Best 3d printing glue

What is the Best Glue for 3D Printing Bonds? PLA, ABS, PETG – 3D Printerly

3D prints can get detached and broken sometimes, so you want to find a way to stick it back together. This leads many people to wonder whether superglue works on PLA and other 3D printing materials, so I decided to look into it.

There are so many options that you can use for gluing 3D prints together and they differ across material types. This article should simplify the process and make it easier for you to choose a solid option that you can stick with.

Keep on reading through this article for some more information about getting the best glue for your 3D prints once and for all.

What is the Best Glue for 3D Printing Bonds?

The best glue for 3D printing is superglue because it provides a strong bond between plastic and is very easy to use. A good brand of superglue cures quickly, so for materials like PLA, ABS, and PETG, it should work great. It doesn’t work so well for flexible filament like TPU or Nylon.

There are other options out there that several 3D printer users have success with, but superglue is the most recommended.

Make sure you are in a ventilated place and are wearing a protective mask and goggles when using some of these adhesives. They can be fairly irritating to your breathing and skin if you come into contact with it.

If you want to get some good quality superglue for your 3D prints, I’d recommend getting yourself some Gorilla Super Glue (20 Grams) from Amazon.

This one does take some extra time to cure, so you can use a separate activator like baking soda to speed up the curing process. Other people have said even water works well to achieve this, although it’s going to run as you would expect.

You can also go with the Bob Smith Industries BSI Maxi Cure Clear Adhesive from Amazon. It comes as a combination pack of the superglue and an accelerator to cure in just 10-25 seconds.

It states that it can bond metal, plastic, wood, ceramics, rubber, leather and more.

A further read into this article will give you an insight into things you can use in gluing your 3D print.

What is the Best Glue for PLA?

The best glue for PLA 3D prints is superglue. Other popular options are 2-part epoxy resins that are mixed together to activate then cures together to bond two objects. A specialized glue that works very well for PLA is PLA Gloop. It bonds PLA 3D prints together strongly, but can also be used as a bed adhesive.

Superglue has a short time for curing and it forms just a thin layer of bonding that is mostly not visible to the eyes when done carefully. One user said you can remove excess superglue with baby oil as it penetrates the bond between the plastic and the superglue itself.

Other adhesives that join PLA are:

- Epoxy Resin

- 3D Gloop

- Contact Cement

- Hot Glue Gun

- Acetone

- Soldering Iron

- 3D Printing Pen

Epoxy Resin

Epoxy resin is a popular solution to gluing and combining up 3D prints, especially for rigid materials like PLA. It does take longer to cure than superglue though, taking around 5 minutes to set, and another 10-15 minutes to fully cure.

It does take longer to cure than superglue though, taking around 5 minutes to set, and another 10-15 minutes to fully cure.

The difference is the level of strength that you get with the right kind of epoxy resin.

It’s a great solution to joining up those larger 3D prints like cosplay items and other similar items. You’ll get the best results with an epoxy resin by clamping it down during the curing process.

I’d recommend going with the Loctite Epoxy Instant Mix from Amazon for your 3D printing needs if you go with this option.

3D Gloop

3D Gloop is a great alternative to superglue and may even be a better product for bonding/gluing PLA 3D prints together. It is known to be a solvent which actually slightly melts the PLA plastic and weld it together.

In the video below by MatterHackers, you can see just how well this product works to stick PLA together. It also can be used as a bed adhesive to help 3D prints stick to the bed while printing.

Contact Cement

Contact cement is also great at bonding PLA, though some people have complained about the visibility of the adhesive after using it. With practice, you should be able to apply is carefully and smoothly to not show up very much.

You can also sand any areas which show the contact cement on your PLA prints with 120 grit sandpaper.

A popular one that I found on Amazon is the Permatex Contact Cement 1.5 oz. It’s known to be great for instant bonding applications, is heat and water resistant, and can even bond rubber to glass and metal.

They mention that no clamping is required for this product to work well.

