3D laser glass printing

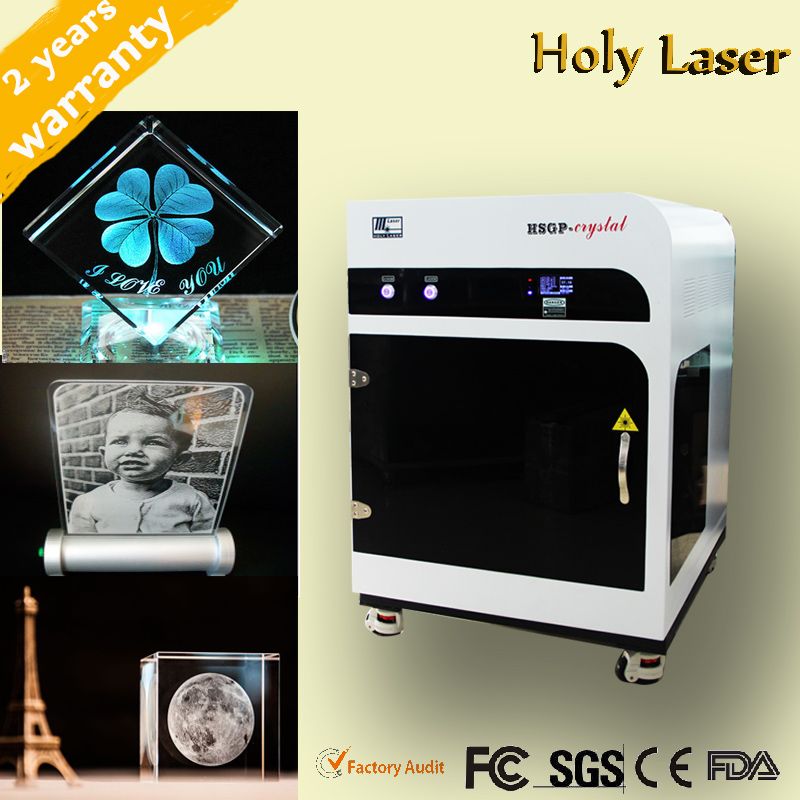

Custom 3D Photo Crystal Gifts & Awards

Featured Products

-

Quick view

Pet Memorial Jeweled Puck

These beautiful laser etched crystals are perfect gift items. The jeweled puck measures 3" x 3" x 1.…

Now $69.00

Choose Options

-

Quick view

Heart Keychain Light

What a wonderful and affordable personalized gift.

The heart shaped photo crystal lighted key …

Now $39.00

Choose Options

-

Quick view

3D Heart

Our 3d crystal hearts are the perfect gift to express your love. Holidays like Mothers Day, Fathers …

Now $159.00

Choose Options

-

Sale

Quick view

Rectangular Pendant

Beautiful rectangular shaped cut crystal pendant, laser etched with the photo of your choice! Perfec…

Now $49.

00

00

Was $59.00

Choose Options

-

Quick view

Crystal 3D Diamond

Great for 3d portraits and 3d corporate logos crystal diamond shaped cubes have one corner cut flat …

Now $59.00

Choose Options

-

Quick view

Photo 3D Crystal Cube

Crystal Cubes are perfect for 3d portraits, memorial keepsakes or company product and logo promotion…

Now $59.

00

00

Choose Options

-

Quick view

Photo Crystal 3D Tower

Tower awards are tall rectangles that may be ordered with an optional black piano finish wood …

Now $189.00

Choose Options

-

Sale

Quick view

Photo Crystal Heart Ornament

The Heart shaped ornament measures 2.

5 inches in width and height. The faceted edges catch the ligh…

5 inches in width and height. The faceted edges catch the ligh…

Now $39.00

Was $49.00

Choose Options

-

Sale

Quick view

Photo Crystal Oval Ornament

The size of the oval ornament is 4 inches tall x 2.5 inches wide. The faceted edges catch the light …

Now $39.00

Was $49.

