Nanoparticles 3d printing

3D printing with nanoparticles - Advanced Science News

by Berta Domènech | May 12, 2020

Assembling nanoparticles into macroscale structures could provide new, durable materials for a range of fields and applications.

Macroscopic materials usually contain numerous cracks, voids, or other structural defects which cause the material to fail at loads way smaller than expected. Their nanoscopic counterparts, in contrast, are virtually defect-free, thus able to withstand higher loads. Integrating the nanoparticles’ mechanical properties into macroscale materials would provide a new niche for applications in a wide range of areas, such as in the aerospace industry. However, assembling nanoparticles into robust macroscale structures still remains a major challenge.

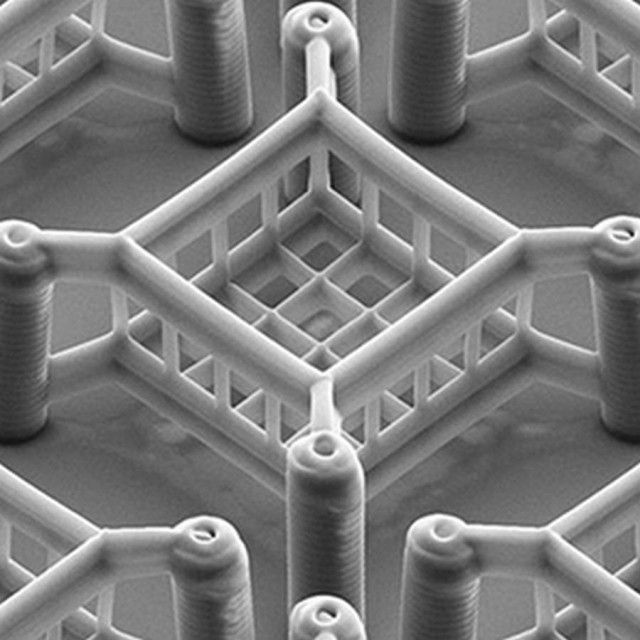

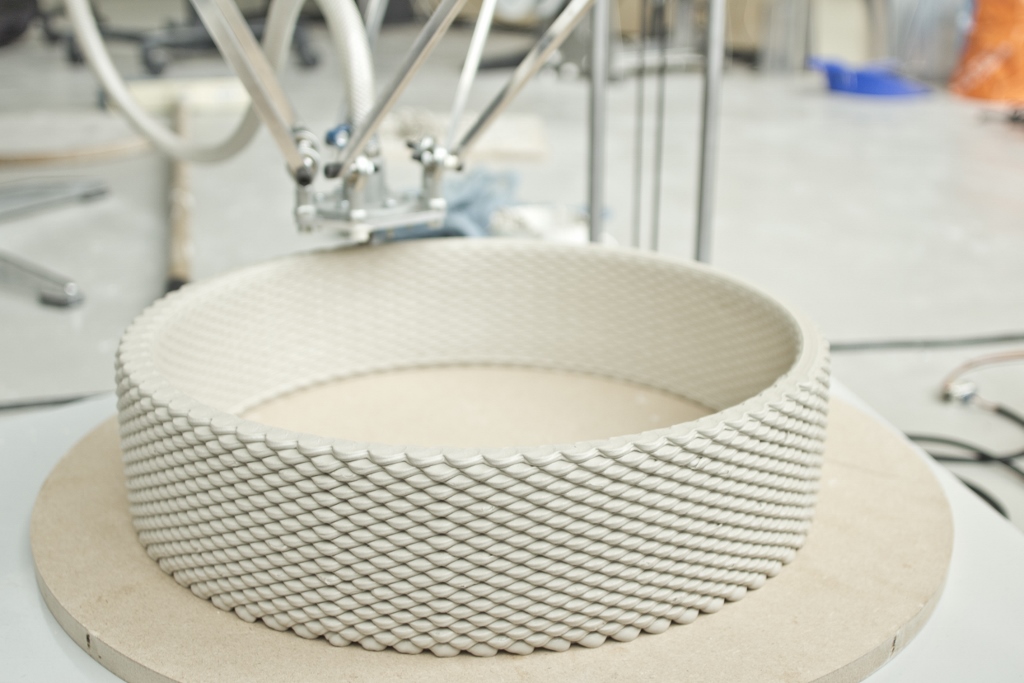

Now, researchers from the Technical University of Hamburg (TUHH) and the Massachusetts Institute of Technology (MIT), in collaboration with the Helmholtz-Zentrum Geesthacht and Bremen University, have achieved the assembly of nanoparticles into strong macrostructures via 3D-printing. “Interestingly, the strength of our 3D-printed materials is in the range of reported values for brick-and-mortar hierarchical composite materials, known for their exceptional mechanical properties,” said Professor Gerold Schneider, head of the Advanced Ceramics department at TUHH.

