0.175-0.75 mm. The results are noticeably smoother and more accurate powder parts — very important in industrial applications like prototype testing.

Despite the higher price tag — starting at around $15,000 — many will consider the precision and larger build area worth it. You get their 3D printer software tool with the printer, Sinterit Studio 2019, and though Sinterit sell their own SLS printer powders, the Lisa Pro accepts third party powders.

Red Rock 3D

- Company based: Russia

- Price: Unknown

- Print volume: 180 x 180 x 180 mm

Pros

Fairly impressive print volume.

The fast printing speed of 20cm³/h.

Compact, weighing 35kg.

Cons

Can only be used with black Nylon PA12.

Red Rock are the only Russian 3D printer company on our list, having released a compact, desktop SLS 3D printer weighing just 35kg. Their printer, the Red Rock 3D, is an SLS printer developed for rapid prototyping of functional parts.

With a fairly impressive print volume of 180 x 180 x 180 mm, the Red Rock 3D is perfect for batch production. With a printing speed of 20cm³/h, parts can be created fairly quickly to be tested for their effectiveness. The Red Rock powder 3D printer is currently only able to be used with black Nylon PA12, but the Russian company plans to expand their product range in the coming months.

Best Industrial SLS 3D Printer:

Most SLS 3D printers are out of budget for all but the most industrial applications. These industrial machines are used for high-quality pre-manufacturing prototypes, R&D, and uses in sectors such as aerospace, automotives and other sectors.

Sintratec S2

- Price: $30,000 for primary parts; extra for polishing station and other add-ons

- Company based: Switzerland

- Print volume: 160 x 160 x 400 mm

Pros

Scalable compact system.

Fast and accurate.

Great to print parts in a small workshop.

Cons

Not suited for large-scale production.

After the success of both the Sintratec S1 and the Sintratec Kit, the Swiss company have broadened their range with the more industrial Sintratec S2 SLS machine. It calls itself a ‘scalable compact system’ and features a Laser Sintering Station, Material Handling Station, Material Core Unit and other key parts that make this powder 3D printer a one stop shop for SLS printing.

One of the main benefits of the Sintratec S2 is its fantastic height — you can print up to 400 mm tall parts. This opens up new possibilities for taller powder prototypes. It’s also double the speed of the Sintratec Kit, and accurate up to an astonishing 0.3 mm. It’s a huge machine however, so if you are looking to print parts in a small workshop, you need to seriously consider how viable this may be.

3D Systems ProX SLS 6100

- SLS 3D printer cost: over $100,000

- Company based: USA

- Print volume: 381 x 330 x 460 mm

Pros

Large build volume.

Can print metal powders like aluminum and carbon fiber.

One of the fastest SLS printers in its price range.

Cons

Expensive for an industrial 3D printer.

3D Systems are the original 3D printing firm, having been around since the mid-1980s when they commercialized stereolithography. They’ve since branched out into many other 3D printing technologies, including SLS 3D printers such as their ProX SLS 6100, taking over from the previous SLS 500 model since its release in late 2017.

- For more information on the history of 3D printing, check out our full feature story here.

This industrial SLS 3D printer offers a much larger build volume at 381 x 330 x 460 mm, as well as a layer thickness of between 0.08 and 0.15 mm. It’s fairly speedy, and also versatile, able to print nylon powders filled with other materials, including metal powders like aluminum, or carbon fiber, as well as food-grade materials.

One of the fastest SLS printers in its price range, the ProX SLS 6100 prints up to 2.7 l/h, using 3D Sprint software to maximize efficiency and manufacturing speed. 3D Systems say the ProX 6100 reaches 95% material efficiency due to the Material Quality Control (MQC) system automatically blending and recycling powder, helping lower part costs.

3D Systems say the ProX 6100 reaches 95% material efficiency due to the Material Quality Control (MQC) system automatically blending and recycling powder, helping lower part costs.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

EOS Formiga P 110 Velocis

- 3D printer price: $175,000

- Company based: Germany

- Print volume: 200 x 250 x 300 mm

Pros

Considered the perfect entry-level SLS machine.

No post-processing is needed to remove the marks left by the removed supporting material.

EOS has been in the SLS game since the beginning.

Cons

One of the most expensive SLS printers.

EOS are another major 3D printer manufacturer and a leader in SLS 3D printers, based in Germany. You can trust EOS; they’ve been in the SLS and DMLS 3D printer game since the beginning, and their excellent reputation precedes them.

EOS consider the Formiga P 110 Velocis SLS 3D printer the perfect entry-level SLS machine, with a decent 200 x 250 x 300 mm build volume as well as a varying layer thickness of 0. 06/0.1/0.12 mm depending on the materials used.

06/0.1/0.12 mm depending on the materials used.

The German company sell the P 110 Velocis as the simplest SLS printer to use, highlighting the lack of any binding agent or any kind of addition — so your costs are only in the materials, and electricity. The SLS process means no supporting structures are required, and therefore no post processing to remove the marks left by removed supporting material.

Another fairly fast 3D printer, the EOS Formiga P 110 offers a speed of 1.2 l/h, and weighs approximately 600kg.

