Best commercial 3d printer 2023

10 Best Commercial & Professional 3D Printers In 2023

- Last Updated: January 19, 2023

- Pat Nathaniel

Are you dreaming of making industrial-quality parts at your SME? Well, stop dreaming and start printing!

Commercial 3D printers let even a tiny garage operation make parts NASA would send to space. A professional 3D printer is a business partner you can’t afford to not have.

But we also know that with an SME budget, you can’t afford to pick the wrong 3D printer, either. You have to choose the right machine for the right application to avoid wasting its potential. But how do you do that?

Read on and meet the best commercial 3D printers in 2022.

Formlabs Form 3+

Build volume: 145 x 145 x 170 mm

Check Latest Price

Raise3D Pro2 Plus

Build volume: 305 × 305 × 605 mm

Check Latest Price

Fusion3 EDGE

Build volume: 355 × 355 × 368 mm

Check Latest Price

Table of Contents

- Best Commercial 3D Printers At A Glance

- 1.

Formlabs Form 3+ (Best Value)

- 2. Raise3D Pro2 Plus (Best Choice)

- 3. Fusion3 EDGE (Premium Choice)

- 4. Ultimaker S5 (Easy to Use)

- 5. Prusa i3 MK3S+ (Best for High-Quality Prints)

- 6. Dremel DigiLab 3D45-EDU (Best for School Use)

- 7. Zortrax M300 Dual (Best for Detailed Prints)

- 8. BCN3D Epsilon W50 (Best for Beginners)

- 9. MakerBot Method X (Best for Easy to Print)

- 10. Delta WASP 2040 Industrial X (Best for Fast Print)

- 1.

- Industrial Quality at Small Business Budgets

- What Is a Commercial 3D Printer?

- What to Look for in a Commercial 3D Printer

- Uses of Commercial 3D Printers

- Conclusion

Best Commercial 3D Printers At A Glance

1. Formlabs Form 3+ (Best Value)

2. Raise3D Pro2 Plus (Best Choice)

3. Fusion3 EDGE (Premium Choice)

4. Ultimaker S5 (Best for Beginners)

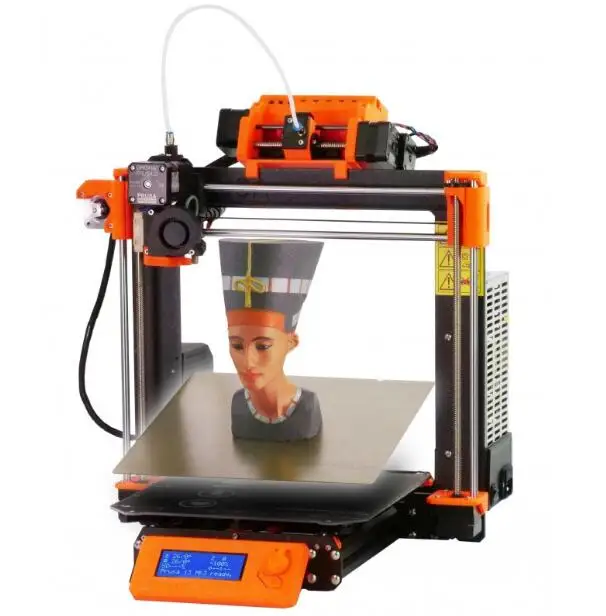

5. Prusa i3 MK3S+ (Best for High-Quality Prints)

6. Dremel DigiLab 3D45-EDU (Best for School Use)

Dremel DigiLab 3D45-EDU (Best for School Use)

7. Zortrax M300 Dual (Best for Detailed Prints)

8. BCN3D Epsilon W50 (Best for Beginners)

9. MakerBot Method X (Best for Easy to Print)

10. Delta WASP 2040 Industrial X (Best for Fast Print)

3D Printer Type: LFS | Materials: Resins | Build Volume: 145 x 145 x 170 mm

Ask any commercial SLA 3D printer user, and they’ll tell you Formlabs Form 3+ is the industry workhorse. That reputation is well deserved.

Form 3+ offers excellent print quality at a fantastic value.

With a layer resolution of only 25 microns, Form 3+ can accurately reproduce even the tiniest details. The advanced monitoring sensors ensure steady part quality.

On top of that, Formlabs has designed the printer to be highly automated. Just set it and forget it — your parts will come out great.

You can also print pretty much whatever you want. Form 3+ supports Formlabs’ extensive material range. It can produce anything from mechanical parts to accurate dental appliances and castable wax models for jewelry.

The printer doesn’t support third-party resins, though, so you’re locked to Formlab’s pricey options. The print chamber is also quite small and the speed (although better than its previous iterations) isn’t the fastest.

But at a price below $4,000, we’ll forgive all that. Formlabs Form 3+ simply provides great versatility and value.

- Affordable

- Excellent part quality

- Wide material range

- No third-party material support

- Small print volume

- Slow-ish

Check Latest Price

2. Raise3D Pro2 Plus (Best Choice)

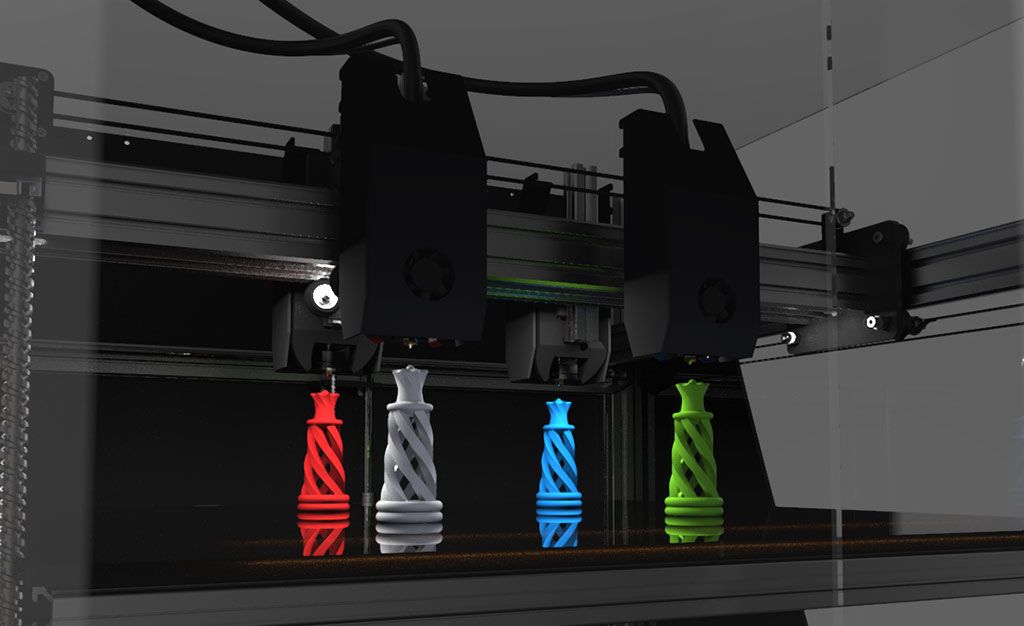

Raise3D Pro2 Plus (Best Choice) 3D Printer Type: FDM | Materials: PLA, ABS, HIPS, PC (Polycarbonate), TPU, Nylon, TPE, PETG, Metal Infused PLA, Woodfilled PLA & Carbon Fiber Reinforced Materials | Build Volume: 305 × 305 × 605 mm

Freddy Mercury probably would’ve liked Raise3D Pro2 Plus. If you want it all and you want it now, this is your machine.

This award winner simply does everything you could need.

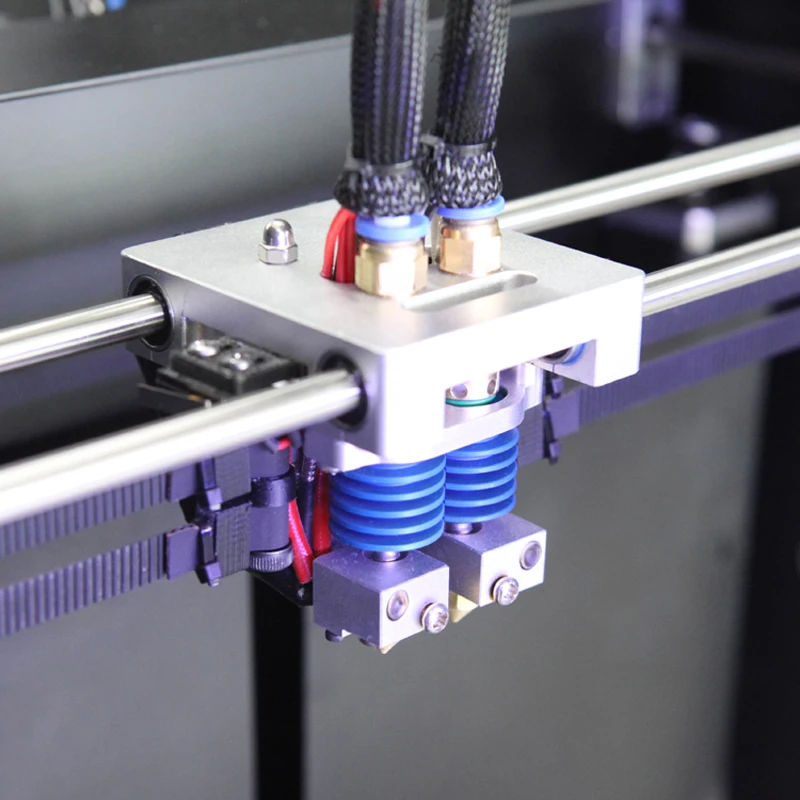

As a particular highlight, the dual extruder of the Pro2 Plus can print with two materials at once. You can mix any two options from its staggering material range into one part in the machine’s well-sized build chamber. This is one printer that really makes you create any part you want.

And you have a lot of options. With a maximum extruder temperature of 300°C (572°F), Pro2 Plus works with anything from basic ABS to advanced carbon fiber-reinforced nylons and more.

Oh, and that print quality. This is one of the most accurate FDM printers we’ve seen.

This is one of the most accurate FDM printers we’ve seen.

Pro2 Plus isn’t the most beginner-friendly 3D printer since it doesn’t have automatic bed leveling. But if you know what you’re doing, Raise3D Pro2 Plus is one of the best 3D printers money can buy.

- High accuracy and part quality

- Supports third-party filaments

- Low price

- Dual extruder

- Difficult calibration

- Some technical issues

- No steel nozzle included as default

Check Latest Price

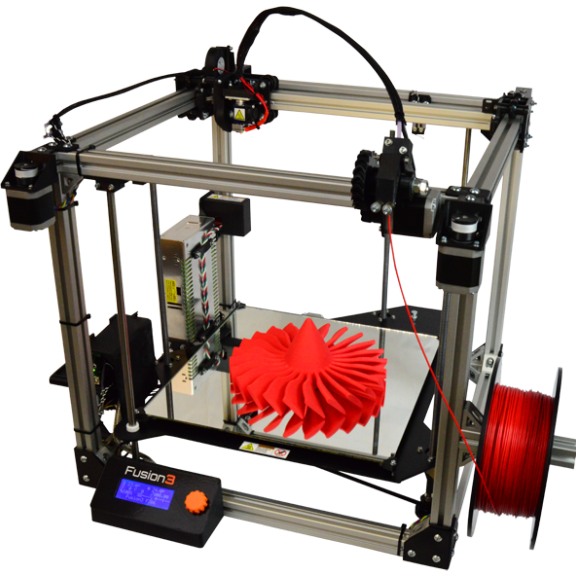

3. Fusion3 EDGE (Premium Choice)

Fusion3 EDGE (Premium Choice) 3D Printer Type: FFF | Materials: PLA, ABS, ASA, Reinforced Materials including Carbon Fiber, Kevlar, and Fiberglass, Flexible, Nylons, PET/PETG & Polycarbonate | Build Volume: 355 × 355 × 368 mm

Fusion3 EDGE is true to its name — this is a cutting-edge 3D printer in many ways. It just launched in early 2022, but it’s already established itself as a great premium printer option.

