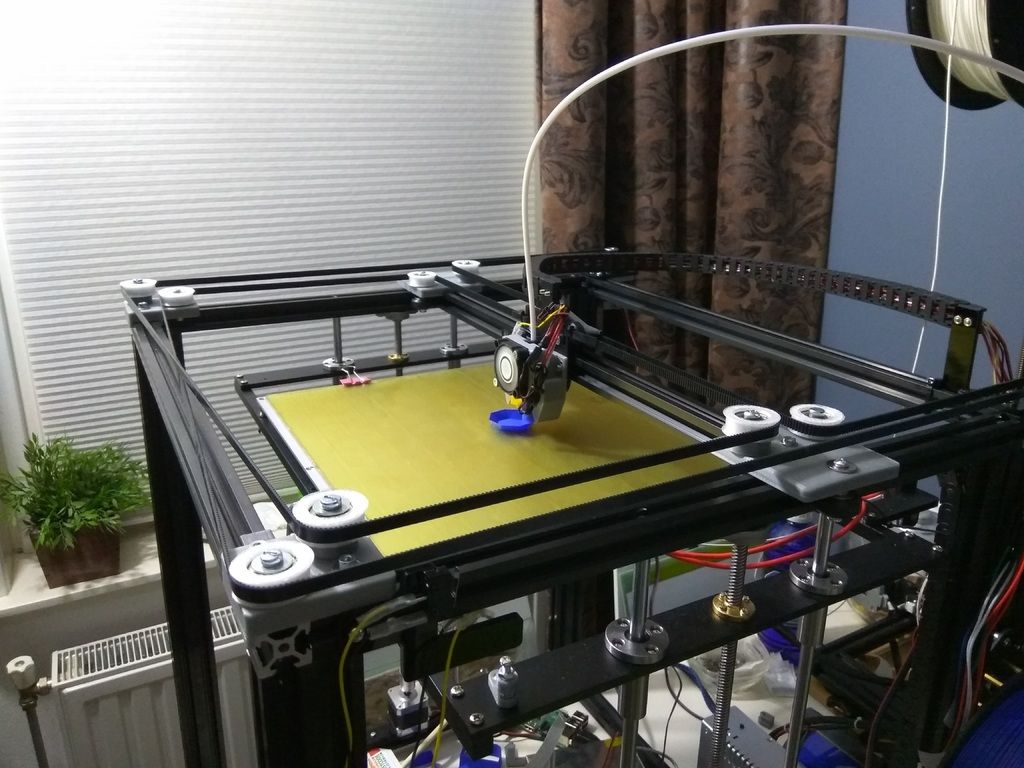

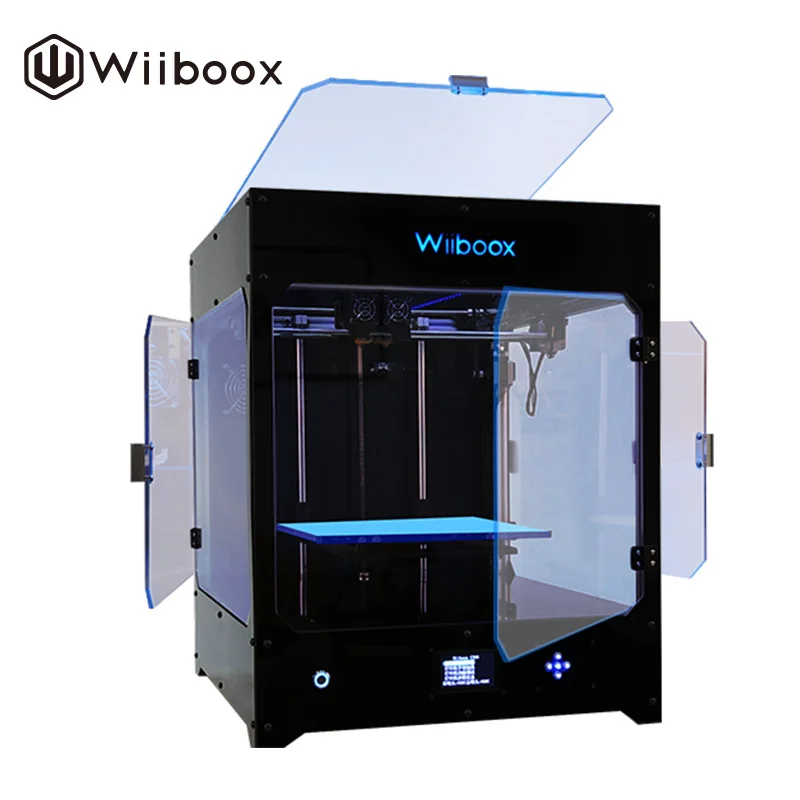

Wiiboox one 3d printer

Wiiboox launches its LuckyBot food 3D printing extruder

0Shares

China-based 3D printer manufacturer Wiiboox has announced the launch of its new food 3D printing extruder.

Named LuckyBot, the device can be integrated with a wide variety of standard desktop 3D printers to transform them into dedicated food printers. Designed as a cost-effective alternative to the often pricey food printers available today, LuckyBot retails at $159 and is compatible with chocolate, peanut butter, cream, cheese, jam, mashed potatoes, salad dressings, and other soft foods.

Aimed at coffee and dessert businesses, chefs, bakers, or just food enthusiasts, the extruder is capable of fabricating both 2D and 3D custom designs.

