3D printer layer shift at same height

10 Ways How to Fix 3D Printer Layer Shift at Same Height – 3D Printerly

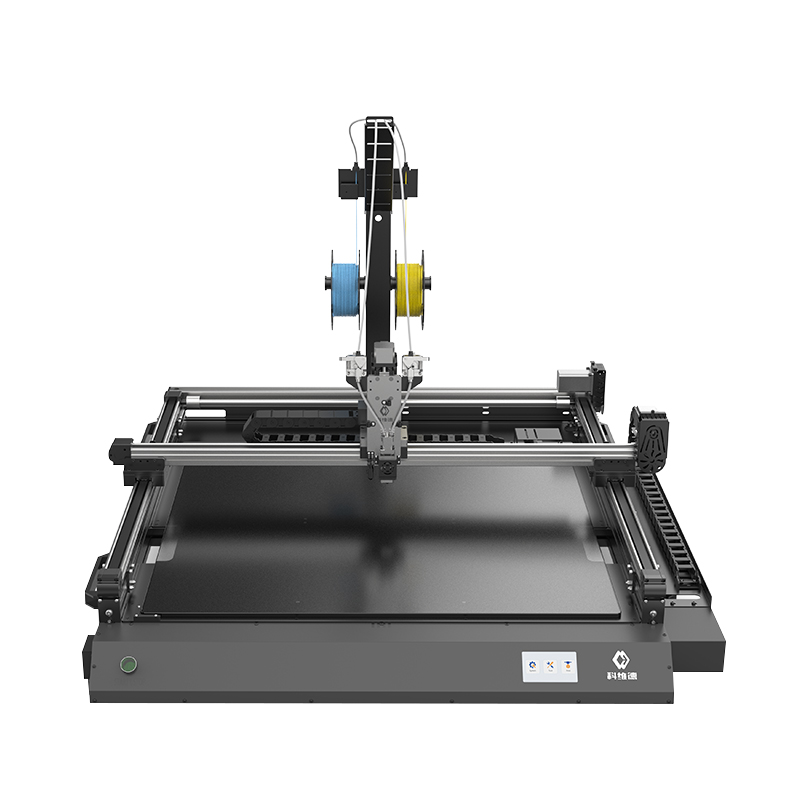

Layer shifts in 3D printers can be very troublesome since they are likely to ruin the look and functionality of your whole print. Sometimes these layer shifts can consistently occur at the same height. This article will help look at the causes and then the fixes for this issue.

Keep on reading for the details behind fixing your layer shifts at the same height.

What Causes Layer Shifts in 3D Printing (At Same Height)

Layer shifts in 3D printing at the same height can be caused by a number of factors like loose X or Y-axis pulleys, belt slack, overheating, excessive printing speed, vibration, instability, and many more. Some users found issues with the actual sliced file or even from a lack of lubrication in their 3D printer.

How to Fix & Stop Layers from Shifting (At Same Height)

There are many methods to stopping layers from shifting at the same height, but they do depend on what’s causing the issue in the first place. You’ll want to run through a few of these fixes so you can see if it helps solve your issue.