As a unique quirk, EDGE uses an inexpensive surgical steel print tube instead of the usual screw-in nozzle. Just because it’s inexpensive doesn’t mean this part isn’t premium, though.

It allows materials to flow through effortlessly, giving EDGE a very fast printing speed. And even though it can’t match Raise3D Pro2 Plus, EDGE’s detail accuracy is still great.

The steel tube heats up to 320°C and can withstand abrasive reinforced filaments, like carbon fiber-filled nylon. Add to that support for third-party filaments and you have a lot of materials to choose from.

That all sounds great. So, what’s the catch?

Price, mostly. As a premium 3D printer, EDGE does have a high price tag. But with Fusion3 EDGE, you get what you pay for.

- Fast printing

- Reliable part quality

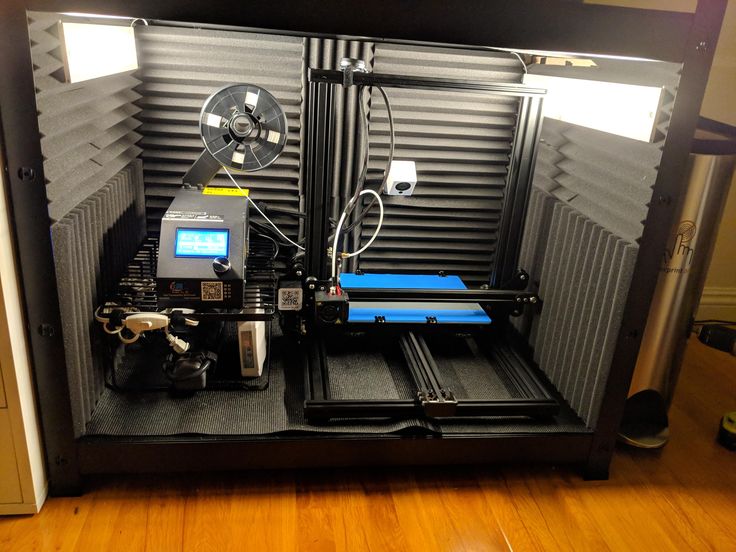

- Quiet and filtered enclosure

- Automatic maintenance reminders

- Pricey

Check Latest Price

4. Ultimaker S5 (Easy to Use)3D Printer Type: FDM | Materials: Tough PLA, TPU 95A, ABS, Nylon, TPU | Build Volume: 330 x 240 x 300 mm

Time is money, and time wasted on tweaking finicky printers is money lost. Ultimaker S5’s simple usability saves you both time and money.

Ultimaker S5’s simple usability saves you both time and money.

The S5 integrates seamlessly with Ultimaker’s own Cura software. Together with the clear touchscreen, the printer’s advanced automated features are straightforward to operate. Just a few clicks and the S5 starts printing.

The easy usability translates directly to high productivity. It’s no wonder Volkswagen, Siemens, and others like this printer.

The S5 also offers good printing quality. It has dual extruders for multi-material printing and a heated print bed for reliable part quality.

Another nice feature is the S5’s modularity. It has swappable print cores that enable you to print with more than 200 materials — and even metal filaments.

The simple performance comes at a high price, though. The S5 is also quite slow, compared to the previously featured printers, and its heated print bed is notorious for cracking.

But if you’re looking for a printer that keeps going with little intervention, Ultimaker S5 is your choice.

- Simple setup and operation

- Good print quality

- Plenty of material options

- Modular print cores

- Expensive

- Slow printing

- Fragile print bed

Check Latest Price

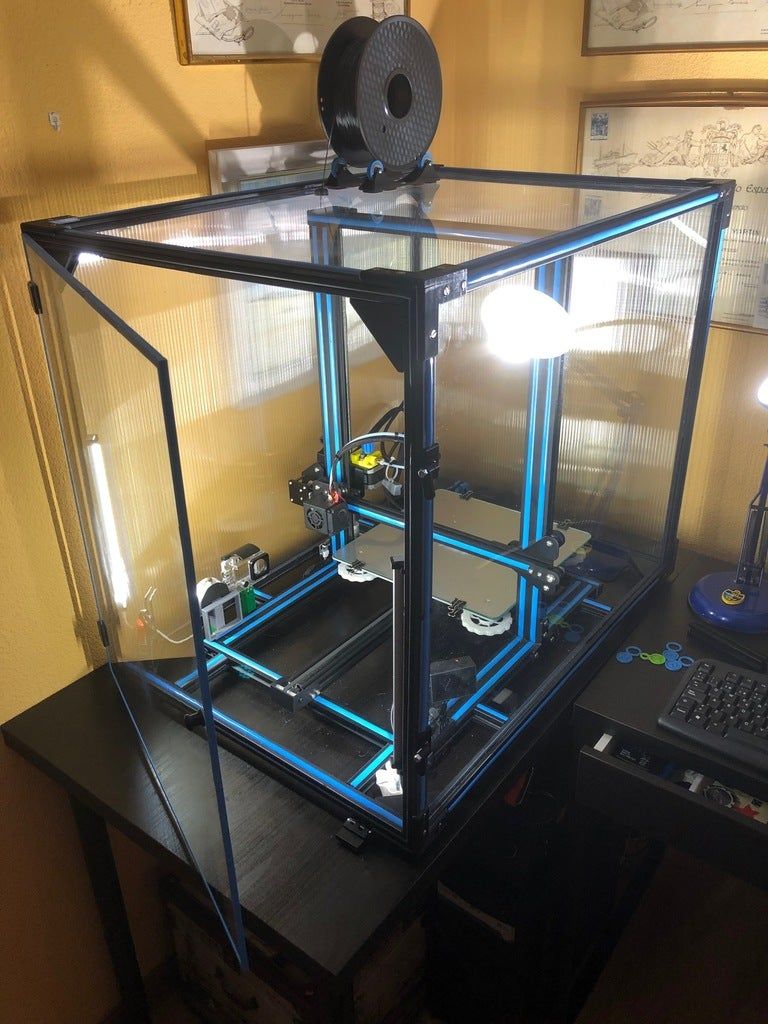

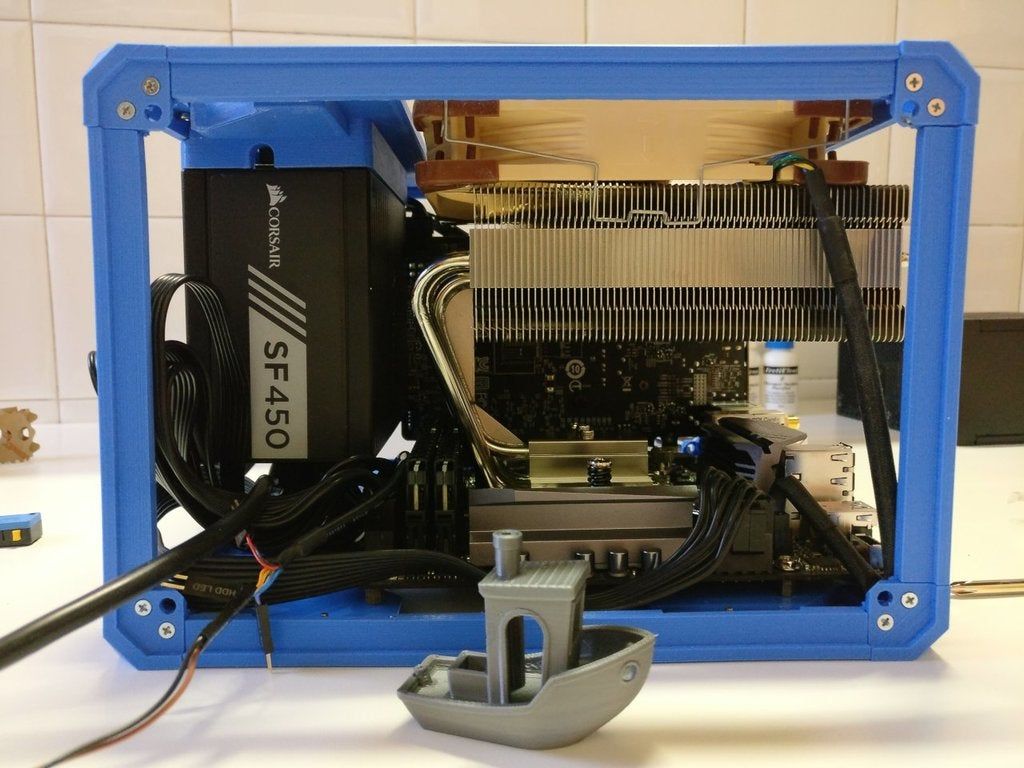

5. Prusa i3 MK3S+ (Best for High-Quality Prints)3D Printer Type: FDM | Materials: PLA, PETG, ASA, ABS, PC, HIPS, Flex, Nylon, Carbon filled & Woodfill | Build Volume: 250 x 210 x 210 mm

Don’t judge a book by its cover or a 3D printer by its price. At only $1,000, Prusa i3 MK3S+ punches way above its weight. It produces high-quality prints you wouldn’t expect from such an affordable machine.

At only $1,000, Prusa i3 MK3S+ punches way above its weight. It produces high-quality prints you wouldn’t expect from such an affordable machine.

Sure, the minimum layer thickness isn’t as impressive as with Raise3D Pro2 Plus or Fusion3 EDGE. But layer resolution isn’t the end-all-be-all of part quality.

The i3 MK3S+ features predefined printing profiles for Prusa filaments. Just pick the right profile — you’ll get reliably successful prints with almost zero effort. You can quickly alter the default profiles to match third-party filaments as well.

And you can print with almost any filament you want.

The i3 MK3S+ has a high-quality extruder that can reach 300°C. Carbon fiber, nylon or other engineering filaments are within your reach. And they print as effortlessly as anything.

You’ll want to get an enclosure to prevent warping with advanced filaments, though. The Prusa also can’t make huge parts, but what it does make is of consistently high quality.

- Reliably great part quality

- Affordable

- Big, helpful online community

- Simple to use

- No enclosure

- Small print volume

- Laggy software

Check For Official Website

Check Latest Price

Check For Kit Price

6. Dremel DigiLab 3D45-EDU (Best for School Use)

Dremel DigiLab 3D45-EDU (Best for School Use) 3D Printer Type: FDM | Materials: PLA, ECO ABS, PETG & Nylon | Build Volume: 254 x 152 x 170 mm

To get good at something, you should start young. Dremel DigiLab 3D45-EDU is a perfect 3D printer for teaching future additive manufacturing experts. Just look at the awards it’s received.

But what makes it so great for schools?

DigiLab 3D45 has a perfect balance of affordability, performance, and ease of use. You can set up and calibrate the printer in 15 minutes. Then you’re ready to start showing students how 3D printing works.

While the Dremel isn’t the most accurate machine, it’s still a professional 3D printer. It produces detailed prints of good quality.

As the students learn, the 3D45 lets them adjust the settings more accurately. The 3D45-EDU package even comes with 30 lesson plans from the 3rd to 12th grades.

The build chamber isn’t huge, but it’s more than enough for school use. Also, Dremel claims 3D45 can handle nylon, but the 280°C extruder temperature seems a bit low for that.

