3D digital printing on fabric

Direct-to-Textile 3D Printing

Since its unveiling at New York Fashion Week last fall, the ability to 3D print directly onto fabric has drawn significant interest from the world of high-end fashion. Exemplified by the works of fashion designers threeASFOUR and Travis Fitch on NYFW’s catwalk, this technological milestone gave the world a preview of what fashion design could look like when combining the geometric and aesthetic freedom of 3D printing with the comfort of fabric.

Since then, Stratasys has been working closely with a number of household fashion brands to optimize its novel PolyJet Technology™ to meet the needs of modern-day apparel fabrication and make customized fashion design commercially viable.

As the company works towards this goal, Stratasys is proud to reveal today two collaborative works with esteemed fashion designers Julia Koerner and Ganit Goldstein. The works form part of Re-FREAM, a collaborative research project funded by the European Union bringing together artists, designers, engineers and scientists to co-explore the use of technology and 3D printing for the future of fashion.

ARID Collection – Julia Koerner.

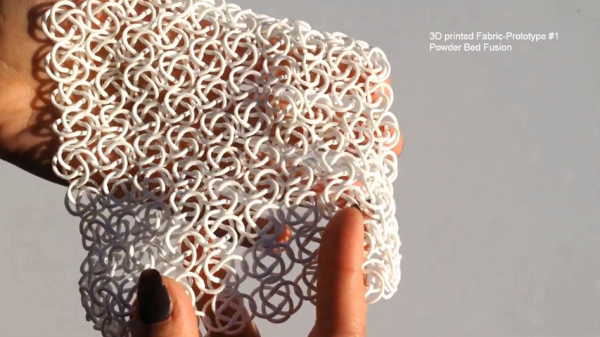

At today’s virtual ARS Electronica Festival, Koerner unveiled her latest collection: ARID. The works are built on research focusing on digital processes from 2D to 3D for nature-inspired geometries and the connectivity and adaptability of textiles with multi-color 3D-printed parts – with an underlying focus on material efficiency and sustainability.

ARID amalgamates this research into a collection of 38 3D-printed parts that can be combined to form a full-dress, or cascade into a number of different looks and combinations. Using Stratasys’ PolyJet Technology, the digital designs were 3D printed directly onto sustainable fabrics in vivid colors, creating an enigmatic shimmer effect when the garment is in motion, while maintaining the comfort and wearability of fabric garments.

The collection also allows for the easy adaption of personalized sizes through modified 3D printed connectors, which are derived from 3D scans of the wearer. There is no sewing involved in the final assembly of the parts. Instead, all seams are connected with 3D printed joinery, which is the first time 3D printed connectors have ever been used in the assembly of textiles.

There is no sewing involved in the final assembly of the parts. Instead, all seams are connected with 3D printed joinery, which is the first time 3D printed connectors have ever been used in the assembly of textiles.

Customized Design – Ganit Goldstein.

Goldstein teamed up with Stratasys to achieve her mission of customized fashion design by combining craft methods with direct-to-textile 3D printing to produce a Japanese-style dress (see video here).

“Looking at the fashion world today, I want to introduce a new way of manufacturing – moving away from mass production to customized design,” says Goldstein. “3D printing has always offered the potential to personalize design in ways not possible before, but to truly create a new way to manufacture requires a new kind of textile. My goal is to create a new hybrid world of crafts and multi-color 3D printing – connecting past, new and future techniques to evolve fashion design.”

My goal is to create a new hybrid world of crafts and multi-color 3D printing – connecting past, new and future techniques to evolve fashion design.”

