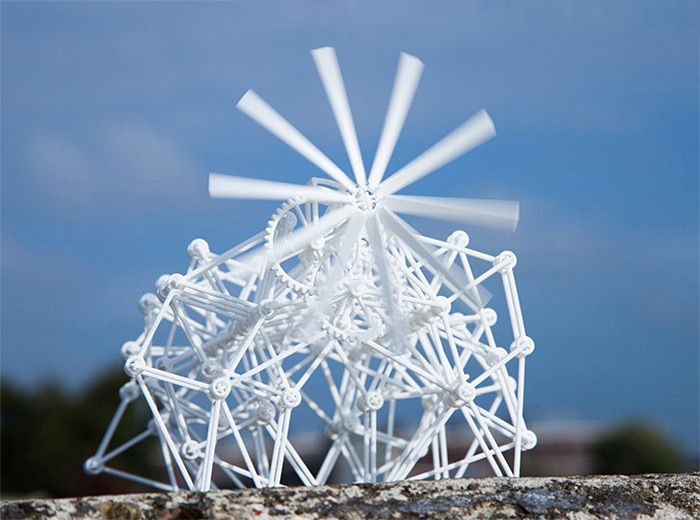

3D printed theo jansen strandbeest

This Fascinating 3D Printed Strandbeest Robot Takes Theo Jansen's Ideas One Step Further - 3DPrint.com

The year is 2015 and 3D printed robots have begun to evolve to a point where they are taking over the world!

OK, maybe we aren’t quite there yet. We are not living in a world that is similar to The Terminator films, but we have seen an ever-increasing use of 3D printing in creating custom robots, and if you are a follower of a man named Theo Jansen, you may actually be led to believe that these creatures are beginning to evolve by themselves. Relax though, this isn’t the case, and robots are far from becoming a threat to human beings. However, for one designer, named Charles Ford, 3D printing has allowed him to create quite the unique robot, based on the designs of Theo Jansen.

Ford, who began building BEAM robots ten years ago, has since graduated to creating more complex robotics via advanced technology such as Arduino.

“There has been an explosion of cheap, reliable sensors in the last ten years, and it is total fun to experiment with them,” Ford tells 3DPrint.

com. “I received a Makerbot Replicator 2 this winter and am just now learning to create 3D designs and print them.”

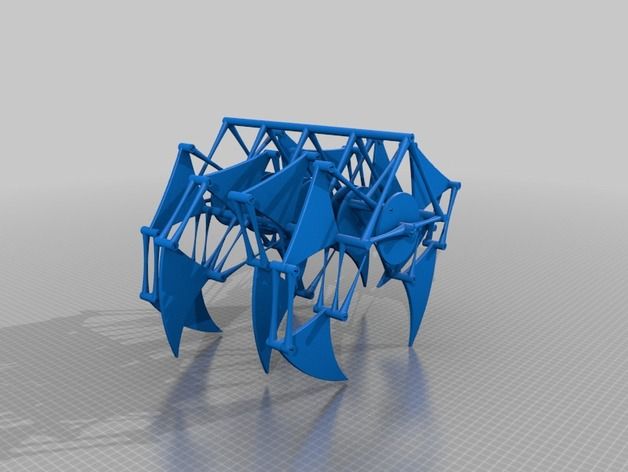

For one of his projects, Ford elected to use an idea that he first saw years ago from Theo Jansen and his unique wind-powered beach creature, called the Strandbeest. The creature, which eventually evolved into 3D printed form, has been an inspiration to Ford in this latest endeavor, has garnered much attention among designers worldwide.

“I did some research on the proportions [Jansen] uses to make the leg mechanisms work,” Ford tells us. “I saved drawings and articles, thinking some day I would make a creature. Then I came across an article in Servo magazine that detailed adding motors to a Strandbeest kit available on Ebay. The idea of a light-seeking walking Strandbeest robot popped into my head.”

