Csu 3d printing

CSU Pueblo 3D Printing | Innovation Lab

EXPLORE THIS SECTION

What is 3D printing? How does it work?

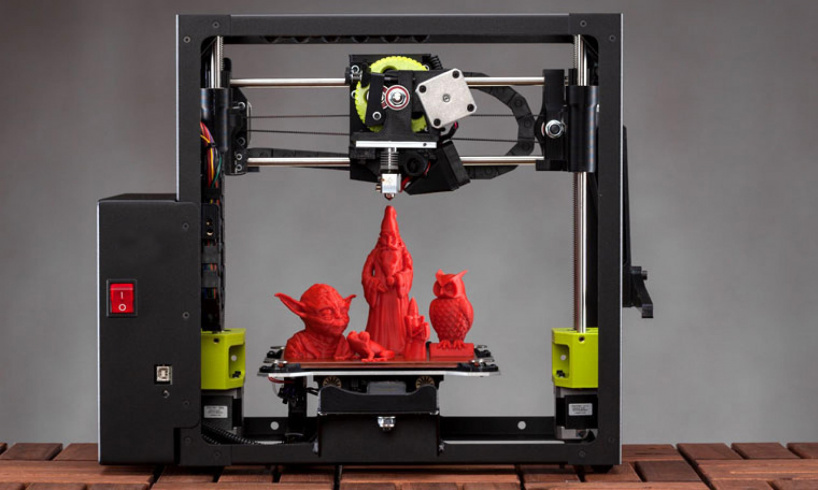

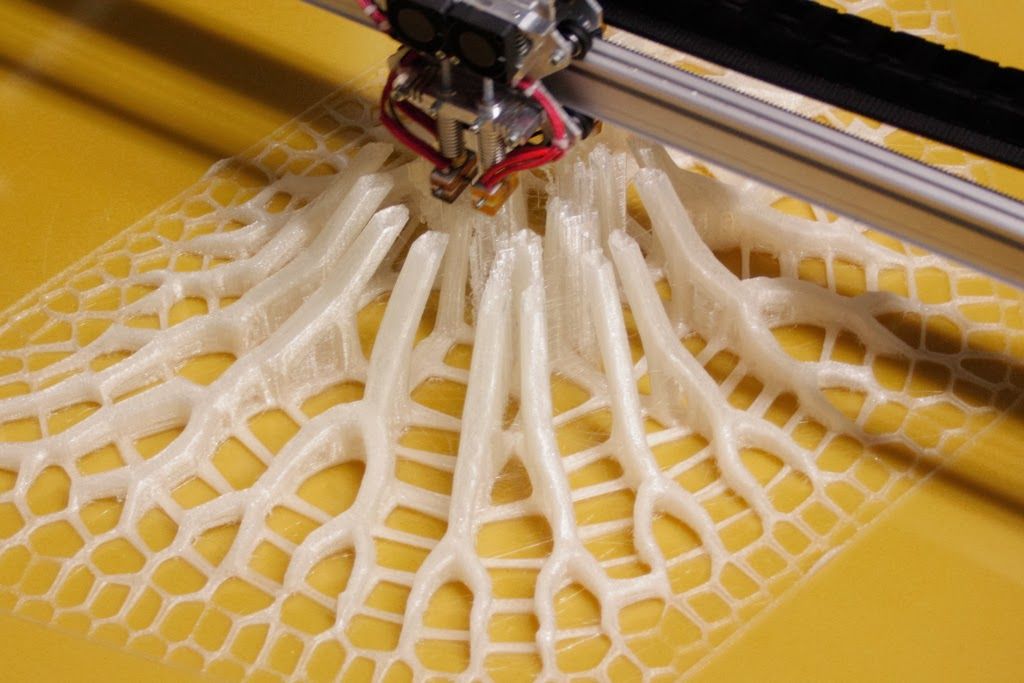

3D printing is the process of making a physical object from a digital model. Also called additive manufacturing, the physical model is built up one layer at a time. Our 3D printer feeds a plastic filament through a heated nozzle which melts the plastic. Computer-controlled motors move the nozzle around to create the shape of a layer, which hardens immediately. Objects are built this way, one layer at a time, from the bottom up.

