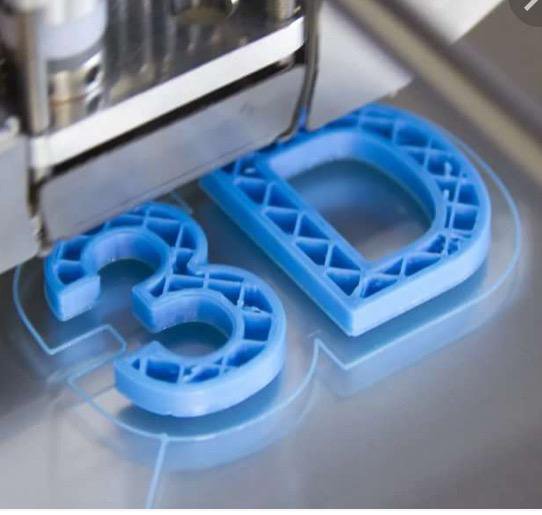

Beyond 3d printing

Beyond Blog - Beyond 3D Prints

Skip to content

Beyond Blog

November 3, 2021

B3DPrints Gaming

To those that were lucky enough to score a set of cards from either BestBuy or Walmart pre-orders, you should buy a lotto ticket as well with that luck in hand! Pre-orders sold out in minutes as soon as they were online. The craze of Animal Crossing will be in full swing when the release […]

Read more

October 21, 2021

B3DPrints Gaming

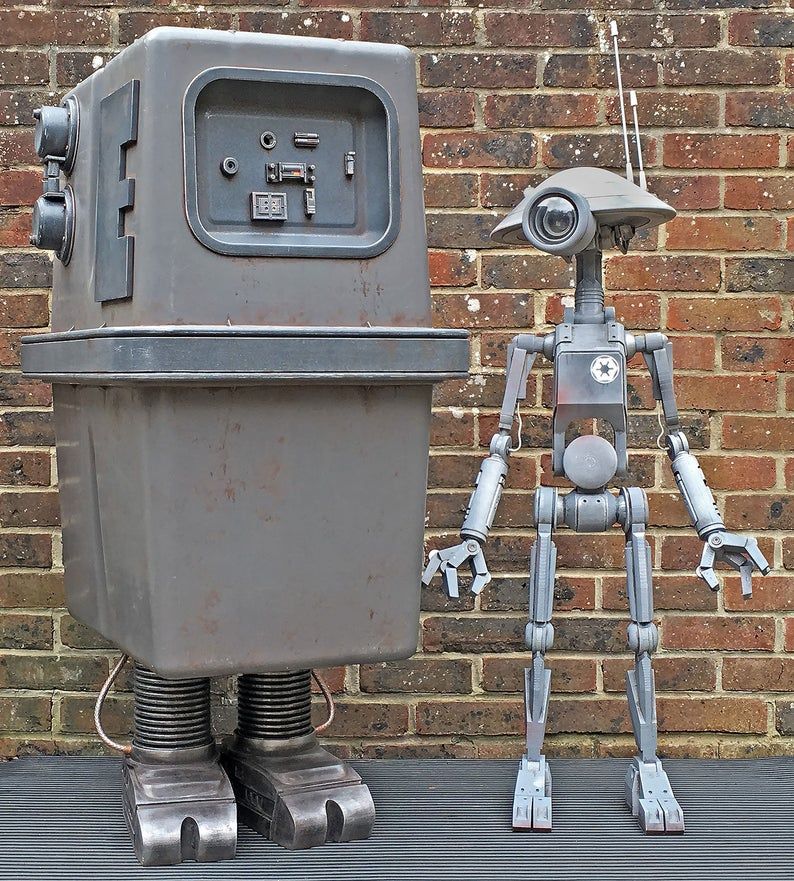

A new Metroid game was released on October 8 and this new side scroller has brought back memories of playing Metroid on the original Nintendo back in the day. You play as Samus Aran as you try to escape from an alien planet and you must survive attacks from a robot that looks like it […]

Read more

May 13, 2021

B3DPrints Cryptocurrency cryptocurrency, harmony, onemoon

Disclaimer: I am not a financial advisor so any information here is just my own opinion and not financial advice. Talk with your own advisor for recommendations. The information on my site is for entertainment purposes. For those that want to quickly get started on using MetaMask to create a ONE wallet and OneMOON wallet. […]

Read more

May 4, 2021

B3DPrints Collectibles, Comics

Today is May 4, 2021 and that means Star Wars day! This year’s Star Wars day feels great because of the reopening of Disneyland and having the theme park open recently just makes me feel happy. There are a bunch of game and toy deals out there today and my shop is no exception. I’m […]

Read more

April 20, 2021

B3DPrints Cryptocurrency bitcoin, cryptocurrency, ethereum

I am not a financial advisor so any information here is just my own opinion and not financial advice. Talk with your own advisor for recommendations. The information on my site is for entertainment purposes. It’s not to late to get started in cryptocurrency! Even if there is a lot of volatility in the market, […]

Talk with your own advisor for recommendations. The information on my site is for entertainment purposes. It’s not to late to get started in cryptocurrency! Even if there is a lot of volatility in the market, […]

Read more

April 8, 2021

B3DPrints Uncategorized

Hey Beyond 3D fans! Come check out the new shop and place your orders! We’re open for business!

Read more

Beyond 3D Printing Basics ⋆ Michael B. Musgrove * Writer * Marketer * Creator * Strategist * Manager * Cecelia * Dogs * Guitars * Music * Business

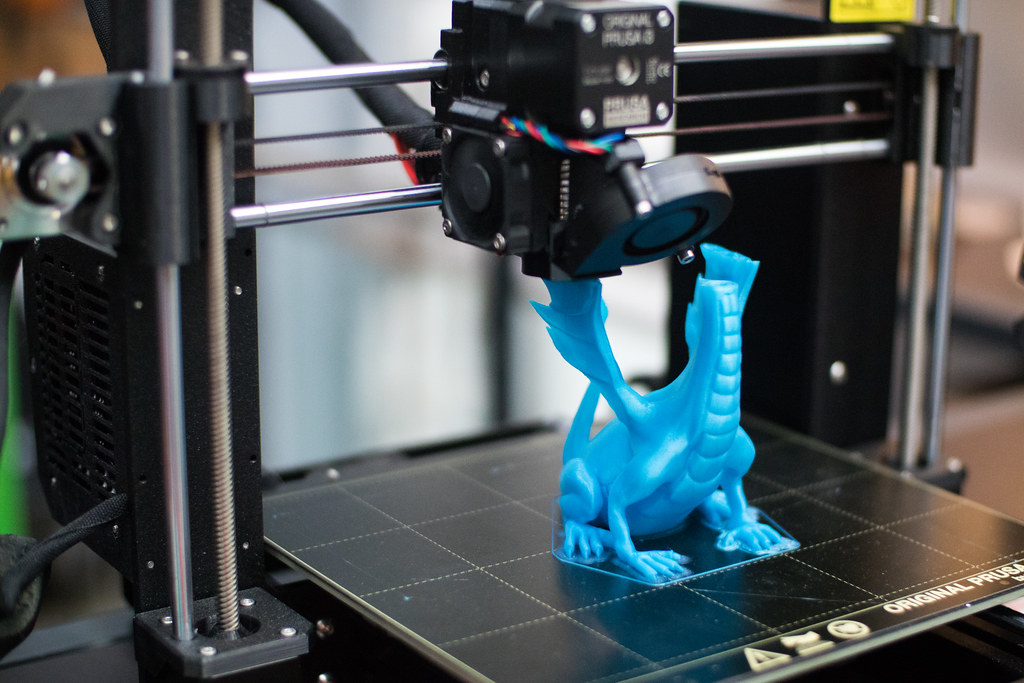

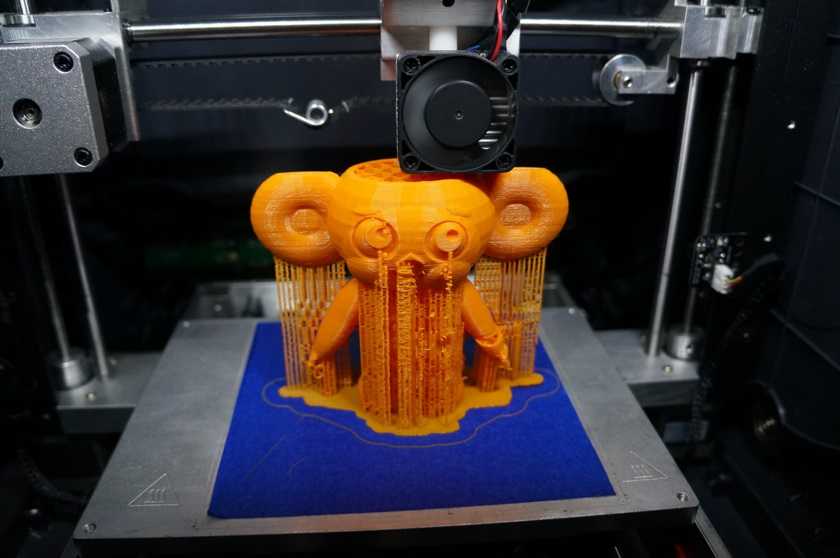

I‘m 81% into the biggest printing project to data, which is a marble-run contraption that has an auger in the center to house the marbles back up to the top so the fun never ends. It was designed by someone else, obviously, but I sliced it and am printing the elements of it to assemble and give to my daughter so she (and I) can fave a little fun and see what’s possible.

