Yeehaw 3d printer

Yeehaw 3D Printer review - The Gadgeteer

We use affiliate links. If you buy something through the links on this page, we may earn a commission at no cost to you. Learn more.

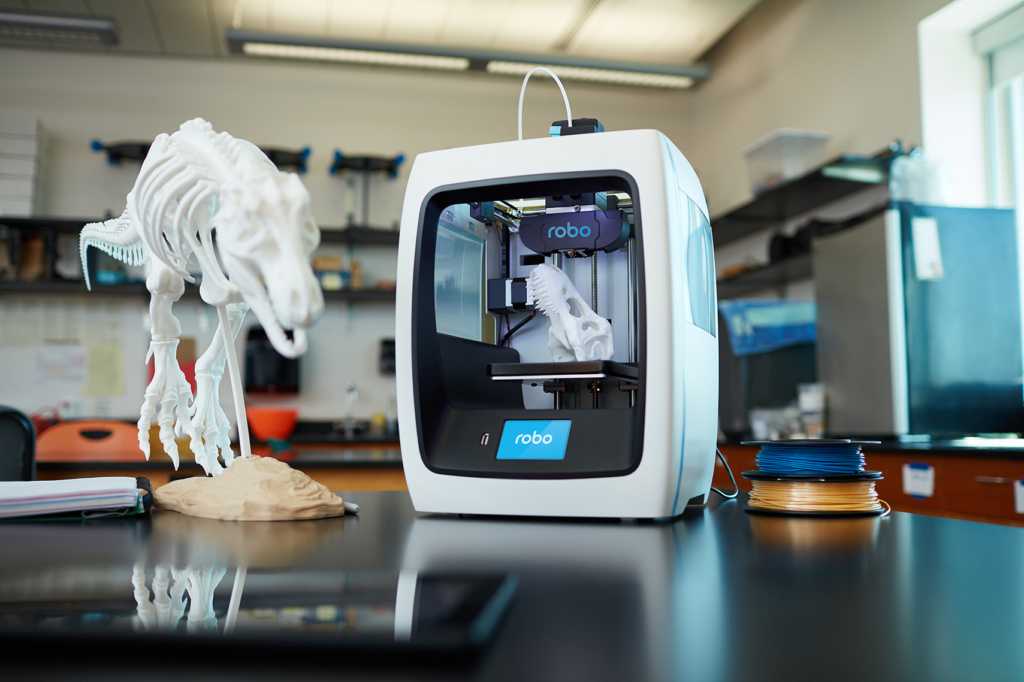

I’ve been interested in 3D printers for a long time but the price and complexity of creating models kept me from buying one. In the last couple of years, the price of 3D printers has come down to a level that ordinary people can afford, but I’m not sure the complexity issue has been changed much… at least until now. The Yeehaw 3D printer, which is currently seeking funding on Indiegogo, has been designed with kids in mind for safety and ease of use. Let’s take a closure look.

What is it?

The Yeehaw 3D printer is a 3D printer made especially for kids. It is controlled with a mobile app or web browser and has safety features take me this printer suitable for kids and adults like me who know nothing at all about 3D printers.

Setup

The Yeehaw 3D printer comes completely assembled as you see it above. It has no buttons or switches.

When I first took the 21.25 x 13.5 inch 3D printer out of the box and set it upright on a table, it wobbled. It took me a few seconds to realize that there was a magnetic base plate attached to the bottom.

The plastic base plate actually goes inside the printer and is what the models are printed on.

The door on the front of the printer opens easily so that the base plate can be positioned under the print head.

Once positioned, the next step is to install the Yeehaw app on an iOS or Android device and calibrate the print head. The app will provide step by step instructions on how to do this. Calibrating a 3D printer might sound a little scary, but it’s easy. All you really need is a sheet of typing paper and the ability to follow instructions. Calibrating the print head will make sure that it’s at the correct height above the base plate so that printed models will “stick” to the plate as the first layers are being printed. The calibration process has you place a sheet of paper on the base plate and then adjust the height of the print head so that the paper can just barely move when the head is touching the paper. You do this at four points on the base plate and then you’re done.

The calibration process has you place a sheet of paper on the base plate and then adjust the height of the print head so that the paper can just barely move when the head is touching the paper. You do this at four points on the base plate and then you’re done.

The next step is to load the spool of filament. I was sent a spool of white filament that reminded me of a huge spool of weed eater string.

The Yeehaw 3D printer uses PLA plastic filament which stands for polylactic acid. It’s made from renewable resources like corn starch, tapioca roots, or sugarcane. The Yeehaw printer uses 1.75mm PLA which is a standard size that is available in a variety of colors and is priced around $30 for a spool like you see above.