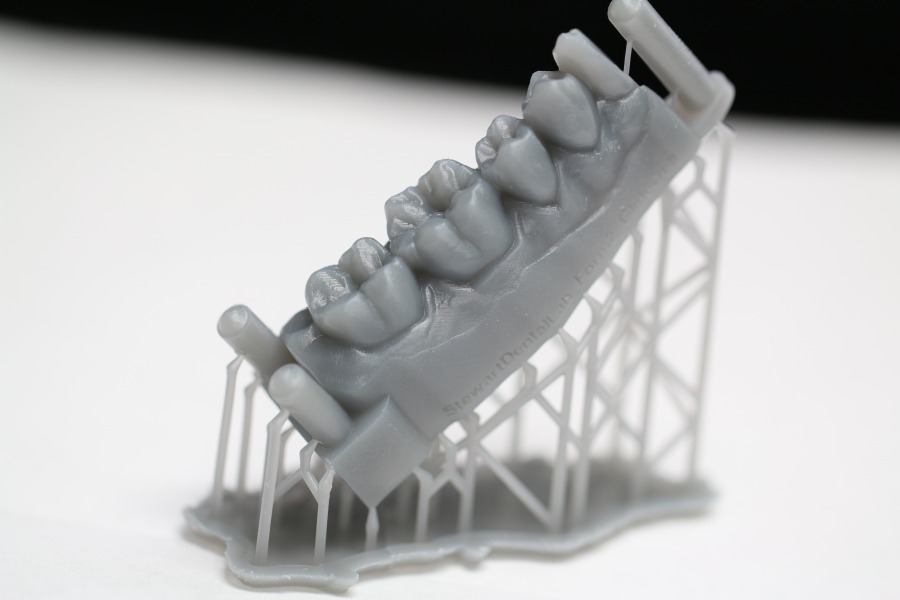

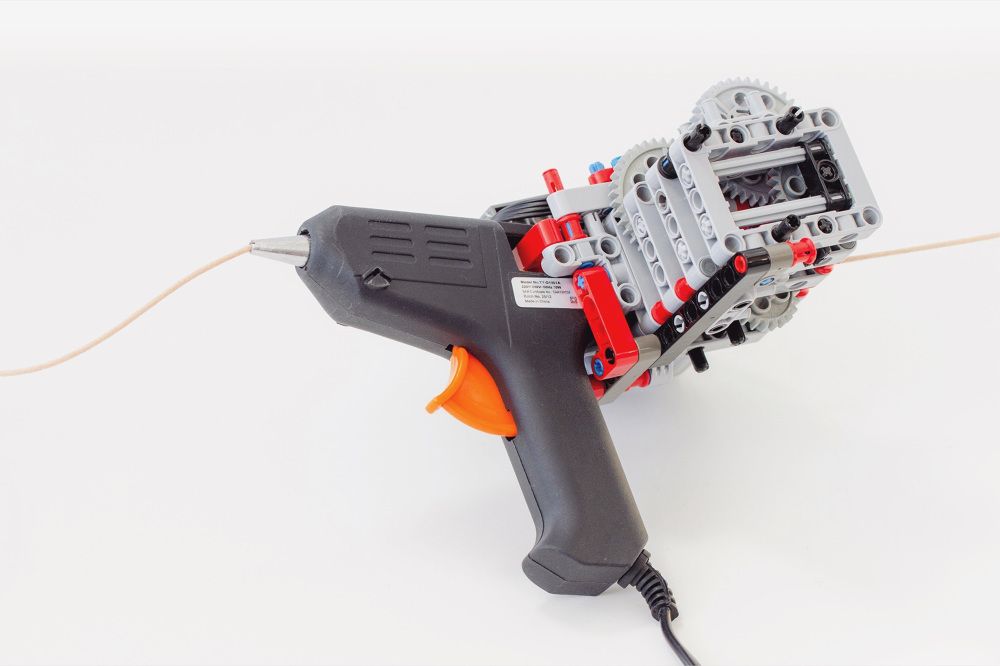

Hot Glue Gun

You can’t go wrong with a hot glue gun when it comes to gluing plastics, being a very popular solution for many applications. It has pretty good strength and isn’t too difficult to apply, with a 45-second application time.

It has pretty good strength and isn’t too difficult to apply, with a 45-second application time.

When you do use this though, the glue tends to be fairly thick, so it would be better for larger 3D prints and big projects like cosplay armor. For something like miniatures or smaller 3D prints, I wouldn’t recommend using a hot glue gun.

I’d recommend going with the Gorilla Dual Temp Mini Hot Glue Gun Kit with 30 Hot Glue Sticks from Amazon.

- It has a precision nozzle that makes operation a lot easier

- An easy-squeeze trigger

- Weather-resistant hot glue sticks so you can use it in or outdoors

- 45-second working time and withstands strong impacts

- Has an insulated nozzle that prevents burns

- It also has an integrated stand to keep the nozzle off other surfaces

Acetone

This has been known to weld and smooth PLA but only with certain types, most likely based on the manufacturing methods and chemical properties. Thomas Sanladerer shows us this in the video below.

Thomas Sanladerer shows us this in the video below.

You can get yourself a bottle of Pure Acetone from Amazon for a pretty good price.

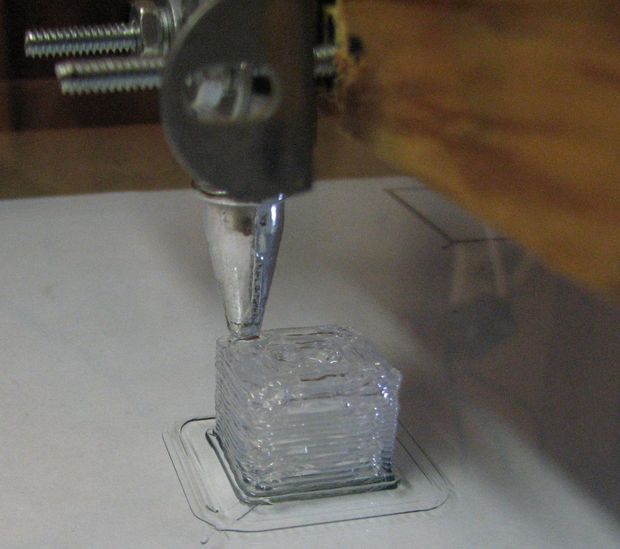

Soldering Iron

Another method of “gluing” PLA together consists of using a soldering iron to apply enough heat to melt the PLA part, then hold it together so it hardens and joins. It’s obviously not a glue, but it works very well to bond PLA parts together.

You can also use a line of the same filament you used to print the object, then solder that into both the 3D printed plastic parts to weld it together as shown in the video below.

The basic instructions of this video are to:

- Get your 3D printed pieces and make sure the surface is good enough to together

- Get your soldering iron and set it to a temperature around 200°C

- Use a length of the PLA filament you used for printing

- Line up the length of filament with the 3D print and melt the filament to use as a solder to combine the pieces together.

You want to filament to actually get into the gaps and holes

You want to filament to actually get into the gaps and holes - Let the PLA cool down and it should be joined together strongly.

A great one that should work well for the purpose of joining PLA together is the Anbes 60W Soldering Iron Kit from Amazon.

