Winsun 3d printing

Shanghai-based WinSun 3D Prints 6-Story Apartment Building and an Incredible Home - 3DPrint.com

The 3D printed home is an accomplishment which many architects and designers have at least been contemplating for a few years now. We have seen numerous companies as well as individuals jump into the space recently, with design concepts which take home building well into the 21st century. Although China has been lagging behind the U.S and Europe in terms of consumer and manufacturing-based 3D printing, one China-based company seems to be leading globally when it comes to the 3D printing of large-scale structures such as homes.

Back in April of last year, Shanghai, China-based WinSun Decoration Design Engineering Co. revealed what many believed was a hoax initially; 10 homes which were almost entirely 3D printed with a recycled concrete material. The company seemingly emerged from nowhere and surprised us all.

Well, today it was revealed that WinSun has made significant progress in their drive to 3D print livable homes and other structures. They have managed to 3D print an entire apartment building, consisting of 6 stories, as well as an impressive home, which certainly doesn’t appear to be 3D printed by any means. These structures were unveiled at the Suzhou Industrial Park, of east China’s Jiangsu Province, and the apartment building alone features a structure which is approximately 1,100 square meters in size.

A stand-alone villa, which has been 3D printed

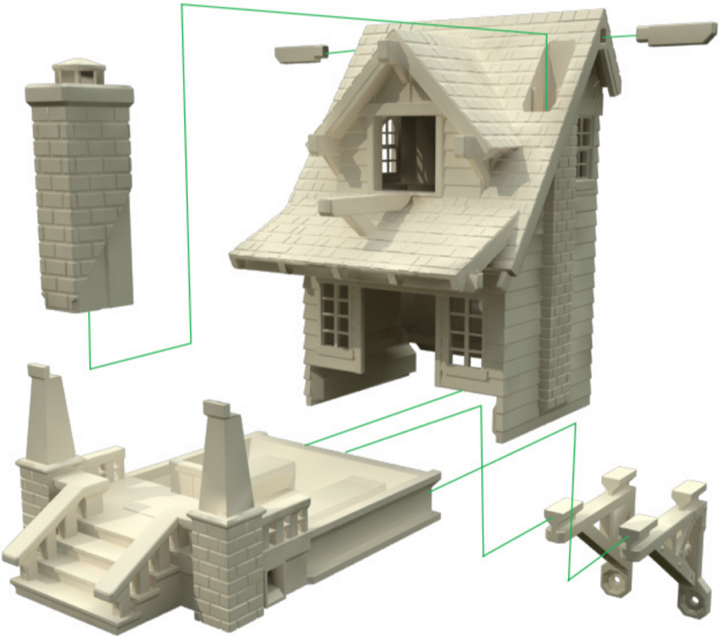

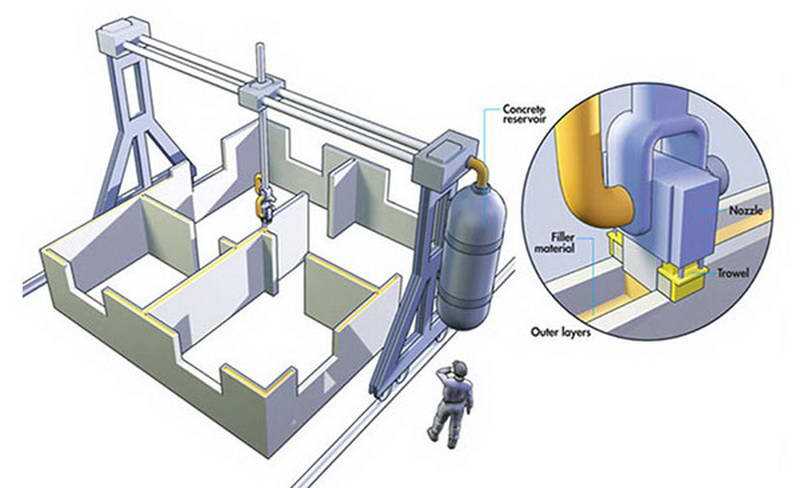

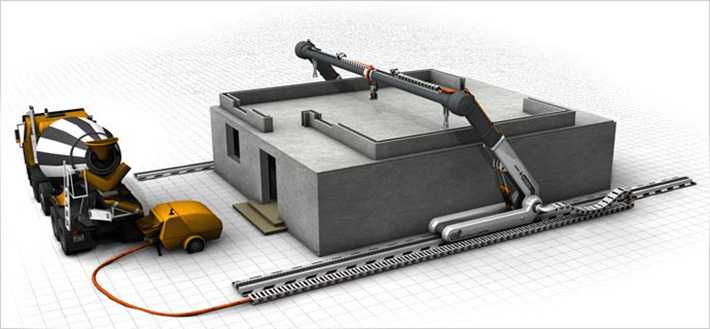

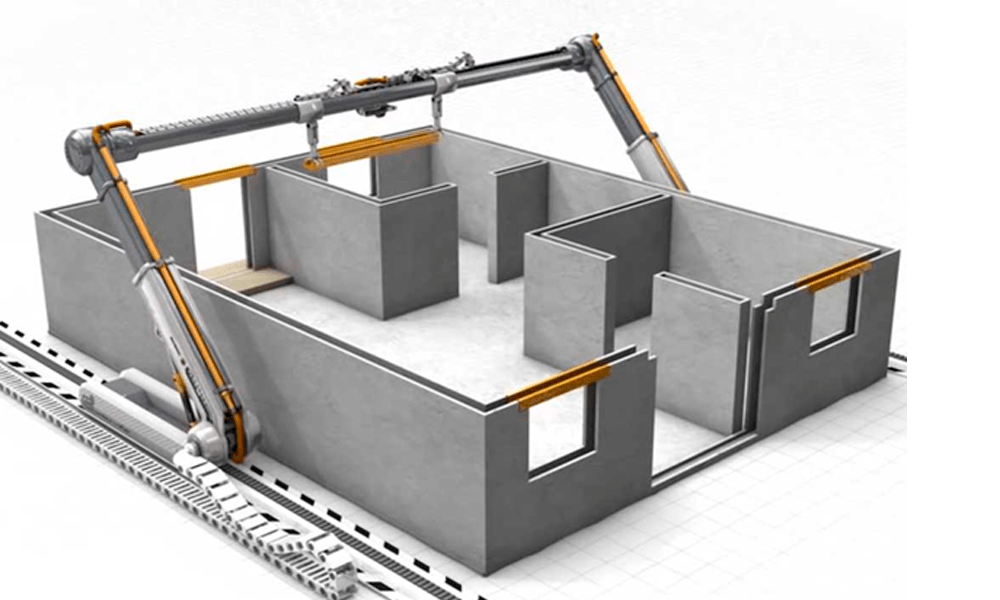

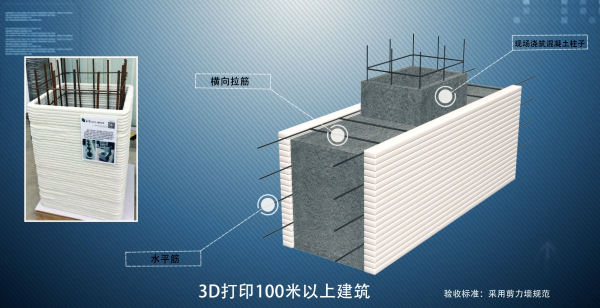

Using a machine which measures a staggering 20 feet tall, 33 feet wide and 132 feet long, the team at WinSun started with a basic CAD drawing which they fed to the massive 3D printer that was able to fabricate the structure piece-by-piece using a specially formulated and patented ‘ink’. The ink, which includes construction waste such as concrete, fiberglass, sand, and a special hardening agent, is an incredible way to recycle general construction materials — not