Wiiboox wrote in a press release, “Many brands of food printers have gained popularity as a result of the coupling of 3D printing technology with food. However, the purpose-built 3D food printers on the market are too expensive.”

The LuckyBot food 3D printing extruder.Covering all bases with Wiiboox

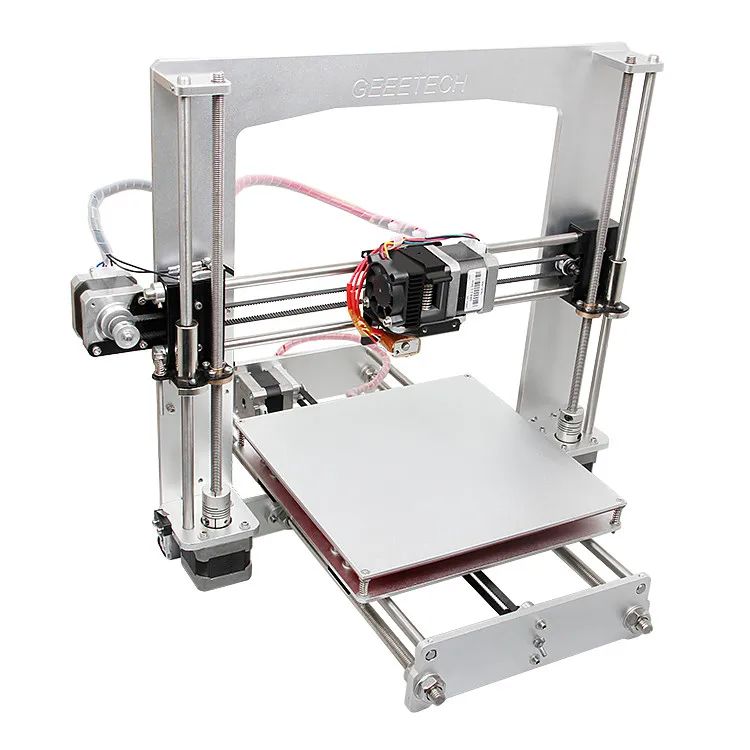

Founded in 2014 in Nanjing, Wiiboox sports an impressive portfolio of 3D printing systems covering the consumer, professional, and industrial sectors. With an R&D team and after-sales technical team from the University of Southern California and Zhejiang University, the company serves a long list of customers including the likes of Procter & Gamble, Oracle, and Jaguar.