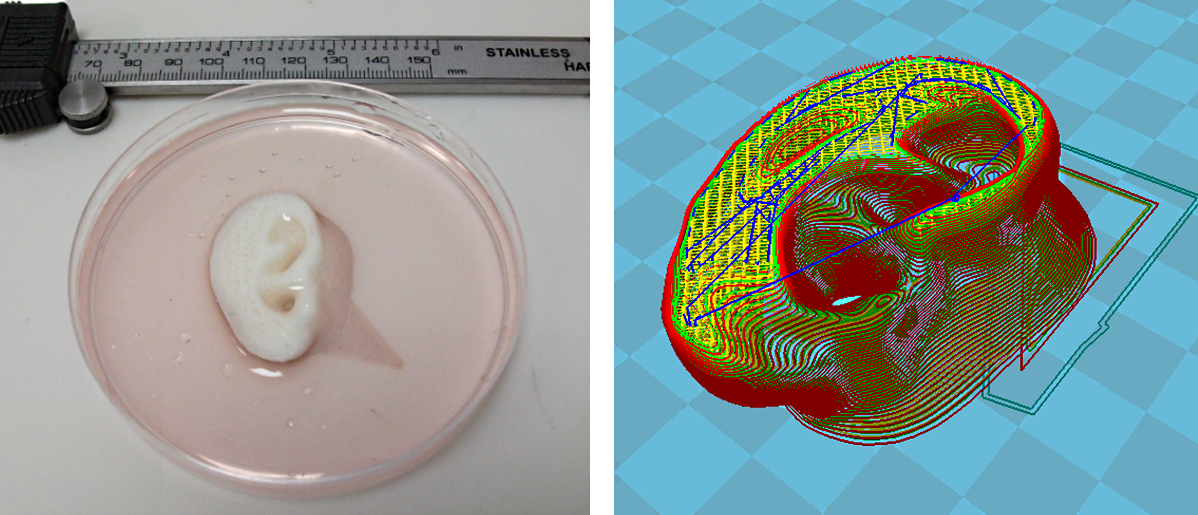

The process was performed using custom-made, benchtop direct-write systems, first developed by Professor John Hart’s team at MIT, and further implemented at TUHH. The team printed free-standing millimetre-scale columns comprising ordered arrangements (supercrystals) of spherical iron oxide nanoparticles (15 nm diameter). The crucial characteristic of these nanoparticles is that their surface is coated with short organic molecules (oleic acid). This surface-functionalization is in fact responsible for the remarkable mechanical properties finally obtained.

First, it allows for a controlled assembly of the nanoparticles into closely packed ordered arrangements (the so-called supercrystals). Second, the organic molecules act as active sites for the additional strengthening of the material. This final strengthening is performed by heat-treatment in an inert atmosphere, which results in the creation of new bonds (through a process called crosslinking) between the organic molecules of adjacent nanoparticles. The crosslinking makes the organic part stiffer, making it resistant to higher loads, similar to the curing process of a common epoxy resin.

This final strengthening is performed by heat-treatment in an inert atmosphere, which results in the creation of new bonds (through a process called crosslinking) between the organic molecules of adjacent nanoparticles. The crosslinking makes the organic part stiffer, making it resistant to higher loads, similar to the curing process of a common epoxy resin.

“3D printing offers a fast and controllable way to develop new materials. Previously 3D-printed particle-based materials were generally weak since their particles were held together mainly by weak forces (like van der Waals). In our case, the crosslinking step serves as a reinforcement mechanism. This creates a tightly packed network of strong covalently bonded nanoparticles throughout the material,” says Dr. Berta Domènech from TUHH, who coordinated the study.

