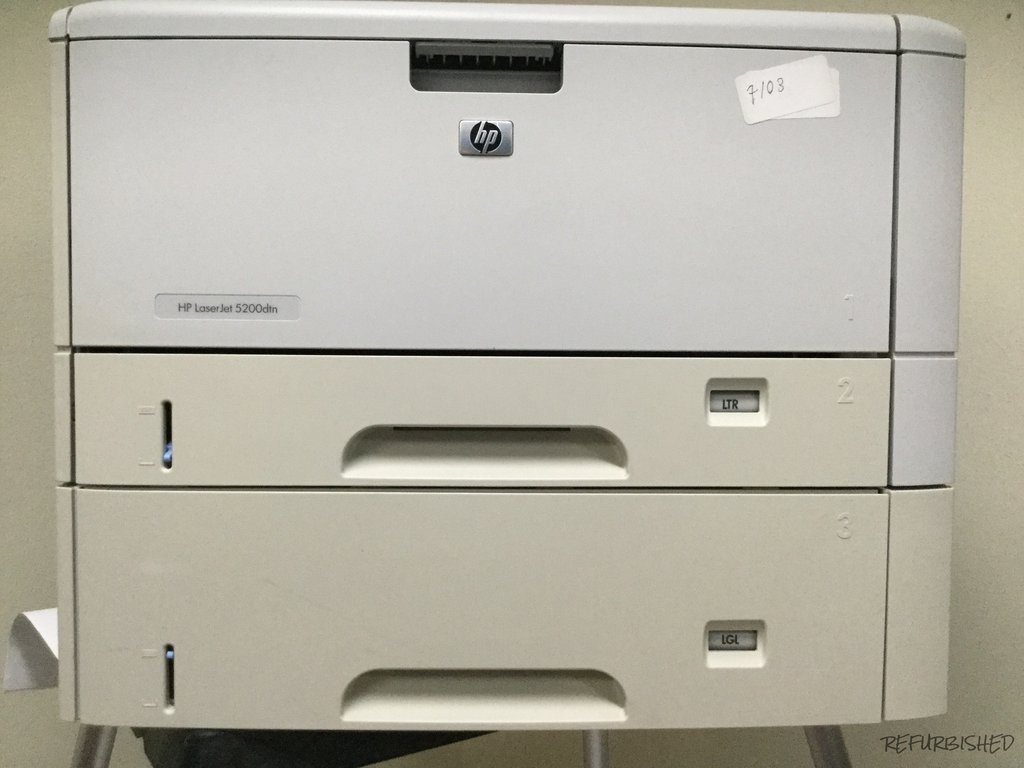

Hp 5200 3d printer

Industrial 3D Printer – HP Jet Fusion 5200 Series 3D Printing Solution

Contact an HP 3D Print expert

Choose the phone number for your country to speak to a local HP 3D Printing sales expert today.

België/Belgique

+32 78 48 44 69

Czech Republic

+420 239 050 531

Deutschland

+49 7031 986 90 13

+49 7031 986 90 17

España

+34 93 003 45 95

France

+33 6 28 78 35 59

Italia

+39 02 8295 2406

Nederland

+31 20 241 5685

Norway

+47 23 96 00 13

Österreich

+43 720 117035

+43 1424 0091

Romania

+40 376 300 174

Sweden

+46 8 446 891 49

Suisse/Switzerland

+41 44 511 2308

+41 44 511 2333

United Kingdom

+44 20 7365 8158

United States

+1 877 468 8369

Expand and scale into volume production with HP industrial 3D printers

Enhanced manufacturing predictability

Breakthrough productivity and automation

Expand into new applications and markets

See how the HP industrial 3D printer works

Explore the complete HP Jet Fusion 5200 Series Industrial 3D Printing Solution

HP 3D High Reusability PP

1enabled by BASF

Chemical resistant,2 weldable, low moisture absorption, functional parts

Data courtesy3

HP 3D High Reusability PA 11

4Ductile,5 quality parts

Data courtesy6

HP 3D High Reusability PA 12

7Strong, low cost,8 quality parts

Data courtesy9

HP 3D High Reusability PA 12 GB

10Stiff, dimensionally stable, quality parts

Data courtesy11

BASF Ultrasint® TPU01

Flexible, functional parts.

