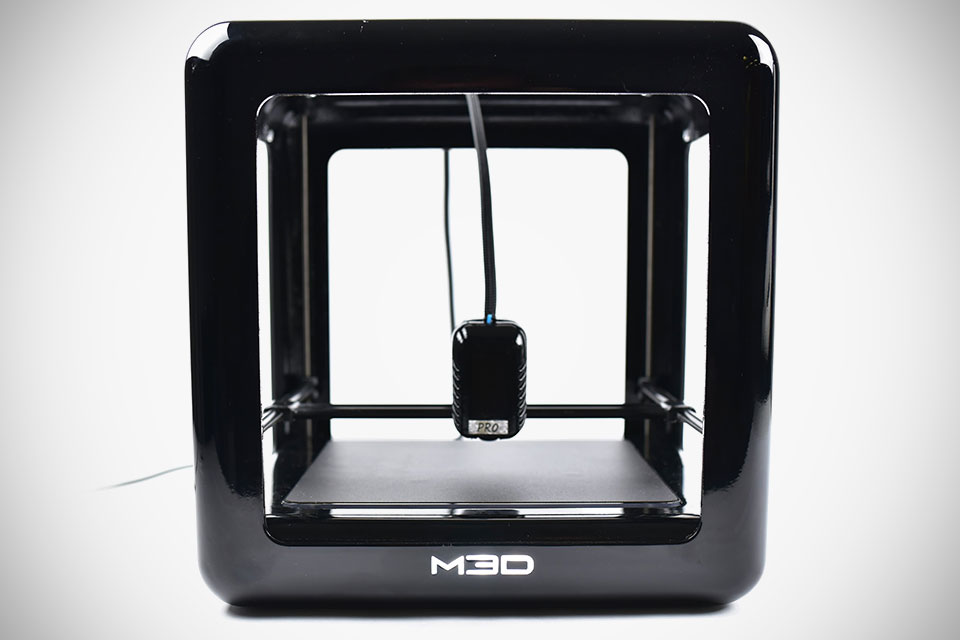

Zee pro 3d printer

Zeepro Zim 3D review | 49 facts and highlights

53points

Zeepro Zim 3D

Zeepro Zim 3D

Why is Zeepro Zim 3D better than the average?

- Weight?

9.07kgvs25.38kg - Nozzle size?

0.35mmvs1.21mm - Layer thickness?

50µmvs98.25µm - Height?

330mmvs493.89mm - Width?

279mmvs469.02mm - Thickness?

330mmvs462.11mm - 3D print speed?

110mm/svs91.91mm/s - Number of extruder heads?

2vs1.32

Which are the most popular comparisons?

Zeepro Zim 3D

vs

Bits from Bytes RapMan 3.2 3D Printer Kit Universal

Zeepro Zim 3D

vs

Felix 2.0

Zeepro Zim 3D

vs

Makemendel RapidBot 2.0 Kit

Zeepro Zim 3D

vs

MakerBot Replicator2x

Zeepro Zim 3D

vs

MakerGear M2

Zeepro Zim 3D

vs

UP! Plus

Price comparison

Components

Creates support structures

✖Zeepro Zim 3D

The printer will automatically build extra structures to support the item as it is printing. The extra support can then be easily removed.

Has a heated build platform

✖Zeepro Zim 3D

A heated build platform helps keep the lowest levels of a print warm as the higher layers are printed. This allows the overall print to cool more evenly.

1.75mm filament diameter

✔Zeepro Zim 3D

The 1.75mm filament diameter is gradually overtaking the previous 3mm standard. The 1.75mm filament feeds into the printer with greater ease and allows for more detail in the printing process.

nozzle size

0.35mm

The smaller the nozzle, the more detailed the final product can be. However, when speed of printing is of greater importance than detail, a larger nozzle may be preferable.

3D print speed

110mm/s

The speed at which 3d objects are printed, measured in millimeters per second.

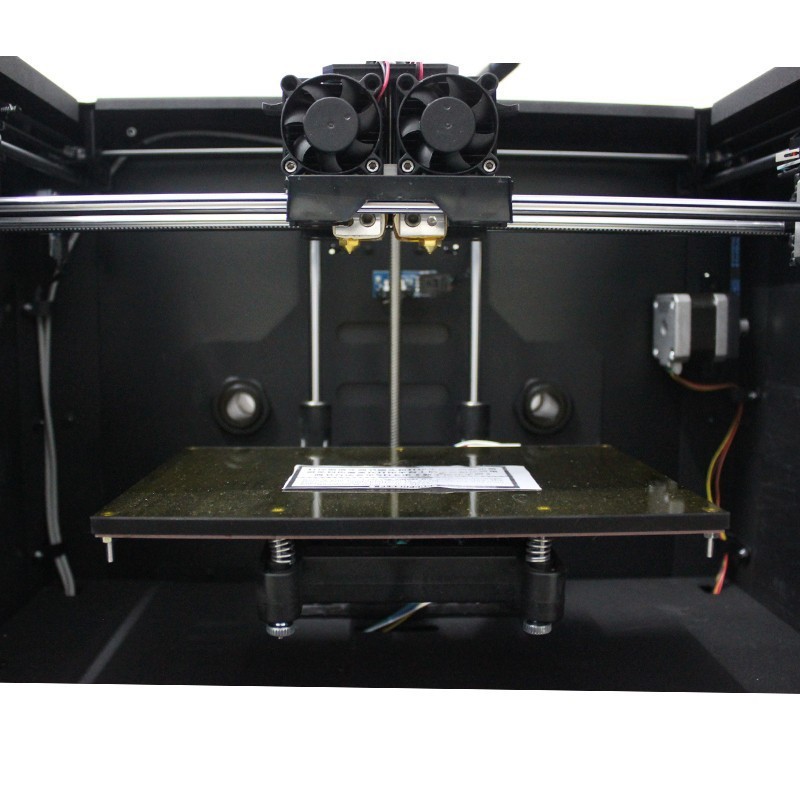

number of extruder heads

More extruder heads allow you to use different colors and different types of material at the same time. A second extruder is also required to build PVA/PLA support structures around items as they are printed.

A second extruder is also required to build PVA/PLA support structures around items as they are printed.

Has an automatic platform calibrator

✖Zeepro Zim 3D

This feature saves time and effort in terms of maintenance, however the build platform itself still needs to be manually levelled.

Prints in hollow mode

✖Zeepro Zim 3D

Hollow mode will build the item quickly and using less material. This will allow you to print quick prototypes of your designs before printing a solid model i.e for presentational designs rather than functional solid ones.

Materials

Prints in PLA

✔Zeepro Zim 3D

Polylactic acid (PLA) is popular in 3D printing as it cools and sets quickly. Unlike ABS plastic, it is biodegradable and therefore better for the environment. It can be used to build support structures for other printouts, as it can then be dissolved leaving no marks.

Prints in full color

✖Zeepro Zim 3D

Similar to regular 2D printers, this type of 3D printer mixes different colors between cartridges. This process allows the printer to reproduce the color spectrum, therefore allowing you to print in almost any color.

