Homemade 3d printer enclosure

9 Amazing DIY 3D Printer Enclosure Ideas – Clever Creations

Open-frame 3D printers, like the Ender 3, have become a common sight amongst consumer printers. Open frames help to keep the manufacturing costs low but make it difficult to 3D print with high-temperature filaments such as ABS and Nylon.

A 3D printer enclosure is an ideal solution for this issue. It increases the safety of your printer and isolates it from the external environment. 3D printer enclosures can be bought off-the-shelf, but there are also plenty of DIY enclosures made of cardboard, plastic, or metal.

Let’s take a look at some of the best DIY 3D printer enclosures that you can build for your printer that do not cost a fortune!

Why Use a 3D Printer Enclosure?

Open-frame hobbyist 3D printers offer limited material compatibility and safety. They expose components to dust and dirt and have no air-filtration system. There is also a risk of pets and children interfering with the 3D printing process or touching the hot elements of the printer.

An enclosure minimizes these drawbacks by isolating the 3D printer in an enclosed space. It helps to maintain a constant temperature which comes in handy when 3D printing with high-temperature filaments like ABS and Nylon. It further aids in noise reduction, making 3D printing at home or in offices more convenient.

You can also add an air filtration system to the enclosure to filter out any 3D printer fumes, thus increasing the safety of your 3D printing area. Not to mention, enclosures also make 3D printers more aesthetically pleasing and easier to integrate into your workspace.

To summarize, a 3D printer enclosure increases the material compatibility, print quality, and usability of your printer.

Which Enclosure to Get?

There are a few options when it comes to 3D printer enclosures. You can buy an enclosure off-the-shelf or make your own from scratch.

DIY 3D printer enclosures can be cheap if you want them to be, but they do require a bit of effort and time to put together. The best enclosures are made from materials that are both sturdy and have good thermal insulation properties.

The best enclosures are made from materials that are both sturdy and have good thermal insulation properties.

If you’re looking for an enclosure that is easy to set up and does not require any DIY skills, then we suggest buying an off-the-shelf 3D printer enclosure. These are typically made out of plastic or aluminum and come with all the necessary fixtures and fittings.

Another alternative is to simply buy an enclosed 3D printer, but those come at a significantly higher cost.

Recommended:

The 9 Best Enclosed 3D Printers

Whichever direction you choose to go in, make sure to measure if you have enough space on your 3D printer table or workbench.

If you want a 3D printer enclosure that is fully customized to your 3D printer model and specific needs, then you will have to make your own. Now let’s look at some cheap and creative DIY 3D printing enclosures!

Cheap 3D Printer Enclosure Ideas

DIY Enclosures

IKEA LACK 3D Printer Enclosure

Image: Mikolas Zuza via Prusa3D

The IKEA Lack enclosure is a recognizable and robust DIY 3D printer enclosure. It is cheap, easy to build and customize, and is modular enough to accommodate any future changes in the enclosure design.

It is cheap, easy to build and customize, and is modular enough to accommodate any future changes in the enclosure design.

This enclosure uses a couple of IKEA Lack tables stacked on top of one another. You can use these tables as per your preferences. Usually, though, the top one is used as a 3D printer bay, with the bottom one for storing tools. The design allows you to move your power supply outside and protects the electronics from high temperatures.

There are a variety of designs available for free with detailed guides, and you can build them within a day. The IKEA Lack table enclosure is great for small to medium-sized 3D printers like the Prusa i3 MK3S+ and Creality Ender 3 as it is. And with some 3D printed leg extensions, you can even fit taller printers like the Creality CR-10 Smart Pro.

If you want to make things as easy as possible, you can even buy the required plexiglass panels as a pre-made kit.

DIYE Pack of 5 Plexiglass V1 1/8 Acrylic Sheet for IKEA Lack 3D./91f3dfd02cdc286.s.siteapi.org/img/70095ab103eae1c6a64808b85496f592e398cf55.jpg) ..

..