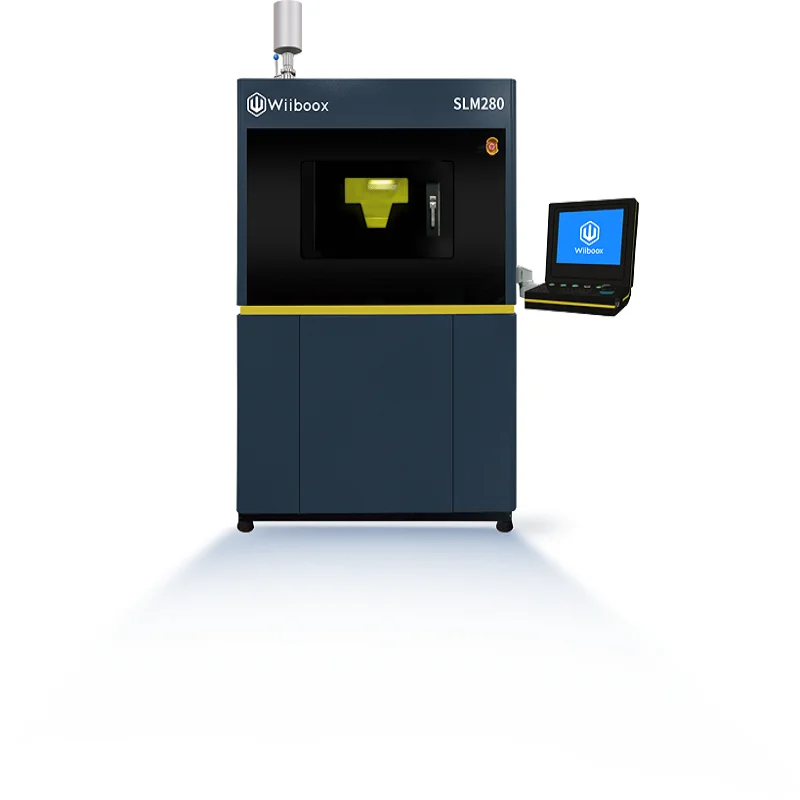

Wiiboox’s FFF lineup includes the Three-M and W200 3D printers, the first of which has an enclosed build volume of 310 x 310 x 350mm. Additionally, the SLA product line comprises the 3DSL360, 3DSL450, and 3DSL600. These large-format machines offer replaceable resin baskets and are built for professional use.

The firm even offers its own set of industrial metal powder bed fusion 3D printers: the SLM150 and SLM280. The systems support a range of metal powders such as stainless steel 316L, aluminium alloys, titanium alloy, cobalt chromium alloy, and die steel.

