3D printing and design

3D-printed design | Dezeen

Search results:

Refine your search:

-

Mighty Buildings completes 3D-printed net-zero home in southern California

Mighty Buildings has delivered what it claims is the world's first 3D-printed net-zero home as part of a 40-unit community in Desert Hot Springs that explores environmental and economic development strategies. More

Kate Mazade | | Leave a comment -

HKU's computer-designed Tidal Stools can be used by humans and sea creatures

Researchers at Hong Kong University's Robotic Fabrication Lab have developed a series of 3D-printed stools featuring complex shapes that provide comfortable seats while also sheltering marine animals. More

Alyn Griffiths | | Leave a comment -

Hannah begins construction on "first multi-storey 3D-printed house in the US"

Ithaca, New York-based design studio Hannah has begun work on Cores, a building in Houston that it says will be the first multi-storey 3D-printed structure to be completed in the United States.

Ben Dreith | | Leave a commentMore

-

Font adaptive cutlery collection combines aesthetics and accessibility

Australian studio Hop Design has used 3D printing to create a cutlery set called Font that can be tailored to people with different disabilities while maintaining a strong and cohesive aesthetic. More

Rima Sabina Aouf | | Leave a comment -

Kelp Mini Clutch is a bioplastic bag based on 3D-scans of seaweed

Austrian designer Julia Koerner has created a 3D-printed clutch bag for her fashion brand JK3D, which is made from bioplastic and modelled on tendrils of kelp. More

Amy Peacock | | Leave a comment -

University of Virginia 3D-prints living soil walls that sprout greenery

University of Virginia researchers have invented a method of 3D printing with seed-impregnated soil, which could be used to create walls and roofs teeming with plant life.

Rima Sabina Aouf | | Leave a comment More

More -

Dezeen Agenda newsletter features an open-source recycling machine for plastic bottles

The latest edition of our weekly Dezeen Agenda newsletter features Polyformer, an open-source recycling machine that can be used to turn PET bottles into filament for additive manufacturing. Subscribe to Dezeen Agenda now! More

Kate McCusker | | Leave a comment -

Polyformer is an open-source machine that recycles plastic bottles into 3D printing filament

California-based industrial designer Reiten Cheng has developed a recycling machine that can be 3D printed using open-source instructions and used to turn PET bottles into filament for additive manufacturing. More

Ali Morris | | Leave a comment -

Greek restaurant interior by Masquespacio takes cues from ancient ruins

3D-printed "broken" columns join walls and floors created with an adobe effect at the Egeo restaurant in Valencia by interiors studio Masquespacio that aims to put a modern spin on traditional Greek architecture.

Jane Englefield | | Leave a comment More

More -

Kelp Collection chair by Interesting Times Gang

Dezeen Showroom: Swedish studio Interesting Times Gang has designed a 3D-printed chair made from recycled fishing nets. More

Dezeen staff | -

Sandhelden and Archisource 3D print sand trophies for drawing competition

Bavarian manufacturer Sandhelden has created four 3D-printed trophies made from locally sourced quartz sand from Bavaria, Germany, for a drawing competition by design and architecture collective Archisource. More

Anna Marks | | Leave a comment -

ICON and Lake Flato build 3D-printed House Zero in Austin

Construction technology outfit ICON and architecture studio Lake Flato have completed a 3D-printed, modern ranch-style home in Austin to be displayed during the SXSW festival.

Ben Dreith | | Leave a comment More

More -

Makhno Studio designs conceptual settlement within Martian crater

Ukrainian architecture practice Makhno Studio has designed a 3D-printed settlement for Mars named Plan C that would encircle the edge of a crater. More

James Parkes | | Leave a comment -

Blast Studio 3D prints column from mycelium to make "architecture that could feed people"

London practice Blast Studio has developed a method for 3D printing with living mycelium and used it to form a column that could be harvested for mushrooms before serving as a structural building element. More

Jennifer Hahn | | Leave a comment -

Valentino Gareri Atelier designs village made from 3D-printed cacao waste

Valentino Gareri Atelier has unveiled renderings of the Cacao Eco Village in Ecuador for local farmers that will feature 3D-printed buildings made from recycled cacao.

Jane Englefield | | Leave a comment More

More -

ETH Zurich develops formwork from 3D-printed foam to slash concrete use in buildings

Researchers at ETH Zurich have used 3D-printed formwork elements made from recyclable mineral foam to create a pre-cast concrete slab, which they say is lighter and better insulated while using 70 per cent less material. More

Jennifer Hahn | | Leave a comment -

Parley for the Oceans creates trophies from 3D-printed ocean plastic for The Fashion Awards

Environmental organisation Parley for the Oceans has turned marine plastic waste from remote island waters into trophies for this year's edition of The Fashion Awards. More

Alice Finney | | Leave a comment -

Pearson Lloyd designs 3D-printed desk accessories made from recycled bioplastic waste

London studio Pearson Lloyd has worked with design and 3D-manufacturing studio Batch.