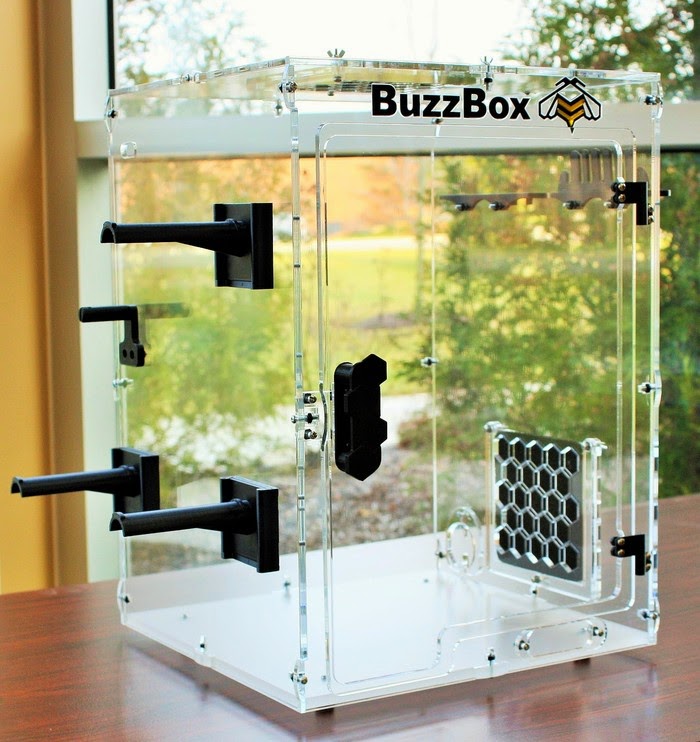

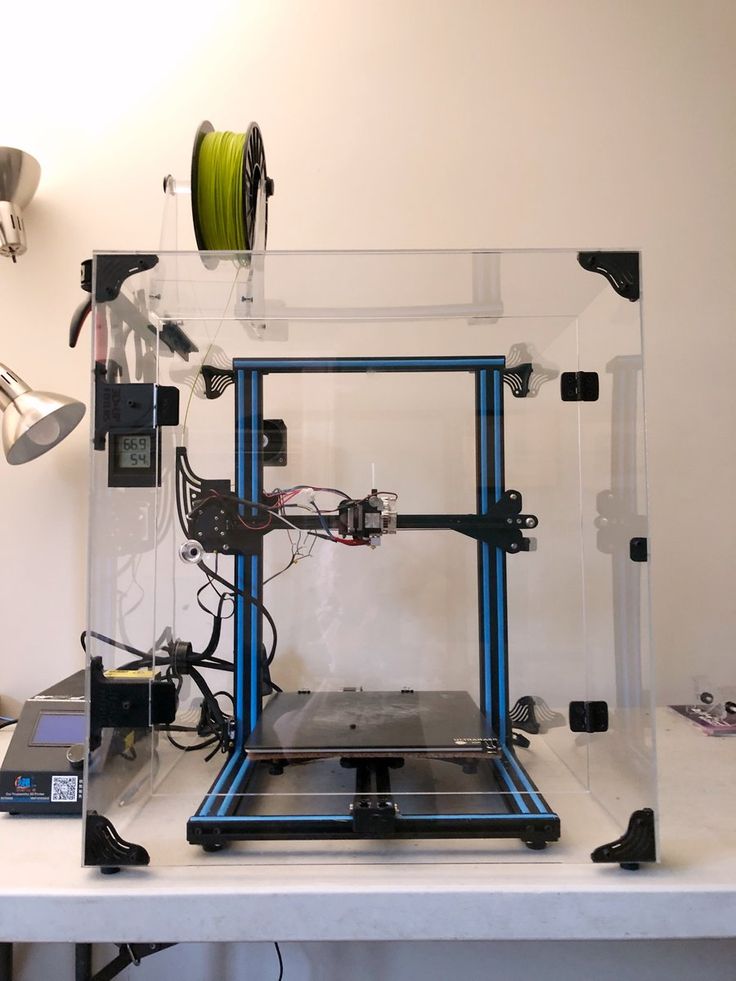

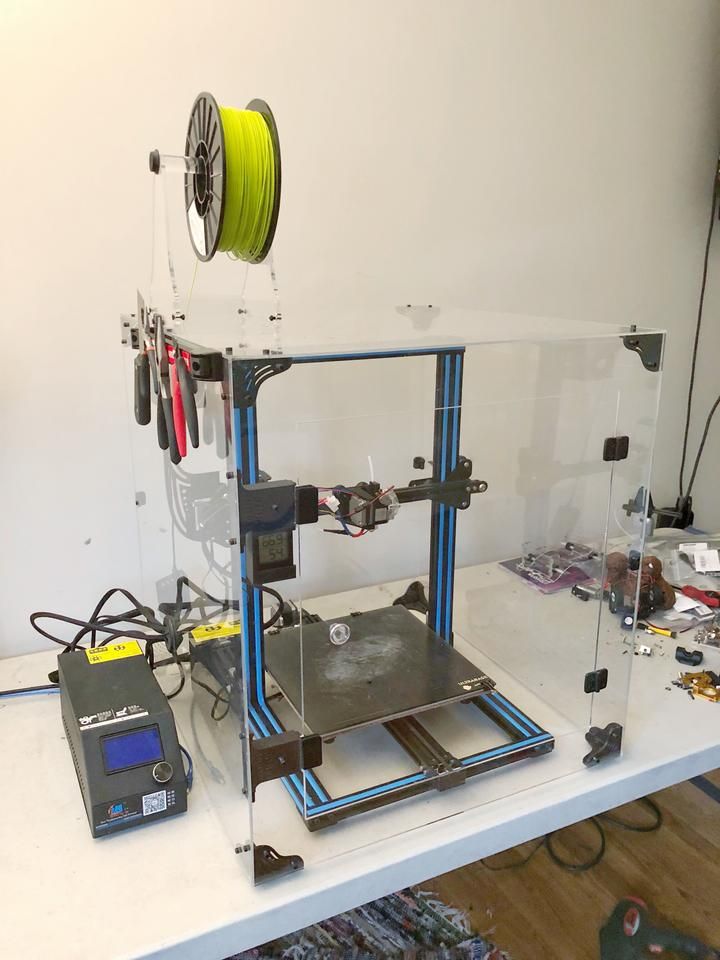

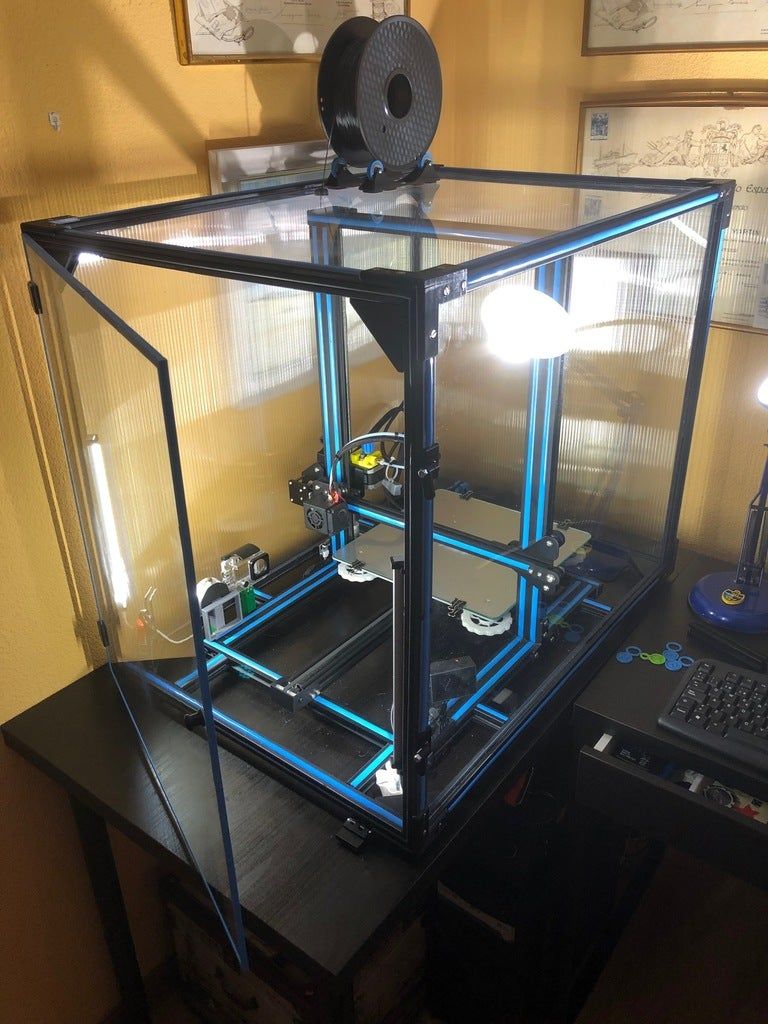

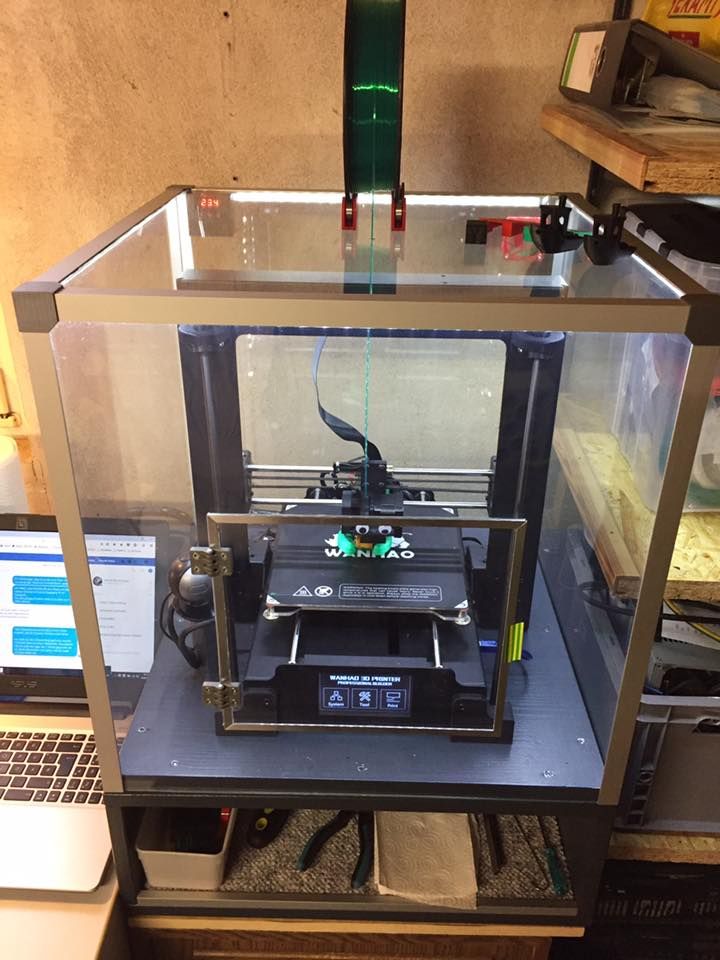

Aluminum Extrusion Enclosure

Image: Namsted via Imgur

Aluminum extrusions are a great and easy way of building a structural frame. These are lightweight, strong, and easy to machine, making them ideal for building a 3D printer enclosure.