What are some practical uses of 3D printing?

There are many practical applications for 3D printing, from aerospace and automotive engineering to prosthetics and other medical uses. 3D printing enables rapid prototyping of design concepts and functional, working models. Additionally, it is used for low-volume, custom, or on-demand manufacturing.

What software can you use to make printable 3D models?

Many different programs can produce printable 3D models. Most 3D modeling software will output the STL file type. Some popular options include SolidWorks, Inventor, 3DS Max, Blender, Creo, AutoCAD, Rhino 3D, Sketchup and Tinkercad. For beginners, we recommend starting with Tinkercad. It is web-based, optimized for 3D printing, and easy to get started with. Free 3D printable files can be downloaded from Thingiverse.

Request a 3D Print Job

What Equipment is Available?

Printers:

- 3x Creality Ender-3 Pro V2

Print Technology:

- Fused Deposition Modeling

- Build Volume

- 22.0 cm L x 22.0 cm W x 25.0 H cm

- Layer Resolution

- 100 microns [0.1 mm]

Software:

- Ultimaker Cura

- PrusaSlicer

- Simplify3D

File Types:

- STL

- OBJ

- 3MF

Scanner

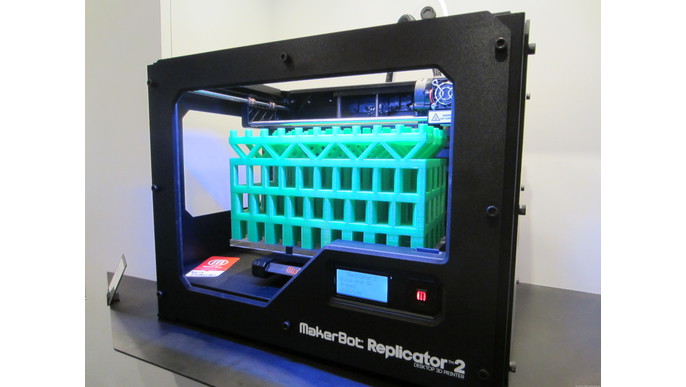

The MakerBot Digitizer outputs standard STL files that can be modified and improved in third-party 3D modeling programs. This is a fast and easy way to create 3D models, quickly turn the things in your world into 3D models that you can modify, improve, share, and 3D print.

This is a fast and easy way to create 3D models, quickly turn the things in your world into 3D models that you can modify, improve, share, and 3D print.

With just two clicks, the MakerBot Digitizer desktop 3D scanner's easy to use, yet sophisticated software creates clean, watertight 3D models that are ready to 3D print. It has optimized the whole process to work seamlessly with MakerBot Replicator desktop 3D printers, but you get standard design files to use on the 3D printer of your choice. You don't need any design or 3D modeling skills to get started, and it all happens in just minutes.

Who can print and scan?

The 3D printer and scanner are made available by Student Technology Fee grant funds, and as such, are available to CSU Pueblo students only. Initially, there will be no charge for printing. When the grant-funded supplies are exhausted, a nominal charge will be assessed based on weight for cost recovery.

Printing is done on a first-come, first-served basis. Priority will be given to objects for coursework. If an item is needed by a deadline, we recommend submitting it 5 days prior to the date.

Priority will be given to objects for coursework. If an item is needed by a deadline, we recommend submitting it 5 days prior to the date.

How do I get my file printed?

Users will need to fill out and submit the 3D Printing Request Form along with their file. A confirmation email to the address provided will be sent to verify that the submission has been received. Once the file has been printed, staff will send another email informing the user of the completion of the job. If you have several files to print, please submit each of these separately by filling out a separate 3D Printing Request Form for each print.

All submissions are subject to approval based on scheduling and availability. There may be times that the printer is malfunctioning, being repaired, or is being used for an event or a course. During such times, the 3D printer may be unavailable for use and there will be a delay in approving submissions and printing objects. Printed objects will be kept at the LINC Innovation Lab. After two weeks, objects will become the property of the University Library and may be displayed or disposed of at that time.

After two weeks, objects will become the property of the University Library and may be displayed or disposed of at that time.

For more information, check the University Library 3DPrinting and Scanning Policy.