Prints in HIPS

✖Zeepro Zim 3D

The printer is able to print in High Impact Polystyrene (HIPS). HIPS is similar to ABS plastic, but uses different solvents (limonene rather than acetone). HIPS is easy to paint and glue.

Prints in ABS plastic

✔Zeepro Zim 3D

The printer prints in ABS (acrylonitrile butadiene styrene). This is up to 30 times stronger than regular plastic and is commonly used in 3D printing.

Prints in PVA

✖Zeepro Zim 3D

Polyvinyl Acetate is another form of plastic used in 3d printing similar to ABS. It can be used to build support structures for other prints, as it can then be dissolved leaving no marks.

Prints in paper

✖Zeepro Zim 3D

The printer is able to print in paper. 3D printing in paper involves an additive process whereby a laser cuts each layer of paper into the correct shape to create the final model. Paper 3D printed objects have a similar consistency to wood.

Prints in wood

✖Zeepro Zim 3D

The printer is able to print in wood. This typically involves printing using a mixture of wood particles and a binding agent, which dries as solid wood.

number of colors per print

A single design can be made up using different colored materials simultaneously.

Print sizes

layer thickness

The thinner each print layer is, the more detailed you can make your designs. Layer thickness is often also referred to as resolution and is measured in microns (µm).

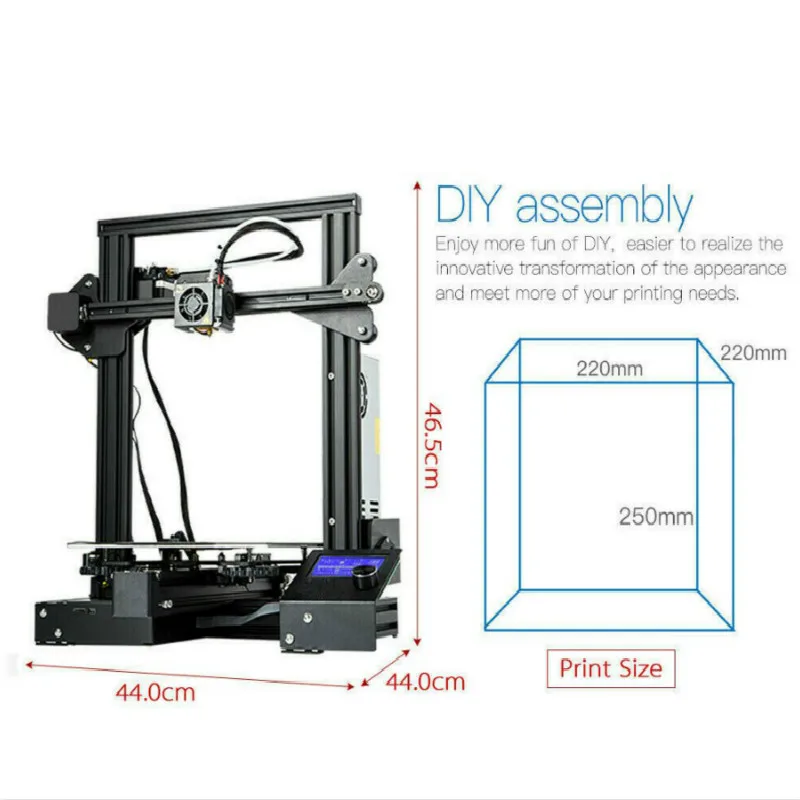

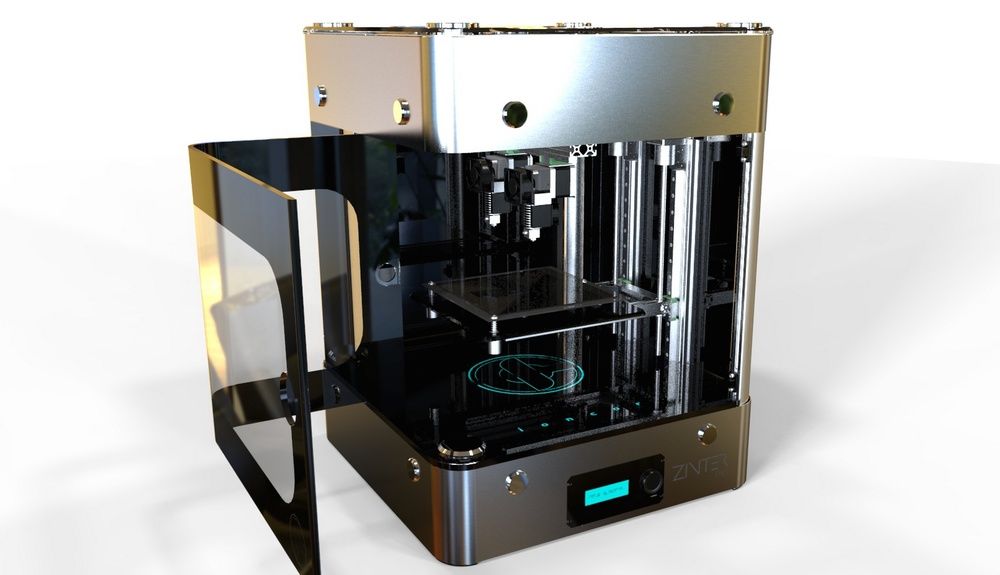

maximum creation size

149 x 149 x 149mm

This is the biggest size of object that you can print.

minimum print size

Unknown. Help us by suggesting a value.

This is the smallest size of object you could print with the printer, in terms of volume (cm³).

x-axis resolution

Unknown. Help us by suggesting a value.

The highest possible x-axis resolution, measured in microns.

y-axis resolution

Unknown. Help us by suggesting a value.

The highest possible y-axis resolution as measured in microns.

z-axis resolution

Unknown. Help us by suggesting a value.

The highest possible z-axis resolution as measured in microns.

Connectivity

has an external memory slot

✖Zeepro Zim 3D

The device has a standard memory slot (such as an SD or micro SD card slot) that enables you to extend the built-in internal storage with affordable memory modules, or easily retrieve data, such as photographs, from the memory card.

USB ports

With more USB ports, you are able to connect more devices.

RJ45 ports

Unknown. Help us by suggesting a value.

RJ-45 ports are used for LAN (Local Area Network) connections. With more ports you can achieve increased bandwidth across a LAN, or connect to multiple networks. It also has the added benefit of not losing connection to the network if one fails.

supports Wi-Fi

✔Zeepro Zim 3D

The device can connect to Wi-Fi.

Wi-Fi version

Unknown. Help us by suggesting a value.

The Wi-Fi versions supported by the device.

Has plug and play feature

✖Zeepro Zim 3D

The device is set up and ready to be used with the included software.

Is cloud enabled

✖Zeepro Zim 3D

Cloud compatibility allows you to control the operation of the device remotely using your smartphone, tablet or other mobile internet devices.