HP Jet Fusion 5200 Series 3D Automatic

Unpacking Station

Achieve consistent unpacking results through an automatic process with an industrial-grade solution.

HP 3D API

12Streamlined data access and automation across industrial management systems.

HP 3D Center

13Dashboard view into production data and remote monitoring for greater efficiency and agility.

Learn

Watch

HP 3D Process Control

14Dimensional accuracy and repeatability—faster—for manufacturing predictability.

HP SmartStream 3D Build Manager

Quickly and easily prepare your jobs for printing with all the elements you need.

Download

Autodesk® Netfabb® with HP Workspace

Provides advanced software for the additive manufacturing of production quality parts.

HP Build Processor

The industry standard software for professional 3D Printing, to unlock the full potential to manage every step in your production process.

Siemens NX AM

Combine design, optimization, simulation, preparation of print jobs, and inspection processes all in a single managed environment and with minimal steps.

HP Jet Fusion 5200 3D Natural Cooling Unit

Designed to remove and cool each build naturally, thereby enabling continuous production.

Hovmand Forklift 5200

HP recommended accessory to remove and place the HP Jet Fusion 5200 3D Natural Cooling Unit from the processing station.

HP 3D Solution Services

Explore new opportunities to scale production and accelerate growth with support and consultancy from HP.

HP 3D Professional Services

Expert guidance to help you and your customers identify viable strategic opportunities, optimize design for breakthrough applications, and streamline manufacturing processes.

Data courtesy15

HP 3D as a Service

Pay based on usage: Gain new levels of cost predictability and the flexibility to scale your business as you grow.

HP Integrated Financial Solutions

Accelerate your time to value. Enjoy the flexibility to meet both your technology and financial plans while allocating your cash to other priorities.

Data courtesy16

Expand your offering with quality white applications

Achieve consistent white - part after part, with the HP Jet Fusion 5420W 3D Printing Solution that delivers enhanced manufacturing predictability and outstanding part quality at the right cost.

Disclaimers

The content of this site is for information purposes only and it is showing the product configuration for the US market only.

Availability, pricing, product configuration and specifications may differ according to geographical location, local laws and practices.

Please contact us or talk to your local HP 3D Printing representative for further information or for product configurations specific to your local country.

- Based on internal HP testing, May 2020.

HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PP enabled by BASF provide up to 100% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and reclaimed powder is tracked by generations (worst case for reusability). Parts are then made from each subsequent generation and tested for mechanical properties and accuracy showing no degradation of properties up to three generations of use.

HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PP enabled by BASF provide up to 100% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and reclaimed powder is tracked by generations (worst case for reusability). Parts are then made from each subsequent generation and tested for mechanical properties and accuracy showing no degradation of properties up to three generations of use. - Based on internal HP testing, May 2020, with tests for mechanical property retention, dimensional stability, and weight change after 7- and 30-day immersion with acids, bases, organic solvents, and aqueous solutions. Due to the material characteristics, extra tuning is required in part design and printing, compared to other rigid HP 3D Printing materials.

- HP 3D High Reusability PA 11 image is data courtesy of NACAR

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 11 provide up to 70% powder reusability ratio, producing functional parts batch after batch.

For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy. - Testing according to ASTM D638, ASTM D256, and ASTM D648 using HDT at different loads with a 3D scanner for dimensional accuracy. Testing monitored using statistical process controls.

- HP 3D High Reusability PA 12 image is data courtesy of Addit.ion

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 provide up to 80% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

- Supplies price, and maintenance costs recommended by manufacturer. Cost criteria: printing 1.4 full build chambers of parts per day/5 days per week over 1 year of 30 cm3 parts at 10% packing density on Fast print mode using HP 3D High Reusability PA 12 material, and the powder reusability ratio recommended by manufacturer, and printing under certain build conditions and part geometries.