The LuckyBot extruder

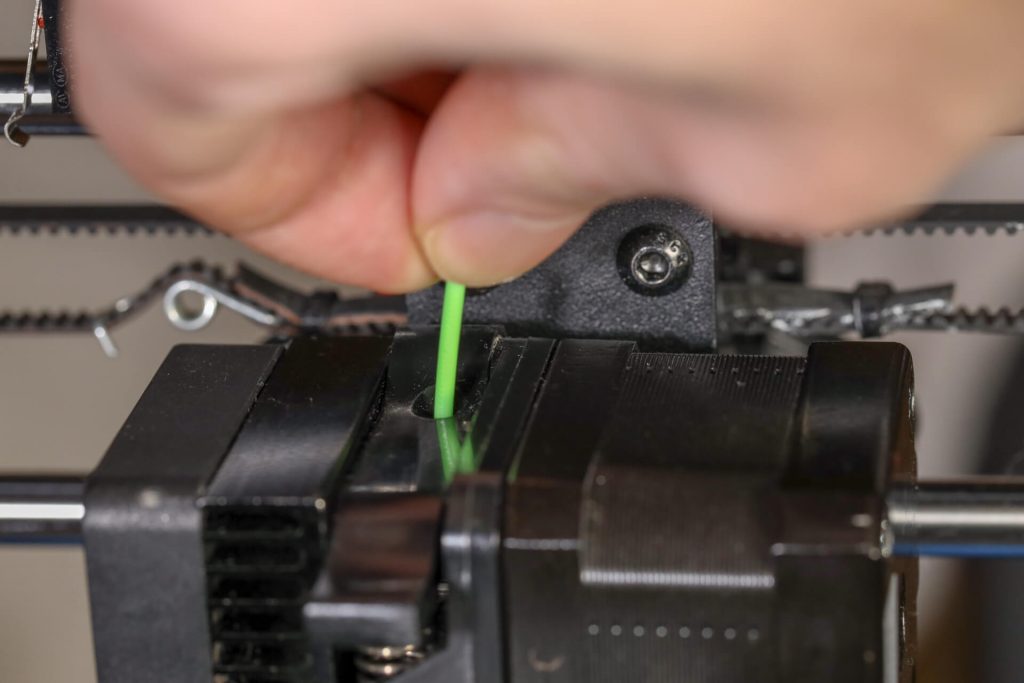

To use the LuckyBot food extruder, users simply need to remove the existing printhead on their 3D printers and connect the device in its place, which reportedly takes just a few minutes. Featuring a lightweight form factor, the extruder comes equipped with an ABS body, a stainless steel nozzle, and food-ready PP tubing. According to Wiiboox, the assembly is FCC and CE certified.

On the front of the LuckyBot is a temperature display along with three buttons to control the temperature and adjust the position of the lead screw. The hotend is capable of maintaining temperatures of up to 50°C with automated power-off functionality for added device safety. Thanks to the firm’s own integrated temperature control algorithms, the heat in the hotend is always accurate to within 0.5°C.

On the software side, LuckyBot doesn’t have its own print preparation program so it can be used in conjunction with standard FFF 3D printing slicers. As it stands, LuckyBot can be installed on “most FDM printers on the market”, including Creality’s Ender series, Anycubic’s Mega series, and the Voxelab Aquila line of 3D printers.

As it stands, LuckyBot can be installed on “most FDM printers on the market”, including Creality’s Ender series, Anycubic’s Mega series, and the Voxelab Aquila line of 3D printers.

Despite its relatively small size, the food 3D printing sector is an active one. Just this month, food 3D printing firm Digital Patisserie announced the launch of its new pastry 3D printer, the Patiss3. Reportedly inspired by 3D printing technology developed at MIT, the extrusion-based system is aimed at pastry chefs, restaurants, and industrial biscuit factories, enabling users to fabricate edible freeform shapes at high speeds.

Elsewhere, Natural Machines, a Spain-based developer of food 3D printing technology, recently printed a replica of the world’s best tiramisu. The heart-shaped dessert took first place at last year’s Tiramisù World Cup (TWC), and has now been faithfully recreated using the firm’s proprietary Foodini additive manufacturing system.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the LuckyBot food 3D printing extruder. Photo via Wiiboox.

Tags AnyCubic Creality LuckyBot Oracle Procter & Gamble University of Southern California Voxelab Wiiboox Zhejiang University