Here is another video which shows you how to weld together two parts. It was from a 3D print that failed halfway, which he split up and managed to print the other half and then combine it with soldering.

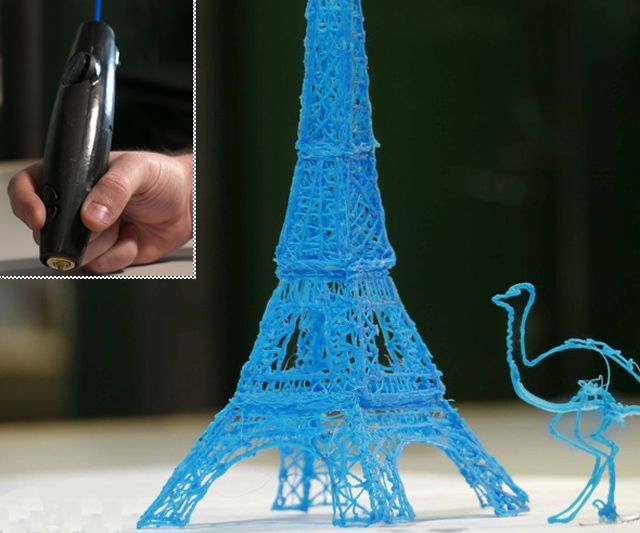

3D Printing Pen

A lesser known solution for gluing or joining PLA 3D printed parts together is to use a 3D printing pen. It’s not as popular since it isn’t as effective as the other solutions, but it definitely has its uses for 3D printing.

It’s similar to the soldering iron in a way, but uses the heat from a 3D printing pen to join PLA plastic parts together.

The MYNT3D Professional Printing 3D Pen from Amazon is a great choice.

One user did mention how they used this specific 3D printing pen to weld pieces of prototype parts together since they were too big to print in one part.

You can get better results with “gluing” pieces together by applying heat from a hair dryer or heat gun. It’s a pretty quick solution since you don’t have to hold things for long periods of time to set.

You should try to use fairly high temperatures to achieve this as compared to what you would usually set, though heat controls for this 3D printing pen is really simple.

It can also be used to fix small imperfections and gaps in your other 3D prints which is very practical.

What is the Best Glue for ABS?

A popular product to glue ABS 3D prints is acetone because it is a solvent which can actually dissolve ABS then harden up again. When you apply acetone to both ABS parts then hold it together, the softened part will start to form a strong bond until it cures fully. This process is called solvent bonding.

When you apply acetone to both ABS parts then hold it together, the softened part will start to form a strong bond until it cures fully. This process is called solvent bonding.

Other great glues or adhesives you can use for ABS are:

- Superglue

- ABS Juice, Glue, Slurry

- Epoxy

- Polyurethane

- Hot Glue Gun

Superglue

As previously mentioned, superglue is great for rigid objects and plastics. You can apply some superglue to your ABS 3D print and have it glue together fairly quickly.

You want to ensure that your objects are aligned nicely before you apply the superglue though because once it cures, you won’t be able to realign it nicely.

ABS Juice, Glue, Slurry

Another great set of products is ABS juice, glue and slurry, which are very similar in characteristics but mainly differ in thickness. You mainly want to use ABS slurry which is the thickest of the three to repair ABS prints and help with gluing pieces together.

It’s also used as a way to repair layer separation.

Epoxy

Epoxies are a great method for bonding and gluing ABS plastic 3D prints.

One advantage of epoxies is that they are water and chemical resistant, making them a suitable choice for high-strength bonding. It requires no heat to cure, although if you want an accelerated result, you can apply heat.

Again, I’d go with the Loctite Epoxy Instant Mix from Amazon.

Hot Glue Gun

This is another fast way of gluing your ABS together. Simply load some filaments into the gun and use the heated extrusion to join the parts. It can also fill gaps. Ensure not to move the nozzle too close to the ABS to avoid melting.

Surface Preparation: It is important to prepare the surfaces of the ABS parts you want to glue by cleaning, degreasing, and sanding.

Caution: The precautionary measure against the dangers that can arise from using acetone is keeping it away from flame because it is highly inflammable. Also, use it in a ventilated space to avoid excessive inhalation.

What is the Best Glue for PETG?

The best glue for PETG is superglue since it holds the parts together strongly and still maintains the quality and integrity of the 3D print.

You won’t need to bother about clamping the parts together as it pretty quickly bonds together and cures fast. Loctite glue and gorilla glue is some of the best.

Other adhesives that can glue PETG are:

- Two-Part Epoxy

- Hot Glue Gun

- Solder Iron

Two-Part Epoxy

A two-part epoxy is pretty popular with 3D printer users to glue PETG parts together. They usually come with another container in the pack called the hardener or accelerator.

The two products are meant to be mixed together before applying it to the surface of the PETG.

Although, the curing time varies; some take 5 minutes, while some take more time. The combination of a hardener and the glue itself will make a long-lasting and strong bond between the parts.

Hot Glue Gun

Most of the tests that were carried out on PETG using a hot glue gun prove its ability to bond two PETG permanently.

Check out this video on YouTube where a series of tests were carried out on different adhesives and the hot glue gun was confirmed to be one of the most reliable.

Again, I’d recommend going with the Gorilla Dual Temp Mini Hot Glue Gun Kit with 30 Hot Glue Sticks from Amazon.

Soldering Iron

A soldering iron with a temperature control option can glue PETG parts when used in melting the surfaces of the print. This process requires patience and it will yield good results in the end.

This process requires patience and it will yield good results in the end.