- HP 3D High Reusability PA 12 GB image is data courtesy of NACAR

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 Glass Beads provide up to 70% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

- BASF Ultrasint® TPU01 image is data courtesy of Kupol.

- Supported industrial management systems for HP Jet Fusion 5200 / 4200 Series 3D Printing Solutions : 3D Control Systems, AMFG, LINK3D, Siemens NX AM, Siemens Opcenter. Access to additional data modules available only for the HP Jet Fusion 5200 Series 3D Printing Solution. Additional purchases required. Supported industrial management systems for HP Jet Fusion 5420W 3D Printing Solution : 3D Control Systems, AMFG, LINK3D. Access to additional data modules available only for the HP Jet Fusion 5420W 3D Printing Solution.

Additional purchases required.

Additional purchases required. - Available only for the HP Jet Fusion 5420W 3D Printing Solution and HP Jet Fusion 5200/4200 Series 3D Printing Solutions. Compatible software. Additional purchase required.

- Available only for the HP Jet Fusion 5200 Series 3D Printing Solution. This software is sold as an HP 3D Solution Service. For more information visit https://h30195.www2.hp.com/v2/GetDocument.aspx?docname=4AA7-7931EEW

- Data courtesy of Meidai

- Data courtesy of Invent Medical

HP Jet Fusion 5200 3D Printer | 3FW25A

Returns

Digital Media Warehouse’s return/refund policy expires 30 days from shipment. Failure to process a return/refund within this term will result in the rejection of the refund request.

Eligible return items must be unused and in the same condition as received in the original packaging.

Non-Returnable Items:

- Software

- Demo Printers

- Used Printers

Completed returns require proof of purchase. Please do not ship returns to the manufacturer unless directed otherwise from the processing department.

Please do not ship returns to the manufacturer unless directed otherwise from the processing department.

There are certain situations where only partial refunds are granted (if applicable)

- Product box is opened, but unused

- Any item not in its original condition, is damaged or missing parts for reasons not due to our error

- Any item that is returned more than 30 days after delivery

Refunds (if applicable)

Upon return receipt and inspection, email notification generates with approval/rejection notice.

If approved, the refund will be processed, and a credit will automatically be applied to the original payment method within 7-12 business days from approval.

Late or missing refunds (if applicable)

Unreceived refunds; first check account utilized for initial payment.

Then contact the account company, it may take some time before a refund is posted based on policies established with the account.![]()

Next contact the bank tied to the payment account. There is often some processing time before a refund is posted.

Once these steps have been exhausted, please contact us at [email protected]

HP

All HP Ink Cartridges, Toner Cartridges, Printheads, Waste Ink Cartridges, and any other HP supplies or accessories will be charged a 20% restocking fee.

Mutoh

All Mutoh Ink Cartridges, Printheads, Waste Ink Bottles, and any other Mutoh supplies or accessories will be charged a 15% restocking fee.

After Market/Refill Inks

All Ink Refills or Non-OEM Inks will be charged a 15% restocking fee.

Paper

All Media and Paper will be charged a 15% restocking fee.

Printers

All Printer sales will be charged a 20% restocking fee and any labor costs involved with the return.

Machine Parts

All machine part sales are final. There are no returns, refunds, or exchanges for any machine part sales.

Clearance, Demo, Used, and Flash Sale Items (if applicable)

Only regular priced items may be refunded, unfortunately clearance, demo, used, or flash sale items cannot be refunded.

Exchanges (if applicable)

Digital Media Warehouse only replaces items defective or damaged as a result of DMW’s neglect. Exchanges for the damaged items must initiate contact via email; [email protected]

Exchanges resulting from miss ships because of the ordering party may incur a restocking fee.

Shipping Charges

To return product, ship to:

Digital Media Warehouse

Attn: Returns

1825 North Walnut,

Oklahoma City, OK 73105

Shipping costs will fall in the responsibility of the returning party, unless otherwise notified. Shipping costs are non-refundable. All refunds will be subject to deduction of initial freight costs.