Also, Dremel claims 3D45 can handle nylon, but the 280°C extruder temperature seems a bit low for that.

Nonetheless, Dremel DigiLab 3D45-EDU is a great package for getting students excited about 3D printing.

Learn more in our guide of the best 3D printers for schools.

(NOTE: Dremel no longer manufactures 3D printers and has licensed its brand to 3PI. The machines are the same, but it’s good to know who to talk to if you need technical support.)

- Included lesson plans

- Easy setup and operation

- Good part quality

- Small print volume

- Slow speed

- Limited materials

Check Latest Price

7. Zortrax M300 Dual (Best for Detailed Prints)

Zortrax M300 Dual (Best for Detailed Prints) 3D Printer Type: LPD Plus | Materials: Most Z-Materials, PLA, Tough PLA, ABS, ASA, PETG, CPE, Nylon, TPU, TPE & PVA | Build Volume: 265 x 265 x 300 mm

Zortrax M300 Dual will surprise you. It creates highly detailed prints — despite the on-paper rough and inaccurate 150-micron layer height.

How on earth does this 3D printer do it?

The M300 Dual’s secret lies in the Layer Plastic Deposition (LDP) technology. It’s essentially Zortrax’s own spin of fused filament fabrication (FFF/FDM). Tailor-made for this system, LDP makes use of M300’s accurate leveling and calibration sensors to deliver very high-quality prints.

Another part of the puzzle is Zortrax’s proprietary filaments. The 3D printer has a complete Zortrax ecosystem, so it knows precisely how to handle the materials to deliver fine details beyond its specs.

The dual extruder also prints with two nozzles, one distributing Zortrax’s water-soluble support material. This is a really handy invention since you can just wash the supports away after printing.

This is a really handy invention since you can just wash the supports away after printing.

Of course, that means you need to buy Zortrax’s filaments. You can use third-party materials, but you may not get as fine detail.

Zortrax M300 Dual will bring more detail than you’d expect to all small businesses.

- Excellent detail and part quality

- Water-soluble supports

- Practically locked to Zortrax filaments

- Mediocre volume

Check Latest Price

8. BCN3D Epsilon W50 (Best for Beginners)3D Printer Type: FFF | Materials: PLA, PVA, PETG, TPU, ABS, PP & PA | Build Volume: 420 x 300 x 400 mm

An entry-level 3D printer often sacrifices production power for simple usability. It’s a good thing, then, that BCN3D Epsilon W50 isn’t an entry-level 3D printer. It’s a professional machine that’s easy enough for beginners to use.

It’s a good thing, then, that BCN3D Epsilon W50 isn’t an entry-level 3D printer. It’s a professional machine that’s easy enough for beginners to use.

The printer’s quick to set up and calibrate. The most laborious part is print bed calibration — it’s not hard, just time-consuming. Even if it’s your first 3D printer, you’ll get Epsilon W50 ready to go in about 20 minutes.

And it still brings serious power to your workshop.

Epsilon W50 uses an independent dual extruder system. It can print two materials at once, print mirrored component halves, or two identical parts at once. Combined with the big print volume, you’ll enjoy industrial-level productivity.

One thing deterring beginners might be Epsilon W50’s admittedly high price point. But think of this high-end 3D printer like a good pair of boots — it costs more upfront but it will keep printing reliably for years.

In a nutshell, BCN3D Epsilon W50 is a beginner-friendly machine with veteran-level performance.

- Easy and reliable printing

- Independent dual extruder system

- Large print volume

- Expensive

- Default hot end doesn’t support reinforced filaments

- Long bed calibration process

Check Latest Price

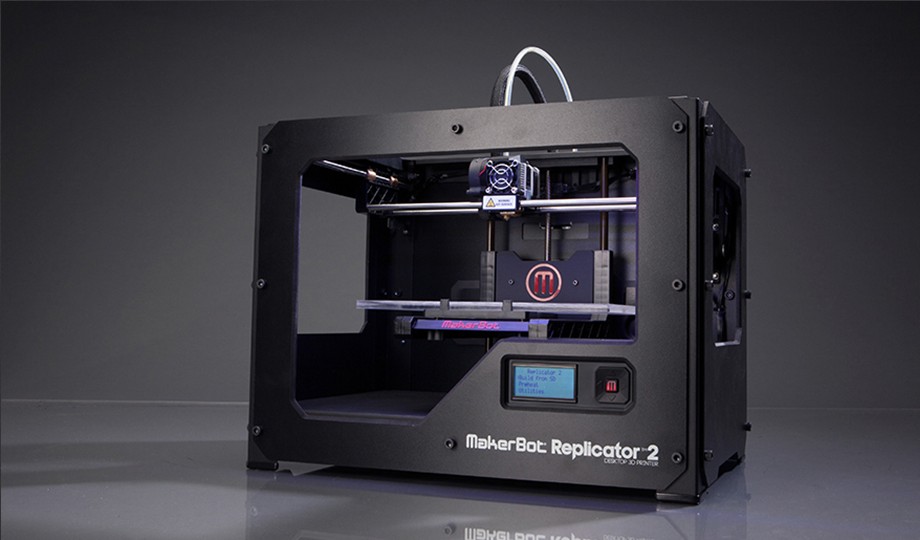

9. MakerBot Method X (Best for Easy to Print)3D Printer Type: FDM | Materials: PLA, Tough PLA, PETG, PETG-ESD, Nylon, PC-ABS, ABS, ASA & PVA | Build Volume: 190 x 190 x 196 mm

It just keeps going and going and going… And that’s good. MakerBot Method X is the commercial 3D printer you need for effortless, reliable production.

MakerBot Method X is the commercial 3D printer you need for effortless, reliable production.

Method X has been designed from the beginning to make printing as easy as possible. It has plenty of features, like thermal regulation and a temperature control filament drawer, that contribute to consistent and predictable part quality.

But MakerBot recently pulled another ace from its sleeve.

The company recently released a new water-dissolvable support material. It rinses pretty cleanly off even under tap water, removing the need for extensive post-processing.

Imagine that — no cutting off supports with FDM.

That said, Method X isn’t a flashy printer. It has a small build chamber and you need to buy separate extruders to make full use of the admittedly wide material range.

But that’s Method X for you. It doesn’t boast, it doesn’t grumble — it just prints.

- Extremely reliable

- Simple to use

- Wide material range

- Needs add-ons for reinforced materials

- Default slicer could be better

Check Latest Price

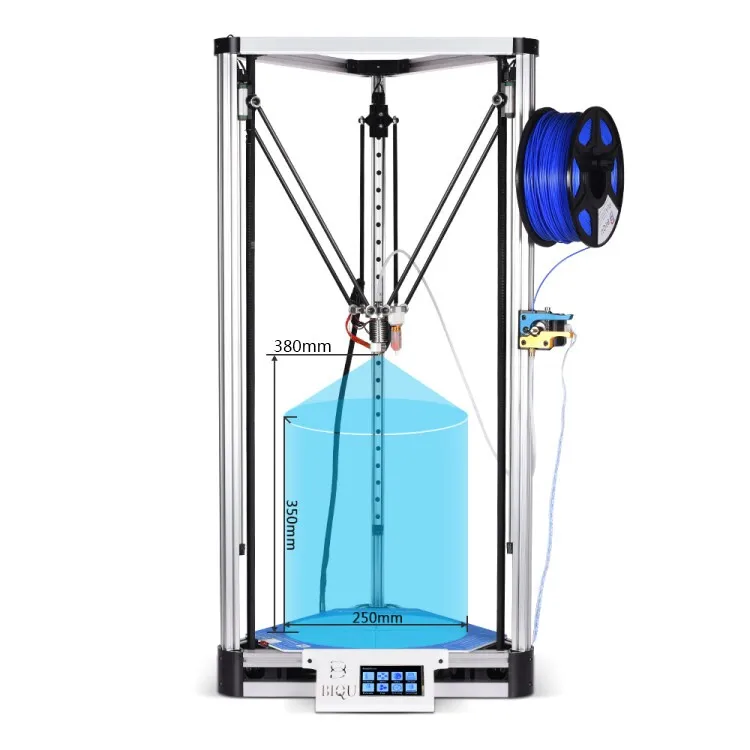

10. Delta WASP 2040 Industrial X (Best for Fast Print)

Delta WASP 2040 Industrial X (Best for Fast Print) 3D Printer Type: FDM | Materials: PLA, ABS, PETG, TPU, TPE, Polypropylene, Polycarbonate, PC+ABS, PPS, PMMA, PVA & PA | Build Volume: Ø 200 x h 400 mm

Do you feel the need? The need for speed? Delta WASP 2040 Industrial X is the speed demon you’re looking for.

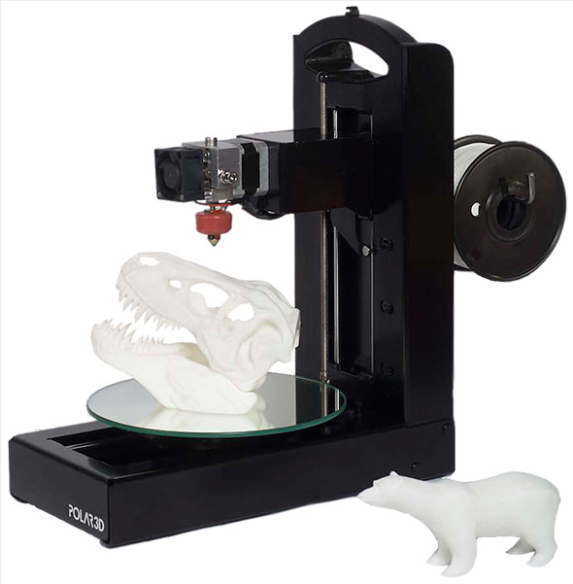

The WASP achieves lightning-fast printing thanks to three robotic arms that move its extruder around. Automatic calibration makes operating this futuristic solution simple.

But wait, there’s more than speed to the WASP!

Its dual gear filament driver pushes material through at a steady rate, resulting in good detail quality. The accuracy doesn’t beat printers like Raise3D Pro2 Plus, but the speed sure does.

You might expect constant maintenance at these speeds, but don’t worry. Delta’s Hot and Cold system controls the machine’s internal and external temperature. You won’t have to constantly blow money on spare parts.

As a cherry on top of it all, the WASP supports third-party materials. The material range isn’t as extensive as with some other printers, but it should keep you in business for a long time.

That’s a good description for Delta WASP 2040 Industrial X, actually. Printing with it is like watching Usain Bolt run a marathon.