Thi project is long. It’s going way up the Z-axis too which is cool, and I’m videoing it in time-lapse to see it created in a matter of seconds/minute. The whole print is taking a couple of days, which is expected given the infill, layer-depth, speed, and all the settings that are optimal for the print on the printer I have.

This leads me to what I’m learning about 3D printing. There are many printers out there, of shapes, sizes, costs, degrees of DIY and community, and customer support behind them, which are two vital considerations, I’ve found. You don’t want to get a printer that has no customer support, no community supporting and building with it, not help anywhere, no integration with third-party software(which a biggie when getting started if you aren’t some sort of wizard)

Every single day there’s more and more media, in articles and videos, popping up about what’s best, how-to, and generally trying to help people move along with this hobby. I’m finding there’s getting to be too many cooks in the kitchen, really. But of course, the people that are going to the effort of providing these things are all passionate about the subject, so I’m certainly not faulting them. I’m just observing and here I’d like to sort it all out.

I’m finding there’s getting to be too many cooks in the kitchen, really. But of course, the people that are going to the effort of providing these things are all passionate about the subject, so I’m certainly not faulting them. I’m just observing and here I’d like to sort it all out.

The first thing is that the technology behind 3D printing isn’t changing that rapidly But the features and software behind it are iterating all the time. So there are subtle differences between what was yesterday and tomorrow.

Take what I bought for example. I think I hit a sweet spot, thanks to my patience and resourcefulness. I bought an ANYCUBIC S, which is the next generation of a few other printers before it. Which are good and still being sold. But the price is about the same with some noticeable and important distinctions. And the distinctions between this model are the same between it and others by different manufacturers that are popular in the same target category.

I’ll describe what those differences are in a second. But let me first say that I was worried for a long time after getting all set up by all the articles and videos and fret by other 3D printer users, “experts” as they are, about settings, bed, leveling, nozzles, adherence, filament types, software and how best to use it therein, tools, and soup to nuts things we should have sleepless nights about.

After absorbing it all and cross-referencing what results I was having and tinkering with a LOT of different things, even taking apart my extruder and rebuilding it and trying different methods of keeping the printing bed clean, which is vital, and so on, here’s what I’ve found, as of today, July 10, 2021.

Patience is a virtue with this hobby. Don’t rush, force or get frustrated when things don’t happen immediately like you “think” they should.

Don’t rush, force or get frustrated when things don’t happen immediately like you “think” they should.

While there are hundreds of printers out there, there are probably 3 within each consideration set to really choose from, as with most things in life. The winners emerge, given time and allowance for competition. When I say “consideration set” I mean whether you’re a solo novice, professional, a parent/child getting into the hobby, a crafter, or whatever the “need” for a printer may be. There are niches that will suit you. And they should be able to grow with your level of knowledge which will also grow pretty fast if you’re really interested in it.

Same with choosing slicing software. There are really only a few options you should really give credence to.

And the same with modeling software. This is where you will be investing a lot of time in learning how to use a very powerful and dynamic set of tools, so you don’t want to get halfway into it, then decide you want to switch to something entirely different. That’s wasteful.

That’s wasteful.

When you buy a printer, usually the most important tools will be included with it, so you don’t have to rush out and worry about finding little odds and ends. That’s nice, but it serves another purpose. And that’s the fact that most of these printers come carefully packaged and shipped from China. Repackaging them and sending them back for repair or maintenance isn’t optimal, to say the least. SO you need to be prepared to fix things yourself, whether that’s hardware or software. That may sound scary to some, but it shouldn’t throw you off. The support behind these machines and the level of ease to work on them has been made to be as rudimental as possible. The engineers behind these things are incredibly efficient and have proven themselves to be considerate and smart.

So while there’s. a load of information available online to help you, likewise, you don’t need to pay attention to 98% of it. Just drill down to the areas that can be most helpful to you your situation, your printer, and your needs and level of comfort and understanding. ‘ve found a lot of the videos and literature are overly simplified. For people that have never used a screwdriver before simple. And while that may appropriate for some, most people don’t need that kind of hand-holding. I hope.

‘ve found a lot of the videos and literature are overly simplified. For people that have never used a screwdriver before simple. And while that may appropriate for some, most people don’t need that kind of hand-holding. I hope.

I’ve provided a list of helpful 3D printing resources on this very website for learning, tools, toys, and more. But I’ll speak to the ANYUBIC MEGA S here, which is what I have, and have been ultimately satisfied with.

Anycubic just released the “S” printer, and they recommend Cura as the slicing software, and as such Ultimaker, the people behind the awesome open-source Cura software, has a set of already defined best settings for the Mega S, so you don’t even have to mess with it.

Learning to use Cura isn’t hard at all, since there are helpful popup tooltips in modals and no lack of help on how to set it in any way you may want it, and save those settings. I’ve watched some pretty long videos going through each individual setting by a helpful but wordy person. Most of the “tips” he provided are just what Cura tells you to do, and when you select the type printer you have, the settings are automatically set for you, which I’ve found to be optimal anyway. Go figure.

Most of the “tips” he provided are just what Cura tells you to do, and when you select the type printer you have, the settings are automatically set for you, which I’ve found to be optimal anyway. Go figure.

And that, I’ve found had eliminated the majority of having to fuss with setting everything “just-so” for this printer. Of course, you need to know how to operate the software and change things like filament type, heat, speed, supports, and fine-tune it. It’s not plug-and-play, and really shouldn’t be for optimal results. And that’s something that draws people like me to the hobby. I like to tinker with things.

You’ll need to learn how to adjust the bed level, for sure. It’s not hard, and there are plenty of resources to help with that.

You’ll need to learn how to operate your printer like a boss. That’s done with reading the manual, trial and error, and seeking help on forums and the manufacturer’s website. The forums for the Mega S are highly populated with very knowledgeable people who are responsive courteous and super-helpful.

I’m keeping my filaments dry by housing them in their bag, in their box, in an airtight tub I got from Target for $6 with Wisedry desiccant I bought off Amazon. I also have a vacuum bag sealer I bought for my kitchen purposes, which is a great item to own if you cook for 1 or 2 people as to not waste food and keep it fresh. It’ll keep your filament fresh as well! Great purchase! As with many things in America these days, there are lots to choose from all over the price and feature matrix. I bought mine for very little and have had excellent results, was given a ton of extra bags, and it’s been great. It’s good for sealing up bags of rice, pasta, breading, and the uses are endless. And it’s so easy. Now 3D printing filament. It’s paid for itself over and over.

And I think this is going to be a great solution, while of course there are $50 boxes PER SPOOL that will keep things dry for you online. Nonsense.

Most of the tools you need for 3D printing are tools you likely already have, or as I pointed out, will be provided in the box your printer came in. Use them. The right tools for the job make ALL the difference. I even printed a caddy to hold all the tools that came with my printer, which I adhered some superstrong magnets to and can just keep attached to the side of my printer. Along with a Swiss Army knife, I have hanging on a hook magnet.

Use them. The right tools for the job make ALL the difference. I even printed a caddy to hold all the tools that came with my printer, which I adhered some superstrong magnets to and can just keep attached to the side of my printer. Along with a Swiss Army knife, I have hanging on a hook magnet.