Shipping costs are non-refundable. All refunds will be subject to deduction of initial freight costs.

Physical shipping address will dictate travel time in the event of an exchange.

Items valued over $75, should consider a trackable shipping service and/or shipping insurance. Digital Media Warehouse holds no guarantee of receipt of items without trackable shipping.

SERIES PRODUCTION 3D PRINTER HP JET FUSION 5200 series

Go digital

Plastic parts manufacturing

Show more Watch video

BENEFITS OF HP

3D PRINTERS- Rapid production of plastic parts with repeatable precision

- Best isotropic properties among 3D printers

- Better manufacturing efficiency and economics than other additive technologies0017

- Integrated solutions for the production of parts and processing of construction materials

contacts

Complex solutions for

digital production

Unique software

for managing production

processes

Solution for serial production

of any geometrically and functionally

complex plastic parts

Simple and intimate work

against conventional technologies

production

The highest resolution of the thermal chamber,

High efficiency of melting

AMP and the highest savings of materials

Uses the entire

volume of

10 С

SAME PRODUCTION TIME

DOES NOT AFFECT PRODUCT COMPLEXITY

80 %

USES

POWDER AND 20% FRESH MATERIAL0003 FOR QUALITY PRINT

HP JET FUSION 5200

3D PRINTER

The HP Jet Fusion 5200 Digital Manufacturing Solution consists of the 3D Printer, Interchangeable Build Unit and Processing Station. For greater productivity in the production of functional parts, the assembly has been supplemented with a replaceable cooling unit. Combined with dedicated software (HP 3D Process Control) for continuous process control to ensure repeatable accuracy, reliability and production consistency, the HP Jet Fusion 5200 is the solution for the medium volume production of plastic parts.

For greater productivity in the production of functional parts, the assembly has been supplemented with a replaceable cooling unit. Combined with dedicated software (HP 3D Process Control) for continuous process control to ensure repeatable accuracy, reliability and production consistency, the HP Jet Fusion 5200 is the solution for the medium volume production of plastic parts.

Print material is filled automatically into the process equipment. Then insert the filled device into the 3D printer and start printing. After printing, you install the cooling unit on the device, into which the still hot printed parts are automatically transferred. Thus, the construction device is immediately ready for further production of parts. After the parts have cooled, the unmelted building material is removed from the cooling block in the process block and used for a new build. powerful software with the necessary tools for preparing data and further manufacturing parts.

The whole technology is based on the precise and at the same time fast application of building materials and special solutions for further interaction with temperature. 3D printing a single layer is permanent, no matter how complex the part you are printing. You can print a 380 x 284 x 380 mm building space on the HP Jet Fusion 5200 in just 9.5 hours.

3D printing a single layer is permanent, no matter how complex the part you are printing. You can print a 380 x 284 x 380 mm building space on the HP Jet Fusion 5200 in just 9.5 hours.

USING 3D PRINTING

HP IN PRODUCTION

Multi Jet Fusion offers a unique growth opportunity for manufacturing companies. You can quickly create both rapid prototypes and thousands of functional final parts on a single device. Thus, HP enters the arena of traditional plastic parts manufacturing technologies such as injection molding.

Plastic injection molding unrivaled with high production volumes and low unit costs. However, production often needs to start quickly, and you can't afford to wait while the mold is produced. Or you need to be flexible in redesigning products for which mold making doesn't make economic sense. In these cases, the HP Jet Fusion 3D printer is a great alternative even for simple parts.

CASE STUDIES

Show examples

Gallery

HP Jet Fusion 5200 3D printers produce thermoplastic parts in large batches with fine details and optimal mechanical properties.

BUILDING MATERIALS

FOR HP 3D PRINTER

In terms of further cost savings, the HP Open Material Platform is a revolutionary innovation in the 3D printing industry - the rapid release of new materials and the natural competition in the market between several manufacturers. The cost of purchasing building materials will rapidly decrease and at the same time their quality will increase.