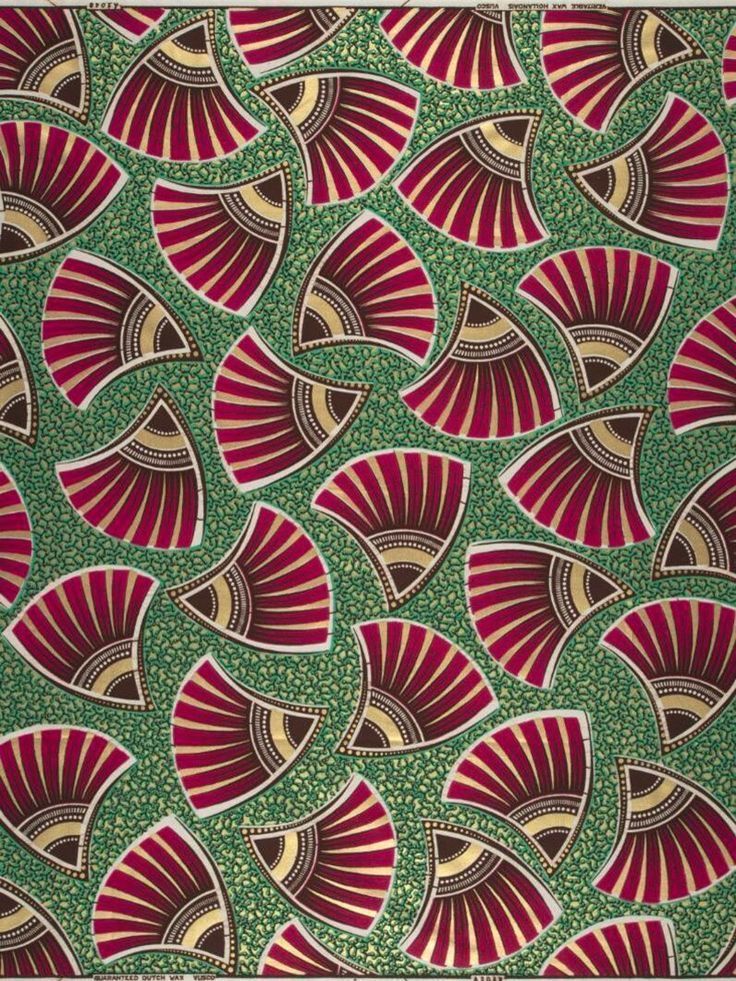

Goldstein spent a year in Japan to learn interweaving and was inspired by Asian craft embroidery and textile painting. Her kimono design follows the Japanese ‘ikat’ coloring method. While Japanese embroidery is the soul of the project, direct-to-textile multi-color 3D printing is at the heart of it. The kimono follows an algorithm that is composed on the 3D body scan and translated to the print surface during the printing process.

For the first time in 3D printed fashion, textiles can be leveraged as the skeleton of the garment. This allows for extra movement within the fabric, but also enables full gain between the capacity and material thickness that is printed on top of the fabric. This enables designers to bring unique designs to market that are not possible in any other way. It also challenges Stratasys to take the technology to places it’s not been before to support the emerging demand for direct-to-textile printing.

“In fashion, it’s important that we continually optimize and evolve to introduce new design forms,” says Goldstein. “During the past year, I experimented with numerous different fabrics and technologies to incorporate 3D printing within textiles. Achieving this milestone takes us away from 2D design and opens up a world of wearable 3D garments.”

Koerner and Goldstein leveraging Stratasys’ direct-to-textile printing technology exemplifies Re-FREAM’s goal of fully digitizing design workflows – from design through to production. In doing so, it demonstrates the possibility for localized manufacturing and mass customization – regarded by many as the future of fashion.

As Goldstein attests to in her video, direct-to-textile 3D printing has the potential to be a game-changer for the fashion industry. With the commercial interest in this innovative technique already at an advanced stage and pilot-testing underway, it may not be long before potential becomes reality.

To find out more about the latest developments from Stratasys in design and fashion, check out the latest podcast from The Artian featuring Stratasys Creative Director for Art, Design, and Fashion, Naomi Kaempfer.

The Digital Textile Tech Behind Kornit's Sustainable Fashion - 3DPrint.com

I recently traveled to Israel to attend Kornit Fashion Week Tel Aviv 2022 and see Kornit Digital (NASDAQ: KRNT) introduce its Atlas MAX Poly and Apollo solutions for digital, sustainable fashion. The company wants to improve the fashion and textiles industry by reducing waste, but still enabling flexibility and creativity with its on-demand textile production and technology, called direct-to-garment (DTG) printing. Using its XDi effects, Kornit’s MAX technology deposits 3D layers onto fabrics, and the results strongly resemble screen printing and embroidery, though it’s actually an additive process. Kornit also offers a single-step, direct-to-fabric (DTF) printing solution for textiles as well.

The first day, we got to see two exciting fashion shows that were, as CEO Ronen Samuel told the crowd, “based 100% on Kornit’s technology.” The next morning, we visited Kornit’s nearby headquarters for a day of presentations and technology demonstrations, starting with Samuel himself. He explained how harmful the current fashion industry is, and reiterated Kornit’s goals to print textiles more sustainably and efficiently, without compromising on quality; connect the physical world with the virtual one; connect demand to supply; and make the world a better, more inclusive place.

Digital Fashion Changes the World

- Photos courtesy of the author.

After Samuel’s opening presentation, we sat in on a Fashion Experience Panel, featuring Yanky & Nataf—the fashion design duo whose work we’d seen the day before—and inclusive fashion design company Palta, which designed the opening ceremony uniform for the Israeli Paralympic team. In an intro video, Yanky & Nataf stated, “Fashion will not change the world, but the way we make it will.” Both design teams expressed how great it is to be able to produce on-demand using Kornit’s technology.

In an intro video, Yanky & Nataf stated, “Fashion will not change the world, but the way we make it will.” Both design teams expressed how great it is to be able to produce on-demand using Kornit’s technology.

“Kornit helped us with our design. Everything that we want to do, they help us with a machine. Everything we want to do, we can do instantly,” Nataf Hirshberg said. “Kornit has the insane machines that helps us to make an insane design, and it’s really exciting.”

According to Palta co-founder Netanel Yehuda Halevi, a social activist, motivational speaker, PR specialist, and lifelong wheelchair user due to muscular dystrophy, clothing is the best way to say something about oneself, and “printing is the best way to do this.”

“Think how much you can say for people with disabilities, like people with autism. You can help them say something,” he said, referencing the kind of visual effects possible with Kornit’s digital print technology.

Shay Senior, Palta’s other co-founder, agreed:

“That shirt Ronen showed us—that is the way of independence,” he said about Kornit’s augmented reality textile capability. “Now we can all see how we can buy through a QR code.”

Direct-to-Garment and Additive Textiles

The last session of the morning was about Kornit’s product strategy and presented by Chief Marketing Officer Omer Kulka. He told us that “make better” is the company’s motto, and that Kornit is doing this in a very proactive way.

“We’re trying to make the industry better,” he explained. “Creating a change like this comes from within. To disrupt something, you have to know what it is.”