to mention it is flexible, self-insulating, and resistant to strong earthquakes. The walls and other components of the structure were fabricated offsite with a diagonal reinforced print pattern and then shipped in and pieced together. The company then placed beam columns and steel rebar within the walls, along with insulation, reserving space for pipe lines, windows and doors.

The walls and other components of the structure were fabricated offsite with a diagonal reinforced print pattern and then shipped in and pieced together. The company then placed beam columns and steel rebar within the walls, along with insulation, reserving space for pipe lines, windows and doors.

A 6-story tall building which has been 3D printed by Winsun

The construction methods, according to the company, are able to save 60 percent of the materials typically needed to construct a home, and can be printed in a time span which equates to just 30 percent of that of traditional construction. In total, 80 percent less labor is needed, meaning more affordable construction, and less risk of injury to contractors.

Without a doubt, this is probably one of the the most exciting accomplishments within the 3D printing space we have covered. To be able to construct a 6-story building with 3D printed material is certainly a feat that’s guaranteed to garner further attention. WinSun is not done by any means. They will continue to further the technology behind this incredible 3D printer, and hope to eventually construct numerous homes at affordable prices within mainland China. Check out some additional photos below of the construction process and the structures themselves. Let’s hear your thoughts on this incredible accomplishment in the 3D Printed Apartment Building forum thread on 3DPB.com.

They will continue to further the technology behind this incredible 3D printer, and hope to eventually construct numerous homes at affordable prices within mainland China. Check out some additional photos below of the construction process and the structures themselves. Let’s hear your thoughts on this incredible accomplishment in the 3D Printed Apartment Building forum thread on 3DPB.com.