BUILDING MATERIALS FOR HP JET FUSION 5200 3D PRINTER

| HP 3D High Reusability PA 12 Durable thermoplastic for functional prototypes and final parts with high density and optimum technical properties. |

|

| VESTOSINT® 3D Z2773 Similar to PA 12 in black Evonik. | |

| Polypropylene and other materials

|

Learn more

SEE PA 11 STABILITY AND FLEXIBILITY TEST

CERTIFICATIONS & OTHERS

DOWNLOAD INFORMATION

Hewlett Packard is committed to providing information about the safety of 3D printing and the technical and other specifications of printed parts. If you do not find the information you need here, please contact us.

BIOINTELLIGENCE OF BUILDING MATERIALS AND PRINTED PARTS

| The Material Modes Pa 12 | Download |

| Declaration on the suitability of parts printed from the material 0004PA 12 for toys | Download |

| Biocompatibility Information TPU Estane

| Download |

Water resistance information for parts

Download

pdf

Flammability information for parts printed in PA 12

Download

pdf

Flammability information for parts printed on PA 12 GB

Information on exposure to UV radiation and other external influences

mechanical properties of printed parts

Information on the chemical resistance of printed parts PA 12 to technical

liquids (lubricants, fuels)

Information about smoothing the surface of parts by vibration processing

pdf0016

If you want to realize the full potential of 3D printing, you need quality 3D modeling. Modern software solutions can not only create 3D models, resize and convert them to the appropriate format, but also provide tools such as topological optimization and full color texture. Before modeling for HP Multi Jet Fusion 3D printing, it's a good idea to review a few basic guidelines.

Modern software solutions can not only create 3D models, resize and convert them to the appropriate format, but also provide tools such as topological optimization and full color texture. Before modeling for HP Multi Jet Fusion 3D printing, it's a good idea to review a few basic guidelines.

DOWNLOAD RULES FOR PREPARING 3D MODELS

Various software tools can be used to create 3D models for 3D printing, including the most commonly used CAD software. If you are already working with CAD software, you can easily use it to prepare data for 3D printing.

View 3D printing software

FINANCING THE PURCHASE

OR OPERATION

We offer financing solutions for HP Multi Jet Fusion. We have an experienced financial team who will recommend an appropriate financial proposal, an attractive grant application, or a combination of the two.

We have an experienced financial team who will recommend an appropriate financial proposal, an attractive grant application, or a combination of the two.

VIEW FINANCING INFORMATION

POST

All 3D powder printing technologies, including HP Multi Jet Fusion, require some further processing of the printed parts. Namely, the removal of residues of unbound printing material from the surface of parts. This is best achieved by sandblasting or using a mixture of fine plastic powder. Other processing may be, for example, painting or coating. We offer functional and cost-effective options for post-processing equipment.

BUSINESS DATA

HP Announces HP Jet Fusion 5200 Commercial 3D Printers

HP Inc. announced the acceptance of orders for Jet Fusion 5200 industrial powder 3D printers using proprietary Multi Jet Fusion technology. The new additive manufacturing platform is designed for serial 3D printing of final products.

HP expands its portfolio of industry-leading 3D printing products with the introduction of the new Jet Fusion 5200 solution, industrial additive systems that bring new levels of predictability, efficiency, turnover and quality to users moving into high-volume production. In an effort to help customers digitally transform their business, HP is also expanding its strategic alliances with industry leaders BASF, Materialize and Siemens and launching the HP Digital Manufacturing Network, a new global community of trusted large 3D printed parts suppliers.

“The Fourth Industrial Revolution is one of the most powerful transformational forces in our lives. It will require technological innovation, new partnership models and new ways of doing business. HP is committed to helping its customers with diverse business needs seize the opportunity by offering a portfolio of innovative solutions and access to a comprehensive ecosystem of leading industry partners. The addition of the new Jet Fusion 5200 3D printing solution to our portfolio, together with the expansion of industrial alliances and the announcement of a new manufacturing network, are important drivers of the move to digital manufacturing,” said Christoph Schell, Head of 3D Printing and Digital Manufacturing at HP Inc. .

