3D barcode scanners

3D Barcodes Explained | What are They and How Do They Work

The barcode system, which automatically transfers and processes data to the digital environment, comes up with many types. Thin/thick lines, big and small spaces, and one question in everyone’s mind, are barcode scanners scanning black lines or white spaces?

Bringing together today's technological developments, barcodes are now more than zebra stripes: QR Codes, 3D Barcodes, and so on.. And in this blog, we’ll dive deep into 3D barcodes, where they’re used, and its advantages over 2D barcodes. Let’s get started!

What is a Classical Barcode System?

Thick, thin black lines and white spaces that we see in the corner of our breakfast cereal or behind our protein bar are referred to as 1D barcodes in the industry. 2D barcodes are square and rectangular and the double-dimensional barcodes are also known as Data Matrix.

Barcodes are like the only living organism in the ecosystem, when alone. You only see a few meaningless lines. But when factors such as barcode readers, barcode printers, computers, barcode labels, and software come into play, it creates a huge barcode ecosystem and you have the only weapon that will perfect your operations.

What is a 3D Barcode?

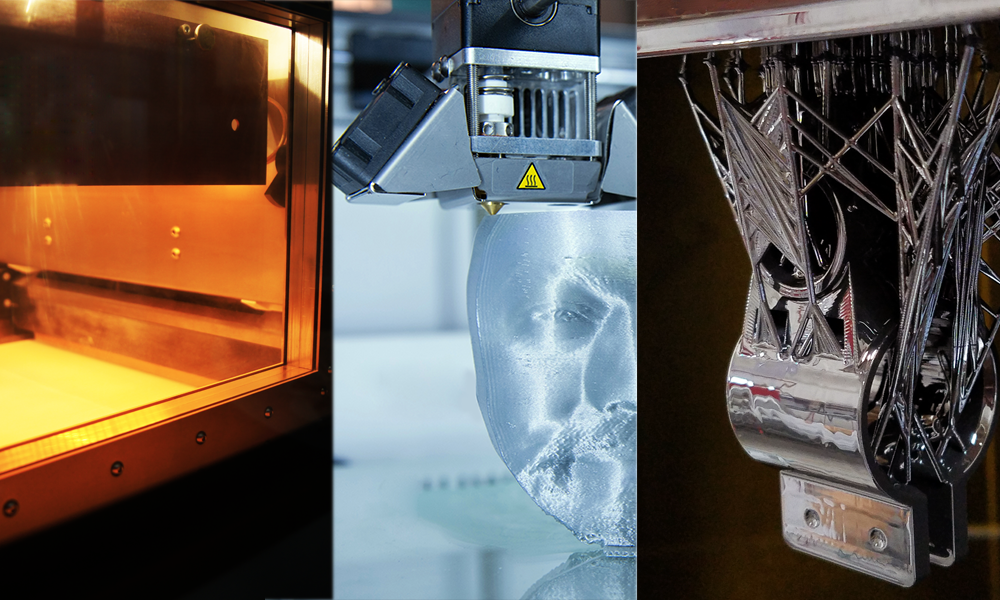

3D Barcode systems emerged quickly, filling a great necessity. Manufacturers realized that a new system was needed due to the high temperature, use of excessive solvents, chemicals that caused the removal of conventional barcode labels with sticks in one motion.

They knew that if they continued to use traditional methods, they would have to disassemble the products one by one to make the data a whole. For this reason, the producers left the Village of Tradition. And the 3D Barcode system was created.

3D Barcodes have the same logic as linear and 2D systems. They’re engraved or placed on a product. 3D Barcodes are not stuck as labels, they are not deleted, their color is not lost, their lines are not lost. It is not a label or sticker, so it is very convenient in terms of practicality and ease of use. In 2D systems, the bars are read with the variances in the reflected light, while in the 3D Barcode system the height of each line is taken as a basis.

It is not a label or sticker, so it is very convenient in terms of practicality and ease of use. In 2D systems, the bars are read with the variances in the reflected light, while in the 3D Barcode system the height of each line is taken as a basis.

