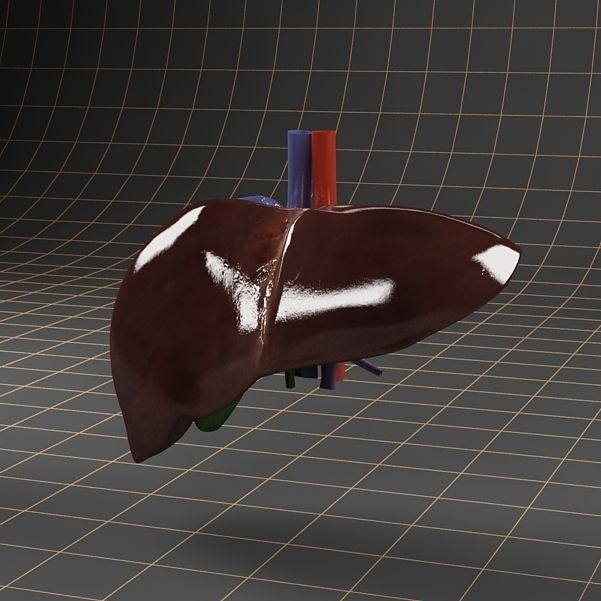

3D liver printer

Breakthrough: Volumetric 3D Printed Livers in Regenerative Medicine

Image courtesy of Testalize Me via Unsplash

Innovative 3D printing promises to deliver replacement human organs.

April Miller | Apr 14, 2022

Watch This Webinar

3D printing has emerged as a major driver of innovation across industrial fields. In regenerative medicine, the technology has been applied to tissue engineering – potentially paving the way toward the bioprinting of entire organs.

This year, a research team successfully fabricated working livers for the first time using 3D bioprinting technology.

For biomaterials specialists and engineers, here’s what to know about recent developments in 3D bioprinting (and the potential implications these developments may have for regenerative medicine as a whole).

3D-Printed Liver Organoids Could Have a Transformative Impact

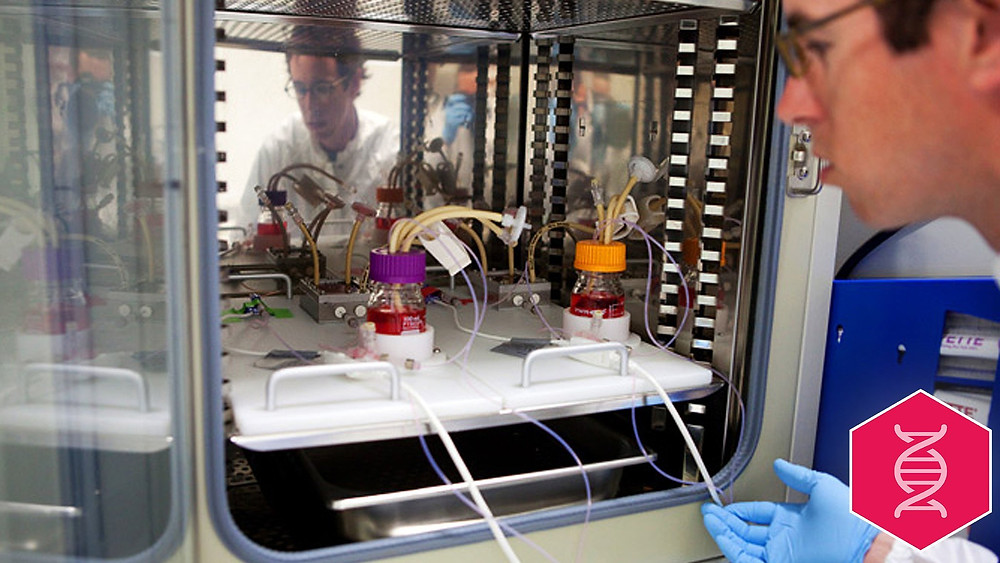

A research team, based at Utrecht University in the Netherlands, developed a new high-speed volumetric 3D printing method to create bioprinted livers.

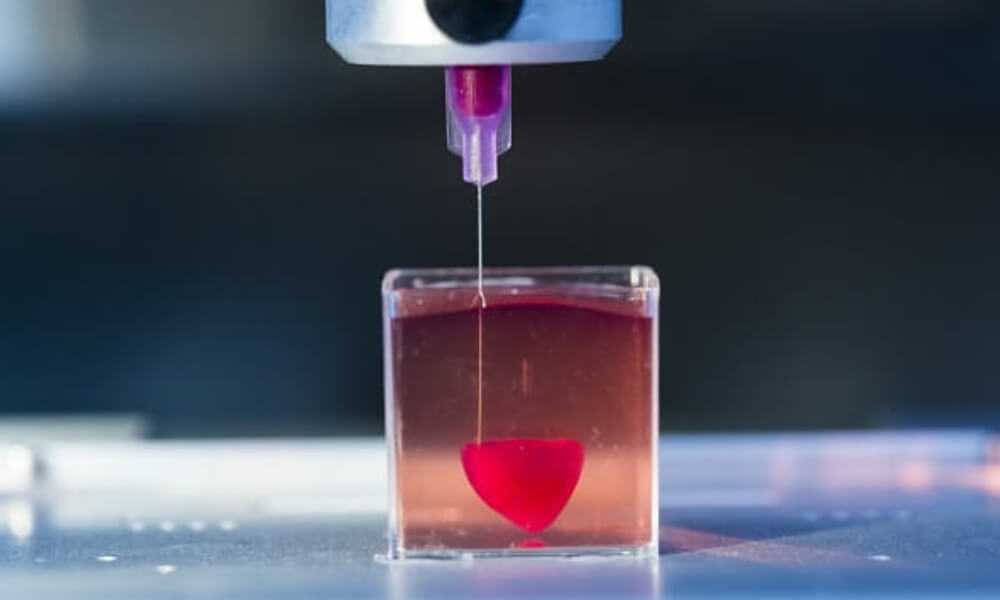

The team’s printing method leverages optical tomography to carefully shape gelatin hydrogels that contain organoids – tiny, three-dimensional tissue cultures derived from stem cells. The organoids were tuned using optical tomography to mimic the function of liver cells.

