Zprinter 850 3d printer

3D Systems Launches New ZPrinter® 850

ROCK HILL, S.C. - 3D Systems Corporation (NYSE:DDD) today announced the immediate availability of its new ZPrinter® 850, the largest format ZPrinter® with higher print volume, greater productivity and vibrant full color that empowers designers, engineers, and architects to create more and larger parts faster.

With double the print volume of the its best selling ZPrinter® 650 and the same premium color printability, the ZPrinter® 850 is the only high speed, large format printer for professionals that need to create more at every stage of the design and development process.

"This is just what we've been looking for," said Wesley Wright, a designer at the Pelli Clarke Pelli international architecture firm. "The larger print format provides the flexibility to work in standard scales, see greater detail and increase our overall capacity. The ZPrinter® 850 will be great for business."

"We're ZPrinting footwear designs nonstop, and the additional capacity will help us better meet the demand of our R&D teams," said Dave Schwirian, model shop/RP manager for Nike. "The ZPrinter® 850 could also open up new uses for sporting equipment where we really need larger, colorful prototypes. I'm certain we'll see a huge demand for this new in-house capability."

The ZPrinter® 850 offers:

High speed: ZPrinters are the world's fastest 3D printers - 5 to 10 times faster than other systems, enabling parts production in hours, not days.

Ease of use: The ZPrinter® 850 provides fully automated set-up and monitoring, no-touch powder and binder loading, and automatic powder recycling.

Affordability: ZPrinters offer economical per-part cost, higher productivity and lower waste than other 3D printers.

High resolution: 600 x 540 dpi produces parts with fine detail and accuracy.

Top-of-the-line color: ZPrinters are the only 3D printers capable of printing simultaneously in full, vibrant color. The ZPrinter® 850 includes five print heads - clear, cyan, magenta, yellow and black - that deliver the highest quality and consistency in 390,000 unique colors plus hundreds of thousands of possible color combinations.

"Our customers have been asking for more and bigger full color parts and the ZPrinter® 850 delivers," said Buddy Byrum, vice president of channel development and product management, for of 3D Systems. "This new large-format professional printer magnifies our speed, color and affordability advantage making it most valuable for our customers throughout their entire ideation to production."

About 3D Systems Corporation

3D Systems is a leading provider of 3D content-to-print solutions including 3D printers, print materials and on-demand custom parts services for professionals and consumers alike. The company also provides creative content development, design productivity tools and curation services and downloads. Its expertly integrated solutions replace, displace and complement traditional methods and reduce the time and cost of designing new products by printing real parts directly from digital input. These solutions are used to rapidly design, communicate, prototype and produce functional parts, empowering its customers to create with confidence.

More information on the company is available at www.3dsystems.com

ZPrinter 150 3D Printer - Buy 3D Printer

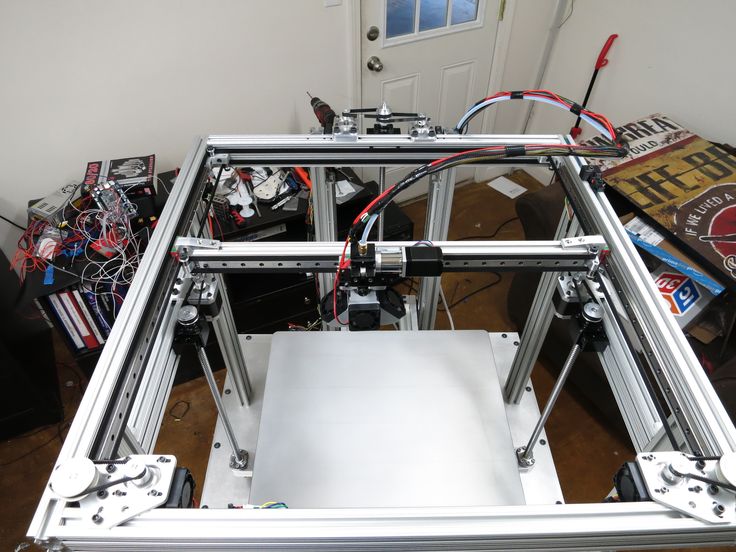

Zcorp 3D printers utilizing the jetting technology are among the fastest professional printers on the market. Speed is what makes Zcorp printers truly unique. These are professional-grade, “no messing around” 3D printers.