The laser spends a certain amount of time reflecting back from the fill lines. This determines the height in the 3D Barcode with the distance and time formulas. In this way, a character is determined by the code and the data is processed in the system.

3D Barcode vs. 2D Barcode! Who will win?

2D Barcode Systems- It consists of lines

- Available on labels and stickers

- There are varieties such as DataMatrix, QR, PDF417

- is two-dimensional

- Error correction algorithms make misreading impossible

- Useless without costly code reader with image-capable base

- High resolution is important

- Also known as "Bumpy Barcode"

- It is processed on the surface of the product

- Can also be machined onto hard surfaces

- Withstands harsh environments - chemical, printing, manufacturing process processes

- Can also be used during production

- Its coding is based on heights and spaces

- Less error rate than other barcodes

- Readable even if overpainted

3D Barcode Systems Are the Superman of Which Industries?

3D Barcodes are used in many industries, including logistics, packaging, jewelry industry, art industries. This is quite logical considering the 2D tag that can be torn off in case of theft of a piece of art or jewelry.

This is quite logical considering the 2D tag that can be torn off in case of theft of a piece of art or jewelry.

But the main sector of the starting point of his invention is production. As we mentioned at the beginning, although 1D and 2D barcode systems are now traditional, most manufacturers do not find them practical. 3D has started to be the first choice of every manufacturer working with intense chemicals and together with very valuable products.

Your 3D Barcode System Operations Offer:

- More reliability in the scanning process

- A barcode system that can be read in more difficult environments

- Increased safety of valuable products

- More durability

- The ability to use barcodes also in the production process

- The ability to use barcodes in the logistics and purchasing

- ALL COLORS, not just black & white!

In addition, 3D barcode systems make it almost impossible to change or even block barcode information.![]() This means fewer inventory errors. All these lower the operational costs of a manufacturing process. A manufacturer's dream!

This means fewer inventory errors. All these lower the operational costs of a manufacturing process. A manufacturer's dream!

So, Are Today's Most Popular Barcode System QR Codes and 3D Barcodes Competing on the Same Lane?

The answer is a yes, and no.

Both systems are based on barcodes, but they have different usage areas and structural differences. QR (Quick Response) system, as the name suggests, is to quickly direct the scanned barcode to the linked link. QR Codes are often used in more post-production processes such as sales, entertainment, cafe/restaurants, and advertising.

While 3D Barcode systems are used in the production itself, they can also be seen in the post-production process. However, thanks to its features such as being more durable and being able to be processed into the product, it is the golden key of more difficult processes.

They both serve the same purpose and use different channels and processes.

The production process of 3D Barcodes is like the fertile rainwater of the Amazon ecosystem. Now you know why!

3D Barcodes - Barcodes Inc.