Loading the PLA in the Yeehaw printer is very easy. It loads from the top of the printer and just requires that you first power on the printer using the included AC adapter. After the printer boots up, you can remove the top cover, and feed the end of the PLA into the small hole until the printer grabs the end of the filament and pulls it in the rest of the way toward the nozzle.

Then you just set the PLA spool in the tray…

And place the lid back on top of the printer. The whole process is quick and easy which is perfect for kids and tech challenged adults.

We’re now ready to print our first 3D model!

Printing models

Printing a 3D model is done through the Yeehaw mobile app or the web browser. Both methods look almost identical so I’ve just attached images from the web app.

The app has a library of models that are ready to print. I chose the MD Soldier model.

Once the app transfers the model to the printer wirelessly using WiFi, printing begins.

See it in action

The Yeehaw printer makes noise as it prints, so you would probably not want to place it in the same room where you watch TV or sleep. The top of the printer also has LEDs that light up in different colors as a status indicator.

The top of the printer also has LEDs that light up in different colors as a status indicator.

Depending on the model, it can take quite a while for a print to complete. The MD Soldier that I printed took several hours. I started printing it around 4pm one afternoon and it was still printing when I went to bed at 9:30pm. The Yeehaw printer prints 60-90mm per second.

But when I checked the next morning it was done! I removed the base tray from the printer and found that the model was really stuck to the plate. After some flexing, it popped off.

But some residue of the print remained on the base plate. I was not able to scrape all the PLA material off the base plate even when I tried using an Xacto knife. I really think the base plate should be made of glass instead of plastic to keep this from happening.

Here’s the finished model. You will notice the extra material under the hands and beard and between the legs. This material is needed in order to provide a base to print from because you can’t just print the bottom of the hand if it’s hanging out in space.

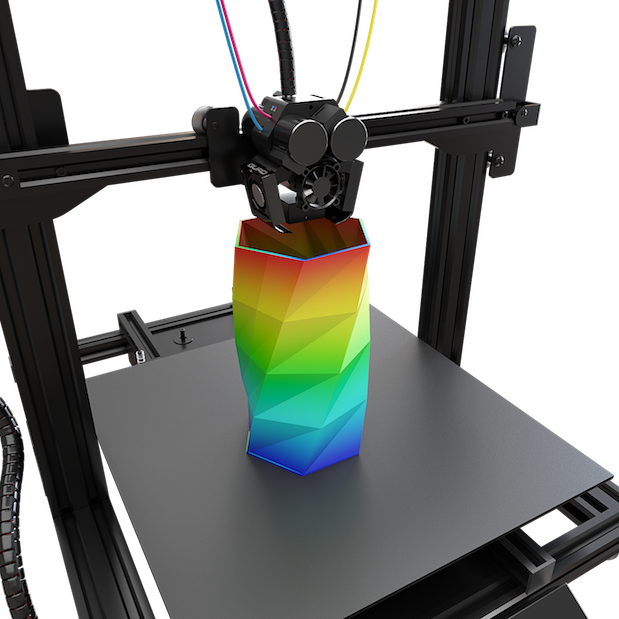

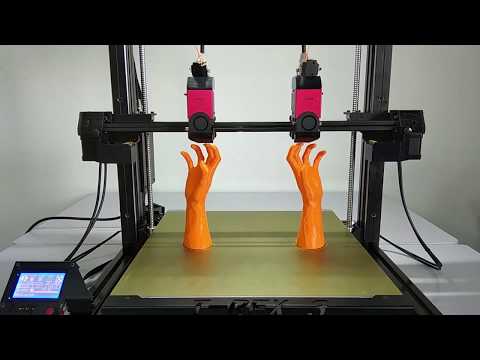

The extra material snaps off pretty easily, revealing the finished model. Too bad the Yeehaw doesn’t have the ability to print from multiple spools of PLA so that different colors could be used in one model. But it’s still really cool and the resolution is very nice at 0.1mm. The head even rotates!

The Yeehaw library has a growing selection of models that are ready to print, but you can also create your own simple models using the 3D builder feature in the app. I say simple models because you use blocks to build the model on a grid. Remember that the Yeehaw has been designed for kids, so that’s why the building feature is so basic and simple.

My first try at making my own model didn’t work out too well. I thought it would be fun to make a Christmas tree. Festive right?

But I wasn’t thinking correctly when I created it. Remember that extra material under the soldier’s hands and beard? I didn’t take that into consideration when I created the tree. So when it came time to start printing the first layer of the tree, the filament had nothing to stick to and just started dribbling around the tree’s base. Oops!

