Worlds largest 3d printer

Largest 3D printers in 2022 for XXL prints

Large-scale 3D printers are able to print massive objects thanks to their gigantic build volumes. This guide covers some of the largest 3D printers in the world that are commercially available.

Last update June 23, 2022

We removed discontinued products and updated the BLB Industries The BOX lineup, which has been replaced by The Industry MAGNUM. We also added MASSIVit's latest solution, the Massivit 10000.

Table of contents

Handpicked related content

Large scale 3D printers (XXL): 2022 selection

BIG-Meter V4

F1000

BigRep ONE v4

400 Series WORKBENCH XTREME

T3500

MAGNUM

Massivit 10000

MAMA

3D printing furniture

3D printing large prototypes

3D printing production series

Customized large scale 3D printers

What are the best large scale 3D printers?

Large-scale 3D printers have been in the spotlight for quite some time. When we say large scale, we mean it– these machines can 3D print objects of over 1 square meter. They can be used to 3D print pieces of furniture, large prototypes, or several series of smaller objects in one go.

The professional 3D printers featured in our article are basically super-sized versions of ordinary desktop 3D printers. They almost all use extrusion 3D printing technology (FFF) and work the same way as regular desktop printers.

Our “largest 3D printers” selection does not include construction 3D printers, which fit into a different category.

Handpicked related content

If these large scale 3D printers (XXL) are too big, check out our other selections:

- Large format 3D printers (XL)

- Large volume 3D printers (L) for desktops/benchtops

- Large resin 3D printers (L)

Large scale 3D printers (XXL): 2022 selection

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. | |

|---|---|---|---|---|---|

| Modix This brand is a certified partner from our network. | BIG-Meter V4 | 1010 × 1010 × 1010 mm39.76 × 39.76 × 39.76 in | Israel | $ 13,50013 723 €11,975 £2,012,256 ¥ | Buy |

| CreatBot | F1000 | 1000 × 1000 × 1000 mm39.37 × 39.37 × 39.37 in | China | $ 29,99930 494 €26,610 £4,471,531 ¥ | Buy |

| BigRep | BigRep ONE v4 | 1005 × 1005 × 1005 mm39.57 × 39.57 × 39.57 in | Germany | $ 30,00030 000 €26,611 £4,471,680 ¥ | Quote |

| 3D Platform | 400 Series WORKBENCH XTREME | 1000 × 1500 × 700 mm39.37 × 59.06 × 27.56 in | United States | $ 49,99950 823 €44,351 £7,452,651 ¥ | Quote |

| Tractus3D | T3500 | ⌀ 1000 x 2100 mm | Netherlands | $ 59,00049 900 €52,335 £8,794,304 ¥ | Quote |

| The Industry | MAGNUM | 1500 × 1200 × 1200 mm59. 06 × 47.24 × 47.24 in 06 × 47.24 × 47.24 in | Sweden | $ 135,000129 990 €119,750 £20,122,560 ¥ | Quote |

| MASSIVit 3D | Massivit 10000 | 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in | Israel | upon request | Quote |

| Modix This brand is a certified partner from our network. | MAMA | 2000 × 5000 × 1000 mm78.74 × 196.85 × 39.37 in | Israel | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Modix This brand is a certified partner from our network. | BIG-Meter V4 | 1010 × 1010 × 1010 mm39.76 × 39.76 × 39.76 in | 1030.3 L | Israel | $ 13,50013 723 €11,975 £2,012,256 ¥ | Buy on Modix |

| CreatBot | F1000 | 1000 × 1000 × 1000 mm39.37 × 39.37 × 39.37 in | 1000 L | China | $ 29,99930 494 €26,610 £4,471,531 ¥ | Buy on CreatBot |

| BigRep | BigRep ONE v4 | 1005 × 1005 × 1005 mm39.57 × 39.57 × 39.57 in | 1015.08 L | Germany | $ 30,00030 000 €26,611 £4,471,680 ¥ | Get a quote |