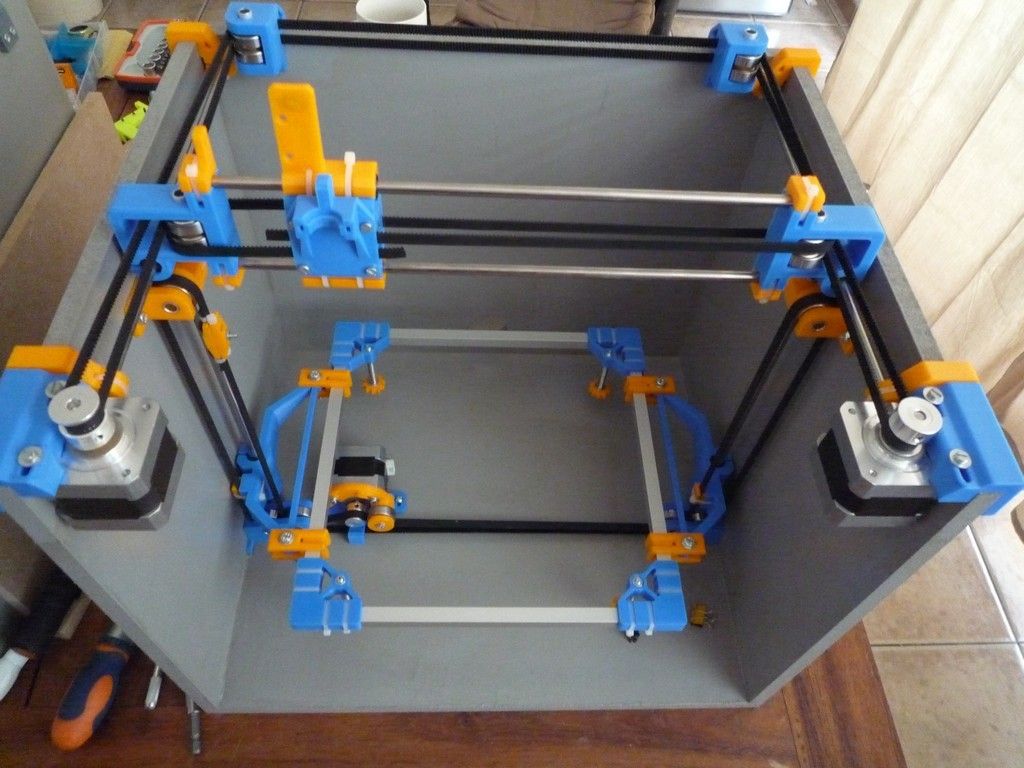

A Brief Explanation of 3D Barcodes – What they are and how they are used.In recent years manufacturing companies have been trying to implement a barcoding system similar to the barcodes for purchases and the retail industry. The only problem is that in manufacturing there are high temperatures, extreme solvents being used, as well as a wealth of chemicals and processes that inhibit the use of a label with bars on it. The manufacturers need to identify individual parts and not just the entire batch as it has been done for years. They wished to improve their inventory and tracking system – and have done so through the use of 3D barcodes.

What are 3D Barcodes?3D barcodes use the same basic principle as linear and 2D barcodes. An image of some sort is applied to a product and then read by a device to log, categorize, inventory, or track an individual product. As previously stated, the manufacturers need a more permanent solution than a label or sticker. The 3D barcode is engraved or applied to the product itself as a part of the manufacturing process. The bars are not read by variances in reflected light as with linear barcodes but by determining the height of each line. The time it takes the laser to bounce back and be recorded determines the height as a function of distance and time and the character represented by the code can be interpreted.

As previously stated, the manufacturers need a more permanent solution than a label or sticker. The 3D barcode is engraved or applied to the product itself as a part of the manufacturing process. The bars are not read by variances in reflected light as with linear barcodes but by determining the height of each line. The time it takes the laser to bounce back and be recorded determines the height as a function of distance and time and the character represented by the code can be interpreted.

3D barcodes are embossed on the product and the scanner recognizes new characters in the string by the lower regions of the code. This works in much the same way as the white lines or spaces in linear barcodes. The gap allows the system to record a new height of a line, and thus a new number or alpha character. The 3D barcodes also make it nearly impossible to alter or obstruct the barcode’s information and results in fewer inventory mistakes and in turn lowers operating costs of a manufacturing process. The code can be part of the manufacturing process or applied after with a press.

The code can be part of the manufacturing process or applied after with a press.

A direct part mark (DPM) barcode reader for 3D barcodes captures the reflected image after passing a laser over it; the same laser technology used in home digital or office scanners for documents and images. Once the data has been recorded it is digitized and a digital processing unit is employed to interpret the image. Since the system works on height variances the addition of color or paint has no effect on the end result, especially since manufacturers are extremely precise with the application of paint in regards to the thickness of the coat which could, but does not, affect the height of the 3D barcode.