Cajsa Carlson | | Leave a comment Works to create pen pots, trays and a mobile-phone stand made from discarded food packaging for office brand Bene. More

Works to create pen pots, trays and a mobile-phone stand made from discarded food packaging for office brand Bene. More -

Nagami 3D prints "aesthetically pleasing" portable toilet using plastic waste

Discarded plastic medical equipment from hospitals across Europe was melted into a filament and 3D-printed to create the mobile toilet cubicle The Throne, designed by Spanish studio Nagami for the To.org foundation. More

Jennifer Hahn | | Leave a comment -

The New Raw 3D prints "zero-waste" Ermis chair from studio's own offcuts

Rotterdam studio The New Raw has recycled misprints and prototypes from its previous experiments in additive manufacturing to 3D print a limited edition chair called Ermis. More

Natashah Hitti | | Leave a comment

Berlin set to build car-free housing and technology district on former Tegel Airport

OEO Studio uses materials in a "playful way" for Designmuseum Denmark cafe and shop

Tom Kundig designs Truckee home with metal "treehouse" for Faulkner Architects founder

Studio Other Spaces creates colourful conical glass pavilion for Californian winery

Six supertall skyscrapers planned for North American cities

Invisible Studio unveils timber shelter "made with many hands" at Westonbirt arboretum

Space Copenhagen adds "otherworldly" pieces to Antwerp restaurant

Alexis Dornier designs Birdhouses resort in Bali to "blend into nature"

Dezeen Events Guide

Dezeen Jobs

{{category}}

{{carousel_title}}

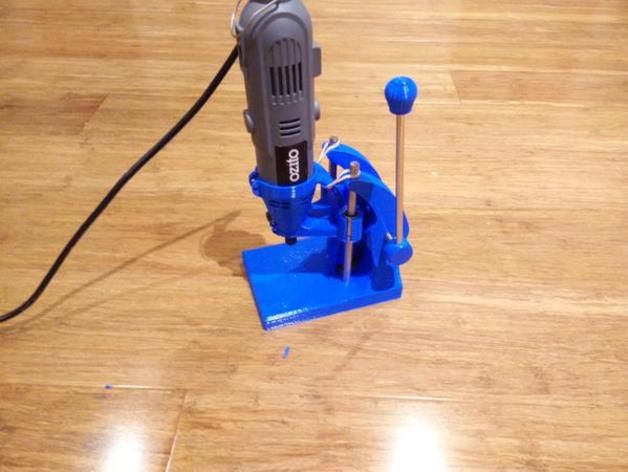

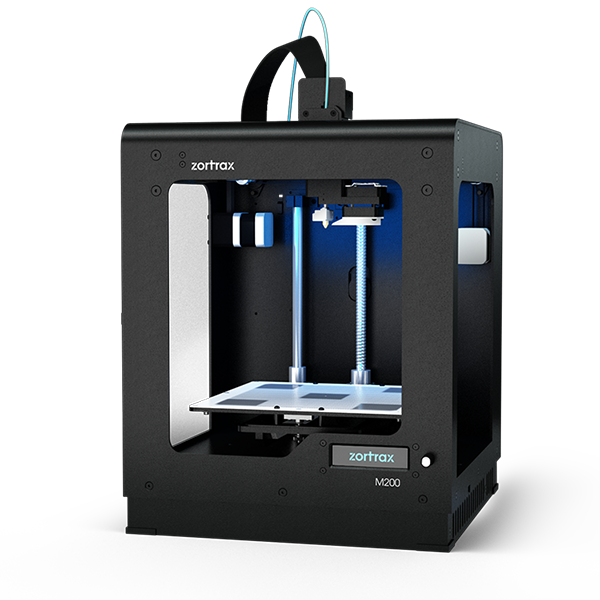

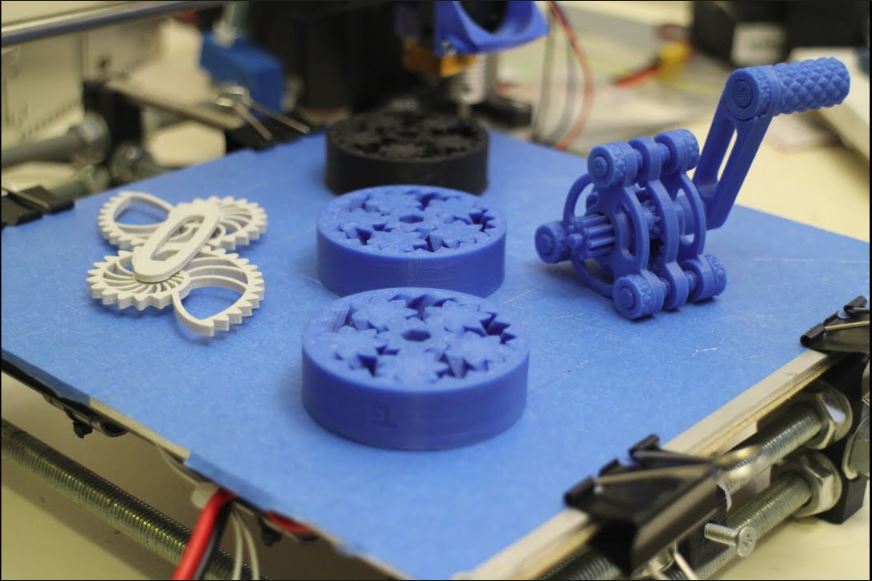

What are the key design elements for 3D printing?