He explained that Kornit sees “the market and the world around us” as the “front of the house.” These are the demand generators, like consumers and e-commerce, and fashion is accelerating in this digital space. The back end is the pollution generated by the “old production means” of fashion, and Kornit wants to bridge that gap using its tools, including KornitX.

Kulka discussed the company’s new Atlas MAX Poly system, which is described in a press release as “an industry-first direct-to-garment (DTG) solution” that delivers colorful, high-quality digital decorations for design on poly-blended and polyester apparel. Kulka said the company couldn’t penetrate the market before and truly transform analog to digital, but that the durable Atlas MAX Poly is making this possible.

Kornit Atlas MAX Poly is the newest member of the proven Kornit MAX family and the industry’s first for high-volume digital production for vibrant design on polyester and polyester-blended apparel. Photo by Kfir Ziv.He explained that, because Kornit has these digital capabilities, it can penetrate the next generation of applications and verticals, like sportswear and promotional brands. One of the best examples of this is the company’s XDi technology, which enables the printing of embossed 3D textures and prints that look like embroidery and includes heat treatment.

Kulka also said the company is expanding horizontally, and that the vision for “the textile production floor of the future” is lights-out, with no human operators. He noted that automation is a journey, so Kornit is not 100% there yet, but the company will begin to show its soon-to-be-available products for automation through its KornitX pixel to parcel solutions.

He told us that next, we’d see the platforms that run these solutions, like the Presto Max, and the unveiling of the Apollo technology prototype, with its various modules. We’d also see the Atlas MAX Poly, which he called the “next generation of polyester technology.”

“The Atlas MAX Poly has a unique application, and opens up a huge market in pure polyester,” he said. “16% of t-shirts are poly-blend materials. The market is moving there very fast. The pandemic accelerated the merging of poly, athleisure, and fashion.”

Semi-Automated Digital Fashion

It was then time for us to split up into groups for the tour, based on the lanyard color of each attendee. The colors were blue, pink, yellow, and black, or CMYK, a clever take on the model most often used in color printing.

The colors were blue, pink, yellow, and black, or CMYK, a clever take on the model most often used in color printing.

We saw Kornit’s microfactory solution, which features its Presto & Cut textile production workflow, complete with roll to roll printing. This concept has major potential in the AM fashion industry. First, a customer goes online to design and order their custom apparel, then chooses the fabric they want.

The design is then sent to the Presto MAX, which can print white ink on dark fabric, neon colors, and XDi 3D decorative applications in a single-step process. The employee explaining the technique noted that this solution is far more sustainable than others, with no water input or output.

Color is only printed on areas of the fabric that will be cut, and the remaining fabric scraps are recyclable. Once the garment has been dried on the machine, it’s cut and sorted.

Every step of the way, the operator scans the bar code to ensure they’re creating exactly what the customer asked for, with no mistakes. This dress had two parts printed and cut, details shown by the barcode. This lets the operator know that two pieces need to come off the printer and go to the next station: sewing…not an automated step.

This dress had two parts printed and cut, details shown by the barcode. This lets the operator know that two pieces need to come off the printer and go to the next station: sewing…not an automated step.

Step six is quality assurance, and once this is finished, the final stage is packing and shipping the garment. Once the bar code is scanned again, the operator gets the customer’s address and prints the shipping label, sending the clothing on to its destination.

We also saw the modules that will make up the digital Kornit Apollo DTG system, which features the company’s MAX technology and textile drying functionality from Tesoma. The system is still in the tech prototyping phase, so the modules aren’t connected yet, but once they are, the Apollo should be able to offer integrated smart curing processes and full automation control in the same platform.

The Apollo system is, according to a press release, “considered a future game-changer for the mainstream mass production of fashion and apparel,” which is a major market opportunity. The company claims it’s the most comprehensive single-step, digital end-to-end system for short and medium nearshore mass production runs. It is also said to offer the “highest output per operator.”

The company claims it’s the most comprehensive single-step, digital end-to-end system for short and medium nearshore mass production runs. It is also said to offer the “highest output per operator.”

Samuel explained in the press release, “These accelerating shifts to nearshore and short- and medium-run production, in addition to the breakthrough digital advancements we are introducing with Apollo, should allow Kornit to address significantly more of the annual global decorated apparel jobs, generating a multi-billion-dollar opportunity for our customers and partners.”

It was interesting to see the automated process of printing on t-shirts, though again, this was more screen printing than 3D printing.

The Kornit Atlas MAX was in the same room, and we got to see the new ActiveLoad garment loading and real-time pallet adjustment. The company suggests that this automated, patent-pending robotic solution can increase throughput by up to 20% and deliver repeatable, high-quality output with few errors.

The Kornit employee explaining ActiveLoad pointed out that, for most customers, finding skilled labor is a major pain point. That’s why “automation is the key to the future of DTG.” The system is made up of two components: the pallet adjuster, which automatically adjusts based on the size of the shirt placed on it, and the auto-loading mechanism, which pulls the shirt into the machine for printing. A human operator is still needed to place the shirt at the beginning, so the solution isn’t completely automated yet. Regardless, the ActiveLoad enables the Kornit MAX to reach its “full potential” and put out 125 shirts an hour.