Get a quote*

*One of our trusted partners will be in touch following a quote request.EOS are pioneers of SLS technology, refining their printers over 30 years of R&D.

Sharebot SnowWhite 2

- Cost: $40,000 / €35,000

- Company based: Italy

- Print volume: 100 x 100 x 100 mm

Pros

Can print multiple powder options such as Nylon, PA11, TPU, glass, carbon and aluminum.

Designed to be simple to use.

Precis, accurate and large.

Cons

Small print volume.

Sharebot are an Italian 3D printer manufacturer that make FDM 3D printers, metal 3D printers, and have recently followed up the original SnowWhite with their fewest printer, the SnowWhite 2 SLS printer. Bringing their metal 3D printing expertise to selective laser sintering, the SnowWhite 2 is very versatile, able to print a variety of different SLS 3D printer powder options including PA12 (Nylon), PA11, TPU, as well as glass, carbon and aluminum powder mixes.

The printer is designed to be as simple as possible to operate, automating much of the printing setup. It falls in between the desktop and industrial ranges, retaining ease of use — it can be set up in just 10 minutes — while still being precise, accurate and large, with a 50-micron Z-axis resolution, 100-micron XY-resolutions, and weighing 120kg.

- We interviewed Sharebot ahead of the release of their first metal 3D printer, the metalONE. Read it here.

Despite being an industrial printer, the Sharebot SnowWhite 2 has a fairly small print volume. At 100 x 100 x 100 mm, this is not ideal for manufacturing multiple parts simultaneously, and is therefore better served for R&D and rapid prototyping of single parts. The printer costs around $40,000, or €35,000.

At 100 x 100 x 100 mm, this is not ideal for manufacturing multiple parts simultaneously, and is therefore better served for R&D and rapid prototyping of single parts. The printer costs around $40,000, or €35,000.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

XYZprinting MfgPro230 xS

- Price: $60,000

- Company based: China

- Print volume: 230 x 230 x 230 mm

Pros

Lower price than many competitors.

Great print speed at 1 l/h.

Uses specialized SLS 3D printer software.

Cons

Skilled operator required.

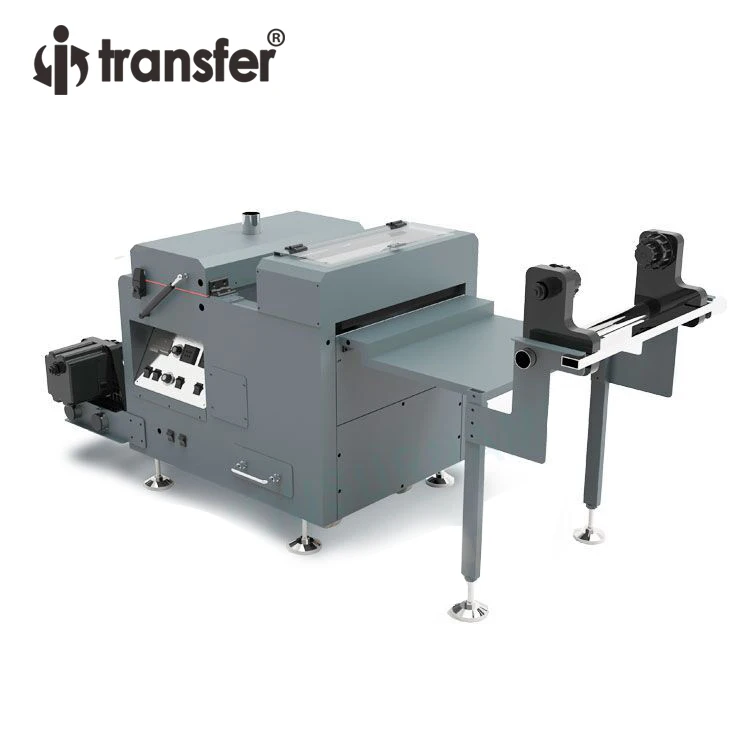

XYZprinting are mostly known for their desktop FDM 3D printers. They have since expanded into other 3D printing technologies, selling an SLA 3D printer and a 3D scanner, as well as their first SLS printer, the MfgPro230 xS. Weighing 360kg, it’s an industrial sized printer, but at a lower price than many competitors.

The MfgPro230 xS prints at 1 l/h speeds, great for small businesses who want to quickly prototype models for engineering and other uses. The printer uses specialized SLS 3D printer software: SLS Build for slicing and optimizing parts for printing, and SLS Ware for remote monitoring and for managing the 3D printing process.

The printer uses specialized SLS 3D printer software: SLS Build for slicing and optimizing parts for printing, and SLS Ware for remote monitoring and for managing the 3D printing process.

- XYZprinting are best known for low cost FDM printers. Check out our ranking of the best low cost 3D printers.