| 3D Platform | 400 Series WORKBENCH XTREME | 1000 × 1500 × 700 mm39.37 × 59.06 × 27.56 in | 1050 L | United States | $ 49,99950 823 €44,351 £7,452,651 ¥ | Get a quote |

| Tractus3D | T3500 | ⌀ 1000 x 2100 mm | 1649.34 L | Netherlands | $ 59,00049 900 €52,335 £8,794,304 ¥ | Get a quote |

| The Industry | MAGNUM | 1500 × 1200 × 1200 mm59. 06 × 47.24 × 47.24 in 06 × 47.24 × 47.24 in | 2160 L | Sweden | $ 135,000129 990 €119,750 £20,122,560 ¥ | Get a quote |

| MASSIVit 3D | Massivit 10000 | 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in | 2364.3 L | Israel | upon request | Get a quote |

| Modix This brand is a certified partner from our network. | MAMA | 2000 × 5000 × 1000 mm78.74 × 196.85 × 39.37 in | – | Israel | upon request | Get a quote |

Overview of the best large scale professional 3D printers

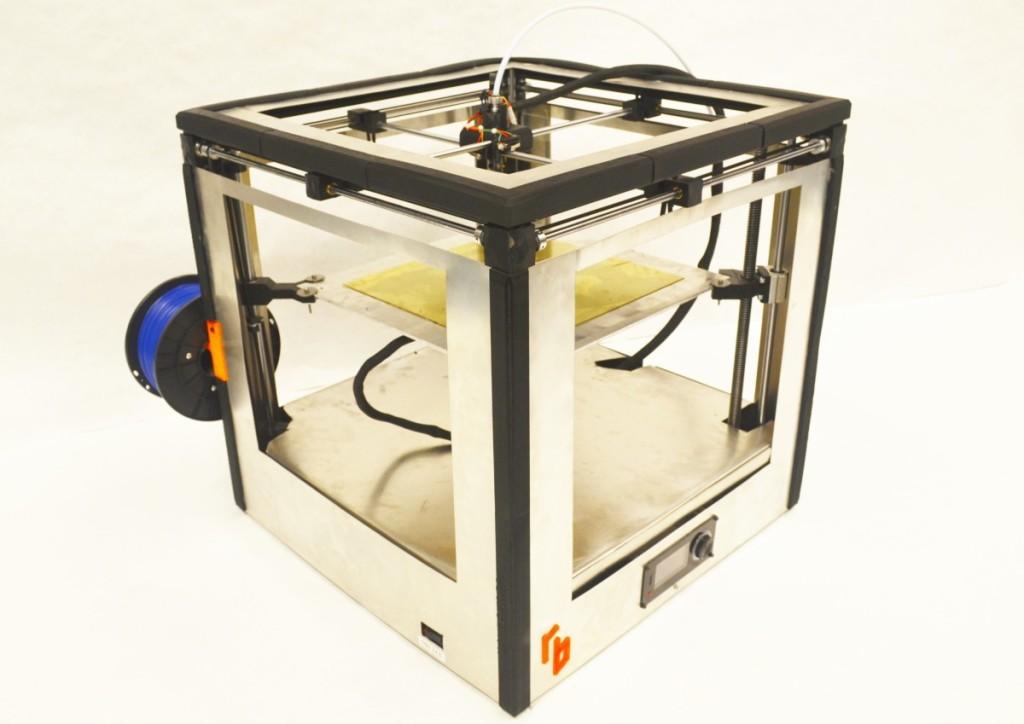

The Modix BIG-Meter offers over one cubic meter of build volume. As all Modix printers do, the BIG-Meter is delivered as a self-assembly kit, which contributes to the printer’s relatively low price point.

This large scale 3D printer comes with a dual extruder (E3D Aero and E3D Volcano print heads), full automatic bed leveling (bed tile and bed mapping), a Wi-Fi controller, and a range of industrial-grade components. The print bed heats up to 120°C.