Features

Has a display

✖Zeepro Zim 3D

The device has an electronic display to present information to the user.

has a touch screen

✖Zeepro Zim 3D

You can operate the device easily, by pressing the screen with your fingers.

audible noise

Unknown. Help us by suggesting a value.

Audible noise is the noise that a device produces while in operation. Reduced audible noise improves quality.

idle noise level

Unknown. Help us by suggesting a value.

The level of noise when it is not in use.

included designs

Unknown. Help us by suggesting a value.

With 3D designs already installed on the printer, you can start printing straight away.

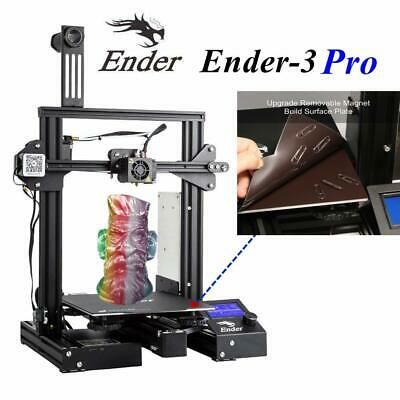

Is pre-assembled

✖Zeepro Zim 3D

As the product arrives fully assembled, you do not have to build it from a kit.

operating power consumption

Unknown. Help us by suggesting a value.

How much power the device consumes when it's switched on.

Price comparison

Which are the best 3D printers?

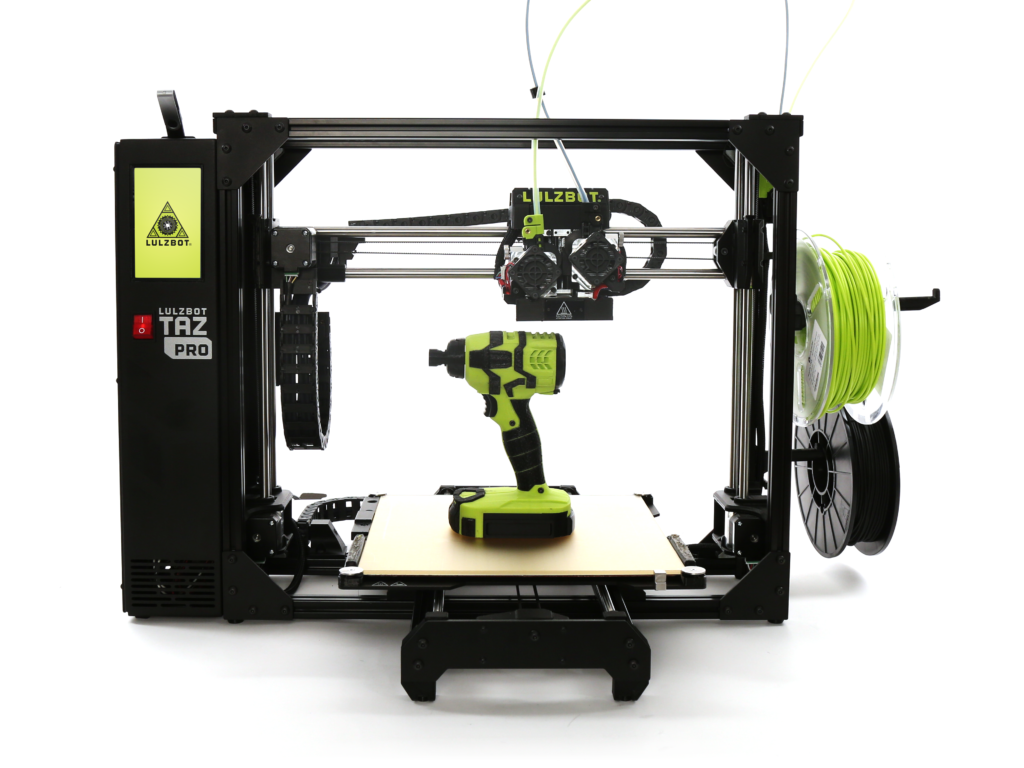

Professional Dual Extruder 3D Printer for Everyone

Professional Dual Extruder 3D Printer for EveryoneSearch for:

Agile Production Made Simple

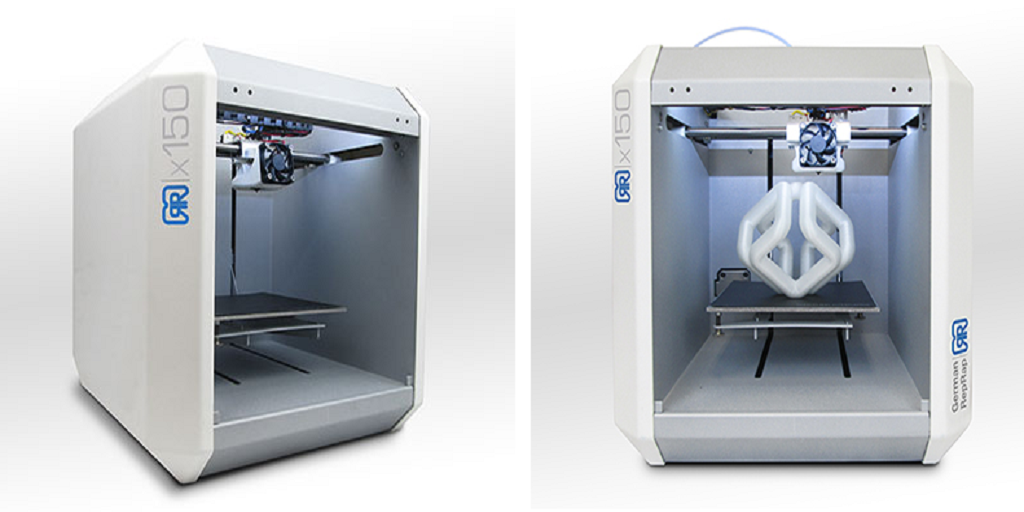

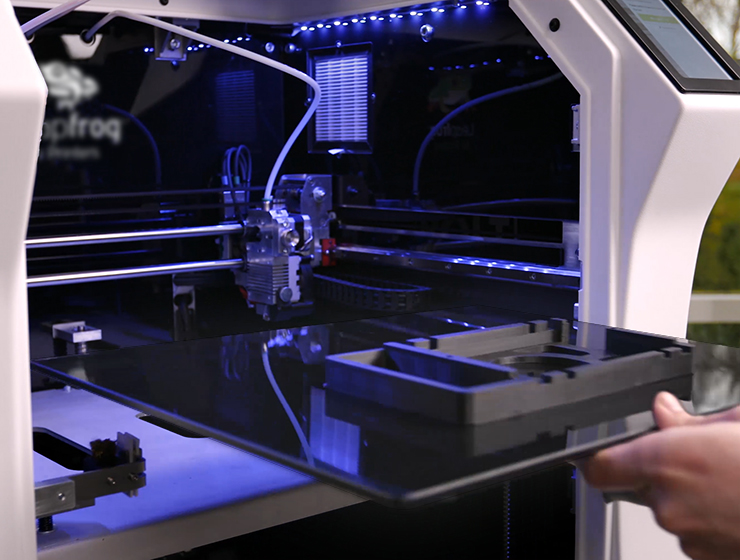

Forged from the Pro2 Series, Raise3D’s newly launched Pro3 Series professional dual extruder 3D printers meet the needs of both production and multi-sized rapid prototyping, with high precision and round-the-clock stable operation. The Pro3 Series is comprised of the Pro3, with a build volume of 300x300x300mm, and the Pro3 Plus, with a build volume of 300x300x605mm, fulfilling the requirements of large-scale production and multi-sized rapid prototyping. A high-quality printer design that includes enhanced features and a smart assistant system known as EVE, all of which make the Pro3 Series dual extruder 3D printers an excellent option for professional 3D printing.