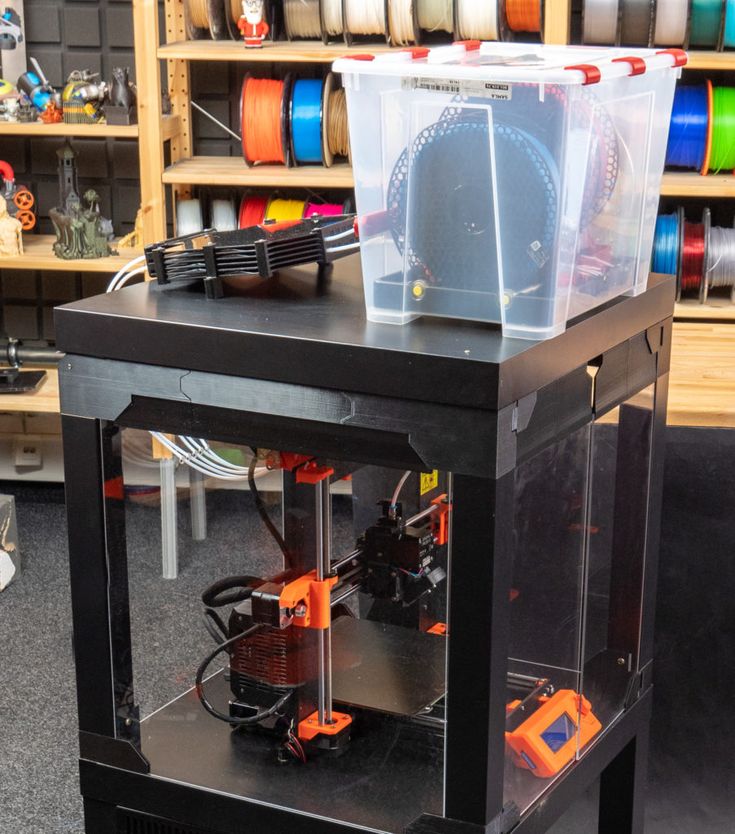

This aluminum extrusion enclosure gives better stability and durability than the IKEA Lack design. The maker has used custom-sized aluminum extrusions to accommodate a Prusa i3 MK3S+ 3D printer in the middle. The top is used for filament spools, and you can store your tools in the bottom section.

The enclosure is covered up with acrylic panels on all four sides, giving the print chamber good visibility. You can adjust the height of all four feet to get a leveled horizontal plane.

The project is not for beginners, as you will need to have some experience with machining and building things. But, if you’re up for it, it will prove to be an excellent learning project for you. An aluminum enclosure is very customizable, lasts longer, and acts as a perfect house for your 3D printer.

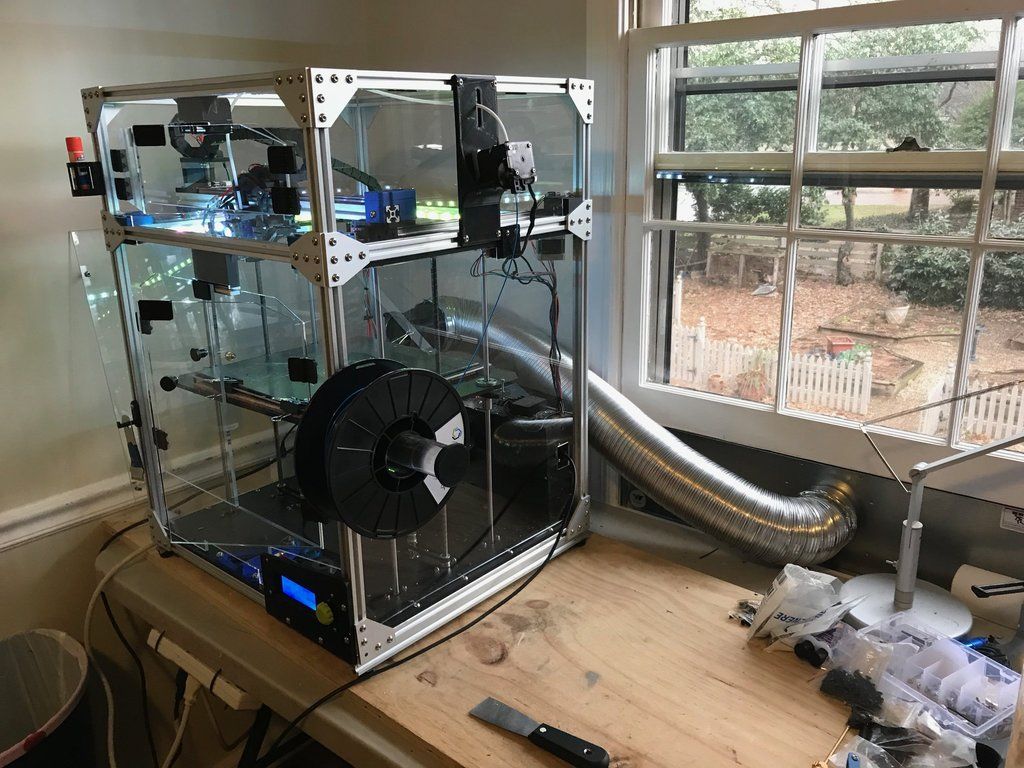

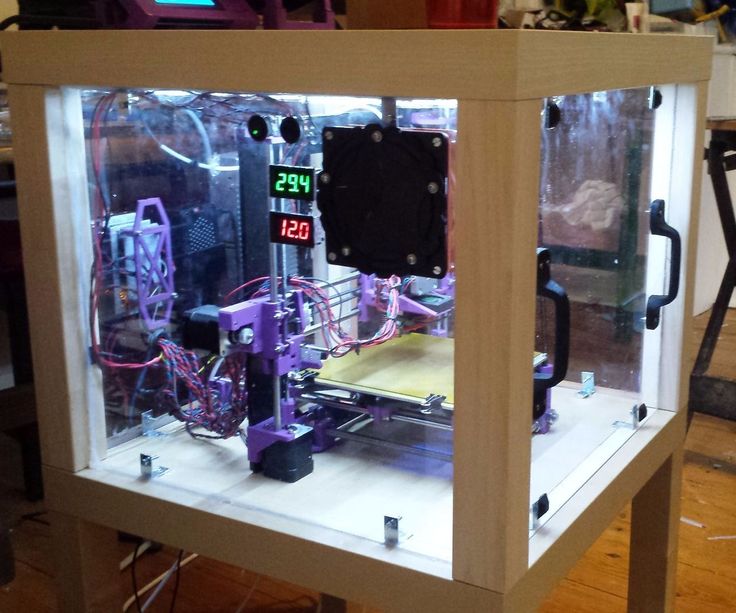

DIY Smart 3D Printer Enclosure

Image: Jure Korber

This smart 3D printer enclosure comes with a suite of electronics and sensors. It has a 3.5 inch LCD screen, a smoke detector, door sensors, air filtration, temperature, humidity sensor, and controllable LED lighting.

