3D printer arizona

3D printing | University of Arizona Libraries

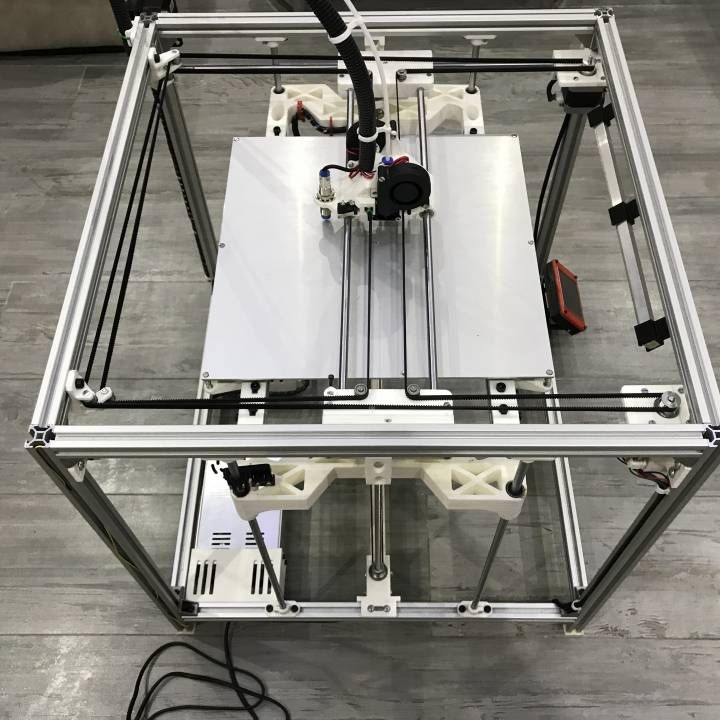

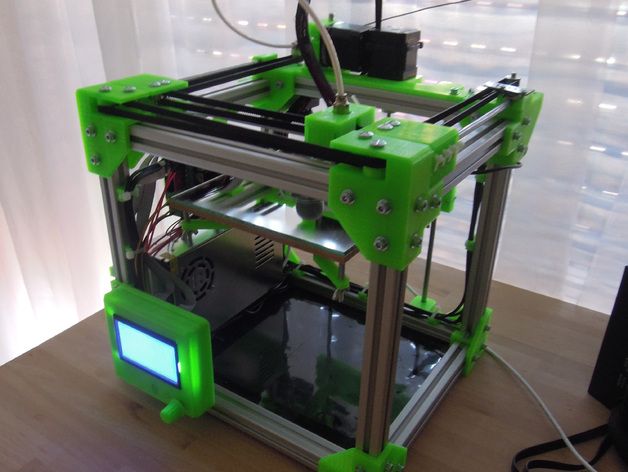

What equipment and materials do you use?We have a variety of 3D Printers across our libraries.

Ultimaker

The Ultimaker 3 and Ultimaker S5 are innovative dual extrusion machines with large build areas (UM3: 200 x 200 x 195 mm & S5: 310 x 220 x 295 mm) that print high resolution, production quality parts. Filaments available for these printers include: ABS, PLA, TPU (Flexy) and PolyCarbonate. Water soluble supports are available upon request.

- Learn more about Ultimaker filament options.