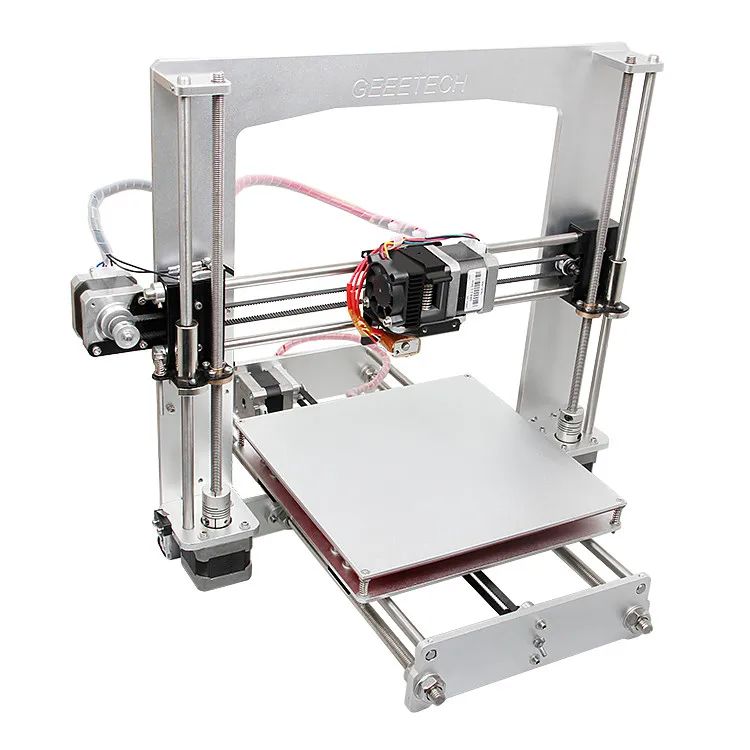

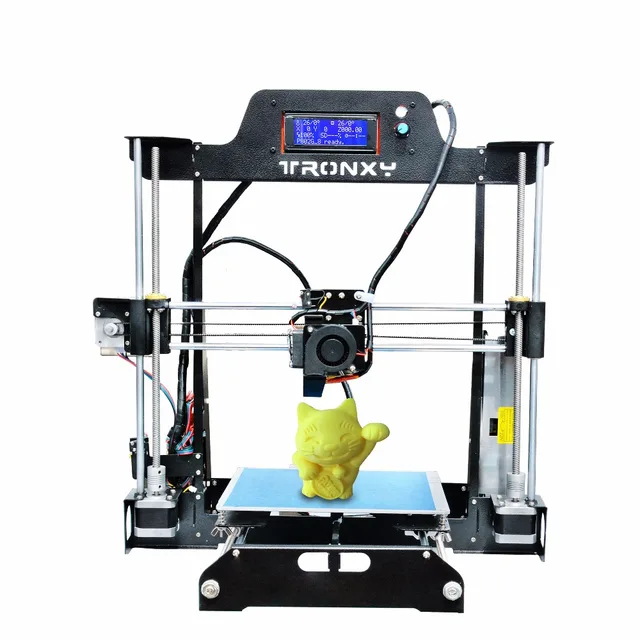

Whether you are learning how to fix layer shifting with an Ender 3 or another machine, this should set you on the right path.

I’d recommend doing some of the easier and simpler fixes first before moving onto the more advanced methods.

- Tighten Belts and Check Pulleys

- Stabilize 3D Printer and Lower Vibrations

- Try Re-Slicing Your File

- Reduce Your Printing Speed or Jerk & Acceleration Settings

- Changing Coasting Setting

- Change Infill Patterns

- Lubricate & Oil Your 3D Printer

- Improve Cooling for Stepper Motors

- Enable Z Hop When Retracting

- Increase VREF to the Stepper Motor Driver

1. Tighten Belts and Check Pulleys

One method of fixing your layers shifting at the same height is to tighten up your belts and check your pulleys. The reason for this is that a loose belt can reduce the accuracy of your 3D printer’s movements, leading to layer shifts.

You’ll want to take a look at the belt on the X & Y axis to see whether they have a good amount of tension. A belt that’s too tight can also cause issues such as binding or not the teeth being skipped during movements.

Check the video below to learn what the correct 3D printer belt tension is.

Another thing to check is that your pulleys are in place and are working properly. Pulleys are the round metal parts that your belt goes around, which have teeth that the belt fits into.

Your pulleys shouldn’t slip and should be tight enough. These can loosen over time so it’s a good idea to check them periodically.

After tightening belts and checking pulleys, users have fixed their issue of layers shifting at the same height.