Zcorp has a whole line of 3D printers from the pint-sized Zprinter 150 to the industrial workhorse Zprinter 850. They all use the same technology and are relatively inexpensive for a non-hobbiest 3D printer.

Zprinter 150

How do Zcorp 3D printers work?

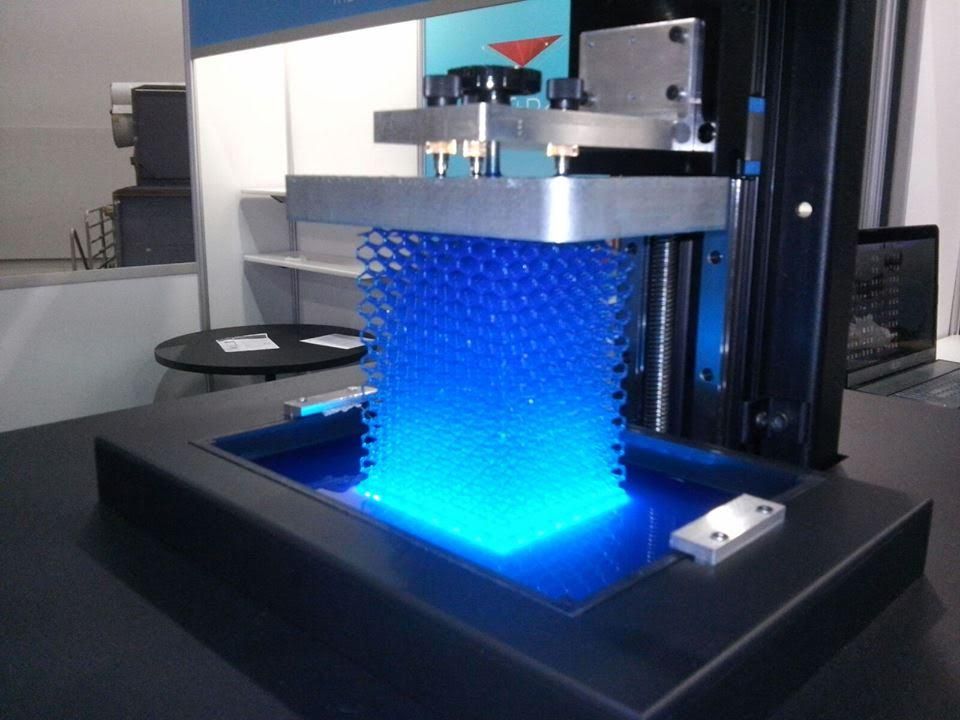

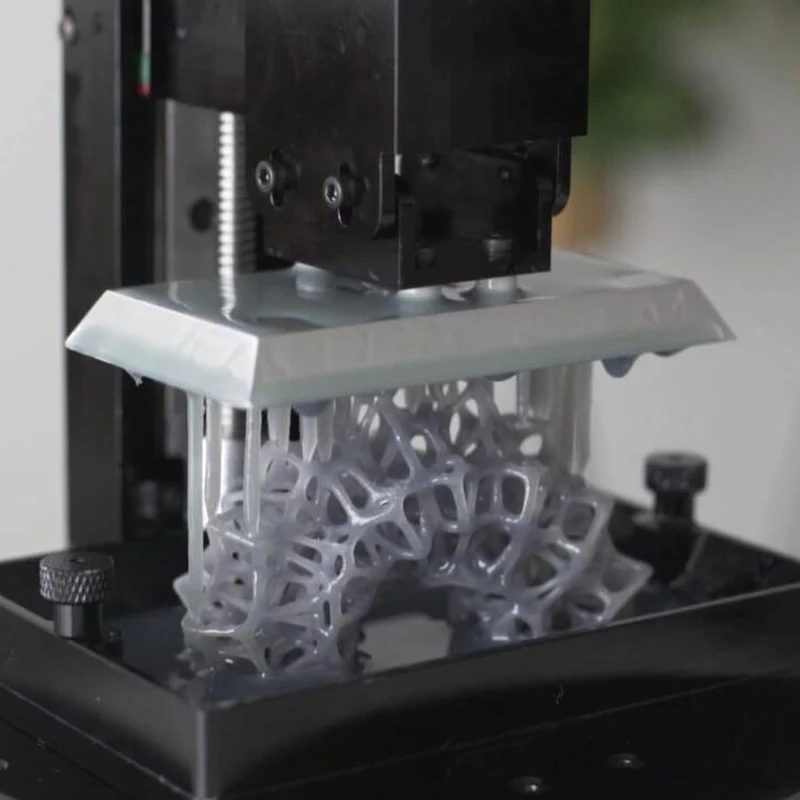

The printers utilize 3D inkjet printing, or jetting. It works by mimicking 2D inkjet printing – tiny specks of fine material are deposited onto a build platform through a printing head that resembles the one 2D printers use.

There are two sub-types of 3D inkjet printing: one which deposits a binder on a powder bed, and one which deposits powdered build material on a platform. Zcorp 3D printers utilize the latter process, letting you create models with high resolution and a smooth surface at high speeds.

Zcorp 3D printers utilize the latter process, letting you create models with high resolution and a smooth surface at high speeds.

However, jetting also has some disadvantages. One of them is a high cost of support material. As well, jetting printer materials are typically sub-par compared to conventional materials. Zcorp solves the latter problem with a high performance composite as its main material on its line of Zprinters.

The following video demonstrates Zcorp 850’s printing process:

ZPrinter 150 Tech Specs:

| Technology | Jetting |

| Frame size (Width x Depth x Height) | ~ 29" x 31" x 55" |

| Weight | ~ 365lbs |

| Build materials | High Performance Composite |

| Vertical Build Speed | Up to 0. 8" / hour 8" / hour |

| Accuracy | 0.1mm |

| Build volume (X,Y,Z) | 9.3" x 7.3 " x 5" |

| Price | Starting at $14,900 at EMS USA store, call 704-527-8171 to purchase materials. |