This professional SLS 3D printer has printing dimensions of 230 x 230 x 230 mm, easily enough to printing multiple functional parts simultaneously. Able to fulfill professional quality demands, with printable layer thicknesses of between 0.08mm and 0.2mm. At $60,000, it offers industrial SLS additive manufacturing at affordable prices.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

XYZprinting have taken over the low-cost FDM 3D printer market in recent times, and will soon release their first SLS printer.Nexa3D QLS 350 — fastest SLS 3D printer in the world!

- Price: Upon request

- Company based: USA

- Build volume: 350 x 350 x 400 mm

Pros

Prints at 4x the speed of comparable machines.

Claims to be the fastest SLS 3D in the world.

Capable of printing many parts simultaneously.

Cons

Might be too large for some people.

Nexa3D recently purchased NXT Factory, who had pioneered what they term Quantum Laser Sintering (QLS), allowing for much faster SLS 3D printing at 4x the speed of comparable machines. QLS involves splitting the printer’s laser beam into millions of micro-lasers, each sintering parts of the powder at faster speeds.

Incorporating QLS tech into their printer range, the QLS 350 claim’s to be the world’s fastest SLS 3D printer, with print speeds reaching up to 8 l/h! The QLS 350 is compatible with PA11, PA12 and tougher PA6 Nylons, as well as with food-grade, carbon and glass powder mixes.

With speeds that rival injection molding and a build volume capable of printing many parts simultaneously, many businesses will be looking on keenly to see how the QLS 350 performs when it releases — planned to be Q1 2021.

SLS 3D printer applications

As SLS printers can create strong Nylon parts, they are commonly used for:

- Strong, durable parts which need to withstand high heats and exposure to abrasive chemicals such as in the aerospace industry

- Highly impact resistant models

- Medical devices and tools

- Investment casting patterns

- Automotive design protototypes

- Engineering part prototypes

- Seals, gaskets and hoses

Desktop SLS 3D printer 2023: hardware selection and more

What desktop SLS 3D printers are available on the market?

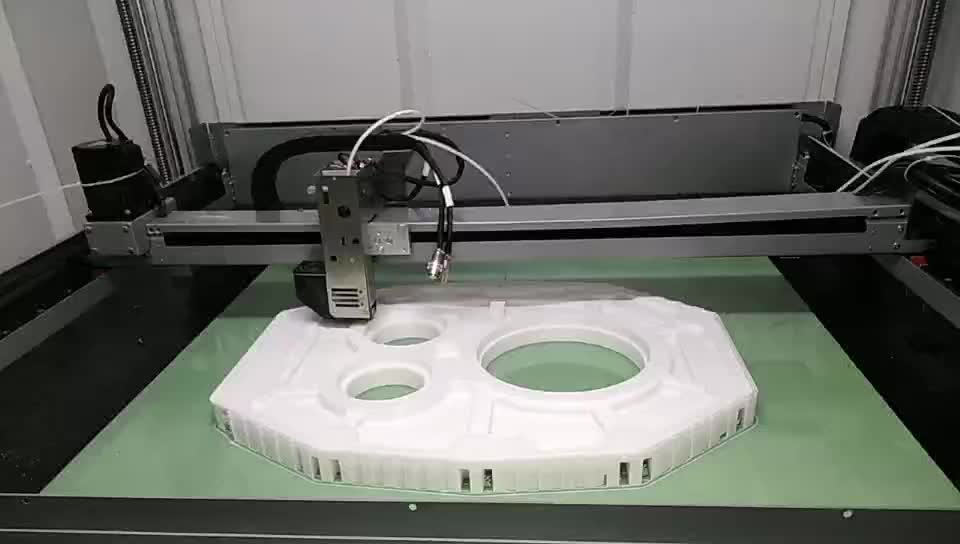

SLS (Selective Laser Sintering) is a 3D printing technology that uses a laser beam to sinter powdered material. This technique enables the 3D printing of detailed functional parts and prototypes.

This technique enables the 3D printing of detailed functional parts and prototypes.

Five to ten years ago, SLS technology was exclusive to large, industrial additive manufacturing systems. In recent years, a more compact SLS 3D printer niche has been slowly emerging, with lower prices and office-friendly formats.

Starting at around $6,000, these benchtop or desktop SLS 3D printers enable SMEs to access accurate and advanced in-house prototyping without having to rely on external 3D printing services. They are able to print with powder materials such as Nylon, TPE, and other thermoplastics.

In this guide, we take a closer look at which desktop SLS printers are available on the market from brands like Sintratec, Sinterit, and Formlabs.