HP Jet Fusion 5200 3D Printers: Breakthrough Cost, Productivity, and New Applications

HP Jet Fusion 5200 Series Additive Manufacturing Platforms combine new systems, analytics, software, services, and material science innovation to deliver users the ability to scale additive manufacturing and grow the business. Building on these innovations, the new solution improves production predictability and delivers optimal output of high quality parts while maintaining industrial efficiency, accuracy and repeatability. The HP Jet Fusion 5200 offers best-in-class economy and productivity, increased flexibility and availability, and simplifies workflow and fleet management in industrial manufacturing environments. New analytics, software, and service capabilities, including HP 3D Process Control, HP 3D Center, and HP 3D Parts Assessment, enable customers to take operational efficiency and repeatability to the next level, discover new 3D printing applications, and optimize manufacturing of parts.

The HP Jet Fusion 5200 offers best-in-class economy and productivity, increased flexibility and availability, and simplifies workflow and fleet management in industrial manufacturing environments. New analytics, software, and service capabilities, including HP 3D Process Control, HP 3D Center, and HP 3D Parts Assessment, enable customers to take operational efficiency and repeatability to the next level, discover new 3D printing applications, and optimize manufacturing of parts.

HP also introduced BASF's new ULTRASINT™ certified thermoplastic polyurethane, which allows customers to expand the use of their Jet Fusion 5200 Series 3D printers in end-product manufacturing. The new material is ideal for the production of flexible and elastic parts and complements HP PA-12, PA-12 Glass Beads and PA11, which are highly recyclable. In the future, the company plans to further expand its range of materials for new additive systems.

Jet Fusion 5200 applications are being explored by many automotive, industrial, consumer and manufacturing companies, including Avid Product Development, BASF, Jaguar Land Rover, Kupol, Materialise, Sculpteo, Prodartis and Vestas.

“Innovation and cutting-edge technology are at the heart of Jaguar Land Rover's commitment to providing our customers with an incredible user experience. Autonomous driving technologies, Internet-connected electric vehicles, car-sharing principles, and a focus on the fourth industrial revolution are central to our development strategy. Our work with HP to expand our 3D printing knowledge and capabilities has been an important step towards producing quality parts to support current customers and the aftermarket. Continuing this collaboration and using the new HP Jet Fusion 5200 3D printers will allow us to explore new areas of application for 3D printing and help us in our research to improve the performance, efficiency and reliability of this technology,” says Ben Wilson, director of additive manufacturing at the company Jaguar Land Rover.

“As the world's largest supplier of wind turbines, Vestas is looking for innovative companies like HP to collaborate on accelerating new product development to create a more sustainable future. The combination of the latest 3D printing materials and breakthrough technology solutions is an important factor in creating new design opportunities, optimizing production and improving environmental sustainability,” said Jeremy Hate, Senior New Technology Development Engineer at Vestas VBIC.

The combination of the latest 3D printing materials and breakthrough technology solutions is an important factor in creating new design opportunities, optimizing production and improving environmental sustainability,” said Jeremy Hate, Senior New Technology Development Engineer at Vestas VBIC.

Information about Jet Fusion 5200 3D printers is available on the official website at this link.

HP strengthens its industrial alliances to advance digital manufacturing

HP announced it is expanding partnerships with a number of manufacturing leaders to help customers move to digital manufacturing.

HP and Siemens, a leader in innovation in automation and digitalization, are expanding their collaboration to create a complete additive manufacturing solution using HP Jet Fusion 5200 3D printers and Siemens Digital Enterprise software products for digital enterprises. HP and Siemens are sharing expertise to help customers create unique products, accelerate time-to-market for high-quality 3D printed parts, and enable the full potential of additive manufacturing.

