Xyz handheld 3d scanner review

3D scanning for under £150

Price when reviewed

I’ve lost a lot of time to the XYZprinting 3D scanner, but not in a good way. What it should offer is a simple way of creating 3D models using a clever USB camera. Unfortunately, my experience was a lot less smooth than I’d like – even for the seeming bargain price of under £150.

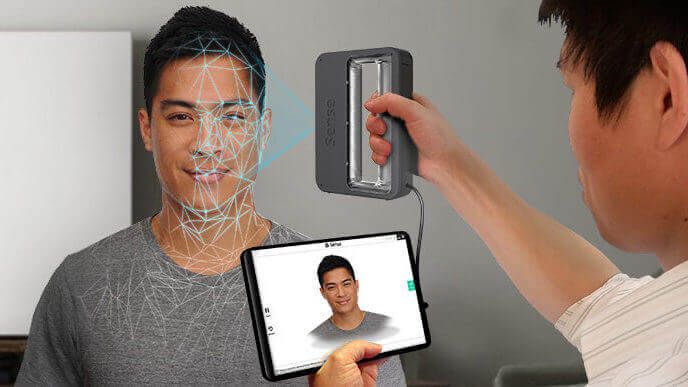

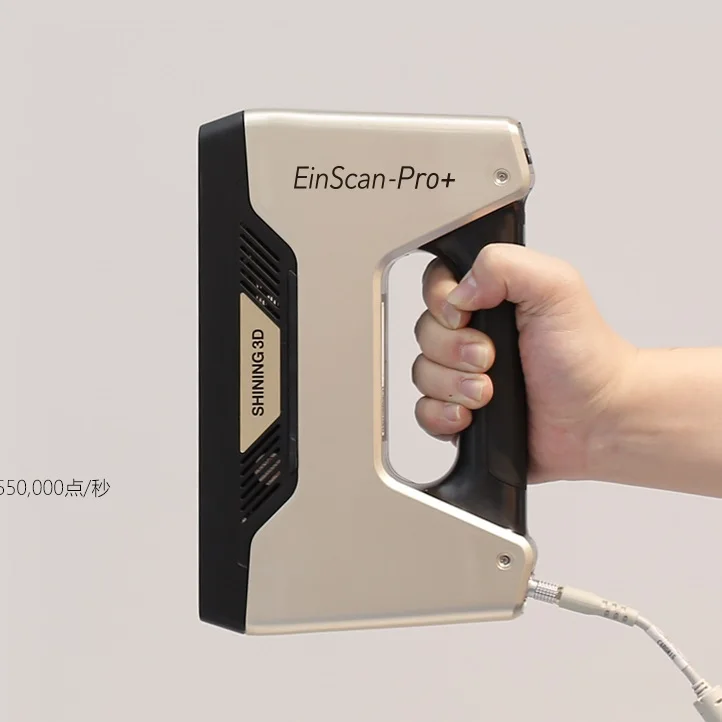

So, let’s start with the promise. The XYZprinting 3D scanner is a handheld USB camera that looks like the love child of a staple gun and a pair of hair straighteners. It can scan a person’s head (up to 40 x 25 x 40cm in size) and objects of up to 60 x 60 x 30cm, and will output to .stl or .obj file format, ripe for 3D printing your figurative or literal mug, or uploading to Google SketchUp or Thingiverse for others to enjoy. You plug it into your computer (Windows only, sorry OS X fans), install the bundled software and you’re away. In theory.

3D scanning made easy?

The instructions that came in the box were rather vague, but then the idea behind it isn’t that complex. You select whether you’re trying to scan a head or an inanimate object in the software, then press the single button on the scanner and you’re good to go. Simply move the scanner around the object, and a replica slowly begins to appear in the viewing window.

In practice, it’s a tricky beast to get good results from. For starters, the scanner insists on being held left-handed – a tough task for right-handers, especially when you have a thick, chunky wire trailing after you. True, you can hold it in your right hand if you adopt a “fingers up” stance, but this isn’t at all natural and is a baffling design decision.

Oh, and guess what? If you make sudden jerking movements – the kind your non-dominant hand is prone to making – the preview window freezes and you have to retry. You’ll be doing this a lot, by the way. What triggers a freeze isn’t consistent: all that remains constant is the sense of frustration and the volley of swear-words that follow (sorry, colleagues). Manage it, though, and you’re ready to output… maybe.