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

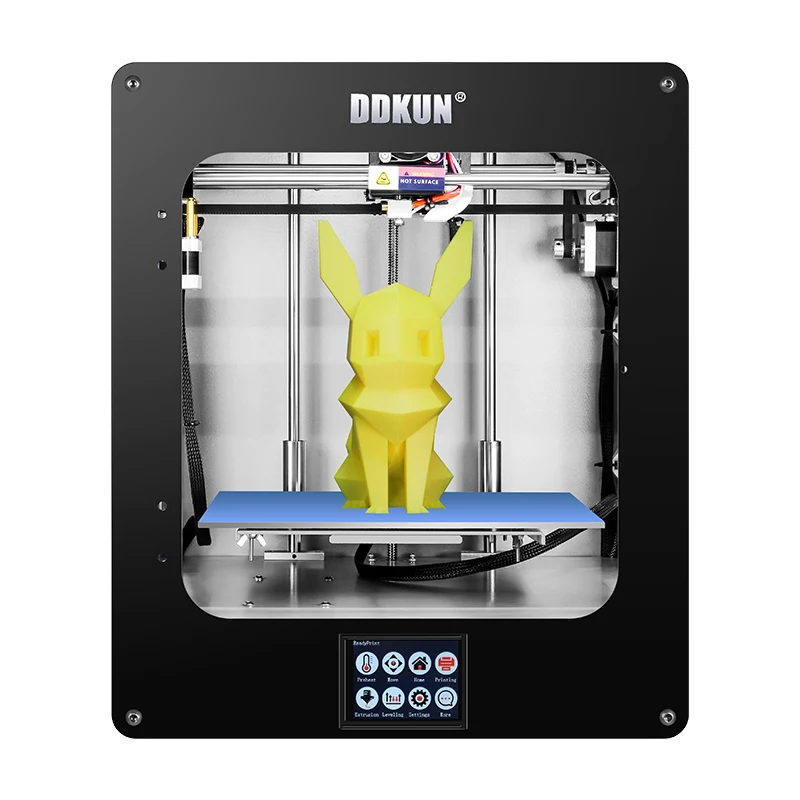

Wiiboox One Mini Review - 3D Engineer

1Posted on by admin

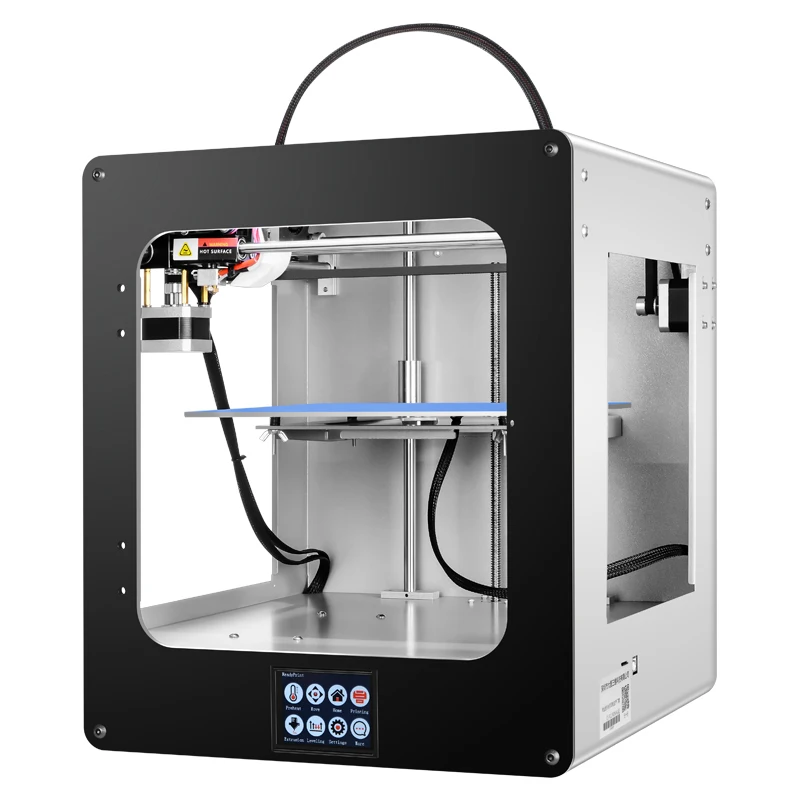

The introduction of 3D printers opened the realms of creative possibilities for hobbyists, architects, engineers, research scientists and other brilliant minds. However, the cost and size of the new technology made the devices unreachable for many. The up and coming Wiiboox company based in Nanjing Jiang, China, set out to solve the problem by recently introducing the Wiiboox One Mini.

However, the cost and size of the new technology made the devices unreachable for many. The up and coming Wiiboox company based in Nanjing Jiang, China, set out to solve the problem by recently introducing the Wiiboox One Mini.