The best desktop SLS printers for professionals

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. | |

|---|---|---|---|---|---|

| Sintratec | Sintratec Kit | 110 × 110 × 110 mm4.33 × 4.33 × 4.33 in | – | $ 5,9994 990 €4,973 £808,473 ¥ | Quote |

| Natural Robotics | VIT SLS | 250 × 250 × 300 mm9.84 × 9.84 × 11.81 in | Spain | $ 12,90011 000 €10,693 £1,738,507 ¥ | Quote |

| Sinterit | Lisa | 150 × 200 × 150 mm5.91 × 7.87 × 5.91 in | – | $ 12,9957 990 €10,772 £1,751,310 ¥ | Quote |

| Sinterit | Lisa Pro This product has been reviewed by our team. | 150 × 200 × 260 mm5.91 × 7.87 × 10.24 in | – | $ 17,99011 990 €14,912 £2,424,476 ¥ | Quote |

| Formlabs | Fuse 1 | 165 × 165 × 320 mm6.5 × 6.5 × 12.6 in | United States | $ 18,49918 499 €15,334 £2,493,073 ¥ | Quote |

| RED ROCK 3D | RED ROCK | 180 × 180 × 180 mm7. 09 × 7.09 × 7.09 in 09 × 7.09 × 7.09 in | – | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Sintratec | Sintratec Kit | 110 × 110 × 110 mm4.33 × 4.33 × 4.33 in | – | $ 5,9994 990 €4,973 £808,473 ¥ | Get a quote |

| Natural Robotics | VIT SLS | 250 × 250 × 300 mm9.84 × 9.84 × 11.81 in | Spain | $ 12,90011 000 €10,693 £1,738,507 ¥ | Get a quote |

| Sinterit | Lisa | 150 × 200 × 150 mm5.91 × 7.87 × 5.91 in | – | $ 12,9957 990 €10,772 £1,751,310 ¥ | Get a quote |

| Sinterit | Lisa Pro This product has been reviewed by our team. | 150 × 200 × 260 mm5.91 × 7.87 × 10.24 in | – | $ 17,99011 990 €14,912 £2,424,476 ¥ | Get a quote |

| Formlabs | Fuse 1 | 165 × 165 × 320 mm6.5 × 6.5 × 12.6 in | United States | $ 18,49918 499 €15,334 £2,493,073 ¥ | Get a quote |

| RED ROCK 3D | RED ROCK | 180 × 180 × 180 mm7.09 × 7.09 × 7.09 in | – | upon request | Get a quote |

What is SLS (Selective Laser Sintering) technology?

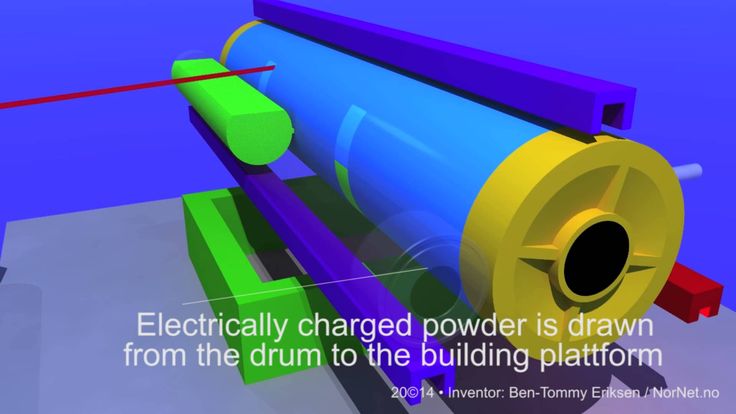

Up until early 2014, Carl Deckard from Structured Polymers held a patent on Selective Laser Sintering 3D printing technology. Selective Laser Sintering (SLS) is part of the Powder Bed Fusion family of 3D printing technologies.

How does Selective Laser Sintering work?

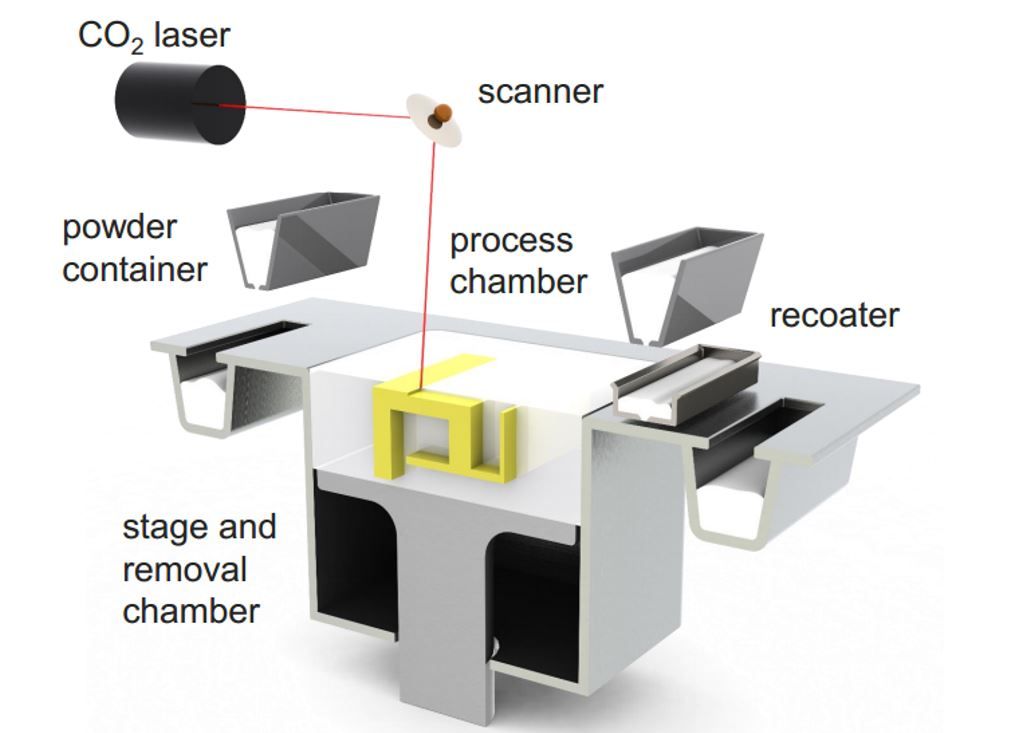

This technology uses a laser to sinter powdered material. In other words, a powerful laser beam selectively melts and fuses tiny powder particles together.