The Pro3 Series dual extruder 3D printers connect with Raise3D’s 3D printing software ecosystem, that includes a 3D slicing program, ideaMaker, an open-software template called ideaMaker Library, and our cloud-based 3D printing software RaiseCloud.

Pro3: Starting at €4,749.00 Pro3 Plus: Starting at €6,249.00 Pro3: Starting at $5,599.00 Pro3 Plus: Starting at $7,599.00 Enhanced Printing Platform FeaturesThe Pro3 Series features upgraded printing platform features for high-quality printing performance and a better overall experience.

- The auto bed leveling makes setting up a 3D printer quicker and simpler.

- The flexible build plate allows for the effortless removal of 3D printed parts.

- The Z-axis rod stiffness increased by 75% to deliver a more stable performance.

These structural changes enable the Pro3 Series to provide better print results and an easier printing experience.

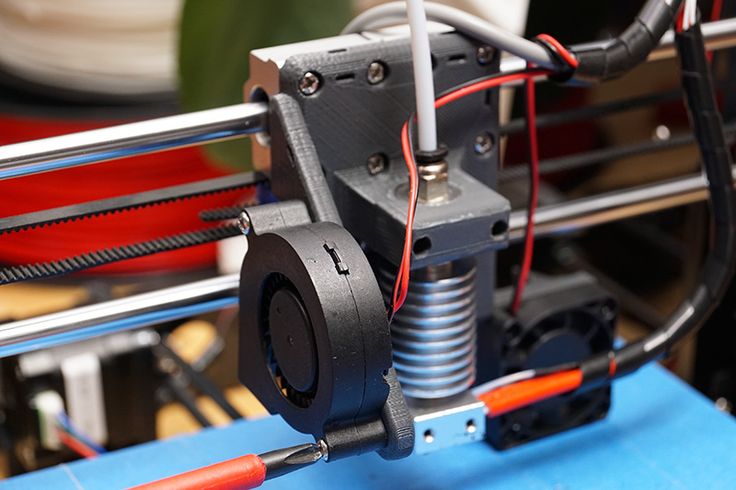

The Pro3 Series is equipped with an independent modular extruder with a dual extrusion system. This allows the Pro3 Series to print using a variety of filaments, reduce clogging, and allow the convenient disassembly and replacement of components. The hot end of the Pro3 Series is easy to remove, which can be done without using tools, making it simple to replace and maintain. Users can also easily take off the front cover of the extruder to accurately locate common printing occurrences such as filament jams.

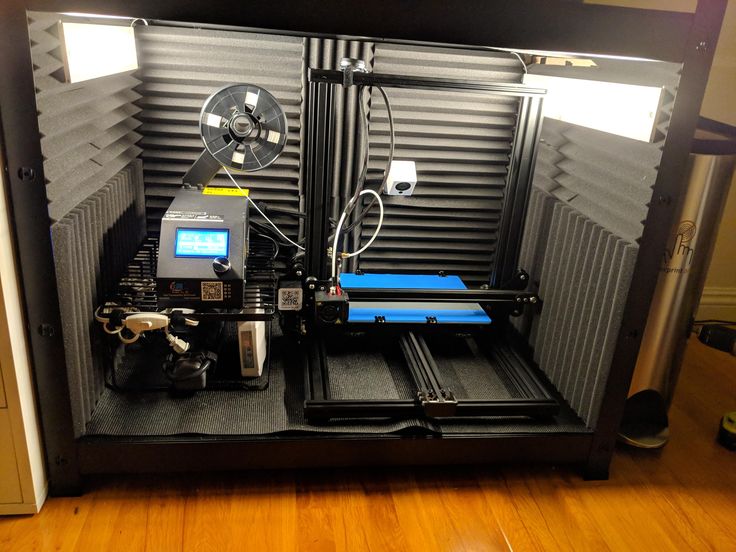

Air Flow Manager for Better Heat DissipationThe Air Flow Manager of the Pro3 Series is located on the back of the printer, improving heat dissipation and air circulation, creating a stable environment inside the print chamber. Equipped with a HEPA air filter, Air Flow Manager can also filter and clean the air inside the chamber.

EVE Smart AssistantThe Pro3 Series has a built-in EVE assistant system, preloaded with common printing problems and corresponding solutions. The EVE assistant can guide users to accurately locate and resolve issues that could affect the final print job. The EVE assistant has a function that gives users reminders about regular scheduled interventions to ensure that printer maintenance is performed on time. It also helps reduce maintenance time and communication costs for an efficient maintenance process.

The EVE assistant can guide users to accurately locate and resolve issues that could affect the final print job. The EVE assistant has a function that gives users reminders about regular scheduled interventions to ensure that printer maintenance is performed on time. It also helps reduce maintenance time and communication costs for an efficient maintenance process.

A dual extruder 3D printer can perform more advanced functions such as producing dual color models and dual material models. A professional dual extruder 3D printer will have additional design features resulting in a higher quality print job.

The Pro3 Series professional dual extruder 3D printers have a single-side nozzle lifting technology with fast nozzle switching. Therefore, the nozzles can lift independently and switch within a second, and without being affected by 3D printing material or temperature.

Technical DetailsHigh repeatability

Lightning speed

1.

5 mm lifting distance Compatible with flexible filaments

5 mm lifting distance Compatible with flexible filaments Why is high repeatability good for a 3D printer? What does high reliability mean?

3D printing is a process where an object is built up by thin layers. The 3D printer needs to move back and forth along the length of the model to create those thin layers. If the printer loses its position during that back-and-forth motion, the 3D printing process will no longer be aligned, and the 3D printed object will be ruined. The high repeatability and reliability ensure the printer does not become misaligned during the back-and-forth movements.

What does lightning speed mean?

Lightning speed refers to the overall amount of time the 3D printer takes to print an object. However, this speed is heavily influenced by the type of project being printed and how quickly the printer can switch directions during the back-and-forth movement. Having a <1 second switch time means the Pro3 Series can change directions while printing an object. This shortens the overall time needed to complete a 3D printing process. Keep in mind, the general time savings will still be influenced by the project type.

Having a <1 second switch time means the Pro3 Series can change directions while printing an object. This shortens the overall time needed to complete a 3D printing process. Keep in mind, the general time savings will still be influenced by the project type.