Colorado State University Opens 3D Laboratory for Community Use

FORT COLLINS – David Prawel and Colorado State University’s Mechanical Engineering Department have begun a new program that assists entrepreneurs and others in the community with 3D printing while training students on this revolutionary new technology.

Prawel, a senior research scientist in the Department of Mechanical Engineering, has opened the Idea-2-Product Laboratory to the community so anyone can use this amazing 3-D printing equipment to create prototypes and products, repair parts, beautiful artwork, or virtually anything they can imagine. The lab is staffed by current and graduated engineering students who can provide design and printing expertise. Prawel charges a small fee to recoup costs of materials and maintenance.

“3D printing is very high-value technology that has been proven to increase innovation and accelerate time-to-market for countless entrepreneurs and companies,” said Prawel, who has 31 years of experience working with 3D software and companies, including six companies he helped create. “We provide the equipment and expertise; our users provide the ideas and innovation. You can’t steer innovation – you just have to provide the tools and put some water on it and let it go.”

“The lab currently has five, soon to be seven, machines that can print up to 18 types of materials and create intricate designs that couldn’t be created any other way,” Prawel added. One or two more machines are available for use in the Morgan Library depending on the demand for the machines in the laboratory.

“We’re already at capacity – we are running these machines full-time,” Prawel explained, noting that staff assists users until they’re are certified to use the devices themselves. “Users learn how to make their ideas become real products, and on the way they learn things like computer-assisted design and manufacturing and all kinds of things they’ve never thought of before. This helps satisfy the educational mission of our lab.”

This helps satisfy the educational mission of our lab.”

Erica Suchman, a professor in the CSU Department of Microbiology Immunology and Pathology, is working with the lab to develop 3-D printed models of virus-antibody models that can be snapped together to create unique epitope binding sites. This allows students to create different antibodies with specificity to different epitopes or shapes on the surface of 3D-printed viruses.

“These models will be given to the students in the class to manipulate creating different antibodies and exploring where on the virus these antibodies can bind, allowing them to visualize a difficult special concept,” said Suchman, who is in the College of Veterinary Medicine and Biomedical Sciences.

I2P software and equipment are funded by contributions from Autodesk, Lulzbot, Advanced Manufacturing Enterprises, the Mechanical Engineering Department and by CSU’s students through the university’s Student Fee Review Board. I2P would also like to acknowledge the vision and assistance of the Morgan Library for space, resources and technical support.

Free STL file of CSU Coin・3D printed model for download・Cults

Harry Potter's Golden Snitch

Free

Decorative Ornament Cage

Free

Best 3D Printer Files in the Miscellaneous Category

Harley Davidson Ashtray

Free

Candy Heart Box

Free

Pop Up Prints : Jackobox - Gift Box

2,50 €

Guimars missile launchers 1/16 and 1/25 scale

€24.45 -10% 22.01 €

Free

herbs Jar

0. 71 €

71 €

Mate Eva Perón

Free

Bestsellers in Miscellaneous category

Starbucks Studded Tumbler Inspired Keychain with Removable Screw Top Pill Box Hex

2.53 €

Wednesday item

€3.91 -20% 3.13 €

Wednesday Addams - Merlina Addams - Funko Pop

2.49 €

Eeveelution articulated mega pack

10 €

nine0003 Mounts for shock absorbers and trx4m escalators1.84 €

TING Addams

8.28 €

ITEMS-WEDNESDAY-COMPANY-HD-PRINT

€1. -24% 0.99 €  30

30

Gremlin rail 640 mm FPV

0.92 €

Starbucks Studded Tumbler Inspired Keychain with Removable Screw Top Pill Box Square STL File for 3D Printing

2,53 €

4th planet Fighting pre-Olympic god

12 €

Gengar - pokemon with flexible articulation (seal in place, without supports)

2,50 €

PS5 Horizontal stand

2 €

5 gnomes (without support)