Oops!

My second try creating a model was a flat smiley face and it was more successful.

The app also allows you to import existing STL files. I tried this with an STL file that I found on Thingverse. The STL file appeared to import successfully, but the app’s web interface popped up a message in Chinese that I couldn’t translate. No matter what I tried, I wasn’t able to print an imported STL file. I think this feature is still in beta so I hope that the kinks will be ironed out soon.

Final thoughts

The Yeehaw 3D printer was my first experience using a 3D printer and now I’m hooked. This printer is great for kids because it’s easy to use and is safe. Printing will immediately stop when you open the door while it’s printing and the nozzle lift out of the way so you won’t get burnt.

Although the application’s current library of ready to print models is small, the ability to import existing STL model files (when that feature actually works) will make this printer useful for adults as well as kids.

I did ask the Yeehaw team about using this printer with other applications in case Yeehaw goes out of business. They told me that you can connect to printer Wi-Fi and use the URL: http://192.168.100.1. I didn’t get a chance to test this because I don’t know what other applications are available. I do plan to test this at some point and will do an update when I do.

For $249, the Yeehaw printer is a fun an inexpensive way to take a first step into 3D printing for kids and those of us who are still kids in our minds.

The Yeehaw Indiegogo project has already met their funding goal and ends in 4 days. Orders are shipping now.

Update 02/09/17

It’s great when a company is responsibile and works hard to make things right when there’s an issue. I received the following email on 1/23:

Good morning Julie,

I hope you had a great weekend. I would like to discuss a common issue that many first time crowdfunding campaigns encounter: production mistakes and their aftermath.

Yeehaw 3D Printer for Kids ran a successful Indiegogo campaign between Nov.-Dec. 2016 They shipped the product to their backers on time for the holidays. Unfortunately, after shipping they found out their manufacturer made some production erros on some of the printers.

Yeehaw, a new and small company, took responsibility for their production mistake, and even though they have limited resources they will be sending all their backers an additional brand new 3D printers for free, even to the ones that did not report any problems.

Many crowdfunding campaigns make production mistakes in their first batch and don’t take action to correct them. We truly believe that your TECH SAVVY audience would like to hear more about how Yeehaw took responsibility for a production error. Yeehaw is an example for crowdfunding campaigners to take responsibility for their errors and help restore confidence in crowdfunding platforms.

If you are interested in writing about Yeehaw taking responsibility, or you have any questions at all, please feel free to contact me or check out the information on the Yeehaw campaign page.

Thanks for taking the time to listen. I look forward to hearing from you soon.

Paul Wang

CEO Yeehaw 3D Printer

Press Release, January 23, 2017

Indiegogo campaign page

Contact: [email protected]

Source: The sample for this review was provided by Yeehaw. Please visit their site for more info and order one through Indiegogo.

The Best 3D Printer for Kids

Electronics

ByGarrett Parker Posted on Updated on

Parents may need to buy a much bigger stocking to fit the Yeehaw 3D printer, recently launched on Indiegogo.com’s crowdfunding site. The Yeehaw is reasonably priced at an early bird special of $249 and is the perfect initiation or upgrade for younger techies. After the special expires, the printer will retail for $500. Printing control is done through a web browser, an app is scheduled for release.

Printing control is done through a web browser, an app is scheduled for release.

3d printers’ designs and functions are updated and refined every year. A decade ago these type of printers were primarily used by engineers, product designers, and small groups of hobbyists. Now the product’s outstanding prices and the range model creation process has been addressed. This holiday season the consumer market continues to expand and target younger users. Yeehaw is recommended for use at school or in the home and is compatible with macOS, iOS, and Windows.

Yeehaw +has added LED “emotion lights” as status lights to keep you informed about your job’s progress. The printer’s design is completely see-through adding to the educational value. Another plus, the printer calibrates, updates, and monitors itself, totally eliminating the need for machine adjustments by users. There is a one year limited warranty included.

An important selling point is its simplicity, the company claims to be the most user-friendly 3D printer currently on the market. Yeehaw has received both the Red Star and Red Dot Design Awards in part because of the sleek appearance and size. Stylish design and details belie the special features included for newbies of all ages. A clear cover is included for protection of little fingers and to reduce operating noise. Tilt sensors trigger an automatic stop of the print session when the machine tilts or the door opens; the retractable nozzle will lift out of the way eliminating the chances of getting burned.