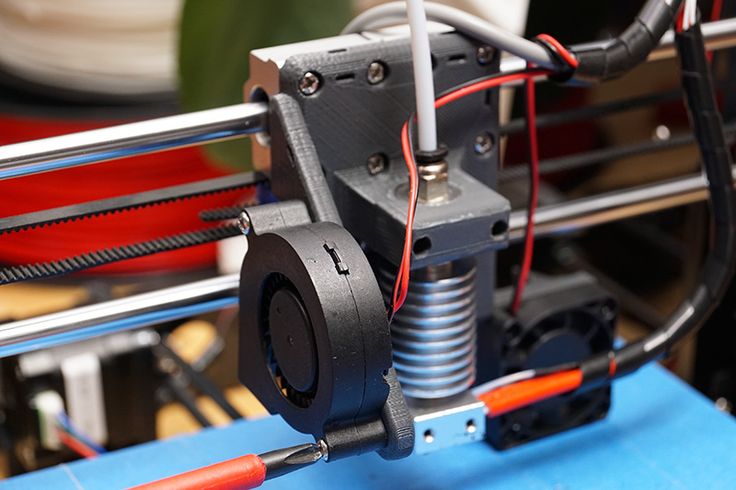

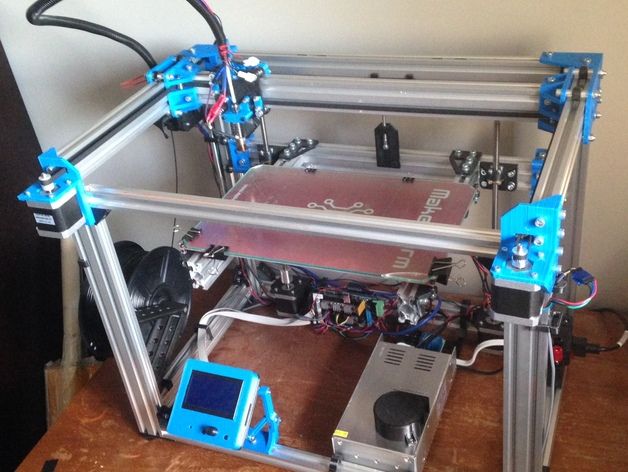

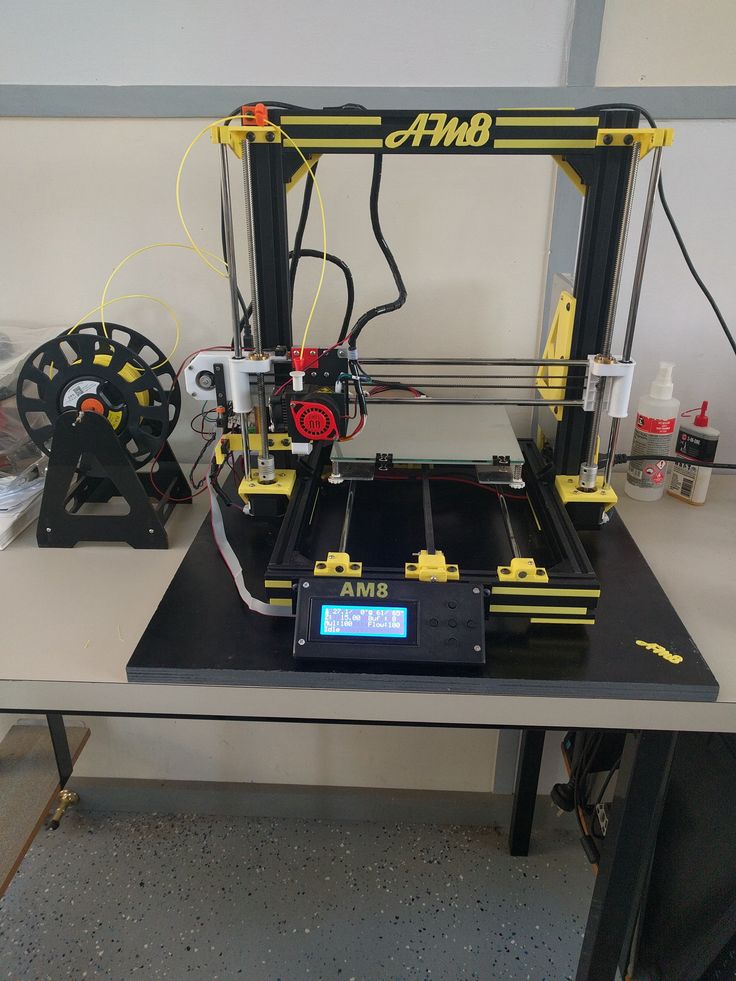

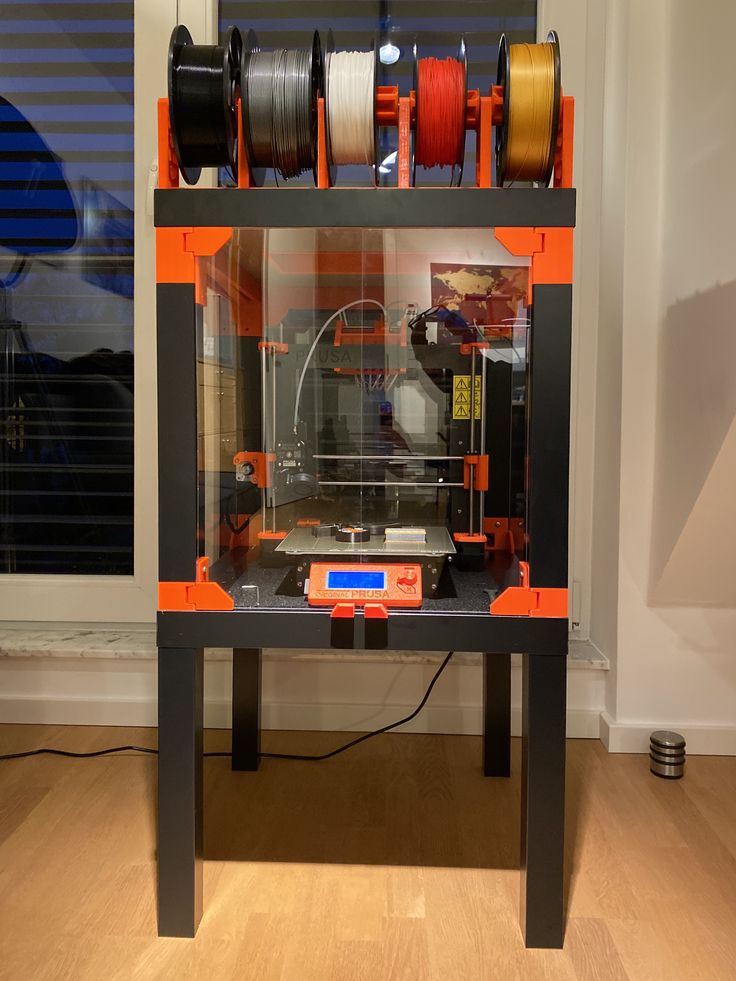

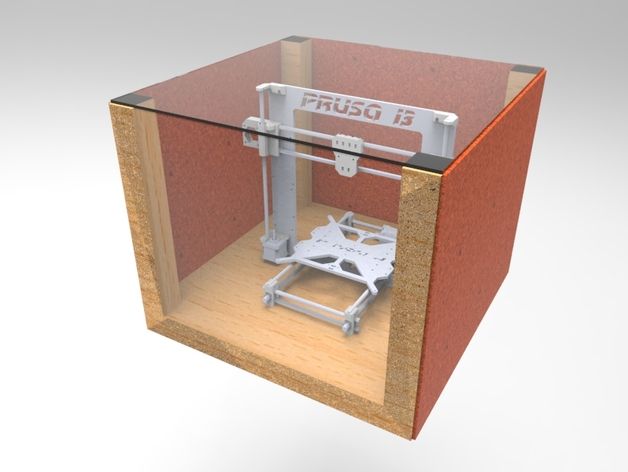

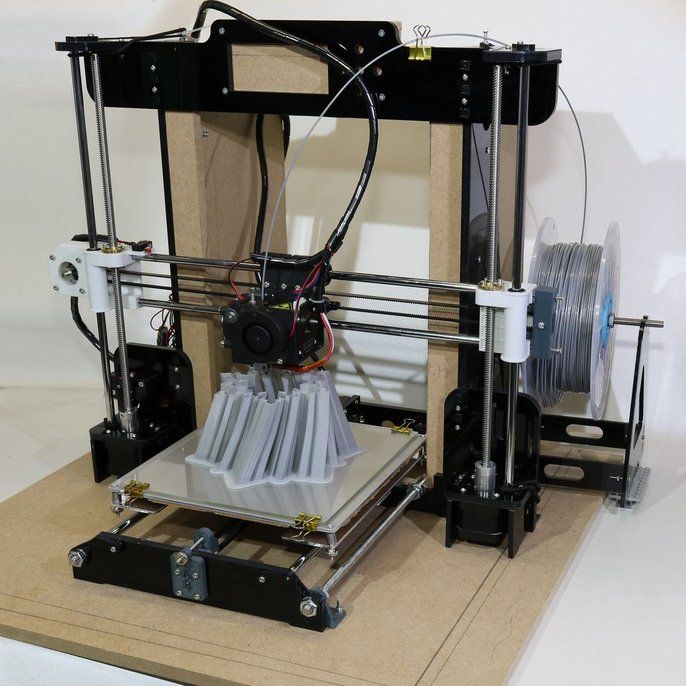

Prusa

The Original Prusa i3 MK3S+ is the latest iteration of Prusa Research’s original fused deposition modeling (FDM) machine. The MK3S+ has a build volume of 250 x 210 x 210 mm build volume and is known for its excellent and reliable prints. Filaments available for these printers include: PLA and PETG.

Learn more about Prusa filament options.

Phrozen

The Mega 8K LCD resin printer allows high resolution & fine detail of SLA but with an increased build plate size, 325 x 175 x 375mm. This machine excels at art and display models, with a single color selection and no engineering resins. This machine is the best choice for objects that need to look excellent with minimal mechanical stress.

Learn more about Phrozen Mega 8k resin

Who can use this service?

The service is open to all, but the priority is for UA students, faculty, and staff. Members of the community may submit requests to the Main Library, but the requests may be backlogged during peak use during the semester.

What does it cost?

| Material Type | Cost |

| PLA & PETG & ABS | $0.10/per gram |

| Specialty Filament (PC, TPU) | $0.15/per gram + $1 set up fee |

| Phrozen 8k Resin (Art) | $. 10/gram + $1 set up fee 10/gram + $1 set up fee |

Set Up Fees

A $1.00 set up fee will be applied to any job printed with specialty filament or resin or that requires special handling.

For those objects printed with regular filament, a $1.00 set up fee may be added to your price quote. This determination is based on: the object's complexity, its build process, and the amount of staff attention needed to complete the job.