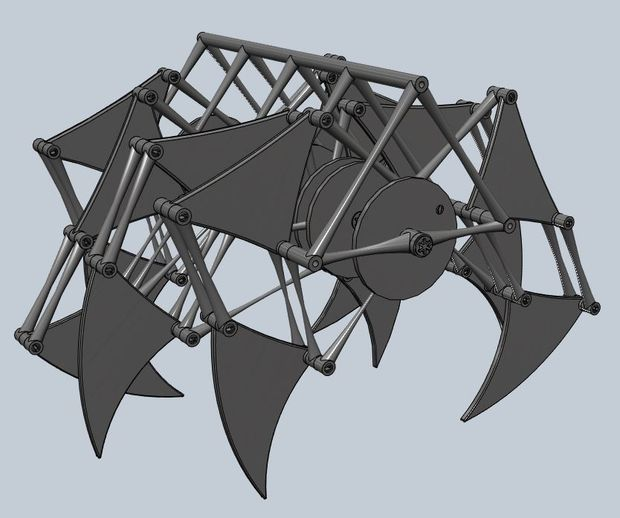

Ford isn’t one for throwing good ideas aside, so he set out to create his very own Strandbeest robot. After creating a quick mockup using foam core, bamboo skewers, coffee stir sticks and hot glue, Ford was able to get a good idea of the motor layout that his robot would require. Using SketchUp, he was able to draw up the required pieces.

Using SketchUp, he was able to draw up the required pieces.

While the leg mechanism is actually part of a kit that Ford purchased, there are several Instructables tutorials on creating your very own 3D printed leg mechanism. He could have easily 3D printed his own leg mechanism, but instead elected to 3D print other parts of the robot.

“The center section where the crankshaft connects to the hacked 9 gram servo motors are attached, and the upper deck with the Arduino, L298N motor controller, and photocell eyes are all 3D printed,” explained Ford. “The robot can walk around the room searching for the brightest light source, avoiding obstacles along the way. The real fun is just watching how the legs work. It is very stable and can traverse rough surfaces easily, but it’s really the motion of the legs that is so fascinating. “

The parts took just a couple hours to 3D print at a layer height of .2mm. As for the electronics used, the robot utilizes a Sparkfun Mini 5 volt Arduino board, with the aforementioned L298N to control the motors. The robot uses sensors that direct it toward the brightest light source, and it features whiskers, similar to those of a cat, that sense if it has run into a wall or other object. When this happens, it automatically backs itself up.

The robot uses sensors that direct it toward the brightest light source, and it features whiskers, similar to those of a cat, that sense if it has run into a wall or other object. When this happens, it automatically backs itself up.

As you can see in the images and videos, this Strandbeest robot has a lot of similarities to Theo Jansen’s original creation, except this one is robotic in nature.

What do you think about this robot? Would you have elected to 3D print the leg mechanism yourself? Discuss in the 3D printed Strandbeest Robot forum thread on 3DPB.com. Check out the video of this robot in action below.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed robot • makerbot • robotics • robots • sketchup • Strandbeest • strandbeest robot • strandbeests • theo jansen

Please enable JavaScript to view the comments powered by Disqus.

How to build a Strandbeest thanks to 3D printing

Posted By Amandine Richardot on Aug 9, 2017 |

Last week, one of our customers, Nicolas Raynaud, went viral on Reddit, posting a gif of the 3D printed robot he made thanks to Sculpteo. He designed a robot, after Theo Jansen’s Strandbeest mechanism. What is it? How to build a Strandbeest thanks to 3D printing? What are our best tips to succeed in creating your own walking device? Discover it right now!

A great 3D printed Strandbeest

Nicolas Raynaud, one of Sculpteo’s customers, posted this gif on Twitter last week, which went viral.