Yeehaw has received both the Red Star and Red Dot Design Awards in part because of the sleek appearance and size. Stylish design and details belie the special features included for newbies of all ages. A clear cover is included for protection of little fingers and to reduce operating noise. Tilt sensors trigger an automatic stop of the print session when the machine tilts or the door opens; the retractable nozzle will lift out of the way eliminating the chances of getting burned.

Yeehaw boasts a database of over 2,000 open-source software choices for printable toys. These are all royalty-free under a Creative Commons (Share-Alike) license, the company gathered projects from various online sites, including Cork Pals and SkullBot Thingiverse pages. The device includes the capability to upload personal .STL model files and creation of new designs.

For the adventurous Yeehaw provides the ability to create your own models using a 3D builder feature in the app. Blocks are used to build your masterpiece on a grid, very simple models are the only option at this time, reinforcing it as an excellent selection for children. Despite the extensive selection of models of toys that can be made, users and testers do find the build time to be slow when compared to other pricier models. Completion of a project may take as long as 6 hours.

Blocks are used to build your masterpiece on a grid, very simple models are the only option at this time, reinforcing it as an excellent selection for children. Despite the extensive selection of models of toys that can be made, users and testers do find the build time to be slow when compared to other pricier models. Completion of a project may take as long as 6 hours.

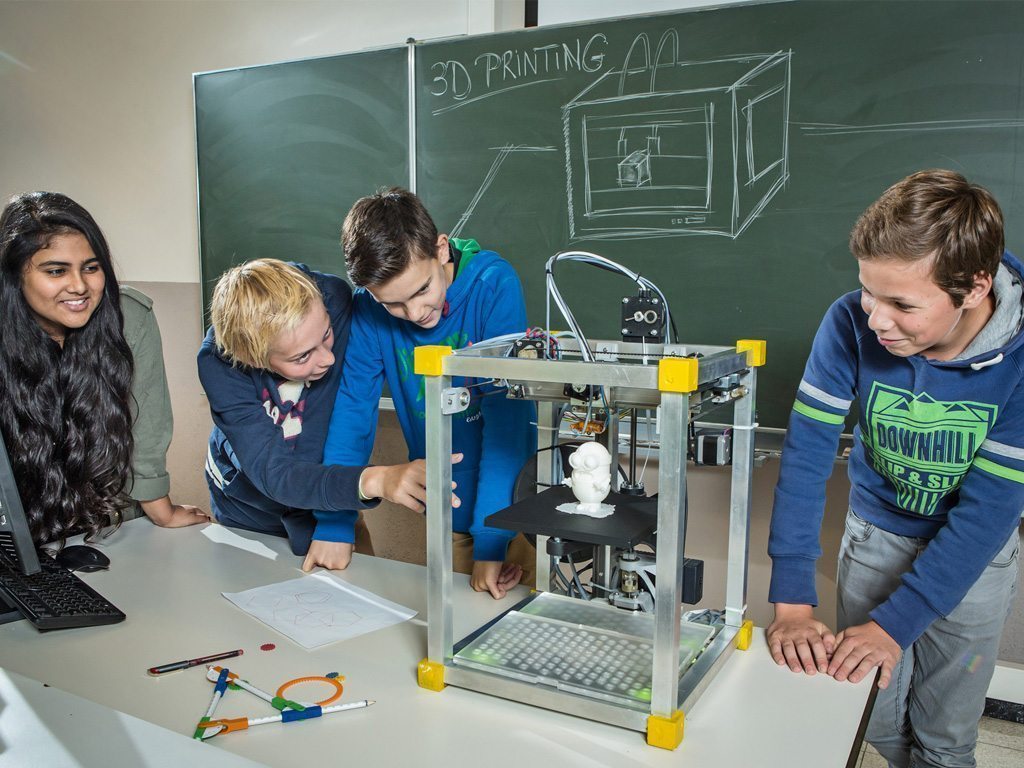

3D printers can improve school projects as well as entertain your children. They can work with models that are provided or import their own, adjust the shapes using a ruler or other measuring tool to obtain correct dimensions, and combine a set of shapes to create a detailed model. Both middle and high school students can develop Grade A projects. Science, technology, engineering, and mathematics (STEM) academic programs are the perfect match for 3D printing, reinforcing the vital aspects of the program. These printers further information interpretation skills and problem-solving abilities. Abstract ideas are actualized in a matter of hours. This technology has proved invaluable for English Second Language and at-risk children who are unable to process information at the same rate as their peers.

Science, technology, engineering, and mathematics (STEM) academic programs are the perfect match for 3D printing, reinforcing the vital aspects of the program. These printers further information interpretation skills and problem-solving abilities. Abstract ideas are actualized in a matter of hours. This technology has proved invaluable for English Second Language and at-risk children who are unable to process information at the same rate as their peers.