Are you new to designing parts for 3D print manufacturing or need a refresher on essential design elements? This article provides the key design elements for creating digital models for 3D printing, no matter the additive manufacturing process.

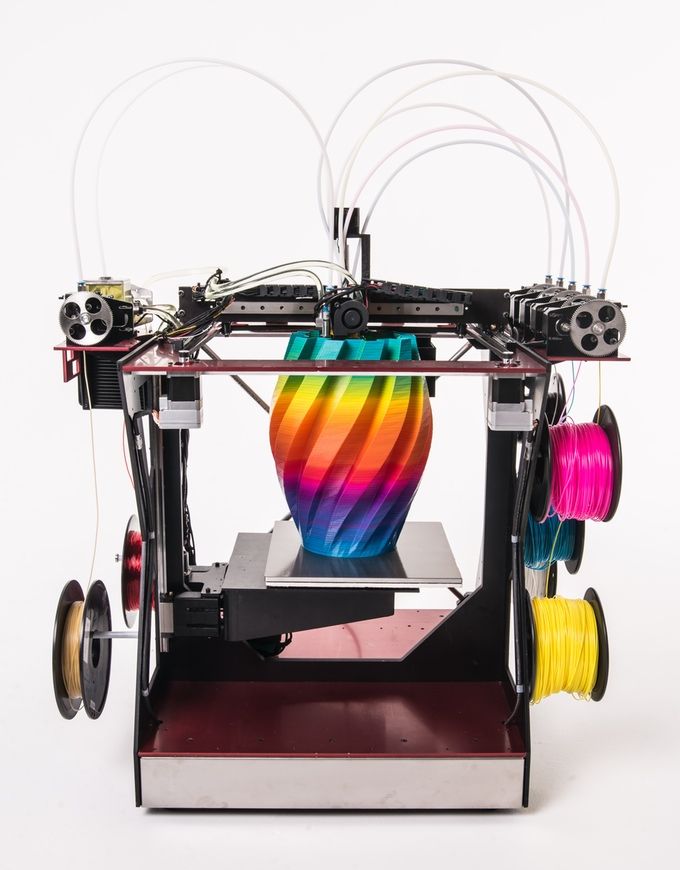

Every 3D printing technology comes with a distinct set of capabilities and its own design freedoms and restrictions. Whether you are a seasoned engineer who’s well-versed in designing for 3D printing or you are new to the field, it’s always a good idea to go over the most essential factors that make or break a design.

This article covers the key design considerations that apply to 3D printing in general, regardless of the printer you choose for manufacturing your custom parts.

Check out this handy infographic for quick access to every essential design element you may need while creating digital models to 3D print.

Each 3D printing process has its own design advantages as well as some limitations. Let’s break down the key design considerations that apply to every 3D printing technology to keep in mind when designing your next custom parts.