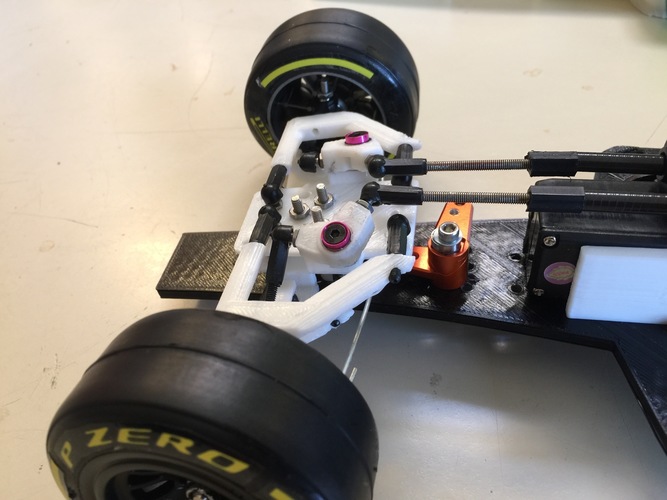

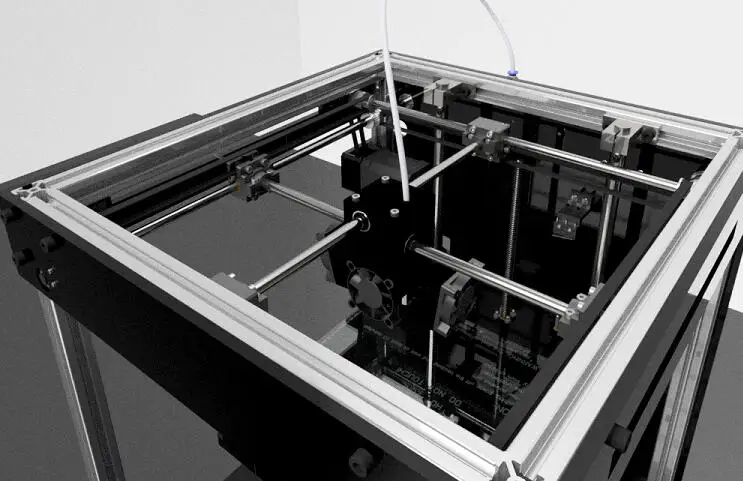

2. Stabilize 3D Printer and Lower Vibrations

Another potential fix to layer shifting at the same height in a 3D printer is stabilizing the printer and reducing any sort of vibrations. Vibrations in many cases can cause layers to shift at the same height, especially on specific parts of a model where the print head is going too fast.

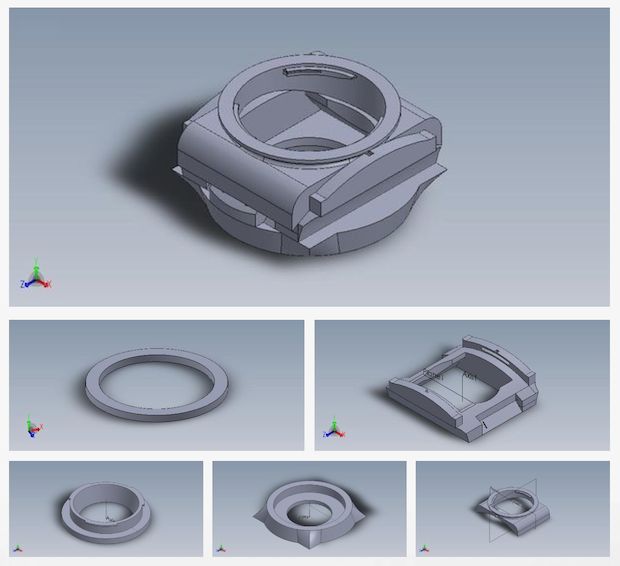

You can stabilize your 3D printer by putting it on a firm and stable surface, as well as attaching rubber anti-vibration feet to the bottom of the machine.

These can even be 3D printed or professionally bought.

Check around your 3D printer for any loose parts, especially in the frame and gantry/carriages. When there are loose parts or screws on your 3D printer, it increases the presence of vibrations which can lead to layer shifts at the same height.

One user suggested you can even put your 3D printer on something heavy like a thick piece of wood or a slab of concrete with some padding under the heavy surface.

Many people overlook their actual print bed being the culprit, having worn out clips on their bed. If you have a glass bed for example, you need to clip it in place. One user found that their worn out clips caused layer shifts as shown in the video below.

If you have a glass bed for example, you need to clip it in place. One user found that their worn out clips caused layer shifts as shown in the video below.

The fix worked for many other users as well.

A user commented that his entire glass bed shifted from its original position due to a clip issue. He also mentioned that this is by far the fastest layer shifting fix out there.

An interesting way someone said to check for vibrations is to put a glass of water on the surface or table your printer is sitting on to see if the water is moving. Small movements in the table can cause shifting issues further in your print.

3. Try Re-Slicing Your File

Simply re-slicing an STL file into the G-Code file can help to fix this issue. A 3D printer hobbyist who had a random y shift after checking their stepper motor and belts. They then re-sliced the file they were printing with and it all printed just fine.

A 3D printer hobbyist who had a random y shift after checking their stepper motor and belts. They then re-sliced the file they were printing with and it all printed just fine.

You could also try to rotate the file by 90° and slice the file again to see if that makes a difference.

4. Reduce Your Printing Speed or Jerk & Acceleration Settings

When it comes to layer shifts at the same height, your printing speed can also contribute to this. The higher your printing speed, the more likely it is to start shifting. You want to avoid excessive print speeds. The default print speeds should work well enough for you at around 50mm/s.

Some 3D printers are designed to move at faster printing speeds without issues, but not all of them can handle these speeds.

I would also check your Jerk & Acceleration settings to make sure these aren’t too high and causing layer shifts.