Educators welcome the stimulating challenges while students fine-tune such skills as sequencing, while creating robots, animal skeletons, and clocks, along with many other items. Missing puzzle pieces can be replaced to fit exactly where the original was slotted. Many schools are introducing the concept to kindergarteners, provide an early base for engagement and consideration of global issues. Adults can enjoy enhancing their décor making table lamps, Christmas tree toppers, and ornaments. Jewelry is another popular option. The truly committed can participate in online forums and communities to learn more and share ideas.

Some more affordable printers may shortchange the buyer with parts, or worse, poor assembly and operation guidelines. Yeehaw comes fully assembled and has no buttons or switches. The device’s footprint is only 21.25 x 13.5 inches, making it ideal for use almost anywhere.

Users need to install the Yeehaw app on an IOS or Android device and calibrate the print head. The app provides instructions to insure the print head is in the correct position related to the plastic base plate. This guarantees that the printed models will affix to the plate as the first layers are printed. The package includes a spool of non-toxic white 1.75mm PLA plastic filament, additional spools are available in several colors and cost about $30.

Yeehaw3D is just one of Indiegogo’s triumphs, the project met 280% of its $25,000 goal and continues to evolve. Indiegogo’s success is the ability to transition an idea to the investor and marketing stages. The group partnered with Amazon Launchpad and coordinates shipping, allows companies to sell products directly, and provides the Order Management platform to track deliveries. Another outstanding collaboration with is with Target, the second-largest discount retailer in the United States.

Another outstanding collaboration with is with Target, the second-largest discount retailer in the United States.

Yeehaw3D started a campaign for the project with perks for donators. Posts appeared on Facebook and Twitter, strongly contributing to the positive activity. Early campaign backers are rewarded with a discounted price.

Overall, the low price does not reflect less power, quality of prints or true speed of 3D printing. This is the real deal for imaginative creativity. In addition to reading this review, browse the site to place an order or watch the video to explore more detailed information. Yeehaw delivers a unique product to make toys and models, enhancing your child’s potential.

Most consumers want high quality at a good price, duplication is not an issue. It is highly unlikely, given its track record thus far, that certain rumors will affect sales or services for customers of Yeehaw3D. However, gossip was circulating about this company. Allegedly, the Yeehaw 3D printer is similar to one in development at Xiaomi Incorporated, an Apple-like power in the technology industry. Online sources state that leaked photographs of Xiaomi’s positioned Yeehaw’s rock star launch.

Online sources state that leaked photographs of Xiaomi’s positioned Yeehaw’s rock star launch.

Garrett Parker

Garrett by trade is a personal finance freelance writer and journalist. With over 10 years experience he's covered businesses, CEOs, and investments. However he does like to take on other topics involving some of his personal interests like automobiles, future technologies, and anything else that could change the world.

Electronics

The Five Best Graphing Calculators on the Market Today

ByGarrett Parker

If you’re shopping for a graphing calculator, chances are you’re one of a few things: a high school math student, a math teacher, or a math professional. Regardless of why you might need a graphing…

Read More The Five Best Graphing Calculators on the Market TodayContinue

Electronics

The Five Best Asus Tablets on the Market Today

ByGarrett Parker

Smartphones are great, but their screens tend to be smaller, making them less ideal for reading. Laptops on the other hand are heavier and bulky, which makes them less suitable when you are looking for…

Laptops on the other hand are heavier and bulky, which makes them less suitable when you are looking for…