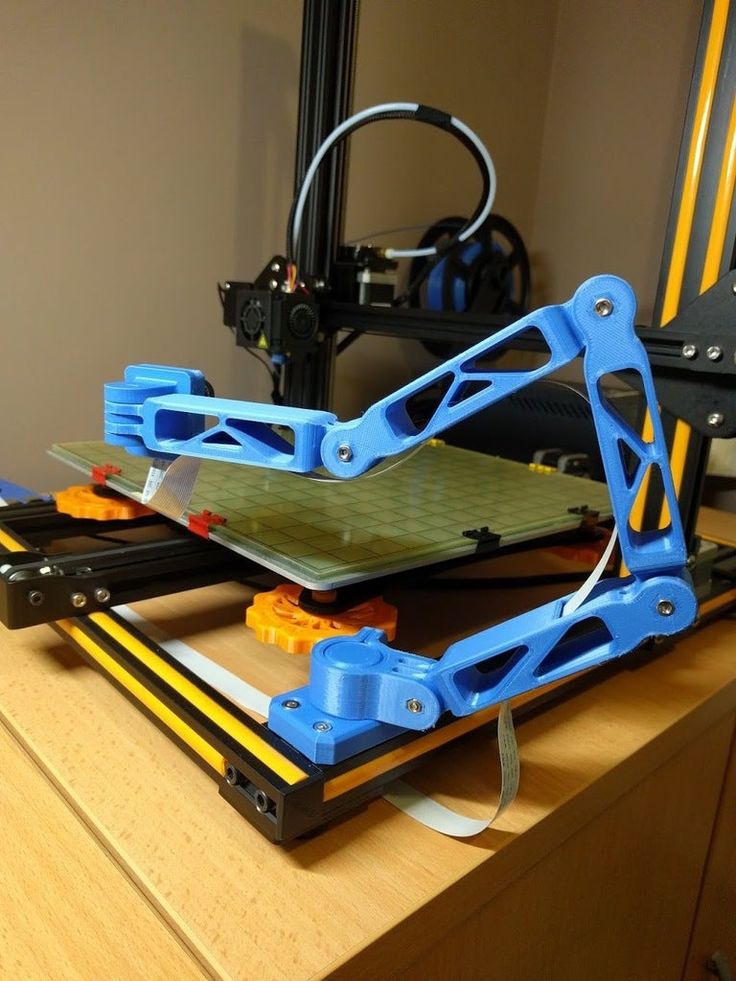

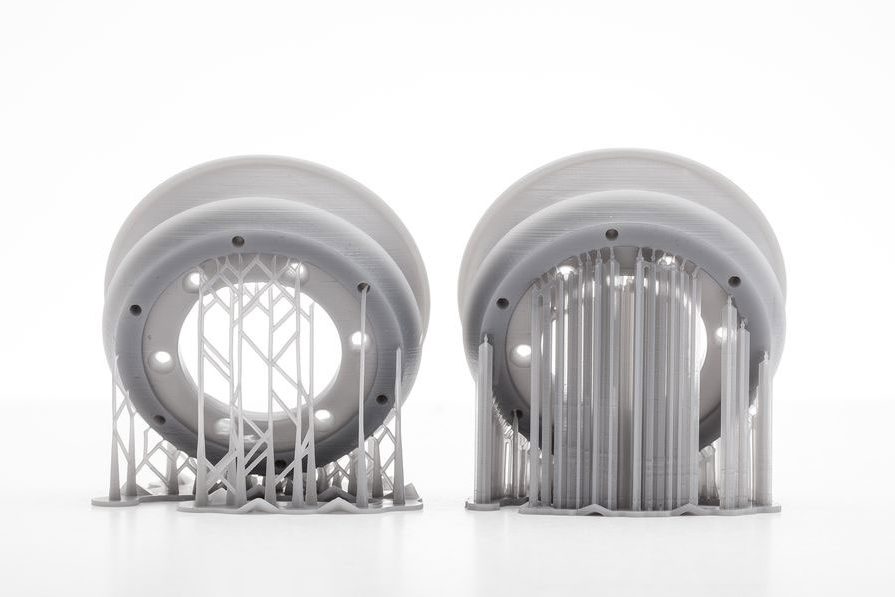

All 3D printing processes build parts layer-by-layer. New layers can’t be deposited onto thin air, so every layer must be printed over some underlining material.

New layers can’t be deposited onto thin air, so every layer must be printed over some underlining material.

Overhangs are areas of a model that are either partially supported by the layer below or not supported at all. There is a limit on the angle every printer can produce without the need for support material. For example, if you’re printing with an FDM and SLA machine, this angle is approximately 45 degrees .

We recommend limiting your model’s overhangs, as layers printed over support structures usually come out with a rougher surface finish.

This image shows the effect of increasing angle on overhang quality for FDM printingWall thickness for 3D printing

The second thing to keep in mind when designing a part to be 3D printed is wall thickness. Every 3D printing process has its own level of precision. FDM, for instance, is the least accurate, while SLA has the tightest tolerances. In terms of part stability, every 3D printing process has a lower limit regarding wall thickness and feature size.

In terms of part stability, every 3D printing process has a lower limit regarding wall thickness and feature size.

For example, imagine you are an engineer designing a new generation of hang gliders. You’ve chosen to 3D print a scaled-down version of the product to test its efficacy. 3D modeling programs allow you to model the sailcloth of the wing, for instance, but you then encounter problems when you would try to 3D print it. This is because the model’s wall thickness is less than the minimum required for successful printing.

It’s essential to make sure that your 3D designs have walls that meet the minimum required thickness for the printing process you choose. All 3D printers can successfully print components with wall thicknesses greater than 0.8 mm.

What is warping and how can you avoid it?

Something that is often easily overlooked while designing a 3D model is the fact that the materials used for 3D printing undertake physical change: they are melted, sintered or scanned with a laser and solidified. The heating and cooling of material can cause the parts to warp while printing.

The heating and cooling of material can cause the parts to warp while printing.

Large, flat surfaces can be especially prone to warping. Warping can typically be avoided by using correct machine calibration and having adequate surface adhesion between your part and the print bed. A good practice is to avoid large flat surfaces and add rounded corners to your 3D models.

When you are creating a 3D model with intricate details, it is important to keep in mind the minimum feature size each 3D printing process can handle. The minimum level of detail is connected to the capabilities and mechanics of each 3D printing process and to the selected layer height .

The process and materials used will have an impact on the speed and cost of your print, so determining whether smaller details are critical to your model is an important design decision.

The most important thing to remember while designing for 3D printing is the fact that your digital design will become a physical object. In the digital design environment, there are no laws of physics to adhere to, such as gravity.

In the digital design environment, there are no laws of physics to adhere to, such as gravity.

Anything can be "drawn" in 3D on a digital canvas, but not everything can be 3D printed. Knowing the key factors that go into designing 3D models will ensure that you produce digital designs that can be successfully printed.

Want to learn the key design elements for every 3D printing technology?

Design parts for FDM Design parts for SLA Design parts for SLS

Ready to transform your CAD file into a custom part? Upload your designs for a free, instant quote.

Get an instant quote10 industries that 3D printing is starting to change

3D printing has come a long way from printing small prototype buildings out of plastic. Today, 3D printing is fulfilling its potential in a range of industries, from aerospace to apparel and footwear.