00

00

Choose Options

-

Quick view

Wide Iceberg

Solid optical crystals shaped to look like icebergs. They are perfect for almost every application a…

Now $139.00

Choose Options

-

Sale

Quick view

Heart Pendant

Beautiful heart shaped cut crystal pendant, laser etched with the photo of your choice! Perfect for …

Now $49.

00

00

Was $59.00

Choose Options

-

Quick view

2D Heart Paperweight

Heart shaped crystal measures 4"x4"x1" and is the perfect gift for Valentines Day or Anniversaries o…

Now $129.00

Choose Options

Reviews

Remembrance And Memorial Gifts | Crystal Prints

Sort By: Featured ItemsNewest ItemsBest SellingA to ZZ to ABy ReviewPrice: AscendingPrice: Descending

-

Quick view

3D Heart

Our 3d crystal hearts are the perfect gift to express your love.

Holidays like Mothers Day, Fathers …

Holidays like Mothers Day, Fathers …

Now $159.00

Choose Options

-

Quick view

Pet Memorial Jeweled Puck

These beautiful laser etched crystals are perfect gift items. The jeweled puck measures 3" x 3" x 1.…

Now $69.00

Choose Options

-

Quick view

Memorial 3D Crystal Cube

Crystal Cubes are perfect for 3d portraits, memorial keepsakes or company product and logo promotion…

Now $59.

00

00

Choose Options

-

Quick view

Crystal 3D Diamond

Great for 3d portraits and 3d corporate logos crystal diamond shaped cubes have one corner cut flat …

Now $59.00

Choose Options

-

Sale

Quick view

Memorial Rectangular Pendant

Beautiful rectangular shaped cut crystal pendant, laser etched with the photo of your choice! Perfec…

Now $49.

00

00

Was $59.00

Choose Options

-

Sale

Quick view

Memorial Heart Pendant

Beautiful heart shaped cut crystal pendant, laser etched with the photo of your choice! Perfect for …

Now $49.00

Was $59.00

Choose Options

-

Sale

Quick view

Photo Crystal Heart Ornament

The Heart shaped ornament measures 2.

