Xrize 3d printer

Rize - xRize Full Color & Carbon Composite Industrial 3D Printer, 12" x 8" x 8" Build Volume, #B101393

$39,995.00 $12,999.00

Reviews (0)

- SKU:

- RIZE-B101393

In Stock - FREE SHIPPING

Current stock: 0

Quantity

Cart Subtotal: $0.00

View cart Checkout

- Description

- Reviews

- Additional Info

- Videos

Description

NOTE: This listing is for a lightly used DEMO unit.XRize is the world’s first industrial Additive Manufacturing solution for creating vibrant, full-color functional parts with minimal post-processing. Through use of their patented Augmented Material Deposition (AMD) process, extrusion and material jetting are combined to produce incredibly strong parts that require almost no post-processing. With an ability to print color (using CMYK Ink), users can embed graphics, logos, instructions and QR codes in the part creating digitally augmented parts for fully traceable and trusted parts. xRize is the only full-color 3D printer capable of producing composite parts. Gain access to vivid colors at a fraction of the cost of other professional color printers.

xRize Standard Features:- Full-color, functional printing - Print graphics and text directly into parts including QR codes, part numbers, instructions, or safety warnings.

- Exceptional Class Leading Z-strength - Ideal for functional prototypes, tooling, and end-use parts.

- Easy to use, fast time to part - Minimal, pre and post-processing with no solvents.

- UL Greenguard certified - People-safe and environmentally friendly thanks to its recyclability. Suits office, production, and field use.

- Digitally Augmented Parts - Text, images and QR codes for traceability, built-in trust and IP controls.

- 1 Year Standard Warranty (Phone/Email Support from Rize directly)

-

Starter Kit: Used Rizium GF, Release Ink, Cyan Ink, Magenta Ink, Yellow Ink, Black Ink cartridges, Ink Waste tray, Accessory Kit, Chamber filter, Build Plate

-

3D Printer

-

Free Shipping to US48

Specifications:

| Build Volume: | 12" x 8" x 8" (310 x 200 x 200mm) |

| Build Materials: | Rizium Carbon/Endura/One/Black, CMYK and Marking Ink |

| X/Y Accuracy: | +/- 0. 127mm or +/- 0.003mm/mm, whichever is greater (0.005") 127mm or +/- 0.003mm/mm, whichever is greater (0.005") |

| Z Accuracy: | +/- layer thickness (see below) |

| Extrusion Layer Thickness: | 0.250mm or 0.125mm (0.0098" or 0.005") |

| Extrusion Tip Diameter: | 0.4mm |

| Jetting Resolution: | X/Y = 300dpi; Z = 200dpi at 0.125mm layer thickness |

| Filament Capacity: | (2) 820g spools with hot-swap; 1640g total |

| Fluids Capacity: | (5) 120ml cartridges; one each of color and release agent |

| Filament Usage: | 7 grams per hour on average; geometry dependent |

| Fluids Usage: | 1ml per hour on average; geometry dependent |

| Connectivity: | Ethernet: RJ45, 10/100Mbps / USB Type A port |

| Compliance: | ANSI/CAN/UL 2904, FCC, RoHS, CE, NRTL |

| Operating Environment: | 59-86 deg F (15-30 deg C), 20-60% humidity |

| Power: | 120-240VAC 50/60Hz, 750W |

| Device Dimensions: | 21. 4" H x 36" W, 25.4" D (535 x 915 x 647mm) 4" H x 36" W, 25.4" D (535 x 915 x 647mm) |

| Weight: | 137 lbs (62kg) |

Reviews

Be the first to review this product.

Write a Review

Additional InfoAdditional Info

- Warranty:

- 1 Year Standard

- SKU:

- RIZE-B101393

- Availability:

- In Stock - FREE SHIPPING

- Shipping:

- $0.00 (Fixed Shipping Cost)

Share:

Related Products

Sale

View Product

$19,995.00 $6,999.00

Sale

View Product

$6,295.00 $5,795.00

View Product

$4,999.00

View Product

$2,989.00

Color 3D Printing Firm Rize3D Shuts Down—Will it Rize Again? - 3DPrint.com

Rize3D has gone out of business. However, if you have a Rize system, you can still obtain service and filament through the firm Palitra3D. The company also aims to license out the technology that it has obtained from Rize3D. So, in a somewhat new form or by being run by someone else, Rize3D could rise again.

So, in a somewhat new form or by being run by someone else, Rize3D could rise again.