The 3D printer enclosure is divided into two compartments. The bottom one is explicitly designed to fit a Prusa printer and the top one to store eight spools of 1 kg filaments at a time. The enclosure has a custom PCB board that lets you easily wire up and control its various features.

You can get the STL files of certain 3D printed parts for free on Thingiverse. But if you want a detailed guide, along with BOM, build photos, and other aids, you will have to pay a fee to the designer. If you have the time and money, a smart 3D printer enclosure like this is an excellent DIY 3D printer enclosure for most popular open-frame 3D printers

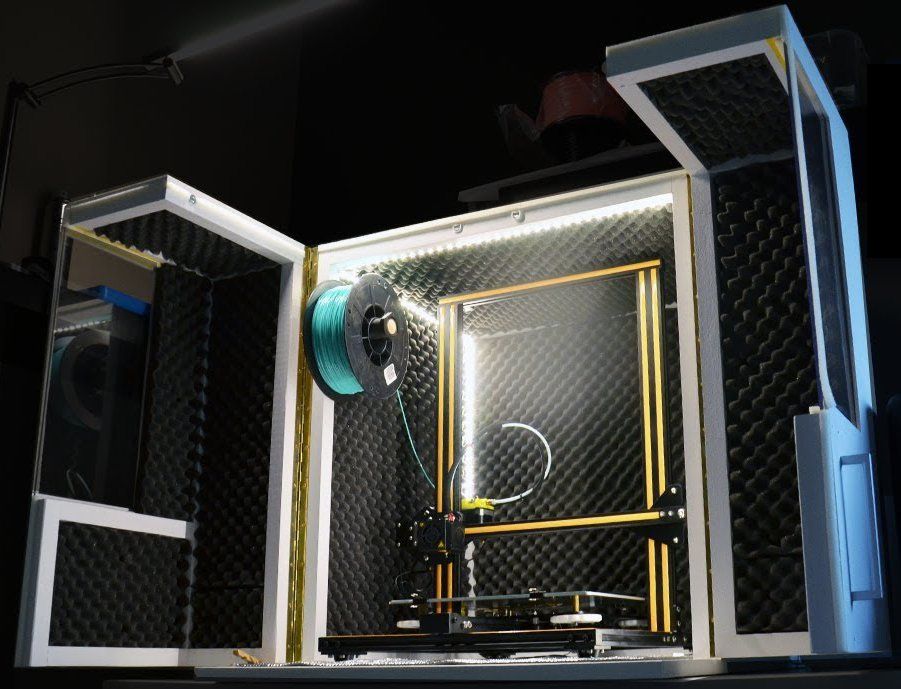

Sound-Insulated Enclosure

Image: Spare Time Shop via YouTube

Open-frame 3D printers can get noisy, and the constant buzzing and the whirring of stepper motors can get irritating after a while. This issue is most relevant if you 3D print in a living space or an office environment. This is where this sound-insulated enclosure steps in.

This issue is most relevant if you 3D print in a living space or an office environment. This is where this sound-insulated enclosure steps in.

As far as traditional enclosures go, they reduce noise up to a certain extent; yet, a sheet of acrylic can only do so much in terms of noise reduction. This sound-insulated enclosure, on the other hand, is made of wood, which has an acoustic foam lining to absorb the 3D printer noises.

This enclosure is big enough to accommodate a Creality CR-10 with filament spool and has dual doors and a transparent window to easily view your 3D printer. You can place the electronics of the CR-10 on the outside of the box, letting you control your 3D printer without opening the build chamber.

The enclosure is relatively easy to build and reduces noise considerably. The sound-insulated enclosure is a great option to get rid of any noises and 3D print in your living areas.

IKEA Pax 3D Printer Enclosure

Image: DollaSign via Reddit

This IKEA Pax enclosure is a wardrobe for your 3D printers. It is cost-effective and saves a lot of floor space when you want to enclose many 3D printers. Compared to the Lack enclosure from above, it offers similar functionality, albeit in a smaller footprint and relatively budget pricing.

It is cost-effective and saves a lot of floor space when you want to enclose many 3D printers. Compared to the Lack enclosure from above, it offers similar functionality, albeit in a smaller footprint and relatively budget pricing.

You can stack up to three 3D printers in the PAX enclosure and still have some room left for filament spools, tools, and other electronics. All power supplies can sit outside the enclosure, thus protecting them from high temperatures. To add to its functionality, you can include some Neopixel LED lights.

Adafruit NeoPixel Digital RGB LED Strip - Black 30 LED [ADA1460]

72 Reviews

Check PriceBecause the shelves are modular, you can easily move them around to fit 3D printers of varying heights. The major drawback of the PAX design, however, is its lack of transparent panels. Other than that, the IKEA PAX enclosure is an easy, quick and cheap solution for enclosing many 3D printers at once.

Resin 3D Printer Enclosure

Image: majorbrogains via Reddit

Even though resin 3D printers come with an enclosure, you need a separate space to store the printers, resin bottles, and prints like your 3D printed miniatures. This enclosure is an IKEA BRIMNES cabinet with ample space to store and display all your resin 3D printing equipment and minis.

This enclosure is an IKEA BRIMNES cabinet with ample space to store and display all your resin 3D printing equipment and minis.

The entire cabinet is divided vertically into two separate parts, giving you the ability to efficiently sort out your goodies. You can store the 3D printer itself in one half, while the other half can take in a washing station. And with a bit of DIY, you can vary the shelves’ heights and customize them to perfectly fit your minis’ collection, resin bottles, and other resin 3D printer accessories.

There is air ventilation within the enclosure with the exhaust on the top. It helps to throw out harmful 3D printer fumes and keep away the foul smell. You have enough space to accommodate popular resin printers like the Elegoo Saturn S and Phrozen Sonic Mighty 4K.

Considering the price, ease of use, and accessibility, using an IKEA BRIMNES as DIY 3D printer enclosure is an excellent solution for clearing up your resin workplace.

Repurposed Dishwasher Enclosure

Image: antialiasedpixel via Reddit

Repurposing things is an excellent avenue in the DIY area, and what better way than to use an old dishwasher as a 3D printer enclosure. This one easily fits an Prusa i3 3D printer and still has room at the top to mount a filament spool.

This one easily fits an Prusa i3 3D printer and still has room at the top to mount a filament spool.

The Prusa’s footprint is 16.5×16.5×15 inches, while the area within the dishwasher is 21x23x25 inches. This dishwasher has enough room to fit in the Creality Ender 3 (Pro/V2) and others of similar sizes. And the spare room that’s left can be utilized to fit in some LEDs, a Raspberry Pi, and a webcam for remote monitoring and control of the 3D printer.

The main disadvantage is that there is not much room for further customization. You will need to change the dish washer to accommodate any future updates to the 3D printer, not very practical!

Otherwise, the enclosure is one of the best ways to repurpose an old machine into something useful and save some money.