Contacting Zcorp:

ZCorp as a separate business entity was purchased by 3D Systems in early 2012. You can see the line-up of Zcorp printers at www.zcorp.com.

The 3D Systems Corporate Headquarters:

333 Three D Systems Circle

Rock Hill, SC 29730 USA

Tel: +1 803 326 3900

Twitter: @ZPrinting

Just getting started? Check out the following 3D printing:

User’s Guide to Rapid Prototyping

Looking for some training and other resources? Anvil Prototype offers seminars and other information on the ZPrinter series.

ZPrinter 150 Pros:

Zcorp 3D printer is very, very good. It’s fast, it’s accurate, and it’s cost isn’t exorbitant for a business model. The high composite material makes the ZCorp printers shine..jpg) The zp150 material can be sanded, drilled, tapped, painted and electroplated.

The zp150 material can be sanded, drilled, tapped, painted and electroplated.

ZPrinters are professional models, which means that they don’t require tweaking and tuning. They will work when you plug them in. The Zprinter 150 is a very straightforward to use. Backed by a large company like 3D Systems, you can expect reliability and dependable support.

Zprinter 150 Cons:

The higher model ZPrinters, like the 850, can print in a range of colours, but unfortunately the Zprinter 150 can only print in monochrome white. It has only one printer head, so if colorful pieces are your thing, you may have to splurge on a beefier ZPrinter model.

The choice of material, while allowing for construction of robust parts, is still limited. The speed is dependent on the volume of prototypes – the larger the volume, the faster the process. For this reason you might want to stick to other printers if you wish to print small models.