The print bed heats up to 120°C.

Buy on Modix Get a quote Add to comparison

The F1000 from CreatBot offers a full cubic meter of fully enclosed and heated (60°C) build volume. There’s also a filament chamber that can hold two spools of up to 5kg each and heat up to 45°C or 65°C.

Its dual nozzles are able to heat up to 420°C, while the print bed heats up to 100°C. Compatible materials range from standard PLA and ABS to PETG and carbon fiber-filled and flexible materials.

Buy on CreatBot Get a quote Add to comparison

The BigRep ONE, currently in its third generation of upgrades and updates, is one of the only large-sized 3D printers to provide independent dual extrusion (IDEX). IDEX can cut production times in half thanks to duplication or mirror modes.

The printer’s large touchscreen grants access to the webcam and allows users to resume prints even after a power outage. The filament holder is able to hold multiple spools of up to 8kg.

Contact manufacturer Get a quote Add to comparison

This large format 3D printer with dual extrusion is customizable. Various extruders are available, and it’s possible to add an enclosure. The enclosure can be heated and/or include an air filter as well.

Various extruders are available, and it’s possible to add an enclosure. The enclosure can be heated and/or include an air filter as well.

It’s possible to choose from two different control systems; with Wi-Fi or with Ethernet connectivity. The automatic leveling probe touches over 400 points on the print bed to ensure optimal calibration.

Contact manufacturer Get a quote Add to comparison

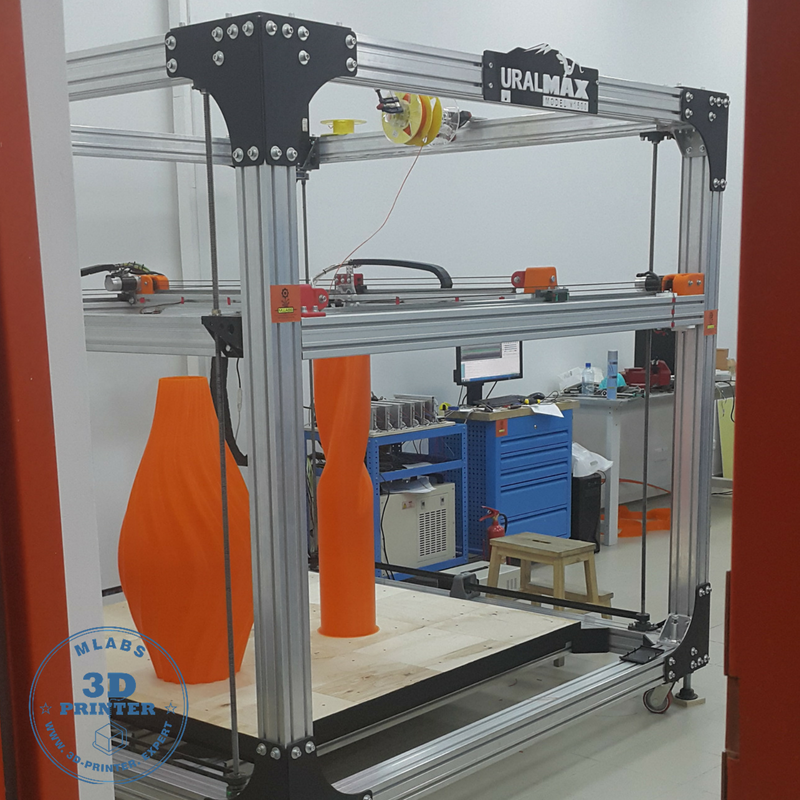

The T3500, a huge delta 3D printer, offers a massive build size that can 3D print to an exact scale of 1:1 up to 2.1 meters high.

The large-scale Tractus3D T3500 can 3D print exotic materials with its hot-end extruder capable of reaching up to 300°C. This 3D printer features a heated bed and can be equipped with an optional dual extruder.