Front view of the 3D printed stand-alone villa

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed apartment • 3d printed apartment building • 3d printed home • 3d printed homes • 3d printed house • 3d printing houses • winsun • winsun 3d print • winsun 3d printed homes • winsun 3d printing • winsun stock

Please enable JavaScript to view the comments powered by Disqus.

Winsun 3D prints isolation wards to curb coronavirus outbreak

3D printing news News Winsun 3D prints isolation wards to curb coronavirus outbreak

Published on February 26, 2020 by Carlota V.

It’s hard these days to miss the coronavirus outbreak – the Covid-19 virus is affecting more and more people around the world. While the disease is spreading mainly in China, it is gradually arriving in Europe, particularly in Italy where 52,000 people have been quarantined. At present, it is estimated that nearly 80,000 people are affected, 97% of whom are in China – the country is facing an extreme situation and must organise its health system to treat as many sick people as possible. In Xianning at least, it would seem that additive manufacturing has facilitated this reorganization: Winsun has indeed 3D printed several isolation houses to accommodate quarantined people and medical staff and thus relieve the overloaded hospitals are facing.

The use of 3D printing in the construction sector is not new and has many advantages, including being able to provide a fallback solution in a crisis situation. Being faster, this method of manufacturing makes it possible to create temporary dwellings in an emergency, regardless of the area. Winsun has understood this and has used its 3D printing technology to address this global crisis. Originally, these small houses were intended for the tourism sector: as they are easily deployable in any location.

Being faster, this method of manufacturing makes it possible to create temporary dwellings in an emergency, regardless of the area. Winsun has understood this and has used its 3D printing technology to address this global crisis. Originally, these small houses were intended for the tourism sector: as they are easily deployable in any location.

These isolation houses include 3D printed walls | Credits: Winsun

3D printing could ease the burden on hospitals

Winsun says that it was able to 3D print the walls of 15 houses in Xianning city in just 24 hours, a printing time of less than 2 hours for each house. It is an extrusion process that was used: the robotic arm, mounted on rails installed all around the construction site, deposits successive layers of concrete that hardens quickly to ensure stability. Each small house has a surface area of 10 square meters, a height of 2.8 meters and was designed to relieve the burden on hospitals by accommodating quarantined people but also medical staff. According to Winsun, they all have showers, air conditioning and toilets, meet the required insulation standards and can each accommodate two people.

According to Winsun, they all have showers, air conditioning and toilets, meet the required insulation standards and can each accommodate two people.

The houses seem to have been 3D printed with a more environmentally friendly material, which could increase the durability of each construction. Ma Yufeng, Winsun General Manager, explains: “We use recyclable materials such as sand and construction rubble. It is very environmentally friendly. When it comes to safety, the constructions are at least twice as strong as concrete constructions.” It’s hard to know if these homes will be as solid as conventional homes as they have not been tested before.

The isolation houses are equipped with a shower, toilet and bed

Each construction would amount to $4,000, costs borne by the manufacturer Winsun itself. The company has already announced the 3D printing of an additional 200 houses for which donations are currently being collected. More information can be found on the manufacturer’s website. Can 3D printing help fight the coronavirus outbreak?

Can 3D printing help fight the coronavirus outbreak?

Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

New building technologies: 3d printer houses

- Articles

- New building technologies: houses on a 3-d printer

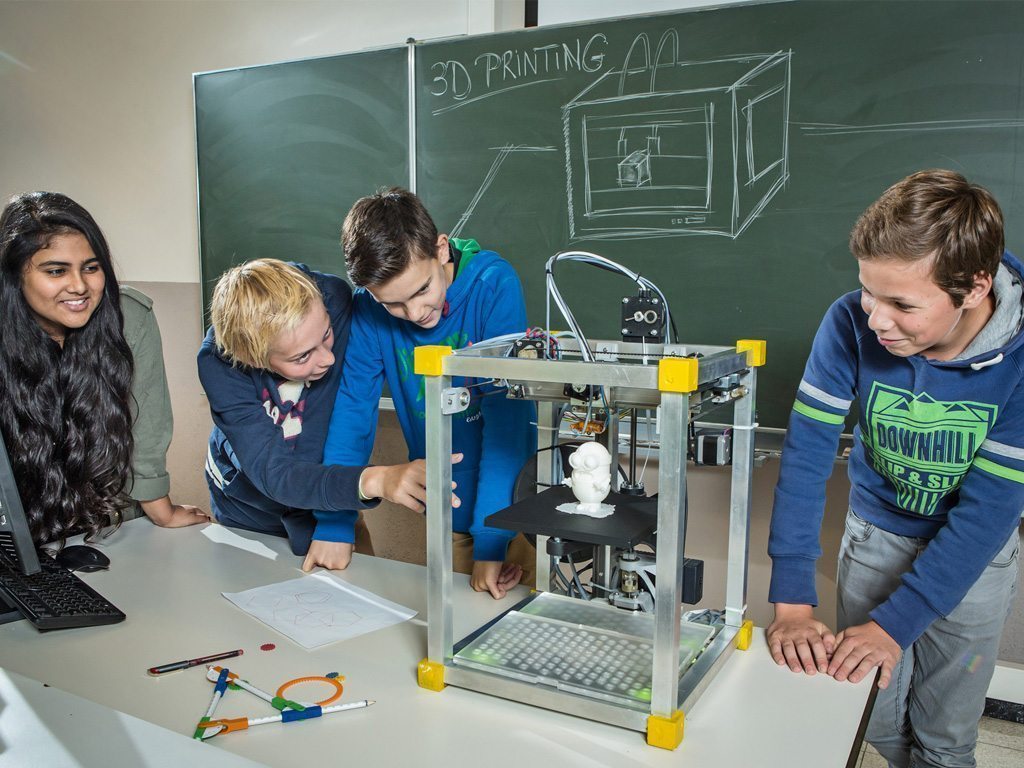

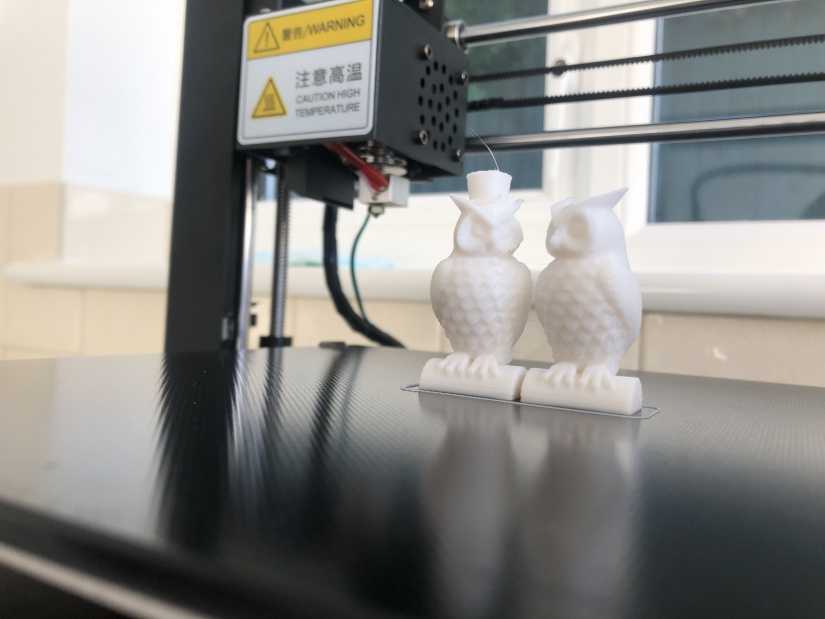

Over the past 5 years, 3D printing has taken a significant place in the construction sector. All over the world we hear about 3D printed buildings: houses, industrial buildings, cottages, offices, bridges, shopping pavilions, large-scale structures, shelters, etc.

Today, home 3D printers are changing the construction industry. We have compiled a selection of the most extravagant 3D printed houses.

We have compiled a selection of the most extravagant 3D printed houses.

Over the past 5 years, 3D printing has taken a significant place in the construction sector. All over the world, we hear about 3D printed buildings: houses, industrial buildings, cottages, offices, bridges, shopping pavilions, large-scale structures, shelters, etc. Although the appearance of such objects began only a few years ago, there are projects that are underway, unique concepts that are changing the construction industry as we know it today.

We list the advantages of a building printed on a 3D printer:

- Respect for the environment: You can print buildings from damp earth, clay or rice husks.

- Inexpensive: Large industrial buildings can be 3D printed at a relatively low cost.

- Timeline: Due to the speed of the process, 3D printing is particularly interesting for building, say, houses for disaster victims or hospitals for COVID.

- Unique Formats: 3D printing can help build uniquely shaped structures that would otherwise be impossible to create (or would be too expensive).

- Research potential: NASA is already planning to use 3D printing to create colonies on Mars.

DFAB HOUSE

Location: Dübendorf, Switzerland

Characteristics: 200 m²

Year of construction: 2019It is the first residential building in the world that was both designed and built using digital technology. This project launched in February 2019year, was implemented by researchers from in collaboration with industrial partners using robots and home 3D printers. The three-story facility sits at the very top of the NEST platform. Its creation is based on the desire to test new technologies in construction or energy in real conditions, the ultimate goal is to increase the efficiency and sustainability of building planning and construction through a digital approach.

Clay and earth house Gaia

Country: Italy

Characteristics: 12 m²

Year built: 2018

Architect: Alberto Chiusoli

This 3D model uses WASP technology, which uses natural materials collected directly on site. Fully in line with the principles of sustainable development, this project utilizes the raw land and natural wastes of rice production, an ideal way to build houses at a lower cost. It should also be noted that this 3D printed house is built in such a way that it does not need heating and air conditioning systems all year round.