The team’s next steps aim to acquire more control over the process parameters, expanding the study to other nanoparticle systems, and varying the geometry of the printed structures. “Enhancing the mechanical properties of 3D printed particle macrostructures is a key step towards applications,” says Dr. Alvin Tan from the Hart group at MIT. As a long-term perspective, the authors envisage that this combination of 3D printing and self-assembly will pave the way towards the integration of nanoscale-building blocks into a variety of macroscopic multifunctional materials, ranging from photonic devices to new structural materials.

“Enhancing the mechanical properties of 3D printed particle macrostructures is a key step towards applications,” says Dr. Alvin Tan from the Hart group at MIT. As a long-term perspective, the authors envisage that this combination of 3D printing and self-assembly will pave the way towards the integration of nanoscale-building blocks into a variety of macroscopic multifunctional materials, ranging from photonic devices to new structural materials.

Reference: Berta Domènech, et al. ‘Strong Macroscale Supercrystalline Structures by 3D Printing Combined with Self‐Assembly of Ceramic Functionalized Nanoparticles.’ Advanced Engineering Materials (2020). DOI: 10.1002/adem.202000352

Related posts:

3D printing at the nanoscale produces powerful possibilities

ASU researcher developing new method to enhance precision of 3D printing at very small scales

May 2, 2022

Kenan Song is excited about the potential of additive manufacturing, also known as 3D printing. Its ability to allow for inexpensive and rapid prototyping of custom designs without the limits of traditional manufacturing drives his interest in the field.

Its ability to allow for inexpensive and rapid prototyping of custom designs without the limits of traditional manufacturing drives his interest in the field.

Song, an assistant professor of engineering in the Ira A. Fulton Schools of Engineering at Arizona State University, is also interested in precise, consistent and efficient production using additive manufacturing. Some of his current research focuses on the exact replication of printed patterns at the nanoscale, with particles more than 1,000 times smaller than the thickness of a sheet of paper.

ASU Assistant Professor Kenan Song (left) examines a 3D-printed sample of the Multiphase Direct Ink Writing technology with recent master’s degree graduate and research collaborator Mounika Kakarla. Song earned a 2022 National Science Foundation Faculty Early Career Development Program (CAREER) award for this method, which can enhance 3D printing precision of ordered patterns at very small scales with a wider range of nanomaterials. Photo by Erika Gronek/ASU

Download Full Image

Photo by Erika Gronek/ASU

Download Full Image

In nanomanufacturing, particularly when it is used in the semiconductor industry, nanoparticles in the form of powders are used to print ordered structures such as dots, lines, pillars and layers. The properties of the nanoparticles are unleashed based on how they are patterned, so it is critical to be able to print them exactly as designed.

“Precise nanomanufacturing that enables patterning on surfaces or interfaces is critical to transferring high-performance nanoparticle properties when scaled up in devices, such as the chips in iPhones,” Song says, noting that the nature of the irregular nanoparticle powders makes this difficult to achieve consistently.

Current additive manufacturing methods use external forces such as electricity, magnets and sound waves to accurately place nanoparticles at certain locations. However, these methods don’t work for all kinds of nanoparticles and have other limitations.

However, these methods don’t work for all kinds of nanoparticles and have other limitations.