Touching Additive Textiles

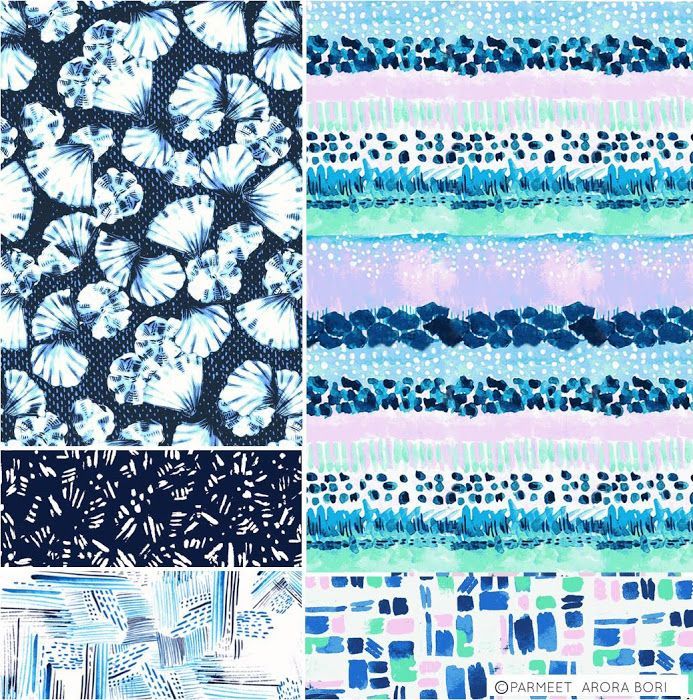

Then, it was time to see the XDi technology up close and personal. Not only can the new high-volume Atlas MAX Poly print photorealistic and semi-gradient images on dark fabric, but it also uses MAX technology to enable smart, autonomous quality control process automation, and high-quality, additive decorative applications. The results were stunning: multiple design effects on polyester are possible, such as screen transfer emulations, high-density vinyl, threadless embroidery, dye sublimation, and 3D effects—available in neon, no less! Using Kornit’s XDi Digitizer tool, users can transform any 2D design into XDi 3D effects and unique textures.

The results were stunning: multiple design effects on polyester are possible, such as screen transfer emulations, high-density vinyl, threadless embroidery, dye sublimation, and 3D effects—available in neon, no less! Using Kornit’s XDi Digitizer tool, users can transform any 2D design into XDi 3D effects and unique textures.

“We are able to print around 100-120 pieces an hour on this machine. The colors, I must say, are exceptionally good,” said Georg Stricker, Technical Manager with Boender & Beute. “It’s more colorful; the designs are looking more bright and beautiful; and we are now able to print a single layer of white where we used double layers before. You can feel it’s something that is unique in the textile industry.”

Another visitor asked how many layers one of these XDi effects had, and the operator said the system was able to print the six layers in just 40 seconds. There were plenty of shirts available, so everyone had the chance to touch the material, and I was amazed at how much these additive effects looked and felt like embroidery. With XDi, you can achieve complex shapes, all kinds of colors and gradients, and even multiple effects in one print, all while reducing waste, water usage, and energy consumption.

With XDi, you can achieve complex shapes, all kinds of colors and gradients, and even multiple effects in one print, all while reducing waste, water usage, and energy consumption.

NeoPigment Inks

Our lab tours at an end, we adjourned for a lunch break before the afternoon sessions, which began with Kobi Mann, Kornit’s CTO.

Mann focused on Kornit’s NeoPigment process. He explained that the company’s pigmented ink is a solid particle which is ground up, put into a water-based medium, and then the “floating solid particles” are dispersed. The dispersion process is where the company gets its “unique value proposition,” as it optimizes ink efficiency for color.

The company formulates, tests, and produces the NeoPigment inks itself to ensure the highest possible quality, and claims they’re the “safest way to print.” According to Kornit, the water-based inks are 100% toxin-free and non-hazardous, don’t contain any animal by-products, and meet important safety applications.

Mann told us that material chemistries are the ‘fundamentals” of the process, and that Kornit is currently focusing on acrylic, silicone, and polyurethane. He also said Kornit is working on physical adhesion, as well as creating a chemical reaction with the fabric. By improving the chemistries, you can control the solution by making them stronger, which takes you into further applications.

Adding Layers to Digital Fashion

Kornit’s patented technology revolves around real-time selective fixation and functional amplifiers. As Mann explained, XDi enables the building of layers on top of layers, and while it’s not quite ready to go to market, “the fundamentals are there to take it from 2D to 3D space.” Polyester screen printing is usually pretty heavy, but Kornit’s technology can create more lightweight layers on shirts. Mann said the shirt he was wearing featured 1.4 mm layers—about the same as puffy paint. The applications include screen printing, heat transfer, and the vinyl look.

“XDi enables ease of use, multiple effects, and is process-certified,” Mann said. “It’s a tool for the workflow.”

The solution can also help in pursuing new applications and leveraging business cases. He explained that there are many different types of stitches, but XDi can make the three most commonly used in embroidery, including counter stitch and step stitch. In addition to functional inks, XDi also enables special effect inks, such as glitter and luminescent.

“So how can Kornit transform this industry to pure digital?” Mann asked. “We started some ideations, which is why we acquired additive manufacturing companies, so we can use complementary technology to transform the market into decoration. Our hybrid equipment can bridge all the different equipment that’s out there.”