A lot of the “Advice” offered online is common sense. “Don’t buy cheap filament!” Why would you? PLA filament is cheap already. You should be able to find it for ~$20/1KG, and even “exotic” filaments like silks, metal, wood, iridescent, glow in the dark, etc… aren’t much more. Hopefully, you know how to spot quality and junk. Who’s selling junky filament? Do your homework. Here’s a tip: When starting out, don’t be afraid to buy a few spools of filament and get a good deal. You’re going to tire of only having 1 choice if you’re anything like me. My MEGA S came with a small amount of white to get things going. But I soon got some glow-in-the-dark green, wood, 3 types of silk/color-changing/rainbow/iridescent type(which is awesome,) red, purple, and I just snagged 4 rolls of yellow, orange, blue, and green for a steal. 4 for the price of 3, 1KG, which made them at about $14.90 each, and I could have gotten them cheaper if I had remembered I had a $2 off coupon. Which I’ll just use later. ka-CHING!

4 for the price of 3, 1KG, which made them at about $14.90 each, and I could have gotten them cheaper if I had remembered I had a $2 off coupon. Which I’ll just use later. ka-CHING!

Having a heated bed on the MEGA S has been a great thing. Its predecessors didn’t have such a thing, and I worried about adherence problems from seeing how owners of the Mega series were coping with them, from glue, tape, new beds, mirrors, all sorts of hocus pocus. And I tried a lot of it thinking “maybe this will work better.” When I shouldn’t have been trying to fix something not broken. Everything has been working as-intended.

I leveled my bed twice since the acquisition, and I haven’t had any issues. I wasn’t really having adherence problems, but I started trying using purple glue to kick it up a notch. And when I tried to clean that off, it became a mess. So I cleaned back down to the pristine glass. And just use a light layer of glue on bigger project snow and nothing more. I’ll clean the glass with light soapy water, dry it, and maybe use alcohol to clean that off. That’s given me the best results. Just stick with what the manufacturer recommends and keep it clean. A little purple glue will go a long way, and that should be kept from creating a sloppy bed, at a micro-level.

That’s given me the best results. Just stick with what the manufacturer recommends and keep it clean. A little purple glue will go a long way, and that should be kept from creating a sloppy bed, at a micro-level.

The MEGA S comes with a spool holder on the side, which may not seem like a big deal but it is. It prevents tangling and bird’s nests of the filament and the operation running smoothly with the printer being fed exactly as it should, and I don’t have to create some contraption to put the filament on or just have it feeding off the table or flow or out of an expensive tub. The humidity monitored tube that allows the filament to be fed from them may be something to look into later for bigger, longer printing jobs, but not now.

Another nice feature is the touchscreen, which at this price point, is amazing. I don’t even know how people interface with their printers before them, and I don’t want to know. It makes matters so much easier to handle, monitor, adjust and use the printer itself. Not all have them, which is crazy.

Not all have them, which is crazy.

The MEGA S has the ability to resume if there’s a power issue and it suddenly stops I can resume where it left off. That’s a big deal if you’re printing something that might take days. It’s not often that’s the case, but in ANY case, it’s nice.

A site that I’m finding to be very helpful with on-off topics for the Mega S is this one, which has Affiliate links, though that’s totally fair. It costs you nothing and is just what the author is talking about. You are no under no obligation. I’ve just found him to be credible and knowledgeable about the Mega S, as well as other 3D printing topics.

It’s easy to get carried away too fast, as with many hobbies. When you’re sitting there, watching the printing being done, looking around at what other people are doing, the temptation is to start trying to do what they’re doing. Resist that monkeyish temptation.

I’ve worked with Raspberry Pis before, which supplements this hobby well. But I’m not going to build an Octorprint setup for no good reason. Yet. I don’t need the ability to monitor my 1 printer from elsewhere. If I had a design shop or was making multiple prints with different printers, or going on vacation with the printer running, then possibly. But I have cameras on hand and can craft setups to monitor things if needed. The whole backbone of the 3D thing is innovation, creativity, and the DIY spirit. So buying other products to do what I can fashion makes no sense to me. It’s where you want to draw the line, I guess. I’m still on the fence with this one, and I’m sure will fall over to the Octoprint side before long. I just know myself too well.

Yet. I don’t need the ability to monitor my 1 printer from elsewhere. If I had a design shop or was making multiple prints with different printers, or going on vacation with the printer running, then possibly. But I have cameras on hand and can craft setups to monitor things if needed. The whole backbone of the 3D thing is innovation, creativity, and the DIY spirit. So buying other products to do what I can fashion makes no sense to me. It’s where you want to draw the line, I guess. I’m still on the fence with this one, and I’m sure will fall over to the Octoprint side before long. I just know myself too well.

There’s also a number of paths to explore with learning G-code and how to tamper with the communication going on between the server and printer. The server being what’s sending the commands to the printer to print. In my case right now, I’m just tethering my Macbook Pro via USB to the printer and printing that way. That’s a short and easy route. I can also do it by saving a file onto an SD card and plugging that into the printer and using the screen to direct the printer. That’s a little easier, maybe, but less helpful should I want to make changes during printing. I even have an old (very powerful) Windows PC I could use as a server. I sold the monitor for it, though. And I could use the Raspberry Pi as one, too, with wireless and Bluetooth capability as well as a camera and other amazing things for a bargain. You have to know what you’re doing in that case, which I do, but that’s from a lot of prior learning I taught myself.

That’s a little easier, maybe, but less helpful should I want to make changes during printing. I even have an old (very powerful) Windows PC I could use as a server. I sold the monitor for it, though. And I could use the Raspberry Pi as one, too, with wireless and Bluetooth capability as well as a camera and other amazing things for a bargain. You have to know what you’re doing in that case, which I do, but that’s from a lot of prior learning I taught myself.

Where I think the best use of my time may be is to learn to use dedicated modeling software, which I’m choosing Blender. There’s Fusion 360, which is owned by Autodesk and a host of others. TinkerCad is another I’m playing with because I think that’s the appropriate road my little daughter would want to begin with. And that isn’t to say is rudimentary or for toddlers. It’s powerful robust and can do anything you want. It just makes things a little easier.

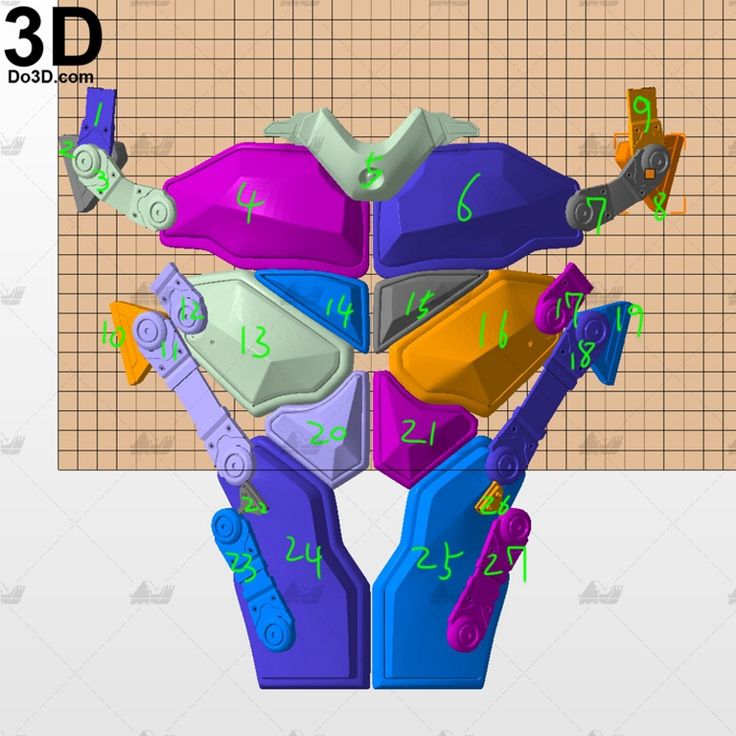

Thingiverse seems to be the top player in finding existing .stl filesready for slicing. Cults 3D has some good free models/.stl files available, but the site itself is slow and sort of weird to me. There are others, too which you’ll certainly come acress. But those are the main hubs for pre-existing models. Make sure you read the author’s notes for updates, tips, help and where the project is. Sometimes the project has been abandoned, and othertimes the files are really that great, or who knows. Somethines there’s a helpful video to accompany it. But checking the notes is a good idea before just downladig, slicing and hitting “print.”