By using a unique, nozzle-less, and unlayered approach to printing with the material, the team was able to minimize mechanical stress on the organoids. A more conventional 3D-printing approach could have damaged the organoids during printing.

The team found that the bioprinted organoids demonstrated many of the functions that the liver performs in the body, like the synthesis of albumin, an important protein, and toxin filtration processes.

The team believes the technology may open up “new possibilities for regenerative medicine and personalized drug testing.”

How 3D-Printed Livers Fit Into the Current Regenerative Medicine Landscape

This 3D-printed liver joins a number of other successful experiments in bioprinting – including 3D-printed ovaries, thyroid glands, and skeletal muscle-like constructs, complete with their own bioengineered nerves.

The early skeletal muscle-like constructs could yield similar benefits – primarily muscle function restoration in patients who need reconstructive surgery following major injury or illness.

These 3D-printed organs and structures could eventually replace donated organs for transplant patients.

In theory, because engineers can use a patient’s own stem cells to 3D print organs, these organs could be recognized by the patient’s immune system as its own, reducing the likelihood of rejection and potentially eliminating the need for transplant patients to take immunosuppressive drugs.

Follow-up treatments for transplant patients can be intensive, and complications like organ rejection can require hospitalization.

Many patients have difficulty accessing medical care easily, like those with mobility disabilities or the roughly 20 percent of Americans who rely on rural hospitals. 3D-printed organs could simplify transplants significantly and potentially reduce the frequency with which these patients need to travel for follow-up care.

The Evolving Bioprinting Industry

The success of the Utrecht team in creating a liver-like organ also demonstrates how quickly bioprinting is evolving. The team first demonstrated their volumetric printing technique in 2019, just three years ago.

Their work led to the founding of Readily3D, a manufacturer of volumetric 3D bioprinters. The business made headlines last year when the company announced it would join a European project to develop a living model of the human pancreas.

If successful, the model could help provide a deeper understanding of the organ, potentially accelerating research of conditions related to the pancreas, like diabetes.

Similar projects could help scientists eventually create living models of most human organs and biological systems, providing living references for researchers studying challenging health conditions like cancer and heart disease.

What the Future of Regenerative Medicine May Look Like

Right now, the healthcare industry and most related sectors are undergoing some major transformations. The lingering impact of COVID-19, ongoing supply chain disruptions, and serious labor shortages have all put a significant strain on healthcare and primed the industry for change.

Innovations in 3D-printed organs and tissues could soon have a transformative impact on regenerative medicine and healthcare as a whole. Recent experiments with 3D-printed organs may pave the way for future innovations in personalized medicine and regenerative medicine.

April Miller is a managing editor of design technology at ReHack Magazine, as well as a contributing writer at sites such as Open Data Science and the Society of Women Engineers.

TAGS: Medical Technology Utrecht University

3D Printed Liver: Everything You Need to Know

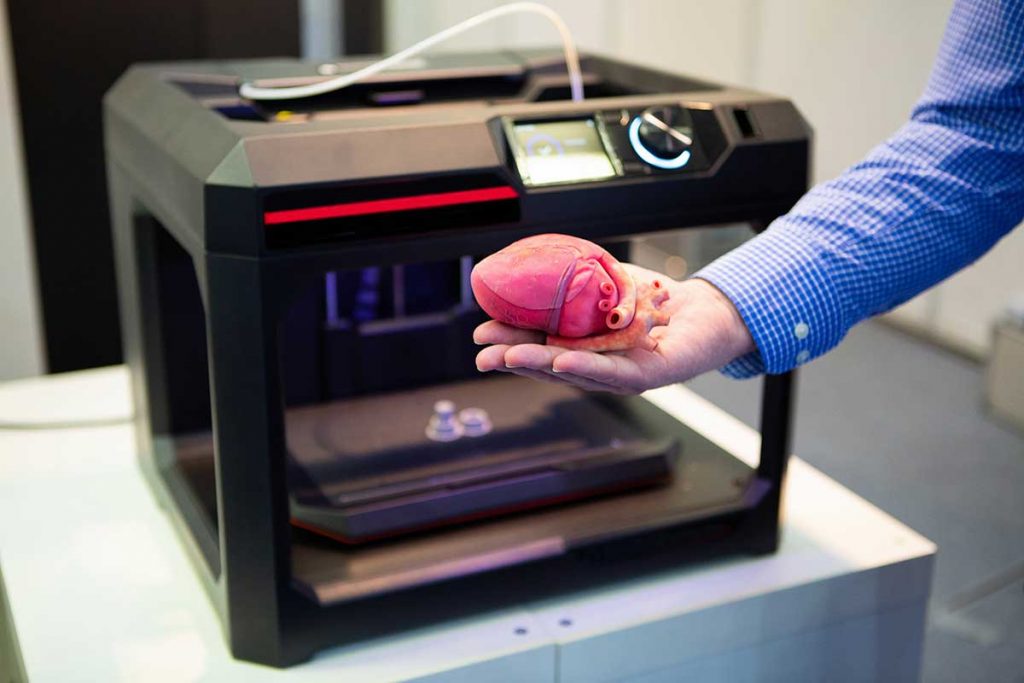

Since being invented in the 1980s, 3D printing has evolved into a catalyst for potential and innovation. Adapting to multiple industries, it’s been used for everything from printing vegan meat to 3D printed homes.

Adapting to multiple industries, it’s been used for everything from printing vegan meat to 3D printed homes.

But today, we’re going to discuss printing that hits closer to home and that’s 3D printed organs, more specifically, 3D printed livers. This science brings a wealth of opportunities to the medical industry that could lead to drastic positive changes in how future transplants and organ diseases are treated.

In this article, we’ll cover what a 3D printed liver is, how to bioprint a liver, and the scientific discoveries currently leading this industry.