Contact manufacturer Get a quote Add to comparison

The Industry MAGNUM is a very large format 3D printer by The Industry (previously called BLB Industries), a manufacturer based in Sweden. This XXL 3D printer offers a build volume of 2. 16m³ and comes with a set of nozzles ranging from 2 to 8mm in diameter. The MAGNUM is based on the company’s previous model, the BLB Industries THE BOX.

16m³ and comes with a set of nozzles ranging from 2 to 8mm in diameter. The MAGNUM is based on the company’s previous model, the BLB Industries THE BOX.

Contact manufacturer Get a quote Add to comparison

The Massivit 10000 is an industrial large format 3D printer produced by MASSIVit 3D. MASSIVit 3D is a 3D printer manufacturer based in Israel. This 3D printer offers a build volume of 1420 x 1110 x 1500 mm.

Contact manufacturer Get a quote Add to comparison

Modix has nicknamed their printer “Personal Car Factory”, a quick way to indicate how big the MAMA (Modular Additive Manufacturing Assembler) system really is. It’s equipped with a high-speed pellet extruder, and is also capable of 3D printing with spools of filament.

This huge FFF 3D printer isn’t available yet.

Contact manufacturer Get a quote Add to comparison

Applications for large scale 3D printing

3D printing furniture

The largest 3D printers can be used to 3D print furniture in one go. This includes tables, chairs, and even bathtubs. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise.

This includes tables, chairs, and even bathtubs. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise.

Hence, customized furniture is becoming more and more accessible thanks to extra-large 3D printers.

The BigRep One is in action. Source: QMES3D printing large prototypes

The professional large-scale 3D printers featured in our article can also be used to 3D print large prototypes. This enables businesses to test out their products before actually launching production. Industrial designers and engineers are able to perform more revisions in significantly less time.

They can test their future products extensively while at the same time reducing the production-to-market time.

3D printing production series

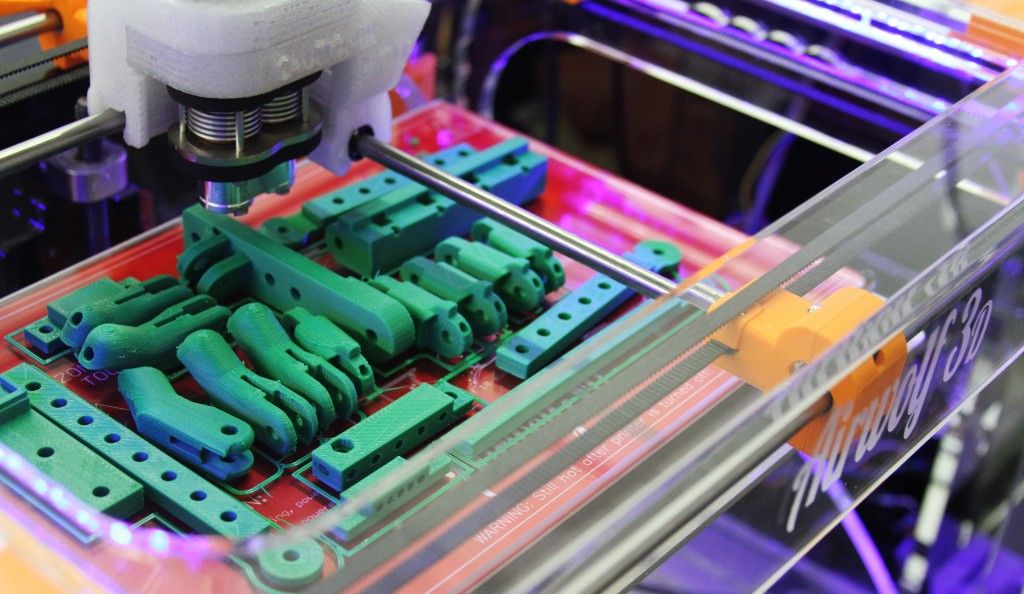

Large-scale 3D printers don’t have to exclusively 3D print large objects and prototypes. Their huge build platform also enables 3D printing big series of smaller objects.