Cults 3D has some good free models/.stl files available, but the site itself is slow and sort of weird to me. There are others, too which you’ll certainly come acress. But those are the main hubs for pre-existing models. Make sure you read the author’s notes for updates, tips, help and where the project is. Sometimes the project has been abandoned, and othertimes the files are really that great, or who knows. Somethines there’s a helpful video to accompany it. But checking the notes is a good idea before just downladig, slicing and hitting “print.”

I can’t say enough good things about the after-sales support I’ve received from ANYCUBIC. I’ve been around the block enough times to have my expectations in check and what to know is whose fault and what can be done and what cannot. And as I’ve already said, patience is a virtue with this hobby. The support staff/engineers in China who made my printer have been extra nice, responsive and done whatever they can do to help me. It’s just a shock from a lot of the “customer service” we experience in America, possibly. But at this price point I’ve been getting concierge service, which is impressive enough that I keep mentioning it. It’s something to consider when buying anything, especially something technical that’s coming to you from the other side of the world.

But at this price point I’ve been getting concierge service, which is impressive enough that I keep mentioning it. It’s something to consider when buying anything, especially something technical that’s coming to you from the other side of the world.

Someting I sense abou tthe little machines is that it’s important to maintain them well. I know from working at Amazon that anything that runs like this 24/7 just gets work down

That about wraps it up for now. This is an ongoing, learning, fun, curiosity-driven exploration, hobby, so every day I’m trying to learn more and have breakthroughs and find out more valuable things than I had and knew the day before. So we’ll see what tomorrow brings. Until then, here’s where I am with this print I’m waiting on:

Run, marble run! This will have an auger in the center to hoist the balls back up from the center so it never stops. It may be fun to motorize it so it’s like a marble fountain.

REC Wiki » Best 3D printing software in 2022

3D printing is a multi-step process, as you first need to design a 3D model, check it for errors, convert it to machine code, and only then the 3D printer goes into business . In this article, we will share examples of programs that can help at every stage of preparatory work and directly during 3D printing.

In this article, we will share examples of programs that can help at every stage of preparatory work and directly during 3D printing.

Contents:

1. 3D modeling software:

- Tinkercad

- ZBrushCoreMini

- 3D Builder

- SketchUp Free

- Fusion 360

- FreeCAD

- Blender

2. Editing and repairing STL files:

- Meshmixer

- MeshLab

3. Slicers:

- Cura

- PrusaSlicer

- ideaMaker

- ChiTuBox Basic

- Lychee Slicer

- Kiri:Moto

- IceSL

4. Control programs:

- OctoPrint

- MatterControl 2.0

- AstroPrint

5. G-code Visualizers

- UVTools

- WebPrinter

- Gcode Analyzer

- Design Software

1.

3D modeling software

3D modeling software If you are ready to create from scratch, you will have to learn special 3D modeling software. Many of them, especially professional computer-aided design systems, can be expensive investments, but on the other hand, there are plenty of quite capable and at the same time free offers on the market.

Tinkercad

Tinkercad is a browser-based application from Autodesk that is great for no-experience users, even kids, because of its simplicity. In this program, 3D models are built on the basis of basic blocks - simple geometric shapes that are joined together and then "filed" to the finished look. You can also convert 2D vector images into 3D models. Of course, you have to pay for simplicity - in the case of Tinkercad, rather primitive functionality that makes it difficult to create truly complex models. But such a task is not worth it: having gained basic skills on Tinkercad, you can always move on to more complex and more capable programs on our list. nine0003

nine0003

Official website

ZBrushCoreMini

ZBrushCoreMini is primarily a 3D sculpting tool, especially popular among those who create human and animal figures, computer game characters, comics, and the like. This software is mainly aimed at beginners and users with moderate experience, but at the same time, it is full of impressive features that make the work easier. For example, dynamic tessellation algorithms constantly analyze the surface of the working model and automatically add polygons so that detail is not violated. nine0003

ZbrushCoreMini is offered free of charge and billed as an entry-level program for learning and gradually moving up to the more capable and sophisticated options ZBrush and ZbrushCore.

Official website

3D Builder

This program was developed by Microsoft and was included with Windows 10 for some time, although now it must be downloaded and installed separately. 3D Builder allows you to edit models in STL, OBJ, and 3MF formats, as well as create models from scratch. In this regard, the program is quite primitive, but it is simple and understandable even for novice modelers. nine0003

In this regard, the program is quite primitive, but it is simple and understandable even for novice modelers. nine0003

One of the interesting features of 3D Builder is the ability to simplify meshes by reducing the number of polygons, file weight and processing time in the slicer - useful in cases where the original designer obviously went too far with polygons. Additionally, you can import models from the library and even use Kinect sensors to 3D scan and import models of physical objects.

Official website

SketchUp

SketchUp is a web application with a great combination of simplicity and functionality. The user-friendly interface is intuitive and greatly facilitates learning, and the set of tools is quite diverse even for advanced users - hence the wide popularity of this program. nine0003

The free version was formerly called SketchUp Make, but is now simply called SketchUp Free. It includes everything you need for 3D modeling for 3D printing, just don't forget to download the module for exporting STL files - it's also free. The kit comes with 10 GB of storage for projects in the cloud and access to the 3D Warehouse, a repository with open source user-generated content.

The kit comes with 10 GB of storage for projects in the cloud and access to the 3D Warehouse, a repository with open source user-generated content.

Official site

Fusion 360

Professional CAD developed by Autodesk and famous for its ease of use and advanced functionality. This includes parametric modeling and mesh analysis and load distribution tools, including through generative design with topological optimization. The program is great for those who are engaged in 3D printing of functional products, for example, for industrial applications. nine0003

Some versions of Fusion 360, such as hobby and student versions, are even available free of charge. FreeCAD FreeCAD The program relies on a parametric approach: at any point in history, you can scroll back and make changes to the parameters. The program even includes finite element analysis and a robotic system simulator. nine0003

Official site

Blender

One of the most popular 3D modeling programs, but quite difficult to master. Not the best choice for a novice designer, but a great tool for those who have already gotten their hands on simpler editors. Fortunately, the popularity of Blender has led to a huge number of guides, tutorials, and visual examples published by experienced users for beginner colleagues.

Not the best choice for a novice designer, but a great tool for those who have already gotten their hands on simpler editors. Fortunately, the popularity of Blender has led to a huge number of guides, tutorials, and visual examples published by experienced users for beginner colleagues.

Developers are trying to make the program more convenient without sacrificing functionality: the interface has recently been updated, rendering has been improved, and 3D design and animation capabilities have been expanded. And yes, it's open source and freeware, so you don't risk anything. nine0003

Official site

2. Editing and repairing STL files

If you find an interesting 3D model on the Internet, this does not mean that it can be immediately sent to a 3D printer. Many models are created for completely different needs, such as animations or video games, and in principle are not intended for 3D printing. But there is a solution: before processing such models into G-code, they must first be repaired so that the slicer can do its job well. The following programs on our list will help you cope with the repair. nine0003

The following programs on our list will help you cope with the repair. nine0003

Meshmixer

Meshmixer is an advanced and free program from Autodesk that allows you to view and check 3D models for errors in polygonal meshes that can ruin 3D printing. If such problems are detected, the program can automatically repair meshes. One example of an application is finishing 3D scans to a state suitable for 3D printing.

Additional functionality includes mesh blending, 3D sculpting, surface writing, cavity creation, support branching, mesh smoothing, and more. nine0003

Official website

MeshLab

MeshLab is another open source program for editing polygonal meshes. MeshLab has the necessary tools for editing, checking, cleaning and converting meshes with the ability to combine meshes into one model and patch holes that can lead to incorrect processing of models into G-code.