Manage it, though, and you’re ready to output… maybe.

Compatibility

It turns out the XYZprinting 3D scanner is incredibly fussy about the computers it works with. Some of these are signposted ahead of time: it won’t work with laptops with Intel RealSense cameras built in, because it conflicts with the scanner, and it only plays nicely with fourth-generation Intel chips or later.

That’s fair enough – you can account for that, in theory. The problem we had was in finding any computer it would accept. We went through a number of review samples trying to find the magic setup. A couple would scan images, but then produce nothing in the editing window, while another would see the camera repeatedly disconnecting, a problem we later learned was down to power output: the camera needs a healthy dose of juice flowing out in order to function. Make sure your machine has a powered USB port, in other words (the one with the lightning bolt next to it), or you’ll fall at the first hurdle.

Should you manage to find the perfect combination, however, the results are pretty good for such a reasonably priced scanner. Obviously, this isn’t top of the range technology, but for a fancy webcam on a wire, it’s not bad at all. Detail is a little lacking, but for approximations of shape and volume, it’s certainly acceptable. See the comparison between the Morph and Chas bookends I scanned in and their digital counterparts:

After editing out any strange artifacts you may have brought in through your scan, you can then output the file to either an .obj or .stl file format. This might sound like a short list, but it’s actually not that bad. The .stl file format, in particular, enjoys widespread support among popular 3D design applications, including the free Google SketchUp, for further edits and beautifying, and online communities such as Thingiverse, meaning your creations can find a home in other people’s homes post 3D-printing.

Scanning someone’s head is a bit harder. It’s certainly something you don’t want to do on yourself, but, even with an accomplice, I found it difficult to pull off. It requires your subject to remain perfectly still, the stray wire of the handheld scanner sometimes gets in the way, and often the scanner will refuse to recognise the whole head, leaving you with just the face. All the same, the results are good enough on a scanner of this type:

It’s certainly something you don’t want to do on yourself, but, even with an accomplice, I found it difficult to pull off. It requires your subject to remain perfectly still, the stray wire of the handheld scanner sometimes gets in the way, and often the scanner will refuse to recognise the whole head, leaving you with just the face. All the same, the results are good enough on a scanner of this type:

Verdict

All of this leaves me in a difficult position when arriving at a verdict. In some ways, the XYZprinting 3D scanner is hugely impressive. It’s cheap but surprisingly effective at picking out detail in objects for passable, if not exceptional, 3D scans. For under £150, that’s really something.

On the other hand, it was an absolute pain to get working, and the software is at times plain awkward. A cautious thumbs up, overall, if this is the kind of thing that would be useful for your school, or if it matches your hobbies. Just be sure to keep the receipt because whether it’ll play nicely with your hardware is anyone’s guess – no matter what the specifications say.

Just be sure to keep the receipt because whether it’ll play nicely with your hardware is anyone’s guess – no matter what the specifications say.

See also: The best laptops of 2016 – your guide to the best portables on the market

XYZprinting 3D Scanner review « 7Review

Digitise real-world objects

This might be the most futuristic gadget we’ve ever seen in the Computeractive office, which makes its affordable price all the more remarkable. It’s roughly the opposite of a 3D printer: you start with an object that already exists, which could be anything from your head to an ornament that you want to replicate, and capture a digital model of it that you can manipulate in 3D-modelling software (such as 123Design), whether as the basis for an art project, to output via a 3D printer, or just for fun.

Check Amazon

And it really is fun – at least in principle. The first problem we had in practice was that the 3D Scanner uses Intel’s RealSense technology, which is good because It standardises things to work with any PC, but also bad because when we tried it with PCs that already included Intel RealSense cameras (the feature Windows 10’s ’Hello’ face-recognition security relies on), the scanner conflicted and refused to work. This will presumably get fixed as RealSense develops.

Other PCs were also reluctant, but this turned out to be mainly because the 3D Scanner needs a fully powered USB port (the kind with the lightning symbol next to it). Once we’d set it up with a suitable machine, it worked as it was meant to – sort of.

The scanning process is a bit like taking a panorama photo with your phone. You hold up the scanner, which feels like a cross between a stapler and a set of curling tongs, and move it carefully around the object. A wobble will spoil the scan, and it’s tricky to keep the trailing wire out of the way, especially if you’re right-handed. To scan a live person, they have to keep very still.

A wobble will spoil the scan, and it’s tricky to keep the trailing wire out of the way, especially if you’re right-handed. To scan a live person, they have to keep very still.