5 inches in width and height. The faceted edges catch the ligh…

5 inches in width and height. The faceted edges catch the ligh…

Now $39.00

Was $49.00

Choose Options

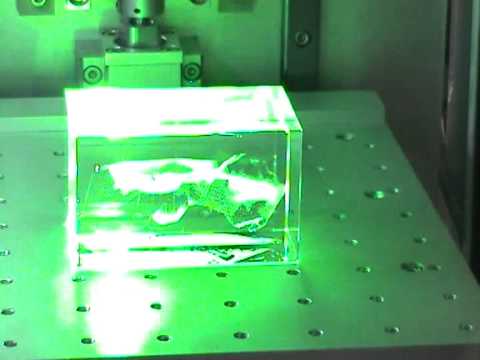

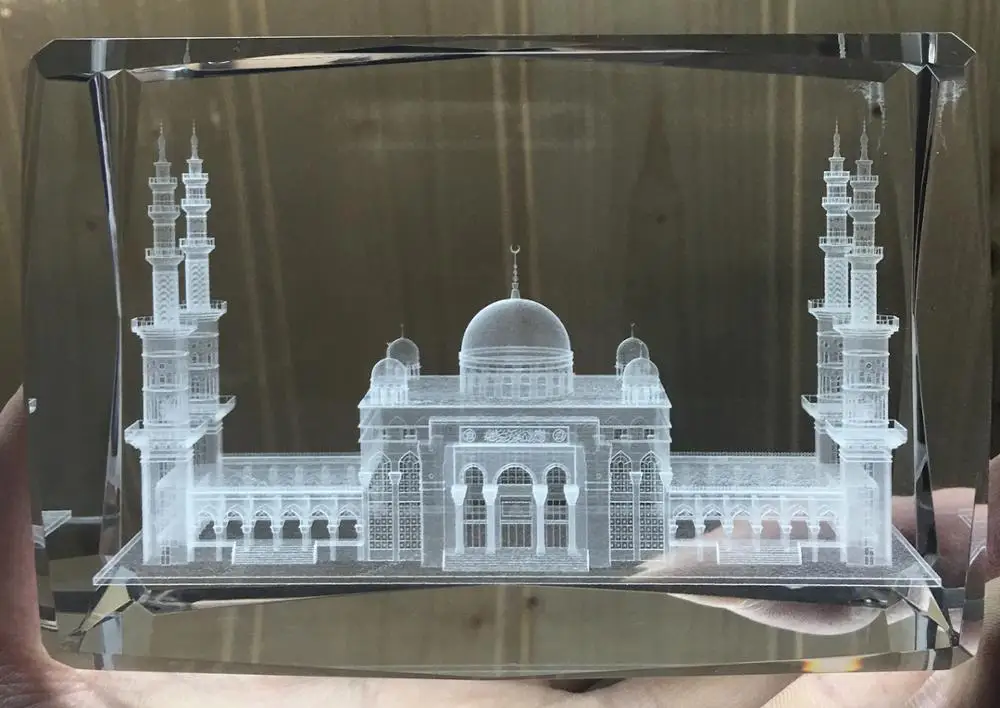

3D laser engraving in glass, glass souvenirs

Please note that laser engraving inside glass is located in St. Petersburg.

Specify the terms and the possibility of making an order with managers.

The World of Gravity offers you a completely new approach to creating gifts to loved ones and business souvenirs - laser engraving of logos, texts and photos in glass.

What can be lasered inside glass?

- Creation of full-fledged 3D models. Presentation of a new installation, a car or an entire building.

- Promo souvenirs with the company logo in the most interesting and unusual options. Your employees and colleagues will appreciate such a gift.

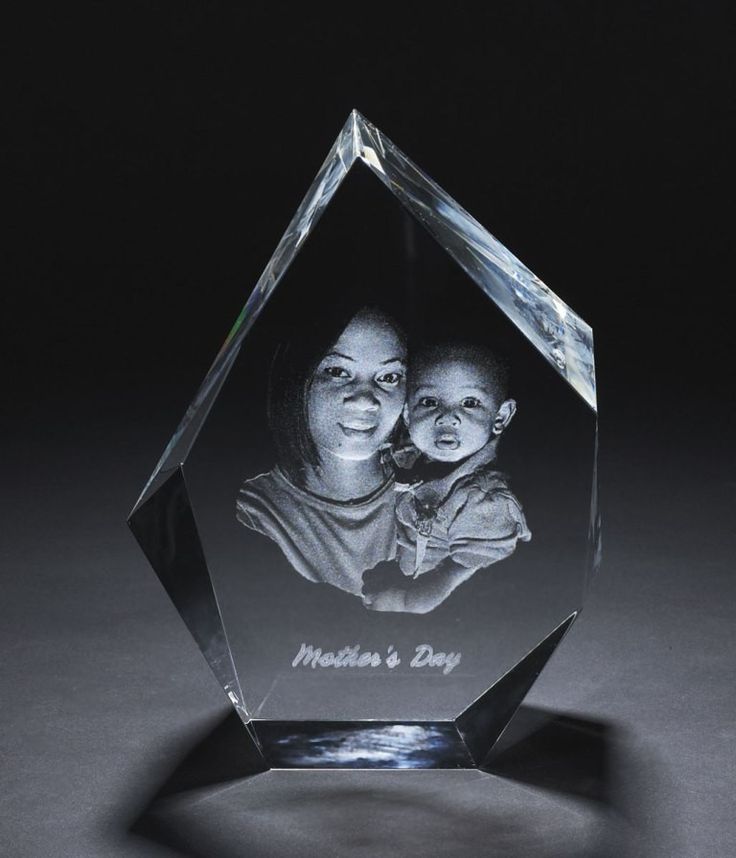

- Creates a three-dimensional image from a regular photo. A unique opportunity to transfer our most beloved photos inside glass and turn them from ordinary flat images into beautiful three-dimensional images.