Fully in line with the principles of sustainable development, this project utilizes the raw land and natural wastes of rice production, an ideal way to build houses at a lower cost. It should also be noted that this 3D printed house is built in such a way that it does not need heating and air conditioning systems all year round. Project of houses for the homeless in El Salvador

Country: El Salvador

Area 60 m²

Year of construction: object under implementation, put into operation in 2017

Architect: ICON and New StoryNew Story is a non-profit organization whose mission is to build affordable and safe homes for vulnerable people. However, traditional construction methods are no longer sufficient to meet housing needs. Designed in partnership with an Austin, Texas-based construction company, the Vulcan 3D Construction Printer is the PERFECT solution for providing homes to people in need. Each of these structures takes between 120 and 240 hours to build.

The price is about 3500 euros.

The price is about 3500 euros. Strange corner

Country: Australia

Size: 3 m²

Year of construction: 2017What is it about ? This structure was designed as part of a competition organized by Kids Under Cover. The idea is to combine free design and additive manufacturing technology. Among the five finalists is this gorgeous 3D printed pavilion dubbed Kooky Cubby. It was conceived by an Australian team of architects, robot designers and engineers. The estimated price of this small architecture object is from 5300 €.

Villa in China

Country: China

Characteristics: 400 m²

Year built: 2016

What is it about ? This two-storey 3D printed villa was created by HuaShang Tengda. This 400 m² house took only 45 days to print. The architect first erected the structure and then proceeded to pour the concrete using a specially designed 3D printing system. The walls are made of 20 tons of C30 concrete and are 250 mm thick. The result: an exceptionally robust construction. Seismic tests have shown that a 3D-printed villa should withstand an earthquake of the eighth level on the Richter scale.

The result: an exceptionally robust construction. Seismic tests have shown that a 3D-printed villa should withstand an earthquake of the eighth level on the Richter scale.

3D printed public toilets

Today, home 3D printers are changing the construction industry. We have compiled a selection of the most extravagant 3D printed houses.

Over the past 5 years, 3D printing has taken a significant place in the construction sector. All over the world, we hear about 3D printed buildings: houses, industrial buildings, cottages, offices, bridges, shopping pavilions, large-scale structures, shelters, etc. Although the appearance of such objects began only a few years ago, there are projects that are underway, unique concepts that are changing the construction industry as we know it today.We list the advantages of a building printed on a 3D printer:

- Respect for the environment: You can print buildings from damp earth, clay or rice husks.

- Inexpensive: Large industrial buildings can be 3D printed at a relatively low cost.

- Timeline: Due to the speed of the process, 3D printing is particularly interesting for building, say, houses for disaster victims or hospitals for COVID.

- Unique Formats: 3D printing can help build uniquely shaped structures that would otherwise be impossible to create (or would be too expensive).

- Research potential: NASA is already planning to use 3D printing to create colonies on Mars.

DFAB HOUSE

Location: Dübendorf, Switzerland

Characteristics: 200 m²

Year of construction: 2019It is the first residential building in the world that was both designed and built using digital technology. This project, launched in February 2019, was implemented by researchers from the collaboration with industrial partners using robots and home 3D printers. The three-story facility sits at the very top of the NEST platform. Its creation is based on the desire to test new technologies in construction or energy in real conditions, the ultimate goal is to increase the efficiency and sustainability of building planning and construction through a digital approach.

Clay and earth house Gaia

Country: Italy

Characteristics: 12 m²

Year built: 2018

Architect: Alberto Chiusoli

This 3D model uses WASP technology, which uses natural materials collected directly on site. Fully in line with the principles of sustainable development, this project utilizes the raw land and natural wastes of rice production, an ideal way to build houses at a lower cost. It should also be noted that this 3D printed house is built in such a way that it does not need heating and air conditioning systems all year round.Project of houses for the homeless in El Salvador

Country: El Salvador

Area 60 m²

Year of construction: object under implementation, put into operation in 2017

Architect: ICON and New StoryNew Story is a non-profit organization whose mission is to build affordable and safe homes for vulnerable people. However, traditional construction methods are no longer sufficient to meet housing needs.

Designed in partnership with an Austin, Texas-based construction company, the Vulcan 3D Construction Printer is the PERFECT solution for providing homes to people in need. Each of these structures takes between 120 and 240 hours to build. The price is about 3500 euros.

Designed in partnership with an Austin, Texas-based construction company, the Vulcan 3D Construction Printer is the PERFECT solution for providing homes to people in need. Each of these structures takes between 120 and 240 hours to build. The price is about 3500 euros. Strange corner

Country: Australia

Size: 3 m²

Year of construction: 2017What is it about ? This structure was designed as part of a competition organized by Kids Under Cover. The idea is to combine free design and additive manufacturing technology. Among the five finalists is this gorgeous 3D printed pavilion dubbed Kooky Cubby. It was conceived by an Australian team of architects, robot designers and engineers. The estimated price of this small architecture object is from 5300 €.