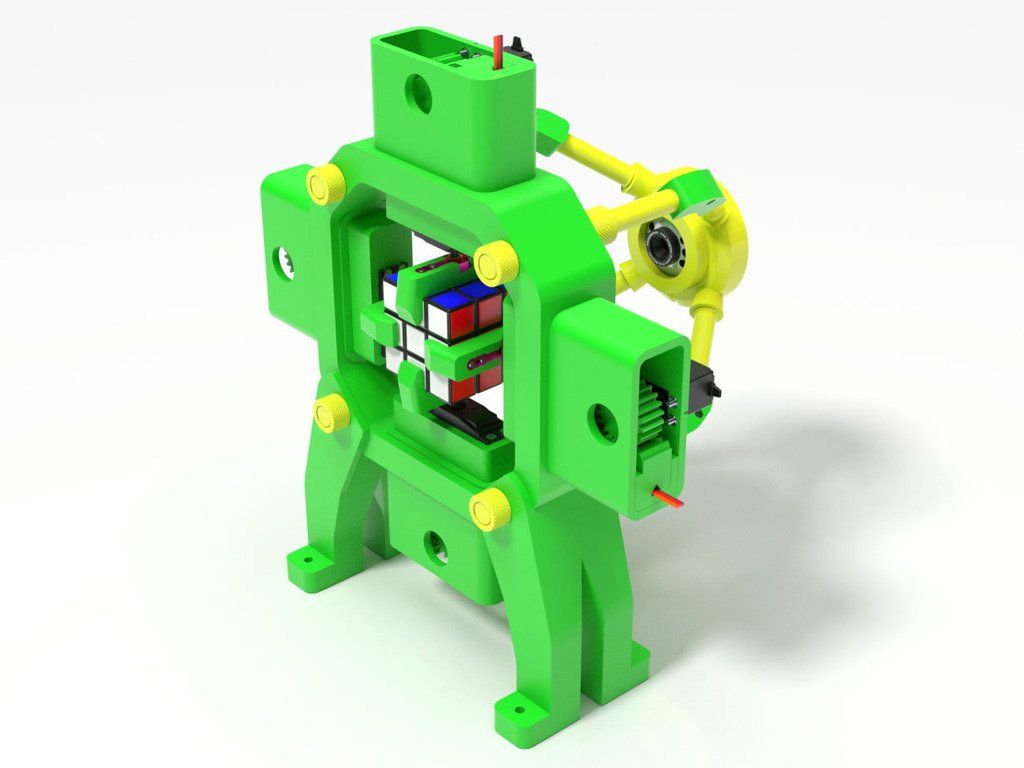

So Song is developing a new 3D printing mechanism called Multiphase Direct Ink Writing to enhance manufacturing precision at very small scales with a wider range of materials.

This work — a project titled “Additively Manufactured Nanomaterial Layers with Submicron Structures” — is supported by a 2022 National Science Foundation Faculty Early Career Development Program (CAREER) award. This award, which supports Song with $600,000 in funding over five years, is given to young faculty members who demonstrate the potential to be education and research leaders and advance the mission of their organizations.

“With unprecedented speeds and resolutions, our additive manufacturing method will provide a fundamental understanding of 3D printing principles involving both machine design and material science studies,” says Song, who is making significant contributions to manufacturing at the ASU Polytechnic campus as a faculty member in The Polytechnic School in addition to his role as a graduate faculty member in aerospace and mechanical engineering, and materials science and engineering, in the School for Engineering of Matter, Transport and Energy, two of the seven schools in the Fulton Schools.

To create this method, Song is leading a multidisciplinary research effort that includes polymer science, nanoparticle synthesis and interfacial engineering to explore interactions of materials at the atomic or molecular level.

The Multiphase Direct Ink Writing method has broad potential use in the rapid prototyping of sensors, actuators and soft robotics, as well as applications in supercapacitors, batteries and regenerative medicine.

Song and his research team will use the method to develop a class of nanoparticles called MXenes with new structures and physical and chemical properties to demonstrate new 3D-printed energy devices.

Another important aspect of CAREER award projects is their educational component. Song is highly involved in including students from underrepresented groups in his research, teaching an entrepreneurial mindset and providing opportunities for research exchange with universities in Israel, France and Qatar.

He believes his efforts in these areas caught the NSF’s attention as he works to increase diversity in the important, growing additive manufacturing industry.

Discoveries Ira A. Fulton Schools of Engineering The Polytechnic School School for Engineering of Matter, Transport and Energy Engineering Research Innovation Grants / Awards Faculty Graduate student Campus student

Monique Clement

Lead communications specialist, Ira A. Fulton Schools of Engineering

480-727-1958

monique. [email protected]

[email protected]

Next Story

ASU student attends Pacific Sociological Association conference

Lynette Hrabik, a senior at Arizona State University studying political science and sociology, believes that students looking to enrich their college experience should pursue undergraduate research opportunities.So far during her time with The College of Liberal Arts and Sciences, she’s done just that.With the assistance of a travel grant offered by the School of Politics and Global Studies, Hra...

Read the article

More from Discoveries

May 2, 2022

Lynette Hrabik, a senior at Arizona State University studying political science and sociology, believes that students looking to enrich their college experience should pursue undergraduate research opportunities.

So far during her time with The College of Liberal Arts and Sciences, she’s done just that. Lynette Hrabik Download Full Image

With the assistance of a travel grant offered by the School of Politics and Global Studies, Hrabik traveled to Sacramento, California, to attend the Pacific Sociological Association’s annual conference.