Why has it been such a success? The way this 3D printed robot walks is hypnotic due to its amazing smoothness. Nicolas Raynaud based himself on Theo Jansen’s Strandbeest mechanism. He designed the CAD models of this walking device on his own, using Fusion 360. Discover our tutorial to learn more about how to design with Fusion 360. He also uploaded its Strandbeest models on Thingiverse.

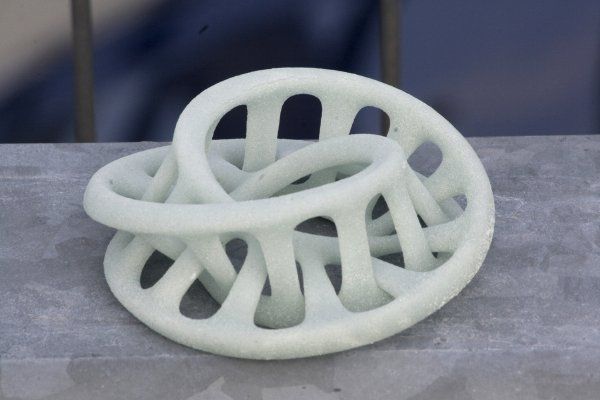

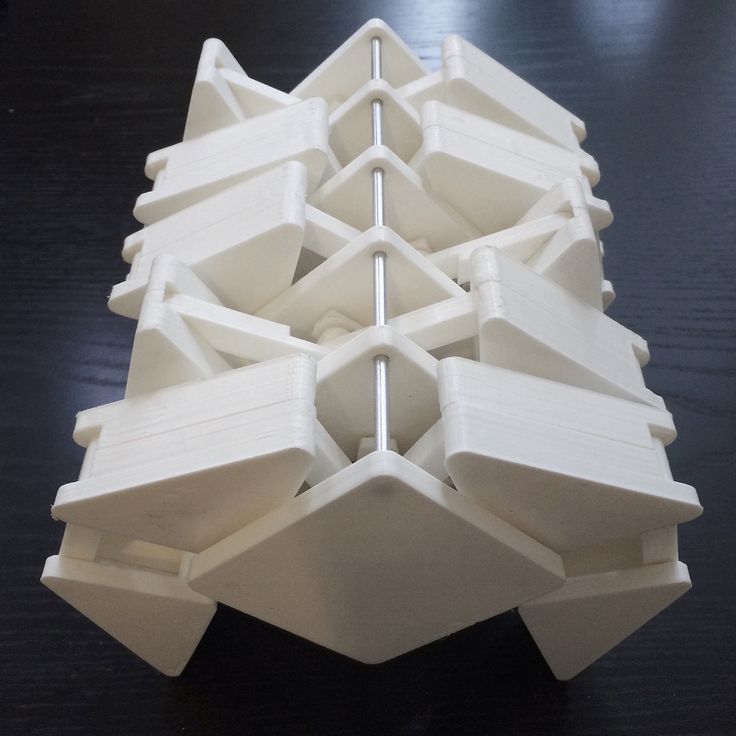

Black parts were made on Nicolas Raynaud’s own printer, and white parts were printed thanks to our 3D printing service, using white plastic and SLS technology. Why using a 3D printing service when you already own a printer? Well, it’s a great way to save you some time.

But now, discover how he succeeded in creating this smooth walking movement thanks to Theo Jansen’s Strandbeest, which helped him build this amazing 3D printed robot.

A quick introduction to Theo Jansen’s Strandbeest

Theo Jansen is a Dutch artist and kinetic sculptor. In the early 1990’s, he started creating large mechanisms in PVC which can move on their own due to the wind only, and which seem to walk. These structures are called Strandbeest, which comes from ‘Strand’ meaning ‘beach’ and ‘beest’ meaning ‘beast’. So a Strandbeest could be called a beach animal.

The work of Theo Jansen is a real fusion between art and engineering. Here’s what the Dutch artist says about this:

“The walls between art and engineering exist only in our minds.