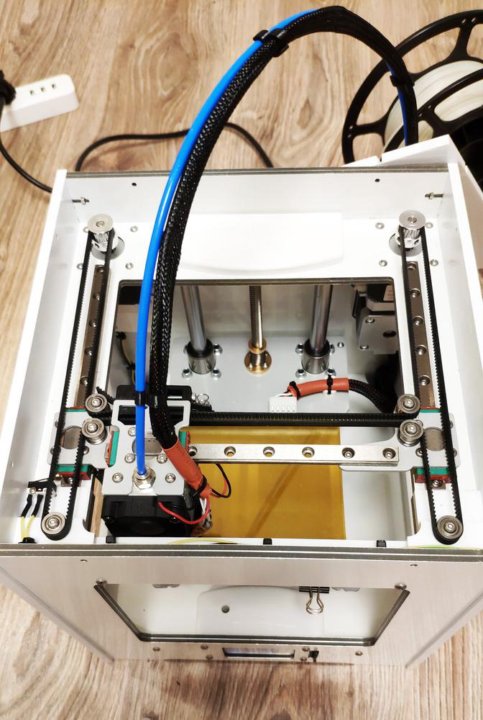

The Wiiboox One Mini is a portable desktop 3D printer designed for home or office use. The device measures 22.44 x 16.93 x 23.23 inches and weighs a mere 22 pounds. The internal mechanics are sturdily constructed of an aluminum alloy and housed in an attractive clear acrylic cabinet that has four doors for easy access. You can also watch the creation process thanks to a series of color-changing LED lights that are contained within the cabinet. The printers exceptional performance, visual appeal and low price helped the unit win some of the highest ratings for 3D printers.

Innovations in Design

While evaluating 3D printers, the Illinois Institute of Technology learned that the majority of machines emit nano-sized particles into the atmosphere. The particles are introduced when the extruded filament heats and is typically deposited on a heated bed. Virtually invisible, the particles pose a potential health threat in industrial or domestic environments. However, the enclosed chamber and air particle filtration system contained within the Wiiboox printer protects against emissions of up to 0.08um. The unit also does not require a heated bed for operation. As such, there is no noticeable odor during or after the printing process. The ingenious technology also enabled the Wiiboox to pass CE, EMC, ERP, PAHs, REACH and ROHS safety tests.

The particles are introduced when the extruded filament heats and is typically deposited on a heated bed. Virtually invisible, the particles pose a potential health threat in industrial or domestic environments. However, the enclosed chamber and air particle filtration system contained within the Wiiboox printer protects against emissions of up to 0.08um. The unit also does not require a heated bed for operation. As such, there is no noticeable odor during or after the printing process. The ingenious technology also enabled the Wiiboox to pass CE, EMC, ERP, PAHs, REACH and ROHS safety tests.

Wiiboox Features and Specifications

The 3D printer has a single head extruder featuring a 0.4mm nozzle. The printer is operable using 110 or 220 AC volts. The Wiiboox One Mini creates three-dimensional objects measuring up to 7.8 x 5.9 x 5.9 inches (20 x 15 x15 centimeters). However, larger projects are possible by printing small components and assembling the finished parts.

While printing, the thickness of each layer is 0. 1 to 0.5 millimeters. The print speed is an impressive 0.8 to 7 inches (20 to 180 millimeters) per second. When in operation, the printer is also extremely quiet. The Wiiboox is additionally lauded for the degree of printing accuracy, which is within 0.00025 millimeters on the Z axis and 0.011millimeters on the X and Y axes. The company proudly boasts that the 3D printer is one of the few machines capable of correctly reproducing the 265 parts needed for a five-cylinder aeronautic engine.

1 to 0.5 millimeters. The print speed is an impressive 0.8 to 7 inches (20 to 180 millimeters) per second. When in operation, the printer is also extremely quiet. The Wiiboox is additionally lauded for the degree of printing accuracy, which is within 0.00025 millimeters on the Z axis and 0.011millimeters on the X and Y axes. The company proudly boasts that the 3D printer is one of the few machines capable of correctly reproducing the 265 parts needed for a five-cylinder aeronautic engine.

The Wiiboox One Mini has a user-friendly LCD screen on the front of the device that displays information in English, Chinese or Korean. The enclosed user’s manual is easy to follow and provides detailed instructions that ensures you will be printing your first project in no time. The unit also comes equipped with ReplicatorG/Cura software and uses STL/G-Code/OBJ formatting. Users can input instructions via devices having Linux, Mac or Windows operating systems. The printer also accepts Micro-USB connections and takes SD cards.