Mann told the room that Kornit is “polluting in a sense,” but still has a goal for the future to decrease its waste and usage of energy and water, and minimize how many harmful chemicals it uses. Specifically, Kornit is looking to lower its VOC usage by 40%.

Specifically, Kornit is looking to lower its VOC usage by 40%.

He said Kornit’s hybrid printing solution will “enable reduced curing time by half,” which will also help reduce energy. Additionally, the electricity saving for the company’s next-generation dryers is about 40%.

Moving at the Speed of Culture

Next, Bobby Sims, a serial founder of companies who works as a strategic advisor to big brands like Coca Cola and H&M, talked about “Moving at the Speed of Culture.”

Sims said while we may think we’re “still in the internet era,” post-COVID we’re actually in a culture and creativity era, as everyone is becoming a creator. He said that clothing is now the highest priority for Gen Z teenagers, as opposed to food. This is obviously good news for companies like Kornit.

Major takeaways from this presentation include the move from Web 2.0, which Sims called a “flat system” that connected people and platforms, to the spatial Web 3. 0, which connects people to digital spaces and assets, like NFTs. For example, he said the first digital dress sold at the end of 2021 for $9,500, and that 108,000 attendees—including Versace—were at the Metaverse Fashion Week by Decentraland, which focuses on skins for avatars. Sims said creators are driving this change to the “digitization of everything,” but that instead of being creator-powered, where influencers help sell products, it’s more creator-led, “where the industry provides access to the supply chain.”

0, which connects people to digital spaces and assets, like NFTs. For example, he said the first digital dress sold at the end of 2021 for $9,500, and that 108,000 attendees—including Versace—were at the Metaverse Fashion Week by Decentraland, which focuses on skins for avatars. Sims said creators are driving this change to the “digitization of everything,” but that instead of being creator-powered, where influencers help sell products, it’s more creator-led, “where the industry provides access to the supply chain.”

Transforming the Supply Chain

Next up was Aaron Yanelli, President of KornitX, which gives stakeholders the tools they need to generate more revenue and digitally transform the supply chain.

Yanelli said that on-demand manufacturing will “change the world for the better,” and that Kornit is addressing the demand for this by reducing over-production, opening new revenue streams, enabling smart routing to its Global Fulfillment Network (GFN), and leveraging social media with direct purchase links for a better customer experience.

“Everywhere we go is an opportunity for commerce,” he said.

He brought up a couple of case studies, the first of which was with retailer Next. Yanelli explained that Next wanted to move faster, while also creating a better customer experience and saving money, and that Kornit is the retailer’s virtual warehouse. Through its integration, Kornit introduced personalization to Next, so customers can go in and customize what they want.

The second case study was with the Hut Group (THG), a British e-commerce retailer that operates over 100 international websites, bringing brands directly to the consumer through its platform. Yanelli said THG found Kornit because it was looking for an end-to-end workflow solution, and “thought ours was better than anything else.” He explained that KornitX is a full-fledged software platform with “hundreds of different solutions and mechanisms.”

He called KornitX “an enabler” of true on-demand. As more businesses look for multi-channel options, the flexible platform can “back into anything where an e-commerce transaction can take place and pull this together. ” Yanelli said to think of KornitX as a buffet, where you can eat everything, or pick and choose.

” Yanelli said to think of KornitX as a buffet, where you can eat everything, or pick and choose.

“The online experience is intended to be seamless, easy, simple,” he said. “You don’t have to click out and go somewhere else. Everything feels like it’s one visit and transaction.”

The customizable, agnostic platform enables on-demand manufacturing from start to finish, including product development, network services, and shipping and logistics. Users simply pick the product, add the artwork, publish to an eShop, route to a relevant fulfiller, fulfill on a digitized shop floor and ship to the warehouse, store, or consumer, and finally confirm the details and receive the payment. It also offers “simple highlights,” like 3D product display, direct purchase links, smart routing, and more.

“So how do people get more comfortable buying attire in a nontraditional manner?” he asked. “They need a good experience to see if it will look good on them, and we enable that.

”

Yanelli said by combining software integration with new technology, Kornit is changing brand integrity.

“If I’m talking about my brand, it matters, the quality and consistency and consumer experience matter. It should be like Christmas morning every time.”

He said the company’s Global Fulfillment Network (GFN) enables distributing and printing, and while not a revolutionary idea, “it’s revolutionary how we enable it,” using proximity production, smart routing, integration, and more.

“The opportunity is simple—capture new opportunities while you keep business going at its best,” Yanelli said. “KornitX makes customized demand possible in high capacity, at any time and location, with no inventory risk. Think about the power if retailers and brands really believed this.”

Yanelli explained what’s coming next for KornitX, which is a wider geographical spread to increase the capacity of its GFN.

Trends in Fashion’s Future

The day’s final presentation was by Lior Fisher Shiloni, who owns The Visionary trend forecasting company.

She explained that trends “start quietly in the margins” before slowly entering the mainstream, while fads come in fast, get very popular very quickly, and disappear just as quickly. The company does a lot of multidisciplinary research, and in the textiles world, found that a major idea in 2021 was “tension between crisis and breakthrough.” This year began very chaotically, and has remained turbulent, so the company defined “extremum” as a mega trend for the next few years.