The scanners of 3D barcode technology can be found in handheld versions as well as integrated into assembly lines as part of the process. They can be used to track a part on the line to assess efficiency of the production process, or to account for the number of man hours needed to create a single part. This can help reduce underpricing products and save the company on production costs. The 3D barcodes can, of course, still be used as an inventory system and for purchases. The parts in question are each scanned before being placed on a truck or train and can then be verified when delivered. The 3D barcodes will become more prevalent in manufacturing in the coming years and will drastically affect the costs and savings of industrial manufacturing companies.

This can help reduce underpricing products and save the company on production costs. The 3D barcodes can, of course, still be used as an inventory system and for purchases. The parts in question are each scanned before being placed on a truck or train and can then be verified when delivered. The 3D barcodes will become more prevalent in manufacturing in the coming years and will drastically affect the costs and savings of industrial manufacturing companies.

from trading to 3D modeling

Few people know that barcodes as we are used to seeing them first appeared in 1949. However, it became possible to use this technology only by the end of the 1960s, with the advent of computers and lasers.

The official birth of barcodes can be considered April 3, 1973, when the most popular version of the barcode to date, the UPC (Universal Product Code), was developed. It is worth noting that the first barcodes were different from their contemporaries and looked like a circle for easier reading by barcode scanners.

This article will describe areas where barcode scanners are actively used to identify encoded information: from trade to 3D modeling.

1. The most popular barcode scanners have received in the field of trade, for which they were developed. With their help, goods are identified when they arrive at the warehouse, inventory, and are sold in the store. At the same time, in stores, goods can be assigned internal barcodes for more detailed accounting. The data that is read by barcode scanners is processed by accounting programs and presented in the form of tables and reports.

2. Barcode scanners are also widely used in medicine. Each incoming patient is assigned an identification number with a barcode, which is subsequently associated with a medical history, prescribed medicines and procedures, test results, etc. Instruments can be marked with a barcode - this way the history of their use and sterilization is tracked, the period of their replacement.

3. All transport companies, express delivery companies, airports use bar coding to mark cargo and baggage. By reading the encoded information using a barcode scanner, you can easily and quickly transmit information about the location of the cargo, the operations performed. Thus, the probability of loss is reduced, and the search is accelerated if the loss does occur.

All transport companies, express delivery companies, airports use bar coding to mark cargo and baggage. By reading the encoded information using a barcode scanner, you can easily and quickly transmit information about the location of the cargo, the operations performed. Thus, the probability of loss is reduced, and the search is accelerated if the loss does occur.

4. Barcode scanners are used in the production of goods and mechanical engineering. The use of barcodes allows you to obtain accurate data on the work performed and the products manufactured. By tracking product elements at each stage, managers can avoid bottlenecks in production processes and overproduction, increasing efficiency.

5. Many libraries use a barcode-based accounting system, and therefore a barcode scanner is also indispensable. With the help of this technology, not only the service of readers is accelerated, theft protection, control over the location of books, etc. are provided.

6. Barcode scanners are indispensable in organizations that keep records of documents by barcode.

7. Barcode scanners are also used to organize a pass system for various events. This eliminates the possibility of getting to the event with one ticket for several people.

All of the above methods of using barcode scanners are generally similar to each other. However, there is another one that has nothing to do with accounting and barcoding, but in which barcode scanners can be used.

8. In 3D modeling, it is also possible to use barcode scanners, reducing the cost and speeding up this process several times. Simple models do not require a lot of time and work from a professional. But if you need to recreate more complex details (for example, complex figurines, decorative elements), it will take much more effort and time.

Using an omnidirectional barcode scanner with specialized software (eg DAVID-laserscanner) helps simplify this procedure. Also, using a multi-plane scanner, you can create three-dimensional sketches. The main thing is to make sure that the scanning beam does not fall into the eyes.

The use of barcode scanners is associated with the widespread use of barcodes. Recently it became known that an anti-counterfeiting 3D barcode has been developed. A certain recess corresponds to its own number from 0 to 9. It will be possible to read a 3D barcode only with the help of an interferometer or a special laser scanner, which is currently under development.