Please also note that a set up fee will apply to each file that must be created in order to print your objects. If your request contains multiple objects, we will combine as many objects onto the same build plate while still maintaining print integrity.

Payment

For students faculty, and staff, we add the charges to your library account, for members of the community, we’ll send a generic login you can use to pay.

What is the turnaround time?

Printing times vary based on size, complexity, and any backlog. If requested, we will contact you within two business days with an approximate turnaround time. To best accommodate large orders, please contact us 4-6 weeks prior to your "need by" date at [email protected]. For instructors, please contact us at the beginning of the semester so we can coordinate the best time for

To best accommodate large orders, please contact us 4-6 weeks prior to your "need by" date at [email protected]. For instructors, please contact us at the beginning of the semester so we can coordinate the best time for

your class to submit their projects.

Where can I get help?

You can prepare your own 3D file for printing and learn how to use the slicing software by visiting CATalyst Studios, located on the 2nd floor of the Main Library. A staff member can help you prepare your model for printing and set up the print job. If you are interested in becoming certified to use 3D printers in CATalyst Studios, please sign up for a 3D printing user certification workshop.

Please note, CATalyst Studios can only accommodate smaller 3D print jobs during their open hours. If you need to print larger items or require special materials, submit a 3D Printing request to our production service and we will take care of your 3D print for a fee.