Villa in China

Country: China

Characteristics: 400 m²

Year built: 2016

What is it about ? This two-storey 3D printed villa was created by HuaShang Tengda. This 400 m² house took only 45 days to print. The architect first erected the structure and then proceeded to pour the concrete using a specially designed 3D printing system. The walls are made of 20 tons of C30 concrete and are 250 mm thick. The result: an exceptionally robust construction. Seismic tests have shown that a 3D-printed villa should withstand an earthquake of the eighth level on the Richter scale.

This 400 m² house took only 45 days to print. The architect first erected the structure and then proceeded to pour the concrete using a specially designed 3D printing system. The walls are made of 20 tons of C30 concrete and are 250 mm thick. The result: an exceptionally robust construction. Seismic tests have shown that a 3D-printed villa should withstand an earthquake of the eighth level on the Richter scale.

3D printed public toilets

Location: Da Yang Mountain, China.

Characteristics: 500 m²

Year built: 2016 Architect: Vincent

This 3D printed public toilet has a very modern look, accentuated by wavy lines. On the territory there are toilets for men and women, as well as separate buildings for children and people with disabilities. Green and yellow 3D printed leaf-shaped sculptures form an architectural ensemble.

Russia

Area: 38 m²

Year built: 2016

The house is located about 100 km south of Moscow and is one of the most successful 3D printing projects of 2017..jpg) The uniqueness of the Apis Cor project is that all the main components of the house are made on site from concrete, which reduces the cost of transportation and assembly. In addition, the 3D printing process itself lasted only 24 hours. By combining solid elements and liquid polyurethane, Apis Cor was also able to provide thermal insulation in place. To polish it all, the outer facade of white plaster was covered with yellow paint. Inside is modern style, beautiful parquet flooring and Samsung appliances. Final visualization: housing in the form of a rotor. This 3D printed house cost £9 to build000 euros.

The uniqueness of the Apis Cor project is that all the main components of the house are made on site from concrete, which reduces the cost of transportation and assembly. In addition, the 3D printing process itself lasted only 24 hours. By combining solid elements and liquid polyurethane, Apis Cor was also able to provide thermal insulation in place. To polish it all, the outer facade of white plaster was covered with yellow paint. Inside is modern style, beautiful parquet flooring and Samsung appliances. Final visualization: housing in the form of a rotor. This 3D printed house cost £9 to build000 euros.

Location: Da Yang Mountain, China.

Characteristics: 500 m²

Year built: 2016 Architect: Vincent

This 3D printed public toilet has a very modern look, accentuated by wavy lines. On the territory there are toilets for men and women, as well as separate buildings for children and people with disabilities. Green and yellow 3D printed leaf-shaped sculptures form an architectural ensemble.

Russia

Area: 38 m²

Year built: 2016

The house is located about 100 km south of Moscow and is one of the most successful 3D printing projects of 2017. The uniqueness of the Apis Cor project is that all the main components of the house are made on site from concrete, which reduces the cost of transportation and assembly. In addition, the 3D printing process itself lasted only 24 hours. By combining solid elements and liquid polyurethane, Apis Cor was also able to provide thermal insulation in place. To polish it all, the outer facade of white plaster was covered with yellow paint. Inside is modern style, beautiful parquet flooring and Samsung appliances. Final visualization: housing in the form of a rotor. This 3D printed house cost £9 to build000 euros. - Respect for the environment: You can print buildings from damp earth, clay or rice husks.

Photo gallery

Categories

- Design10

- Engineering systems11

- Metalworking5

- Construction40

Tag cloud

fittings sandwich panel buildings food manufacture building industrial warehouses workshop cost construction price prices workshop

Top 15 Chinese 3D Printing Companies in 2022

China has established itself as a global manufacturer..jpg) Many of the products sold worldwide are made in China.

Many of the products sold worldwide are made in China.

Would you like to know more about manufacturing in China? How is 3D printing contributing to manufacturing in China? Are you interested in 3D printing services in China?

The manufacturing industry is a huge contributor to China's growth. The country produces many goods used locally and for export. 3D printing simplifies manufacturing and industrial production.

If you are interested in 3D printing services in China, here are the top 15 Chinese 3D printing companies you should know about.

Content

- 1 Sychuan Revolution

- 2 Regenov Biotechnology

- 3 Shining 3D

- 4 Vincans

- 5 MOUSH

- 6 Prototypes HLH 9000

- 10 Dach Group

- 11 ProtoFab

- 12 LK Mold

- 13 Visotech

- 14 Intermsis

- 15 Uniontechnic

- 16 CONSENTION

SICHUAN COSTECTION

Focus on 3D-printing, Revotek creates synthetic tissues that are used in research. To do this, the company uses the best bioprinters that ensure the accuracy and speed of production. The company is a pioneer in 3D printing of organs, even producing blood vessels.