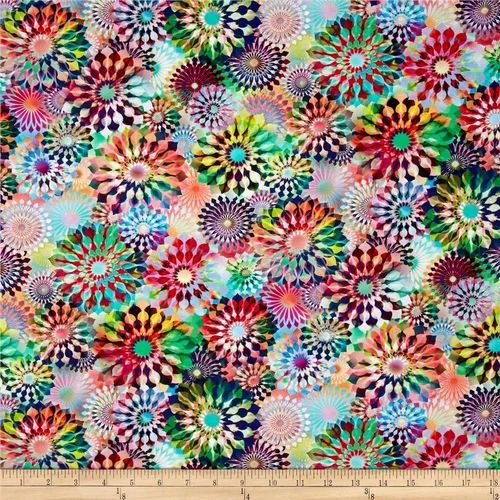

The first existing key trend Shiloni identified is in meta-textiles, and digital, neon colors, have been all over the runways; we definitely saw this at the Yanky & Nataf fashion show the day before. Meta-prints is a computerized idea, but it can be seen on textiles, along with the glitchcore microtrend. She explained that virtual textiles are “portals between the physical and virtual worlds. ” For instance, the textile might react to human touch, but once you’ve wearing VR goggles and your avatar interacts with it, the reaction occurs in both the physical and virtual worlds.

” For instance, the textile might react to human touch, but once you’ve wearing VR goggles and your avatar interacts with it, the reaction occurs in both the physical and virtual worlds.

The next trends were hypernaturalism and the evolution of sustainability; examples were companies and brands looking for innovative solutions like creating textiles from plant roots, fruit leather, mushrooms, and more. The last major trend she mentioned was space, as we’re seeing “a cultural shift in society of people interested in living outside of Earth.” Fashion design is responding with elements like metallic textiles, tech wear focused on protection and functionality, and colors and patterns influenced by envisioning life in outer space.

This session closed out the afternoon for us, and we were taken back to the hotels, before enjoying dinner together in groups at various restaurants around Herzliya.

Making Inks

Courtesy of Globes, Israel business newsThe last day began with a trip to Kiryat Gat to see Kornit’s new scalable, state-of-the-art ink manufacturing facility. The groundbreaking of the modern, high-volume production facility took place three years ago, and process qualification was completed in 2021. The factory is in the ramp-up process now, with a “huge potential” for delivering Kornit consumables to customers.

The groundbreaking of the modern, high-volume production facility took place three years ago, and process qualification was completed in 2021. The factory is in the ramp-up process now, with a “huge potential” for delivering Kornit consumables to customers.

The facility includes offices, logistics, ink production, a lab, and a clean room, in addition to the large warehouse. We were told that Kornit has four main warehouses—one each in Chicago, Germany, and Hong Kong, and the main hub in Kiryat Gat.

The vertical warehouse is automated, with 60 drawers, and between two or three drawers, there are a couple hundred pallet positions. Each container has up to 40 pallets of ink. In addition, there’s also a temperature-controlled warehouse that stays at 30°C.

The new production plant for Kornit’s NeoPigment ink has three times the capacity than the previous facility, and in addition to an area for producing colored inks, there’s also a place for making white ink. The HMI system can transfer ink from section to section with just the touch of a button, and thanks to a monitoring system, multiple batches can be produced with the same color. This is a big deal, as the colored inks and white inks have a completely different chemistry and process. As for the container filling process, operators first check for leaks, and then the container is weighed and plugged; after another few necessary steps, it’s packaged up.

The HMI system can transfer ink from section to section with just the touch of a button, and thanks to a monitoring system, multiple batches can be produced with the same color. This is a big deal, as the colored inks and white inks have a completely different chemistry and process. As for the container filling process, operators first check for leaks, and then the container is weighed and plugged; after another few necessary steps, it’s packaged up.

In the quality control lab, every raw and intermediate material, and all finished products, are tested according to specification, as it’s all batch production. Kornit’s facility received the EccoTec certification earlier this year, and is hoping that it will receive the BlueSign certification for safety in the near future. Additionally, over 40,000 print heads are assembled at the facility each year.

On the Road Again

Once we left the ink manufacturing facility, we hit the road for lunch and sightseeing in Jerusalem, which was amazing. Then all that was left was the gala event that night, with more good food, drink, conversation, and another opportunity to see the amazingly colorful Yanky & Nataf runway show again. Right before I left the event for the night, the K-Band came on to perform, and the crowd was delighted to learn that it was a group made up of Kornit employees. I witnessed many Kornit team members get up to dance and support their colleagues, which made me smile; after all, this was a celebration of the company and all its hard work.

Then all that was left was the gala event that night, with more good food, drink, conversation, and another opportunity to see the amazingly colorful Yanky & Nataf runway show again. Right before I left the event for the night, the K-Band came on to perform, and the crowd was delighted to learn that it was a group made up of Kornit employees. I witnessed many Kornit team members get up to dance and support their colleagues, which made me smile; after all, this was a celebration of the company and all its hard work.

All in all, it was a fantastic trip, and I feel like I learned a lot. Screen printing is not my forte, but I overheard a lot of other visitors on my VIP tour excitedly discussing what Kornit’s technology can do for that industry, so that’s pretty exciting.

As for 3D printed fashion, a lot of it can be unwearable and pretty far out there, which is why I often say that fashion accessories like handbags, bow ties, and others are a more realistic application for the technology in the fashion world. But I was blown away by Kornit’s MAX digital printing technology and the XDi effects it enables. This solution seems like it might actually have staying power. Additionally, I was happy to hear of Kornit’s ongoing sustainability efforts, especially in the face of an industry as wasteful as fashion.