This technology not only allows you to create items with incredible precision, but also saves money.

Today, there are many materials that allow you to make a wide variety of objects using 3D printing.

Below we will talk about the industries in which this technology is applied.

1. Aerospace

In the aerospace industry, everything must be made with high precision. Precision plays a very important role here in the execution of every space mission, and the industry itself is extremely important for the development of mankind.

3D printing has already begun to change the industry, it is used to replace many parts that have become too expensive to produce. In addition, the technology is used to test prototypes.

ULTEM 9085 is a thermoplastic commonly used in aircraft construction that can be melted down and used in 3D printing.

2. Architecture

3D printing technology saves building construction time.

With this technology, printing houses is as fast as printing documents.

And when creating a design, you can share it with other users by placing an object in the database.

3. Food

While 3D printing doesn't save lives, it could change the way we think about food.

Nevertheless, experts note that in the future humanity will face a shortage of food, it is already becoming increasingly difficult to feed the growing population of the planet.

However, science is looking for ways to grow meat and use alternative materials to produce food.

4. Product design

Technology allows you to design something on a computer, then print it in an hour, test it, find flaws, redesign, print a second prototype - and all this takes only half a day.

Previously, concepts were produced, but now 3D printing technology makes it possible to get closer to an almost identical product representation in a very short amount of time.

5. Medicine

3D printing plays an important role in almost every aspect of medicine. When it comes to prototyping, technology allows you to create ready-made models that will cost less and take less time to create, and these will be ready-made models that are completely usable.

When it comes to prototyping, technology allows you to create ready-made models that will cost less and take less time to create, and these will be ready-made models that are completely usable.

Clarity and precision allows you to print ultra-fine lines that allow you to create the smallest tools.

In addition, 3D printing technology makes it possible to recreate parts of the human body using various materials. Scientists are constantly working to create new materials and textures.

6. Dentistry

Making tooth models is very useful, but it is not always possible to make them taking into account the individual characteristics of a person.

3D printing technology makes it possible to make exact replicas of a patient's teeth to replace them, or crowns that can last longer.

Objet Digital is a dedicated 3D printer designed for use in the field of dentistry.

He uses materials that are very similar in structure to bone to print teeth.

7. Construction

In Dubai, 3D printing is an increasingly common way to construct buildings. Cazza, a 3D printed construction company, plans to build the world's first 3D printed skyscraper.

They created special machines that can build buildings from the bottom up.

Companies around the world have expressed interest in such machines.

In addition, this method of building construction leaves less debris. During construction, environmentally friendly materials can be used.

8. Agriculture

It may seem strange to use this technology in agriculture, but it is true. Many farms need specialized tools, which cost between $8,000 and $12,000 and can take months to complete.

PLA, or polylactic acid, is a material that is used for 3D printing and costs $0.25 per 1.5 cu. m. This can significantly save money and time for farmers who are looking to upgrade their machines.

9. Making clothes and shoes

So far, 3D printed clothes have not entered the mass market, but the idea of such clothes has been developed since 2013.

The idea is that in the future, customers can print clothes, which suits their individual sizes.

10. Organ printing

3D bioprinting is a new application that is developing at a rapid pace.

Scientists have made great progress in printing ribs, but they also believe that in the future it will be possible to print hearts, kidneys, livers and other organs.

Cell Link is a company that works with products of this kind, donor organs will soon become mostly artificial.

The use of artificial organs can save money and time for those patients who need a quick transplant.

Source

Tags:

ULTEM Material 9085, 3D Printing, Architecture, Aerospace, 3D Printing Technology, Food, Product Design, Special 3D Objet, Human Body Parts , dentistry, construction, PLA, organ printing, 3D bioprinting

Possibilities of 3D printing: art, fashion, medicine

Sculpture by Monika Gorchikova (Czech Republic)

Expressive sculptures by contemporary artists, dresses for fashion shows, architectural models and parts of the human body - a short guide on how to use 3D printing was compiled by Artyom Dezhurko.