Official website

3. Slicers

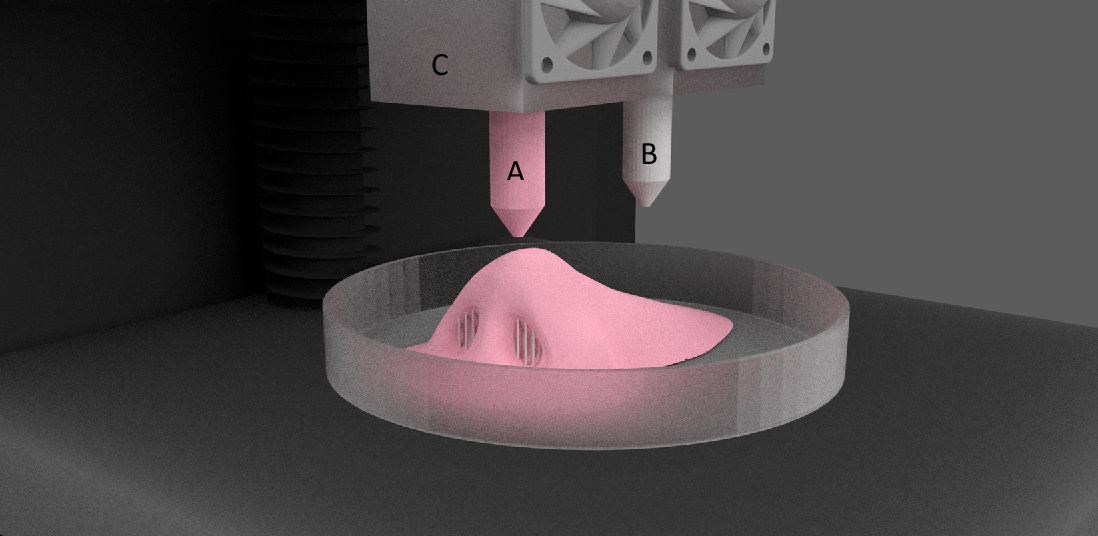

After receiving a 3D model, it must be converted into machine code - a series of commands understandable to CNC machines, including 3D printers. Slicers are responsible for this task - programs that accept digital models (usually in the form of files with STL, OBJ or 3MF extensions), analyze their structure, and then compile lists of actions for 3D printers, called G-code (Gcode). Such lists contain all the information necessary for the equipment: to what temperature to warm up the extruders and tables, whether to use airflow, along what trajectory and at what pace to lay the plastic. nine0003

Slicers are responsible for this task - programs that accept digital models (usually in the form of files with STL, OBJ or 3MF extensions), analyze their structure, and then compile lists of actions for 3D printers, called G-code (Gcode). Such lists contain all the information necessary for the equipment: to what temperature to warm up the extruders and tables, whether to use airflow, along what trajectory and at what pace to lay the plastic. nine0003

Cura

Cura is a slicer from the Dutch company Ultimaker, designed primarily for branded 3D printers, but open source and compatible with most other FDM/FFF systems. The program is easily customizable with various plugins. Since this is a very popular program, the chances are that it already has a profile with optimal settings for your 3D printer. If not, then nothing prevents you from creating a profile manually or using profiles prepared by other users. nine0003

The program has several levels of difficulty depending on the level of training - basic, advanced, expert and complete. The higher the level, the more access to customizable options. At a basic level, the program takes the bulk of the work on itself, helping inexperienced users.

The higher the level, the more access to customizable options. At a basic level, the program takes the bulk of the work on itself, helping inexperienced users.

Cura is constantly being developed and improved through regular updates and is also offered free of charge, although a paid version of Cura Enterprise is available to professional users with licensed plug-ins from the Ultimaker Marketplace, technical support and additional security measures. nine0003

In addition to converting 3D models to G-code, Cura can also take on the role of a control program, but this will require a constant connection between the 3D printer and the computer throughout the 3D printing. Professionals appreciate another feature of Cura - seamless integration with professional computer-aided design systems such as SolidWorks and Siemens NX.

In general, Сura is suitable even for novice users, especially since a huge number of training videos and step-by-step guides are available for this program, both from developers and enthusiasts. nine0003

nine0003

Official website

PrusaSlicer

3D printer manufacturer Prusa Research, under the leadership of the legendary Czech engineer Josef Prusa, whose designs are copied and refined around the world, has developed its own open source software based on the Slic3r slicer. PrusaSlicer quickly gained popularity as it not only retains the original program's extensive customizations, but also adds a number of useful features not found in Slic3r. nine0003

A redesigned interface, support for Original Prusa branded 3D printers, and profiles with settings to work with many common polymers are just some of the improvements. Additionally, algorithms for generating support structures have been improved, support for multimaterial 3D printing and the ability to dynamically adjust the layer thickness have been added.

PrusaSlicer can process models not only for FDM 3D printers, but also for stereolithographic systems printing with photopolymers. As with Cura, the user can select a difficulty level with appropriate access to fine-tuning. nine0003

nine0003

Official website

ideaMaker

Raise3D's slicer is optimized for branded additive hardware in the same way that PrusaSlicer is optimized for Original Prusa 3D printers, and Cura is optimized for Ultimaker 3D printers, but this does not mean that it cannot be use with third party systems. The organization of workflows and the interface is somewhat more complicated than in Cura and PrusaSlicer, but on the other hand, ideaMaker allows you to set up individual layers and apply textures for product customization. nine0003

ideaMaker users can connect to the cloud platform and access hundreds of 3D printer profiles and materials created by other operators, or create their own library of settings.

Add the ability to customize support structures, split models for more efficient 3D printing of large parts, integrated mesh repair tools, and OctoPrint compatibility, and you have a flexible, versatile program to suit the needs of most 3D printers. nine0003

nine0003

Official website

ChiTuBox Basic

This is a specialized slicer for those who use stereolithographic 3D printers that print with photopolymer resins. Most budget LCD masked stereolithography (MSLA) 3D printers rely on motherboards and firmware from ChiTu Systems, which also developed this software.

Users gain control over technology-specific parameters such as layer exposure time, as well as access to predefined profiles with settings for many popular 3D printers. The slicer takes into account such moments as the orientation of the model and the automatic construction of support structures with the possibility of manual optimization. nine0003

Official website

Lychee Slicer

A program from the independent Franco-Belgian team Mango 3D, not associated with 3D printer manufacturers, but with support for many popular stereolithographic 3D printers, including those from Elegoo, Anycubic, Phrozen and Creality.

One of the features of this program is the high level of automation. If you wish, you can simply click on the "magic" button (it's called Magic), and the slicer will do everything by itself: it will orient the model on the platform, generate supports, and so on. Although, here you are lucky: the results are not always optimal, but usually adequate for relatively simple models. Otherwise, everything can be configured manually. nine0003

The program is offered in free and paid versions. The functionality of the free version is slightly reduced, but it has everything you need.

Official site

Kiri:Moto

Browser solution for those who lack computing power. Kiri:Moto can prepare 3D models for both 3D printing and laser engraving or milling. The settings are somewhat more primitive than in locally installed slicers, but are sufficient for most users. nine0003

Official website

IceSL

IceSL is a combination software that combines slicing with 3D modeling. In the left window, you can edit 3D models using scripts in the Lua language, which makes it possible to perform parametric modeling. On the right side, the 3D printing settings are displayed. For beginners, pre-configured settings are available, while experienced users can take advantage of features such as specific adjustment of parameters for individual layers with automatic gradation of intermediate areas. For example, this allows you to gradually reduce or, conversely, increase the filling density of the product as it is built, or gradually change the thickness of the layers. nine0003

In the left window, you can edit 3D models using scripts in the Lua language, which makes it possible to perform parametric modeling. On the right side, the 3D printing settings are displayed. For beginners, pre-configured settings are available, while experienced users can take advantage of features such as specific adjustment of parameters for individual layers with automatic gradation of intermediate areas. For example, this allows you to gradually reduce or, conversely, increase the filling density of the product as it is built, or gradually change the thickness of the layers. nine0003

Official website

4. Control programs

Control programs are designed for exactly this - managing workflows during 3D printing. Although you can insert a G-code drive into almost any 3D printer and press the start button, this is not always convenient, especially when you have to work with several 3D printers at the same time, and even more so when you do it remotely. This is where control programs come to the rescue. In addition, some of them offer additional functionality, including slicing and even editing 3D models. nine0003

In addition, some of them offer additional functionality, including slicing and even editing 3D models. nine0003

OctoPrint

A web-based appliance that requires connection to a 3D printer via a microcomputer such as a Raspberry Pi equipped with a Wi-Fi module. This system allows you to control 3D printers remotely. OctoPrint accepts G-code from almost any slicer and provides the ability to visualize - view files before and during 3D printing. Alternatively, STL files can be loaded and processed directly in OctoPrint.

