Zeiss 3d scanner

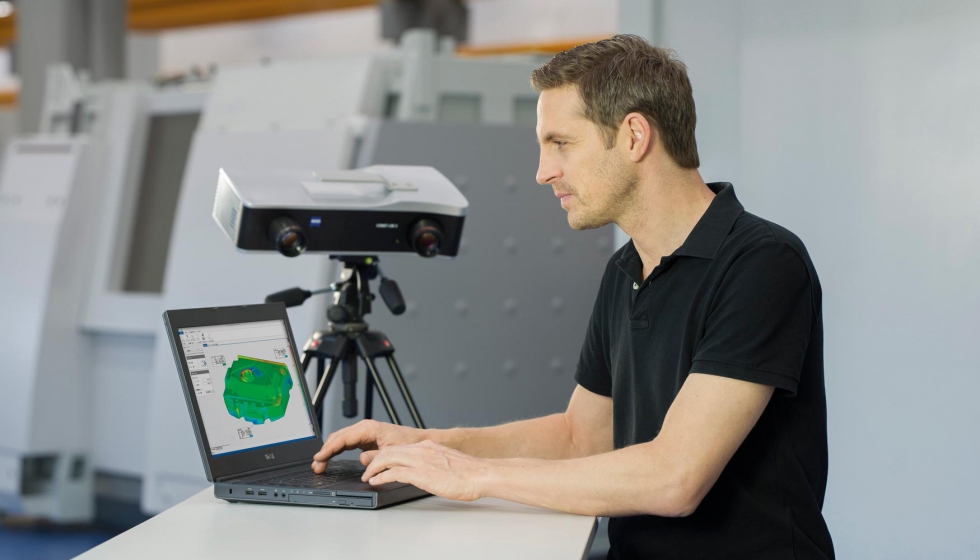

ZEISS colin3D - Optical 3D capture and 3D analysis

- Download information

Overview

Brochures & Technical Data

Success Stories

Recommendations

Contact us

Highlights

- Perfectly matched to optical 3D sensor systems from ZEISS Optotechnik

- Fast triangular network generation

- Surface comparison with report function

- Intuitive network processing

- Documentation of calibration

- Monitoring of system accuracy

- Automatically high-quality measured data through intelligent quality criteria

Innovative functionality

The ZEISS colin3D software platform is designed to ideally complement the COMET, COMET Photogrammetry and T-SCAN sensor systems. The program independently identifies the ideal strategies for merging individual images (matching) and guides you to the ideal result using a completely redesigned, project-oriented user interface. Thanks to the CAD integration, you receive continual feedback about the component surface areas that still need to be captured.

Maximum performance

Based on years of programming experience with 64-bit operating systems and the corresponding hardware such as graphics cards and multi-processor systems, the new algorithms of ZEISS colin3D achieve maximum performance and data quality.

Optimal user support

To quickly and efficiently position the T-SCAN system from ZEISS, the measurement field and scanner can be optionally displayed in ZEISS colin3D, making it easier to determine the ideal tracker position. Measuring programs for applications using the rotary tables COMETrotary and COMETdual rotary can be easily generated and executed. All individual measurements in a measurement sequence are subjected to quality checks and automatically repeated if necessary.

Measuring programs for applications using the rotary tables COMETrotary and COMETdual rotary can be easily generated and executed. All individual measurements in a measurement sequence are subjected to quality checks and automatically repeated if necessary.

Quick triangular network computation using high-quality data reduction

Simple off-color comparison

Data analysis functions

For quality assurance applications, the scan data can be compared on the surface of a CAD model using a simple best fit alignment. ZEISS colin3D contains a simple false color display with a color gradient and fixed values. To more precisely analyze deviations, users can place the flyers on the surface individually as required. Reports for documenting the measurement results can be easily and quickly generated and managed.

Reports for documenting the measurement results can be easily and quickly generated and managed.

Download more information

See how other customers use this product:

3D data opens door to New Knowledge

University of Würzburg uses a ZEISS COMET to document and evaluate archeological finds at excavation sites.

A precise grip and perfect trajectories

August Mössner GmbH & Co. KG optimizes production and programming with ZEISS T-SCAN

KG optimizes production and programming with ZEISS T-SCAN

Digitizing Cast Parts with Laser Scanners

VULKAN Measures Coupling Components Optically

For perfect Gap and Joints

BMW in Munich increases process reliability for front and rear end assembly with ZEISS T-SCAN

Improving Speed, Quality and Employee Retention

Landolt inspects delivered parts prior to assembly with ZEISS T-SCAN and performs reverse engineering jobs.