Customized large scale 3D printers

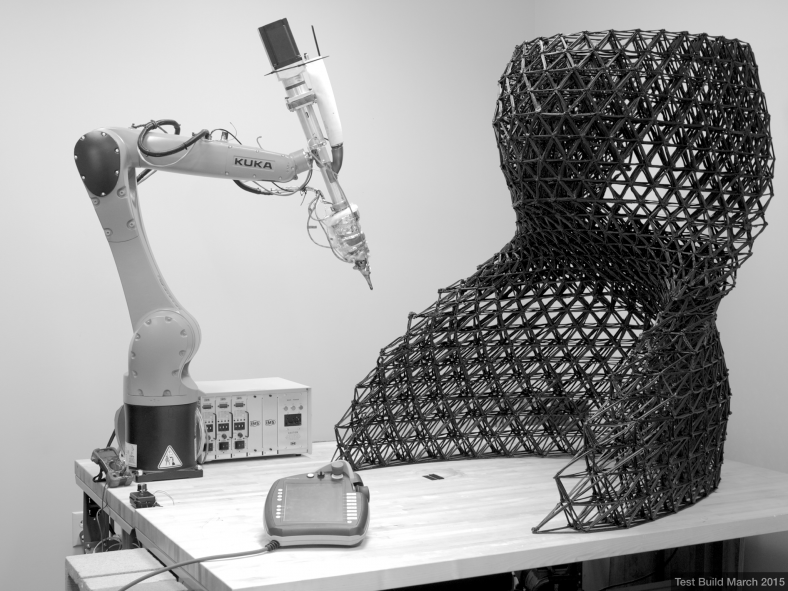

There are several manufacturers that mainly offer tailored solutions rather than standardized 3D printer models. Tobeca, for instance, is a French team that builds 3D printers from scratch and is based entirely on their customers’ needs and requirements.

US-based Erectorbot also provides on-demand builds, although they do have a lineup of standard models. Then there’s Colossus, a company in Belgium that constructs 3D printers within shipping container-like structures. CNC Barcenas, a Spanish manufacturer, also offers tailored, large-scale 3D printers with a range of options to choose from.

University of Maine creates the world's largest 3D printed boat

Published on October 16, 2019 by Carlota V.

A team of researchers from the University of Maine revealed the largest 3D printed part in the world. It is a boat, the 3Dirigo, designed on a large-format polymer 3D printer developed by the UMaine Advanced Structures and Composites Center. The piece is 7.62 meters long and weighs 2.2 tons! The project teams were awarded 3 World Records: the largest 3D printed solid part, the largest 3D printed boat and finally the largest 3D printer. This is a promising initiative for the maritime sector, which take advantage of the benefits of additive manufacturing.

More and more additive manufacturers are turning to large-format 3D printing, hoping to create large structures in one go and avoid assembly or post-processing steps that are expensive and time-consuming. The University of Maine is therefore joining this trend, with an emphasis on the use of composite materials. Last May, its partner the Oak Ridge National Laboratory (ORNL) received $20 million to develop a large-format additive manufacturing program based on 3D printing materials that contained wood fiber. The 3D printing of the boat is therefore a significant step forward in this government-supported project.

The 3D printing of the boat is therefore a significant step forward in this government-supported project.

The large-format 3D printer, next to the 3D printed boat | Image via UMaine

3D Printed Boat: The Manufacturing Process

The UMaine teams worked with Ingersoll Machine Tools to develop their 3D printer, it presents a printing volume of 30 x 6.70 x 3 meters (length, width and height) and a speed of 227 kilos per hour. The print head is fixed on a gantry mounted on rails, making it easier to move along the length. As of today, the manufacturer is not offering a wide-range of compatible materials, however the machine was designed to use raw materials of biological origin, in particular cellulose from wood. Apparently, the 3D printer was designed for rapid prototyping applications for civil, defence and infrastructure applications.