- See also: Our feature story on 3D printed houses.

- For more on bioprinting: our complete guide to 3D bioprinting organs.

What Is a 3D Printed Liver?

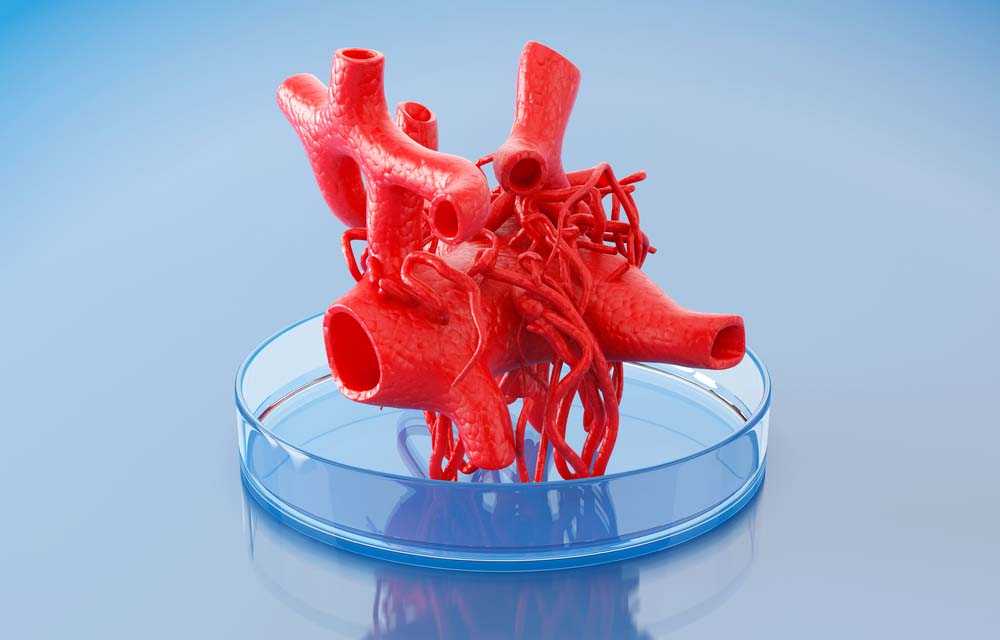

A 3D printed liver is well… a liver created through 3D printing. However, instead of simply printing an object shaped like a liver, scientists are using bioprinting to create a liver using a patient’s own cells.

Your liver is a filter for your body that constantly processes the toxins and nutrients in your blood and diet, breaking them down. Creating a 3D printable liver that contains all the necessary vascular intricacies and that can perform the acts above is complicated, but recent studies look promising.