Ready-to-Buy Enclosures

Official Creality Enclosure

The official Creality enclosure is one of the best ready-to-use designs to cover up your 3D printer. While it is designed for Creality 3D printers, you should have no issues using it for other 3D printers of similar sizes.

The enclosure uses aluminum rods for its structural strength and an aluminum-lined fabric to enclose the 3D printer on all its sides. The internal aluminum lining is made up of flame-retardant material.

The Creality enclosure does a good job at keeping hot air inside and maintains stable temperatures well. It also comes with a single window on the front of the box to view your 3D prints in progress.

With a little bit of wiring, you can move out the LCD controller and power supply to the outside of the enclosure to work with even higher temperatures. For just under $70.00, the Creality’s Enclosure is an effective solution to print with warping filaments while keeping fumes in and dust out.

Creality Ender Enclosure for 3D Printer, Fireproof Dustproof 3D...

Check PricePhotography Lightbox

Image: Make360

While a photo lightbox is not designed for 3D printers, it does a great job as a 3D printer enclosure. It doubles as both a photo studio tent and an enclosure and gives you great lighting for pictures of your 3D prints.

This lightbox has two adjustable LED bars that cumulatively house 126 LED lights giving you a bright and well-lit inside area. It also gives you four PVC backgrounds for shooting various scenes and highlighting different shades of your 3D prints. And you can adjust the front cover to either fully cover up the 3D printer, or keep it open for ventilation.

It is a decent step up over the Creality enclosure and aids in photographing and taking videos of your 3D prints. The enclosure is easy to assemble and use, while also being convenient to store when necessary.

This enclosure is an ideal choice for enclosing your 3D printer and still having the flexibility to use it as a photo lightbox when you need it.

Photo Box, SAMTIAN Photo Light Box 32x32x32 Inches 126 LED Light...

Check PriceBuying or making a DIY 3D Printer enclosure: What to consider

Size

The size of the DIY enclosure should be just enough to fit your 3D printer. It should not be too big, as this makes it more difficult to heat the print area and makes it harder to move around if you need to.

Ease of Access

You should be able to easily access your 3D printer when it is in the DIY enclosure. Locking latches are a great addition that lets you lock and open the enclosure at will

Material

A DIY 3D printer enclosure should be made of a durable and heat-resistant material. The material should also be easy to clean. Plexiglass is a good option for 3D printer enclosures as it is durable, easy to clean, and heat resistant.

Smoke Alarm

Installing a reliable smoke alarm at the top of the enclosure can alert you in time if your 3D printer catches fire. It is a worthwhile investment that can help keep you safe.

First Alert SCO501CN-3ST Wireless Interconnected Combination Smoke...

Check PriceFire Suppression

If you want to be extra safe, you can install a fire suppression system that kicks in when the 3D printer enclosure gets too hot. A popular choice is the Blazecut T-series.

Soundproofing

One of the main disadvantages of 3D printing is the noise it produces. This can be a problem if you are trying to print in a shared space or if you just want to keep the noise down.

This can be a problem if you are trying to print in a shared space or if you just want to keep the noise down.

3D printer enclosures can help with this by soundproofing the area around the printer. Adding acoustic foam panels to your enclosure will help reduce sound levels significantly. Always make sure you get fire resistant ones, however.

TroyStudio Acoustic Studio Absorption Foam Panel, 12 X 12 X 2 inches...

1,412 Reviews

Check PriceWindows

Adding a window to the 3D printer enclosure can help you monitor the progress of your 3D prints.

Lighting

You might want to consider installing LED lights inside the 3D printer enclosure. This will help you see the 3D prints better and also aid in taking pictures or videos of them.

Price

The price of 3D printer enclosures can vary depending on the size and features. 3D printer enclosures can be bought or made. If you are making your own 3D printer enclosure, you will need to factor in the cost of all the materials as well as your time.

Frequently Asked Questions

Is a 3D printer enclosure necessary?

A 3D printer enclosure is not strictly necessary, but it can be beneficial in terms of safety and maintaining optimal printing conditions. Enclosures can help to minimize drafts and other external factors that can impact the print quality, and they also provide a barrier between the hot printer components and curious fingers (especially important if you have young children or pets in the home).

If you are interested in purchasing a 3D printer enclosure, there are many different options available on the market to suit a variety of budgets and needs.

How do 3D printer enclosures work?

3D printer enclosures work by creating a controlled environment for the 3D printer. This helps to protect the 3D printer from dust, debris, and fumes. It also helps to maintain a constant temperature around the 3D printer, which is important for preventing warping of high-temperature filaments.

How do you enclose a 3D printer?

A 3D printer can be enclosed in a variety of ways. Some printers come with an enclosure that is already built in, while others use the addition of an enclosure for safety reasons.

Some printers come with an enclosure that is already built in, while others use the addition of an enclosure for safety reasons.

One common way to enclose a 3D printer is by using a box made out of cardboard or plastic. The box should be large enough to fit the printer and the printing material, and it should have openings for the print head, filament feeder, and other cables. The box can be sealed shut with tape or clamps to keep fumes and heat from escaping.

Another option is to build an enclosure out of plywood or acrylic sheeting. This type of enclosure is more permanent and can be customized to fit the specific needs of the user and 3D printer.

Do 3D printer enclosures need ventilation?

3D printer enclosures do not need ventilation if the material being printed is not fumes-emitting. If you are printing with PLA, for example, there should be no issue with keeping your enclosure sealed. However, if you are printing with ABS, it is recommended that you provide some form of ventilation to deal with the build-up of fumes.

Do I need an enclosure for PLA printing?

PLA prints very well without an enclosure, so you likely don’t need one unless you’re printing in extremely cold temperatures. If you do want to use an enclosure, make sure it’s well-ventilated so your print doesn’t overheat.

How hot should a 3D printer enclosure get?

There is no definitive answer to this question as it depends on the specific 3D printer and filament being used. As a ballpark range, a temperature somewhere between 30 and 60 degrees Celcius is the right range for FDM 3D printer enclosures.

Should I enclose my Ender 3?

You should enclose your Ender 3 if you want to protect it from dust, dirt, and other debris. Additionally, enclosing your printer will help to maintain a consistent temperature and protect against accidental contact.

An enclosure is one of the top Ender 3 upgrades we recommend people to start with when modding their printer.

Recommended:

The Best Ender 3 (V2 / Pro) Upgrades

Should a 3D printer enclosure be airtight?

There is no single answer to this question as it depends on the specific printer and application. In general, though, airtight enclosures can be helpful in preventing fumes and particles from escaping the printer and contaminating the environment. They can also help protect the printer from dust and other debris.

In general, though, airtight enclosures can be helpful in preventing fumes and particles from escaping the printer and contaminating the environment. They can also help protect the printer from dust and other debris.

However, if the enclosure is too tight, it can create problems with heat retention and airflow, which could lead to a decrease in printing quality or even damage to the printer. It’s important to find a balance between creating an effective enclosure and maintaining optimal printing conditions.

Conclusion

A 3D printer enclosure is an effective way to increase your 3D printer’s material compatibility. It further aids in printing with warping filaments like ABS and Nylon by maintaining a constant temperature. It saves the printer from external dirt and dust and improves the print quality.