In order to demonstrate the capabilities of their large format 3D printer, the teams created the 3D printed boat 3Dirigo. It was manufactured in just 72 hours from a mixture of plastic and wood cellulose. The part is 7.62 meters long and weighs 2.2 tons, making it the largest solid structure ever 3D printed.

The part is 7.62 meters long and weighs 2.2 tons, making it the largest solid structure ever 3D printed.

The boat has been tested by the Alfond W2 Ocean Engineering Laboratory test site

Other Projects

The University of Maine took the opportunity to present a second project, a 3.6-metre long 3D printed communication shelter for the US military. The university worked in collaboration with the Combat Capabilities Development Command (CCDC), a branch of the army that consists of rapidly deploying shelter systems for soldiers. Col. Frank Moore, Military Assistant at CCDC Soldier Center, explains: “The innovation that we have witnessed here at the University of Maine will revolutionize how the Army prototypes and manufactures shelters, vehicles and other large systems. The lighter yet stronger 3D printed systems will advance the state of the art in additive manufacturing, forging the future of expeditionary equipment IAW with the Army’s new policy on advanced manufacturing. ”

”

The boat took 72 hours to be 3D printed

The machine is also expected to meet the needs of rapidly deployable and logistically weak infrastructure systems. With this in mind, the teams printed a 2.2-ton, 6.4-metre-long 3D mold to make a 23-metre-long bridge girder. The bridge is expected to be built in Hampden, Maine, in the summer of 2020. Habib Dagher, Executive Director of the UMaine Advanced Structures and Composites Center concludes: “We are truly honored to be working with leaders from the Maine boatbuilding industry, Maine Forest Products Industry, the national construction industry, Maine Technology Institute, Oak Ridge National Laboratory, the U.S. Dept of Energy Advanced Manufacturing Office, the U.S. Office of Naval Research, the U.S. Army, and the U.S. Army Corps of Engineers. With this large printer, we will be able to accelerate innovation and prototype development in both the civilian and military sectors.” Find more information HERE.

What do you think of these achievements coming from the University of Maine? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

The largest 3D printer in the world has printed a boat

The largest 3D printer in the world has printed a boatNow men don't have to bother with gifts. It will be enough to order a boat that a 3D printer can print.

The world's largest 3D printer is located at the University of Maine in the USA. In 72 hours, the polymer device printed a boat over 7 meters long and weighing 2.26 tons. Thus, the printing process immediately broke 3 world records, which were successfully recorded by representatives of the Guinness Book of Records:

1. The largest prototype polymer 3D printer;

2. Largest 3D printed solid object;

3. The largest 3D printed boat.

But at this point, the employees of the Center of Excellence and composites stop at going. They claim that this 3D printer can print and more global objects, up to 30 m long, 7 m wide and 3 m high. Performance super 3D printer is 226 kg of polymers per hour.

Read also: Transformer bed that will solve the problem of dividing the territory

pleasure. To create the entire installation and put it into operation, spent about $2.5 million. The bulk of the money was allocated by the US Army. Later on she plans to work closely with the company to create mobile shelters for soldiers, as well as bridges. Thus, the army will become one of main customers. The company received financial support in the amount of $500,000 from the Maine Institute of Technology.

The aim of this project was the idea of using 3D printing in shipbuilding. The printed boat was named "3Dirigo" and have already tried it in the pool. Soon the ship will set sail. It is worth noting that about $40 thousand was spent on its printing.

Soon the ship will set sail. It is worth noting that about $40 thousand was spent on its printing.

US Senator Angus King noted that the printing of the 3Dirigo polymer boat was truly a great event in the field of technology, because it opens up many new opportunities. In addition, Angus joked that the first great event for the university was admission at 1965 year of the famous writer Stephen King.