Why is a 1.5 mm lifting distance beneficial to a 3D printer?

Lifting distance refers to the clearance between the idle printing nozzle and the object being printed. There needs to be some distance between both to ensure the printer’s nozzle does not interfere with the printing. The 1.5 mm lifting distance on the Pro3 Series maintains enough distance between the idle nozzle and the model to not affect the printing process.

User Friendly Features

Lightweight Cable with Digital Temperature Measurement

The Pro3 Series replaces the drag chain cable with a lightweight cable, to reduce the weight of the extruder and keep the center of gravity in the middle during printing for more stable print quality. The Pro3 Series also uses digital temperature measurement, for an accurate temperature reading to help prevent jamming.

The Pro3 Series also uses digital temperature measurement, for an accurate temperature reading to help prevent jamming.

Bed leveling is the process of confirming that the printing platform is as level as possible. The Pro3 Series has this leveling procedure as an automated function. Auto bed leveling will maintain the distance between the print nozzles and the bed, to create a uniform build area. This improves bed adhesion and allows the nozzle to adjust to even the most minor surface contour changes.

Live Monitoring HD Camera

The Pro3 Series uses a HD camera to monitor the entire 3D printing process of every print job. This camera operates by connecting to RaiseCloud, allowing users to keep track of every print job remotely and while on the move. This ability to check the 3D printing process gives peace of mind. The Pro3 Series also comes with an upgraded CMOS sensor to ensure better image quality.

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/ Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Buy Filaments

Safety Features

Power Loss Recovery

Either a power outage or a filament outage (when the filament runs out) can cause a print job to be lost if they occur in the middle of the 3D printing process. However, the Pro3 Series has a filament run-out sensor on its extruders to alert when the filament is about to run out and saves the print job. It also has a second-generation power loss function to save the printing status in the event of a power outage and can continue printing from the same point when power is restored.

Automatic DetectionAnother safety feature of the Pro3 Series is that it can automatically detect when a door is opened and will immediately pause the print.

Material Compatibility Flexible Build Plate HEPA Air Filter Touch Screen & Software Monitoring Full Metal Frame

The Pro3 Series is compatible with a variety of 3D printing materials (known as filaments) to meet project requirementsDepending on the project goals, more than one 3D printing filament is necessary to accommodate varying structural or functional requirements (for example, some requirements may include flexibility, and strength). Sometimes multiple filaments are required within the same print job. Having a 3D printer that is compatible with different filament types is both cost-saving and practical for print jobs requiring multiple filaments, giving it extra versatility other printers cannot match.

The Pro3 Series is equipped with flexible build plate. The flexible build plate can be used to easily remove printed parts while minimizing potential damage to the final print. Additionally, the flexible build plate can quickly regain its shape and return to printing quickly. The Pro3 Series is also compatible with a rigid build plate, as well as a high-temperature borosilicate glass build plate.

The updated HEPA air filtration removes toxic particles released during the 3D printing processThe Pro3 Series uses HEPA air filtration to clean the air of any particles (including nano-particles) released during the 3D printing process. The HEPA air filter works effectively in classrooms, offices, and in large and small workspaces and operates silently, quietly working in the background of any work area.

7-inch touch screen for efficiency and monitor the printing process with 3D printing softwareThe Pro3 Series’ 7-inch touch screens allow users to interact with the printer directly. It also provides on-screen assistance and visual model selections to simplify operating and monitoring both the 3D printer and 3D printing process. As with all Raise3D 3D printers, the Pro3 Series is compatible with ideaMaker, a 3D slicing program, and RaiseCloud, a cloud-based 3D printing management platform. This wireless connection allows users to keep track of every print job while on the move.

It also provides on-screen assistance and visual model selections to simplify operating and monitoring both the 3D printer and 3D printing process. As with all Raise3D 3D printers, the Pro3 Series is compatible with ideaMaker, a 3D slicing program, and RaiseCloud, a cloud-based 3D printing management platform. This wireless connection allows users to keep track of every print job while on the move.

High-quality 3D printing comes from high-quality 3D printers. The Pro3 Series professional dual extruder 3D printer uses a full metal frame to create a specific motion system that allows the machine to smoothly glide as it prints. This motion system works with precise positioning to ensure 3D print jobs are as accurate as possible. Interchangeable nozzles allow the Pro3 to print at different levels of detail.

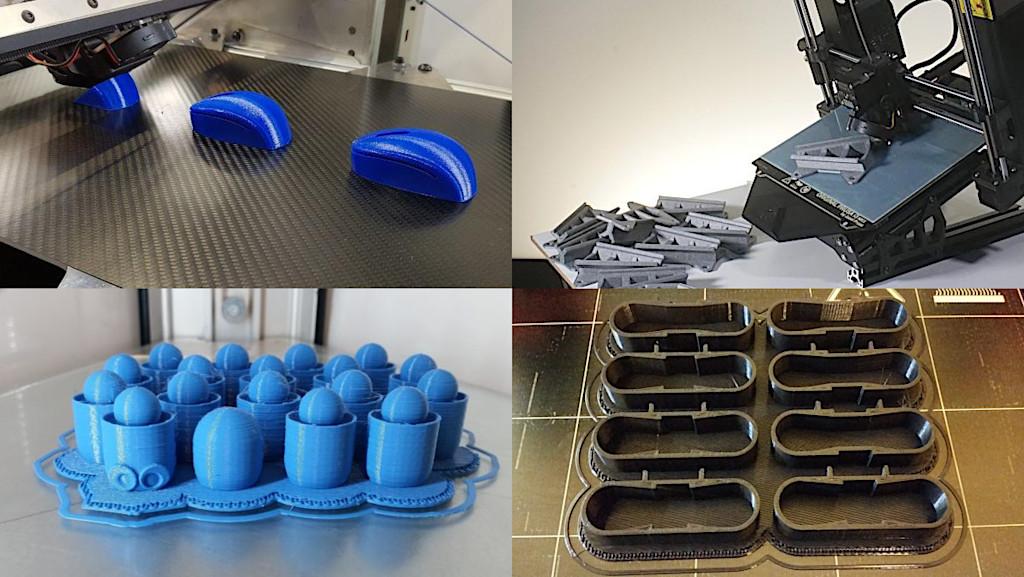

Print Results

Check out the Pro3 Series’ print performance from different aspects.

Flatness and Smoothness

Overhang Structure

Geometry Accuracy

Raise3D EcosystemPair ideaMaker and RaiseCloud with any of our 3D printers to create a Raise3D ecosystem for the best efficiency when 3D printing.

ideaMakerideaMaker is a free 3D slicing software from Raise3D, compatible with Raise3D printers and third-party printers.

Learn More

RaiseCloudRaiseCloud is a cloud-based 3D printing management platform capable of remotely monitoring the printing process and organizing print jobs for more efficient 3D printing.