SPECIFICATIONS

Handheld Intel RealSense camera • Scan volume 50x50x50mm to 400x400x25mm or 300x600x600mm • USB 3.0 port • Requires 4th generation or later Xitel Core 15 processor and Windows 8.1 or later (64-bit) • One-year warranty

7Review earns Amazon affiliate commissions from qualifying purchases. You can support the site directly via Paypal donations ☕. Thank you!

When it worked, we got convincing scans, albeit after a bit of cleaning up.

You don’t get ultra-fine detail, but you can recognise objects, and simple shapes are captured well. The resulting .obj or .stl files can be edited in free apps such as 123Design (www.snipca.com/21022) or 3DSlash (www. snipca.com/21021).

snipca.com/21021).

When It works, this Is a good-value accessory for 3D enthusiasts, but we still await that foolproof version

7Review earns Amazon affiliate commissions from qualifying purchases. You can support the site directly via Paypal donations ☕. Thank you!

High precision portable 3D scanners HandySCAN

Reviews

Get to know the capabilities of this equipment and the real experience of using a 3D scanner in the production of helicopters.

About

Creaform is a Canadian company that is the world's leading provider of 3D scanning solutions. The equipment manufacturer offers a wide range of 3D scanners, including devices for metrological measurements. The company has patents for its advanced developments and continues research in the field of 3D scanning.

The organization is part of the largest AMETEK holding. To date, Creaform supplies its equipment to Europe and Asia, North and South America.

HandySCAN 3D is the third generation of metrology-grade handheld portable 3D scanners that allow you to measure various physical objects in minutes and get high-resolution results.

Two models are available for users HandySCAN BLACK and HandySCAN BLACK | Elite. These robust 3D scanners allow you to quickly digitize objects ranging in size from 0.1 to 4 meters. The equipment is perfect for specialists in various fields: design, production, metrology for quality control and product development.

With HandySCAN you can scan in almost any environment and digitize objects of various shapes and sizes. 3D scanners are simple and easy to use, with an elegant ergonomic design.

The youngest model in the Creaform HandySCAN | BLACK Series. High accuracy and speed of work allows you to quickly digitize objects up to 4 m in size. HandySCAN | BLACK does not require fine tuning - the multi-parameter positioning system allows you to achieve excellent results.

HandySCAN | BLACK does not require fine tuning - the multi-parameter positioning system allows you to achieve excellent results.

The advantage of Creaform handheld scanners is complete freedom of action. The absence of wires and the need to use a tripod allows you to scan in any, even in hard-to-reach places.

Each HandySCAN | BLACK complies with international standards for metrological equipment and comes with a certificate confirming the results of acceptance tests.

Specifications:

- Scan technology: Optical laser illumination

- Scanning accuracy: 0.035 mm

- Camera resolution: 3.1 MP

- Number of cameras: 2 pcs.

- Scanning zone: 310x350 mm

- Scanning / Measurement speed: 800 000 measurements / sec

- Object to facility: 300 mm

- Scan of textures / color: no

- tutor: no Not supported

- Light source: 7 blue laser crosses

Top of the range HandySCAN | BLACK Elite is suitable for solving complex tasks, such as organizing quality control in production or reverse engineering. The scanner allows you to get the most accurate result even in aggressive production conditions. Insufficient lighting, vibrations and dust do not affect the quality of the scan.

The scanner allows you to get the most accurate result even in aggressive production conditions. Insufficient lighting, vibrations and dust do not affect the quality of the scan.

HandySCAN | BLACK Elite does not require fine tuning, so scanning is accessible even for beginners. Ergonomic design, no wires and compact dimensions allow you to work in any conditions.

The 3D scanner is certified according to metrology standards.

Specifications:

- Scan technology: Optical laser illumination

- Scan accuracy: 0.025 mm

- Camera resolution: 3.1 mp.

- Number of chambers: 2 pcs.

- Accuracy: 0.02 + 0.04 mm/m

- Scan area: 310x350 mm

- Scanning / Measurement speed: 1 300 000 Izm. / S

- The operating distance to the facility: 300 mm

- Texture / color scan: no

- Rogue table: not maintained

- source : 11 blue laser crosses + 1 extra line

Advantages of HandySCAN | BLACK Series

- 4x higher resolution: fast digitization of both small and large objects, even with the most complex surfaces, down to the smallest details.