Despite the invention of other methods of identification, simple and inexpensive barcoding technology continues to be used, and along with it, barcode scanners do not stop developing.

Compass-S Distribution of equipment for business automation

Compass-S Distribution of equipment for business automation Log in

Register now!

Distribution of equipment for

business automation

Tel.: (495) 691-96-25

Tel.: (495) 690-18-54

Tel.: (495) 695-74-49

Tel: (495) 646-84-98

- About company

- News

- Catalog

- Label printers (barcode)

- Barcode Scanners

- Data terminals

- Slot card readers

- Price checkers and info kiosks

- Manual label applicators

- Label winders

- Industrial marking

- Industrial Label Applicators

- Data collectors

- Magnetic card encoders

- Ribbons for label printers

- Consumables

- Cash register equipment

- Cable marking equipment

- Software

- Sensor Monoblocs

- External label roll holders

- Service and support

- Service Center, drivers and software

- Download instructions

- Product certificates

- TSC printers discontinued

- Non-warranty case!

- Regions

- Articles

Contrary to what some people say, the Data Matrix and QR code are not 3D barcodes (for that matter, UPC and Code 128 are not 2D either). Recall from a high school geometry course: data encoded along the x-axis or along the y-axis is a one-dimensional or 1D barcode. Data encoded along the X and Y axis is a two-dimensional or 2D barcode. Thus, data encoded in three planes: X, Y and Z is a 3D barcode.

Recall from a high school geometry course: data encoded along the x-axis or along the y-axis is a one-dimensional or 1D barcode. Data encoded along the X and Y axis is a two-dimensional or 2D barcode. Thus, data encoded in three planes: X, Y and Z is a 3D barcode.

Still, I wonder why 3D barcodes appeared, because for the vast majority of cases, a large data capacity is not required. In general, the 3D barcode arose from the need to use a barcode on certain parts in high temperature or aggressive chemical environments where a conventional barcode would not last long. To identify parts such as metal assemblies, methods such as engraving, mechanical, chemical, or laser etching are used to emboss a barcode image on the surface of the part. While these barcodes do not have the usual reflective elements (black and white, as we are used to) required for normal decoding, they do have a unique feature, a new property - height. Bars and spaces now not only have a length and width, they now also have a third dimension - Z. This means that a barcode can now contain more information, but despite this, this possibility is not the only driving force behind 3D code technology, this is just an added benefit, although the third dimension can be used to augment the encoded data, as long as the code should be thought of as a permanent marking overlay that can be used for a variety of purposes.

This means that a barcode can now contain more information, but despite this, this possibility is not the only driving force behind 3D code technology, this is just an added benefit, although the third dimension can be used to augment the encoded data, as long as the code should be thought of as a permanent marking overlay that can be used for a variety of purposes.

While the UPC symbol will continue to identify products across the entire market, the 3D barcode can combine these functions, also defining 1D and 2D barcodes, while having a separate element along the Z axis. In other words, every can of Coca-Cola carries the same UPC number throughout the market, from Alaska to California. The additional axis allows manufacturing to assign individual information in the overall product range; for example, a serial number or an individual license plate. The most common application of this method is in production, where important components must be uniquely identified and tracked. Other applications will no doubt be explored.

Other applications will no doubt be explored.

Although 3D barcode scanners are quite specific, we are not talking about exotic here. Portable versions are quite affordable, as are stationary scanners that can be mounted in a pipeline or run in other embedded systems. And precisely because 3D barcodes don't rely on reflective distinctions between bars and spaces for decoding, they don't have the color rules restrictions that normal barcodes follow. 3D barcodes can be painted or anodized, while retaining their data storage and retrieval properties.

3D barcodes also do not need an error detection or correction algorithm, as they are exceptionally reliable and almost immune to damage. This factor also makes them suitable for some security applications in order to be able to accurately identify those items that are susceptible to theft. Microscopic versions of 3D barcodes can be used to mark gemstones or works of art. A more widespread application of the 3D barcode could be the labeling of medicines.