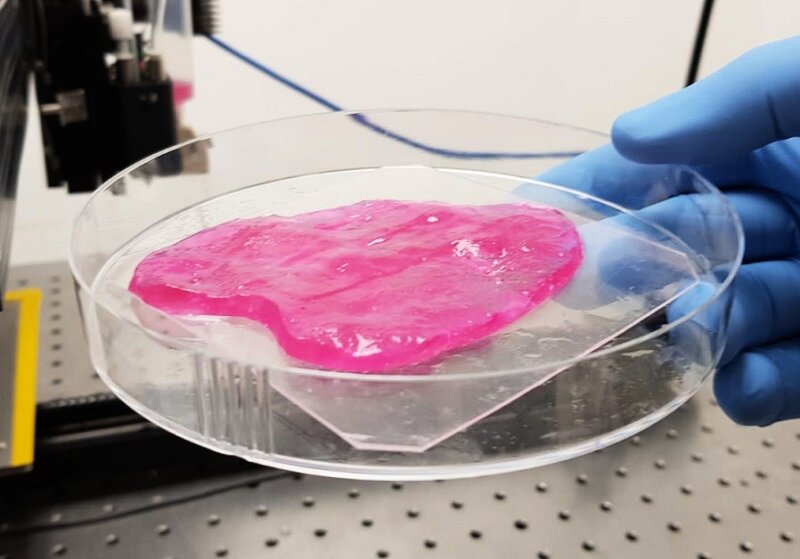

Full color 3D printed model of a heart made with Simpleware on an XRIZE 3D printer. Image courtesy of XRIZE.

On the Palitra3D website, the company stated, “RIZE is no longer functioning as a company but don’t worry! Eugene Giller founded RIZE with one mission – to bring functional printing to the masses with advanced features like composite materials & full-color 3D printing. Thanks to the incredible core team who worked tirelessly to create a technology ecosystem unlike any other filament 3D printer in the world, his vision became reality. While we are incredibly thankful for everything RIZE was able to accomplish, it was time to close that chapter to keep the initial vision alive. Welcome to the next chapter. Palitra3D.”

Since its 2016 launch, Rize3D released a number of different 3D printers. While they all relied on a form of material extrusion technology, the company was best known for its Augmented Polymer Deposition (APD) process. APD combined the melting of thermoplastic filaments with the use of a specialty inkjet printhead that made it possible to deposit colorful and functional inks onto printed parts. With the XRIZE system, this meant jetting cyan, magenta, yellow, and black inks onto engineering-grade material. A specialty release Ink was also jetted between the automatically-generated supports and the part itself, so that users could quickly peel the supports away for a smooth surface finish with no additional finishing required.

APD combined the melting of thermoplastic filaments with the use of a specialty inkjet printhead that made it possible to deposit colorful and functional inks onto printed parts. With the XRIZE system, this meant jetting cyan, magenta, yellow, and black inks onto engineering-grade material. A specialty release Ink was also jetted between the automatically-generated supports and the part itself, so that users could quickly peel the supports away for a smooth surface finish with no additional finishing required.

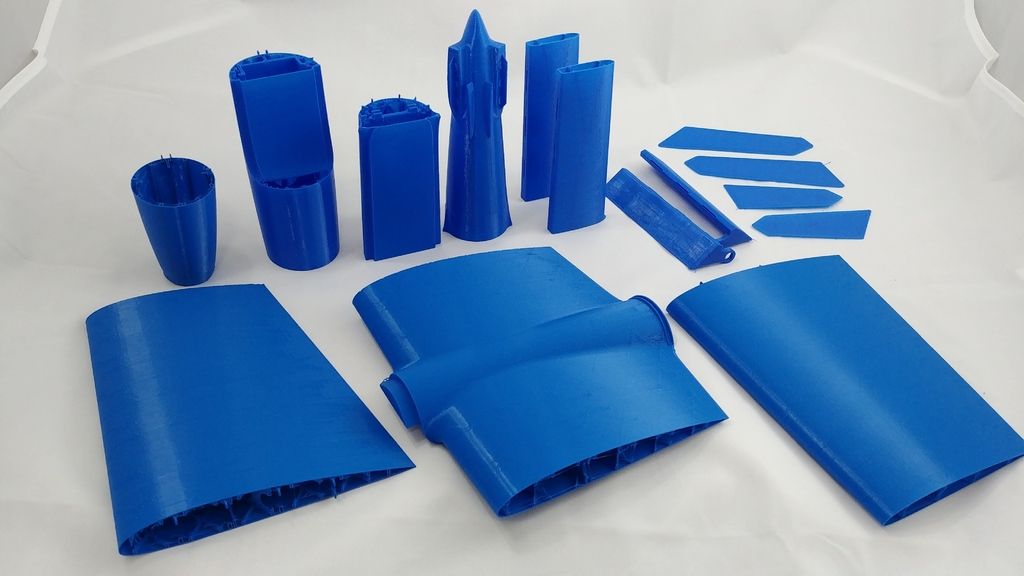

APD gave people interesting parts to look at. Moreover, these components were reasonably affordable as well. The systems could be used in a variety of environments, particularly factories and offices, due to their high level of safety. By combining inexpensive filament with color, you could produce effective parts with good labelling. There were a lot of potential applications for Rize’s process and I could see someone commercialize the technology again.