- High speed - up to 1,300,000 measurements per second.

- Instant Mesh: Generates a digital file based on scanned data.

- High quality optics.

- Accuracy up to 0.025 mm.

- Volumetric accuracy: 0.020 mm + 0.040 mm.

- The base package includes the improved VXelements 7.0 software, which greatly simplifies the work with the device due to many functions.

- Scanners are included in the State Register of Measuring Instruments.

How to get started with HandySCAN 3D

Industrial applications of HandySCAN 3D

Bell Helicopter, an American company specializing in the production of helicopters and rotorcraft, develops vertical takeoff and landing vehicles. The company purchased a HandySCAN 3D scanner to check the setup of a gear machine. Thus, Bell Helicopter specialists successfully use the HandySCAN BLACK 3D scanner for quality control, in particular, for automatic verification of the parameters of manufactured products. Using a portable device, the green casting is measured to identify possible deformation. According to the company's employees, this is the most effective way to maintain a high quality standard for aircraft parts.

Using a portable device, the green casting is measured to identify possible deformation. According to the company's employees, this is the most effective way to maintain a high quality standard for aircraft parts.

Thank you all, the material was prepared by a team of LIDER-3D specialists, we will be glad to hear your questions in the comments.

If you are interested in HandySCAN 3D scanners, you can get detailed expert advice and purchase this equipment on the LIDER-3D website.

Follow us on social networks: VKontakte, Telegram, Instagram, YouTube, Ya.Zen, Twitter, Facebook to be the first to receive the most interesting materials!

We also advise you to look at our selection of 3D scanners for education, business and production at the end of 2021.

More interesting articles

3Dtool

Loading

11/17/2022

947

5

Subscribe to the author

Subscribe

Don't want

Hello everyone, friends! With you 3DTool!

It so happened that the first 3D printer from the new. ..

..

Read more

3Dtool

Loading

10/31/2022

1016

2

Subscribe to the author

Subscribe

Don't want

Hello everyone, Friends! 3DTool is with you!

We continue to introduce you to the updated...

Read more

nk.xcfg

Loading

05/10/2016

38401

118

Follow author

Subscribe

Don't want

“A good tester doesn't even launch the app.” (heard at work) Based on real...

Read more

3D technologies, types, how 3D devices work

Many digital engineering strategies that power the future of design, manufacturing, quality control, and product release begin with 3D scanning. 3D scanners work with advanced technologies and specialized software to create a tool that allows you to achieve revolutionary results. For those still working with power tools and traditional coordinate measuring machine (CMM) technology, 3D scanners serve as an easy gateway to advanced manufacturing and engineering strategies.

3D scanners work with advanced technologies and specialized software to create a tool that allows you to achieve revolutionary results. For those still working with power tools and traditional coordinate measuring machine (CMM) technology, 3D scanners serve as an easy gateway to advanced manufacturing and engineering strategies.

Read below to learn more about how 3D scanners work and what this technology can do, so you can start enjoying its benefits now.

What are 3D scanners?

A 3D scanner works by capturing data from the surface of a physical object to describe its shape in an accurate digital 3D format. Unlike CMM measurement data, high quality 3D scan data is used for more than just inspection and dimensional analysis. The data obtained by non-contact measurement allows faster and more accessible digital analysis and inspection using a visual, in-depth method of examination.