Another user who changed their Jerk setting from 20mm/s to 15mm/s found that their layer stopped shifting after this. The default Jerk setting in Cura is now 8mm/s if you enable Jerk Control, so double check these values.

The default Jerk setting in Cura is now 8mm/s if you enable Jerk Control, so double check these values.

Sometimes your 3D printer’s firmware will have its own Jerk setting that it follows.

Another user also suggested to turn off Acceleration Control & Jerk Control in your slicer. They had the same issues and after doing this, their models were coming out very nicely.

5. Changing Coasting Setting

One user mentioned that a potential fix for this issue is to change your coasting setting in their slicer. If you are experiencing layer shifts at the same height, try changing your coasting setting, by enabling it if it’s disabled, or disable it if it’s enabled.

In one instance, enabling coasting can help fix the issue because it can slow down your 3D printer more before the end of the move. On the other hand, turning coasting off can let your firmware know that it needs to slow down sooner for a corner.

6. Change Infill Patterns

It’s possible that your infill pattern is contributing to the issue of layers shifting at the same height since some infill patterns have sharper corners. When your layer always shifts at the same spot, it’s likely that a sudden movement at high speed is happening at that spot.

When your layer always shifts at the same spot, it’s likely that a sudden movement at high speed is happening at that spot.

You can try changing your infill pattern to see if that helps fix this issue. The Gyroid pattern could be a good one to test out whether this is causing the issue since it doesn’t have sharp corners and is more of a curved pattern.

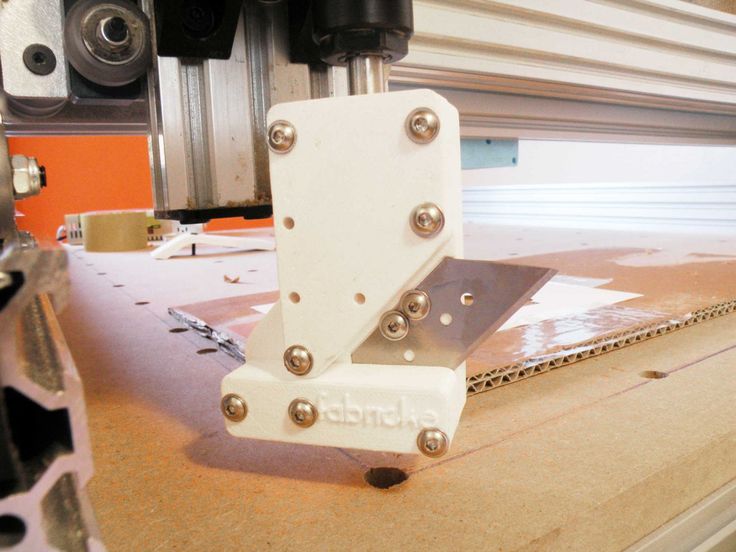

7. Lubricate & Oil Your 3D Printer

Another fix that has worked for users that experience layer shifts at the same height is to lubricate and oil their 3D printer parts. If there is too much friction on the moving parts of your 3D printer, that can cause issues, so you’ll want to lubricate these parts.

I’d recommend using something like Super Lube Synthetic Oil with PTFE, a staple lubricant for your 3D printer.

I wrote this article called How to Lubricate Your 3D Printer Like a Pro – Best Lubricants to Use so you can get the key information on how to do this properly.

The video below is very useful to learn how to lubricate your 3D printer.