There were a lot of potential applications for Rize’s process and I could see someone commercialize the technology again.

I really like the combination of inkjet and filament. This really would give a firm with a lot of inkjet expertise a toe hold in the market. They could then focus on jetting inks onto parts, not just color, but also things like conductive materials and coatings. This would allow the filament to produce the cheap, rough bulk of the part and the additional inks to provide added functionality.

I’ve always loved Rize3D´s groundbreaking way to get the best of both inkjet and material extrusion. However, with so many potential exit partners and such potential, why did Rize3D fail? Over the past several years, the firm has released a handful of systems starting with the monochromatic Rize One, the full-color XRIZE, the home office 2XC, and the larger but still cost effective RIZE 7XC.

One problem off the bat is that I didn’t until just know know that the firm even had the 2XC printer. Rize never really had the funds to make a huge marketing impact. It also didn’t develop the applications or stories necessary to stay relevant. It never was completely able to punch through to our collective consciousness to be top of mind.

The Rize 2XC 3D printer made with Sindoh. Image courtesy of Rize3D.

Part of that is a funding issue. Another part, however, is that if you have great, colorful components and a safe process to make them with, you might be lulled into a false sense of security. It seems like you’re inherently useful and good and, thus, relevant. But, in our market you need the perfect fit for the perfect application to be relevant enough for people to purchase your system and really engage with it. This is especially true if you are one firm pushing a technology by yourself.

If you can’t manage to convince the world that you’re an earth-shattering revolution, then you need a tightly knit army of converts to your cause. And with something great and ephemeral, you’re not going to cut it. So, Rize never had a small core of passionate users extolling its virtues and singing its praises. APD was a very interesting technology that also had a lot of different potential uses from toys and prototypes to end-use components and spare parts. With such a broad application area and such potential, it can be hard to focus and find your true north.

And with something great and ephemeral, you’re not going to cut it. So, Rize never had a small core of passionate users extolling its virtues and singing its praises. APD was a very interesting technology that also had a lot of different potential uses from toys and prototypes to end-use components and spare parts. With such a broad application area and such potential, it can be hard to focus and find your true north.

If you have a technology that can only really create small medical parts well and is expensive, then this is super limiting. However, you also know what you have to do to get customers and where to get them. You can’t do toys, you can’t do bulk, you can’t do prototypes, you can’t do volume, you can’t even do inexpensive medical devices either. What this does is give you a lot of focus. You know you have to succeed in a tight market and you know you have to execute really well there.

Toys made with Rize3D’s full color 3D printing process. Image courtesy of Rize3D.

My view is that, with Rize3D, there were just so many potential markets and customers that the team really was overwhelmed with the possibilities. With such choices, they were subsequently unable to filter through the noise to get enough signals to sustain them. With a broad field of potential clients and applications, it can be almost impossible to find the right clients and applications. And without a few crucial clients that have profitable key applications, it’s difficult to grow a business and a user base. In this case, therefore, we have to conclude that there were just too many possible roads that all obscured the path to revenue.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printing business news • color 3d printing • color printing • company closure • full colour 3d printing • inkjet • Palitra3D • Rize Augmented Polymer Deposition (APD) • rize3d

Please enable JavaScript to view the comments powered by Disqus.

RIZE Introduces XRIZE Full Color Desktop 3D Printer and New Materials

3D Printing

Boston-based additive manufacturing company RIZE has announced the release of a new XRIZE full-color desktop industrial 3d printer, along with two new materials: RIZIUM CARBON and RIZIUM ENDURA, and the RIZE CONNECT cloud platform.

The new XRIZE 3D printer will allow users to create functional resin and composite parts in a full range of colors. As with RIZE ONE's first product, the printer uses a patented Advanced Polymer Deposition (APD) process. To obtain full-color products, extrusion of thermoplastics and inkjet printing with functional compounds (“ink”) through industrial printheads are simultaneously used. Depending on the composition, the ink can impart color to the product (cyan, magenta, yellow, and black) or change the properties of the thermoplastic. RELEASE INK special repellent ink is sprayed between the backing and the product, loosening the bond between them, making it easy and quick to manually remove the backing immediately after printing is complete.