- Lightning-fast printing

- Affordable

- Low maintenance

- Mediocre detail

- Bulky machine

Check Latest Price

Industrial Quality at Small Business Budgets

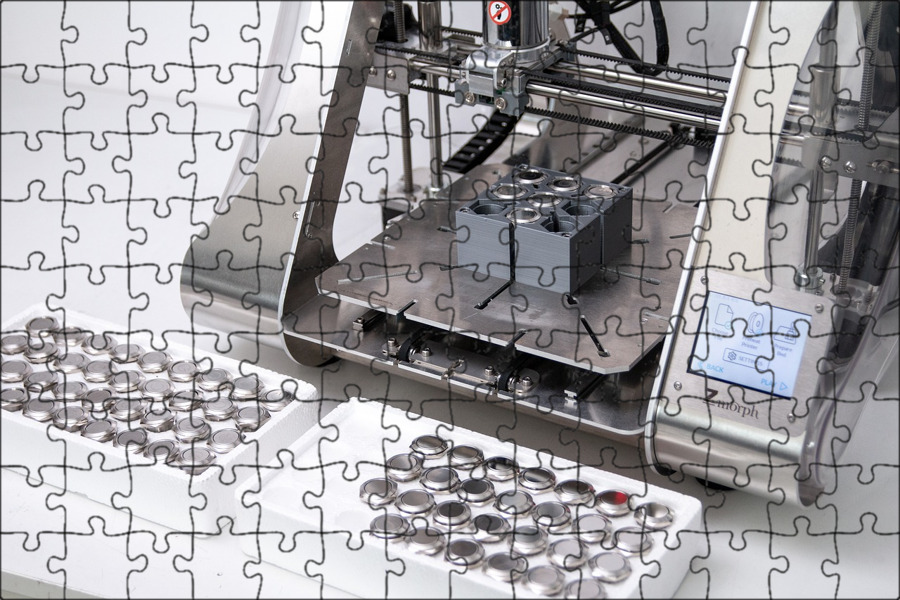

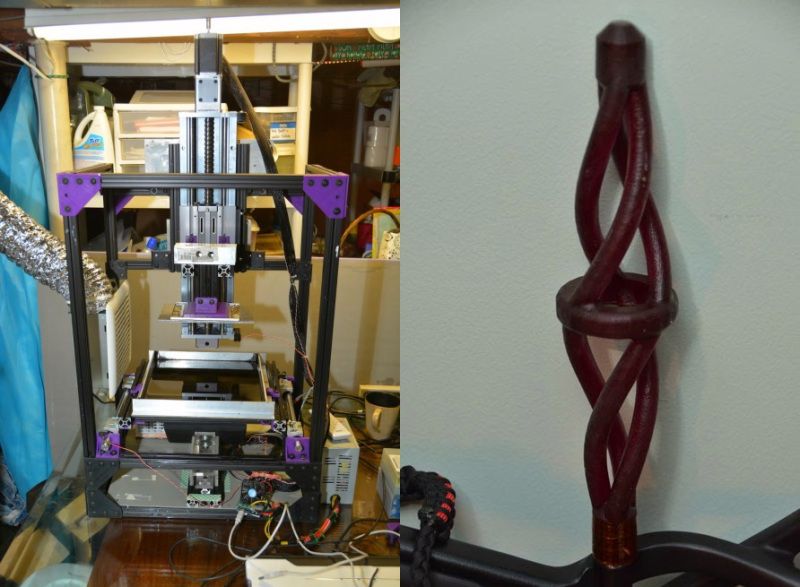

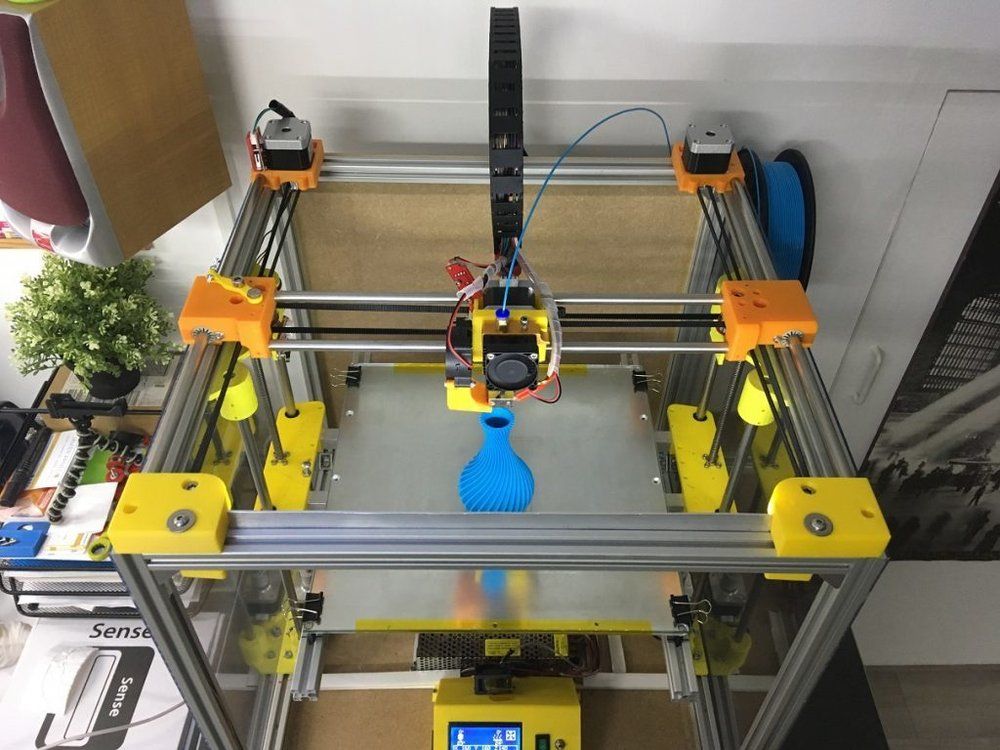

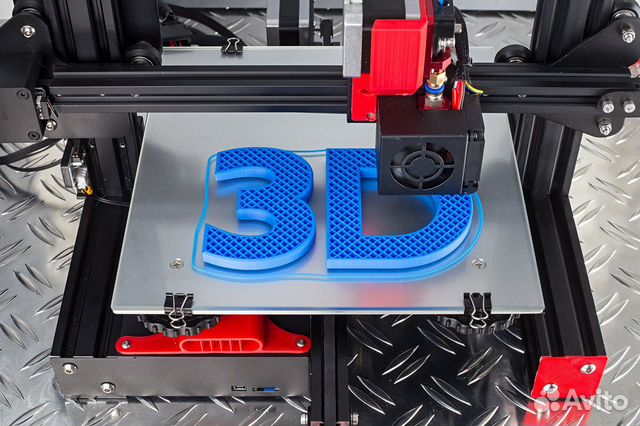

Source: Youtube Marvin Medina (3D Printed Cellphone Case)Commercial 3D printers are great equalizers. They’re quickly changing the SME landscape by narrowing the gap between small and large businesses.

They’re quickly changing the SME landscape by narrowing the gap between small and large businesses.

The best professional 3D printers make printing plastics easy, fast, and affordable. You can produce components with detail quality comparable to injection molding and strength that can surpass metal.

But not just every 3D printer deserves the title of a “commercial 3D printer.” What is it that makes a 3D printer professional?

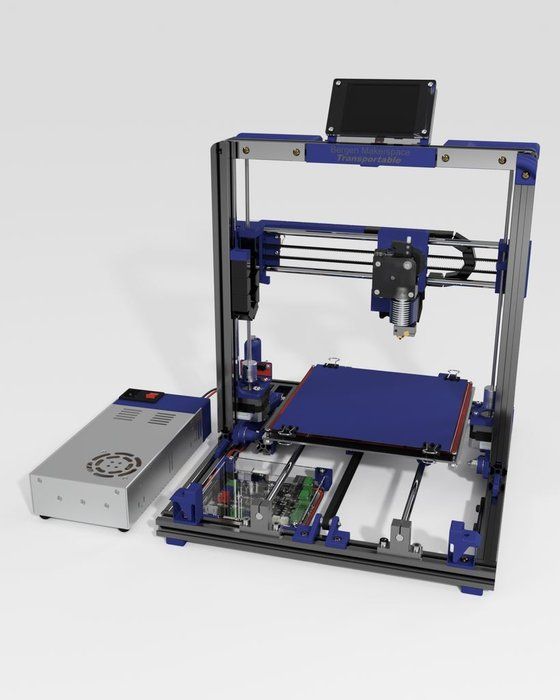

What Is a Commercial 3D Printer?

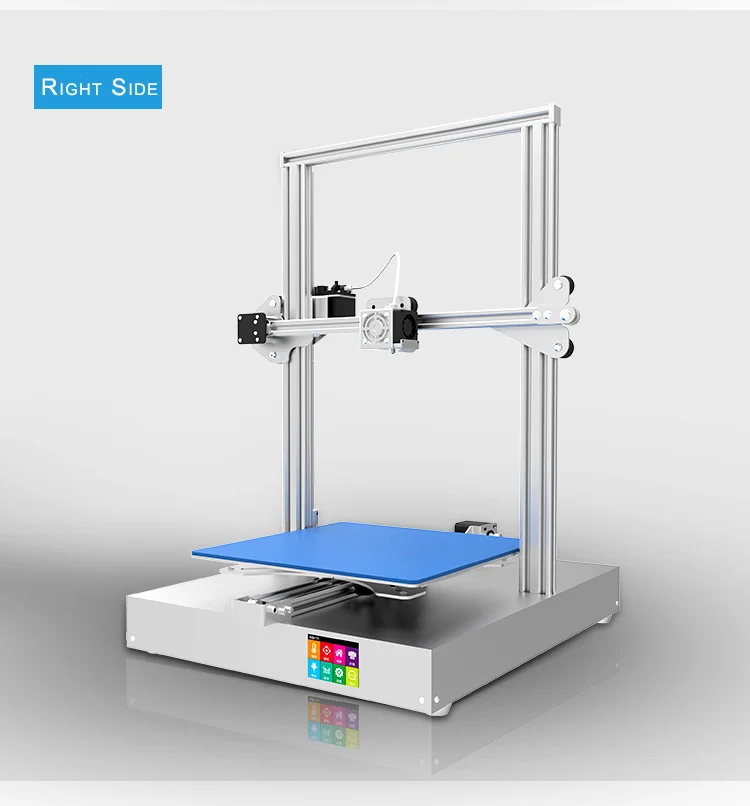

Source: Youtube Tech HD (3D Printed VW Bus Toy)Commercial 3D printers — also called prosumer or professional 3D printers — sit in the space between consumer 3D printers and full-blown industrial 3D printing behemoths.

In general, a commercial 3D printer costs less than $10,000. They have features that only the most advanced hobbyists might need but which are valuable for professional applications.

At the same time, they’re not meant for large-scale mass production like industrial printers. In short, they’re a low-cost method for SMEs to make use of industrial-grade materials.

In short, they’re a low-cost method for SMEs to make use of industrial-grade materials.

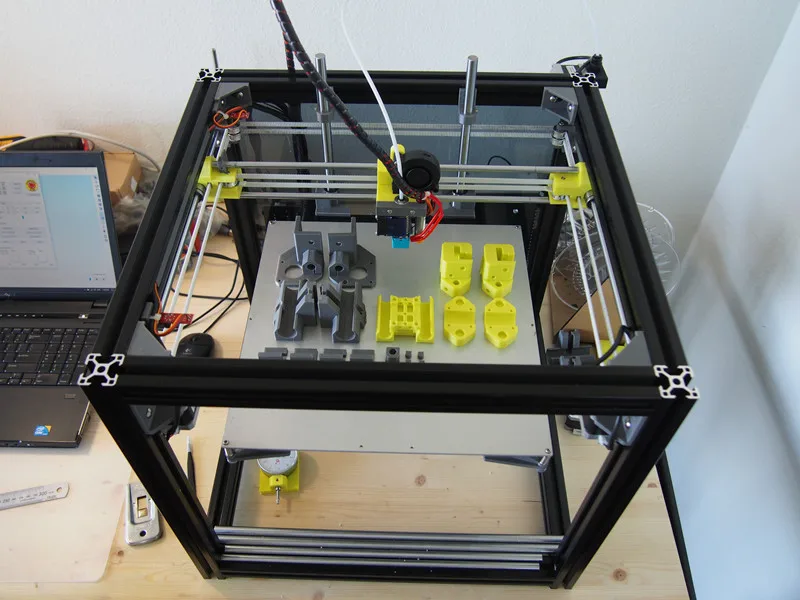

What to Look for in a Commercial 3D Printer

Source: Youtube Tech HD (Car Parts)Are you about to buy the first printer for your business? You might feel a bit lost among all the options for professional 3D printers — and we sympathize.