”

He now even tries to equip his structures with Artificial Intelligence so that they can be fully autonomous and avoid obstacles on their own. For instance, if a Strandbeest enters the water, it can detect it and it moves away from it right away.

This work has been exhibited for instance at the Peabody Essex Museum.

Theo Jansen’s linkage: How does the Strandbeest mechanism work?

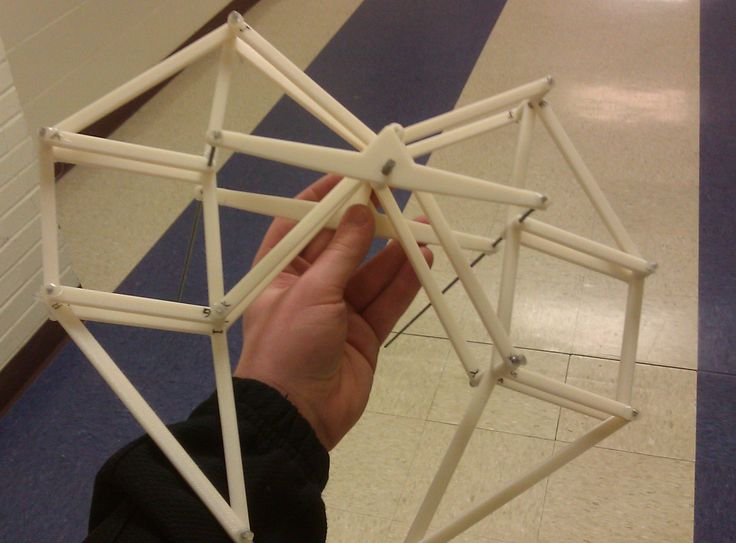

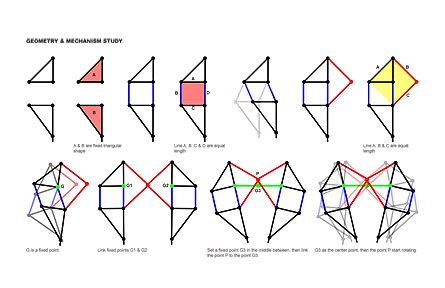

To create its Strandbeest, Theo Jansen designed a whole mechanism, known as Jansen’s linkage. It’s made in order to create a smooth walking motion, without the classic sharp movements of usual robots.