With RIZE ONETOUCH software, users can quickly and easily apply text, graphics, and texture maps to monochrome part files and import color CAD files. The

XRIZE also features a heated build chamber, auto-calibration bed, automatic filament change, and an intuitive, high-resolution touch screen for process control and diagnostics.

The XRIZE 3D printer can be used in a variety of applications from full color prototyping, marketing, entertainment, consumer products, to medical and surgical applications.

Key features:

• Four channels for color printing and a dedicated channel for Release Ink

• Build area (camera dimensions) XYZ: 200 x 200 x 310 mm

• Layer thickness: 250 µm or 125 µm

• Resolution: x/y 300dpi; Z 200dpi at 0.125 mm layer thickness

• Plotting accuracy: X / Y: +/- 127 µm, or +/- 3 µm / mm, whichever is greater, and Z layer thickness: +/- (250 µm or 125 µm)

• Device dimensions: 535 x 915 x 647 mm

• Weight: 61 kg

RIZE also introduced two new materials. The first is RIZIUM CARBON, an engineering grade thermoplastic filament reinforced with carbon fiber. RIZIUM CARBON is ideal for functional prototyping. The second is RIZIUM ENDURA, a fibrous filament that provides high print accuracy and good impact resistance. It is ideal for making large functional parts and is also compatible with RIZE color inks.

The first is RIZIUM CARBON, an engineering grade thermoplastic filament reinforced with carbon fiber. RIZIUM CARBON is ideal for functional prototyping. The second is RIZIUM ENDURA, a fibrous filament that provides high print accuracy and good impact resistance. It is ideal for making large functional parts and is also compatible with RIZE color inks.

The company also announced a new RIZE CONNECT software solution that will allow RIZE ONE and XRIZE 3d printers to be remotely controlled from computers or mobile devices, control and receive notifications, which will increase production efficiency. With RIZE CONNECT, users can also improve production safety by implementing digital part identification (QR codes, version control for part tracking). RIZE CONNECT will be available in 2019.

Material source: 3dVision

~~~

Follow us!

3DVISION - Art to embody ideas

3D printing, casting plastics, mocking and other production

Sale of 3D printers, scanners and materials

~~ ~~

Subscribe to the author

Subscribe

I do not want

1

More interesting articles

6

Follow author

Subscribe

Don't want

Introduction

So, good day to all! This is my second post. ..

..

Read more

199

Subscribe to the author

Subscribe

Don't want

Here I am again :)

With good and joyful news.

But first I want...

Read more

dagov

Loading

11/08/2017

195

Subscribe to the author

Subscribe

INSTEAD OF RISE

You are here

Home

THE BOSTONON RIZE COMPANY, THAT DEVELOPED THE FULL COLOR 3D PRINTING PROCESS AND IMPLEMENTED IT IN THEIR XRIZE SYSTEM, IS SUSPECTED TO END OPERATIONS.

Kerry Stevenson, founder of the popular online 3D printing publication Fabbaloo, announced this in his article "The Demise of RIZE?" yesterday.

Recall that RIZE has developed an innovative approach to 3D printing that combines FFF and inkjet technologies. This made it possible to use special inks for easy separation of models and supports, the ability to apply serial numbers and various markings to products during the printing process, print color products, etc.

During his investigation, Kerry Stevenson contacted Eugene Giller, co-founder of RIZE, and learned that the company was experiencing financial difficulties in 2021, which led to the departure of employees. Apparently, the $40,000 XRIZE system was priced too high for the market.

In the fall, the company auctioned off its intellectual property portfolio and other assets, which Eugene Giller himself purchased for his new company, Palitra.

In her second article yesterday, "The Rise of Palitra and Low Cost Full Color 3D Printing For All," Kerry Stevenson notes that the new Palitra company intends to support existing RIZE customers as well as distribute equipment and materials. But the most interesting thing is that with Palitra it is planned to bring RIZE full color technology to the market at a much lower price - less than 10 thousand US dollars, and possibly less than 5 thousand if there are enough orders.

But the most interesting thing is that with Palitra it is planned to bring RIZE full color technology to the market at a much lower price - less than 10 thousand US dollars, and possibly less than 5 thousand if there are enough orders.

The explanation is that the RIZE full color system was simply too expensive. Its cost largely depended on the use of extremely expensive components, which were the only ones available at the time the machine was developed. Meanwhile, today there are many alternative components that can significantly reduce the cost of developing a similar full-color 3D printing system.

For example, according to Giller, each printhead in the XRIZE system cost about $1,500, and the system required THREE of them. Whereas now it is possible to purchase equivalent printheads almost an order of magnitude cheaper.

Palitra isn't quite ready to launch yet, Giller said, but it's expected to be something to see on the company's website in February.