The conference focused on collective memory. Hrabik attended sessions on mental health, the carceral system, globalization and education.

“As a research assistant for the Arizona Youth Identity Project (AZYIP), I also presented some of our preliminary survey and interview findings,” Hrabik said. “My presentation covered Native American young adults’ civic engagement in Arizona during the 2020 elections and COVID-19 pandemic.”

“My presentation covered Native American young adults’ civic engagement in Arizona during the 2020 elections and COVID-19 pandemic.”

Attending the Pacific Sociological Association’s conference not only provided Hrabik the opportunity to share and receive feedback on her research, but also learn from others.

“Also, as a political science and sociology student, I loved seeing how experts from across the country are applying the concepts I’m learning in their research,” she said.

Hrabik shared some of her experiences from this conference with ASU News:

Question: What were some of your takeaways from this experience?

Answer: There were so many inspiring presentations. One of my takeaways is the value of research in understanding social issues and facilitating change. I was quite moved by one talk on mental health in Filipino communities since I'm Filipina, and this topic is personal for me. While many Filipinos struggle with mental health, seeking help is stigmatized. Mental health service utilization is low — for a variety of reasons. This is a problem since many don’t receive support until it's too late. The presenters discussed how they were interviewing both older and younger generations to heal intergenerational traumas and work towards increasing mental health service utilization. Personally, I think this is a powerful example of how valuable research can be.

Mental health service utilization is low — for a variety of reasons. This is a problem since many don’t receive support until it's too late. The presenters discussed how they were interviewing both older and younger generations to heal intergenerational traumas and work towards increasing mental health service utilization. Personally, I think this is a powerful example of how valuable research can be.

Q: How do you think this trip will help you attain your career aspirations?

A: I’m interested in public interest law, becoming a policy analyst or working in public service in some capacity, so the knowledge I gained through this opportunity is indispensable. I also came back more confident in my research abilities and with greater resolve. Whatever path I take, I believe the experience will make me a better researcher and advocate.

Q: What advice would you give those who are interested in a similar experience?

A: When Dr. Angela Gonzales and Dr. Michelle Pasco originally suggested that I could present at a conference, I was hesitant. However, despite being an undergrad, I was surprised by how supportive other conference attendees were. My advice is to not sell yourself short! Pursue research opportunities, even if they seem intimidating, because you’ll learn and grow substantially.

Angela Gonzales and Dr. Michelle Pasco originally suggested that I could present at a conference, I was hesitant. However, despite being an undergrad, I was surprised by how supportive other conference attendees were. My advice is to not sell yourself short! Pursue research opportunities, even if they seem intimidating, because you’ll learn and grow substantially.

Sun Devil Life School of Politics and Global Studies T. Denny Sanford School of Social and Family Dynamics The College of Liberal Arts and Sciences Politics Academics Student

Matt Oxford

Manager of marketing and communications, School of Politics and Global Studies

480-727-9901

moxford@asu. edu

edu

University News New Regents Professor has a passion for public service Downtown Phoenix campus Sandra Day O'Connor College of Law Law Academics

Discoveries CS'fly': Insect data holds clues to crimes West campus New College of Interdisciplinary Arts and Sciences School of Mathematical and Natural Sciences Forensic science

Global Engagement O’Connor Justice Prize ceremony honors UN human rights commissioner Sandra Day O'Connor College of Law Law Grants / Awards Community

University News AAAS honors 2 ASU anthropologists as lifetime fellows The College of Liberal Arts and Sciences School of Human Evolution and Social Change School of Life Sciences Julie Ann Wrigley Global Futures Laboratory

Arizona Impact Comprehensive statewide study tracks rapid spread of SARS-CoV-2 variants Tempe campus Biodesign Institute Biodesign Center for Fundamental and Applied Microbiomics School of Life Sciences

University News Teach for America CEO to visit ASU Tempe campus Educational Outreach and Student Services Barrett, The Honors College Mary Lou Fulton Teachers College

An innovative technology for 3D printing with gold nanoparticles has been developed