Read More The Five Best Asus Tablets on the Market TodayContinue

10 Benefits of a 3D Printer: Save Time and Money

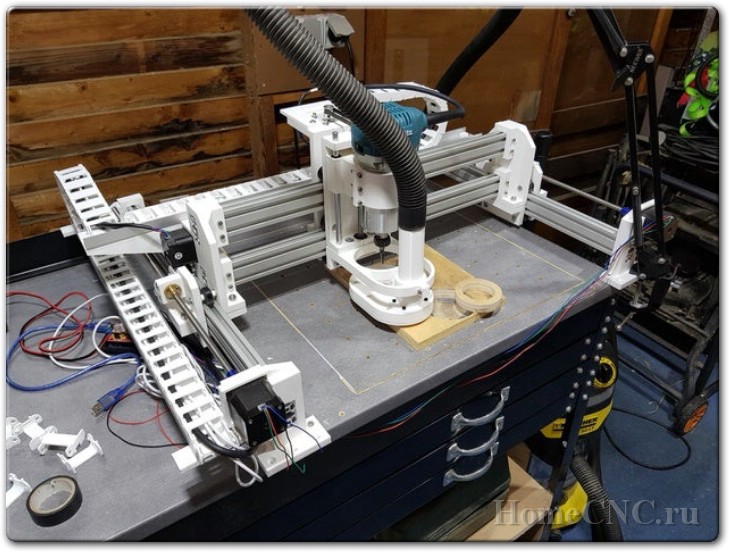

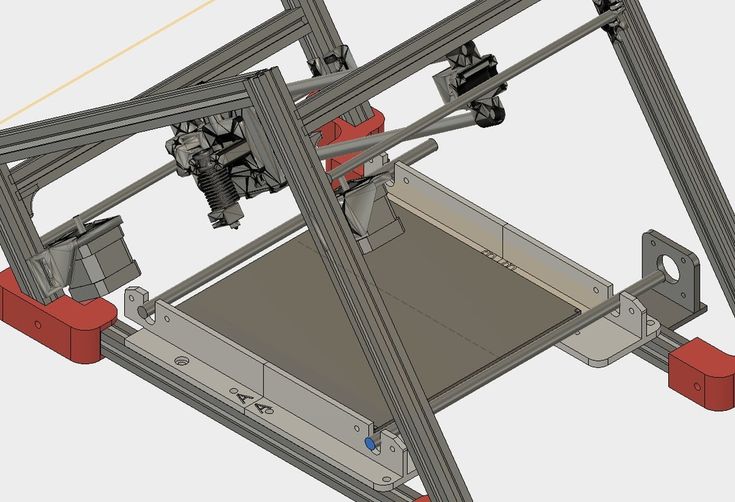

More recently, 3D printing has been viewed as something completely new. The technology was underdeveloped, the hardware was too expensive for widespread use. But only a few years have passed, and the situation has changed radically. Not only did more and more 3D printers begin to appear in stores, but also some enthusiasts began to assemble this equipment themselves.

1. Economy

Although large-scale projects with thousands of 3D printed parts are not cheap, they are still much more profitable than other technologies. Many manufacturers use 3D printing for small runs or for prototyping. Plastic can also be used for injection molding, but casting small batches can require expensive equipment. But even in this case, manufacturers can produce cast 3D parts several times cheaper than using aluminum.

Prototype parts printed on Prusa i3 Bizon 3D printer, layer height 0.1mm, PLA material

2. Faster production cycle

Compared to traditional production methods, the entire process can take weeks or days, and most products are printed in hours. Some manufacturers have even begun to make parts to order, which has also allowed them to optimize their warehouse capacity and resource management scheme, making them more flexible. With this new approach, the manufacturer does not need to store every single part or component, they can simply be printed as needed and immediately put into action.

Miniature parts printed by Wanhao Duplicator 7 photopolymer 3D printer, layer height 0.5mm, photopolymer resin material

It not only affects the reputation of the company in its industry, insufficient technical control can lead to injury to employees and customers. Since 3D printing uses a completely different production method than most machine tool operations, the process has significantly fewer weaknesses and flaws overall.

Model printed on Picaso Designer X PRO 3D printer, 0.2 mm layer, ABS materials, HIPS

4. Less waste

The press is gaining more and more support in the form of supporters of the "green" movement. Because 3D printing produces significantly less waste than traditional processing, the technology is more environmentally friendly while reducing costs. 3D printing has even made its way into the textile industry, allowing clothing and prototypes to be printed.

Hercules Strong 3D printed yacht steering parts. Details printed in 15 hours with a 0.5 mm nozzle and a layer height of 0.3 mm at a speed of 60 mm/s.

5. Greater customization

3D printed products are also highly customizable. Parts can be printed not only with light plastic, some next-generation models may also have a metal coating. As a result, objects are not only aesthetic, but also functional. In addition, they can acquire thermal and chemical resistance. The existing metallization method can also be used for plastic.

The existing metallization method can also be used for plastic.

Functional parts printed on Hercules. Material ABS, nozzle diameter 0.5 mm, layer height 150 µm, filling 100%. The model consists of 3 parts: the body and 2 halves of the latch, after printing and processing, the parts were glued together with acetone.

6. Customer Accessibility

If some craftsmen set up small mechanical workshops, for example, in garages, then most of us cannot afford such a luxury. 3D printing allows you to bring a significant part of the manufacturing process directly into the home, made possible by the availability of user-grade 3D technology. While it turns out to be quite expensive for one-off projects, the price of 3D printers and consumables is dropping rapidly.