Due to the nature of the support material process, the extraction of the finished part can be a bit of a hassle.

The bottom line:

The only real problem with the ZPrinter 150 is its limited material choice. Everything else – its speed, accuracy, surface finish, cost – is all on par with what you would expect from a professional grade 3D printer.

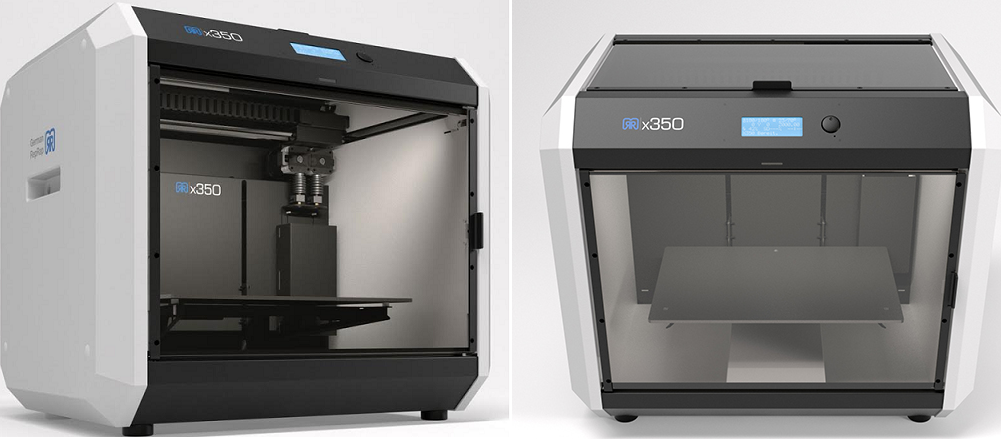

3D printer 3D Systems ProJet 860Pro (ZPrinter 850)

0 reviews

- Description

- Characteristics

- Reviews

3D Systems ProJet 860Pro (ZPrinter 850) 3D printer allows you to print color products and is equipped with a large camera.

Features:

nine0007

The model has good color reproduction and is capable of rendering 390,000 shades, quickly aligns objects and has a simple user interface. As a consumable material, a special powder is used, which contains gypsum. The device is used for printing products in construction, development of new designs, design, marketing and the field of general goods. Printing is carried out according to the principle of layer printing: powder particles are glued together with a liquid-based adhesive, which is applied by the print head. The composition is applied in layers in accordance with the preset settings and quickly hardens. After complete construction, the model is simply removed from the powder, and the rest can be used in the next print. nine0007

The device is used for printing products in construction, development of new designs, design, marketing and the field of general goods. Printing is carried out according to the principle of layer printing: powder particles are glued together with a liquid-based adhesive, which is applied by the print head. The composition is applied in layers in accordance with the preset settings and quickly hardens. After complete construction, the model is simply removed from the powder, and the rest can be used in the next print. nine0007

Materials used:

Printed with a special material based on gypsum - VisiJet PXL Core. The powder particles are white, and the VisiJet PXL binder gives the model a tint.

Contents:

- Printer;

- Instructions;

- SW.

Software:

The printer can be controlled remotely using the 3DPrint software. An Ethernet cable is used to connect to a PC, and files are broadcast in many popular formats. nine0007

nine0007

Product examples:

Video review:

- performance5-15 mm/h

- Dimensions, mm11190 x 1160 x 1620

- Software 3D PRINT, 3D EDIT

- Country

- Automatic cleaning of the working platform 9000

- built-in component Cleaning

- Number of nozzles 1520

- Minimum layer height0.5 mm

- Printed

- Resolution, DPI600 x 540

- Signal printing mode

- Material Material

- Office of the working chamber508 x 381 x 229 mm 9000 industry

- Number of printheads5

- Materials usedVisiJet PXL

- Layer thickness from 100 µm

- Print colorColor

- Weight, kg363

Recommended to look at

- 3D printer Ultimaker 2 Extended Plus 0 Product discontinued

- 3D printer BigRep One v3 0 Preorder

- 3D printer DigitalWax (DWS) 029X 0 Pre-order

- 3D Printer EnvisionTEC Perfactory Mini Desktop Digital Shell Printer 0 Preorder