Learn More

ideaMaker LibraryideaMaker Library provides users with slicing profiles for various filaments, including Raise3D filaments and OFP certified filaments, simplifying the settings of printing parameters for different filaments.

Learn More

Raise3D AcademyAccess Raise3D Academy for step-by-step guides and “how-to” articles, covering topics ranging from setting up and giving maintenance to the 3D printer to performing 3D printing.

Learn More

Raise3D SupportContact Raise3D’s Support Center with any questions regarding a specific printer.

Learn More

Pro3 Series Technical Specifications

DownloadPro3

Pro3 Plus

GENERAL

Build Volume (W × D × H)

Single Extruder Print: 11.8 × 11.8 × 11.8 inch/ 300 × 300 × 300 mm

Dual Extruder Print: 10 × 11.8 × 11.8 inch/ 255 × 300 × 300 mm

Single Extruder Print: 11.8 × 11.8 × 23.8 inch/ 300 × 300 × 605 mm

Dual Extruder Print: 10 × 11. 8 × 23.8 inch/ 255 × 300 × 605 mm

8 × 23.8 inch/ 255 × 300 × 605 mm

Machine Size (W × D × H)

24.4 × 24.6 × 29.9 inch/ 620 × 626 × 760 mm

24.4 × 24.6 × 43.5 inch/ 620 × 626 × 1105 mm

Print Technology

FFF

Print Head System

Dual-head with electronic lifting system

Filament Diameter

1.75 mm

XYZ Step Size

0.78125, 0.78125, 0.078125 micron

Print Head Travel Speed

30–150 mm/s

Build Plate

Flexible Steel Plate with Buildtak

Max Build Plate Temperature

120ºC

Heated Bed Material

Silicone

Build Plate Leveling

Mesh-leveling with Flatness Detection

Filament Run-out Sensor

Available

Supported Materials

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/

Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Layer Height

0. 01–0.25 mm

01–0.25 mm

Nozzle Diameter

0.4 mm (Default), 0.2/ 0.6/ 0.8/ 1.0 mm (Available)

Max Nozzle Temperature

300ºC

Connectivity

Wi-Fi, LAN, USB port, Live camera

Noise Emission (Acoustic)

<55 dB(A) when building

Operating Ambient Temperature

15-30ºC, 10-90% RH non-condensing

Storage Temperature

-25℃ to +55℃, 10-90% RH non-condensing

Filter

HEPA filter with activated charcoal

EVE Smart Assistant

Available

Net Weight

49 kg

61. 6 kg

6 kg

Gross Weight (Carton Only)

67 kg

80 kg

Gross Weight (Carton with Pallet)

75 kg

88 kg

ELECTRICAL

Power Supply Input

100-240 V AC, 50/ 60 Hz 230 V @ 3.3 A

Power Supply Output

24 V DC, 600 W

SOFTWARE

Slicing Software

ideaMaker

Supported File Types

STL/ OBJ/ 3MF/ OLTP

Supported OS

WINDOWS/ macOS/ Linux

Machine Code Type

GCODE

PRINTER CONTROLLER

User Interface

7-inch Touch Screen

Network

Wi-Fi, Ethernet

Power Loss Recovery

Available

Screen Resolution

1024 × 600

Motion Controller

Atmel ARM Cortex-M4 120 MHz FPU

Logic Controller

NXP ARM Cortex-A9 Quad 1 GHz

Memory

1 GB

Onboard Flash

16 GB

OS

Embedded Linux

Ports

USB 2. 0 × 2, Ethernet × 1

0 × 2, Ethernet × 1

Equipment and 3D printers of the Russian manufacturer Total Z

Products

The Total Z team is the first in Russia to launch mass production of industrial 3D printers.

The machines print with all plastics available for additive manufacturing, including high-temperature ULTEM 9085, ULTEM 1010, PEEK, PEKK, PPSU, PSU, PEI.

The PRO Series printers are used by organizations in the aerospace, automotive, agro, and shipbuilding industries. nine0003

AnyForm 450-PRO

The most compact and affordable model from the Total Z line of industrial 3D printers.

The working chamber size of 450×450×450 mm is suitable for solving most engineering tasks in production.

Learn more

AnyForm 500-PRO

Compact printer that fits in openings from 900 mm.

Working chamber volume increased to 500×500×500 mm. nine0003

Learn more

AnyForm 650-PRO

650×500×650 mm printer. Suitable for tasks when an increased volume of the build chamber is needed, but it is not possible to install a large-sized industrial machine due to the size of the premises or due to connection power requirements.

Suitable for tasks when an increased volume of the build chamber is needed, but it is not possible to install a large-sized industrial machine due to the size of the premises or due to connection power requirements.

Learn more

AnyForm 950-PRO

The printer is suitable for building models up to 950x650x950mm. Automation and a video surveillance system ensure strict quality control throughout the entire printing process. nine0003

Learn more

AnyForm 1200-PRO

One of the largest industrial 3D printers on the market. The size of the working chamber is 1200×650×1200 mm, which allows you to build a one-piece dimensional part or print a small-scale batch in one installation.

Learn more

LPRO Series High-Performance FDM 3D Printers

LPRO printers outperform industrial models in terms of build area with the same external dimensions of the machines themselves. They are cheaper and easier to maintain. nine0003

The LPRO models completely fill the need for printing with impact-resistant, design, flexible, wear-resistant plastics with an operating temperature of up to 130 ° C and a tensile strength of more than 50 MPa.

AnyForm 1000-LPRO

Model for high-speed printing of large-sized products with a closed working chamber measuring 1200x1000x1000 mm. One of the largest 3D printers for 3D printing on the market.

Learn more

nine0002 AnyForm S1000 LPROAn evenly heated bed and high-performance extruders allow you to create professional-looking objects of impressive size and save time on construction.

Learn more

Granular 3D Portal Systems

Total Z has introduced pellet printing technology to a new line of 3D gantry machines with an area prints up to 12 meters in length. Screw printing is implemented in conjunction with five-axis milling, which allows get large parts with a high quality surface. nine0003

New 3D machines build 3D models under tight deadlines. Productivity depends on the model of auger extruder and can reach up to 50 kg per hour, which is an order of magnitude faster than classic filament printing.

Total Z AnyForm FGF

Gantry machine with integrated high speed 3D pellet printing.