By MichaelFrey – Own work, CC BY-SA 4.0, Link

By MichaelFrey – Own work, CC BY-SA 3.0, Link

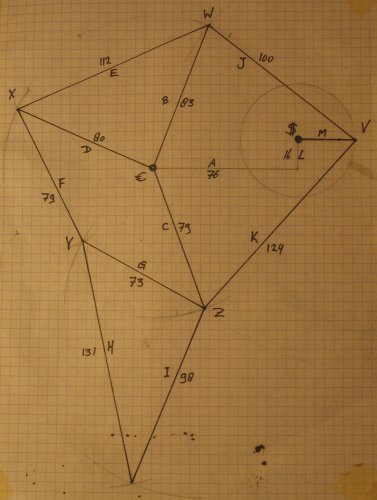

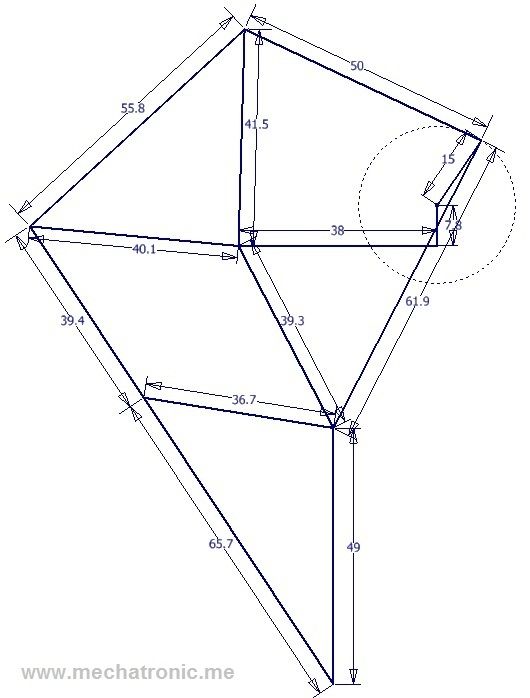

To make one of these walking devices, you need to design tubes – the Dutch artist used PVC pipes – which respect the following proportions and to insert a rotation mechanism in the blue part. It took many months of research for the Dutch artist to find these precise ratios, but finally, he succeeded using an algorithm which came out with these numbers.

By Mliu92 – Own work, from Jansen, Theo (2016). Theo Jansen’s Strandbeest: leg system. Strandbeest. Retrieved on 27 July 2016., CC BY-SA 4.0, Link

To ensure stability, Theo Jansen started designing wider structures, with a larger number of legs. Moreover, he started inserting tubes parallel to the ground, which are like the spinal cord of the Strandbeest. Thus, you should think of these rules if you want to build your own Strandbeest.

Theo Jansen’s linkage can be used on its own to create structures that will move with the wind, but you can use it for other kinds of uses. Indeed, it’s used a lot in the making of 3D printed robots to create a smooth walking movement instead of the classic robotic movement.

Our best tips on how to build a Strandbeest using 3D printing

As you already foresaw, it’s totally possible to build a 3D printed robot thanks to this Strandbeest walking mechanism. We already told you where you could find Nicolas Raynaud’s Strandbeest model, but you might want to try to build this 3D printed robot on your own. It can be quite difficult due to the many technical constraints, but here are our best tips on how to build a Strandbeest!

It can be quite difficult due to the many technical constraints, but here are our best tips on how to build a Strandbeest!

Find the right motor for your Strandbeest

Since there won’t necessarily be wind around you all the time to make your Strandbeest move, we advise you to make it a 3D printing robot. Indeed, Theo Jansen’s linkage can be used to create robots with a smooth walk, as Nicolas Raynaud did. But finding the right motor is not an easy task, due to the fragility of a Strandbeest structure. If it’s not powerful enough, your structure will not move. If it’s too powerful, it will break your creation.

Also, to make sure that your Strandbeest walks, you need to find a way to transmit the movement coming from the motor. We recommend you to use a gear mechanism. You can even design your gears using laser cutting, discover our tutorial now!

Choose the right material

The weight of each part of this 3D printed robot is essential. As a result, you need to find the right material for your need. We strongly recommend choosing a light material that will respect these constraints. Indeed, if it’s too heavy, the movement of your 3D printed robot will not be as smooth as expected.

As a result, you need to find the right material for your need. We strongly recommend choosing a light material that will respect these constraints. Indeed, if it’s too heavy, the movement of your 3D printed robot will not be as smooth as expected.

At Sculpteo, we offer a wide range of materials, from plastics to metal. Looking for lightweight options? No problem, discover our PA12 plastic! That’s the material that has been used by Nicolas Raynaud in order to build his Strandbeest 3D printed robot.

Focus on stability

It can take many many iterations before getting the right Strandbeest. One of the main challenges you face is finding stability. How many legs should you make? It’s hard to know before trying to assemble your final structure.

Leg linkage is key. The assemblies of each tube should be robust but flexible at the same time to ensure a smooth movement. Also, the camshaft assemblies parts are key. They shall really be well proportioned and properly aligned to equilibrate the whole structure. A good solution to these issues can be to use spacers inside of the leg joints to widen them without adding a lot of weight.

A good solution to these issues can be to use spacers inside of the leg joints to widen them without adding a lot of weight.

Beware with friction

Using Jansen’s mechanism, there are many potential friction areas due to the fragility of the structure and of its ongoing movement. Indeed, each leg has 7 individual joints that are both applying force against each other. If friction is too important, your 3D printed robot could break.