When browsing through our list of machines, keep an eye on these details to find the right machine for you.

3D Printing Technology

Different types of 3D printers excel at different tasks. If you need strong parts that don’t necessarily look amazing, FDM technology can create components tougher than metal. But if intricate detail is your key to success, SLA resin printers will blow you away with their detail quality.

Printing Performance

Pay attention to the maximum nozzle temperature (with FDM printers) and print speed. The higher the maximum temperature, the more materials you can print with. And, of course, the faster you can print, the higher your productivity.

Material Range

Good professional 3D printers will support a wide variety of materials, from flexible ones to reinforced engineering plastics. But wider material compatibility can add to the price. If you know you only need one or two materials, don’t sink money into a machine that can do it all

Build Volume

Commercial applications often require you to create large prints. Make sure your printer can build big enough parts — otherwise, it’s just a waste of money.

Printer Features

High-end 3D printers often come with advanced features, like a heated print bed and chamber, a built-in camera, and more. These aren’t just expensive toys. You want them to ensure consistently high part quality.

Uses of Commercial 3D Printers

Source: Youtube 3d Printed ProfitsProfessional 3D printers are versatile machines that can benefit many different types of SMEs. If you create a product, you can probably reduce costs, shorten lead times, and streamline workflows with a 3D printer. Here are just some of their leading commercial uses.

Here are just some of their leading commercial uses.

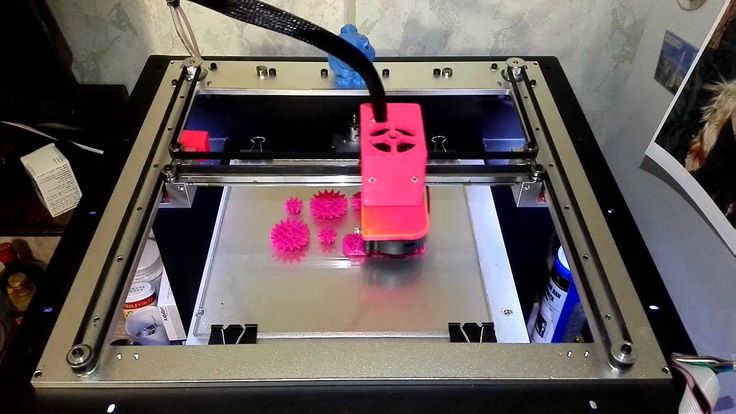

Part Design & Prototyping

3D printing enables a higher degree of design freedom when compared to traditional manufacturing. Combined with materials that can create true-to-life surface textures and detail, you have a powerful prototyping technology in your hands.

The best professional 3D printers produce accurate prototypes in a matter of hours — featuring shapes that are impossible for conventional production methods. You can save time and money by creating your prototypes in-house.

Small-Scale Manufacturing

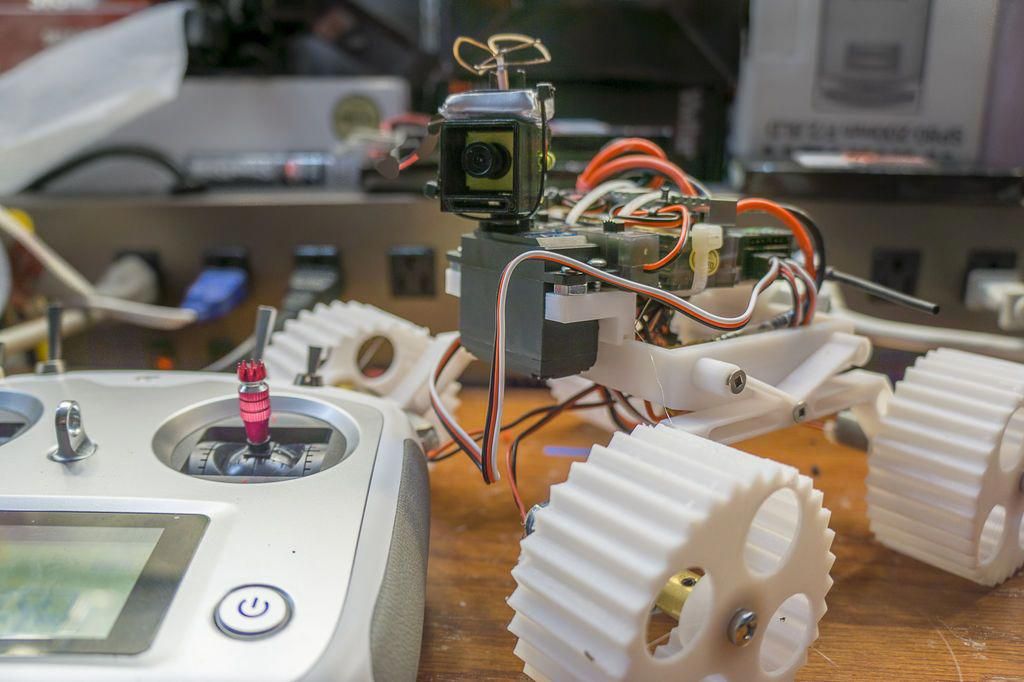

Commercial 3D printers support end-use ready materials, such as nylon or PEEK, and produce durable parts with smooth surfaces. You can print ready-to-sell components for cars, drones, or functional tools.

Alternatively, you can print spare parts for machinery you use for different jobs. Save money and keep your machines running, how about that?

Medical Applications

SLA resin printers — like Formlabs Form 3+ we listed — can create accurate medical appliances from durable, biocompatible materials. These printers are quickly becoming standard fixtures in every dentist’s office, for example. Read our review of the best dental 3D printers here.

These printers are quickly becoming standard fixtures in every dentist’s office, for example. Read our review of the best dental 3D printers here.

But even filament printers have their medical uses. They let doctors produce all kinds of useful tools, like hooks, trays, or medical models.

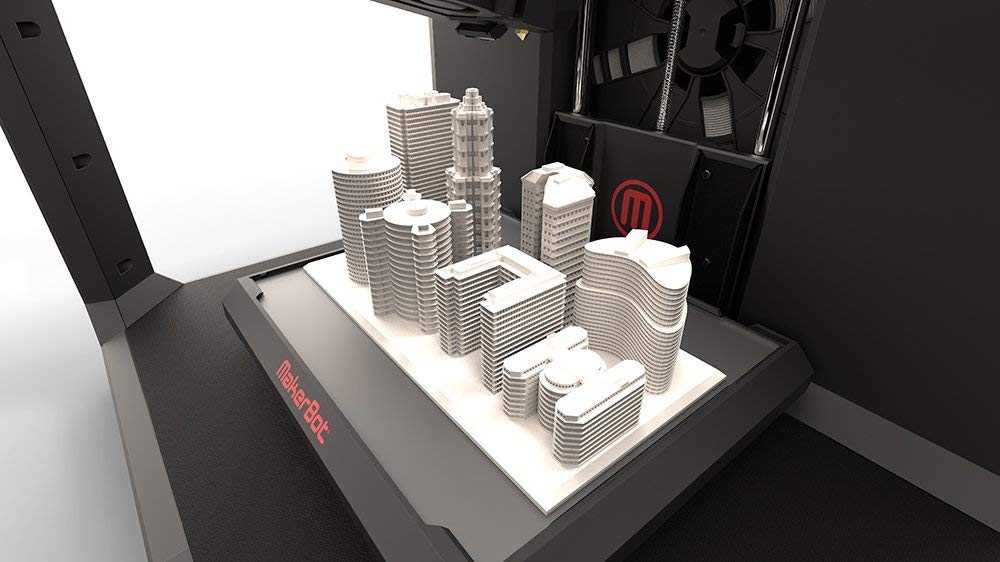

Architecture

Every major building began its life as a blueprint and a model. In the past decade or so, a professional 3D printer has become an architect’s best friend.

Building models by hand can take weeks and cost a fortune. Now, imagine designing a building in 3D modeling software and printing it overnight for a meeting in the morning.

Conclusion

Commercial 3D printers have done to SMEs what industrial printers did to large-scale businesses. They’ve made manufacturing faster, cheaper, and more accessible. A professional 3D printer will be a welcome addition to your business.

If you’re still wondering what the best commercial 3D printers for you are, here are our suggestions:

- For the highest detail quality, consider Formlabs Form 3+ or Zortrax M300 Dual.

- For durable end-use parts, go for Ultimaker S5 or Makerbot Method X.

- Dremel DigiLab 3D45-EDU introduces professional 3D printers to classrooms.

- Finally, the one printer to rule them all is Raise3D Pro2 Plus.