Visit our 3D modeling resources page for modeling software, design libraries, and tutorials. Consultants from the Office of Student Computing Resources are available in the OSCR Zone to answer software questions.

Consultants from the Office of Student Computing Resources are available in the OSCR Zone to answer software questions.

Contact us

520-621-6442

3D Printing Service Phoenix, AZ | Instant Quotes Online

Our 3D printing capabilities

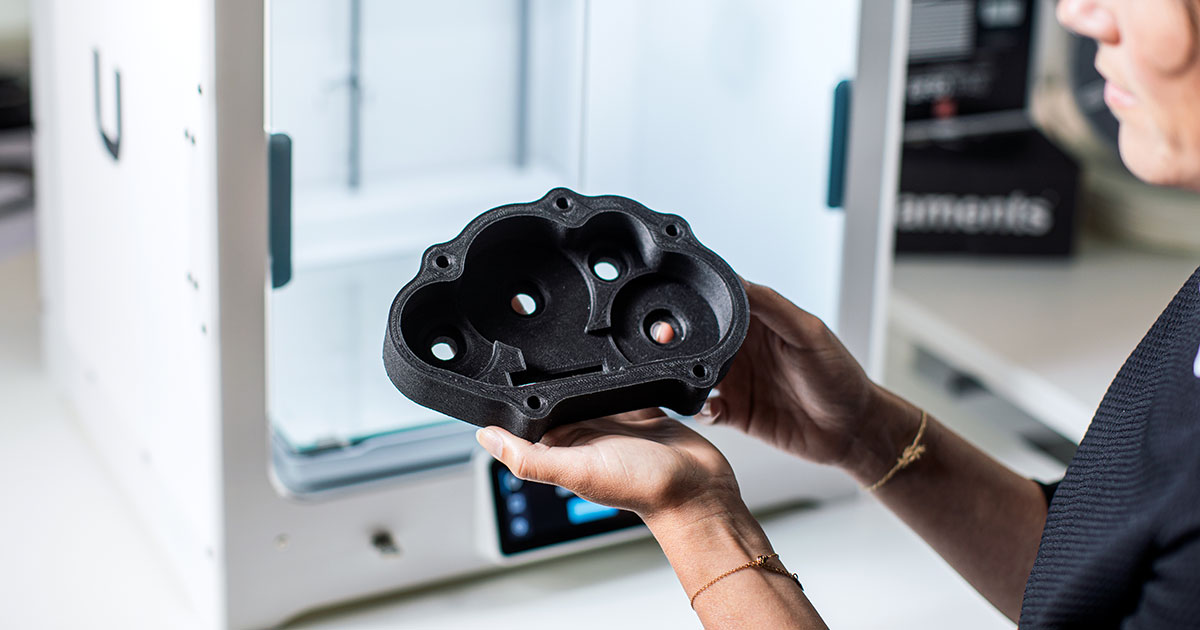

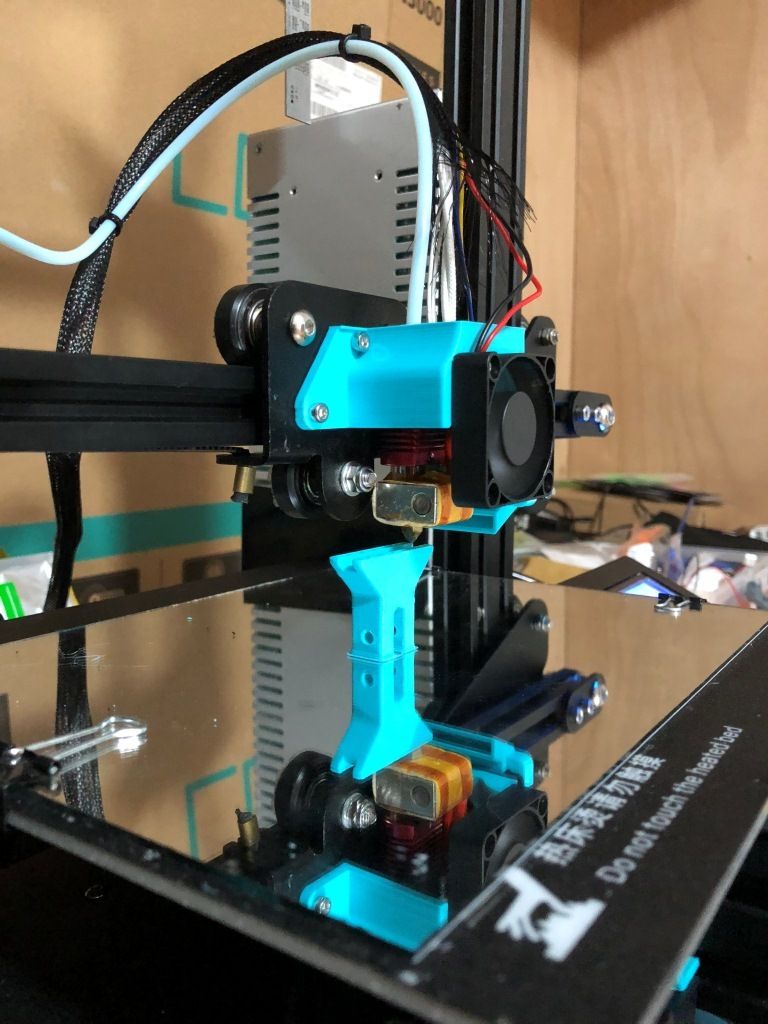

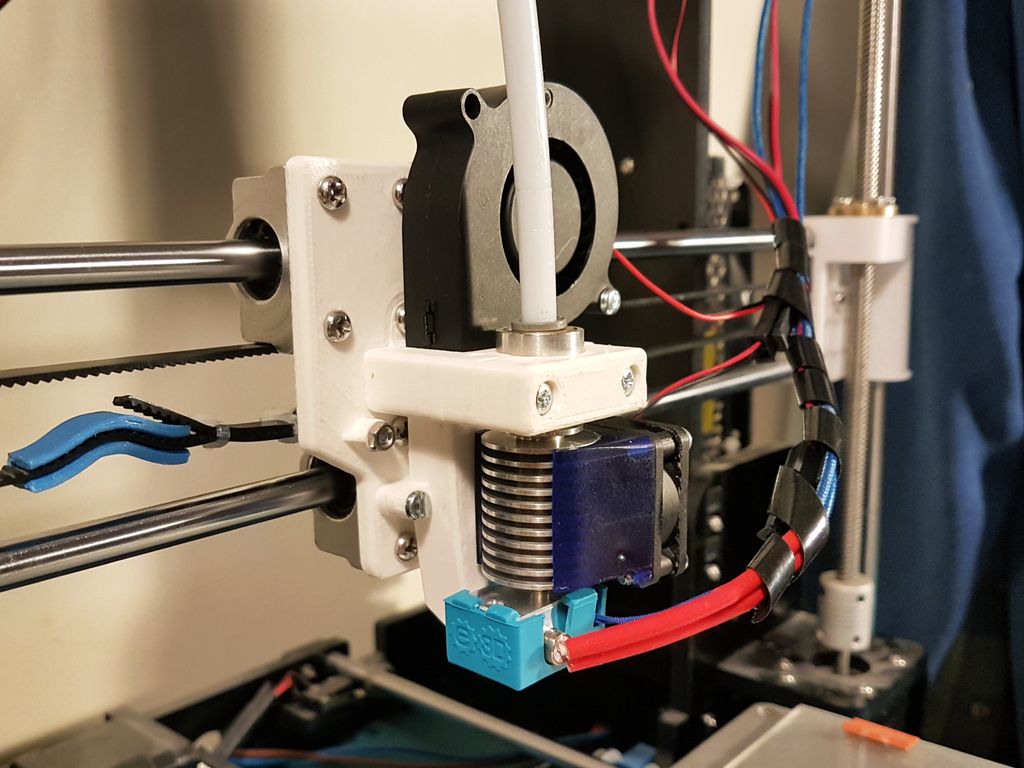

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc..

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.

9/5

9/5 Over 306 customers are satisfied with our 3D printing service.

“Got exactly what I needed in a short amount of time with friendly service!”

“Great service. Got all the parts I ordered quickly and in great condition.”

“Quality product at affordable price. Will be ordering again!”

“Good customer service and the parts were printed to our specifications.”

“Excellent quality printing and the resin look is much more elegant than abs. ”

“Excellent work, would be happy to use your service again. ”

“This seller is absolutely amazing! Great communication and extremely easy to work with. Thanks for making this such a pleasant experience. ”

“Great communication, knowledgeable, and friendly! I’ll be coming back!!”

“Went above and beyond to make the parts awesome”

“Good communication, good work. Would recommend to others and will use for future projects.”

Would recommend to others and will use for future projects.”

“Order processed as expected - good communication throughout the process. Will use again.”