Precision for Guaranteed Stability

PERI checks key components for formwork and scaffolding systems with ZEISS COMET and ZEISS T-SCAN.

The Foundation for Innovation? Perfect 3D Models

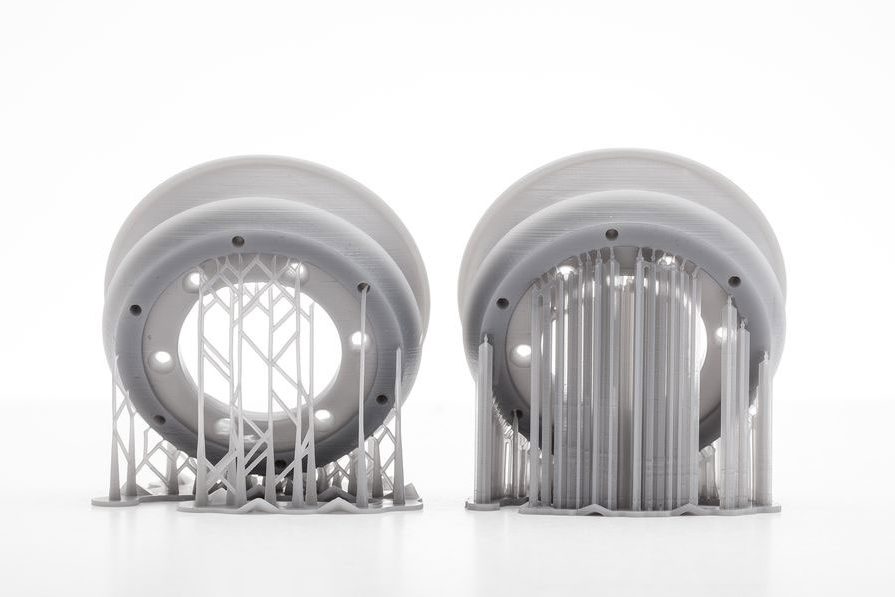

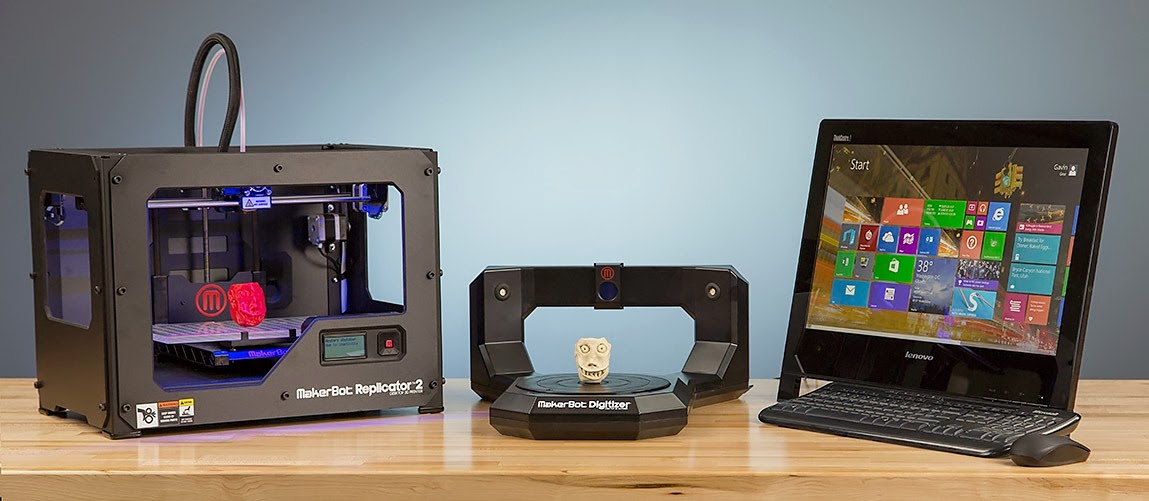

JP3D TecVision specializes in additive manufacturing methods and uses the ZEISS COMET in its production processes

The superlative in measuring technology

Swiss manufacturer of water fittings increases quality with ZEISS T-SCANCompatible CMM:

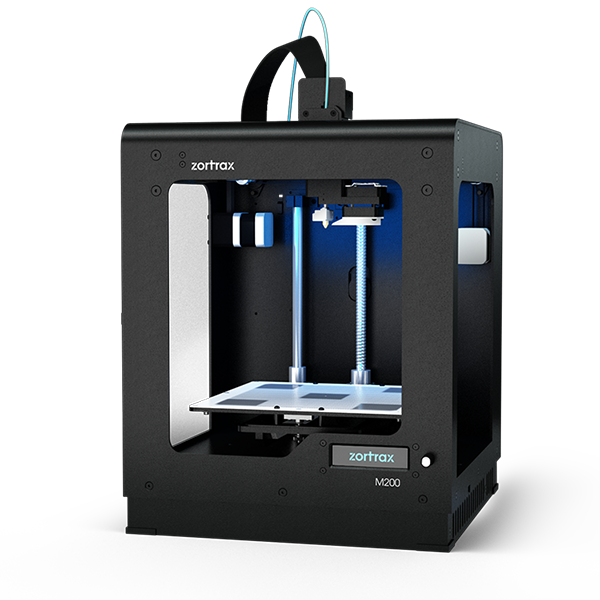

ZEISS COMET 6

High-end 3D sensor for high-precision 3D digitization

Available software:

ZEISS REVERSE ENGINEERING

Reverse engineering, tool correction and volume calculation

Available services:

ZEISS Academy Metrology

Qualification tools and services, customized to your needs and ready to elevate your skills and expertise.

ZEISS Metrology Portal

Your digital access point to all metrology services

Welcome to the 3D Scanning World

#HandsOnMetrology – Made for makersOn #HandsOnMetrology, ZEISS offers 3D scanning solutions, know-how and a user community that wants to get things done.

#HandsOnMetrology is a unique 3D scanning platform that connects technology buffs, designers, engineers, scientists and experts around the world. The platform provides exciting insights into the modern world of metrology and shows one thing above all: enthusiasm for the diverse applications. Be it scanning or CAD, interested newbies and users learn everything they need to know to realize their ideas, optimize processes, get inspiration or talk shop about new 3D metrology applications.

A small scanner for high demands

The compact and portable GOM Scan 1 3D scanner is versatile and fast. The sensor uses industrial standards such as GOM’s fringe projection technology and Blue Light Technology to ensure detailed and accurate 3D meshes. Thanks to the integrated GOM Inspect software you can use it for any kind of project.

Inspiring maker stories for the 3D scanning community

People who are driven by innovation, quality and perfection need the necessary tools and skills to turn their goals and ideas into reality. This is where state-of-the-art 3D scanning solutions come in because they open up new horizons for solving problems and optimizing processes. Our inspiring and informative maker videos on HandsOnMetrology.com reflect this innovative spirit: Makers from the community talk about 3D metrology and how they use it for all kinds of projects. You can really feel each maker's passion for technology while they are telling their stories or contributing to the #HandsOnMetrology network. This creates a sense of belonging and encourages the constant development of new solutions.

This creates a sense of belonging and encourages the constant development of new solutions.

The MMG company from Waren an der Müritz is a case in point. This well-established company with 150 years of experience builds the world's largest marine screw propellers. It takes three to four months from design to shipment to build such propellers from up to 300 tons of molding material. Different types of control and inspection steps are required throughout development and production. Michael Beuster, Head of Optical Measurement, is thus especially excited about the flexible use cases for the portable equipment: "The great advantage of our measuring system is that we can use it wherever we need it in our company."

At the Brussels-based Cowboy company, on the other hand, the focus is on the benefits of 3D scans for design development. The start-up was established in 2017 and specializes in e-bikes for urban commuters. The wheels boast a purist design and the engine uses algorithms to calculate the power required for optimal driving comfort at any given moment. Olivier Fourier, head of the development team, especially appreciates the high measuring speed: “We can now scan a bicycle or bicycle part in no time with 3D scanning. This helps us to optimize processes to better match the parts, identify the design flow, or to improve performance.”

Olivier Fourier, head of the development team, especially appreciates the high measuring speed: “We can now scan a bicycle or bicycle part in no time with 3D scanning. This helps us to optimize processes to better match the parts, identify the design flow, or to improve performance.”