Semy3d

Loading

23. 01.2020

01.2020

985

Miscellaneous

Subscribe to

Subscribe

I do not want

1

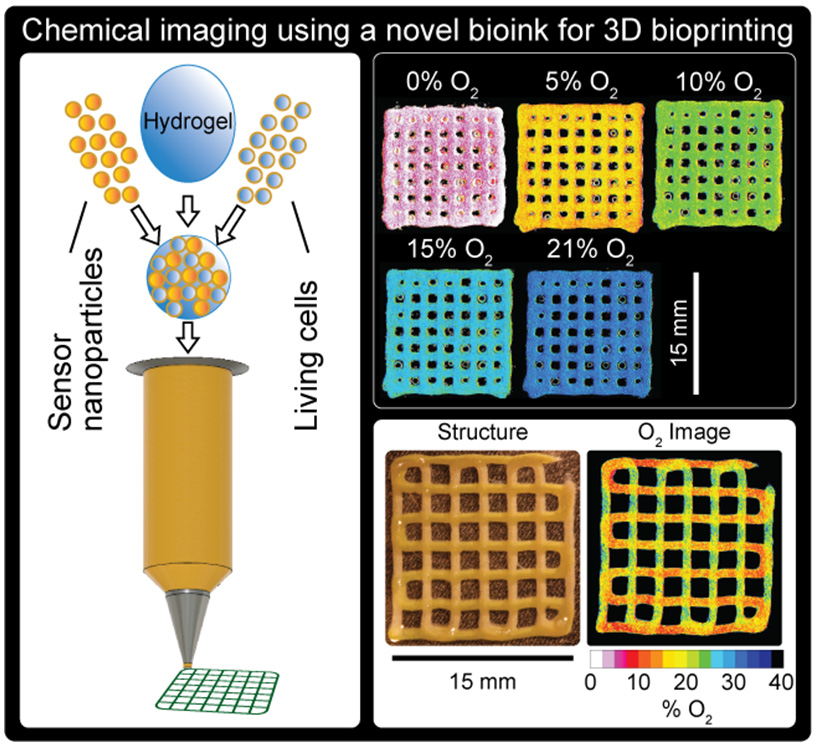

Research group, which included Spanish and English scientists from the universities of the cities of Sevilla and Notingham , which allows you to print 3D images from gold nanoparticles stabilized with biodegradable and biocompatible polymer materials. nine0003

The first demonstration printing of the Seville University logo in 3D showed the promise of the technology for practical applications (in pharmaceuticals and other fields).

Principle of the method

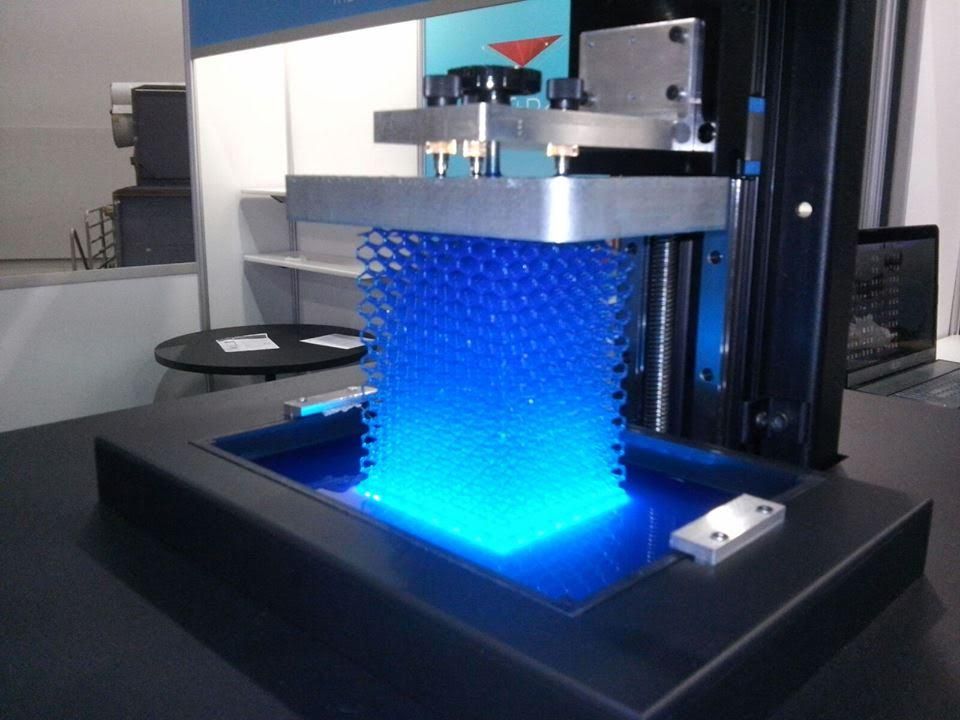

An international research team has created an inkjet 3D printing technology that uses multiple materials simultaneously to stabilize colloidal gold particles and use their conductive capacity as specialized biological sensors. nine0003