Once a layer is finished, more powder is rolled and spread onto the print bed. The process repeats itself layer after layer. The excess powder stays in the powder bed, thus automatically providing support for the object and its intricacies (though supports are still needed when it comes to metal 3D printing).

When the 3D printing process is finished and the powder bed has cooled down, the objects can be removed. The excess powder material is then to be brushed off to reveal the final part. Aside from powder removal, the parts require little to no post-processing for basic applications.

Overview of the best desktop SLS printers

The Sinterit Lisa is a plug-and-play desktop SLS 3D printer made by Polish manufacturer Sinterit. It is one of the most affordable SLS 3D printers actually available on the market.

This 3D printer offers a relatively large build volume for a desktop 3D printer, and even more so for an SLS 3D printer in this price range. With the Lisa it is possible to 3D print flexible material (Flexa Black/Grey) or rigid, strong material (PA12).

With the Lisa it is possible to 3D print flexible material (Flexa Black/Grey) or rigid, strong material (PA12).

Contact manufacturer Get a quote Add to comparison

In comparison with the regular Lisa, the Lisa Pro boasts various upgrades and features. For starters, the Pro version is equipped with a Nitrogen chamber, for wider material compatibility.

The Lisa Pro SLS printer also provides a bigger print volume as well as a larger touchscreen than the Lisa.

Our review at Sinterit headquarters: Sinterit Lisa Pro review

Contact manufacturer Get a quote Add to comparison

The Sintratec Kit started out as an Indiegogo crowdfunding campaign in 2014. It is one of the most affordable SLS 3D printers available today.

The Kit requires around four days of assembly. Users can freely adjust the laser’s height, speed, and temperature in order to try out different materials.

Contact manufacturer Get a quote Add to comparison

Formlabs, originally an SLA 3D printer manufacturer, introduced their first SLS 3D printer – the Fuse 1 – mid 2017. It is officially available since January 2021.

It is officially available since January 2021.

The printer works with Formlab’s PreForm software, and features two separate build chambers. This enables users to immediately launch a second build once the first job is complete.

After the printing process, the chamber can be directly placed as-is in the Fuse Sift, an all-in-one sieving machine that collects unused powder and prepares it for future builds by mixing it with fresh powder. The Fuse 1 can work with up to 70% of recycled powder, so each new build only requires 30% of fresh material (which costs around $100/kg).

Contact manufacturer Get a quote Add to comparison

Note: Natural Robotics launched the VIT SLS via Kickstarter in 2017. As of January 2021, some backers are stating that they still haven’t received their printers, although the company claims to be shipping products.

The VIT SLS offers a relatively large build volume compared to the other 3D printers in this range.

Contact manufacturer Get a quote Add to comparison

Note: This 3D printer is only available in a limited geographical region.

RED ROCK 3D is a new 3D printer manufacturer from Russia. Its RED ROCK SLS 3D printer offers a relatively large build volume compared to most of the other desktop SLS 3D printers in this selection.

Little information about this SLS 3D printer is available on the RED ROCK 3D website, which hasn’t been updated in a while (as of January 2021).

Contact manufacturer Get a quote Add to comparison

Compact industrial-grade SLS 3D printers: our picks

The following printers are larger than the benchtop SLS printers from our main selection but are still relatively compact considering the usual size of industrial SLS systems.

The Sintratec S2 is an all-in-one modular and scalable SLS 3D printing system with an onboard camera and large, intuitive touchscreen. It integrates a material preparation module as well as a depowdering station for semi-automatic workflows.

Optional stations include a blasting station, vortex unit, and a polishing station, enabling easier part post-processing.

Contact manufacturer Get a quote Add to comparison

The SnowWhite 2 features a powerful CO₂ laser that is able to sinter a range of materials including PA 12, PA 11, and TPU, as well as powder loaded with carbon or glass fiber or even aluminum.

All unused powder can be recycled. The printer can be powered up in ten minutes and the minimum amount of powder required to start a print is 300g.

Contact manufacturer Get a quote Add to comparison

XYZprinting’s range of products is one of the industry’s most diverse in terms of technology, suiting both consumers and businesses.

The MfgPro230 xS is an open-source system, meaning that its powerful 30W CO2 can print with any powder that’s available on the market. Hence, users can experiment with different types of Nylons and TPU materials, and even light-colored ones, which is not the case with entry-level SLS printers.