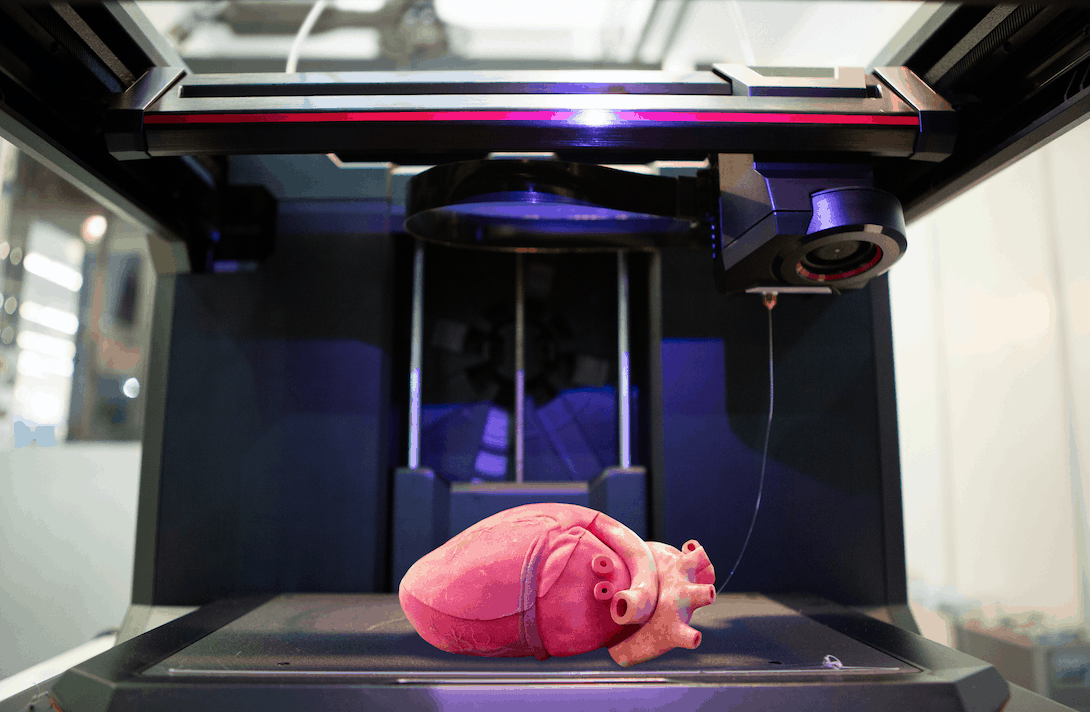

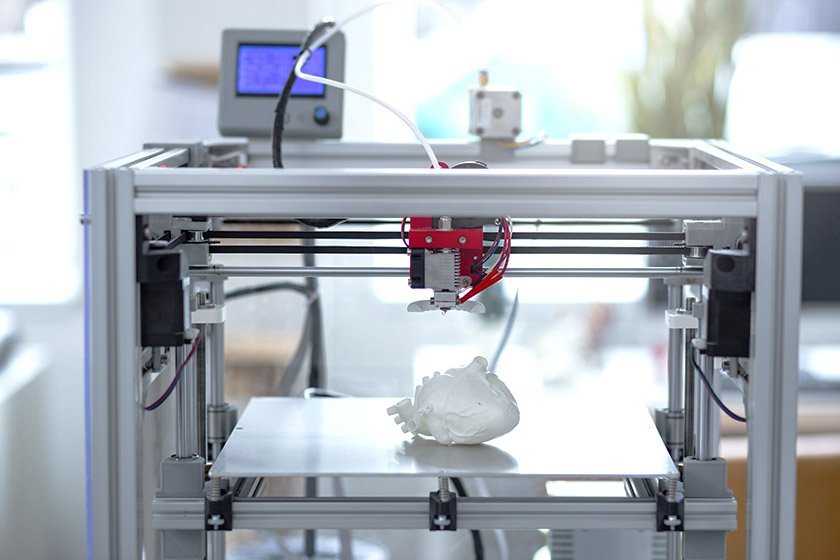

3D bioprinting livers are only the beginning as many organs, like the heart, are getting the bioprint treatment as scientists work to create transplantable tissues and organs from scratch.

Now, the liver isn’t perfected yet, but sizeable growth is happening.

See also: If you want to learn more about 3D printed hearts, check out our complete guide.

Using 3D Bioprinting to 3D Print Livers

Bioprinting is the technology that’s currently making this dream a reality.

Much like normal 3D printing, it uses a moldable substance to create 3D objects, but instead of plastic or other traditional materials, it uses a blend of bioink and biopolymer gel to create a hydrogel.

Think of bioink as the pigment and biopolymer gel as the plastic.

Bioink is made up of cells, and when bioprinting, the bioink uses the patient’s cells. That way the liver is an exact genetic match, and you can avoid transplant complications like rejection.

Biopolymer gel is the molecular scaffold that keeps the structure stable, and together they create a living material.

As it’s printed, it’s cryogenically frozen with carbon dioxide to solidify it into shape. To keep the cells alive throughout this process, the hydrogel maintains a liveable environment for the cells or an extracellular matrix.

When using a printed organ for human use, it has to have living functioning cells. Bioprinting is what makes that possible.

Industry Leaders

With an expected industry value of $1.95 billion by 2025, it’s no surprise that being the first to create a functioning printed liver is a huge motivation in multiple countries.

In a race to see who can monopolize this industry first, we’re greeted with back-breaking effort all over the world. However, only a few possess the ingenuity to lead this race.

However, only a few possess the ingenuity to lead this race.

University of California Breakthrough

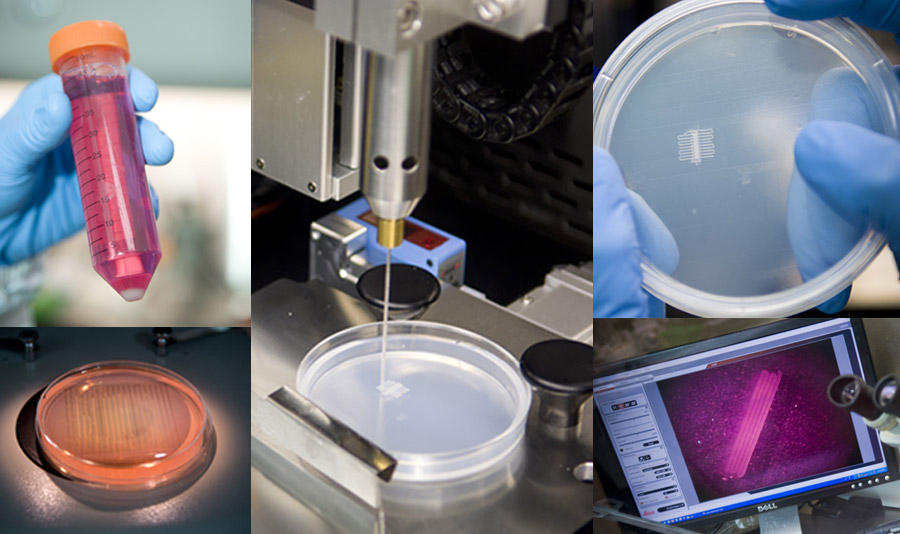

In 2016, in San Diego at the University of California, Dr. Shaochen Chen, a nanoengineering professor, 3D printed liver tissues that mimicked the liver’s structure and actions. It perfectly matched a real liver when examined under a microscope.

Stem cells harvested from the skin were combined with endothelial and mesenchymal cells and turned into liver cells. Endothelial cells are a single cell layer that lines blood vessels and helps develop connective tissue cells. Mesenchymal cells are bone marrow stem cells.

Stem cells are unique because they have the ability to become any type of cell. Skin, heart, blood, or liver, they’re the stem of all cells.

The tissue printing happened in two phases. Printed first was a honeycomb pattern of 900-micrometer-sized hexagons containing the stem-turned-liver cells. Then the supporting endothelial and mesenchymal cells were printed in between the hexagons.

The cells were printed on 3 x 3 mm squares, 200 micrometers thick, and sat to develop for 20 days.

Testing showed these samples sustained higher levels of enzymes necessary for the liver to metabolize many drugs.

When asked about the future of these tissue samples, Dr. Chen stated:

“I think that this will serve as a great drug screening tool for pharmaceutical companies and that our 3D bioprinting technology opens the door for patient-specific organ printing in the future.”

Dr. Shaochen Chen

Organovo’s 3D Printed Liver Tissues

Credited with setting the industry standard with the ExVive kidney and liver tissue and creating separate capillary blood networks that mimic the body’s function, pioneers Organovo are leading the race in California.

Following their ExVive success, and a multi-year deal with pharma giant Merck, they’ve begun working on clinical trials and developing 3D bioprinted liver tissue transplants.

Tremendous progress aside, bioprinting full-sized livers to help the medical community save millions is not yet possible.

However, Organovo’s 3D printed tissue patches can provide immediate benefits to patients on the transplant waitlist. Representing the difference between life or death, these small but powerful dollar bill-thick patches increase survivability and offer temporary solace as they can sustain a patient by 1-2 more years while they wait for a life-saving organ transplant.