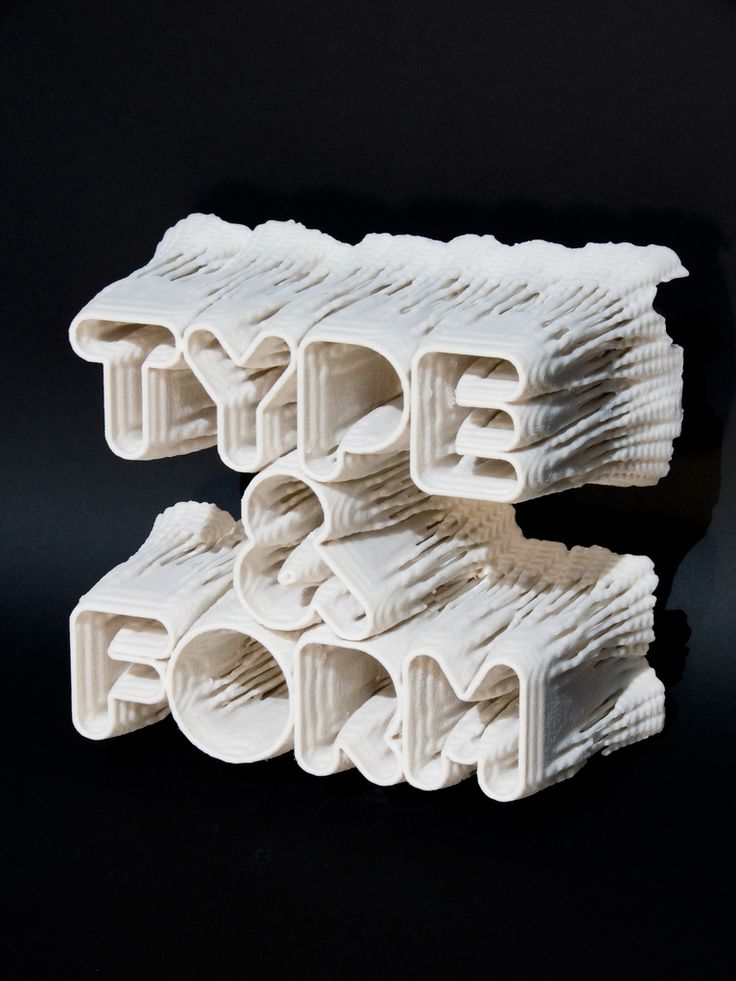

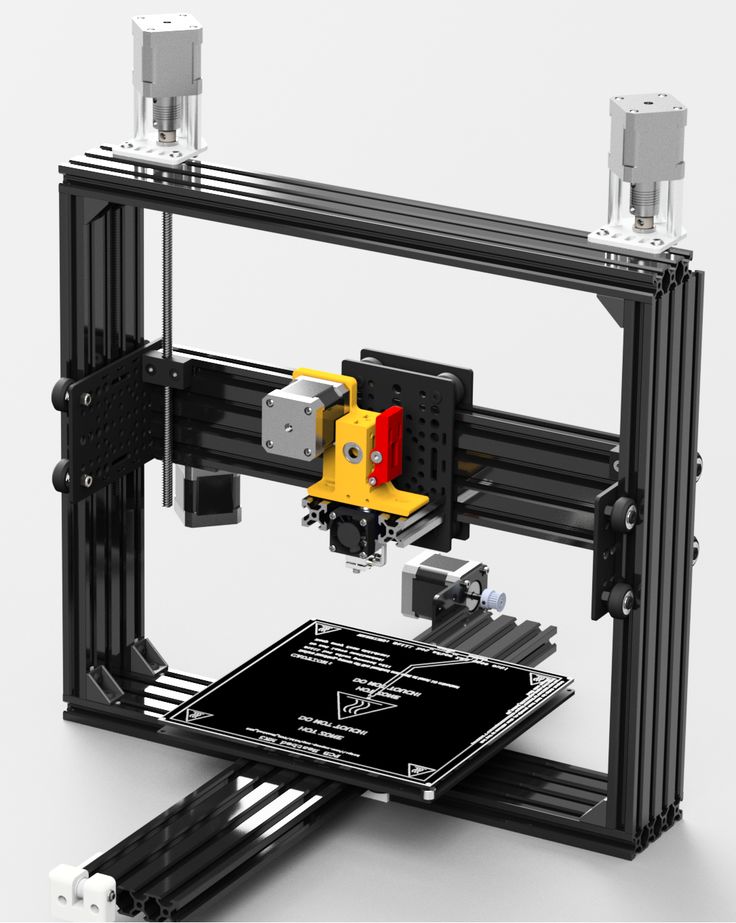

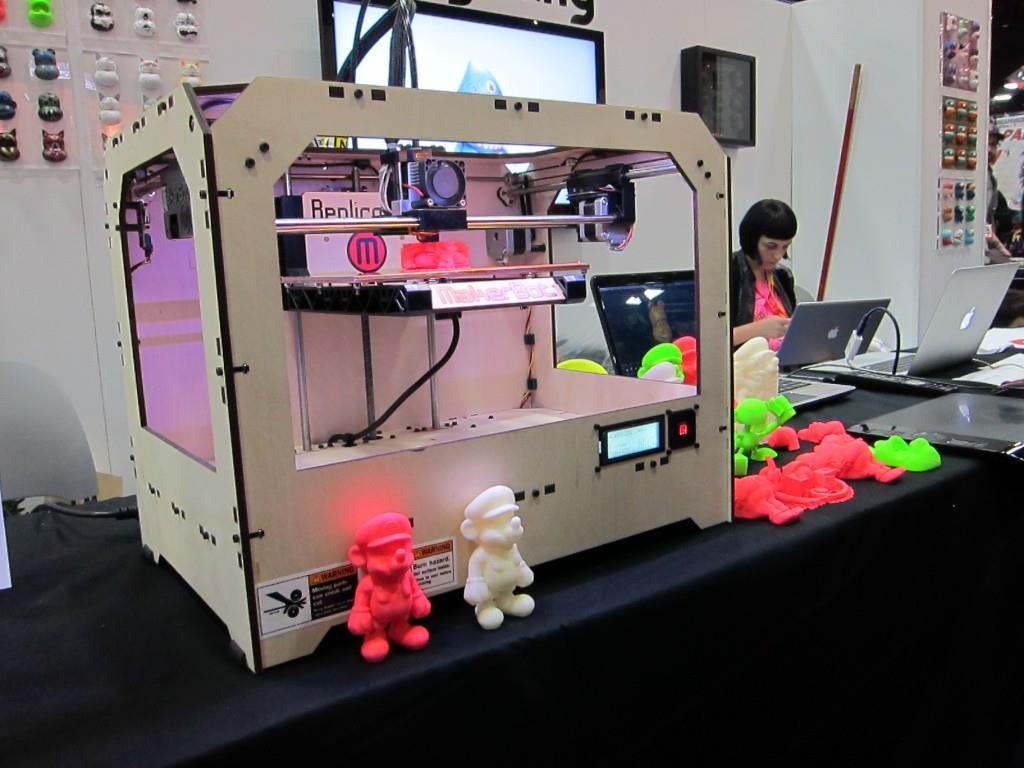

3D printing was invented by American Chuck Hull in 1984. Modern 3D printers are capable of printing large objects, up to a car body; and use different printing techniques (stereolithography invented by Chuck Hull is just one of them). However, whatever the technique may be, the essence is the same: the printer creates an object by building up the material in layers. Thus, you can create an arbitrarily complex shape. 3D printers print from different materials: plastic, cellulose, ceramics, metals, sugar.

This material is an illustrated overview of how 3D printing is used today in various fields: art, architecture, technology, fashion, medicine.

Richard Dupont, USA

Nick Erwink, USA

"Princess", Eric van Straten, Netherlands