Learn more

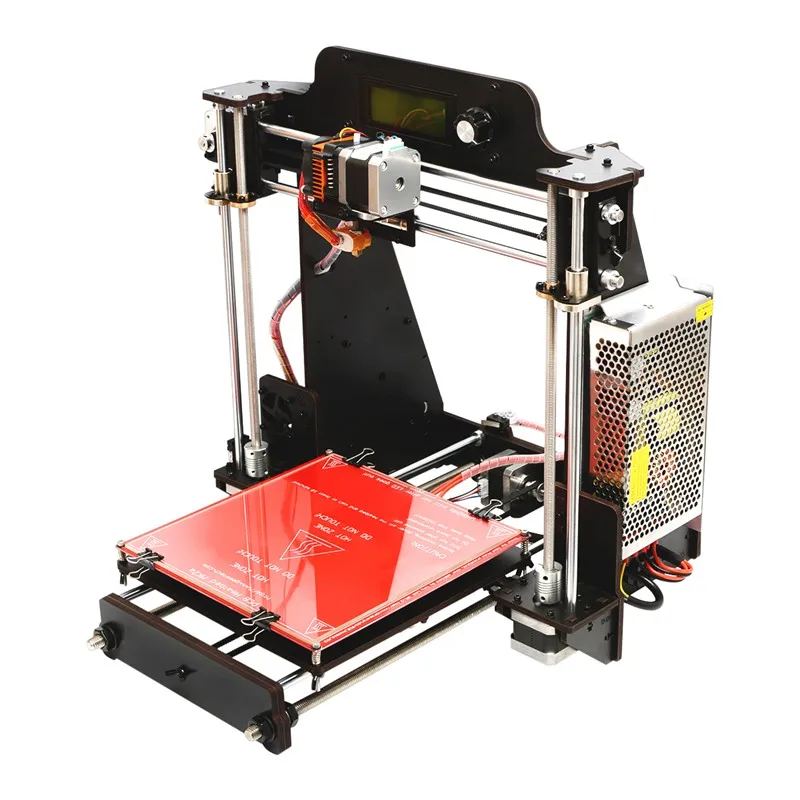

G3 and G5 Series Desktop 3D Printers

Total Z desktop printers G3 and G5 series solve the problems of rapid prototyping, allow you to print piece products and small-scale products. nine0003

AnyForm 250-G3

The smallest model with a printable area of 250x250x250mm. Reliable extruders provide precise and economical work.

Learn more

AnyForm L250-G3

Model with increased print height up to 400 mm. The construction area is 250×250×400 mm.

Learn more

AnyForm XL250-G3

3D printer with a maximum print height of 550 mm. Simultaneous work with different materials when choosing a dual extruder. nine0003

Learn more

G5

Compact high temperature industrial printer.

Learn more

SLS 3D printers

Builds a model by layer-by-layer sintering of powder materials with a laser. Support material is no longer needed.

Support material is no longer needed.

AnyForm SLS 250

For printing objects with complex geometry. SLS technology allows you to print products with moving elements. nine0003

Characteristics for strength, flexibility, detailing and thermal stability meet the requirements of high-tech industries.

Learn more

Drying and post-processing machines

Vacuum dryers

Help prepare plastic for printing. Remove moisture from hygroscopic materials. Reduce the risk of plastic "boiling", extruder breakage, deterioration of the surface quality of the product.

Learn more

Acetone baths

Equipment for chemical post-processing of finished objects. Helps to achieve a glossy and smooth product surface. Total Z assembles acetone baths according to the customer's specification.

Dimensions up to 1200 mm.

Reagent - water, alcohol, limonene.

Learn more

Ultrasonic cleaners

Machines for physical and chemical post-processing of models. Remove the supporting plastic from the surface of finished products. They clean the material in places inaccessible for manual processing. The assembly of equipment takes place in accordance with the customer's specifications. nine0003

Remove the supporting plastic from the surface of finished products. They clean the material in places inaccessible for manual processing. The assembly of equipment takes place in accordance with the customer's specifications. nine0003

Dimensions: up to 1200 mm.

Reagent: water, alcohol, limonene.

Learn more

How metal 3D printers work. Overview of SLM and DMLS technologies. additive manufacturing. 3D metal printing.

Metal 3D printing. Additive technologies.

SLM or DMLS: what's the difference?

Hello everyone, Friends! 3DTool is with you!

BLT metal 3D printer catalog nine0003

Selective laser melting ( SLM ) and direct metal laser sintering ( DMLS ) are two additive manufacturing processes that belong to the family of 3D printing , using the powder layer method. The two technologies have much in common: they both use a laser to selectively melt (or melt) metal powder particles, bonding them together and creating a pattern layer by layer. In addition, the materials used in both processes are metals in granular form. nine0003

In addition, the materials used in both processes are metals in granular form. nine0003

The differences between SLM and DMLS come down to the basics of the particle bonding process: SLM uses metal powders with a single melting point and completely melts the particles, while in DMLS the powder consists of materials with variable melting points.

Specifically:

SLM produces single metal parts while DMLS produces metal alloy parts.

Both SLM and DMLS technologies are used in industry to create final engineering products. In this article, we will use the term "metal 3D printing" to summarize the 2 technologies. We will also describe the main mechanisms of the manufacturing process that are necessary for engineers to understand the advantages and disadvantages of these technologies. nine0047 There are other manufacturing processes for producing dense metal parts, such as electron beam melting (EBM) and ultrasonic additive manufacturing (UAM). Their availability and distribution is rather limited, so they will not be presented in this article.

nine0047 There are other manufacturing processes for producing dense metal parts, such as electron beam melting (EBM) and ultrasonic additive manufacturing (UAM). Their availability and distribution is rather limited, so they will not be presented in this article.

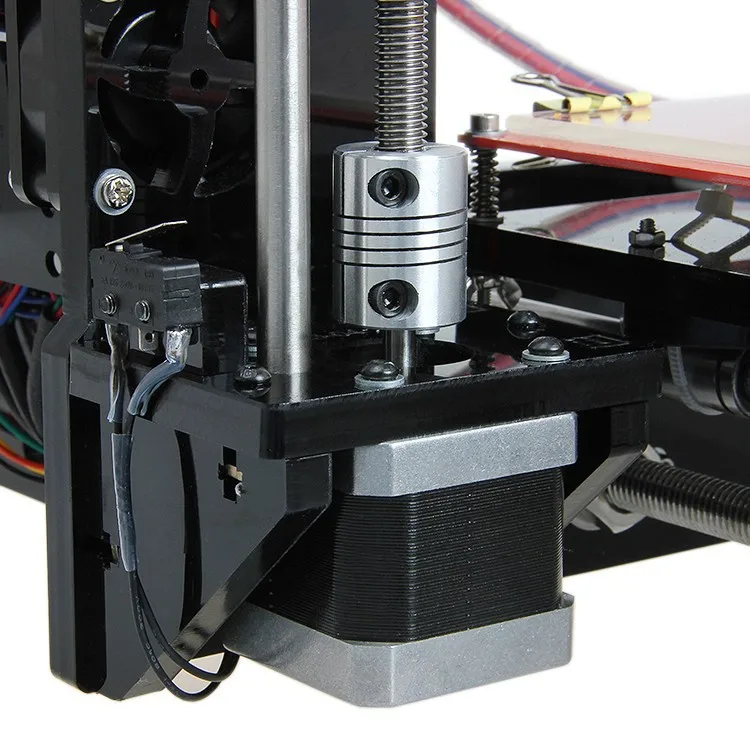

How metal 3D printing SLM or DMLS works.

How does metal 3D printing work? The basic manufacturing process for SLM and DMLS is very similar.