Their goal was to start using these transplants in 2020, but we hope to see them in action this year.

Brazil’s 3D Printed Liver Spheroids

Last on our world tour is Brazil.

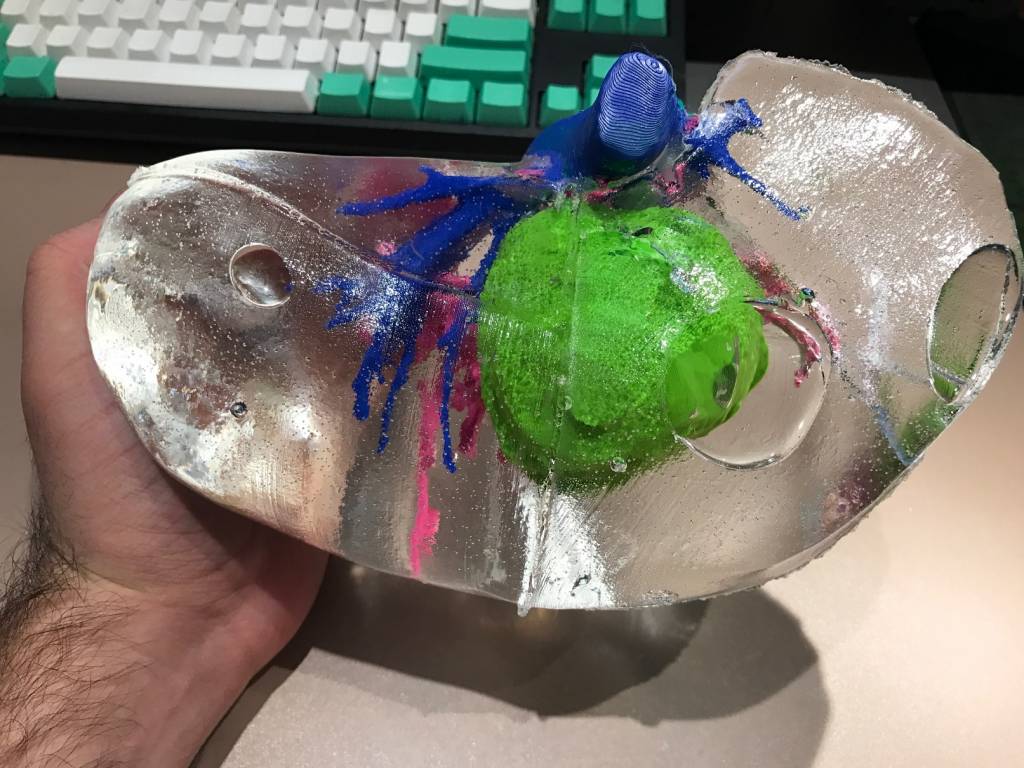

In recent 3D bioprinting developments, researchers in Sao Paulo have created a way to bioprint miniature livers, or liver spheroids. Using human blood vessels and Cellink’s Inkcredible bioprinter, it’s said this miniature liver can carry out all the functions of a normal liver.

From collecting the volunteer sample to manipulating the stem cells and personalizing the bioink, to finally printing the end product, the entire process took 90 days. Growing the actual cell structure took 18 days.

Growing the actual cell structure took 18 days.

If this liver became transplant viable, it would decrease wait times significantly.

According to Ernesto Goulart, co-author of the study, the researchers found a way to group cells together before printing, rather than printing them individually. The improved cell contact from being printed together allowed the spheroids to function for much longer.

Now, they’re working on completing this experiment on larger scale organs.

How Can 3D Printed Livers Save Lives?

There are multiple ways 3D printing saves lives. From early stages of testing to full-on transplants, 3D printable organs help speed up the medical process.

Faster and More Reliable Transplants

The main way 3D printing saves lives is through organ transplants.

30,000 people a year die from liver cancer alone. And that’s not including the dozens of other liver diseases that are equally as fatal.

Between all these diseases, thousands join an endless transplant waitlist, hoping not to become part of that statistic. Waiting for the unfortunate accident of a liver to become available, that’s free from damage and healthy, is not a reliable solution.

Waiting for the unfortunate accident of a liver to become available, that’s free from damage and healthy, is not a reliable solution.

Then on the off chance you do get a liver transplant, there’s always the possibility of your body rejecting it because it’s a foreign object.

However, with viable 3D organs, there’s the potential to cut down wait times or at least sustain a person’s liver for longer while they wait for a transplant.

A 3D printed liver from a person’s own cells also eliminates any possibility of rejection.

Transplant rejection poses a huge threat to patients’ lives because it’s our immune response to detect foreign objects and get rid of them. But when you use a 3D printed organ made from the patient’s cells, there is no foreign object to reject, and you help the body heal itself.

Taking away that possibility of rejection increases the success rate exponentially.

Efficient Animal-Free Testing

Another benefit is more efficient testing and clinical trials.

One of the big ethical debates in the medical world is animal testing. Before human trials can take place, scientists are bound by law to test on animals first.

With 3D organs, there’s no need to test on animals because there are no “unknown” factors. If you’re using someone’s cells to create treatments for them, there’s no surprise variable. You can also create surplus organs that can be used for testing as opposed to the unethical use of animal testing.

This would allow drugs and treatments to accelerate through the clinical trial process at a rapid pace and without harming animals in the process.

Better Training

Finally, there are some incredible training benefits.

Medical school students go through rigorous coursework and hands-on training with human organs, which is dependent on donated bodies.

3D printable organs would make it easier and more ethical to source organs for students to practice on, leading to more structured training and better-skilled medical professionals on the field.

Setbacks

One of the main struggles that keep 3D printing from saving lives is function.

Livers are an intricate design of capillaries, vessels, and structures that need to be printed perfectly to stay functional. Failing to do so restricts blood flow and shortens the lifespan of the 3D organ.

The printed liver also needs to be able to filters toxins as well as many other endocrine system functions, and achieving this is incredibly difficult.