OctoPrint not only provides all the necessary tools for remote management, but also allows you to track the work in progress using notifications via various instant messengers. nine0003

This is a completely free, open source program with many plug-ins created by enthusiasts and available on the official website.

Official website

MatterControl

MatterHackers offers its own control program, slicer and 3D editor in one package. MatterControl allows you to directly control and observe 3D printing, slice, export G-code to SD cards for offline printing, and even create 3D models from scratch. The 3D printer will need a Wi-Fi or USB connection to run MatterControl. nine0003

MatterControl allows you to directly control and observe 3D printing, slice, export G-code to SD cards for offline printing, and even create 3D models from scratch. The 3D printer will need a Wi-Fi or USB connection to run MatterControl. nine0003

The interface is well structured: on the left side there is a file browser and a library of simple geometric shapes. Interestingly, these shapes can be dragged into the 3D model and used as support structures.

Basic functionality is available in the free basic version, advanced users can pay to upgrade to MatterControl Pro.

Official website

AstroPrint

AstroPrint is a cloud-based management platform that allows you to remotely monitor and control multiple 3D printers simultaneously, store files, convert 3D models to G-code, and track workflow statistics. The functionality ranges from basic in the free version to advanced with different levels of paid subscriptions. nine0003

The 3D printer will require a Wi-Fi module to fully work with AstroPrint. In conjunction with the Raspberry Pi, the system is similar in functionality to OctoPrint: you can process models and send the finished code to a 3D printer via a web interface without the need for additional software. Another plus is integration with popular repositories of 3D models Thingiverse and MyMiniFactory, as well as 3D editors 3D Slash and Leopoly.

In conjunction with the Raspberry Pi, the system is similar in functionality to OctoPrint: you can process models and send the finished code to a 3D printer via a web interface without the need for additional software. Another plus is integration with popular repositories of 3D models Thingiverse and MyMiniFactory, as well as 3D editors 3D Slash and Leopoly.

Official website

5. Programs for visualizing G-code

What if you find an old file with a G-code, but you have no idea what it is and why - maybe garbage, or maybe an excellent, but long-forgotten model without a clear marking in the file name? The programs in this section will help you visualize the contents of such files.

UVTools

This program combines file browsing with layer editing and even model repair for stereolithographic 3D printing. The program can also be used as a plug-in for PrusaSlicer, adding support for third-party photopolymer 3D printers - although PrusaSlicer is open source, support for stereolithographic systems is still limited to branded equipment. At the same time, UVTools allows you to print calibration samples to check the exposure time and other parameters, which can be useful, for example, when working with new photopolymers that have not yet been tested. nine0003

At the same time, UVTools allows you to print calibration samples to check the exposure time and other parameters, which can be useful, for example, when working with new photopolymers that have not yet been tested. nine0003

Official website

WebPrinter

A simple browser tool for quick G-code preview, developed by the same team that created the IceSL slicer and 3D editor. The application works very simply: follow the link, upload the file with the G-code and see how the 3D printer will grow the model according to the commands provided. Unfortunately, the functionality is limited: for example, the application does not provide information about temperature settings. On the other hand, you can quickly figure out what kind of model is hidden in a file with an incomprehensible name. nine0003

Official website

Gcode Analyzer

An old but still very capable and popular G-code analysis web application. The 3D simulation doesn't work very well, but the 2D and G-code previews work great. In 2D mode, you can conveniently view individual layers, moving from layer to layer and following the construction path step by step using two sliders. G-code viewer displays a complete list of commands, allowing you to see what a particular line of code is doing. nine0003

In 2D mode, you can conveniently view individual layers, moving from layer to layer and following the construction path step by step using two sliders. G-code viewer displays a complete list of commands, allowing you to see what a particular line of code is doing. nine0003

Official website

Adapted translation of The Best Free 3D Printing Software of 2022 article.