Ensure to wear a protective mask and goggle when using any of these adhesives. Use it in a ventilated area.

It works in the same way that it would with PLA, so you can watch the video in that section to see how you would do this with PETG.

What is the Best Glue for TPU?

The best glue for TPU is flexible superglue like Loctite 406 Superglue. It is designed in a way that allows it to bond rubber and flexible materials together with ease. The bonding and curing times of this glue is very quick and provides a strong bond which can’t easily be broken.

Other glues that work well with TPU are:

- Flexible Superglue

- DMF (N-Dimethylformamide)

- THF (Tetrahydrofuran)

- Soldering Iron

Flexible Superglue

A tried and tested product that works great to glue TPU 3D prints is the Genuine Loctite 406 Superglue Instant Adhesive from Amazon.

It has the following features:

- Rapid bonding with plastic and flexible materials

- Great adhesion of materials that are hard to bond

- Multi-purpose and works in many applications

- Very easy to use

It does have a pretty small margin of error, so you want to be very quick and accurate when using this stuff. It has an early bond strength said by users to be in just seconds, showing just how strong it is.

One user even bonded a broken rubber roller belt with this product. It’s best used to join TPU with another type of material like PLA. For TPU to TPU, it can still work well, but the solvents below are more efficient.

DMF (N-Dimethylformamide)

DMF is a solvent that can melt your two pieces of TPU or flexible filament together. When it comes to joining up TPU with another TPU 3D printed part, using a solvent is usually the best solution.

When it comes to joining up TPU with another TPU 3D printed part, using a solvent is usually the best solution.

THF (Tetrahydrofuran)

THF is another pretty strong solvent which dissolves TPU and allows you to bond two separate TPU prints by applying it on the surface and holding it together.

Soldering Iron

Similar to using a soldering iron for PLA and other materials, it can also be used for TPU and flexible 3D prints.

In the video below, he uses a soldering iron with a flat mouth to create a specific space for the TPU to be bonded together. He then filled it up with TPU filament and heated it up to let the parts soften and bond together.

After the TPU parts harden, it should create a very strong bond that can’t easily be pulled apart, unless the soldering wasn’t done accurately.

What is the Best Glue for Nylon?

The best glue for Nylon is a hot glue gun. Superglue doesn’t work as well with Nylon unless you have a flexible superglue. Many people have gotten great results when gluing Nylon with a hot glue gun. You can choose a method of heat like a soldering iron to bond Nylon 3D prints together.

Superglue doesn’t work as well with Nylon unless you have a flexible superglue. Many people have gotten great results when gluing Nylon with a hot glue gun. You can choose a method of heat like a soldering iron to bond Nylon 3D prints together.

Other methods you can adhere nylons are:

- Hot Glue Gun

- Soldering Iron

- 3D Printing Pen

You may think epoxy and superglue can work well on Nylon but it doesn’t have the same effect, mainly because of the flexibility and composition. You could do well with some of the flexible superglues mentioned in the TPU section above.

I’d recommend going with the hot glue gun or the soldering iron option. Another great method for “gluing” Nylon together would be a friction welding method which works with a rotary tool to heat up the surface and bond it together with friction.

It actually works pretty well for all sorts of materials, though you’ll want to keep safety in mind due to the dust and fumes it can cause. Some people even recommend combining the hot glue gun and friction welding method for even better results.

Some people even recommend combining the hot glue gun and friction welding method for even better results.

Another technique which isn’t talked about a lot of friction welding. You don’t need any kind of adhesive, but you do need a special tool to get this method working properly.

A Dremel Lite 7760 Cordless Rotary Tool from Amazon is a great product to use for friction welding.

Can You Use Superglue on PLA? What To Do If It Doesn’t Work

You can use superglue on PLA as a way to join parts together. It’s one of the best options for bonding PLA 3D prints, especially for smaller parts.

In some cases where superglue doesn’t work on PLA, it could be because:

- There are too many cavities or gaps where the parts are supposed to join together

- There was the presence of moisture or water on the surface which inhibits bonding

- The quality of your superglue isn’t at its best

- The PLA is exposed to heat which might break the bonding

If it doesn’t work, I’d recommend sanding the surface of both PLA parts to ensure a better fit. You want to use fairly low grit sandpaper like 120 grit to really prepare the surface to be glued together.

You want to use fairly low grit sandpaper like 120 grit to really prepare the surface to be glued together.

You also want to get another brand of superglue that cures faster and has better bonding properties, especially if your superglue is not very effective.

Does Contact Cement Work on PLA?

Yes, contact cement does work on PLA to glue 3D printed pieces together. It usually has a strong bond and also leaves you room for correction unlike with superglue.

Contact cement dissolves the surface of the PLA when applied and this process aids the bonding. A 3D enthusiast agreed with the fact that contact cement works on PLA, but you do need to use a good, reliable product that is known to work with your material.

When you follow the instructions of the specific contact cement you have, you should be able to have success in joining your parts together.

Best Glue for 3D Printed Miniatures (Minis)

The best glue for 3D printed miniatures is standard superglue (Cyanoacrylate). It provides a strong bond for your 3D prints and cures pretty quickly. You’ll usually have to hold the piece on the model for it to set, but you can use an activator to speed up the curing process.

It provides a strong bond for your 3D prints and cures pretty quickly. You’ll usually have to hold the piece on the model for it to set, but you can use an activator to speed up the curing process.

Accessibility is easy as compared to some solvents, it is very effective and easy to use, as well as being really cheap and long-lasting.