Technical wing caps in REC RUBBER or REC FLEX. The models are printed on a Prusa i3 Steel 3D printer.

7. High complexity

In most cases, when it comes to complex parts and elements, the manufacturing process imposes certain limitations. Techniques used in casting and finishing objects may not be subtle enough for sophisticated design details. 3D manufacturing processes make it possible to realize almost any design solution, regardless of its complexity, and in a reasonable time. This not only eliminates the extra assembly steps required by traditional methods, but also provides more freedom to create future-proof designs.

Techniques used in casting and finishing objects may not be subtle enough for sophisticated design details. 3D manufacturing processes make it possible to realize almost any design solution, regardless of its complexity, and in a reasonable time. This not only eliminates the extra assembly steps required by traditional methods, but also provides more freedom to create future-proof designs.

Zenit 3D Printing Big Details From Engine 3D Printer

8. Less risk

While there are inherent risks associated with these new technologies, in terms of day-to-day business, 3D printing risks are significantly lower than with traditional manufacturing methods. Not only is 3D printing much cheaper when it comes to testing a new design or product, the printed prototypes themselves can stir up investor and customer interest and get them to decide whether to proceed with mass production of a product, whether it is worth the time and effort required.

Wanhao Duplicator i3 3D Printer Miniature Printing

9. Variety of materials

The materials used in today's 3D printers are much more diverse than most raw materials in traditional production methods. 3D printing also provides the ability to mix different substances, a luxury that is not always available with conventional methods. Although many 3D printer manufacturers offer their own, very limited set of sources, 3D printers can work not only with original materials, allowing you to simulate ceramics, metal, glass and more.

Wanhao D6 3D Printer PEGT, ABS-PC, PLA, SBS

The manufacturer not only needs to clearly understand what the customer wants, the manufacturer must also be able to explain what he himself can. Drawings, diagrams, diagrams are all good, of course, but there is nothing better than a real prototype that you can hold, look at and study. The fact that the materials are inexpensive, coupled with the short prototyping time on today's 3D printers, helps a lot during the prototyping phase, keeping all stakeholders connected.

THE PAST, PRESENT AND FUTURE OF 3D PRINTING

Despite a relatively slow start, the concept of 3D printing is finally gaining momentum and popularity among manufacturers and customers. We already see a lot of benefits of 3D printing, including shorter production cycles, more complex designs and improved quality, and the peak of the popularity and functionality of this technology is yet to come.

What material does the 3D printer print with? Plastic for 3d printer.

Layer-by-layer printing of three-dimensional models is made from a variety of materials, be it plastic, concrete or metal, and even hydrogel, chocolate and living cells.

For 3D printing, the use of ABS plastic is most optimal. Acrylonitrile butadiene styrene (official name ABC plastic ) is valued for its lack of foreign smell, toxicity, in addition, it is impact resistant, flexible and elastic. The material begins to melt from 240 to 248 degrees Celsius. Plastic goes on sale in a powdered state, or in the form of bobbins with plastic threads wound around them. Despite the fact that plastic does not tolerate direct sunlight, models made from it are famous for their durability. Plastic for a 3D printer can be bought in our online store.

Plastic goes on sale in a powdered state, or in the form of bobbins with plastic threads wound around them. Despite the fact that plastic does not tolerate direct sunlight, models made from it are famous for their durability. Plastic for a 3D printer can be bought in our online store.

Unlike ABC plastic, which models are opaque, acrylic is used to create transparent objects. But acrylic is more capricious in the process of use: the melting point of acrylic is reached later, which means that it will take more time and energy to heat up, and at the same time it quickly cools and hardens. The very process of manufacturing the product is laborious, since heated acrylic contains a lot of air bubbles that can distort the finished product.