The portable 3D scanning solution

T-SCAN hawk is the portable all-in-one solution for 3D scanning and inspections. Thanks to its compact design, it is well suited for confined spaces and hard-to-reach areas. The preinstalled GOM Inspect software manages every step from scanning down to reporting.

For all those who want to dive deeper

#HandsOnMetrology helps interested users to put their applications into practice. The Getting Started videos have become a regular feature of the site, while the How to videos deal with specific questions. In One-Minute insights professionals give in-depth explanations of the GOM Inspect 3D metrology software functions.

Do you have any specific questions or have you reached a dead end with a challenging project? The global network of experts is happy to discuss your project with you. Our worldwide virtual demos are ideal for dealing with specific issues: Join online sessions in small groups and discover, for instance, how GOM Scan 1 can simplify your professional scanning jobs. You can even send in a part beforehand and then discuss the measuring tasks and results with the other participants during the session.

Even better, meet up with us live on our #HandsOnMetrology Tour and test out our 3D scanning solutions for yourself. Discover the pioneering measuring systems of ZEISS together with experts and other users.

GOM Inspect SoftwareGOM Inspect is the comprehensive, user-centric 3D metrology software that tackles every challenge. It has one user interface that handles the entire workflow, which covers complex inspection tasks in different applications. You can easily visualize surface inspections, perform GD&T analyses, generate reports and more.

You can easily visualize surface inspections, perform GD&T analyses, generate reports and more.

ZEISS Reverse Engineering is our software solution for professional reverse engineering of geometric, freeform or organic shapes. It quickly transforms 3D scan data, such as polygon meshes or point clouds, into highly precise CAD models.

ATOS QVersatile 3D scanning system for the industry

The precise, flexible and reliable ATOS Q 3D scanner was designed specifically for industrial purposes and complex measurement and inspection tasks. Its Triple Scan Principle is ideal for measuring reflective surfaces and rough objects.

3D scanner Zeiss T-Scan LV in Kaluga (Optical instruments for measuring linear dimensions)

Price: Specify the price

for 1 unit.

Product Description

• Innovative all-in-one scanning and tracking solution with manual laser scanner, optical tracking unit and stylus

• Large measurement volume and high accuracy

• Superior measurement speed

• Redundant free dynamic autoscale set ( hardware / software) for in-field calibration

• Measurement on moving objects with dynamic reference

Characteristics of Zeiss T-Scan LV 3D scanner

- — Country of manufacture: Germany

- — Brand: Carl Zeiss

Items similar to Zeiss T-Scan LV 9 3D Scanner0008

Don't wait, order Zeiss T-Scan LV 3D Scanner from Carl Zeiss Optotechnik (Steinbichler RUS), LLC in our BisOrg catalog.

Why Carl Zeiss Optotechnik (Steinbichler RUS), Ltd.:

- quality assurance and timely fulfillment of the assumed duties;

- various payment methods;

- Carl Zeiss Optotechnik (Steinbichler RUS), LLC offers special conditions for users of the BizOrg platform;

- Carl Zeiss Optotechnik (Steinbichler RUS), Ltd. works with well-known manufacturers.

Contact us now - don't wait!

FAQ:

- How to submit a request

Call Carl Zeiss Optotechnik (Steinbichler RUS), Ltd. using the contacts listed in the upper right corner in order to submit a request for a Zeiss T-Scan LV 3D scanner . Be sure to indicate that you found the company while on the BizOrg marketplace.

- The description is incorrectly priced, the phone is not answered, etc.

Please contact our support team if you have any difficulties while working with Carl Zeiss Optotechnik (Steinbichler RUS), Ltd.

Technical information:

- the offer was placed from 01/03/2017, the renewal period is 01/03/2017.

Follow the changes on the site to see important information in time;

Follow the changes on the site to see important information in time; - "Zeiss T-Scan LV 3D scanner" are in the categories: "Instruments and automation", "Instruments for linear and profile measurements", "Instruments for control of engineering products", "Optical instruments for measuring linear dimensions". In the same sections, you can find other products or services that may be of interest to you;

- the number of views of information on the presented page of the resource - 225 times.

Please note that the BizOrg.su trading platform is for informational purposes only and under no circumstances is it a public offer.

The price declared by Carl Zeiss Optotechnik (Steinbichler RUS), Ltd. for the product "Zeiss T-Scan LV 3D scanner" may not be the final selling price. For detailed information on the availability and cost of these goods and services, please contact the representatives of Carl Zeiss Optotechnik (Steinbichler RUS), LLC at the specified phone number or e-mail address.