Contact manufacturer Get a quote Add to comparison

Released in 2020, the Gravity SLS 3D printer by Swedish manufacturer Wematter is the most recent printer in our selection. The printer features integrated powder recycling and easy material handling with user-friendly packaging.

Wematter’s cloud-based slicing software automatically optimizes the build area, packing parts efficiently and as close together as possible thanks to advanced algorithms.

Contact manufacturer Get a quote Add to comparison

Benefits and limits of SLS 3D printing

Main benefits of SLS 3D printing

No need for support: 3D printing complex and functional parts

Since unused powder remains in the powder bed, it naturally acts as support for the following sintered layers. This support, which is present all over, allows the 3D printing of very complex and/or functional parts and prototypes.

It’s also possible to 3D print objects within objects, also known as nesting. This is not possible with other 3D printing technologies such as FFF and FDM (extrusion) or SLA and DLP (resins).

Waste reduction

It is possible to re-use powder that has not been sintered. This significantly reduces material waste and costs compared to other 3D printing techniques. Also, no material is wasted on support structures.

Main limitations of powder SLS 3D printing

Just like any technology, SLS 3D printing has its downsides.

Porosity/rough surface

SLS 3D printed objects are porous, though it is possible to apply sealant to alter their sandy, granular-like surfaces.

Expensive material

The price for one kilogram of PA12 powder can range from around $55 to about $180.

Logistics and post-processing

Due to the volatile nature of powder, extra caution is required when handling the material and taking the final 3D print out of the powder bed. The prints must be depowdered; either manually, which is time-consuming, or with a dedicated powder removal solution.

SLS vs FDM vs SLA

SLS vs FDM (FFF)

Compared to Fused Filament Fabrication, SLS can:

- achieve higher quality prints

- provide thinner layers and wall thicknesses

- generate complex 3D prints without the need for support

However, Selective Laser Sintering 3D printers offer much less material choice (and colors).

SLS vs SLA

Compared to stereolithography 3D printing technology, Selective Laser sintering offers:

- thinner wall thicknesses

- complex 3D prints without support structures

That being said, SLS 3D prints have rougher surfaces than SLA 3D prints.

Sinterit’s 3D printing technology comparison.SLS 3D printing: what materials are available?

Main desktop SLS 3D printing powders

Most desktop SLS 3D printers use Polyamide (PA) powdered material, also known as Nylon. The main PA powders available on the market are:

- Nylon PA12

- Nylon PA11

Then, there are composite or “charged” powders, meaning that different materials are mixed with PA. The most common are the following:

- Alumide: PA mixed with aluminum (shiny, metallic appearance)

- Carbonamide: PA reinforced with carbon fiber (stiff and lightweight)

- Nylon 3200: PA filled with glass (more chemical and heat resistant than PA12)

There is also PEBA 2031, a flexible, rubbery, and resistant plastic powder. Some manufacturers produce elastic 3D printing powders (such as Sinterit’s Flexa Black and Flexa Grey) to 3D print shock absorbers, clothing parts, bellows, etc.

Nylon SLS 3D printing material

Nylon, or Polyamide (PA), is the most common powdered material used by SLS 3D printers. It boasts many interesting characteristics:

- Lightweight: Polyamide is a lightweight 3D printing material.

- Robust: this material can bear loads or be used for mechanical parts.

- Flexible: Nylon can bend and come back to its original form.

- Resistance: PA offers good heat and chemical resistance.

Manufacturers generally sell their own, branded powder material.