The Best Cheap 3D Printers for 2023

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

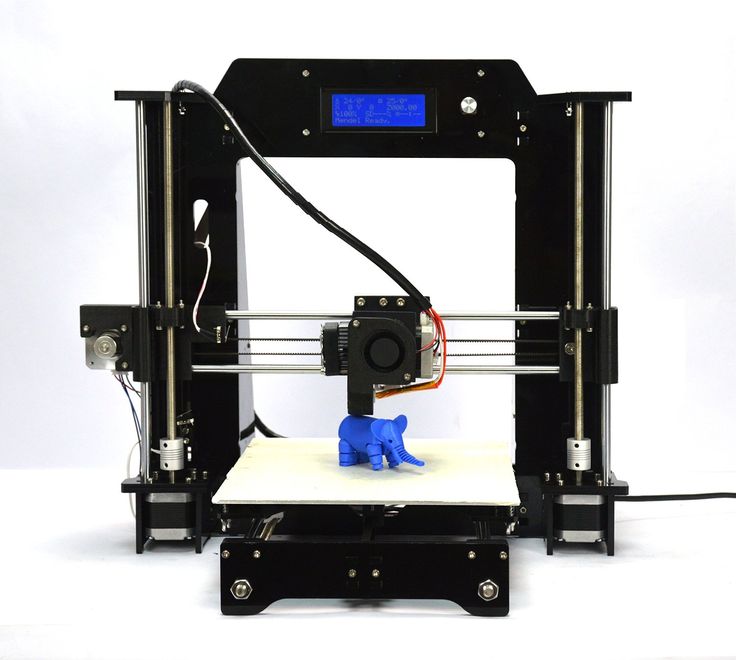

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

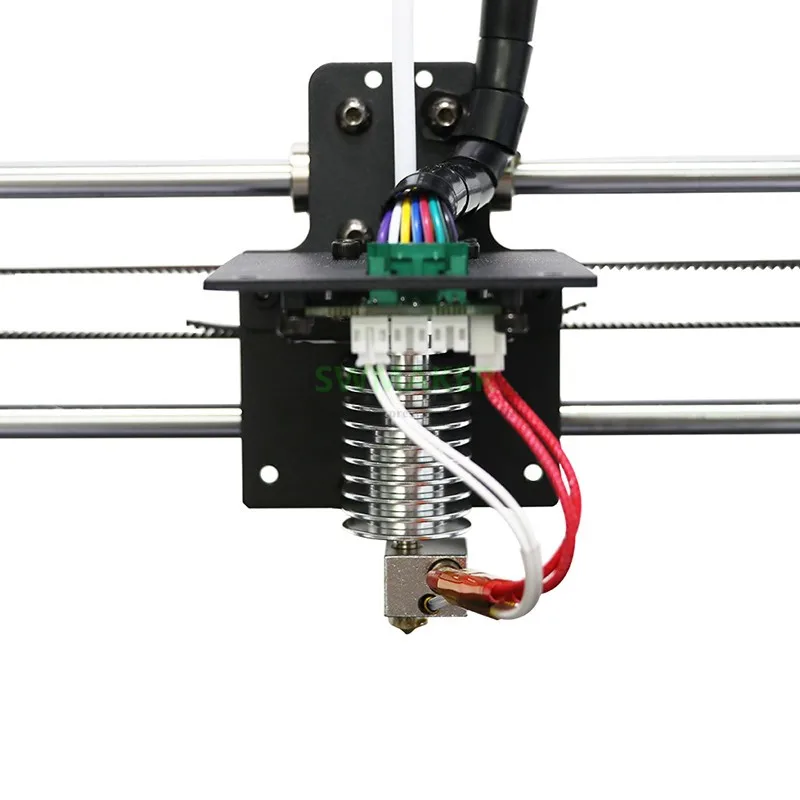

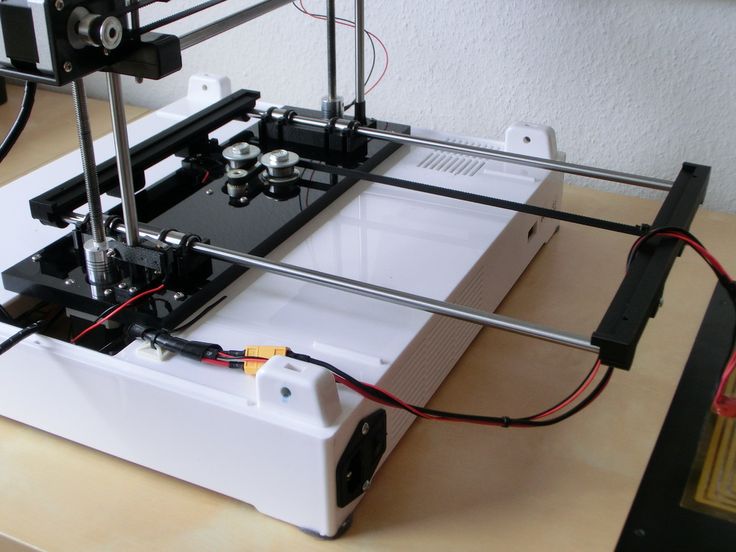

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Deeper Dive: Our Top Tested Picks

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399. 00 00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

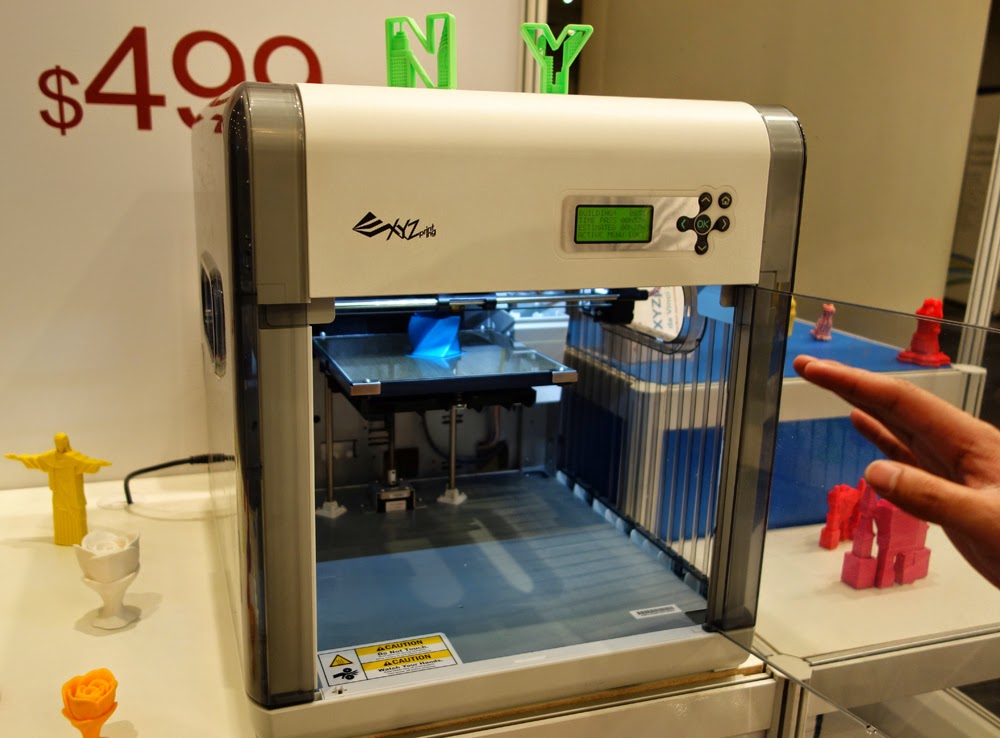

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $199. 95 95 | $199.95 | See It (Opens in a new window) |

| Walmart | $199.95 | $199.95 | See It (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $299.00 | See It (Opens in a new window) |

| Toybox Labs | $379.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

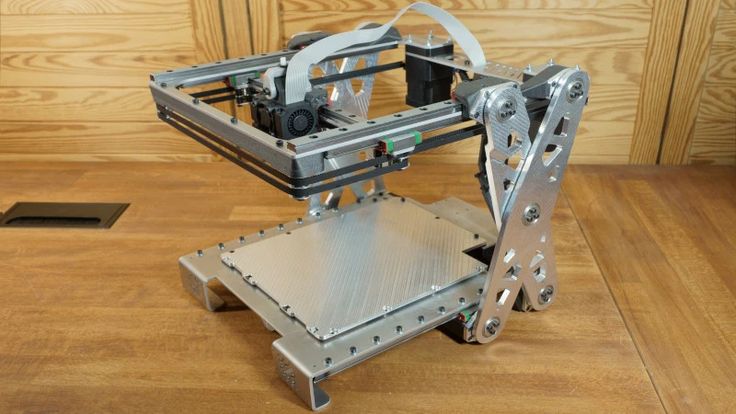

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $323. 98 98 | $323.98 | See It (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229. 98 98 | $229.98 | Check Stock (Opens in a new window) |

| AnyCubic | $279.00 | $279.00 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $339. 99 99 | $339.99 | See It (Opens in a new window) |

| AnyCubic | $369.00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

Creality Ender-3 V2

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $246.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $259.90 | $259.90 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.95 | $199.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $449.99 | $369.26 | See It (Opens in a new window) |

| Walmart | $429.99 | $369.26 | See It (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2023

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

Should I Get an Open-Frame or Closed-Frame 3D Printer?

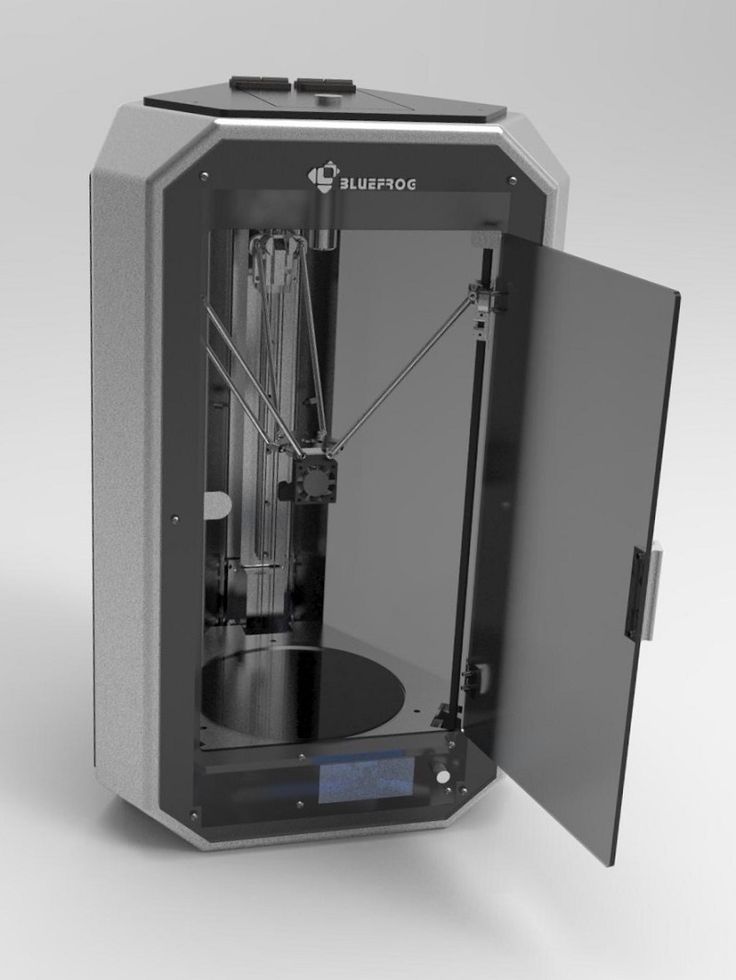

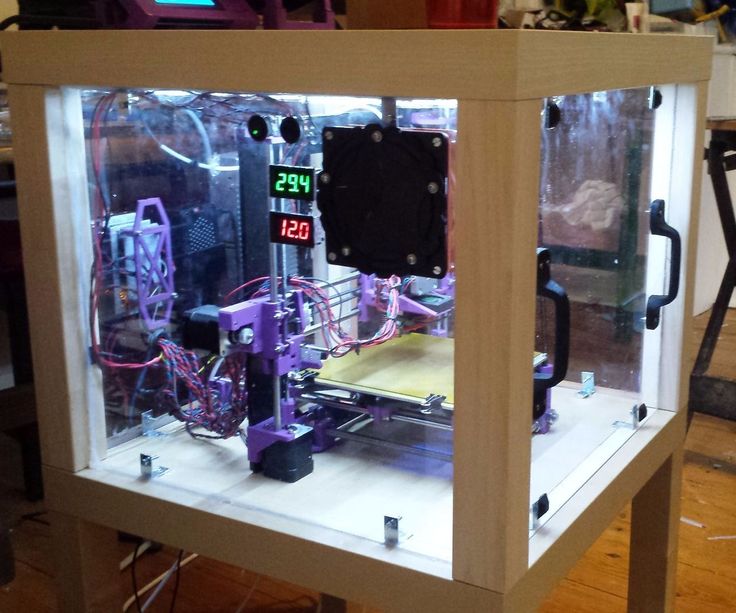

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

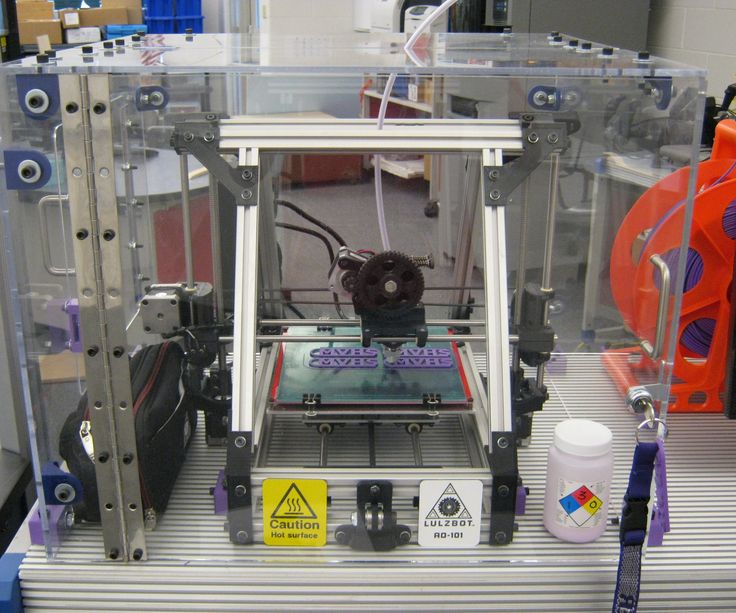

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

top 10 rating according to KP

A 3D printer opens up incredible opportunities for a person. The first prototype of such a device was born back in 1984. The idea of the invention belongs to the American Charles Hull, he received a patent for it only two years after development. The printer was a rather massive industrial installation and, despite many inaccuracies and shortcomings in operation, the technology was used.