prospects, development and future of 3d printers

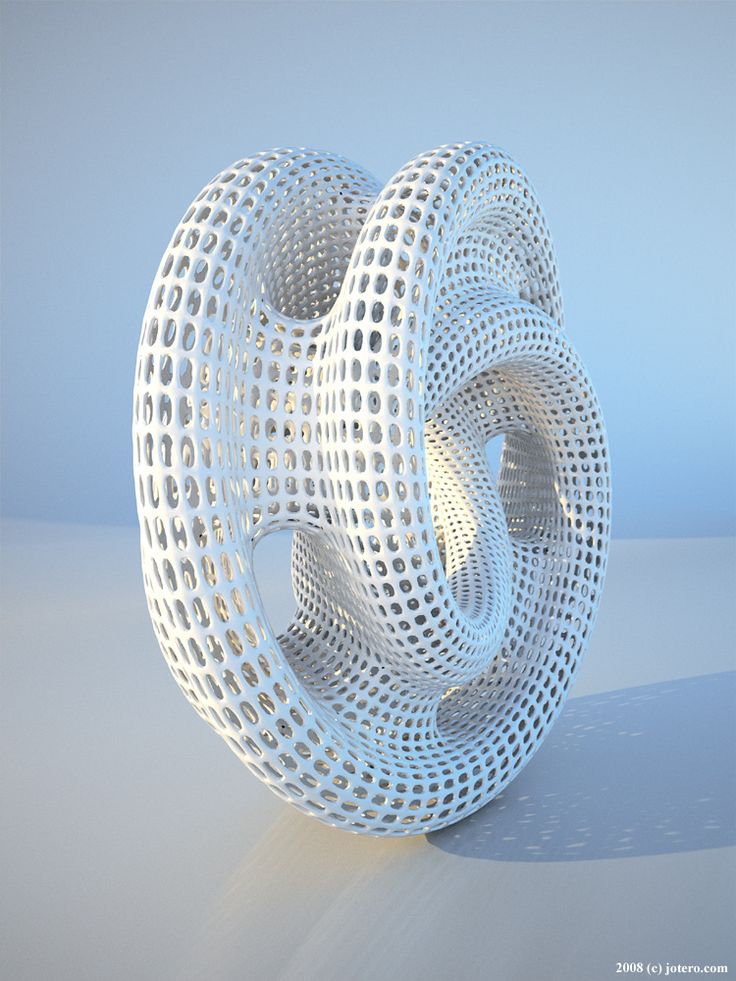

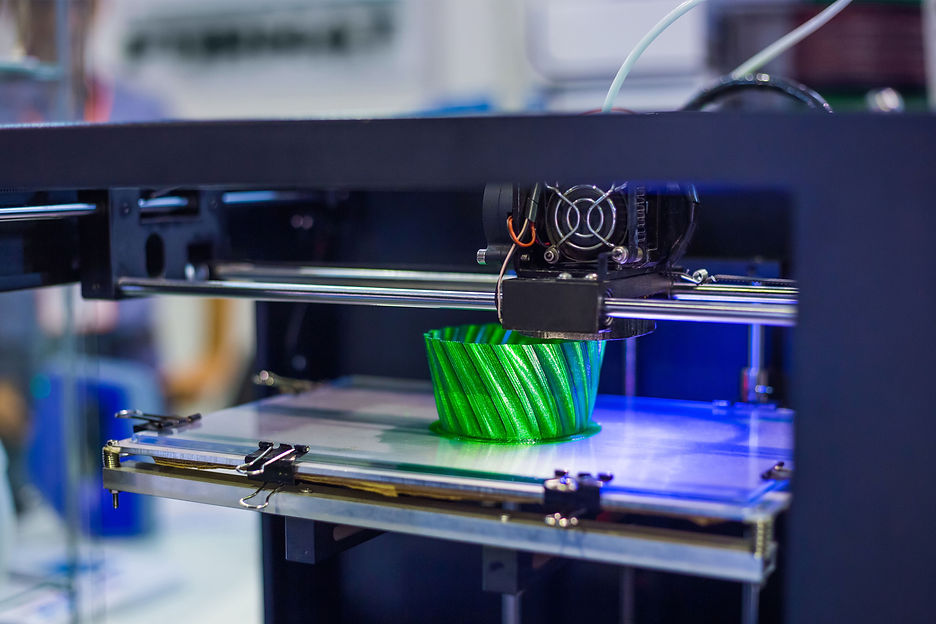

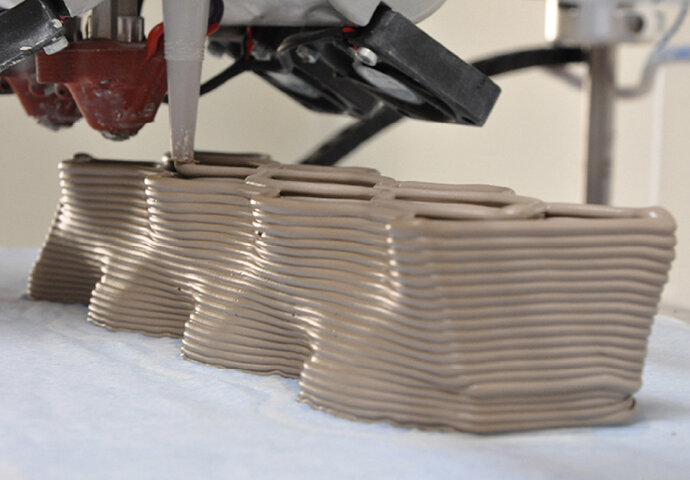

3D printing is an extremely promising technology that can change the way many things are made. In addition, the use of 3D printers will significantly reduce the production time of various products and reduce their final cost. Let's consider in which areas the use of 3D printing is most promising, what is the future of this technology and how quickly it will develop. nine0003

The relevance of 3D printing

3D printing technology is relevant due to its ease of use and saving time spent on the production of various types of products.

Printing of 3D objects also provides high-precision reproduction of the necessary shapes and details of a particular object. At the same time, manual labor is practically reduced to zero, which means that the cost of the operator and maintenance of the 3D printer will be minimal. Subsequently, this will reduce the cost of the finished product. nine0003

Thanks to these advantages, 3D printing is successfully used in many industries and in everyday life.

The promise of 3D printers in various fields

3D printing technology has quite a lot of promise when applied correctly. The following areas of activity are most in need of 3D printing services:

- Construction. In the construction industry, 3D printing can be a powerful addition to traditional construction methods. Since this technology does not require the involvement of a large number of people to perform hard work. A few operators and craftsmen are enough to service the construction 3D printer.

The first successful experiments in the manufacture of building parts and the construction of houses have already been carried out in China and the United Arab Emirates. nine0012

The first successful experiments in the manufacture of building parts and the construction of houses have already been carried out in China and the United Arab Emirates. nine0012 - Electronics. In the manufacture of digital devices, 3D printing will reduce the time for the manufacture of labor-intensive parts, microcircuits and hardware electronics. In particular, 3D printing is already developing the first samples of graphene batteries that have an unlimited service life.

- Mechanical engineering and automotive industry. In this area, with the help of three-dimensional printing, experimental models of future spare parts and parts are created, which later allow the production of products of perfect quality. This is possible due to the detailed study of a three-dimensional object during its creation and printing of a finished computer model, which has a high level of detail. nine0012

- Aerospace industry. The use of 3D printing in this industry is explained by the ability to create innovative designs of any complexity.

Details of satellites, rockets and other space objects are printed from metal, polymers and other types of heavy-duty materials.

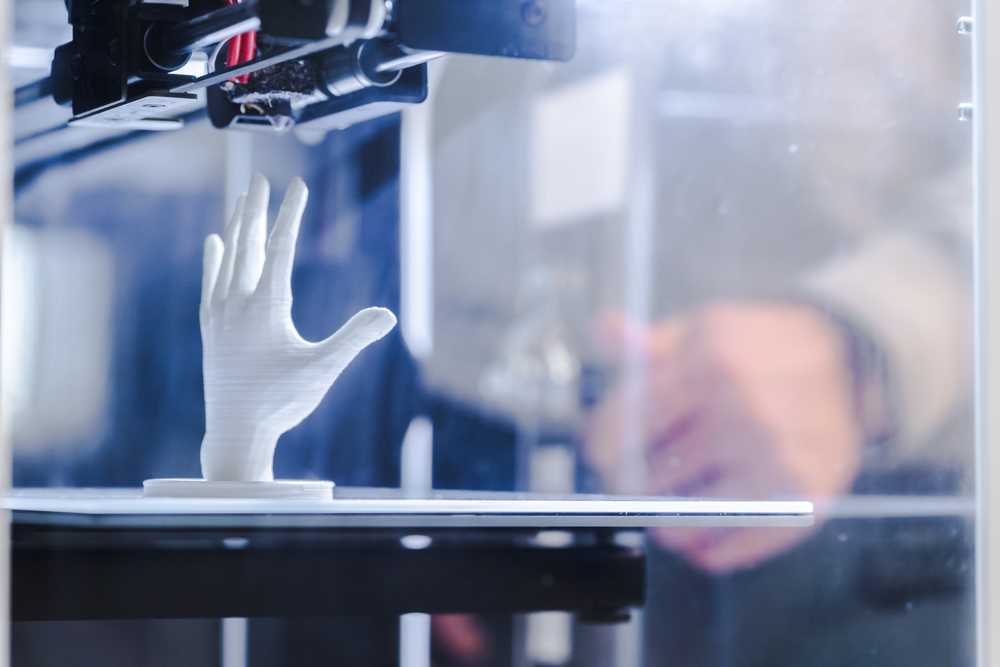

Details of satellites, rockets and other space objects are printed from metal, polymers and other types of heavy-duty materials. - Medicine and pharmaceuticals. In medicine, 3D printing technology is extremely important. Therefore, in this industry it is studied in great detail. With the help of a 3D printer, it is possible to print prototypes of human organs, prostheses, bone tissue implants. Even the first steps are being taken to develop and print real organs that will take root well in the human body. In the pharmaceutical industry, 3D printing is mainly used to create tablets that will gradually release active substances after ingestion. nine0012

- Advertising. For advertising purposes, 3D printers print prototypes of various products, demonstration and handouts.

- Food industry. 3D food printers are especially interesting because they allow you to create edible objects from familiar foods. 3D printing makes it possible to create unique decorations and complex multi-color objects with high detail.

The future of 3D printing

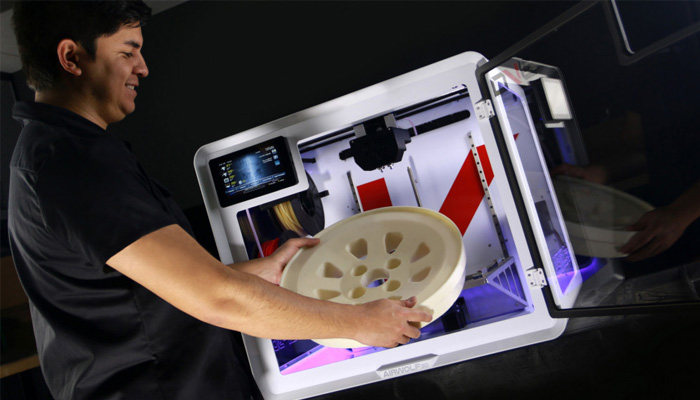

3D printing, if properly developed and explored, will be more accessible in the future. Since 3D printers will be common as a work unit in many areas. At the same time, prices for such equipment are likely to fall. Since they will be produced by various companies in large quantities to satisfy the demand of all buyers. nine0003

The growing demand for 3D printing will lead to the development of new types of 3D printers and materials for creating products.

Also for larger 3D printing, large-scale equipment will be created that will allow printing very large products for construction needs, engineering and other industries.