Future Expectations

The future looks bright for 3D printed livers and the involvement of 3D printing in the medical industry as a whole.

With laboratories moving onto clinical trials and the race to enter the 3D printing market, the future of medicine has the potential to evolve quicker than anticipated.

And the medical industry isn’t alone. 3D printing has gone on to change the food and fashion industry too, truly becoming the Swiss Army knife of technology.

Other articles you may be interested in:

- 3D printed organs: bioprinting projects

- 3D printed hair and follicles

- 3D printed kidneys

- 3D printed livers

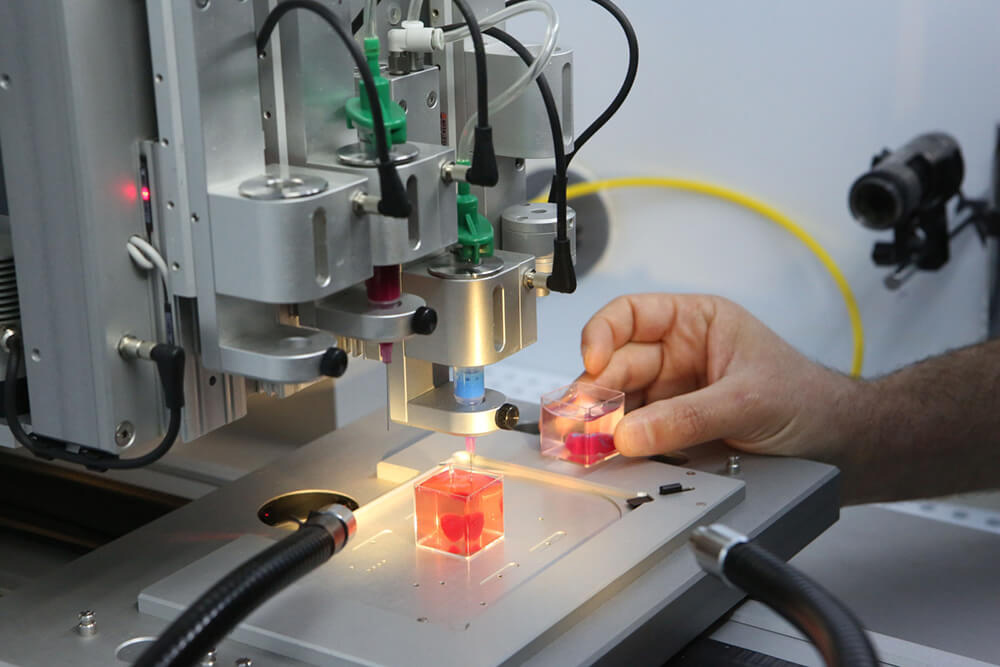

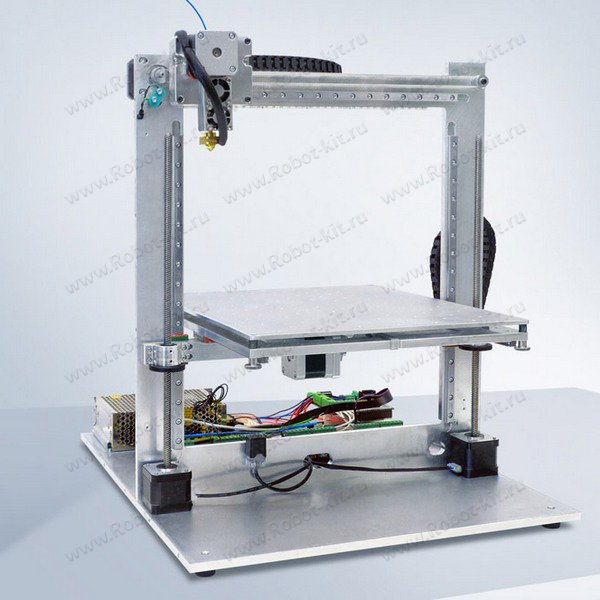

Robot printer for your liver.

What organs are scientists already able to print? | Science | Society

What organs are scientists already able to print? | Science | Society According to the UN, from 15 to 30% of patients die from the fact that they cannot find donor organs. Therefore, scientists are looking for ways to create them artificially. One way is bioprinting on a 3D printer. The technology is complex, with a lot of nuances, but progress is inexorable: science is moving medicine forward, bringing it to a new level.

As real

A human ear, grown from the cells of a 20-year-old female patient, was recently printed in the USA. The girl suffered from microtia, a rare congenital disease in which both external ears are underdeveloped or absent altogether.

Scientists from 3DBio Therapeutics first scanned the patient's healthy ear, then took cartilage samples from her and grew as many cells as needed for the second ear. The resulting material was mixed with collagen-based bioink, poured into a 3D printer, and an artificial organ was printed.

An implant called AuriNovo is already in clinical trials. The ear printed on the printer is almost impossible to distinguish from the real one. In addition, the implant contributes to the restoration of hearing. The developers expect that their technology will further significantly improve the quality of life of people with microtia. In addition, they hope that it can be used to restore other cartilage parts of the body, such as noses.

The ear printed on the printer is almost impossible to distinguish from the real one. In addition, the implant contributes to the restoration of hearing. The developers expect that their technology will further significantly improve the quality of life of people with microtia. In addition, they hope that it can be used to restore other cartilage parts of the body, such as noses.

The bioprinting method is used more and more in medicine. The first experiments in this area were carried out on conventional household 3D printers, which were modernized in laboratories. It was about twenty years ago, at the very beginning of the XXI century. In 2018, the global market for 3D printing in medicine was estimated at $973 million; by 2025, analysts expect it to grow to $33 billion, and by 2027, over $40 billion.

A heart for a midget

The pioneer of the industry is the American company Organovo. Its engineers pioneered the technology to print liver tissue. They also printed kidneys that can last up to two weeks. Medicines are tested on these organs. But the 3D printers used by Organovo are already capable of creating tissues for surgery and transplantation.