But I was blown away by Kornit’s MAX digital printing technology and the XDi effects it enables. This solution seems like it might actually have staying power. Additionally, I was happy to hear of Kornit’s ongoing sustainability efforts, especially in the face of an industry as wasteful as fashion.

Right now, it seems like the only true competition Kornit has is Stratasys. But, the company’s next Fashion Week is coming to London May 15-17, and I have it on good authority that Kornit will have more news to share, so it will be exciting to learn what else is going on there.

Enjoy some more pictures from my trip to Kornit in Israel below:

Repping 3DPrint.com in Jerusalem

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d fashion • 3d print fashion show • 3d print textures • 3D printed fashion collection • 3d printed sustainable clothing • 3d printed textiles • 3d printing on fabric • 3D printing presentations • ActiveLoad • apparel • apparel industry • automated system • custom clothing • customization • demonstration • digital decoration • digital supply chain • direct-to-fabric • direct-to-garment • Direct-to-textile 3D printing • DTG • embroidery • fashion industry • fashion show • garment industry • inkjet • inkjet printing • inkjet technology • israel • kornit • Kornit Apollo • Kornit Atlas Max • Kornit Digital • Kornit Presto Max • KornitX • mass production • microfactories • NeoPigment • on-demand manufacturing • polyester • printheads • prototype • Ronen Samuel • screen printing • supply chain • sustainable • tel aviv • XDi

Please enable JavaScript to view the comments powered by Disqus.

What is 3D printing - applying 3D images to fabric and souvenirs

Today, 3D printing on fabric is a fairly popular way to create exclusive items. This type of drawing, due to the visual volume and realism, easily attracts attention, which means that it will be in demand among people of different ages for a long time to come.

You can apply 3D drawings on different types of textiles, namely:

- On natural fabrics.

- For synthetic fabrics.

- For tarpaulin.

This type of print is also often used for large format printing, for example, for wallpapers, theatrical scenery or exhibitions. The range of use and application of this type of image is great, it would be a fantasy.

Wallpaper with 3D drawings can transform any space

For example, 3D printing on phone cases has also become a fairly popular service among the population. nine0003

nine0003

3D printing on fabric

In order for 3D printing to be applied by the desired method and the image to be bright and durable, it is necessary to take into account a number of factors when choosing the fabric on which the pattern will be applied. Namely, you need to pay attention to:

- Material composition.

- Structure.

- Density.

- Processing.

- Storage conditions for textiles.

Fabrics can be of textile and knitted weaving. Materials with textile weaving - jeans, linen, silk, velveteen, satin, and with knitted - footer, cooler, interlock, etc. nine0003

3D printing is an original way of applying high-quality images of any complexity to fabrics or clothes. Thanks to the latest printing technologies, such designs will perfectly behave after numerous washings and ironings. The main thing is to choose the right transfer method for the image.

There are several technologies for applying images of this type to textiles:

- Digital printing.

The image is applied directly to the fabric, without the use of additional media. nine0010

The image is applied directly to the fabric, without the use of additional media. nine0010 - Sublimation. A special dye is used that penetrates the fibers without changing the properties of the material.

- Screen printing. Drawing is applied through a special stencil by pushing paint, viscous consistency.

- Thermal transfer printing. Used film or paper, high temperature and heat press.

All of these 3D printing methods have their pros and cons. For example, digital printing is most often used because of its inexpensive cost, and the silk-screen printing method makes the image durable even on rough fabrics. But the sublimation method limits the client in the choice of fabric, as it is applied only to synthetic materials, but the colors of the image will remain for a long time. So if you need a print on a product that will not lose its appearance for a long time, then it is better to choose a sublimation printing method on a synthetic or semi-synthetic canvas. nine0003

nine0003

3D printing on fabric and not only from PROpechat

Today, few people do not know what 3D printing is. Images of this type can be used for different purposes due to the originality of the result.

For example, it is practical and profitable to use this type of pattern for advertising purposes to attract customers - printing a three-dimensional image of the company logo will clearly attract potential buyers or partners. So the considered option of applying a print is not only a way to transfer pictures, but also an excellent method of promoting a business. nine0003

And so, we draw conclusions. In order for the image to turn out as realistic and durable as possible, it is necessary to take into account only a few components:

- Choice of 3D printing technology.

- Selection of the material on which the image will be applied.

- Scope of the finished product.

3D printing on fabric and more is a great way to make an original piece of furniture, a souvenir, promotional items, etc. So turn on your imagination and act. Have questions? Call us right now or contact the manager online! nine0003

So turn on your imagination and act. Have questions? Call us right now or contact the manager online! nine0003