To do this, the company uses the best bioprinters that ensure the accuracy and speed of production. The company is a pioneer in 3D printing of organs, even producing blood vessels.

Currently, Revotek has patented 3 printers and more will be coming soon. The services offered by this company have had a great impact on the healthcare sector. Their workflow consists of 6 stages, ensuring efficiency and fast service.

Pros

- Use advanced technology

- They do various researches

- Making a big contribution to the health sector

Address: No. 1 Dikang Ave, Chengdu, Sichuan 610000, China

Source: www.revotekhealth.com

Regen Biotechnology

This company offers biomedical solutions using the best technologies. Regenovo Biotechnology also develops high quality 3D printers. Their 3D printing involves creating models of tissues and organs.

The company makes models of healthy and infected organs to aid in drug research and testing. Models from Regenovo Biotechnology have helped in drug development and testing. The company offers a wide range of services and products.

Models from Regenovo Biotechnology have helped in drug development and testing. The company offers a wide range of services and products.

Pros

- Use 3D printing to improve healthcare and research

- Variety of products and services

- Innovative to keep up with demand

Address: Room C1101, Building No. 2, 452 6 th Street, Hangzhou Economic and Technological Development Zone

Source: www.regenovo.com

printing, Shining 3D have become experts in this field. To meet the needs of their customers, they offer services for large volumes of products. The company is focused on promoting and improving 3D.

The company is located in selected strategic locations to offer global services more effectively. The company supports its customers by always being innovative. The company guarantees good quality and fast turnaround time.

Pros

- Innovation team

- Handle high volume products

- Has a global presence

Address: No. 1398, Xiangbin Road, Wenyan, Xiaoshan, Hangzhou, Zhejiang, China, 311258.

1398, Xiangbin Road, Wenyan, Xiaoshan, Hangzhou, Zhejiang, China, 311258.

Source: www.shining3d.com

Vinsan

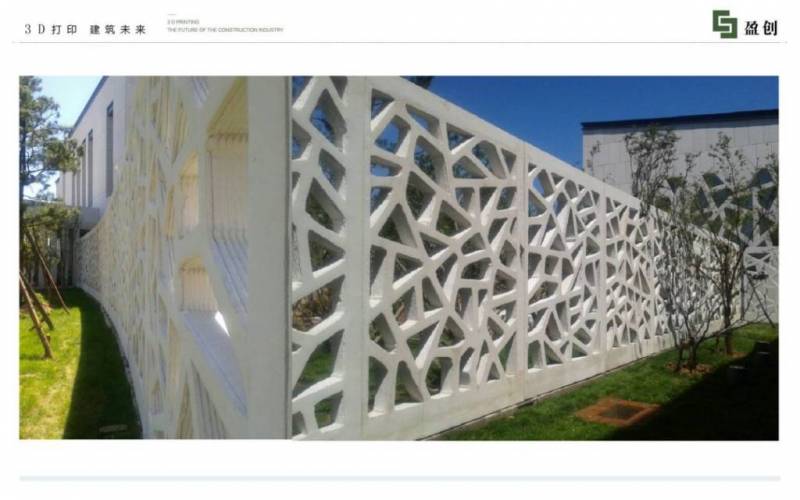

The company has many years of experience in the field of 3D printing using the most advanced technologies. Winsun is proud to be the pioneer of 3D in China. The company is mainly engaged in architecture and construction.

The company works to improve the environment by creating environmentally friendly structures. Winsun ensures that its customers receive the highest quality products. The company also produces materials that are used in 3D printing.

Pros

- Pioneer in the field with many years of experience

- Environmental activities

- We offer high quality products

Address: No. 789, Xinjin Road, Qingpu District, Shanghai

Source: www.winsun3d.com

Mohu

The company offers a wide range of services, including 3D design, scanning and printing. They use cutting edge technology in all their activities. Mohou also uses the best printers to ensure your models are well detailed and of high quality.

They use cutting edge technology in all their activities. Mohou also uses the best printers to ensure your models are well detailed and of high quality.

To meet the needs and requirements of an ever growing customer base, the company offers its customers a wide range of materials. Because the company offers online 3D printing services, they can reach customers from all over the world.

Pros

- Offer global services

- Quality and variety of services

- Competitive rates

Address: 1903 Fuhaiguoji Plaza, Haidian, Beijing, China

Source: www.en.mohou.com

HLH Prototypes

Since its inception, HLH Prototypes has been committed to achieving reliability by offering fast service without sacrificing quality. The company is constantly looking for new ways to offer its customers the services they need. HLH Prototypes uses both the latest technology and traditional methods to create models.