- Realize your creative ideas and the most creative ideas, and we will help you in this as much as possible. Experienced managers and designers, a huge selection of different shapes and sizes of glass souvenirs, as well as the most modern laser equipment are at your service.

Glass engraving – opens up new possibilities for photography lovers. Drawing an image by laser engraving is the most popular type of processing and decoration of various materials, known since ancient times. But the creation of a three-dimensional inscription, drawing or even a photo in a crystal with the help of a laser is a new word in the creation of glass souvenirs.

A bit of history.

Man's acquaintance with glass began at least five thousand years ago. First natural (most often obsidian), and then made independently, it has always played an important role in many areas of human life. At first it was rare and expensive and was considered a real luxury item. But gradually glass became more accessible and became widespread.

With the spread of glass, the development of the art of its decoration, in particular, the method of engraving, is also connected. Already three millennia ago, craftsmen were able to create original and complex drawings, ornaments, inscriptions on the surface of glass, creating real glass masterpieces.

Along with the development of mankind and progress, the methods of engraving on glass became more and more perfect. Finally, in the second half of the 20th century, experiments began on the use of laser equipment for these purposes. And by the beginning of the current century, laser graphics had already become a whole trend in the art of engraving not only on the surface of glass, but also inside it. With internal engraving, the surface on the outside of the glass remains invariably smooth and even, and a full-fledged three-dimensional image is obtained inside.

With internal engraving, the surface on the outside of the glass remains invariably smooth and even, and a full-fledged three-dimensional image is obtained inside.

Application technology.

Engraving is possible on almost any glass. Only here it is not recommended to do it on crystal and glass types close to it in structure. You should not try to engrave a three-dimensional image with a laser and on tempered glass or glass with a high amount of metal.

The process of engraving inside a glass blank is based on such a physical phenomenon as optical breakdown. Simply put, the laser destroys glass, forming microscopic dots, which, when magnified, turn into “stars”, and they, in turn, form a three-dimensional image. At the same time, not a single laser alone is able to heat the glass to the required temperature, so two beams are used in the work. Colliding with each other, they overheat the material. As a result, bubbles form in the glass structure, which, bursting, create the desired effect.

Creating a picture inside the glass is divided into three successive stages:

- Taking a photo, sketch, drawing or layout as a basis, the designer creates a 3D model using a specialized computer program.

- Using other software, a cloud of points is placed, which recreates a computer model of a three-dimensional image.

- A fine laser beam is used to create a precise pattern at specially specified coordinates.

All work is carried out using a special engraving machine equipped with a variety of sensors that regulate the movement of lasers and the workpiece. Therefore, to obtain a clear beautiful picture, it is enough to set the parameters correctly.

Advantages of laser engraving and its nuances.

- The most commonly cited benefit of laser glass engraving is the beauty and aesthetics of the resulting product.

- Clarity of the image, which is worked out in great detail, further enhancing the effect of "live picture".

- Image durability. It will be possible to “erase” it only by breaking the object itself.

- Possibility to apply a drawing or an inscription on finished products.

Drawing made with a laser is colorless, but thanks to the diode illumination, the 3D model inside the glass will shimmer with all colors and look especially impressive and fascinating in the dark.

Where is it used?

Like any engraving, laser engraving of volumetric inscriptions and photos in glass is most often used for making gifts. This method is also widely used in advertising, production and marketing. Indeed, what could be more beautiful and original than a company logo in a glass prism or a family photo inside a crystal. By the way, the engraving of a three-dimensional photo in a crystal is a separate direction in which the so-called "Conversion" method is used, and I would like to talk a little about it in our other article, 3D photo in glass