1. The printing chamber is first filled with an inert gas (such as argon) to minimize the oxidation of the metal powder. It then heats up to the optimum operating temperature. nine0047 2. A layer of powder is spread over the platform, a powerful laser makes passes along a predetermined trajectory in the program, fusing the metal particles together and creating the next layer.

3. When the sintering process is completed, the platform moves down 1 layer. Next, another thin layer of metal powder is applied. The process is repeated until the entire model is printed.

When the printing process is completed, the metal powder already has strong bonds in the structure. Unlike the SLS process, parts are attached to the platform via support structures. The support in metal 3D printing is created from the same material as the base part. This condition is necessary to reduce deformations that may occur due to high processing temperatures. nine0047 When the 3D printer's chamber cools down to room temperature, excess powder is removed manually, such as with a brush. The parts are then typically heat treated while they are still attached to the platform. This is done to relieve any residual stresses. They can then be further processed. The removal of the part from the platform occurs by means of sawing.

The scheme of the 3D printer for metal.

In SLM and DMLS, almost all process parameters are set by the manufacturer. The layer height used in metal 3D printing varies from 20 to 50 microns and depends on the properties of the metal powder (flow, particle size distribution, shape, etc.). nine0047 The basic size of the print area on metal 3D printers is 200 x 150 x 150 mm, but there are also larger sizes of the working area. Printing accuracy is from 50 - 100 microns. As of 2020, metal 3D printers start at $150,000. For example, our company offers 3D metal printers from BLT.

The layer height used in metal 3D printing varies from 20 to 50 microns and depends on the properties of the metal powder (flow, particle size distribution, shape, etc.). nine0047 The basic size of the print area on metal 3D printers is 200 x 150 x 150 mm, but there are also larger sizes of the working area. Printing accuracy is from 50 - 100 microns. As of 2020, metal 3D printers start at $150,000. For example, our company offers 3D metal printers from BLT.

Metal 3D printers can be used for small batch production, but the 3D printing capabilities of such systems are more like those of mass production on FDM or SLA machines. nine0047 The metal powder in SLM and DMLS is recyclable: typically less than 5% is consumed. After each impression, the unused powder is collected and sieved, and then topped up with fresh material to the level required for the next production.

Waste in metal printing, are supports (support structures, without which it will not be possible to achieve a successful result). With too much support on the manufactured parts, the cost of the entire production will increase accordingly. nine0047

With too much support on the manufactured parts, the cost of the entire production will increase accordingly. nine0047

Adhesion between coats.

3D metal printing on BLT 3D printers

SLM and DMLS metal parts have almost isotropic mechanical and thermal properties. They are hard and have very little internal porosity (less than 0.2% in 3D printed condition and virtually non-existent after processing).

Metal printed parts have higher strength and hardness and are often more flexible than traditionally made parts. However, such metal becomes “tired” faster. nine0003

3D model support structure and part orientation on the work platform.

Support structures are always required when printing with metal, due to the very high processing temperatures. They are usually built using a lattice pattern.

Supports in metal 3D printing perform 3 functions:

• They form the basis for creating the first layer of the part.

• They secure the part to the platform and prevent it from deforming.

• They act as a heat sink, removing heat from the model. nine0003

Parts are often oriented at an angle. However, this will increase the amount of support required, the printing time, and ultimately the overall cost.

Deformation can also be minimized with laser sintering templates. This strategy prevents the accumulation of residual stresses in any particular direction and adds a characteristic surface texture to the part.

Since the cost of metal printing is very high, software simulations are often used to predict how a part will behave during processing. These topology optimization algorithms are otherwise used not only to increase mechanical performance and create lightweight parts, but also to minimize the need for supports and the likelihood of part distortion. nine0003

nine0003

Hollow sections and lightweight structures.

An example of printing on a BLT 3D printer

Unlike polymer powder melt processes such as SLS, large hollow sections are not typically used in metal printing as the support would be very difficult to remove, if at all possible.

For internal channels larger than Ø 8 mm, it is recommended to use diamond or teardrop cross-sections instead of round ones, as they do not require the construction of supports. More detailed recommendations on the design of SLM and DMLS can be found in other articles on this topic. nine0003

As an alternative to hollow sections, parts can be made with sheath and cores, which in turn are machined using different laser power and pass speeds, resulting in different material properties. The use of sheath and cores is very useful when making parts with a large solid section, as it greatly reduces printing time and reduces the chance of warping.

The use of a lattice structure is a common strategy in metal 3D printing to reduce part weight. Topology optimization algorithms can also help design organic lightweight shapes. nine0003

Consumables for 3D metal printing.

SLM and DMLS technologies can produce parts from a wide range of metals and metal alloys, including aluminum, stainless steel, titanium, cobalt, chromium and inconel. These materials meet the needs of most industrial applications, from aerospace to medical applications. Precious metals such as gold, platinum, palladium and silver can also be processed, but their use is of a minor nature and is mainly limited to jewelry making. nine0003

The cost of metal powder is very high. For example, a kilogram of 316 stainless steel powder costs approximately $350-$450. For this reason, minimizing part volume and the need for supports is key to maintaining optimal manufacturing cost.

The main advantage of metal 3D printing is its compatibility with high-strength materials such as nickel or cobalt-chromium superalloys, which are very difficult to machine with traditional methods. Significant cost and time savings can be achieved by using metal 3D printing to create a near-clean shape part. Subsequently, such a part can be processed to a very high surface quality. nine0047

Significant cost and time savings can be achieved by using metal 3D printing to create a near-clean shape part. Subsequently, such a part can be processed to a very high surface quality. nine0047

Metal post-processing.

Various post methods. treatments are used to improve the mechanical properties, accuracy and appearance of metal printed products.

Mandatory post-processing steps include the removal of loose powder and support structures, while heat treatment (heat annealing) is typically used to relieve residual stresses and improve the mechanical properties of the part.

CNC machining can be used for critical features (such as holes or threads). Sandblasting, plating, polishing, and micro-machining can improve the surface quality and fatigue strength of a metal printed part. nine0003

Advantages and disadvantages of metal 3D printing.

Pros:

1. Metal 3D printing can be used to make complex custom parts, with geometries that traditional manufacturing methods cannot provide.

Metal 3D printing can be used to make complex custom parts, with geometries that traditional manufacturing methods cannot provide.

2. Metal 3D printed parts can be optimized to increase their performance with minimal weight.

3. Metal 3D printed parts have excellent physical properties, metal 3D printers can print a wide range of metals and alloys. Includes difficult-to-machine materials and metal superalloys. nine0003

Cons:

1. Manufacturing costs associated with metal 3D printing are high. The cost of consumables is from $ 500 per 1 kg.

2. The size of the working area in metal 3D printers is limited.

Conclusions.

• Metal 3D printing is most suitable for complex, one-piece parts that are difficult or very expensive to manufacture using traditional methods, such as CNC.

• Reducing the need for building supports, greatly reducing the cost of printing with metal. nine0047 • 3D printed metal parts have excellent mechanical properties and can be made from a wide range of engineering materials, including superalloys.