Medicines are tested on these organs. But the 3D printers used by Organovo are already capable of creating tissues for surgery and transplantation.

Organs are printed in Russia by bioengineers from 3D Bioprinting Solutions. They developed a device on which they printed and transplanted the thyroid gland into an experimental mouse.

Bioprinting technology places strict demands on the equipment. Firstly, very small nozzles are needed - much less than a human hair thick. Secondly, high precision is needed to lay out the cells exactly where they are needed. Thirdly, special bio-inks are used, which then function like normal tissue. It is also necessary to create microchannels that will feed some of the cells - a kind of blood substitutes.

In 2019, the world's first human heart was printed in Israel. Scientists have grown heart muscle cells from stem cells, which, in turn, have been “reprogrammed” from fat cells. The process took three hours. “The heart we received is completely biocompatible and fits the patient. This is a full-fledged working body, ”said the lead author of the study, Professor Tal Dvir .

This is a full-fledged working body, ”said the lead author of the study, Professor Tal Dvir .

True, a patient for such an organ would have had to be found somewhere in Lilliput - it was only 2.5 centimeters in size. Nevertheless, the authors of the experiment expressed the hope that in 10 years it will be possible to print a heart that is completely ready for transplantation to a person.

"Patches" from the inside

A few years ago, the Institute of Regenerative Medicine in Wake Forest (USA) made a device that prints two layers of a patient's own skin directly onto his wound. But even here there are reservations: experimental animals are still acting as the patient.

It looks like this. Inside the bioprinter (and it is quite large, the size of a room) they put a pig that has a wound on the skin. The built-in scanner studies the defect, the program calculates how many layers of skin need to be applied to eliminate it, builds a structure for wound healing, after which collagen (connective tissue cells) and the pig's own cells, or rather, the outer layer of its skin, are applied to it. This is how rejection is avoided. The printer can close a small defect in less than an hour.

This is how rejection is avoided. The printer can close a small defect in less than an hour.

When the device is ready for use in humans (and it shows great results in pigs), it can be placed directly in hospitals. It will come to the rescue of patients with burns, diabetic ulcers and other skin lesions that are unable to heal on their own. And, of course, it will come in handy in hospitals where soldiers and officers who have received wounds or burns come from the combat zone.

Chinese scientists went even further. They presented a robotic microprinter that can be introduced into the human body, where it will begin to produce new tissues. The device is 3 centimeters wide and 4.3 centimeters long. It is introduced into the patient's body through small incisions. Once inside, the device unfolds up to 6 centimeters and begins to form new tissues using 3D printing. Having done its job, the microprinter...dissolves.

Chinese researchers believe that it will be possible to treat stomach ulcers and other damage to internal organs. Such pathologies, they argue, have one in eight people in the world, and conventional methods of treatment have certain disadvantages. The robot-printer, which produces living cells for the formation of tissues and organs, can be launched first of all into the gastrointestinal tract, where it will “patch” the same ulcer.

Such pathologies, they argue, have one in eight people in the world, and conventional methods of treatment have certain disadvantages. The robot-printer, which produces living cells for the formation of tissues and organs, can be launched first of all into the gastrointestinal tract, where it will “patch” the same ulcer.

And in the more distant future, when the technology is improved, it will come to the aid of people waiting in line for organ transplants. These queues will simply disappear, and donors will no longer be needed. After all, a microprinter launched inside the body will print the organ we need from our own cells.

Probably many of us would very much like our liver to live to this time.

The liver will go to print - Nauka - Kommersant

Professor Vladimir Mironov is working to create spare parts for the human body as simply as for a car: take and print a human organ on a 3D printer.

Professor Vladimir Mironov

Photo: Courtesy of 3D Bioprinting Solutions

People have already learned how to print houses, cars, weapons, intricate details - almost everything. But the human organ, of course, is a much more complicated thing: firstly, in manufacturing, and secondly, then it will have to be used for a long time! A task for the Creator!

But the human organ, of course, is a much more complicated thing: firstly, in manufacturing, and secondly, then it will have to be used for a long time! A task for the Creator!

In 2003, Professor Vladimir Mironov discovered that individual ring fragments of the heart of a chicken embryo can merge, collect into a tube, when placed in a hydrogel in the form of a ring. Having discovered this, Professor Mironov and his colleagues took an inkjet printer, instead of ink, they placed cells in it and printed it. And a miracle: the cells survived. The authors of the miracle wrote an article in a scientific journal, and the idea of 3D bioprinting of biological objects was born.

And now there is a bioprinting company, 3D Bioprinting Solutions: Vladimir Mironov accepted the invitation of Alexander Ostrovsky, managing partner of Invitro, to become the head of the first laboratory in Russia that will directly deal with bioprinting, that is, the printing of living organs. In 2013, the laboratory began work.

“Five major achievements over the years, which show that we do not waste time in vain,” says Mironov, raising his hand with spread fingers.

3D bioprinting requires raw materials. In bioprinting, this role is played by tissue spheroids - microballoons consisting of thousands of living cells. The spheroids are stacked layer by layer, forming what should become a living organ. Previously, in tissue engineering, they used the technology of scaffolds (scaffolding, if in Russian): they did not allow the structure to fall apart. The first achievement of the 3D Bioprinting Solutions laboratory was to establish the production of tissue spheroids of standard shape and size, which made it possible to significantly speed up the bioprinting process.

Bioprinted mouse thyroid construct

Photo: Courtesy of 3D Bioprinting Solutions

The second achievement is the 3D printer itself, it was called Fabion: fabrication plus biology, Professor Mironov explains and says with a smile that the main thing is still beautiful sound . Approximately 80 companies produce such printers, Fabion is consistently in the top five, ahead of only a few competitors from the USA, Germany and Switzerland.

Approximately 80 companies produce such printers, Fabion is consistently in the top five, ahead of only a few competitors from the USA, Germany and Switzerland.