Prior to the practical implementation of the technique, 3D printing with gold nanoparticles was considered a rather difficult task due to their instability. The mixing of gold particles did not allow the reproduction of high-precision details. Therefore, researchers had to develop a new way to stabilize them using polymeric materials with a comb structure.

The mixing of gold particles did not allow the reproduction of high-precision details. Therefore, researchers had to develop a new way to stabilize them using polymeric materials with a comb structure.

The polymers used in this technology were made from arabinose (natural biodegradable biocompatible monosaccharide). The ink made from arabinose effectively stabilized the gold nanoparticles and, as tests have shown, this polymeric material is able to maintain stability for at least six months. nine0003

Follow author

Follow

Don't want

1

Article comments

More interesting articles

10

Subscribe to the author

Subscribe

Don't want to the rationality of the deed under the great. ..

..

Read more

ameron

Loading

01/29/2023

2286

nine

Subscribe to the author

Subscribe

Don't want

Good day!

I had a home-made dryer for two chambers, but it was crooked...

Read more

CEPKO777

Loading

02/08/2018

141905

273

Subscribe to the author

Subscribe

Don't want

Hello everyone. After buying a printer and realizing the principle of operation of CNC machines, I began to look at others ...

Read more

Read blogs

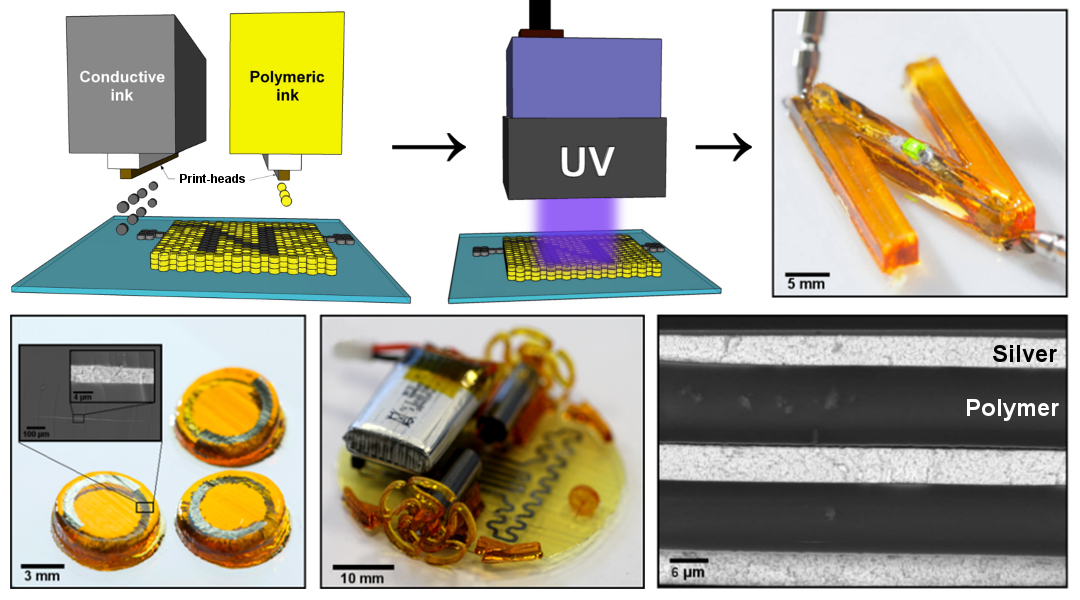

MIPT scientists have developed a laser-assisted aerosol 3D printer for printing electronics