“Parts were printed and shipped fast. Print quality was perfect, and I can't even spot where the supports were connected.”

“Great communication and very high quality print. Thanks again!”

“Excellent service! Excellent model! Thank you so much!”

“Great! Second print job, this time with some model changes to my files. Quick turnaround and awesome service!”

“Fast and professional yet friendly service!”

“Ben has done an outstanding job with all of the print orders!”

“Great provider, super helpful, will use again.”

“Very fast and also very attentive to the particulars of the order. Will definitely use again in the future ”

“Excellent service. Now my go-to for anything I need 3D printed.”

“Solid work, Great prints and more than willing to work with you and help you out!”

“Went the extra mile to make the print work. ”

”

“Brilliant! In summation, an excellent hub. Ben thoroughly answered all my questions in regards to my special applications. The parts were printed beautifully, with spot-on accuracy, and in a timely manner. I really appreciate your service.”

“Fast and the print came out well. thank you”

“Prints look good, turn around was good...very happy with my experience.”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Phoenix, AZ

Scottsdale, AZ Peoria, AZ Phoenix, AZ

Glendale, AZ Surprise, AZ Tempe, AZ

Mesa, AZ Prescott Valley, AZ Avondale, AZ

Chandler, AZ

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

Arizona 135 GT - UV Flatbed Printer

Arizona 135 GT - UV Flatbed Printer - Canon AzerbaijanUV Flatbed Printers

Access new sources of income with superior printing options on a wide range of media with an affordable premium Arizona printer.