“We are excited to expand our partnership with HP. The development of innovative partnerships and advanced technologies, such as additive manufacturing, are key factors in the digital transformation of companies in various industries. Siemens and HP are thinking in terms of the future and intend to combine their competencies in a comprehensive industry solution that will accelerate the adoption of industrial additive manufacturing technologies and help our customers increase the flexibility, efficiency and speed of digital manufacturing,” commented Klaus Helmrich, CEO of Siemens Digital Industries and member Management Board of Siemens AG.

HP and leading global chemical group BASF are expanding their alliance to create innovative materials certified to work with HP's new industrial 3D printers. The companies will work to expand the market and plan to help customers design new products and develop applications using their unique expertise in materials science and 3D printing. BASF and HP are already working with the world's largest wind turbine supplier Vestas and 3D design and additive manufacturing services provider Sculpteo on new products created using BASF's ULTRASINT™ thermoplastic polyurethane and HP Jet Fusion 3D printers.

BASF and HP are already working with the world's largest wind turbine supplier Vestas and 3D design and additive manufacturing services provider Sculpteo on new products created using BASF's ULTRASINT™ thermoplastic polyurethane and HP Jet Fusion 3D printers.

“Co-innovation by key industry players helps customers unlock the full potential of 3D printing. The launch of the new material based on thermoplastic polyurethane is an important milestone in the cooperation between BASF and HP and is fully in line with our common goal of accelerating the industrialization of additive manufacturing,” said Dr. Markus Kamit, a member of the Board of Directors of BASF.

HP is partnering with Materialize, a leader in 3D printing services and software, to combine the HP Jet Fusion 5200 and HP Jet Fusion 500/300 additive manufacturing platforms with the Materialize Build Processor and Materialize Magics 3D Print Suite software solutions. As one of the first companies to operate the Jet Fusion 5200 systems, Materialize is also researching and developing new applications for its customers with BASF thermoplastic polyurethane and other available consumables. In addition, Materialize is the first partner in the new HP Digital Manufacturing Network and is using HP's 3D printing technologies for high-volume additive manufacturing of parts for the European market.

In addition, Materialize is the first partner in the new HP Digital Manufacturing Network and is using HP's 3D printing technologies for high-volume additive manufacturing of parts for the European market.

“It is clear that the market is increasingly using 3D printing technologies in production. As a longtime HP partner, we are proud to expand our collaboration and start working together in new areas. Our customers are delighted to develop our partnership with HP and work together to expand the scope of 3D printing and new materials, our desire to develop the production of high-quality parts. Together, we are helping our customers succeed in an increasingly competitive marketplace,” said Fried Vankraen, Founder and CEO of Materialize.

HP Launches Digital Manufacturing Network: High Volume Production of Quality Parts

Many companies are looking to digital manufacturing service providers to help accelerate new product development, reduce time-to-market, create leaner supply chains, and reduce their carbon footprint. To meet these needs, HP introduced the new HP Digital Manufacturing Network, HP's global manufacturing partner community to help design, manufacture and commercialize both plastic and metal parts using HP's additive manufacturing technologies. Members of the HP Digital Manufacturing Network have a high level of expertise in advanced additive manufacturing, streamlined quality management procedures and integrated manufacturing processes, and have sufficient resources to fulfill high-volume orders.

To meet these needs, HP introduced the new HP Digital Manufacturing Network, HP's global manufacturing partner community to help design, manufacture and commercialize both plastic and metal parts using HP's additive manufacturing technologies. Members of the HP Digital Manufacturing Network have a high level of expertise in advanced additive manufacturing, streamlined quality management procedures and integrated manufacturing processes, and have sufficient resources to fulfill high-volume orders.

The HP Digital Manufacturing Network initially includes partners in the US, Asia, and Europe. Network members meet the most stringent HP requirements. The new community includes Forecast 3D, GKN Powder Metallurgy, GoProto, Jabil, Materialize, Parmatech and ZiggZagg NV. HP will continue to expand its manufacturing network in other target markets and add qualified new partners in the coming months.

For more information about HP Digital Manufacturing Network Partners, click here.