And we recall that in April 2019 in Israel for the first time it was possible to print a living heart on a 3D printer. They made it from human fat cells, which they turned into stem cells of the cardiovascular muscle. The size of the printed heart was about 2.5 cm. Scientists note that in the future it will be possible to print absolutely any human organ in this way, depending on the individual characteristics of the body of each patient.

US builds largest metal 3D printer

News

Subscribe author

Subscribe

Don't want

2

metal products. The system will rely on adapted friction welding technology and will be able to grow parts up to ten meters long.

The work is carried out in the interests of the US military: such 3D printers are planned to be used primarily in the production of mine protection for army vehicles. During the Vietnam War, 73 percent of equipment losses were due to explosions on anti-personnel and anti-tank mines. Modern armored vehicles and armored personnel carriers are designed with enhanced protection, and an important role is played by thick, armored bottoms, often V-shaped and with a minimum of welds.

An American Cougar armored vehicle that hit a mine in Iraq in 2006 and drove another three kilometers to the safe zone. The personnel escaped with minor injuries. Photo: Marine Sergeant Christopher Clare

Previous work on the Jointless Hull project of the Army ManTech research program has looked at forging, forming and welding at high current density to reduce weld porosity. The results were rated as satisfactory in terms of strength, but at the same time, there was a lack of geometric freedom and manufacturing flexibility.

As a result, they decided to abandon forging, forming and welding in favor of another technology - production by the method of additive friction deposition with mixing (Additive Friction Stir Deposition, AFSD), that is, Friction Stir Welding, adapted for 3D printing, FSW).

Development work consists of two stages. Not the first one is planned to assemble a demonstrator with a construction area measuring 1x1x1 meter to test the technology and software. The design must then be scaled up to a working volume of 10x6.5x4 meters - the largest among "metal" 3D printers. Length is a conditional characteristic, since the portal structure will move along the rails. Siemens is responsible for the control systems and software.

The large-format version is already being assembled by Ingersoll, which has considerable experience in working on large additive systems. In 2019, this venture helped the University of Maine set three Guinness records at once: to make the largest 3D printed boat (seven meters in length), aka the largest one-piece 3D printed object, on the largest 3D printer for working with polymers and polymer composites. The same system is used in the production of large molding tooling, for example for the manufacture of helicopter blades.

In 2019, this venture helped the University of Maine set three Guinness records at once: to make the largest 3D printed boat (seven meters in length), aka the largest one-piece 3D printed object, on the largest 3D printer for working with polymers and polymer composites. The same system is used in the production of large molding tooling, for example for the manufacture of helicopter blades.

The new 3D printer, as already mentioned, will deposit metals using friction stir deposition. This technology is being developed by MELD Manufacturing using the Edison Welding Institute (EWI). The build-up is carried out by plastic deformation at temperatures below the melting threshold, thereby achieving high isotropy and density without shrinkage and the risk of hot cracks, without the need for a vacuum chamber or protective gas environment. The technology also allows you to create gradient structures from different metals or alloys. Consumables are usually rounded bars with the possibility of using powders of different fractions and even metal shavings.

MELD Manufacturing already offers several models of additive systems. The latest commercial offer is the L3 3D printer released in 2020 with a working area of 1143x584x584 mm, although the K2 system with a useful volume of 2100x1100x1000 mm is the leader in terms of dimensions. The equipment allows you to work with various steel grades, as well as aluminum, copper, titanium, magnesium and nickel alloys. As a rule, such 3D printers stack layers about one millimeter thick and 38 mm wide, keeping the temperature of the material at 60-90% of melting point. Since the resolution of 3D printing is low, the resulting blanks require intensive machining, but with much less labor and waste than milling from blanks, and with high scalability, which is planned to be demonstrated in practice by the joint efforts of Ingersoll, MELD Manufacturing and Siemens. The commissioning of the large-format system is scheduled for the fourth quarter of this year.

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).