The technology allows you to print electronic boards with directed flows of nanoparticles on surfaces of complex shape, as well as to use inexpensive polymer substrates, that is, to create integrated and flexible electronics. nine0003

nine0003

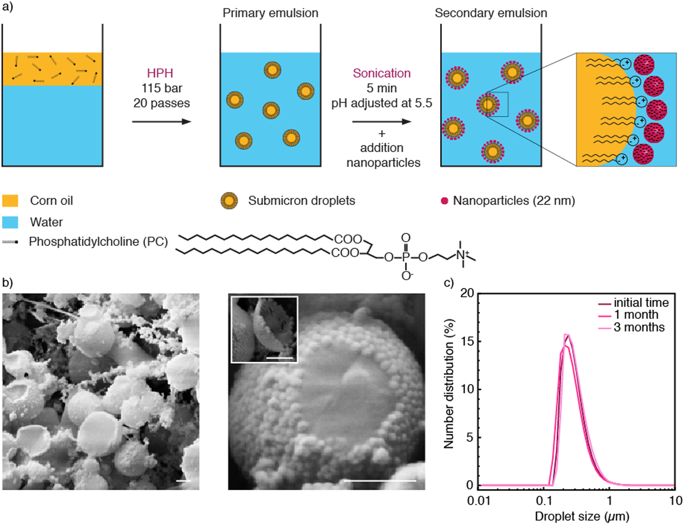

According to the press service of the Moscow Institute of Physics and Technology, employees of the Laboratory for 3D Printing of Functional Microstructures of the Physical-Technical School of Electronics, Photonics and Molecular Physics of the Moscow Institute of Physics and Technology have developed an experimental model of a laser-assisted aerosol 3D printer and created the scientific foundations of a new technology aerosol printing of 3D microstructures. Three processes are integrated in one device: obtaining, local delivery and local laser sintering of nanoparticles on a substrate. nine0003

Unlike traditional methods of forming electronic products, which involve the use of a larger number of technological operations with the removal of a significant part of the materials, the developed equipment and technology involve the rapid manufacture of products by layer-by-layer deposition of material in the form of nanoparticles with its subsequent monolithization using local laser sintering of nanoparticles on a substrate .

The technique involves the use of "dry" chemically pure nanoparticles 2-20 nm in size, obtained in a repetitively pulsed gas discharge. Through a fixed head, particles are sprayed onto a moving substrate and sintered by a laser, forming a pattern. Due to the particle size effect, local laser sintering at low temperatures (400°C and below) becomes possible and, thus, the formation of fundamentally new 3D electronic devices on thermosensitive flexible polymer substrates. nine0003

Laser-assisted nanoparticle 3D aerosol printing technology has a number of advantages over existing microstructure additive manufacturing methods that use nanoparticle inks. Aerosol 3D printing provides higher electrical conductivity and mechanical strength of microstructures, since the surfaces of “dry” chemically pure nanoparticles obtained in a repetitively pulsed gas discharge do not contain solvent and surfactant residues. An important advantage is the reduction of

the number of steps for fabricating functional microstructures, since no preparation and drying of the nanoink before laser sintering is required. Preparation, local delivery and local laser sintering of nanoparticles are carried out simultaneously. Users have the opportunity to vary the types of materials (metals, semiconductors and dielectrics), the size, shape and packing density of nanoparticles by changing the material of the electrodes and modes of obtaining nanoparticles in a repetitively pulsed gas discharge. nine0003

Preparation, local delivery and local laser sintering of nanoparticles are carried out simultaneously. Users have the opportunity to vary the types of materials (metals, semiconductors and dielectrics), the size, shape and packing density of nanoparticles by changing the material of the electrodes and modes of obtaining nanoparticles in a repetitively pulsed gas discharge. nine0003

“The uniqueness of the technology we developed for aerosol 3D printing by nanoparticle flows with local laser sintering lies in the combination of high resolution up to 25 µm, high mass productivity up to 300 mg/h and low cost of forming functional 3D microstructures, which will determine its further growth. popularity,” explains Aleksey Efimov, Leading Researcher at the Laboratory for 3D Printing of Functional Microstructures at MIPT.

The developed technology and equipment can be used to produce a wide range of functional micro-sized components and products for electronics, photonics, alternative energy, medical and aerospace technology: microantennas, 3D spatial interconnects, microheaters, active (transistor, diode) and passive (resistor , capacitor) electronic components, light-emitting devices (flexible displays, OLED matrix cells), solar cells, gas, bio-, temperature sensors, and so on.