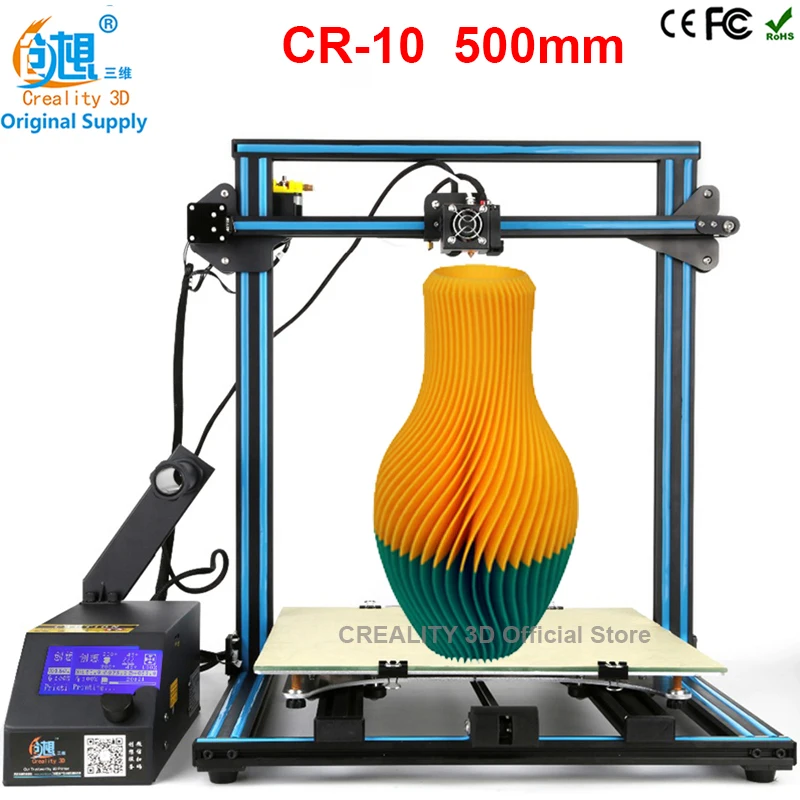

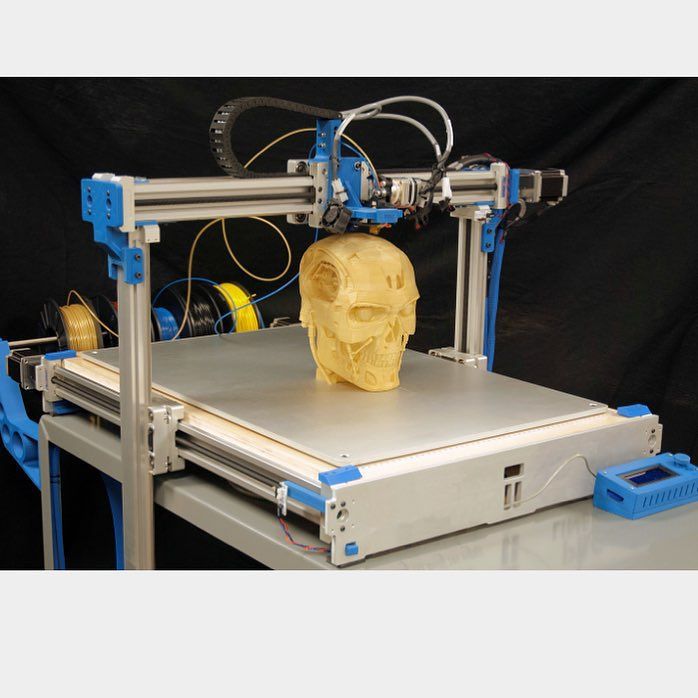

3D scanners are also used to replicate parts in reverse engineering, check the fit, shape and function of components in remote locations, and check CAD models of 3D printed parts. 3D printers can use 3D scan data to create physical objects.

3D printers can use 3D scan data to create physical objects.

What is 3D scanning?

3D scanning is the process of collecting data about the surface of an object in digital format to determine its shape, allowing users to either reproduce the part by reverse engineering or verify it by dimensional analysis.

To do this, operators use scanners that use lasers, light or sensors to determine the surface of the scanned object and assign data points to this surface. These data points will eventually recreate the . Depending on the type of laser, light, or sensor used, the level of detail and scanning performance may vary.

3D Scanning Technologies

Photogrammetry

Originating from photography, photogrammetry is an incredibly useful technology in various fields. This technology allows you to take multiple images taken at different positions and triangulate points on those images to determine their location in 3D space.

For example, cartographers use this technology when compiling maps. When it comes to hard-to-reach places like mountains, surveyors can use photogrammetry to take measurements.

Many modern technologies use photogrammetry, and the quality of the images is the main factor determining accuracy. If the images are poor quality, there will be holes in the grid. The more images you can get, the higher the scan accuracy will be.

Shining 3D offers a solution - DigiMetric Photogrammetric System.

Read also DigiMetric case study “Scanning with a Digimetric Photogrammetric System and a FreeScan Handheld 3D Laser Scanner”

Structured Light

This technology is created by applying geometric patterns to an object while simultaneously capturing an image with a camera. In this case, the camera registers the deviation of the image.

Based on this template offset, all existing points can be located. It is necessary to conduct many scans from different positions, and then merge them until the mesh is 100% complete. Computer programs automatically combine all images to form a complete grid.

Computer programs automatically combine all images to form a complete grid.