2000 m

2 A smart investment for printing over 2000 m 2

per year

VariaDot for

900 award-winning technology0014 Stunning printsRolled printing

Continuous printing on hard and

flexible media

Instant inclusion

low energy consumption

Access to the benefits of Arizona

ARizona 135 GT - this and print service providers to discover new business opportunities. Enjoy the convenience of Arizona's first-class devices, renowned for their exceptional quality, impressive reliability, and low total cost of ownership. nine0003

Access to full flatbed printing

This full flatbed printer is built for ease of use and delivers the professional quality you expect from a world leading flatbed printer. The Arizona 135 delivers unparalleled print quality and print speeds of 34.2 m 2 /h on virtually any rigid or flexible media.

Access to new sources of income

Arizona's full flatbed technology and photopolymerization allow you to create a large variety of durable printed products of consistently high quality. Arizona Classic's efficient high-pressure vacuum system ensures that the media is held securely during printing, including smoothing out uneven, rigid media. Experience new printing possibilities with an upgradeable roll printer and create printed products on flexible media. nine0003

Access to quality printing

Experience exceptional print quality with VariaDot grayscale printing technology. It uses advanced droplet size selection techniques. Experience even more consistent results and true-to-life images with excellent color reproduction and our best white reproduction ever.

Print production made easy

Arizona Xpert prepress software makes it easy to design and print high quality projects such as textured print jobs. The kit includes ready-made recipes for easy creation of projects. Arizona delivers consistently high print quality to avoid reprints, reduce waste and reduce production costs, resulting in higher profit margins and faster order fulfillment. nine0003

Arizona delivers consistently high print quality to avoid reprints, reduce waste and reduce production costs, resulting in higher profit margins and faster order fulfillment. nine0003

Long uptime

Uptime is key to any printing process, which is why the Arizona 135 has a range of maintenance features. An automated maintenance system keeps the printhead healthy and selectively restores nozzles in just a few seconds. Remote Service allows you to access authorized remote diagnostics by our certified and experienced technicians. nine0003

Hard and flexible carriers

Standard and textured surfaces

Composite glass

9000 9000

9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000

MDF

Cardstock

Hard and flexible plastic

Materials

Signage & Outdoors

Help your customers with bright signage. From durable outdoor banners that will last for several seasons in any weather to indoor posters that can be updated regularly, large format printing will give you a wide range of creative options.

From durable outdoor banners that will last for several seasons in any weather to indoor posters that can be updated regularly, large format printing will give you a wide range of creative options.

Display cases for retail stores and points of sale

Point-of-sale display draws the attention of shoppers to special offers or products of the right brands, allowing you to create a better offer and showcase the benefits of the product. This marketing tactic is very effective because it is applied in the place where the buyer is located in order to directly make a purchase decision.

Industrial

Industrial printing is the use of printing technologies as part of a manufacturing process. In this area, printing is an integral component of the final product. Membrane switches, interior décor, floor plans, glass printing, wallpaper, automotive interiors, and texture printing—the ability to create these products will allow you to expand the range of services you provide to your customers. nine0003

nine0003

-

ARIZONA 135 GT

Book. Download the brochure [PDF, 1299 KB]

- 9000 9000

Technical description of the Arizona 135 GT

Technical description [PDF, 106131

-

Up to 34.2 m 2 per hour

-

Modifiable on-site to print products up to 220 cm wide and 50 kg in weight, including thin and heat sensitive flexible media. nine0003

-

125 x 250 cm

-

Smart investment when printing over 2000 m 2 per year

-

5-channel system of piezoelectric stamp with Variadot

9000 9000 9000 9000) droppings from 6 to 6 to 6 to 6 to 6 to 6 to 6 to 6 to 6 to 6 to 6 to 6 to 6 to 30 picolitres for the most lifelike prints with clarity previously only available at 1440 dpi or higher.

View full specifications

Sustainability and practicality

Canon is a firm believer in developing and manufacturing products sustainably, as well as providing services to customers while supporting their sustainability initiatives and delivering exceptionally low total cost of ownership.

The Arizona print process requires 50% less ink than other 5-color fixed droplet flatbed printers, making the Arizona 135 a cost-effective and environmentally friendly solution. The photopolymerized inks used are UL GREENGUARD Gold certified, making them suitable for retail, education, healthcare and hospitality applications. Arizona printers use less power than competing models. nine0003

-

COMMUNITY

graphiPLAZA Community

At graphiPLAZA you will find new market trends, best practices from around the world, product news and exciting new applications.

NEED HELP?

Want to access Arizona benefits?

Request information

If you see this message, you are browsing the Canon website using a search engine that blocks non-essential cookies. Only essential (functional) cookies will be used on your device. These cookies are essential for the website to function and are an integral part of our systems. To learn more, check out our Notice about cookies.

To learn more, check out our Notice about cookies.

Delete item or clear [category] because there is a limit of 8 products. Press Change

Reset all selection?