Other adhesives like epoxy work too, but they tend to have a longer curing time. There are definitely some quick-curing epoxies that you can make use of for minis, which many people have had success with.

Contact cement glue is another good option for plastic minis. They bond quickly too (although not as quick as glue) through melting and subsequent fusion. This bond is lasting and more durable than CA.

I wouldn’t use contact cement for very small minis because of the noticeable damage the corrosion will do to the parts.

How Do You Connect & Join PLA Filament Together?

It’s possible to connect and join two pieces of filament or even rolls of filament using a piece of a PTFE tube and a lighter. This is great for when you have small strands of filament left over from spools, which you can join end-to-end.

This is great for when you have small strands of filament left over from spools, which you can join end-to-end.

The method consists of pushing through the filament through the tube, lighting one end with a lighter so it’s softened, pulled it back through the PTFE tube and pushing the second piece of filament in the tube so it can then join together and harden.

The video below shows how it’s done very clearly.

On a final note, if you have followed the instructions above in terms of avoiding certain adhesives for certain materials (like superglue for nylons), you should be good to go by sticking to the recommended ones.

What is the Best Glue to Use for 3D Printing?

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

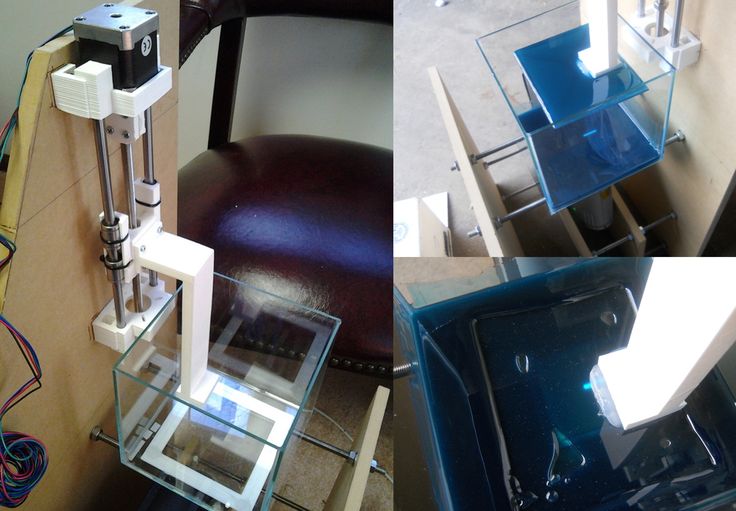

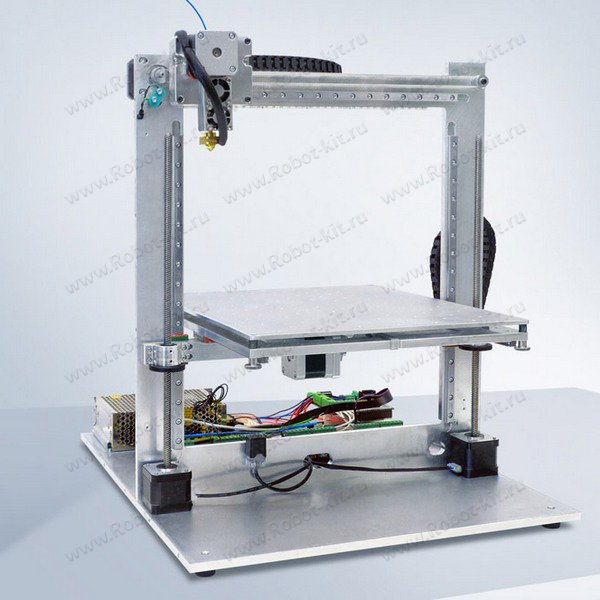

There are many instances in 3D printing where you have to glue together several pieces that were printed separately. This can be due to the build size limitation of your printer, or simply because it’s easier to have the parts separated during printing. In any case, glue should certainly be an essential part of your toolkit.

Now, the question is – what kind of glue should you be using? The answer greatly depends on the type of filament you’re printing with and the use case of your 3D printed project. Here are some of the best glue options, along with the factors you should consider.

Superglue

Best for: PLA, but applicable to almost all materials

Recommended brand: Gorilla Super Glue

Cyanoacrylate glue, more commonly known as super glue, is the default option for gluing not just 3D prints, but practically every single thing around the house. Even if you’re not planning to use super glue to put together your 3D prints, it’s still a good idea to have one of these lying around.

The great thing about super glue is that you can spread it super thin and still have good adhesion. This is ideal if you want the seams in your finished print to be as invisible as possible. Super glue works best when applied on clean and smooth surfaces, so you will need to do a bit of sanding and polishing as surface preparation.

When dried, super glue creates a thin but rigid layer. This makes super glue less suitable for flexible material, or any 3D printed part that is meant to bend, flex, or twist.

One difficulty of working with super glue is that it sets really fast. This gives you less time to manipulate and position a part in place. You will also likely end up with patches of glue on your hands. When working with super glue, make sure that your table tops and floors are covered. Super glue is very fluid-like and tends to get all over the place.

Epoxy resin

Best for: PETG, ABS, but applicable to almost all materials

Recommended brand: MAS Table Top Pro Epoxy Kit

Epoxy resin is another common adhesive that is found in most households. Epoxy resin is typically packaged as two compounds that need to be combined before the resin starts setting. Epoxy usually takes a long time to set, so there isn’t as much pressure to work very quickly once the two components have been mixed.

Epoxy resin is typically packaged as two compounds that need to be combined before the resin starts setting. Epoxy usually takes a long time to set, so there isn’t as much pressure to work very quickly once the two components have been mixed.