SLS 3D printing in general

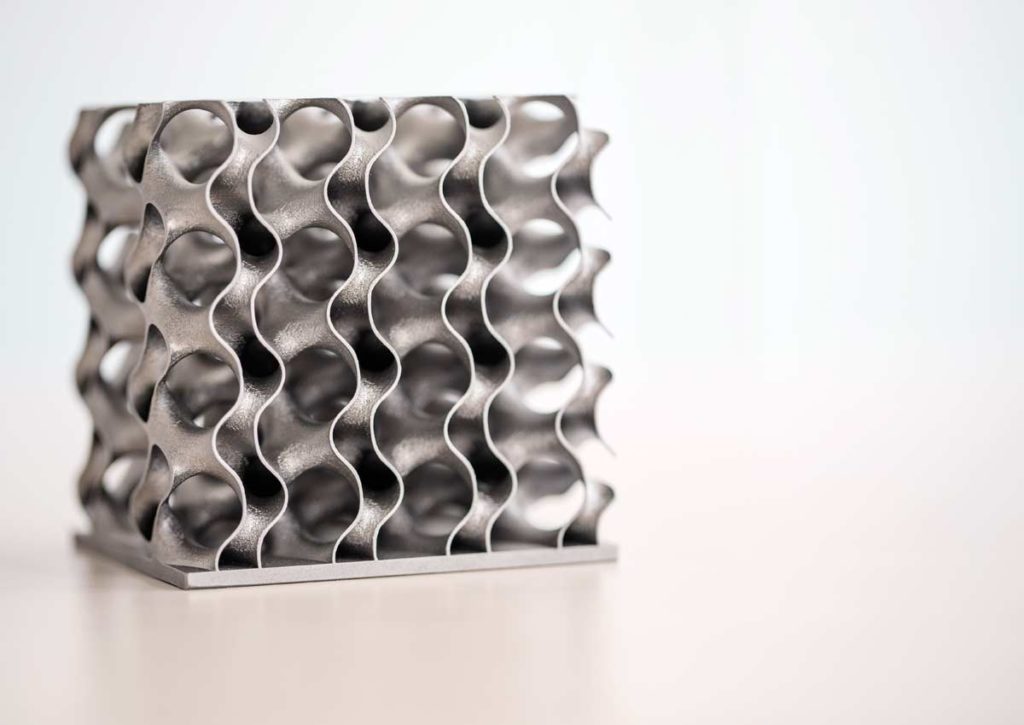

Desktop SLS printers are limited to plastics when it comes to material choice. However, when using larger, more expensive powder industrial 3D printers, it is possible to 3D print metal powder. Some industrial SLS 3D printers are also able to 3D print ceramics.

3d powder printing | Powder 3D printers

Today, 3D printing has received active development. Many different devices have been created that can create three-dimensional objects. Moreover, various technologies and materials are used for printing, including metal.

What are 3D powder printers?

3D powder printers are devices that, under the action of a laser, bind metal powder particles, creating a product in layers.

Metal 3D printing is a huge investment. The price of printers can reach several hundred thousand dollars. If you add to this the cost of maintenance and service, consumables, training and salaries, you get an impressive amount.

However, the high cost is offset by the economy of the processes. For example, in the aviation industry, up to 90% of raw materials go to waste. In the case of 3D printing, this figure will be no more than 5%. The unused powder is sieved, a new one is added to it and reused for printing.

The advantage of powder 3D printing is the ability to create products from any known alloys. In addition to the generally accepted metal compounds, there is a wide base of special alloys, products from which are made for specific customer tasks.

Purpose

About 20 tested alloys are already used in additive technology. For example, tool, stainless, heat-resistant, aluminum, titanium, etc. Such opportunities bring 3D printing to a new level, expanding its scope.

Powder printing applications:

- aerospace industry;

- large and small machine building;

- oil and gas extraction;

- electrical engineering;

- medicine and dentistry;

- food industry;

- experimental work.

Technologies

All 3D printers are divided into several main categories according to the printing method:

- 3DP - three-dimensional inkjet printing.

- SLM - selective melting of metal powder. In this case, the powder is melted by a laser to a liquid state.

- SLS and DMLS - metal sintering. Here, the temperatures are not so high, so the powder particles simply sinter, sticking together.

Popular 3D powder printers

Today, there are several companies that specialize in the production of 3D powder printers. The most popular models are shown below.

EP-M100T

Industrial 3D printer manufactured by Shining 3D. Works on the basis of SLM technology and is intended for the implementation of individual metal structures. This printer will be relevant for the production of crowns, abutments, bridges and clasp prostheses. It can also be used in jewelry.

The device supports printing with fine powders, such as nickel, cobalt and chromium alloys, copper, titanium.

Model advantages:

- One layer only 0.15-0.05 mm thick. This allows you to create high-precision models.

- Built-in software that allows you to control the parameters and workflow.

- Can be controlled by mobile phone.

- Automatic supply and circulation of inert gas.

- Multifunctional security system.

- Compact size that allows you to install the printer even in a small space.

- Low power consumption - 1 kW of energy.

Up to 110 crowns can be placed on the working platform. During the day, this printer is able to work out 3 cycles, that is, to produce up to 330 products.

Mid2019

Mid2019 is a highly detailed printer with a minimum print layer of just 0.1mm. The height of the manufactured parts is up to 220 mm.

Advantages of the model:

- The operator does not need special training, because there is already a configured program for 3D printing, where the optimal parameters are already set.

- Possibility to install a more powerful laser for higher productivity.

- Individually developed firmware designed to control the operation of components and systems of this particular printer.

- The presence of encoders allows you to stop and resume the printing process at any time.

- Remote monitoring capability.

FS301M

Farsoon FS 301M is a 3D printer based on SLM technology. It is considered one of the best in the world in terms of price and quality. At the request of the customer, it is equipped with two or one laser.

The dual scan and calibration algorithm greatly improves the quality and speed of large part production. The printer has a special inert gas supply and filtration system.

The open platform makes it possible to use all materials available today. The operator can control the operation of the system, including the sintering algorithm, temperature, laser power, layer thickness.

Model advantages:

- High quality and performance. Allows mass production without sacrificing quality.

- Integrated powder loading station. This improves security and processing time.

- Small size. The dimensions of the device help to place it even in small production areas.

- Large printing table. Allows you to create large parts in 1 cycle.

3D Systems ProX DMP 300

This printer is equipped with DMP or DMLS direct printing technology. This machine is equipped with automatic loading and disposal of materials.

This technology also uses a laser, but it melts the powder to create the desired object. The metal powder is spread on the platform by means of a special roller or a coating mechanism.