The first prototype of such a device was born back in 1984. The idea of the invention belongs to the American Charles Hull, he received a patent for it only two years after development. The printer was a rather massive industrial installation and, despite many inaccuracies and shortcomings in operation, the technology was used.

Hal co-founded 3dsystems, a leader in industrial 3D printers. However, this material is not dedicated to these large machines. 3D printing is becoming more and more part of everyday life. Thus, the technology is used to create unique toys, various models, figurines, packaging, clothes, shoes and jewelry. For these purposes, it is not at all necessary to purchase a large-sized printer. You can get by with a small device. It has a compact size, and its technology is completely identical to the industrial one. Heated plastic is fed through the nozzle (spout) of the device, which is laid out on the surface in accordance with the drawing specified in the program. And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone.

And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone.

Top 10 rating according to KP

1. Creality3D Ender 3

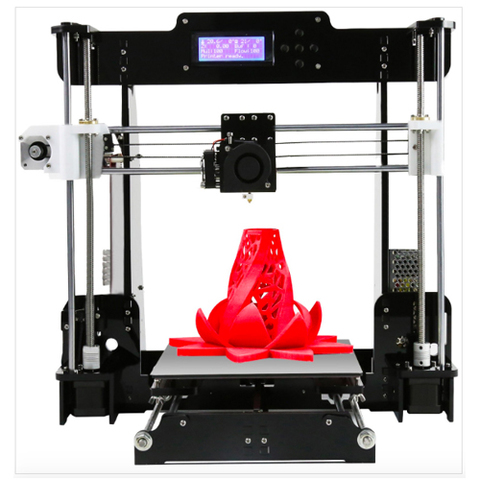

Creality3D Ender 3. Photo: market-yandex.ruOur rating opens with a model from the world's largest manufacturer of 3D printers. The Ender 3 features an elegant and thoughtful design, excellent print quality and a wide build area. Manufacturers have provided a good arrangement of wires that do not get confused during operation. The small control unit of the device is located to the right of the work surface. The gadget prints perfectly with various types of plastic. In particular, we are talking about varieties of ABS, PLA, TPU and PETG. The scope of this printer is quite wide. It can be used to produce minifigures, do artistic modeling, and make small prototypes of parts and functional elements.

The main characteristics

| Print technology | FDM/FFF/PJP | ||

| for the house/DIY | |||

| PLA, Wood | |||

| Workspace width | 220 mm | ||

| Workspace height | 250 mm | ||

| The depth of the workspace | 220 mm | ||

| Features | Heated table, displays, active cooling, nozzle change, USB, Micro SD | ||

| Press speed | 180 mm 900 mm | Number of extruders | 1 |

Pros and cons

Possibility of using various types of plastic, high quality of parts, reliable design

A small display that displays only basic information

2.

FlashForge Adventurer 3 FlashForge Adventurer 3. Photo: market-yandex.ru

FlashForge Adventurer 3 FlashForge Adventurer 3. Photo: market-yandex.ru The model from the Chinese developer FlashForge took the second position in our rating. The device is equipped with a Wi-Fi receiver, a removable heated pad for printing. In addition, manufacturers have provided a built-in webcam, a closed case and a color touch-screen display. The latter, although it does not support the Russian language, is intuitively understandable. The ergonomics of the device is provided by the filament sensor: if the printer runs out of plastic, it automatically goes into standby mode and does not idle.

Pros and cons

Webcam and Wi-Fi receiver allows you to monitor the work, unusual design, simplicity from anywhere in the world in the setup, the presence of a filament sensor

Despite the rather wide functionality, this model is hardly suitable for an experienced printer or a small production due to the small area of the working space, high price

3.

FlyingBear Ghost 5 FlyingBear Ghost 5. Photo: market-yandex.ru from FlyingBear is ideal for semi-professional use. Uniform supply of filament (plastic) provides good opportunities for creating three-dimensional figures with a fairly high resolution. High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display.

FlyingBear Ghost 5 FlyingBear Ghost 5. Photo: market-yandex.ru from FlyingBear is ideal for semi-professional use. Uniform supply of filament (plastic) provides good opportunities for creating three-dimensional figures with a fairly high resolution. High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display. The main characteristics

| Print technology | FDM/FFF/PJP | |||

| for the house/DIY, Essential level | ||||

| Open Cam | Open Camera | Open Cam | ABS, PLA, Wood, HIPS | |

| Workspace width | 255 mm | |||

| Workspace height | 210 mm | |||

| Working space | 210 mm | |||

| Features | Heated table, display, active cooling, nozzle adjustment, temperature control | |||

| Wi-Fi | Wi-Fi, SD Wi-Fi, SD 9001||||

| Print speed (extruder speed) | 150mm/s | |||

| Number of extruders | 1 | |||

| Printing accuracy | X, Y 0. 01 mm 01 mm | |||

| Positioning accuracy | Z 0.002 mm |

Pros and cons

Short power cord, inaccuracies in the Russian-language menu, weak airflow system.

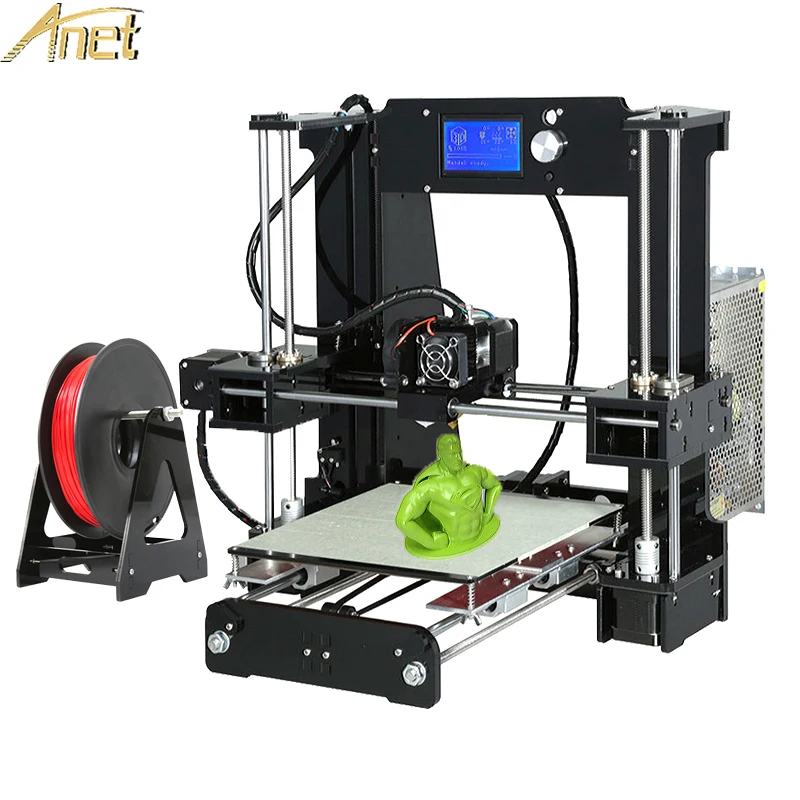

4. Anet N4

Anet N4. Photo: market-yandex.ruThe budget model from the Chinese manufacturer Anet N4 is equipped with all the necessary functions for a small domestic production. The base of the device is made of cast aluminum alloy. The weight of the gadget does not exceed 9kg. A transparent tinted hood protects the work surface from external sources of ultraviolet radiation. It can be removed to remove the finished product and clean the printer. Also, manufacturers have provided a removable resin bath and a working platform, which greatly facilitates the use of the device.

Key Features

| Print Technology | LCD | |

| Application | Home/DIY Professional | 30 mm/h |

Pros and cons

Ability to use photopolymer resins from any manufacturer, high polymer curing speed

Small work surface, slightly inferior to competitors in some parameters

Photon Scu0bic0 Anycu0bic08 5. S. Photo: market-yandex.ru

S. Photo: market-yandex.ru In the middle of our rating is the Anycubic Photon S model. It is equipped with an advanced optical system and a large working camera. The device has a matrix light source that provides a uniform luminous flux over the entire plane of the desktop. This allows a very high curing speed of the layers to be achieved. In addition, the printer has an original function that allows you to simultaneously print eight identical models. According to the developers, the target audience for this device are orthodontists and jewelers. Most parts of the device are made of plastic. This factor significantly reduces the weight of the device and makes it convenient to transport.

Plus and disadvantages of

9000 Small worktop6. ELEGOO Mars Pro

ELEGOO Mars Pro. Photo: market-yandex. ru

ru This model is significantly different from its predecessor Elegoo Mars. Thanks to the advanced Z-axis mechanics and directional UV light from the diode array, it is suitable not only for hobbies, but also for fields of activity such as dentistry and jewelry. In addition, the developers moved the USB connector to the front of the device. Now there is no need to constantly rotate the gadget in the process. The weight of the device is only 7.5 kg, which makes it very convenient for transportation. A translucent plastic cover will reliably protect against extraneous radiation and will allow you to monitor the production process.

The main characteristics

| Print technology | LCD |

| Field | for the home/diy, for medicine |

| Print speed: (layer build-up) | 22. 5 mm/h 5 mm/h |

| Print precision | X, Y 0.047 mm |

| Positioning accuracy | Z 0.125 mm |

| The wavelength of light source | 405 Nm |

PLASS AND MINCOUS COURENTIONAL CENTURE, LIGHT price, good UV light 9000 9000 9000 7. Two Trees Bluer

Two Trees Bluer. Photo: market-yandex.ru This is one of the most popular home models of 3D printers. It is ideal for getting acquainted with technology, various experiments, training and prototyping. Distinctive features of Two Trees Bluer are: "quiet" drivers, which are the engine of the device, a heated table, two-way airflow and a thread break sensor. The mechanics of the printer is quite simple, and at the same time very effective. The open type case will be very convenient when cleaning the work surface. The firmware of the device provides the functions of auto-calibration and automatic resumption of printing in case the power was accidentally turned off.

Pros and cons

Low price, easy and convenient to use

Lack of protection for the work surface, poor quality of spare parts

8. Wanhao Duplicator i3 Mini

Duplicator Mini i3. Photo: market-yandex.ruMiniature 3D printer does not look like other devices. However, this feature does not affect its technical characteristics. The plastic spool is located on the right side of the bracket. Wanhao branded coating is pasted over the table. There is no platform heating, so it is recommended to use PLA plastic for printing. The manufacturer clearly states in the manual that the printer is designed to work only with PLA material and nothing else. The body of the gadget is made of sheet steel. The memory card slot and all printer control elements - a monochrome liquid crystal display, a universal knob-button and a Reset micro-button - are placed on the front panel of the printer.

The main characteristics

| Print technology | FDM/FFF/PJP |

| educational, for house | PLA |

| Working space width | 120 mm |

| Working space height | 100 mm |

| The depth of the working space | 135 mm |

| Features | displays, active cooling, speed control, temperature control | USB, SD card |

| ) | 70 mm/s |

| Number of extruders | 1 |

| Printing accuracy | X, Y 0. 012 mm 012 mm |

| Positioning accuracy | Z 0.004 mm |

Pros and disadvantages

Good price

Lack of heating and protecting the working surface, high probability of problems with a working coil

9.