Filament Specifications

The One Mini 3D printers requires filaments measuring 1.75 millimeters in diameter. The device is compatible with both ABS and PLA filaments. Both products are available in a wide range of colors. However, PLA adds to the particle safety factor while reducing environmental harm by being produced from corn fibers.

For the price, ease of use and accuracy of the unit, the Wiiboox One Mini printer is a worthwhile investment whether a 3D printing novice or an experienced craftsman.

3D Printer Reviews3D food printing, pastry and food 3D printers

Food 3D printing, pastry and food 3D printers | project news 3DPulse.Ru3d pulse.ru

Our new report "Construction 3D printing in Russia" has been published

Our report "Construction 3D printing in Russia" has collected information about domestic companies and start-ups that produce...

Vladimir Viktorovich Molodin (SIBSTRIN): "The idea [of printing with polystyrene concrete] appeared three years ago, and it took 30 years to get there. "

"

Interest in 3D construction printing is growing rapidly around the world, with most of the developed 3D printers working with...

Mass 3D printing of individual houses: reality or utopia? - public study by Techart group

In its public survey, Techart explores whether 3D printing can bring something really new to the construction industry...

Viktor Mann (RUSAL): "In Russia, additive manufacturing is one of the fastest growing industries"

RUSAL is a leading company in the global aluminum industry and the largest aluminum producer with a low carbon footprint. Her...

"3D Printing in the Oil and Gas Industry: Incentives and Constraints" - Techart Group Public Study

Techart Consulting Group published a study analyzing the current state and development prospects...

Current news

Food

3D food printer from Moscow scientists prints chocolate, cakes and nuggets

Scientists have created a 3D food printer with a system of "smart" recipes that prints food with specified properties. ..

..

Food

Wiiboox Launches $159 LuckyBot Food 3D Printing Extruder

Chinese 3D printer manufacturer Wiiboox has announced a new food 3D printing extruder.

Food

SavorEat and Sodexo to Pilot Robot Chef 3D Food Printer at US Universities

SavorEat, an Israeli startup developing plant-based alternatives to meat products through 3D printing,...

Food

Chocolate printer from STANKIN

Director of the Center for Work with Students Ramil Nezhmetdinov suggested that the guys from the team of the youth project office...

Food

Dry heat treatment of wheat starch produces hydrogels suitable for 3D printing

Brazilian scientists from the University of São Paulo and their French colleagues from the National College of Veterinary Medicine,...

Food

Cakewalk3d will teach a home 3D printer to print food

Cakewalk3d, founded by Marin Core-Baye, who previously served as Deputy Director of a well-known 3D service. ..

..

Food

"Meat of the future": KFC and 3D Bioprinting Solutions will print KFC nuggets on a bioprinter

KFC takes the next step in developing its innovative concept of "the restaurant of the future" and begins cooperation with...

Food

Startup Legendary Vish to commercialize vegan 3D printed salmon

An international group of students has developed a 3D printing technology that allows complex binders to be printed and...

Food

Redefine Meat introduces printed plant-based meat substitutes

Israeli startup Redefine Meat has unveiled the first plant-based Alt-Steak products. Supposed to be later in this...

?

3D printing events

Email:

By submitting this form, I consent to the processing of my personal data in accordance with Policy regarding the processing of personal data.

1 23...89Next

What is 3D printing and how it can be used! Interesting!

What is 3D printing

3D printing technology was patented in the 80s of the last century, but gained popularity relatively recently. New, promising techniques have been developed and the possibilities of 3D technologies have reached a completely new level. However, to this day, the technique is not known in all circles, and not everyone is aware of what 3D printing is. In today's article, we will try to explain in detail and in an accessible way what 3D printing is and where it is used.

In short, 3D printing is a technique for manufacturing three-dimensional products based on digital models. Regardless of the specific technology, the essence of the process is the gradual layer-by-layer reproduction of objects.

This process uses a special device - a 3D printer, which prints certain types of materials. More details about it are written here. Other names for the technology are rapid prototyping or additive manufacturing. Often the phrase "additive technologies" is used in the meaning of "3D technologies".

Other names for the technology are rapid prototyping or additive manufacturing. Often the phrase "additive technologies" is used in the meaning of "3D technologies".