The company is focused on the production of small volumes. HLH Prototypes can handle your projects no matter how complex they are. The team will offer useful information and help you throughout your project.

Pros

- Fast and quality services

- Use modern and traditional production methods

- Handle complex projects

Address: 1801 Xing Ji Building, Xin Sha Road Shajing, Baoan, Shenzhen, China 518125

Source: www.hlhprototypes.com

wider client base. The company offers a wide range of services including 3D scanning, molding and injection molding. Thanks to the three-stage process, the company's production process runs smoothly and without delay.

Working with a number of industries, the company has accumulated a wealth of experience. You can trust them with your project and be sure of accurate and high-quality results. FacFox uses the most suitable materials to create the most realistic models.

Pros

- Online services to attract more customers

- We offer a wide range of services

- Use the most suitable material to achieve the desired results

Source: www.facfox.com

Boston Micro Fabrication

Boston Micro Fabrication has a presence in various locations including Shenzhen. This makes their service delivery more efficient as they can reach more clients. The company has been offering 3D services for many years and manages to keep up with the demands of its customers.

In addition to 3D printing, Boston Micro Fabrication also develops printers. When working with this company, you will have a wide choice of materials for your prototypes. The team will offer full details of the different materials to make your decision easier.

Pros

- International Presence

- Attentive to customer requirements

- Work with a helpful team

- Wide choice of materials to choose from

Address: Floor 5, Building 8 East, GS Park, Wuhe Avenue North, Longhua New Area, Shenzhen City.

Source: www.bmf3d.com

Guangzhou Klarm Prototyping Limited

Guangzhou Klarm Prototyping Limited offers 3D printing worldwide. The company has worked with various industries, giving them much-needed expertise in this area. They have competitive prices for their quality services.

The company produces realistic prototypes not only to facilitate production, but also to aid in presentations. Guangzhou Klarm Prototyping Limited uses different materials for your models to make them fully functional. When prototyping, they use the best technology to ensure they get all the parts right.

Pros

- Work with experts with years of experience

- Good prices for services

- Design solutions that meet customer needs

Address: Jiangcheng 16. th Road, Shiji City, Panyu District, Guangzhou City, China 511450

Source: www.3dprinting-china.com

products, making them a one-stop-shop for your 3D printing needs.

The company is present in different places for better service. The Duch Group has been in the 3D printing industry for over two decades and has worked with numerous clients, giving them extensive experience.

The company is present in different places for better service. The Duch Group has been in the 3D printing industry for over two decades and has worked with numerous clients, giving them extensive experience. To give its customers peace of mind, the company offers updates on the progress of their projects. They also have competitive prices for their services. Duch Group guarantees the quality of its services and products.

Pros

- Tracking during production

- Services at a good price

- Quality Assurance

- Fast turnover time

Address: #899 Ma Qing Road, Hai Tsang District, Xiamen, Fujian Province, China

ProtoFab offers on-demand 3D printing services to provide customers with exactly what they want. The company helps bring ideas to life with its accurate and functional models. ProtoFab offers a wide range of materials for your projects.

This company also deals with 3D printers and other services. ProtoFab is strategically located and has branch offices to reach more customers and improve service delivery efficiency. The company provides its services to clients in various industries.

The company provides its services to clients in various industries.

Pros

- Industry experience

- We offer services on request

- Strategic location for better service

Address: 899, Maqing Road, Haicang District, Xiamen, China, 361026

helps its clients to do this. As a global service provider, the company has managed to maintain the quality of its products and the trust of its customers.

LK Mold ensures that the individual needs of each client are taken into account. The company also offers various services to attract and maintain its customers. They have a friendly team to help you with your project.

Pluses

- Guaranteed quality of services and goods

- International Trust

- Competitive prices

Address: No. 15, JinShen Road, Jin Xia District, Changan Town, Dongguan 523850 Guangdong, China

Source: www.lk-moulds.com

Visitech

Visitech is committed to offering the best solutions to its customers. It can be production, presentation or staging. The company offers good prices and value for money for the price you pay.

It can be production, presentation or staging. The company offers good prices and value for money for the price you pay.

Their international presence enables them to serve their customers more effectively. In addition, you can entrust the design of their specialists. Visitech guarantees the quality of the products you develop and those they develop for you. Their activities are environmentally friendly to ensure sustainability.

Pros

- International Presence

- Keep up with trends and technologies

- Environmental activities

Address: Room 401, Building 2, Road No. 258 Jinzang, Pudong, Shanghai 201206.

Source: www.visitech.no

The company offers on-demand 3D services to its customers for a customized experience. The company has a team of experts who make sure your projects run smoothly and the results you get exceed your expectations.

This company specializes in aerospace, medical, automotive and other industries.