A modern 3D printer prints layers so thin that they can no longer be seen with the naked eye. Therefore, sculptors love it: 3D printing is the same casting, but technologically simplified and allowing endless replication of the object. Sculptures with her help are very different: from photographically accurate images of famous football players to the vicious postmodern statuettes of Eric van Straten.

Sculptures with her help are very different: from photographically accurate images of famous football players to the vicious postmodern statuettes of Eric van Straten.

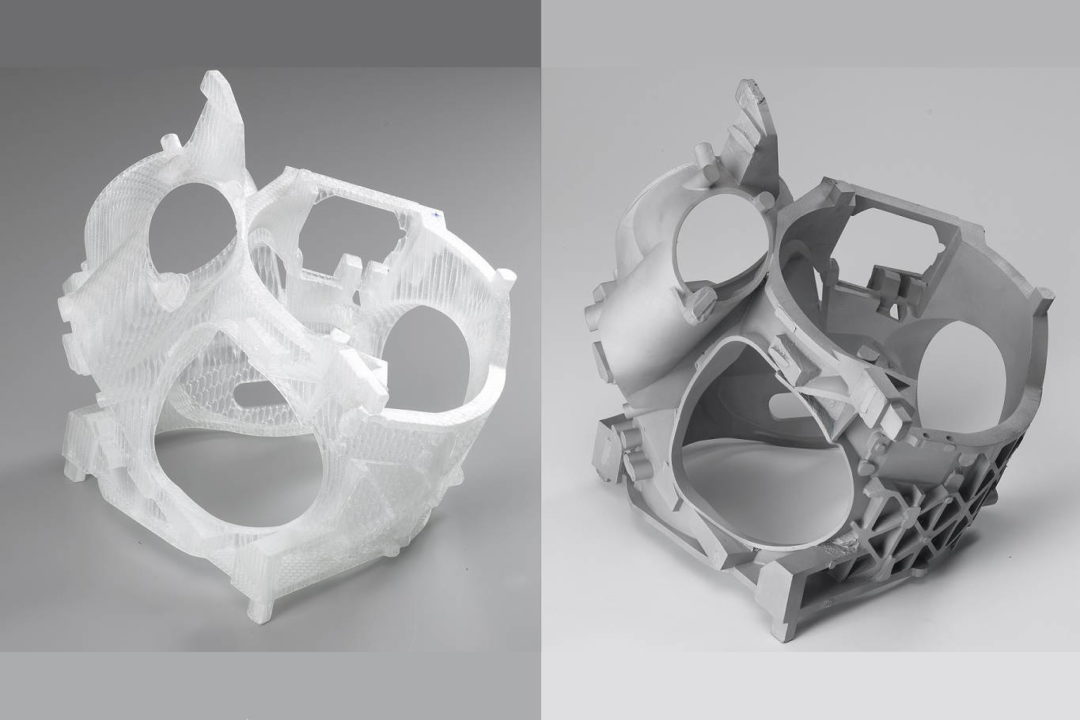

Michael Hansmeyer and Benjamin Dillenburger. Digital Grotesque, 2015

Study paper by Andy Zheng and Christina Eromenok at RPI School of Architecture

PTW Architects. Model of the Beijing National Water Sports Center, 2007

Most often, 3D printing is used for rapid prototyping - creating models of mechanisms and, especially often, architectural models. In addition, now 3D printers have begun to be used to produce large parts from which prefabricated houses are created. The Chinese company Winsun is experimenting with this technology.