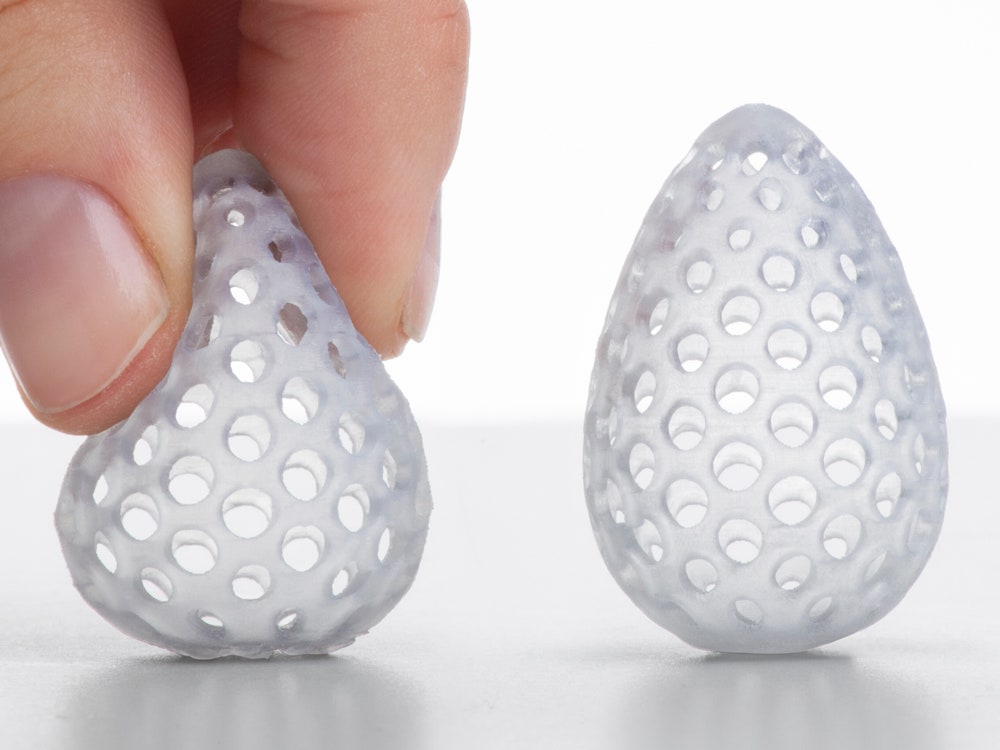

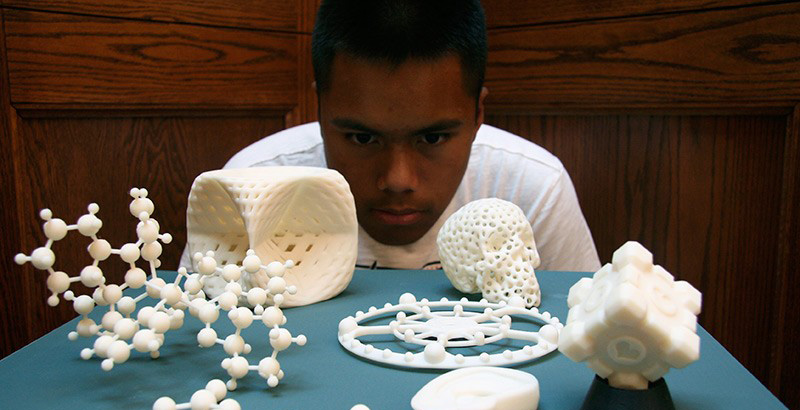

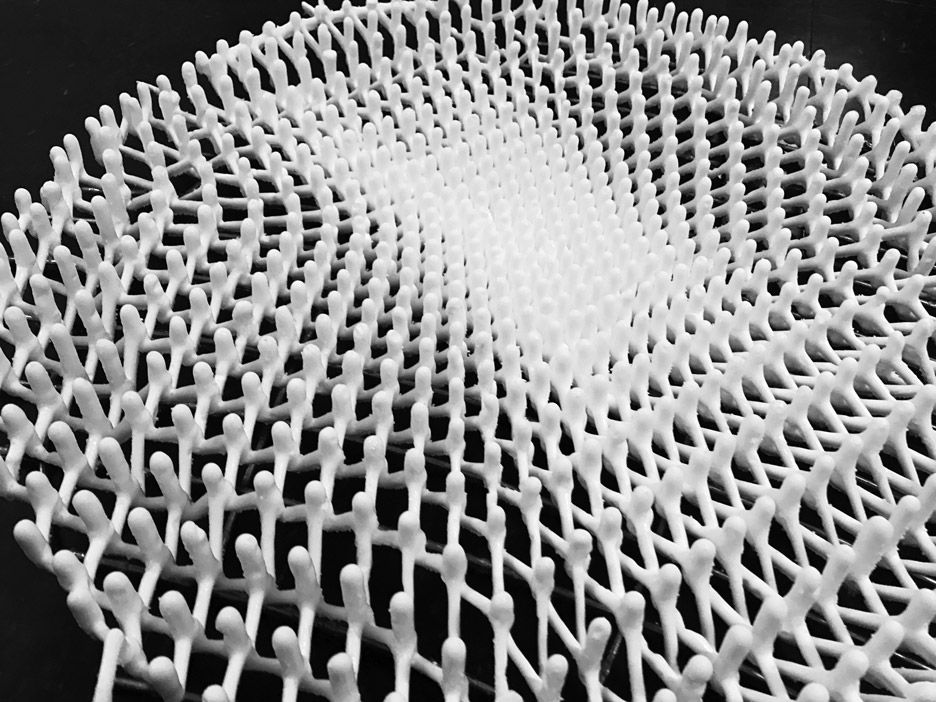

Unexpected possibilities of 3D printing

In addition to the standard creation of three-dimensional objects, the development and 3D printing of unique and customized products is also available on a 3D printer. Their shape, structure and design features are limited only by the user's imagination. It is possible to produce unusual products. For example, non-melting ice sculptures, curly perfectly fried pancakes or fine jewelry. nine0003

It is possible to produce unusual products. For example, non-melting ice sculptures, curly perfectly fried pancakes or fine jewelry. nine0003

Who is the future of 3D printing?

First and foremost, the future of 3D printing depends on inventors who create new types of printers and develop new printing technologies depending on the type of material used. Most often, 3D printing novelties appear in research centers, industrial enterprises and technical departments of various universities. This is due to the fact that people working in such institutions are interested in the development of new technologies. Since innovation will help to improve and improve the processes of creating products in specific areas. In addition to researchers and students, a large number of developments are carried out by children and 3D printing enthusiasts. For example, the invention of the first 3D-printed prosthesis belongs to 17-year-old Easton LaChapelle. nine0003

In addition to inventors, organizations that sponsor new developments are also responsible for the continued development and improvement of printing methods.

Help. Three companies are considered the most famous in the field of 3D printing: Shapeways, Sculpteo and Materialize. They are engaged in the professional development and release of new models of 3D printers, materials, as well as the improvement of existing technologies and the creation of new ones.

What's in store for 3D printing in the next few years? nine0327

Experts in the field of 3D printing in 2021 make the following forecasts for its development:

- The spread of 3D printing will be massive. Studios for creating three-dimensional objects will be distributed in much the same way as studios for photocopying and printing materials. 3D printing will be carried out both on standard models and on individual projects.

- Small-scale production of various products will completely switch to 3D printing technology. This will help to significantly reduce the price of finished products. nine0012

- Medical scientists will master the creation of full-fledged and fully compatible organs on a 3D printer, which will be printed from dividing human cells.

- With due diligence confirming the safety of 3D printing for construction purposes, many companies in the industry will start using powerful industrial printers to create the necessary building elements. At the same time, the time to build houses will be reduced and the proportion of hired workers who perform hard work will decrease. nine0012

Materials revolution

Standard 3D printing uses plastic materials as filament. However, technology development continues at an accelerated pace. Thanks to this, innovative materials appear on the market, such as:

- Metal powder. This material is mixed with a polymer during printing and is used in the technology of laser sintering of metals. Products printed from a mixture of polymer and metal powder have increased strength comparable to real metal. nine0012

- Graphene. This carbon material is being used experimentally to develop a new composite. Ideally, a 3D-printed graphene sheet would be one molecule thick.

By weight, the material will be lighter than air, but its strength properties will be very high - the sheet is ten times stronger than steel.

By weight, the material will be lighter than air, but its strength properties will be very high - the sheet is ten times stronger than steel.

- Ceramic foam. Such material has flexible characteristics that can be changed depending on the purpose of use. From ceramic foam on a 3D printer, you can print both a very light figure and a heavy monument. In theory, development already exists. But it requires a series of tests and stabilization of functional properties. nine0012

What are the unusual technology projects of the future?

Among the unusual 3D technologies of the future, special attention should be paid to:

- the creation of individualized clothing and footwear, which will be produced on the basis of 3D body scanning;

- make-up created by special portable 3D printers, which is very fast and very precise in fine details;

- bioprinting with living cells and creation of tissues and organs from hydrogel. nine0012

3D printing has very great prospects in various fields of industry and human activity.