- 3D printer EnvisionTEC Perfactory 3 Mini Multi Lens 0 Pre-order

- 3D printer EnvisionTEC Xede 3SP 0 Preorder

- 3D printer EnvisionTEC Perfactory 4 Standard with ERM 0 Pre-order

- Felix Pro 1 3D printer 0 Product not available for order

Accessories for ZPrinter 3D printers

|

Genlab Waxing System

Waxing is an economical, quick and easy-to-use method for impregnating plaster prototypes. With the help of waxing, the strength of the products is increased and the quality of the color is improved. The system consists of two heating ovens. One heats wax with a temperature range of 40 to 100 degrees Celsius (melting point of wax 52°C) with a working chamber with a capacity of 40 liters and an oven for heating gypsum prototypes with a temperature range of 40° to 250°C. The system is suitable for location in any office space. Does not require air extraction systems. nine0007

Oven for heating OV/100/SS/F/DIG

Oven for heating gypsum prototypes with a volume of 100 liters and a temperature range from 40° to 250°C. The body of the stove is made of steel and coated with powder paint, which is easy to clean. The inside of the chamber is made of stainless steel. Inside the stove there are guides for shelves. The furnace is completed with lattice regiments.

The furnace is completed with lattice regiments.

The control system includes a microprocessor controller with two displays for displaying the current and set temperature. nine0007

Heating is provided by a protected Incoloy heating element located around the fan on the side wall of the chamber.

- Suitable for finishing in 3D production.

- Volume 100 liters.

- Temperature range 40-250°C.

- Fluctuations ± 0.75°С.

- Stainless steel internals.

- The body is powder coated for easy cleaning. nine0004

- Internal dimensions (cm): 45 (height) x 49 (width) x 46 (depth).

- External dimensions (cm): 56 (height) x 85 (width) x 61 (depth).

- The control system consists of a microprocessor controller with two displays showing the current and set temperature, an independent thermostat, a temperature controller and a heating indicator.

- Ventilation system. nine0003 Complete with 3 shelves, 4 positions possible. 220-240 V, power 1 kW, frequency 50 Hz, 1 phase.

Wax heating oven WTK100/400

Wax heating oven with 40 l volume and temperature range from 40° to 250°C. The body of the stove is made of steel and coated with powder paint, which is easy to clean. The inside of the chamber is made of stainless steel.

The control system consists of a thermostat, temperature controller and heating indicator. Heating is carried out by a protected Incoloy heating element located at the base of the chamber. The oven is supplied with a dipping basket for easy loading and retrieval of samples. nine0007

- Volume 40 liters.

- Temperature range 40-100°C.

- Stainless steel internals.

- The body is powder coated for easy cleaning.

- Internal dimensions (cm): 28 (height) x 40 (width) x 29 (depth).

- External dimensions (cm): 55 (height) x 53 (width) x 48 (depth).

- Adjustable thermostat. nine0004

- Non-adjustable thermostat.

- 220-240 V, 50 Hz, 1.5 kW, 1 phase.

- Top opening lid with support legs.

- Includes a dipping basket for easy loading and retrieval of samples.

Stands

The oven stand is designed to hold the oven at a comfortable height and also has a large work surface on top. The stand for the wax heating oven allows you to place the oven at a convenient height. Both deliveries can be docked. nine0007

Oven stand OV/100/SS/F/DIG:

- for positioning the oven at a convenient height;

- tubular steel structure, powder coated;

- large work surface.

WTK 100/400 Oven Stand:

- designed to position the tank at the level of the oven stand;

- tubular steel structure, powder coated.

Learn more

Trolley for ZPrinter 850

Trolley for ZPrinter 850