With DIY 3D printer enclosure designs, you have the flexibility to customize the enclosure to your specific needs and install as many features as you’d like in it. It is also relatively easy to build a cheap, low-cost solution, for example with a simple cardboard box.

It is also relatively easy to build a cheap, low-cost solution, for example with a simple cardboard box.

But, it can be tedious for many users, requiring lots of time, effort, and money. Whereas the ready-to-buy designs lack customizability but offer an easy, quick, and cheap solution.

Let us know your thoughts on the list, and if you have anything else to add, feel free to comment below.

What Is a 3D Printer Enclosure & Can You Build Your Own?

File settings, printer parts, and an array of other factors impact the quality of every 3D print that you produce. An enclosure can be an excellent tool for those who want to improve the quality of their 3D printing projects, but what exactly does a 3D printer enclosure do?

Let’s take a look at the key features of a 3D printer enclosure, along with some ideas that can help you to build your own.

Enclosed vs. Open 3D Printers

Image Credit: ESA/Wikimedia Commons When most people think about 3D printers, they will imagine a bony-looking frame-type design like the one in the image above. For hobbyists, common printers like the Creality Ender 5 and the Original Prusa i3 are very popular choices, but most of the printers in this price range don’t come with enclosures.

For hobbyists, common printers like the Creality Ender 5 and the Original Prusa i3 are very popular choices, but most of the printers in this price range don’t come with enclosures.

The Strateo3D IDEX420 3D (pictured above) is a fully enclosed 3D printer featuring plastic paneling that is wrapped around a heavy-duty steel frame. As you can see, this type of machine looks quite different from the types of 3D printers that most hobbyists choose to buy.

Fully enclosed 3D printers aren’t the only option. Many of today’s 3D printer manufacturers offer enclosures to fit specific printers, and you can even find generic enclosures that can do a good job. It’s important to keep in mind that some “enclosed” 3D printers actually have open tops, making them far more similar to open 3D printers.

The Key Benefits of an Enclosed 3D Printer

Keeping your 3D printer enclosed can seem a little over-the-top, especially when you’re used to very forgiving materials like PLA. There are plenty of excellent reasons to choose a 3D printer with an enclosure, though, and this goes beyond simply making your machine look cool.

There are plenty of excellent reasons to choose a 3D printer with an enclosure, though, and this goes beyond simply making your machine look cool.

More 3D Printing Materials

Warping, poor adhesion, and other 3D printing problems can often be caused by the environment around a printer. Warping, for example, is usually caused by a temperature differential between the top and bottom of the object that is being printed. With materials like PLA and PETG, a heated bed can be enough to solve this issue.

Materials like ABS and nylon are near-impossible to print effectively without an enclosure. You need to be able to control the temperature surrounding your prints, stop airflow from cooling the material early, and minimize dust and other debris while printing. An enclosure can help you to achieve all of these goals, making it possible to print with a wider range of materials.

Improving 3D Printing Quality

Improving 3D printing quality takes time, effort, and knowledge, at least in most cases. Using an enclosure can be an easy way to skip the hard steps, giving you higher-quality prints thanks to the greater control we mentioned in the last section. Most 3D printing hobbyists are very happy to be able to achieve this goal by simply covering their printer.

Using an enclosure can be an easy way to skip the hard steps, giving you higher-quality prints thanks to the greater control we mentioned in the last section. Most 3D printing hobbyists are very happy to be able to achieve this goal by simply covering their printer.

Health & Safety

There are a lot of questions around the web surrounding 3D printing and safety. PLA is widely considered to be safe to print with adults, children, and pets in the room, but materials like ABS can be more dangerous.

As an example, ABS releases a carcinogenic substance called styrene gas when it is heated up. Using an enclosure can help you to trap this gas, venting it out of the building using fans and ducting, to make your print space safer.

Having an enclosure on your printer also provides a line of defense between the machine and your children/pets. Young people and animals won’t always understand the danger of a working 3D printer, but you can keep them safe without having to stop your project.

Sound Dampening

It’s no secret that 3D printers can be very noisy. Fans, stepper motors, and even PCBs can make a racket when you are using your printer, but an enclosure can help to dampen these sounds and make the printer easier to live with. This is great for 3D printing hobbyists who have to share their space with other people who may not be quite as enthusiastic about 3D printers.

Buying a 3D Printer Enclosure

Getting your hands on a pre-made 3D printer enclosure can be achieved in a couple of different ways. Budget will often be the most significant constraint that people will face when choosing an enclosure, so we have organized this from most expensive to cheapest.

3D Printers With Enclosures

Buying a 3D printer that already has an enclosure is arguably the most expensive route to go down. This is only because you are also buying a new printer at the same time, though, so it may not be such a bad option for those already in the market for a machine.

The Creality CR-200B represents the most affordable end of this market, but this printer comes with a small build volume: just 200mm x 200mm x 200mm. The FlashForge Creator 3 is considerably more expensive but features dual extruders and a much larger build volume, and you can find other fully enclosed printers from different companies.

An Enclosure for Your 3D Printer

As 3D printing retailers stock an increasingly wide variety of printing materials, enclosed printers are becoming more popular. This has prompted companies like Creality to sell their own 3D printer enclosures that are “designed” for the printers they sell. In reality, these enclosures are very similar to indoor plant growing tents, though this doesn’t mean that they don’t perform.

Generic 3D printer enclosures can also be found on the market. Buying the right product can be trickier when you go down this route, as you will have to measure your own printer to make sure that you buy the right size.

Related: The Best 3D Printers

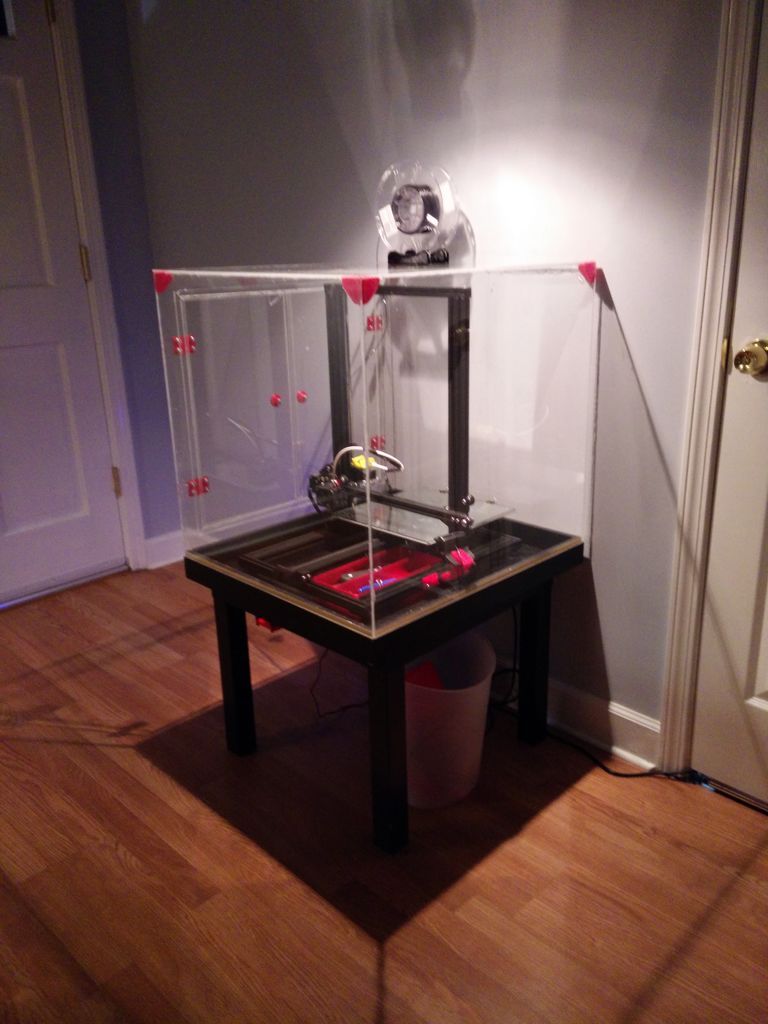

Building a DIY 3D Printer Enclosure

Finally, it’s time to discuss the most popular way to get your own 3D printer enclosure: building it yourself. DIY 3D printer enclosure projects can be found across the web, making it nice and easy to get started. You even have one of the key tools you’re going to need: a 3D printer.