3D printing will form the basis of the data centers of the future Doctors - for prosthetics. Ford and GM companies - to create prototypes of brake pads, levers and other spare parts. This new kind of industrial equipment is capable of reproducing any material object, at least in theory it can. nine0003

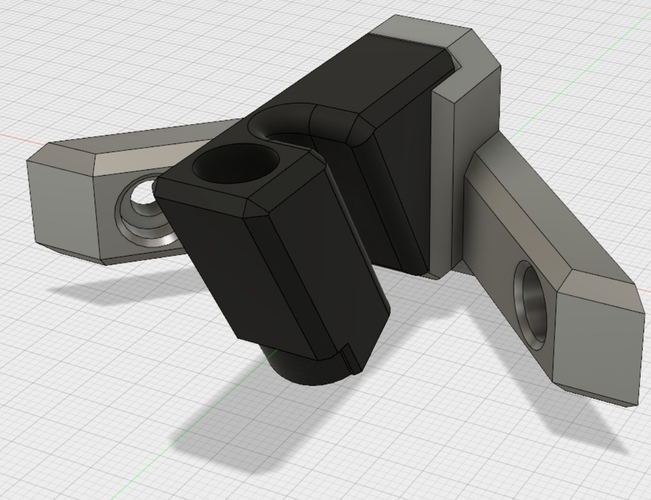

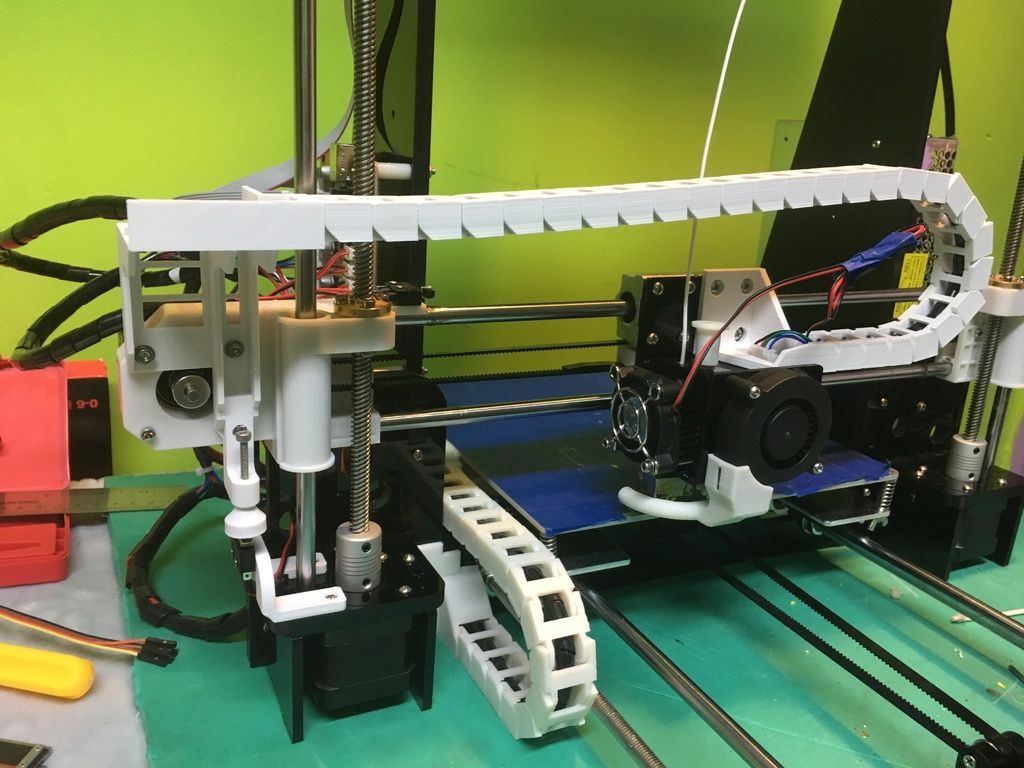

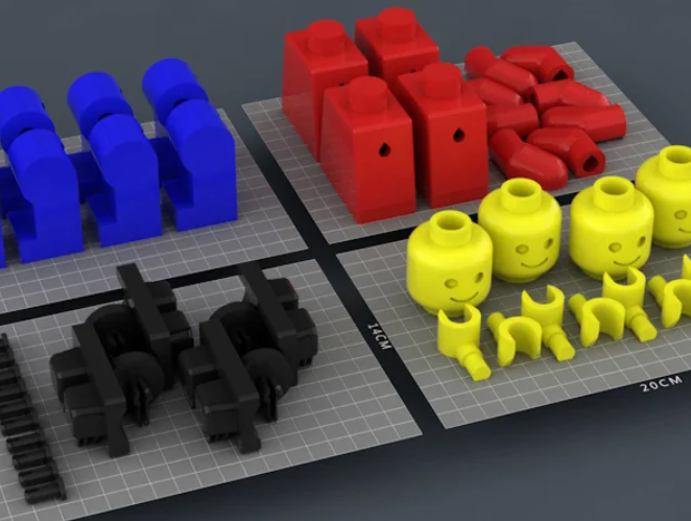

It's no surprise that the tech world is now trying to use 3D printing to build data centers. IO at its plant in Chandler, Arizona, is using 3D printers to prototype data center modules, sort of like giant legos. Almost as easily as GM and Ford, IO can build, test and modify car prototypes. “This significantly speeds up the process and makes it more flexible,” says Vice President Andreas Zoll.