The chief advantage of epoxy resin is that it creates a very tough and rigid layer, more durable than what you will get with super glue. This makes epoxy resin for more heavy-duty applications. If you’re printing with tough materials like PETG and ABS, then epoxy resin might be one of the best glues for complementing them.

Epoxy resin is quite thick when applied, making it less than ideal if you want seams to be invisible. However, it is perfect for filling in any gaps and voids in the joints of your 3D print. It also does not require any surface preparation.

Once cured, the hardened epoxy resin can be sanded smooth, polished, and painted over. If you’re going to paint over your 3D print anyway, then epoxy resin is worth considering.

Acetone

Best for: ABS, HIPS

Recommended brand: Chemcorp Acetone

Acetone is unique in that it’s not really an adhesive. Instead, it’s a solvent that can dissolve specific 3D printing filaments – ABS and HIPS. If you’re ever finished an ABS print using an acetone vapor bath, then you probably already know how this works.

To use acetone as glue, just brush a thin layer of it on the surfaces to be glued together. This will melt a thin layer of the plastic, allowing them to form molecular-scale bonds with each other. Acetone will naturally evaporate at room temperature, leaving the plastic with no traces.

The main advantage of using acetone is that it’s not just an interface that holds the two surfaces together. Instead, acetone allows for the molecules of the plastic to form bonds with each other, creating a very strong and permanent bond.

The obvious drawback of acetone is that it can only be used very selectively. Outside of filament based on ABS or HIPS, there really is no other way that you can use acetone to glue your 3D prints together.

Outside of filament based on ABS or HIPS, there really is no other way that you can use acetone to glue your 3D prints together.

Hot glue gun

Best for: Rigid materials

Recommended brand: Gluerious Mini Hot Glue Gun

Everyone has probably used a hot glue gun for other arts and crafts projects. This can also be useful for gluing together 3D printed parts, with just a few caveats.

Glue from a hot glue gun tends to be thick and very viscous. This makes it unsuitable for high-precision works, such as for small figures and miniatures. However, a hot glue gun is very easy to apply over a large area quickly. It also sets fast, usually in less than a minute. If you’re working with large parts, a hot glue gun might just make the job a lot easier.

Hot glue gun does not require much surface preparation. Just wiping the surface clean with a dry cloth should be fine, just to get rid of any powder residue. Hot glue gun does tend to partially melt the surface of the 3D printed plastic, so make sure not to use it on the super-fine details of your model.

Plumber’s cement

Best for: ABS, PLA, PETG, HIPS

Recommended brand: Loctite Plumber and Marine Adhesive

Plumber’s cement, as the name implies, is the type of adhesive that plumbers use to fix leaking kitchen and toilet pipes. As such, it is very strong, waterproof, and weather-proof. If you have 3D printed parts that will likely be exposed to the outdoor elements, then using plumber’s cement might be the best way to keep them together for a long time.

There is a wide range of different types of plumber’s cement or marine adhesives right there. Many of these are solvent-based, so you may want to check the compatibility of your filament with the solvent. The particular adhesive we’re linking to dries clear, making it easier to make invisible seams.

Silicone glue

Best for: All materials

Recommended brand: Loctite Silicone Waterproof Sealant

Silicone glue is often used for surfaces that need to be waterproof and thermally stable. This is worth keeping in mind, should you need to make bonded seams that are weather-proof and can withstand elevated temperatures.

This is worth keeping in mind, should you need to make bonded seams that are weather-proof and can withstand elevated temperatures.

Again, there are a lot of silicone adhesives out there. Silicone glue is quite thick, making controlled application a bit difficult. However, you can remedy this by using tubes that have small and thin applicators. Conversely, there are large cylinders of silicone glue that are more appropriate for gluing large parts.

Silicone glue can take a very long time to set. When using silicone glue, you will need to come up with a way to fasten the parts together temporarily while the glue hardens. The good thing is that it also gives you a lot of time to adjust and position the parts as needed.

3D pen

Best for: Best for PLA, but other materials are possible if you can find matching filament

Recommended brand: MYNT3D Super 3D Pen

A 3D pen isn’t exactly designed as an adhesive tool, but it does just fine in some cases. A 3D pen gives you very precise control over where plastic will end up, making it ideal for retaining the aesthetic value of your 3D prints.

A 3D pen gives you very precise control over where plastic will end up, making it ideal for retaining the aesthetic value of your 3D prints.

The best way to use a 3D pen for gluing parts is to use a filament that matches the material of the 3D print. For instance, gluing together PLA parts is very easy since almost all 3D pens can use PLA. The 3D pen we have linked to here from the MYNT3D brand can also use ABS. Matching the same material creates stronger bonds, as similar molecules can bond to each other at the molecular level.

Unfortunately, even with this advantage, parts glued using a 3D pen are not very durable. If you’re designing parts that are meant to be functional, then a 3D pen is far from being the best tool. We recommend only using 3D pens for gluing together parts that are meant to be displayed. As mentioned, the precise control that 3D pens provide makes them excellent for preserving the visual appeal of your project.

Final thoughts

Glue is one of the things that someone who’s into 3D printing should have on hand. However, not all glues are made equal. If you’ve stuck with using just super glue with all your 3D printing projects, you might be missing out on equally good or better alternatives.

However, not all glues are made equal. If you’ve stuck with using just super glue with all your 3D printing projects, you might be missing out on equally good or better alternatives.

Gluing does not just fulfill the purpose of putting parts together. Given the right material, you can also use glue to fill in gaps, voids, and other imperfections. You can think of gluing as just another part of post-processing, like sanding or polishing. There are lots of tools available – it’s just a matter of picking the right one for your situation.