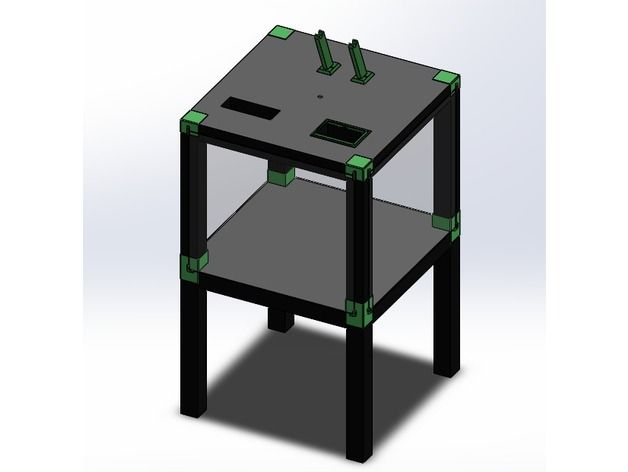

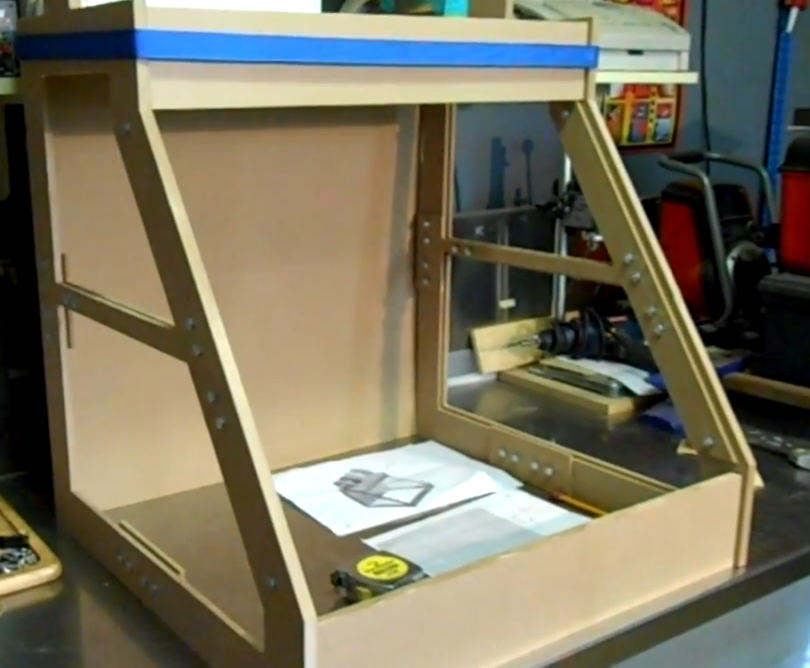

DIY 3D Printer Enclosure and Standing Desk

This DIY 3D Printer Enclosure and Standing Desk by Morley Kert is a large option for printers that have significant build volumes, but it can be scaled down to fit your machine. You will need woodworking skills (and some power tools), a range of materials, and, of course, a 3D printer to complete this project.

Once completed, this tall 3D printer enclosure can act as a standing desk with an additional cabinet for your 3D printing tools and accessories.

DIY 3D Printer Enclosure for Under $50

While you may not be able to get exactly the same materials as used in the project video, this low-cost DIY 3D printer enclosure by Just Barran demonstrates creativity and ingenuity. Very few projects of this nature can be achieved so affordably, especially when the end result looks so good.

Very few projects of this nature can be achieved so affordably, especially when the end result looks so good.

The enclosure itself can be upgraded with fans to give you the ability to ventilate the enclosure with ducting or simply into the space around you.

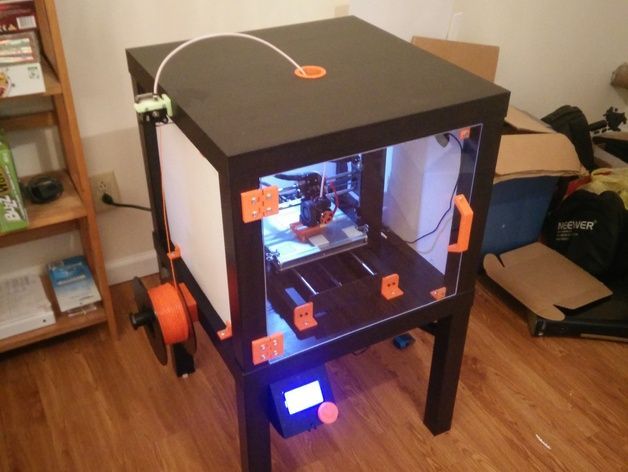

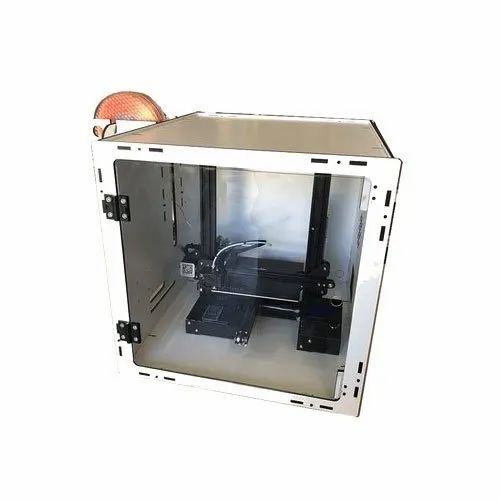

IKEA 3D Printer Enclosure

If you’ve been interested in 3D printing for some time, it’s likely that you’ve seen ideas like this IKEA 3D printer enclosure by BaldGuyDIY before. You will need to 3D print some brackets, get your hands on some acrylic, and put together some IKEA furniture, but this option is easy, tidy, and fits many of the most popular printers on the market. Adding some lighting, fans, and even cameras can be excellent upgrades for this enclosure.

Using a 3D Printer Enclosure

3D printer enclosures are great tools for hobbyists and professionals alike. Improving your print quality, the range of available printing materials, and the safety of your 3D printing, even DIY enclosures are a great choice. That said, you could always choose a 3D printer that already comes with an enclosure.

That said, you could always choose a 3D printer that already comes with an enclosure.