Phones:

+79190375753

+79105118086

Buy Zeiss T-Scan LV 3D scanner in Kaluga:

st. Automotive 1A

3D scanner Zeiss T-Scan LVscanning - Technology Center, FSUE "NAMI"

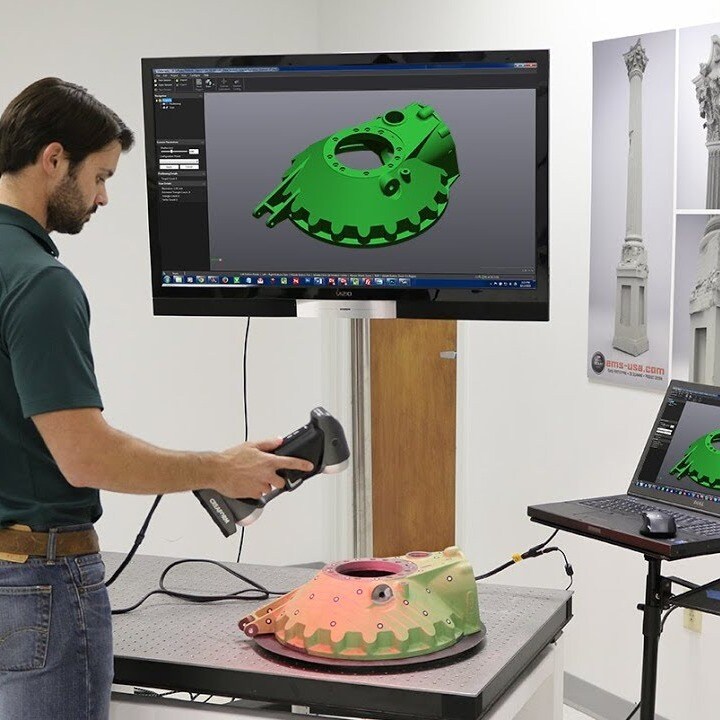

3D scanning and reverse engineering

Non-contact geometry control

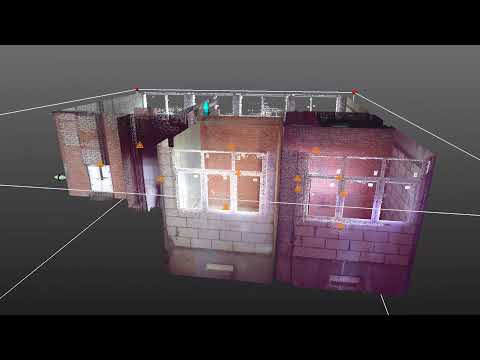

| 3D Scanner Field of view: up to 3700 x 2600mm | Geometry control using 3D scanning is applied at every stage of the production of a part. The geometry of products is controlled on a non-contact scanner and a coordinate measuring machine. To control deviations of the part surface geometry, a 3D scan of the object surface is first performed. Deviation maps will allow you to draw a conclusion about the deviation of the part geometry from the CAD model, and are convenient when choosing a strategy for further processing, since they allow you to "fit" the part into existing allowances. The geometry comparison report (nominal/actual comparison) is saved as a PDF file. |

Reverse engineering

In cases where there is no design documentation, it is necessary to scale or change the geometry of the part, reverse engineering (reverse engineering) is used.

This procedure produces an editable CAD model using scanned data.

3D scanning provides source data in the form of a Point Cloud. This data set contains points taken from the surface of the part, they are described by three coordinates.

The point cloud is almost never used for further work and is immediately converted to a polygonal mesh (Mesh).

Using a polygon mesh, the designer creates a solid CAD model.

The resulting model can be edited or used as input for designing other parts.

You can save the CAD model as a native PRT file or in universal formats - STP,

IGES and STL.Reverse engineering stages

| Scan metal part | The result of the 3D scanner is a point cloud (Point Cloud) | Polygonal surface (Mesh) - processed scan data | Solid CAD Model | Deviation field - the result of comparing scan data and CAD model | Drawing |

Geometry contact control

| Coordinate Measuring Machine Coordinating-measuring machine | Coordinate Measuring Machines are used for high-precision control of the geometry of parts after machining. Used to check the dimensions of parts: |

| Technology Center |

039 µm

039 µm