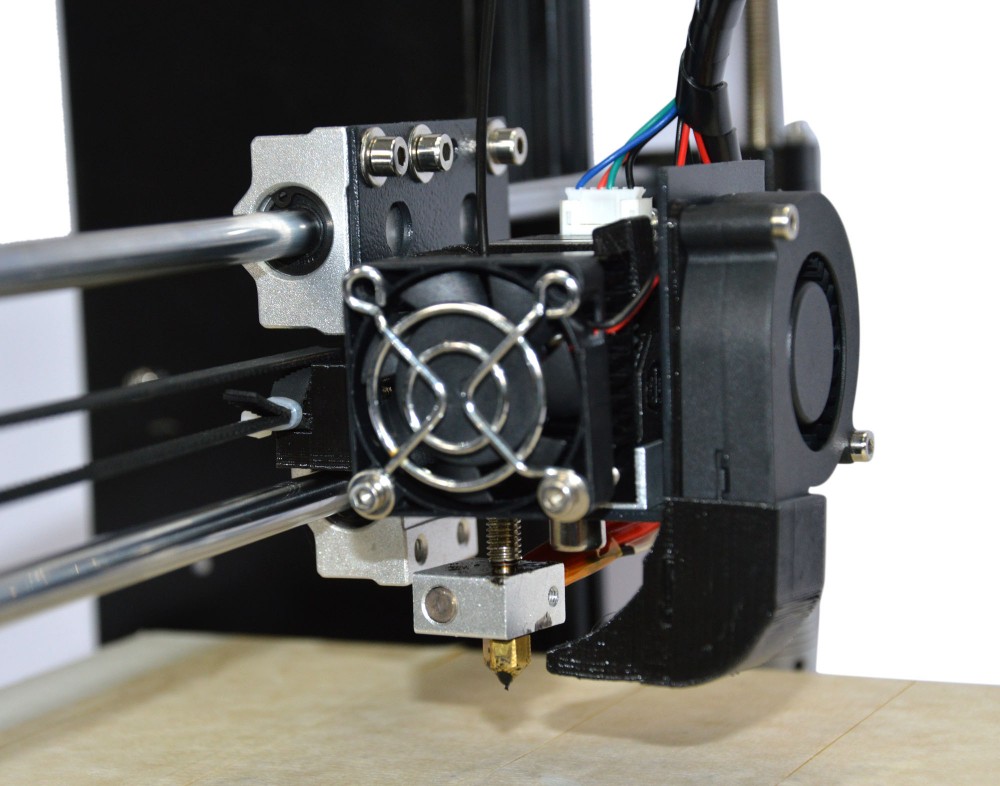

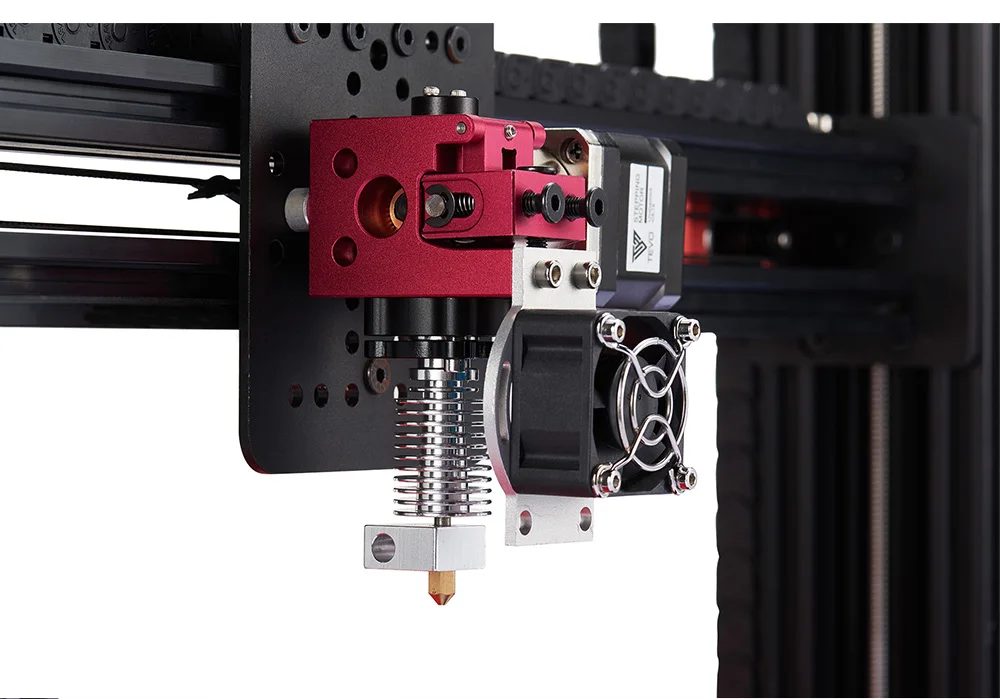

8. Improve Cooling for Stepper Motors

One user found that the reason this was happening was due to their stepper motor driver overheating at a certain point in their print. This can be due to a lot of current needing to be used for the 3D print.

To fix this, you can implement better cooling for your stepper motors by adding heatsinks or a cooling fan blowing air directly on the motor.

I wrote an article called 7 Ways How to Fix Extruder Motor Getting Too Hot which you can check out for more details.

This video from Tech3C goes through how important are cooling fans and how they can get you quality prints.

Another user even mentioned an issue with a motherboard heating up in the case of an Ender 3 with a 4.2.2 motherboard. They upgraded it to a 4.2.7 motherboard and it solved the problem.