In the automotive industry, 3D printing scale model production is widespread and seems to have completely supplanted the old plasticine sculpting technique. A model of James Bond's car from the movie "Skyfall" was printed on a 3D printer. And in 2010, a prototype of the Urbee car was created, the entire body of which was printed on a 3D printer.

ideas2cycles, Finland, The Fixer, 2012

Several bicycle frames have been created using a 3D printer (and even an entire Airbike bike - developed by EADS), but in their case there is no talk of mass production yet. More promising is the printing of couplings made of durable plastic, with the help of which in small "garage" bicycle workshops it is possible to assemble frames from factory metal tubes.

Chair Gaudi (Bram Genen)

A mold is printed on a 3D printer, which is then used to cast the supporting structure of the chair.

Hot Pop Factory

Sculpture of Charles and Ray Eames DSW chairs scanned and 3D printed.

LINK system

Christian Sjöström, Sweden, 2015.

Prototype Node

Modeling in Grasshopper. Charles Freed, UK, 2015.

3D printed as whole furniture (e.g. Gaudi chairs, designed by Bram Genen, 2009) and piece by piece (designed by Benjamin Vermeulen), as well as connections with which prefabricated furniture can be assembled without using bolts and nuts. Such joints have been made before, but 3D printing has greatly simplified their production.

Such joints have been made before, but 3D printing has greatly simplified their production.

Noah Raviv. Hard copy collection. 2014

Noah Raviv. Hard copy collection. 2014

Chromat. Formula 15 collection. Spring-summer 2015

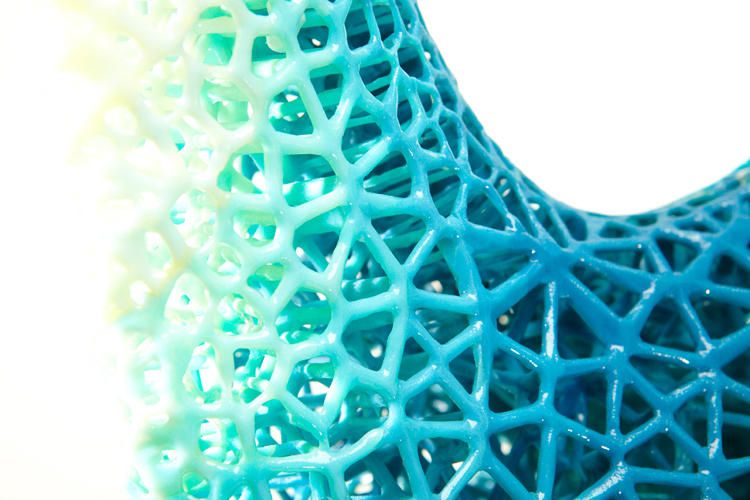

Michael Schmidt, Francis Bitonti. Dita Von Teese dress. Laser printing (SLS). 2013

Iris van Herpen, Julia Koerner, Voltage Show. Print materialize. 2013

Iris van Herpen. Crystallization Collection. Summer 2010

Iris van Herpen. Autumn-Winter 2013-14

On a 3D printer, you can print elements from which plastic fabric is then woven. Either from this fabric, or directly from plastic, dresses, bathing suits, shoes are created. Iris van Herpen has released several collections of 3D printed dresses and shoes. United Nude prints shoes designed by famous designers and architects: Zaha Hadid, Rem Koolhaas, Ross Lovegrove. But the most famous piece of clothing created using this technology is Dita Von Teese's mesh nylon dress.

#Cast is a custom tire consisting of the letters that the patient most often typed on Twitter. Manufacturer FATHOM, designer Eva DeCapri (USA). 2014

Prosthesis on the model of the patient's skull. Photo from Walter Reed Hospital in Washington

Arm splint. The developers are UCLA School of Architecture and Urban Planning students Nicholas Solakian, Peter Nguyen and Derek Buell. 2013

Medicine is the most promising application for 3D printing. By scanning the surface of the body, it is possible to create fixation bandages that exactly match the anatomy of a particular patient, “custom” prostheses and implants that reproduce lost parts of the skeleton. One unfortunate man who lost half of his face had the missing half printed on a 3D printer. There is no photo of this person here, but you can easily find it if you wish.

Printer self-reproduction

There are printers that can print parts of themselves. Undoubtedly, in the coming years they will learn to breed.

Growing donor organs

3D printing technologies for living tissues and organs are being developed. Living cells are used as the material, with which the printer "seeds" the matrix.

The text was first published in the online magazine of the Rizoma Design School, edited by Tatyana Bakina.

Artem Dezhurko

Art and design historian, exhibition consultant and curator, architectural journalist.

More

Fashion Architecture

Direction of study

Direction "Fashion" at the HSE School of Design

The HSE School of Design is a meeting place for the most talented students in Moscow and Russia who see their career in the fashion industry. They learn under the guidance of curators - current designers and industry professionals who immerse students in the current context. Deep theoretical and practical training allows students to choose any profession in the fashion world, not limited to fashion design, and a student portfolio and participation in specialized competitions and fashion weeks helps to express themselves in a professional environment while still being students.