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

Found the best adhesive

jrBush

Loading

24.04.2019

3109

Personal diaries

WANHAO DUPLICATOR I3 MINI

Hello everyone, the time has come for me to share my experience in the field of 3D printing, I don’t know how experienced I am, but at the moment I printed 2kg. Filament.

Filament.

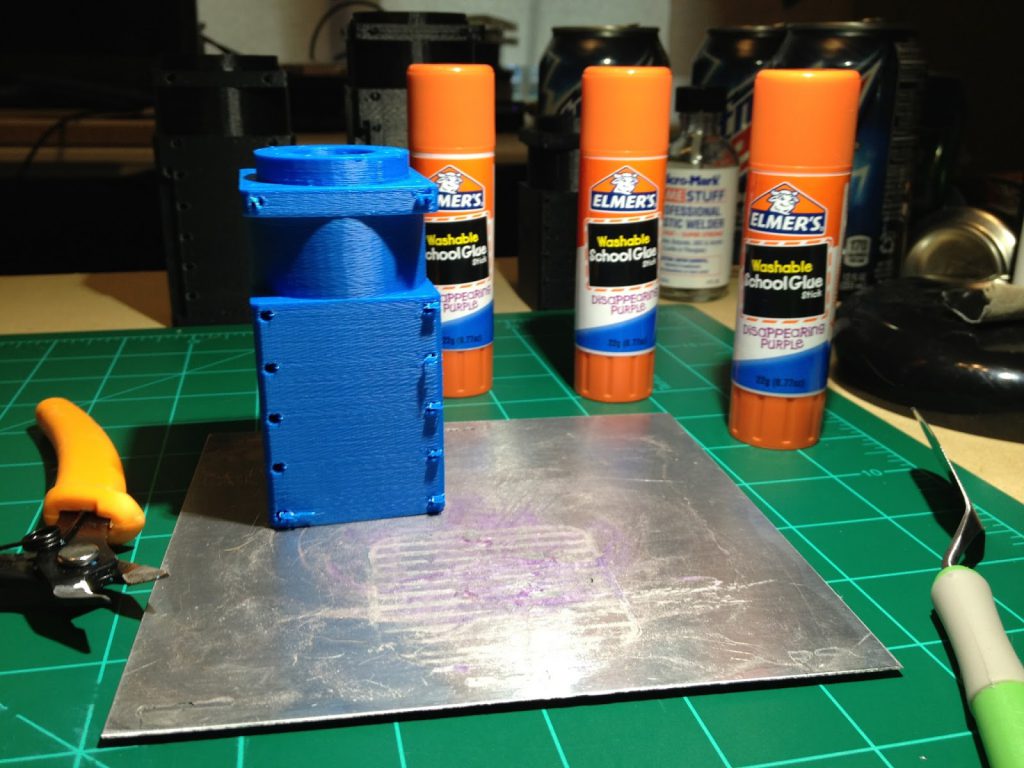

So we're talking about table glue.

I will say that from the moment I was given a printer and until this post I had no problems with adhesion, but after the tube of pencil that came with the printer ran out and I went to the store for the first glue I came across, I had to go online and find out what many users of 3D printers experience problems with sticking to the table, or rather the lack of it, so I’ll say that not all glue sticks are really suitable for this,

For myself, I think the ideal glue is "Erich Krause" to spread thicker and there are no problems. By the way, it is not necessary to clean the glue with alcohol or window cleaner after each print, you can safely apply a layer on top of the old glue.

So there is one glue that made me write this post, and not because it was difficult for me to extract the part, but because I could not do it, see for yourself:

0006 Don't want

1

Article comments

More interesting articles

pl32

Loading

11/08/2022

2227

24

Subscribe to the author

Subscribe

Don't want

Good afternoon, colleagues!

It so happened that the topic of induction heating caused a discussion. ..

..

Read more

ski

Loading

02.12.2022

1078

5

Subscribe to the author

Subscribe

Don't want

Joel's video post about Mimaki at FormNext'2022 in Frankfurt

Read more

103

Follow author

Follow

Don't want to

So I had the opportunity to try to implement everything based on MMU2 (1h, 2h, 3h, 4h, 5h,). I have ...

Read more

90,000 We test liquid adhesions for adhesionTechnician

Subscribe to

Subscribe

I do not want

10

So I managed to collect the entire liquid team to increase the table adhesion at 3D -print. And this means that Mnogo3D, obsessed with adhesion, is back with you. Picaso 3D glue, 3DM 3D glue and I made 4D glue gathered in our hands at the same time. The first two are already familiar to the readers of the portal according to the test "Adhesion means: professional versus amateur". The last one just arrived. And so we will do a test of who is capable of what. In order not to be bored, the glue stick "Kalyaka-Malyaka" and Eeeee ... Povidone on isopropyl alcohol will take part in the test. Kalyaka is the standard of adhesion and it is needed as a guideline. And povidone to debunk or confirm the myth that a professional remedy can be created at home.

And this means that Mnogo3D, obsessed with adhesion, is back with you. Picaso 3D glue, 3DM 3D glue and I made 4D glue gathered in our hands at the same time. The first two are already familiar to the readers of the portal according to the test "Adhesion means: professional versus amateur". The last one just arrived. And so we will do a test of who is capable of what. In order not to be bored, the glue stick "Kalyaka-Malyaka" and Eeeee ... Povidone on isopropyl alcohol will take part in the test. Kalyaka is the standard of adhesion and it is needed as a guideline. And povidone to debunk or confirm the myth that a professional remedy can be created at home.