2.49 €

Haslab Ghostbusters Proton Pack Ion Arm Box

5.69 €

Articulated Gyarados

1. 99 €

99 €

PINOCCHIO MOBILE GUILLERMO DEL TORO PINOCCHIO

2,93 €

Do you want to support Cults? nine0013

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online by following our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Chelyabinsk inventor patents a bioprinter for printing human organs

nine0005 MedicineOctober 21, 2022

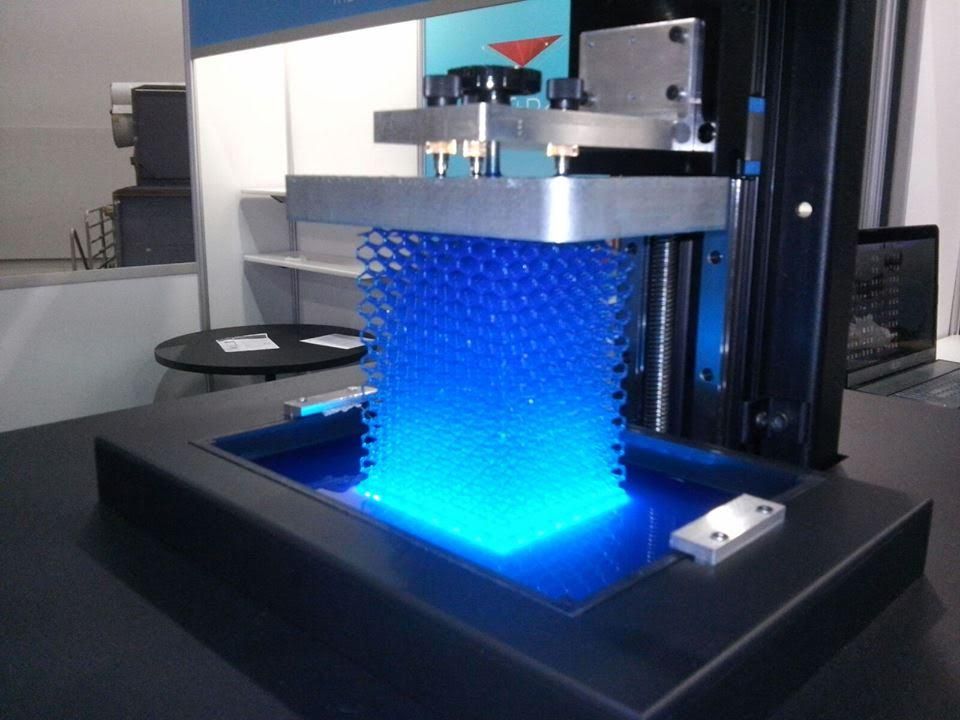

CSU physicist and biotechnologist Anton Trostin has filed an application with the patent office for approval of a 3D bioprinter assembled entirely from Russian components. He presented a device for bioprinting human organ scaffolds at an international scientific and practical conference.

He presented a device for bioprinting human organ scaffolds at an international scientific and practical conference.

The bioprinter, originally created from scratch by a ChelSU graduate student literally at home, brought to "mind" over several years by a number of important and significant modifications by its creator, looks harmonious and holistic. Presenting it at the conference, the young scientist did not exaggerate at all: the device was successfully tested, constantly changed and improved, became reliable, universal, today it has a low cost, unlike Western analogues. nine0006

Over the past few years, the device has learned to print structures of various organs from biological materials, for example, the auricle.

“This is a completely autonomous device for creating three-dimensional medical, biological or food products, as well as products from various types of plastic,” said Anton Trostin, “the versatility of the device is ensured by an originally made removable module with the possibility of sterilization, which allows it to be used as a material for printing various solutions, both used for medical or biological purposes, and in the food industry, as well as allowing the use of standard types of plastics for 3D printing. nine0006

nine0006

The accessibility of the device is ensured by the design of each part of the device in such a way that its full interchangeability with budget components is possible.

The design of the presented device allows it to be used in a variety of institutions with different budgets: these are biological laboratories where the creation of three-dimensional biological objects is appropriate (for example, the creation of prostheses for animals). Medical institutions: creating three-dimensional objects from various tissues (for example, prosthetics of bones, skin of joints), food industry, printing with food materials (for example, creating a three-dimensional model of a person from a photograph from chocolate). nine0006

Anton's application for a universal modified 3D bioprinter was accepted by Rospatent.

ChelGU

Medicine

18+

Chelyabinsk review online

Registered by the Federal Service for Supervision of Communications, Information Technology and Mass Communications (Roskomnadzor).