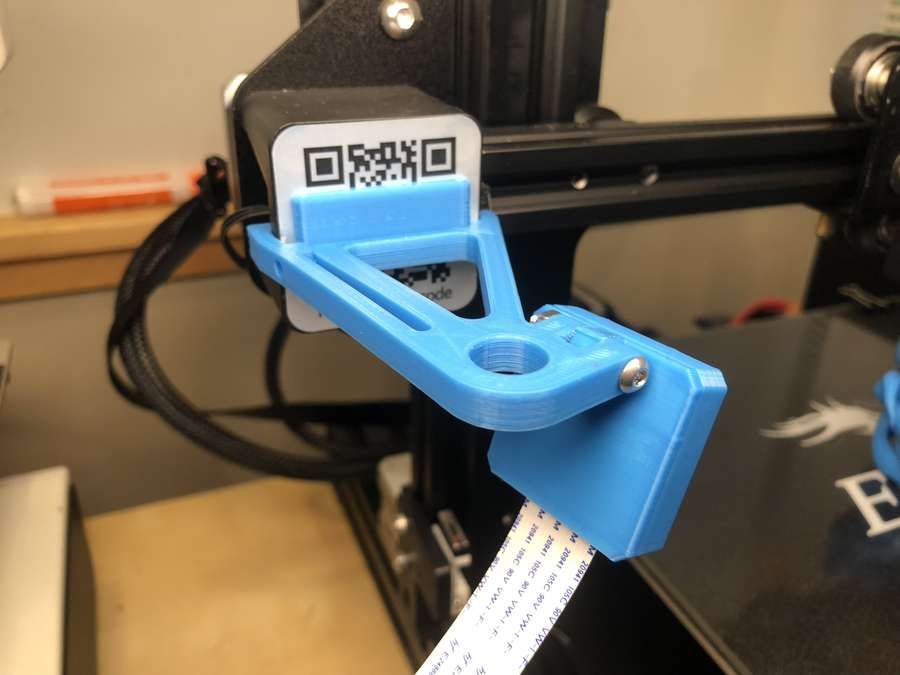

9. Enable Z Hop When Retracting

Enabling the Z Hop When Retracting setting in Cura is another method that has worked to fix layer shifts at the same height. One user who had an Ender 3 was experiencing layer shifts at a height around 16mm on all his parts.

They checked whether their leadscrew was smooth, checked their wheels and aluminum extrusions and all of that looked fine. He also checked for any stabilization issues such as wobbles or blockages but all looked good.

As he watched the print get to that specific height, the nozzle started hitting the prints and the supports.

To fix this, he ended up adding a Z Hop of 0. 2mm for travel moves. This basically lifts up your nozzle by 0.2mm each time your nozzle retracts to move from one place to another. This does add time to the overall 3D print but it’s useful to avoid your nozzle hitting your prints.

2mm for travel moves. This basically lifts up your nozzle by 0.2mm each time your nozzle retracts to move from one place to another. This does add time to the overall 3D print but it’s useful to avoid your nozzle hitting your prints.

Below is what their layer shifts looked like.

View post on imgur.com

10. Increase VREF to the Stepper Motor Driver

This is a slightly less common fix but still, something that has worked for users, and that is to increase the VREF or current to your stepper motors. The current is basically the power or torque that your stepper motors can generate to make movements on the 3D printer.

If your current is too low, movements can skip a “step” and cause a layer shift in your model.

You can increase the VREF in your stepper motors depending on whether they are low or not. Check out the video below to learn how to do this, though keep safety in mind because these electronics can be dangerous if you don’t know what you are doing.

Best 3D Printer Layer Shift Tests

There aren’t too many layer shift tests out there but I did find a few that has worked for some users.

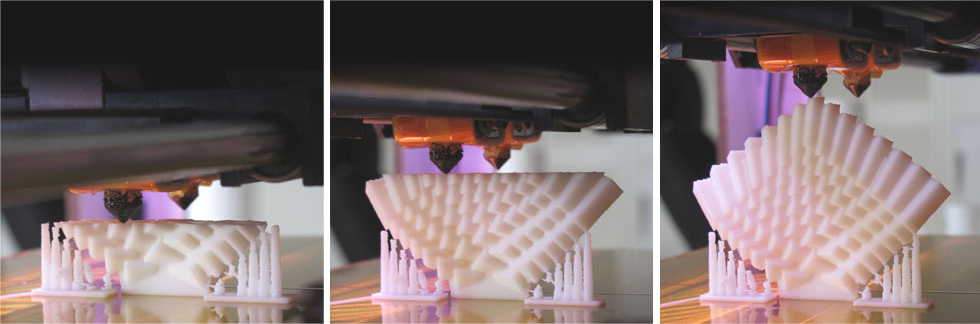

Layer Shift Torture Test

One user who tried looking for layer height torture tests couldn’t find one, so he made one himself. The Layer Shift Torture Test works well to quickly diagnose any layer shifting issues.