Artillery Genius. Photo: market-yandex.ruThe base of the device consists of an aluminum case, in which all the electronics are hidden. An aluminum portal is also attached to it. The latter is also a guide for the moving parts of the printer. At the top of the portal is a plastic jumper to which the spool holder and filament sensor are attached. As for the control screen, its functionality is seriously curtailed. However, it is sufficient for simple tasks, but it is impossible to configure the printer.

The main characteristics

| Press technology | fdm/fff/pjp |

| Educational, for the house/DIY, Industrial, Professional material | for printingABS, Flex, Nylon, PLA, PETG, SBS, CopperFILL, DuraForm TPU |

| Working width | 220 mm |

| The height of the workspace | 250 mm |

| DEMPLE DIFFICULATION | 220 mm |

| Features | The heated table, Active speed, Contact control, Contactive |

| USB, micro-SD | |

| Print speed (extruder speed) | 150 mm/s, |

| Number of extruders | 1 |

Pros and cons

Spacious work surface, robust housing

Little functionality for a rather high price, lack of work surface protection, few functions on the control screen.

10. Tianfour Sparkmaker

Tianfour Sparkmaker. Photo: market-yandex.ruThis model is ideal for beginners, as it does not require additional settings at all before starting work. Externally, the printer has the shape of a cylinder with a height of 27.5 cm and a diameter of 17 cm. The realistic contours and smooth curves of the figures are ensured by LCD technology. The printer works with any photopolymer resins for 3D printing with a flash length of 405nm.

How to choose a 3D printer

Choosing a 3D printer is not such a difficult task as it might seem at first glance. Despite the relentless interest in 3D printing and the incredible number of devices on the market, the basic requirements for models remain unchanged. Komsomolskaya Pravda turned to Svyatoslav Vulf, a blogger and host of a YouTube channel about modern technologies and experiments, for help in this matter. He regularly monitors new products on the 3D technology market and tests them at home.

Product size

Initially, you should decide what size of products you expect to receive in the end. The required area of the working surface depends on this. Note that the price of the device also depends on the size of the latter. For work at home, there will be enough indicators: 200 × 250 × 200 (WxHxD).

Technology

Today, there are several technologies for printing on a 3D printer. They differ significantly from each other. Let's consider some of them.

SLA-technology — works on the basis of a liquid photopolymer, which under the influence of laser light changes its physical properties and hardens. It allows you to create figurines with the highest precision of microforms.

DLP technology is an alternative SLA method. However, instead of laser systems, LED projectors are used here, which significantly reduce the cost of 3D printers. When using this technology, the future prototype is formed layer by layer.

The FDM method is ideal when prototypes are required that will be actively used and not just sitting on a shelf. Here, high-strength industrial plastics will be used for production. Please note that there are other technologies, but they are very similar to the above.

Material

Before buying a printer, you should also pay attention to what materials it works with, as they have significant differences from each other. For example, ABS can take many different polymeric forms. This is a very durable plastic. It is easily sanded and processed. PLA plastic is considered more environmentally friendly. It is made from agricultural products - corn, potatoes, beets and others. In its original form, it is transparent and can be colored. PLA is just as strong but tougher than ABS. The ductility and heat resistance of SBS make it the material of choice in engineering and mechanical applications.

Noise level and drivers

An important factor when choosing a 3D printer are drivers - device engines (not to be confused with software). They affect the overall noise level of the device. For example, if you buy a printer with cheap A4988, then even neighbors will hear its work. In this case, you should pay a little more and purchase a gadget with more expensive drivers.

They affect the overall noise level of the device. For example, if you buy a printer with cheap A4988, then even neighbors will hear its work. In this case, you should pay a little more and purchase a gadget with more expensive drivers.

Self-assembly

Some manufacturers prepare the model completely before sale. The buyer can only get the printer out of the box and connect the power. However, there are some models that require self-assembly. Be sure to consider this factor before purchasing. If you are purchasing such a device for the first time, then it will not be easy for you to assemble it.

4 3D printing trends in 2023

Analytics and business

Experts recommend

Author: Viktor Naumov

Author: Viktor Naumov

Year after year, the adoption of additive manufacturing reaches new heights. What can we expect from 2023? Materialize, a leader in the global 3D printing market, offered its forecast based on four key trends that will drive the industry over the next twelve months:

-

the rise of smart, distributed manufacturing;

-

focus on cost reduction;

-

transition from automation of individual processes to complex automation of the workflow;

-

data security and integrity becomes a priority.

By addressing these issues, companies will be able to bring 3D printing to the level of mass production and accelerate the adoption of additive technologies.

Over the past three decades, 3D printing has established itself as a versatile and flexible tool in the manufacturing arsenal. Being a relatively new technology, it has spent most of this time somewhat isolated from the traditional manufacturing process. But in recent years, the wall between classic manufacturing and 3D printing has begun to disappear. We are starting to see these two separate worlds coming together, and the implications are enormous.

In 2023, the above trends will be the key to overcome the barriers that are still associated with the introduction of technology into industrial production. Addressing these issues will help companies scale up 3D printing to mass production and accelerate the adoption of 3D printing.

Fried Vankran, CEO of Materialize

© Materialise

1.

The rise of smart, distributed manufacturing

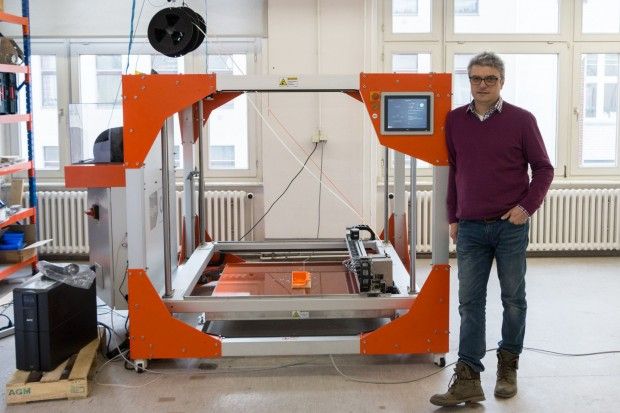

The rise of smart, distributed manufacturing Traditionally, production has always been concentrated in one place - usually a factory in another country. This system worked well until it stopped working. Over the past few years, we have seen how the COVID-19 crisis has paralyzed production and disrupted supply chains. We have witnessed an increase in geopolitical tensions and environmental concerns. All this taken together forced manufacturing companies to reconsider their model of centralized production. And with the help of smart digital technologies like 3D printing, manufacturers can move to multiple, smaller sites closer to customers.

Find the right 3D printer for you

However, many of the recent implementations owe their success to quick decision making in the face of scarce funds, such as reaching out to local 3D printing service providers to produce essential medical devices during the coronavirus pandemic. It can be said that 3D printing has been used as a temporary replacement. But, fortunately, such decisions have sparked new conversations about the future of production.

But, fortunately, such decisions have sparked new conversations about the future of production.

Now we see that many companies are ready to take a more strategic approach. These companies need to carefully consider which applications will deliver the most value in terms of supply chain efficiency or environmental sustainability. And this requires a change in thinking, moving from short-term solutions to the use of additive technologies as a stable method for the production of certified final parts.

A good example is CNH, an agricultural machinery company. During the pandemic, CNH was 3D-printing a vital part that could not be obtained due to COVID-related logistical constraints. The experience has proved useful, and the company is now looking at 3D printing as part of its strategy to manage supply chains in a more cost-effective way.

3D printing at CNH © cnhindustrial.com

Thus, the potential is real even in such a highly regulated field as medicine. We are seeing hospitals increasingly turning to 3D printing to create medical models and personalized implants in situ, close to patients.

We are seeing hospitals increasingly turning to 3D printing to create medical models and personalized implants in situ, close to patients.

We can say that this is the medical equivalent of a decentralized model of industrial production. Ultimately, we have smart, distributed manufacturing enabled by 3D printing that, when approached strategically, can be a recipe for success rather than an ad hoc response to problems.

Hanne Gielys, Innovation Manager, Mindware

2. Focus on cost reduction

The history of 3D printing is a history of added value. Additive manufacturing allows for design optimization, delivering performance, weight savings, time savings and supply chain savings that traditional manufacturing methods cannot achieve. In many cases, these benefits create opportunities for cost savings that affect overall manufacturing costs, from design to delivery.

Manufacturers planning to scale additive manufacturing to thousands or even millions of parts must ensure that the 3D printing process is efficient, reliable, and repeatable across multiple manufacturing sites.

Peter Lace, Executive Chairman, Materialize

A recent survey showed that the ability to reduce overall manufacturing costs is cited as the most important benefit of 3D printing. But this does not necessarily mean that the additive process itself is cost effective. Rising material and energy prices have only further increased costs.

The cost of 3D printed parts is determined by several factors, including the materials needed, the lead time per part, and the type of printer. There are two really important ways to reduce these costs. The first is more efficient work to increase production capacity. Software plays a big role in this, allowing you to optimize your designs. We can also customize the printing process to make it more efficient and repeatable. The second way is to use tools and improve quality. And you have to pay for quality.

© Materialise

If we take a certified production in the medical or aviation industry, we will see that up to 70 percent of the cost of production is accounted for by quality control. 3D printing continues to transform factory floors as companies increasingly turn to the technology for large-scale production. But to accelerate this adoption, our industry will have to work harder to bring down the cost of 3D printing.

3D printing continues to transform factory floors as companies increasingly turn to the technology for large-scale production. But to accelerate this adoption, our industry will have to work harder to bring down the cost of 3D printing.

Brian Crutchfield, Vice President and General Manager, North America

3. Transition from single process automation to integrated workflow automation

3D printing is a digital manufacturing technology, but it still requires a lot of human intervention. And such skilled workers are becoming increasingly difficult to find. According to a recent study by Materialize, finding the right people with the right knowledge and experience is a major challenge for companies that already use or are considering using 3D printers.

At the same time, scaling industrial additive manufacturing to thousands or millions requires repeatability and stability of the printing process. These two issues have increased the need for automation in recent years. The software allowed us to automate various steps in the 3D printing process, from preparing and editing files to creating supports, optimizing object placement in the build chamber, and even post-processing.

The software allowed us to automate various steps in the 3D printing process, from preparing and editing files to creating supports, optimizing object placement in the build chamber, and even post-processing.

But these are all separate processes. In 3D printing, they follow each other, merging into a complex digital manufacturing process. The promise of large-scale industrial 3D printing requires us to automate not only each individual process, but also the workflows between them. And this is what we call end-to-end workflow automation.

© Materialise

We see the same thing in the medical industry, where complex process automation is needed to cope with the surge in custom 3D solutions. The good news is that opportunities to meet this need are growing with the creation of software platforms that allow manufacturers to customize their own unique 3D printing process.

Isabelle Rombaugh, Director of Global Sales and Business Development Medical

4.

Data security and integrity becomes a priority

Data security and integrity becomes a priority We have already talked about such an important trend as distributed production. Smart digital technologies, including 3D printing, are making it possible to move production to several smaller sites closer to customers. This is a clear sign that the factory of the future will not have a single, central location. This new digital distributed manufacturing environment revolves around one key asset - data, and this data must be protected so that an unscrupulous supplier cannot steal the design and print the product on their own 3D printer.

Of course, data security is important in any kind of manufacturing, be it traditional or smart. In both cases, companies share their unique designs with contractors and suppliers, and they want to know that their design data will remain secure. But in the case of 3D printing, that's not all. Manufacturers planning to scale additive manufacturing to thousands or even millions of parts must optimize and fine-tune their unique printing process to ensure it is efficient, reliable and repeatable across multiple manufacturing sites.