To deal with this issue, you can use ball bearing inside your joints, or substitute them with Teflon washers.

You’re now ready to try to create your 3D printed robot using Theo Jansen’s Strandbeest structures. Feel free to share your projects with us!

Looking for some CAD design tutorials? Discover our now, either on Fusion 360, or on Inspire, and FreeCAD.

Photocredit: Plaudens Vela MarcoZwinkels

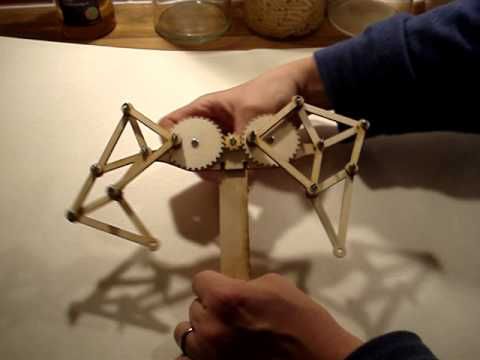

R\U Walker based on Theo Jansen's mechanisms

Creativity

Subscribe to the author

Subscribe

Don't want

26

Hello everyone. For a very long time, I wanted to build a walker based on Theo Jansen's mechanisms. But there were no simple and well-thought-out projects, and there was no time to model everything from scratch. But recently I came across an interesting project, for the assembly of which I already had everything I needed. I could not pass by and finally decided to assemble such a walker for myself. Link to the project page - click.

For a very long time, I wanted to build a walker based on Theo Jansen's mechanisms. But there were no simple and well-thought-out projects, and there was no time to model everything from scratch. But recently I came across an interesting project, for the assembly of which I already had everything I needed. I could not pass by and finally decided to assemble such a walker for myself. Link to the project page - click.

All parts printed in PLA from Bestfilament. Nozzle 0.5, layer 0.2. Filling 30%. Plastic consumption is approximately 340 grams. The walker is assembled from 60 individual parts, not counting the studs, screws, nuts and electronics.

Video - assembly guide:

In terms of filling, everything is very simple and cheap. We need a couple of cheap motor-reducers, a couple of regulators for collector electric motors, a battery and radio control equipment with a receiver.

The walker turned out to be very smart and funny. I even thought about building a bigger version in the future. So much more that such a walker could take away at least one adult. I think it will be a very interesting project =) bestfilament robot RC AKW Theo Jansen walker

Follow author

Follow

Don't want

26

Article comments

More interesting articles

3DMPD

Loading

12/15/2022

834

twenty

Subscribe to the author

Subscribe

Don't want

After a year of viewing posts and discussing printers and models from the 3DTodey website, my colleague and I decided to . ..

..

Read more

12

Subscribe to the author

Subscribe

Don't want

Hi all.

Finished an order from fans of the "alien" universe. Made with great pleasure...

Read more

NotJes

Loading

14.02.2017

39391

213

Follow author

Subscribe

Don't want

Greetings to all readers of the portal! After my article, many people asked what paintwork I used...

Read more

Theo Jansen's Kinetic Art • Interior+Design

Dutch genius Theo Jansen continues to develop his art and presents all new kinetic sculptures created according to the same idea.

C 19In the 1990s, the artist Theo Jansen creates Strandbeest - "beach animals" that can move under the influence of the wind on the sand (in Dutch strand - beach, beest - beast). Mechanisms are being improved from generation to generation: today they are rather complex structures capable of interacting with the environment, including responding to its changes. Theo Jansen's "beasts" store wind energy by inflating a "stomach" consisting of plastic bottles, can determine the type of soil they walk on, and throw out anchors if the wind blows too hard. They do all this without involving complex electronics.

Delft University of Technology graduate Theo Jansen became a hippie in the 70s and painted landscapes, trying his hand at painting.

"Today, there are few people in any field who cross art and science as beautifully as Jansen has done for nearly 30 years," says Honor Harger, executive director of the ArtScience Museum.