He tried finding where a normal print failed, which took a few hours, but with the torture test, it only took 30 seconds.

Y-Axis Layer Shift Test Model

If you are having a Y-axis shift issue specifically, this is a great layer shift test to try. The user designed this Y-Axis Layer Shift Test Model to help identify his own Y-axis shifting issue. He got positive results along with many users who have tried 3D printing this test.

He got positive results along with many users who have tried 3D printing this test.

This model failed 100% of the time for a layer shifting issue he had, but he also added a second Y axis test model that his friend requested that you can also try.

print quality - Ender 3 V2 Layer Shifting, No Apparent Reason, Desperate

I first want to say thank you for taking the time to read this. I've been trying to print out some parts for another project of mine. These parts use up around 70% of the bed so they are fairly large, unlike the smaller trinkets and things I normally print.

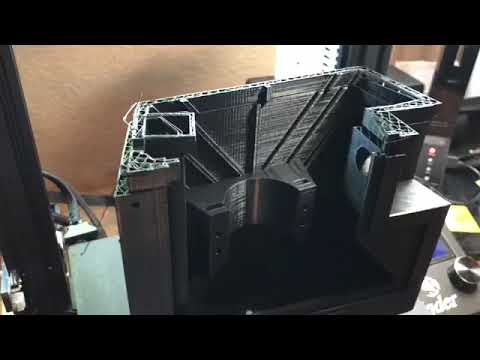

However, I have yet been able to print one of these larger parts without any layer shifting. The part I've been trying to print is a lid to the bottom of a case. It's square, with rounded corners, about 160mm x 160mm.

It will print the first layer without shifting most of the time. However, upon starting the second layer it will almost have at least one layer shift. I have tried a number of things to remedy this, which I will list further down this post.

The layer shifting seems to be unrelated to jerk, acceleration, bed shifting, and z offset at the very least. There is an audible clunk sound that can be heard when it does this. In the image I've linked, you can see the correct path of the print head through the green arrows. However, upon a layer shift, it follows the path of the red arrows. It never shifts during a direction change, only when it is following a straight path. It's almost as if one of the motors gives up for a second. I am aware the print is under extruded, this is one of my trials hoping it was merely the nozzle clipping against the print.

Allow me to share with you my setup:

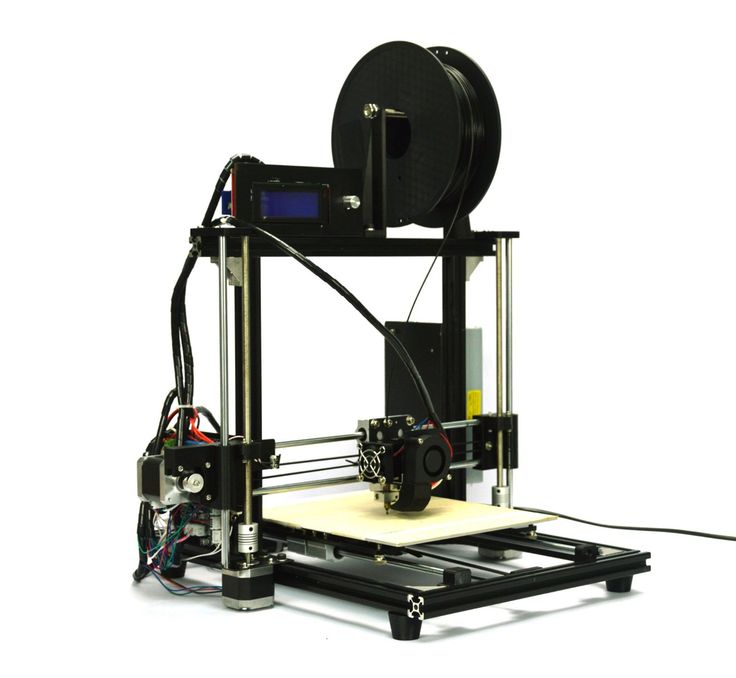

I have an Ender 3 V2, with the stock mainboard, stock glass bed, and stock hotend.

I've replaced the extruder assembly with an all-metal one from Creality.

I have the stiffer bed springs. As well as the better PTFE tube fittings and Capricorn tubes.