3D printing steps

To make it clearer what 3D printing is, let's take a look at the playback process step by step. Below are the specific stages of 3D printing. How it works:

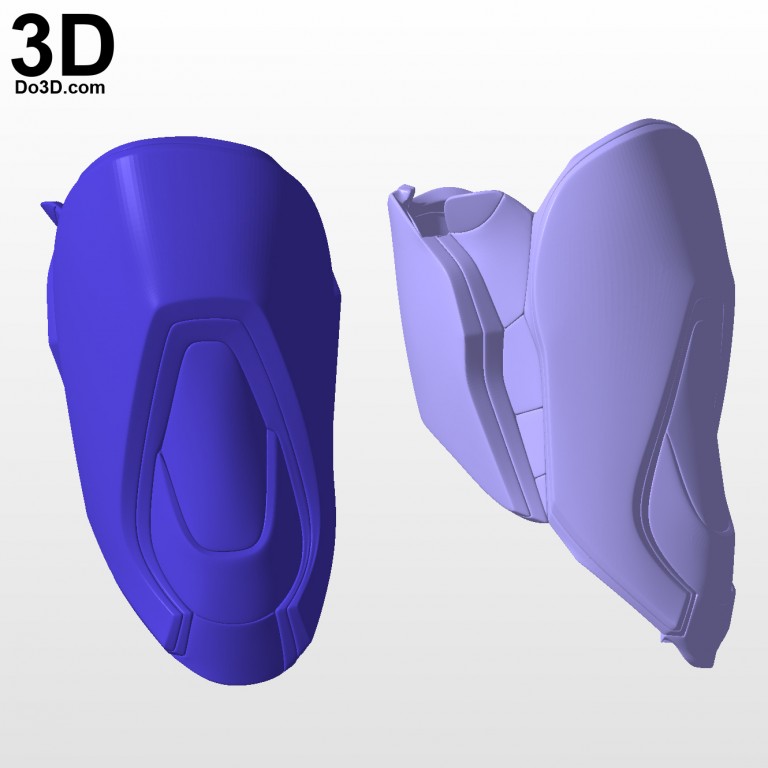

- 3D modeling of the required object is performed according to certain rules;

- The file with the digital model is loaded into the slicer program, which generates the control code for the 3D printer;

- Sets required 3D printing options;

- The code is written to a removable memory that connects to a 3D printer;

- The 3D model is reproduced.

Objects are rendered gradually. According to the required shape, the selected material is applied layer by layer, forming the finished product. It is worth noting that the possibilities of 3D printing are almost limitless, that is, anything can be made. In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

Naturally, this is a very simplified description of the stages of 3D printing, but they give a very clear idea of the essence of the technique.

Other questions and answers about 3D printers and 3D printing:

- Basics What is 3D scanning?

- Basics What is a 3D model?

3D Printing Technologies

Different 3D printing technologies are used to reproduce different objects. They differ both in the consumables used, and in the speed and accuracy of printing. Here are the main 3D printing technologies:

- Fused deposition modeling (FDM) . One of the most common 3D printing technologies, used in most desktop 3D printers, and represents an ideal price / quality ratio. Printing occurs by layer-by-layer supply of a thread of molten plastic;

- Laser stereolithography (SLA) .

The formation of the object occurs due to the layer-by-layer illumination of a liquid photopolymer resin by a laser, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage;

The formation of the object occurs due to the layer-by-layer illumination of a liquid photopolymer resin by a laser, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage; - Selective laser sintering (SLS) . Reproduction is performed by layer-by-layer melting of a special powder under the action of laser radiation. This 3D printing method is widely used in the industry for the manufacture of durable metal elements

3D Printing Applications

As you may have guessed by now, 3D printing is extremely versatile. The second name of the technology - rapid prototyping - speaks for itself. In the manufacture of prototypes and models of models, 3D printing can be simply indispensable. It is also a very cost-effective solution for small-scale production. In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.

In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.

Well, that was a brief description of what 3D printing is. We hope we were able to provide the necessary information in an accessible way. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.