Since the last test, we have diluted our "Nurofen", bringing the concentration to approximately 1 sachet of medicine per 0.5 liter of alcohol. And very thoroughly mixed, getting rid of the flakes. Thanks for the recommendations on finalizing the solution to Ilya Pinchuk and advice on the test in general.

This time we decided not to test on nylon, ABS is enough. For the purity of the experiment, we will carry out the test on the material from two manufacturers. Black is Chinese, sold under the Good3D brand, and gray is from REC.

For the purity of the experiment, we will carry out the test on the material from two manufacturers. Black is Chinese, sold under the Good3D brand, and gray is from REC.

Disclaimer: I express my gratitude to the portal 3DToday because 3DM glue, as well as REC gray plastic are winnings in competitions held by him. Let's not forget Top3DShop either. Glue Picaso provided by them for the last test free of charge.

4D glues "I made" and "Kalyaka-malyaka" were bought from office. dealers without informing about the intention to conduct testing.

Introducing the participants. Glue from Picaso and 3DM are longtime players in the 3D printing market. Their composition is declared the same: Water, Isopropyl alcohol, P-complex and flavor. But manufacturers are different. 3DM smells stronger of alcohol. Either they saved on the fragrance, or the spirit was vigorous. 4D glue "I made" is different. In its composition, PVP is immediately indicated. It has a yellowish tint and is thicker. The smell of alcohol is less noticeable. On the contrary, there is a pronounced woody smell. Apparently the wombat is on the label for a reason. All three are supplied in 250 ml squeeze bottles. "I did" is also available in 100 ml bottles.

The smell of alcohol is less noticeable. On the contrary, there is a pronounced woody smell. Apparently the wombat is on the label for a reason. All three are supplied in 250 ml squeeze bottles. "I did" is also available in 100 ml bottles.

Homemade remedy is simpler and cheaper. In a pharmacy, we buy a sachet of medicine Enterodez 5 grams with the active ingredient POvidone and dissolve it in 0.5-1.0 liters of isopropyl or ethyl alcohol. Doesn't dissolve well. Therefore, you need to periodically shake the bottle until the flakes disappear. Why Povidone and where does the pharmacy?! It's simple, PVP is polyvinylpyrrolidone. And its other name is just povidone or polyvidone. This substance has a very wide range of applications in medicine and chemistry. But it is one thing to know the composition, and another to know the recipe. In the last test, homemade did not show itself in any way. Let's see what happens this time.

Magic glue stick "Kalyaka-Malyaka" is also not simple and has its own legends. We took several briquettes of this glue. we prefer this particular method of adhesion and can debunk a few more myths about it. Actually everything is in the photo.

We took several briquettes of this glue. we prefer this particular method of adhesion and can debunk a few more myths about it. Actually everything is in the photo.

Even in one briquette there are tubes of different shades of yolk with contents of different shades of pink. Also different ends of the glue. Some are pointed, while others are flat. And all this in one sealed pack from the dealer.

And so... to the test!

Test piece:

Frame with a 0.8mm wall measuring 15x150mm and a height of 50mm. We print with a nozzle of 0.8 mm and a layer of 0.3. The first layer is 50% of the base layer height. Speed up to 50 mm/sec. Brim at 5 perimeters. Printer open Corexy with ball screw. The temperature in the room is 22-25 degrees, without drafts. The surface is a mirror. The conditions are deliberately set to be unrealistic, so that it would be easier to evaluate the result by the amount of printed material.

The idea was to put 4 parts side by side and see what happens.

But the idea turned out to be so-so. A part that went out of the way caused the test to stop. Here, either apply the Olympic system, or test it for a long time and dreary piece by piece.

We settled on the last method and started printing the same code with different adhesives. Accordingly, they waited for the platform to cool down, washed it, dried it, degreased it with pure alcohol, dried it, and applied the composition.

Contrary to advertising, one coat of compound does not work! Not even two work. Applying a large amount is also not an option. You need at least three layers. And for 3DM, even three layers do not work. In this regard, for the outsiders of the first round, the adhesives 3DM and "I did" were given a second chance to prove themselves. In the second attempt, only 3DM was given a second chance. The concentration of the substance, apparently, is less in it. Therefore, after a failed attempt on 3 layers, the printing was repeated on 4. The difference, as they say, is "on the face. " Assigned seats are our subjective decision on typing comfort. And it wasn't easy. You run the test. You control that the brim began to stick to the table. If the composition is small, then a new layer of the composition was applied and the test was started again. If the print has gone, then you sit and wait for the coveted click and crackle of the extruder on skipping steps. You fix the % of the task completion and the separation. Stop printing. Table cooling, washing, drying and new. Over 100 photographs were taken. Let's show some.

" Assigned seats are our subjective decision on typing comfort. And it wasn't easy. You run the test. You control that the brim began to stick to the table. If the composition is small, then a new layer of the composition was applied and the test was started again. If the print has gone, then you sit and wait for the coveted click and crackle of the extruder on skipping steps. You fix the % of the task completion and the separation. Stop printing. Table cooling, washing, drying and new. Over 100 photographs were taken. Let's show some.

Picasso 1st attempt.

Most printing stopped within 30-50%. The best results were shown only by "Kalyaka-Malyaka".

3DM glue and its 3rd attempt.

It should be noted that REC plastic, unlike Good3D, is more rigid and more prone to delamination. On it, the subjects showed poorer results. In particular, in the second attempt, when printing on a painter, the plastic tore the brim, and not completely tore it off, as in all other cases.

.jpg)