3D laser scanning method

3D laser scanning data collection

3D laser scanning process

The object to be laser scanned is placed on the scanner platform. Specialized software directs the laser probe over the surface of the object. A laser probe projects a line of laser light onto the surface, and 2 sensor cameras continuously record the change in distance and shape of the laser line in three dimensions (XYZ) as it passes along the object.

Received data

The shape of an object is displayed as millions of dots, called “point clouds”, on a computer monitor as the laser moves around, capturing the entire shape of the object's surface. The process is very fast and laser scanning is more accurate than infrared.

Point cloud data for inspection

If the data is to be used for inspection, the scanned object can be compared with the designer's nominal CAD data. The result of this comparison is provided as a “color map deviation report” in PDF format, which clearly describes the differences between scanned data and CAD data.

The result of this comparison is provided as a “color map deviation report” in PDF format, which clearly describes the differences between scanned data and CAD data.

Reverse engineering CAD model

Laser scanning is the fastest, most accurate and automated way to obtain digital 3D data for reverse engineering. Again, with the help of specialized software, point cloud data is used to create a 3D CAD model of the geometry of the part.

The CAD model can accurately reproduce the scanned object, or the object can be modified in the CAD model to correct imperfections.

Types of 3D scanners

Active scanners emit some radiation or light. The scanner detects the reflection to collect information about the object. Let's take a look at the active views of 3D scanners below.

3D Laser Scanners

3D Laser Scanners use a process called trigonometric triangulation to accurately display a 3D shape as millions of dots. Laser scanners work by projecting a laser line or lines onto an object and then capturing its reflection using one or more sensors.

The sensors are located at a known distance from the laser source. Accurate point measurements can be made by calculating the angle of reflection of the laser light.

Laser scanners are very popular and come in many designs. These include handheld, manipulator-based, CMM-based handheld devices, long-range trackers, and long-range single-point trackers.

Benefits of 3D laser scanners:

- Ability to scan complex surfaces such as shiny or dark surfaces.

- Less sensitive to changes in lighting conditions and ambient light.

- More accurate data, available for inspection.

Learn about FreeScan UE 3D laser scanner features, features, features and benefits.

An example of using FreeScan UE and photogrammetry can be found on our blog page - Large Part 3D Inspection.

As well as the article The rebirth of historic motorsport icons.

Projected or structured light 3D scanners

Historically known as “white light” 3D scanners, most structured light 3D scanners today use blue or white LED projected light. These 3D scanners project a pattern of light onto an object, consisting of stripes, blocks, or other shapes. A 3D scanner has one or more sensors that look at the edges of these patterns or structural shapes to determine the object's 3D shape.

These 3D scanners project a pattern of light onto an object, consisting of stripes, blocks, or other shapes. A 3D scanner has one or more sensors that look at the edges of these patterns or structural shapes to determine the object's 3D shape.

Using the same trigonometric triangulation method as in laser scanners, so the distance from the sensors to the light source is known. Structured light scanners can be mounted on a tripod or hand held.

Benefits of Structured Light 3D Scanners:

- Very fast scan times of only 2 seconds per scan.

- Versatility - multiple lenses for scanning small and large parts in one system.

- Portability - hand systems are highly mobile.

- Eye friendly for 3D scanning of people and animals.

- 3D color scans available.

- Various price ranges from inexpensive to expensive depending on resolution and accuracy.

An excellent solution of 3D scanners with structured light, are models:

- Einscan HX

- manual 3D scanner Einscan H.

Examples of scanning using 3D 3D scanners EINSCAN:

- HTTPS: // www.shining3d.ru/blog/perfectly-equipped-for-emergency-with-the-einscan-hx/

- https://www.shining3d.ru/blog/at-the-intersection-of-craftsmanship-and- technology-einscan-h-and-fusion-360-in-traditional-boat-building/.

Coordinate Measuring Machine (CMM)

Coordinate Measuring Machine (CMM) is mainly used for parts inspection. The machine can be controlled manually or through autonomous control by software and computers. Measurements are determined by attaching a sensor to the machine. The sensor usually has a small ball at the end of a shaft of known diameter. The CMM is then programmed to make contact with the part. When the machine senses contact with the probe tip, a value in XYZ space is measured. The most common type of CMM is the bridge type, which has 3 x, y, and z axes. The attached sensor system can be rotated to provide an additional 3 xyz axes, giving a total of 6 degrees of freedom (DOF).