Laser process for 3D glass printing

You are here

Home

History

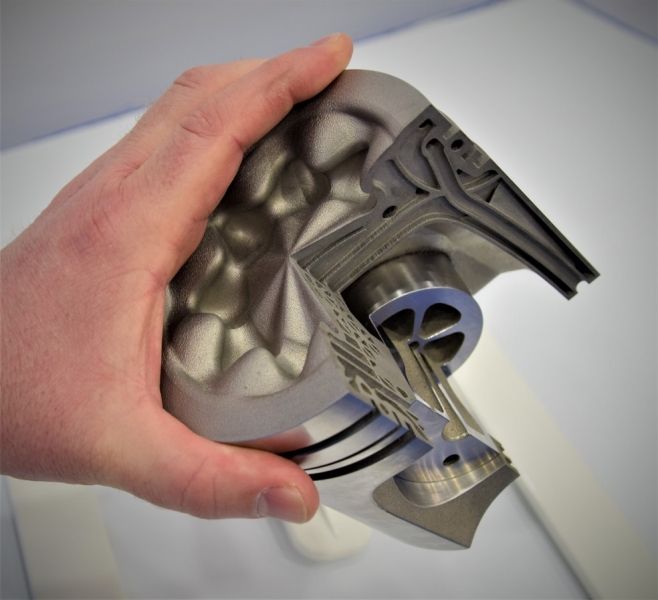

Researchers have developed a new laser process for 3D printing complex glass parts. With further development, the new method could be useful for creating complex optics for vision, imaging, illumination, or laser-based applications.

With further development, the new method could be useful for creating complex optics for vision, imaging, illumination, or laser-based applications.

"Most 3D printing processes create an object layer by layer," said research team leader Laurent Galle of the Fresnel Institute and Ecole Centrale Marseille in France. "Our new process avoids the limitations of these processes by using a laser beam to convert or polymerize liquid melt into solid glass."

Galle and research team members Thomas Dual and Jean-Claude André demonstrate in The Optical Society (OSA) how they used a new technique to create detailed objects in 3D without using the classic layering approach. Using this approach, they have created many quartz glass objects, such as miniature models of a bicycle and the Eiffel Tower, without any pores or cracks.

The 3D printing approach is based on multi-photon polymerization, which ensures that polymerization, the process that binds liquid monomer molecules together into a solid polymer, occurs only at the exact focus point of the laser. It allows direct fabrication of 3D parts ranging in size from a few microns to tens of centimeters, with a resolution that is theoretically limited only by the optics used to form the laser beam.

It allows direct fabrication of 3D parts ranging in size from a few microns to tens of centimeters, with a resolution that is theoretically limited only by the optics used to form the laser beam.

“Glass is one of the main materials used to make optics,” said Galle. "Our work represents the first step towards developing a process that will one day allow scientists to 3D print the optical components they need."

Finding the right material

Using the traditional layered approach to create 3D glass objects has several limitations. The speed of the printing process is limited by the time it takes to create layers, and it can be difficult to create consistent thickness layers when using high viscosity resins. The fabrication of complex parts typically requires supports that must be precisely positioned and then removed after the object has solidified.

Although multiphoton polymerization can be used to avoid a layered approach, 3D printing of glass objects requires a material that is transparent at the laser wavelength, both during the initial liquid phase and after polymerization. It must also absorb laser light at half the wavelength of the laser in order to initiate the multiphoton polymerization process.

It must also absorb laser light at half the wavelength of the laser in order to initiate the multiphoton polymerization process.

To do this, the researchers used a mixture containing a photochemical initiator to absorb laser light, resin, and a high concentration of silica nanoparticles. In addition to working well with a laser, the high viscosity of this mixture makes it possible to form a 3D part without deformation problems or to hold an object in place during 3D printing.

“Critical to this technique were high-power ultrashort lasers based on Strickland and Moore's chirped pulse amplification technology, which won the Nobel Prize in 2018,” Galle said. "Only intense and very short pulses will create a non-linear photopolymerization with high precision and no thermal effects."

Testing the process

After confirming that a solid object could be created using mixtures of silica nanoparticles, the researchers used their 3D printing approach to create objects of complex shape.