“The process of bioprinting is similar to creating a book on a printing press, that is, ink is needed,” says Vladimir Mironov, and if we follow the analogy, then 3D Bioprinting Solutions figured out how to make bioink - they became a viscous collagen (pork) protein. And that was the third achievement.

It's time to print the organ!

Question - which one? The heart or kidneys are too complicated, there are a lot of blood vessels. The liver is more homogeneous, but it is a large organ. Thyroid!

Raw material taken from mouse embryos. It took only nine spheroids (three for the gland itself, six for the vessels) to print the organ. The printed gland was then transplanted into a mouse whose own organ had been killed by targeted radiation. The implanted organ took root and began to work - albeit only by 50%, but this allowed the sufferer to live on.

“Thus, for the first time in the world, a functional, vascularized (that is, with vessels) mouse organ has been printed,” Vladimir Mironov minted every word.

This was the fourth achievement.

And here we come to the fifth, but the first most spectacular achievement of the laboratory 3D Bioprinting Solutions.

“We created an organ in space,” Professor Mironov effectively concludes the story.

— Why?

“It's all about weightlessness,” he replies.

There is a magnetic levitation, that is, in a floating state, bioassembly: the object is created not from the bottom up, but from all sides at once. The installation, which creates the necessary magnetic field, operates in the Dutch city of Nijmegen. 3D Bioprinting Solutions won a grant and received five days to install. Everything went great. But the electricity for the experiments took so much that it would be enough for the whole of Nijmegen. It became clear that an alternative method was needed.

Space, Professor Mironov understood. In two years, a bioprinter with six magnets instead of two was created, it received the name “Organ. Aut". Roscosmos supported the idea, and in October 2018 the bioprinter went into space on the Soyuz-10 spacecraft. Alas, it was an emergency launch. The astronauts, fortunately, managed to evacuate, and the remains of Organ. Avta can now be seen on display in the laboratory, they will soon be transferred to the Museum of Cosmonautics.

“Can you imagine our situation? Two years of work!” the professor winces.

But by December, in just two months, 3D Bioprinting Solutions had made a new Organ. Aut". And for the first time in the world, human cartilage and the thyroid gland of a mouse were printed in space using magnetic levitation on a 3D printer.

Professor Mironov had to hear many skeptical comments after the results of the experiment were made public: is it advisable to use such resources? And the criticism can not be called unfounded. But Vladimir Mironov explains: space technology is the 22nd century, European and American colleagues spend huge amounts of money on such projects, we must not fall behind!

But Vladimir Mironov explains: space technology is the 22nd century, European and American colleagues spend huge amounts of money on such projects, we must not fall behind!

And the value of a printed organ in the conditions of a catastrophic shortage of donor organs is cosmically high. Now patients are waiting for a transplant for several years - and they do not always wait, complains the director of the National Medical Research Center for Transplantology and Artificial Organs. Academician V. I. Shumakov Sergei Gauthier: “If bioprinting helps us create new organs as quickly as required, I will only support it. But so far, although there are successes, they are quite far from the final success. The mouse thyroid gland is undoubtedly a big step forward, but it should not be confused with a full-fledged human organ, even if only because of its size.”

Bioprinting will only make sense if the organ is printed directly from the patient's cells, academician Gauthier is sure: “If the organ is initially created from foreign cells, then for the patient, from the point of view of both ethical and purely medical aspects, it will be just as alien organ, as in organ donation. Although, in my opinion, bioprinting does not solve the ethical issue of transplantology simply because this issue simply does not exist, the ethics of transplantation is an international and generally recognized concept. Bioprinting should solve the problem of shortage of donor organs.”

Although, in my opinion, bioprinting does not solve the ethical issue of transplantology simply because this issue simply does not exist, the ethics of transplantation is an international and generally recognized concept. Bioprinting should solve the problem of shortage of donor organs.”

Of course, not only Professor Mironov has the results: in April, Israeli scientists managed to print a real heart exactly as Academician Gauthier says - from the patient's fat cells, which were converted into heart muscle stem cells, and then mixed with connective tissue and placed in a 3D printer.

Here the professor expresses skepticism: “Firstly, in their article, Israeli scientists call the heart personalized, although it is about two and a half centimeters in size, which corresponds to the size of a rabbit's heart. Is the rabbit a person? Secondly, so far it is just a piece of meat, not suitable for transplantation, or for anything else. No experiments have been done to confirm that the heart can function successfully. ”

”

— Why do we have an atomic bomb? - Vladimir Mironov asks a rhetorical question. - Because the state invested huge resources in its creation, and scientists were given opportunities and means for serious work. In China alone, two and a half million people are waiting for organ transplants. What kind of market is this? And we can take over a large part of this market. We have smart young people, we have experience and understanding of where and how to develop. The only thing missing is sufficient financial support!

— All hope for the state?

— Well, why is it necessary for the state? What, we have few wealthy people?

— And if there is enough funding, then when will we be able to...

— You understand, — Vladimir Mironov interrupts, — it's hard to answer this question, and I really don't like it when people ask me it. We work at the level of the Nobel Prize, but we will never get it. But the more active the funding is, the sooner the day will come when a 3D-printed organ will be successfully transplanted into a human. And whoever does this will have every chance of winning the Nobel Prize.

And whoever does this will have every chance of winning the Nobel Prize.

Yousef Hesuani, co-founder and managing partner of 3D Bioprinting Solutions, gave a more specific answer to this question: “I have less faith in private investors. Still, the time when their investments can pay off is still quite far away. Therefore, in my opinion, the state should play a leading role here.”

According to Mr. Khesuani, countries like South Korea or Singapore should be followed, where there are whole government programs to support young scientists involved in bioprinting research.

— When do you think, with sufficient funding, when will a printed organ be successfully transplanted into a human?

“It's hard to say exactly, but, according to rough estimates, by 2030,” he says.

Vladimir Mironov actually sees the same prospects as Khesuani: “My dream is to create a Russian national bioprinting center, in ten years to be the first in the world to print a functional, vascularized human organ and successfully transplant it into a patient.