Direct printed parts have high density: 95-98% versus 70% with SLS technology.

Important! Sealed powder loading and circulation keeps it free from contamination and makes the printing process safer for the operator.

Benefits of 3D Systems ProX DMP 300:

- increased working surface with the ability to adjust the thickness of the deposited layer;

- high performance DMP technology;

- sealed loading and disposal system;

- multifunction software.

Weaknesses:

- large;

- expensive.

Benefits of 3D printing:

- Ability to produce parts with complex geometries that cannot be reproduced with traditional methods.

- Parts have excellent physical properties. Almost all known alloys are available for processing.

Disadvantages:

- The production costs are very high, so powder printing is not suitable for making parts that can be made using traditional methods.

- The list of materials available today is small and limited to the most common alloys (titanium, aluminium, 316L, Inconel 718). Other powders can only be obtained for a huge amount of money.

- Limited area of application, which does not allow the manufacture of large products.

Metal powder 3D printing has significant potential in many industries. More and more companies and research organizations are adopting this technology. For example, such global brands as General Electric, Airbus, Boeing, Michelin. They have already moved from the production of piece products to mass production.

- March 21, 2021

- 3640

Get expert advice

Total Z industrial 3D printers

FDM and SLS 3D printers, drying and post-processing equipment

About company

FDM 3D printers

Industrial 3D printers Total Z PRO series

450-PRO 950-PRO

Total Z High Performance LPRO Series 3D Printers

1000-PRO-LL

Total Z G3 Series Desktop 3D Printers

250-G3 250-G3 (2X) XL250-G3(2X)

Total Z G5 Series Desktop 3D Printers

G5

SLS 3D printers Total Z

SLS-250

Portal systems for 3D printing with granules

Total Z AnyForm FGF

Total Z machines for drying and post-processing

Total Z D5Vacuum drying chambers

Help prepare plastic for printing. Remove moisture from hygroscopic materials. Reduce the risk of plastic "boiling", extruder breakage, deterioration of the surface quality of the product.

Watch →

Total Z MPC-310Acetone baths

Equipment for chemical post-processing of finished objects. Helps to achieve a glossy and smooth product surface.

Watch →

Total Z UB-450; 500; 650; 950; 1200;Ultrasonic baths

Machines for physical and chemical post-processing of models. Remove the supporting plastic from the surface of finished products. They clean the material in places inaccessible for manual processing.

See 5 models →

Our capabilities

The equipment complies with Russian and international standards

Consumables for printers and equipment are always in stock

We participate in R&D, cooperate with research institutes

We work with defense enterprises and government customers

Operational warranty service

Departure and training on the territory of the customer

Implemented projects by industry

Aviation industry and special products

Supply of an industrial 3D printer for the project of the MS-21 passenger aircraft of Irkut Corporation.

Supply of high-temperature 3D equipment for the laboratory of additive technologies of VIAM.

Supply of a 3D printer for printing with experimental materials for the production of the Central Institute of Aviation Motors.

Shipbuilding

Selection of samples of engineering plastic for the project of printing body elements for a shipyard.

Auto industry

Supply of equipment for 3D prototyping to the plant of the AvtoVAZ group.

Rocket and space

Supply of the first production equipment for 3D printing to the Center for Additive Technologies of JSC RCC Progress.

Foundry

Fabrication of a matrix using FDM 3D printing for the production of piece metal parts that have been discontinued or to replace parts with a long delivery time.

Education

Production of a desktop 3D printer for schoolchildren and students in collaboration with a team of developers of teaching materials for classrooms.

Electronics

Implementation of 3D equipment at the Simvol East Kazakhstan region.

Prototyping of lighting equipment for the Pyaterochka grocery store chain.

Agroprom

Complex equipping of the research agro-engineering center with equipment.

Aviation industry and special products

Supply of an industrial 3D printer for the project of the MS-21 passenger aircraft of Irkut Corporation.

Supply of high-temperature 3D equipment for the laboratory of additive technologies of VIAM.

Supply of a 3D printer for printing with experimental materials for the production of the Central Institute of Aviation Motors.

Shipbuilding

Selection of samples of engineering plastic for the project of printing body elements for a shipyard.

Auto industry

Supply of equipment for 3D prototyping to the plant of the AvtoVAZ group.

Rocket and space

Supply of the first production equipment for 3D printing to the Center for Additive Technologies of JSC RCC Progress.

Foundry

Fabrication of a matrix using FDM 3D printing for the production of piece metal parts that have been discontinued or to replace parts with a long delivery time.

Education

Production of desktop 3D printers for schoolchildren and students in collaboration with a team of developers of teaching materials for classrooms.

Electronics

Implementation of 3D equipment at the Simvol East Kazakhstan region.

Prototyping of lighting equipment for the Pyaterochka grocery store chain.

Agroprom

Complex equipping of the research agro-engineering center with equipment.

Services

3D printing

Casting

Reverse engineering

prototyping

Upcoming Events

New models of Total Z equipment in Moscow at the Metalworking exhibition

The annual exhibition brings together key companies in the metalworking industry and machine tool building.

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).