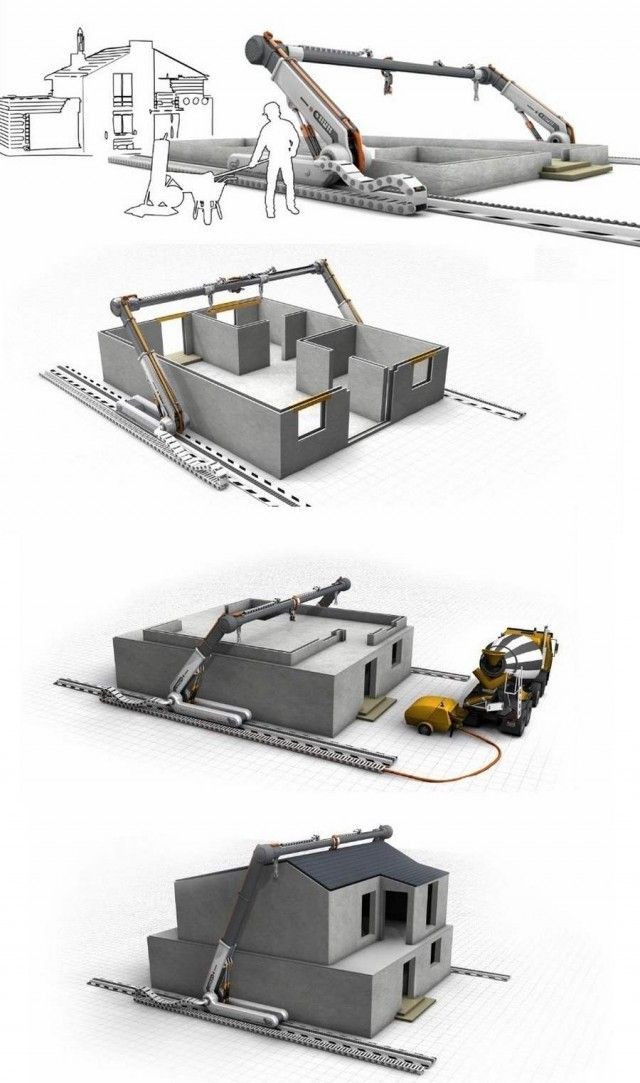

Concrete applied for 3D printing , improved, and has a formula that differs from the formula of conventional cement by 5%. The “printing” of a residential building with an area of 230 m2 on a 3D printer will take no more than 20 hours, during which it carefully “lays out” building blocks and structures from concrete.

The use of hydrogel for 3D printing was successfully tested by scientists from the University of Illinois, who used a 3D printer to print miniature (5-10 mm) biorobots. Living cells isolated from the tissue of the heart muscle were placed on them, which, spreading through the hydrogel, set the biorobot in motion. The speed of such a biorobot is 236 µm/s. As planned by scientists, in the future, with the help of such biorobots, tumors and toxins in the body will be detected and neutralized, and they will also be used to deliver medications to diseased human organs.

There are 3D printers that use ordinary office paper as a material. Pre-cut layers of paper are applied one on top of the other and attached with glue. Paper models are cheap enough that they are accessible to users, but at the same time, paper models are not durable and not aesthetically pleasing. Models created in this way are ideal for prototyping in computer projects.

Gypsum used for 3D printing is a fragile, short-lived material, but at the same time it has a low cost. Therefore, models made of plaster are mainly suitable for presentations, perfectly conveying the shape, structure and size of the original product. The resistance of gypsum to heat treatment makes it possible to use it in the foundry as samples for casting.

Therefore, models made of plaster are mainly suitable for presentations, perfectly conveying the shape, structure and size of the original product. The resistance of gypsum to heat treatment makes it possible to use it in the foundry as samples for casting.

Fans of natural wood and products made from it will also enjoy 3D printing, as there is a specially designed “wood” fiber that contains wood and a polymer, and its properties are similar to polyactide (PLA). Outwardly looking like natural wooden models with the smell of fresh wood, they are quite strong and durable. Currently, the material can only be used in the RepRap self-replicating printers.

3D printing with ice is perhaps the most exotic way of making small figures today. The temperature at which the figures are printed is quite low and is -22 degrees Celsius, and the printing material is water and methyl alcohol heated to 20 degrees Celsius.

The pleasant soft sheen and high strength of the metal are far ahead in quality of any plastic used in 3D printing, therefore light and precious metal powders are successfully used in this area. Copper, aluminum and its alloys, gold and silver in powder form are used for printing, adding fiberglass and ceramic inclusions to them.

Copper, aluminum and its alloys, gold and silver in powder form are used for printing, adding fiberglass and ceramic inclusions to them.

Nylon printed parts are similar in many ways to ABS plastic parts, but are softer and more practical. Nylon manufacturing technology is more capricious, in particular, it has a longer curing period, the printing temperature reaches 320 degrees Celsius, and it is more toxic.

3D printers of the near future will be able to print shaped chocolate molds, which should be in high demand in restaurants and pastry shops.

It is also impossible not to mention polycaprolactone, the most popular consumable for 3D printing. This material is so valued for its excellent physical properties and the possibility of being used in various printing technologies.

Of the plastic materials for printing, it is also worth highlighting polycarbonate (hard plastic), polylactide material obtained from biomass, sugar beet or corn silage, polypropylene, polyphenylsulfone, which came from the aviation industry, and an unsurpassed leader in the field of 3D printing, used in any of its areas - polyethylene low pressure.