We print the simplest case for a homemade device / Sudo Null IT News

Printing a suitable case for your device is probably the most popular thought when introducing any inventor to 3D printing technology. But in practice, everything turns out to be not as simple as in an advertisement for a 3D printer, and under the cut, I will tell you in more detail what conclusions I came to in trying to compose a convenient case design.

Everything is fine with 3D printing - it's just a magic wand for the craftsman, except that most will only be able to afford models of printers in the lower price range. And after taking possession of a 3D printer, most, like me, will face the imperfection of budget 3D printing technology, namely FDM technology (layer-by-layer deposition - uses most of the available printers), regardless of whether you assembled the printer yourself or bought it in a store. The main problems are the shrinkage of the material after cooling, which causes deformations and inaccurate linear dimensions of the printed parts. If you came up with some cool design in the likeness of mass-produced cases, then the case of your device will be generously saturated with neat bevels, holes or snaps exactly in size for ease of assembly ... even being a professional in modeling and taking into account the problems listed above when printing, you will get tired of mixing all these sizes and think in what position it is better to print each detail so that nothing bends during shrinkage, as is often the case. Shrinkage is evil, especially frustrating and time-consuming when your design has many dimensions that need to be accurately maintained for assembly and a beautiful look. But not everything is so bad and this is not a reason to retreat).

The main problems are the shrinkage of the material after cooling, which causes deformations and inaccurate linear dimensions of the printed parts. If you came up with some cool design in the likeness of mass-produced cases, then the case of your device will be generously saturated with neat bevels, holes or snaps exactly in size for ease of assembly ... even being a professional in modeling and taking into account the problems listed above when printing, you will get tired of mixing all these sizes and think in what position it is better to print each detail so that nothing bends during shrinkage, as is often the case. Shrinkage is evil, especially frustrating and time-consuming when your design has many dimensions that need to be accurately maintained for assembly and a beautiful look. But not everything is so bad and this is not a reason to retreat).

Based on my printing experience, I came up with a simple design for a prototype device box that will be easy to print on any fdm printer and suitable for many projects.

The design consists of two parts: the chassis - on which we will mount the parts, and the casing itself - which will hide all the shame that we soldered) One is easily inserted into the other and, for reliability, is fixed with a single screw at the back of the case.

The chassis is printed in a horizontal position to easily accommodate horizontal component mounting locations. Then I just glue them in the corners with droplets of hot glue, it's faster and easier to disassemble them later if necessary.

Chassis I recommend to generously pierce the bottom and sides to save material, less deformation during shrinkage and easier peeling off the table. I just extrude circles, do you remember what bubbling is?)

And I print the casing vertically. In this position, you can make thin even walls and the texture on almost the entire visible part of the body is obtained in one direction, it looks neat. If necessary, you can finish the mounting ears or legs.

Even if you can't exactly maintain the size the first time and you have to grind off the edges of the chassis a little with a file, there will be absolutely no traces of processing from the outside of the device.

The tapered feet on the bottom of the body are printed without supports, eliminating post-processing and saving material/time.

If you print on adhesive tape or glue, the surface that sticks to the table is usually uneven and needs to be processed. With this approach, it will be on the back side of the case (on the side of the interface connectors), which no one usually sees.

I printed this case from PLA plastic with a 0.3mm nozzle on a Russian-made MZ3D-256 printer with the following structure settings: wall thickness 0.6mm, infill 23%, without substrate printing.

The size of the case in my example allows you to place inside an arduino uno, a pair of relays, a stepper motor driver, a voltage converter, various communication connectors and control / indication elements.

Of course, you will draw the chassis of the required size for your modules, as long as the printer's printable area is enough to print the casing in one piece. In my opinion, this design will be the most simple and convenient.

The benefit from the case is obvious) The design does not fall apart, wires do not stick out of the device, it does not look like a bomb, no one knows that it works on an arduino and it is not a shame to show it at an exhibition or give it to programmers to write firmware.

I hope this information was useful to someone, thank you for your attention.

The pictures show not an audio amplifier, but an irrigation controller, just audio connectors are very convenient for connecting low-current loads.

UPD. Thanks to UFO for taking the community on board and to all the participants for the warm welcome :)

And of course files, I save time for inventors)

We print a case for a transceiver on a 3D printer

August 22, 2022

Finding a suitable case is always a problem. In my projects, shielded enclosures are needed, which introduces additional complexity. I tried to buy ready-made cases on AliExpress. It wasn't cheap and I had to wait a long time. Hulls were sometimes lost or arrived damaged. I tried to make cases from sheet aluminum myself. Processing metal with hand tools, and I don’t have others, is, let’s say, an amateur task. In addition, with my hands, the cases come out crooked. This time it was decided to try 3D printing. Yes, with a little imagination, you can achieve normal shielding here.

In my projects, shielded enclosures are needed, which introduces additional complexity. I tried to buy ready-made cases on AliExpress. It wasn't cheap and I had to wait a long time. Hulls were sometimes lost or arrived damaged. I tried to make cases from sheet aluminum myself. Processing metal with hand tools, and I don’t have others, is, let’s say, an amateur task. In addition, with my hands, the cases come out crooked. This time it was decided to try 3D printing. Yes, with a little imagination, you can achieve normal shielding here.

Enclosure designed in OpenSCAD:

This is an enclosure for an HF transceiver. Its dimensions are 198 x 198 x 100 mm. The case takes 45 hours 37 minutes to print continuously and requires 584 grams of plastic. The source code of the project along with STL files can be downloaded here.

I printed the corpus in the evenings on weekdays, and also for ~9 hours on weekends. In total, it took a week of real time. Fortunately, the light was not turned off, and the models did not come off the table. I printed with 40% infill to keep the walls stiff and not bend. White PLA plastic was used.

Fortunately, the light was not turned off, and the models did not come off the table. I printed with 40% infill to keep the walls stiff and not bend. White PLA plastic was used.

Result:

The quality of the housing depends on the calibration quality of your 3D printer. My case came out with some minor flaws, but overall, quite nice. Definitely better than my handmade would have looked.

Remove the walls, and we see the following H-shaped structure:

For the central part, an aluminum sheet 1 mm thick is used here. The design allows, for example, to place the entire receiving path in the upper half of the case, and the digital part and PA in the lower half. They will be well shielded from each other, and the mounting holes for the boards will be hidden inside the case. Having removed four walls, we get access to all components at once. Comfortable.

The inside of the case, as well as the mounting brackets, are glued with aluminum tape. This is done for shielding. The case is designed so that in the assembled state there is contact between any two points of the screen. Everything is held on by M3 nuts and M3 screws x 6. The nuts are soldered into the mounting brackets with a soldering iron:

This is done for shielding. The case is designed so that in the assembled state there is contact between any two points of the screen. Everything is held on by M3 nuts and M3 screws x 6. The nuts are soldered into the mounting brackets with a soldering iron:

The case will cost you anywhere from $13 to $23, depending on which PLA you use, plus some for aluminum sheet, aluminum tape, as well as nuts and screws. It turns out 2+ times cheaper than a self-made case of the same size made of aluminum. A finished case of the same size is not yet a fact that you can find it.

It takes a long time to print the case, but it's still faster than shipping from Aliexpress. Its main disadvantage, it seems to me, is its vulnerability to high temperatures. I am now interested in QRP CW transceivers, where there are no high temperatures. In other projects, you have to figure out how to remove heat outside the case.

Addition: This case was used for the HBR/3B transceiver.