Stratasys Direct Fabric 3D Printing • Print Industry • PrintIndustry.ru

Digital printing

To read 4 min Posted by

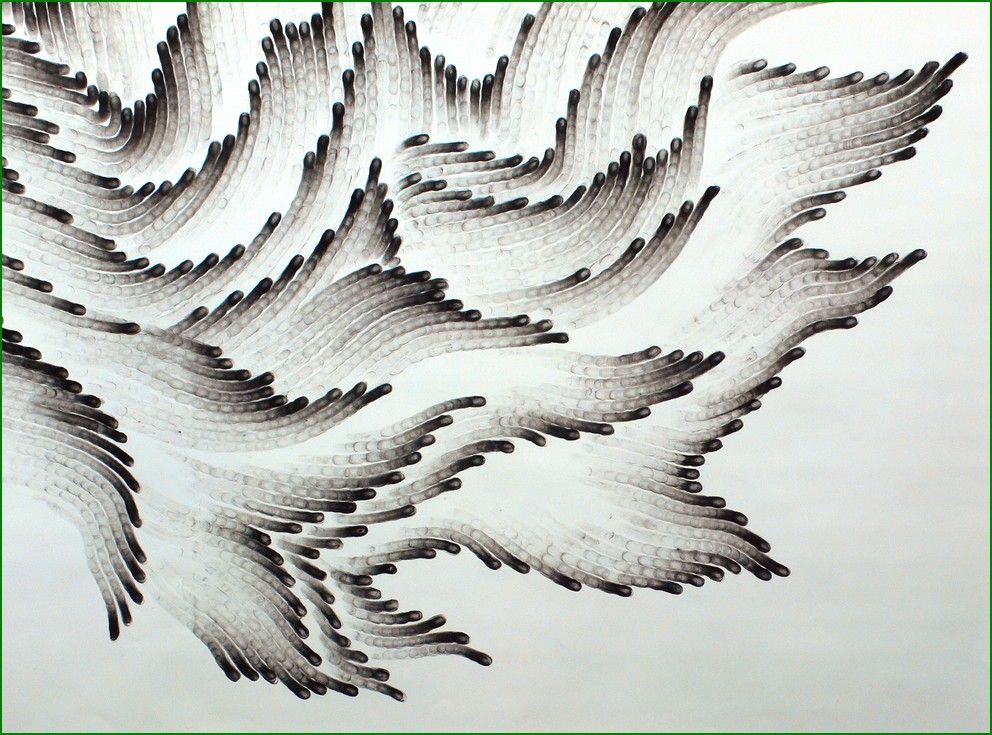

For the first time, the possibilities of direct textile 3D printing using technology developed by Stratasys were seen by guests of New York Fashion Week two years ago. Fashion brand threeASFOUR then presented the Chro-Morpho clothing collection, which was created in collaboration with fashion guru Travis Fitch, and is decorated with many small elements that mimic the play of light and color on the wings of insects. nine0003

The Greta-Oto dress, named after the lepidoptera of the same name, managed to achieve a lenticular stereographic effect, so that as the model walked down the runway, it literally came to life. Thousands of transparent microspheres with colored inserts distributed over the dress would previously have had to be 3D printed and then sewn on. But the resourceful Stratasys has found a way to simplify the process.

Thousands of transparent microspheres with colored inserts distributed over the dress would previously have had to be 3D printed and then sewn on. But the resourceful Stratasys has found a way to simplify the process.

Revealing the meaning of the proprietary technology, the creative director of the art, design and fashion firm Naomi Kaempfer noted that the main task here is the harmonious combination of volumetric elements and textiles, without excesses towards 3D: “Smooth, flowing fabric comes into contact with the skin, 3D printing decorates surface. It took several months of experimental testing to offer designers bold opportunities for the implementation of creative ideas. This will revive, complicate, make brighter and more attractive their models. nine0003

Naomi Kaempfer also announced Stratasys' intention to focus on the haute couture segment, where advanced forms of additive manufacturing could be especially in demand. “Over the past five years, we have seen 3D printing take more and more space in fashion design. Collaborations with well-known brands prompted us to focus on promoting the aesthetics of optical illusions. Thus, thanks to 3D printing, a new trend in fashion design is emerging on the market.”

Collaborations with well-known brands prompted us to focus on promoting the aesthetics of optical illusions. Thus, thanks to 3D printing, a new trend in fashion design is emerging on the market.”

A milestone in moving its solutions to the heights of the fashion industry for Stratasys could be the current collaboration with the Italian research and development laboratory D-House. It is the scientific division of the Dyloan production agency, founded in 1987, is committed to bringing innovative solutions to high fashion and the latest such innovation was printing on Woolmark merino wool knitwear on a Stratasys PolyJet J850 3D printer.

The Knitting of the Future project for Milan Design Week involved fashion designers from all over the world, a group of students from the Royal College of Art in London and several knitters from a factory in Italy. The principle of operation of PolyJet J850 is to apply a liquid photopolymer on the basis for the layer-by-layer formation of a natural texture - under the skin, wood, accurately conveying color nuances or maintaining transparency like that of glass. nine0003

nine0003

D-House co-founder Loreto Di Rienzo was impressed by the process: “What immediately surprised me about PolyJet was the color accuracy: we can achieve the desired color with maximum accuracy – this is not discussed in fashion design.” In addition, he noted, the breadth of application of the device gives incredible freedom of implementation: “Not only can we immediately print various textures and decor details on fabric, we can also include various functional elements in clothes. This allows us to offer outstanding visualization solutions to our clients.” nine0003

The Illusion jacquard coat by Vittorio Brancicio and Uroš Mihic with a four-colour 3D effect stands out in the knitwear collection of the future. The texture of the 3D print, which is an array of densely planted cubes, creates the illusion of iridescent colors that change depending on the viewing angle. The cubes on the back of the product are placed precisely so that their surface filters the light, creating a change in tones and shades.