The idea of a modular data center was born at Google about a decade ago. Instead of designing each of its data centers from scratch, the search giant began to use the so-called. container building. They are based on conventional shipping containers that include computing, cooling and electrical equipment configured to work in concert. Using rail, road and sea transport, Google was able to move them around the world and put them together on one site. It was a way to speed up not only the construction process itself, but also to increase the efficiency of such modules. nine0003

Instead of designing each of its data centers from scratch, the search giant began to use the so-called. container building. They are based on conventional shipping containers that include computing, cooling and electrical equipment configured to work in concert. Using rail, road and sea transport, Google was able to move them around the world and put them together on one site. It was a way to speed up not only the construction process itself, but also to increase the efficiency of such modules. nine0003

Over the years, many have adopted this simple approach to designing data centers. Microsoft is using modular data centers to host their web services, many hardware manufacturers are now selling modular solutions, and many enterprises can in turn use them to build their own data centers. Among the manufacturers are such giants as Dell and HP, along with IO, whose equipment is now used by one of the world's largest commercial banks, Goldman Sachs. nine0003

In the past, when IO was just designing modules, you had to bring in various component manufacturers to get the prototype you wanted. To produce even a tiny light bracket on top of the module, the company had to spend hundreds of dollars and wait two to three weeks for a prototype to arrive on site. But recently they used a Makerbot 3D printer to speed up the process. Now, as Zoll stated, we can get a small part, say a bracket, in a couple of hours at most, which is comparable to a lunch break in time. Such a product will cost the company 75 cents, of course, not including the cost of the printer, which costs several thousand dollars. “The beauty of this technology is that it can reproduce a potentially complex object without involving specialized organizations, leaving this process to companies like us, or even in the hands of specific people,” Zoll said. nine0003

To produce even a tiny light bracket on top of the module, the company had to spend hundreds of dollars and wait two to three weeks for a prototype to arrive on site. But recently they used a Makerbot 3D printer to speed up the process. Now, as Zoll stated, we can get a small part, say a bracket, in a couple of hours at most, which is comparable to a lunch break in time. Such a product will cost the company 75 cents, of course, not including the cost of the printer, which costs several thousand dollars. “The beauty of this technology is that it can reproduce a potentially complex object without involving specialized organizations, leaving this process to companies like us, or even in the hands of specific people,” Zoll said. nine0003

The company can produce a basic structure from drawings using a CAD system. After a model is created by a 3D printer, and the creation process can be imagined as the application of one layer of molten plastic to another, the possibilities of this technology become more evident. “Instead of studying the part in a graphics editor, we can print it out pretty quickly and see it live, which is an amazing opportunity. Having created a layout, it is easy to answer the questions: where will we place the interface, where will human access be limited? It's like Lego. We can move the elements of the module during the design process - from the beginning to the very end,” Zoll shared his impression of 3D design. The created models are certainly not full-size prototypes. The modules themselves are about the size of a room, and would require a huge printer. But even the models produced by the IO team, which are only two or three iPhones in size, provide new, better design opportunities. nine0003

“Instead of studying the part in a graphics editor, we can print it out pretty quickly and see it live, which is an amazing opportunity. Having created a layout, it is easy to answer the questions: where will we place the interface, where will human access be limited? It's like Lego. We can move the elements of the module during the design process - from the beginning to the very end,” Zoll shared his impression of 3D design. The created models are certainly not full-size prototypes. The modules themselves are about the size of a room, and would require a huge printer. But even the models produced by the IO team, which are only two or three iPhones in size, provide new, better design opportunities. nine0003

In the future, 3D printing may be used not only for prototypes, but also for the production of data centers themselves, including computer motherboards and other circuits, but this is the prospect of the next decades, tomorrow this will not happen - if at all. “You can print little things and play with them. Architects do this all the time,” says 3D printing specialist Burok Kosniewitz, professor of industrial and systems engineering at the University of Southern California. “It is not possible now to print the entire container. Today's reality of 3D printing is such that it will not work to reproduce all the necessary nodes of the server module, this requires other technologies, other materials. 3D printing can be a drug that will speed up, improve design and construction methods, but it is not a panacea.” At IO, however, they are only just beginning to delve into 3D printing technology as a prototyping tool, and only time will tell where this road will take them. nine0003

Architects do this all the time,” says 3D printing specialist Burok Kosniewitz, professor of industrial and systems engineering at the University of Southern California. “It is not possible now to print the entire container. Today's reality of 3D printing is such that it will not work to reproduce all the necessary nodes of the server module, this requires other technologies, other materials. 3D printing can be a drug that will speed up, improve design and construction methods, but it is not a panacea.” At IO, however, they are only just beginning to delve into 3D printing technology as a prototyping tool, and only time will tell where this road will take them. nine0003

IO claims to be a pioneer in the use of 3D printing technology for commercial data center design, but they also believe the technology will be widely adopted by their competitors. Frank Frankowski has privately admitted to following the hardware projects of Facebook, a company that he says is at the very center of the data center efficiency movement per se, and the company is heavy on 3D printers, which means only one thing.