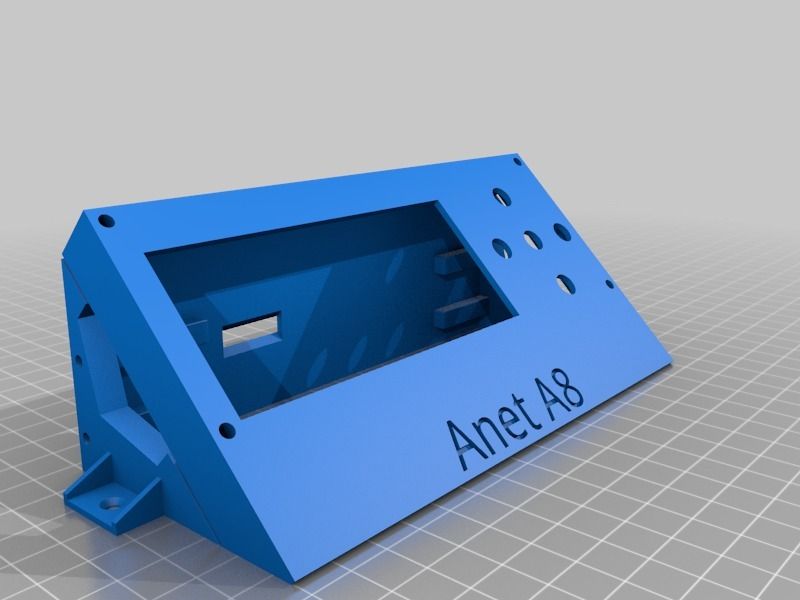

I've put together a cooling pack on Thingiverse.

https://www.thingiverse.com/thing:4644985 The mainboard and hotend fans were replaced with Noctua performance fans that I'll talk more about later.

https://www.thingiverse.com/thing:4644985 The mainboard and hotend fans were replaced with Noctua performance fans that I'll talk more about later.The hotend assembly is a hero me gen 5 with dual 4010 fans and a BLTouch.

I'm using Smith4D's 5x5 high-speed firmware (Previously the 4x4 high speed).

Now let me share my tried solutions.

I firstly, disassembled the printer, checking all belt teeth and motor gears (which are pressed onto their shafts without a grub screw). Afterward, I readjusted all eccentric nuts to get the perfect amount of tension while maintaining smooth operation on both X and Y axes. I've used brake cleaner and dish soap to remove the grease on the Z-axis lead screw and replaced it with WD-40 dry lubricant.

Continuing, I've releveled the bed and checked all axis operation to ensure it was smooth and without any bumps, hitches, or anything of the sort.

I tightened all the frame screws, hotend screws, fan screws, grub screws.

2 and 10mm/s.

2 and 10mm/s.I've adjusted my Z offset so that it slightly under extrudes to prevent the filament from bunching up.

I've calibrated my e steps.

I've formatted the SD card and changed my firmware from Smith 3D's 4x4 high speed to 5x5 high speed.

I've updated Cura to the latest version 4.8 and ensured my hero me home offset is correct.

I've tried moving the model to different corners in Cura and ensured the software's jerk and acceleration control are disabled.

I've checked the bed movement with its clips, it doesn't move easily and both clips have very good tension.

I've checked the stepper driver voltages (I did not change them). E: 1.34V Z: 1.16V Y: 0.99V X: 1.15V.

I have Z hop enabled with a 0.2mm hop, no issues or noises when it moves across the print.

I've purchased a filament dry-box from SUNLU along with a new spool of SUNLU black filament.

The dry box has Capricorn PTFE tubing that leads the filament straight into the extruder. There is very little friction inside the tube.

The dry box has Capricorn PTFE tubing that leads the filament straight into the extruder. There is very little friction inside the tube.I've slightly tightened the tension on the extruder although I didn't have problems with it skipping.

Again, I'd like to reiterate, nothing is loose on this printer, it doesn't skip when it rapidly changes directions, only when following either a straight or diagonal line. The printer movement is very smooth and near-silent with all of my modifications. It's frustrating to me that I can't solve this problem. I feel like the printer has a mind of its own. I have begun to suspect either the mainboard or something else hardware related is amiss. However, I have chosen not to mess with it until posting this. If you've read through this, I thank you for your patience and time reading it.

Any advice or possible causes to this problem are welcomed. I am at a complete loss and am desperate for a solution.

(Solution available) Letterpress layer offset (per model)

creality-ender-3 prusaslicer layer-shifting

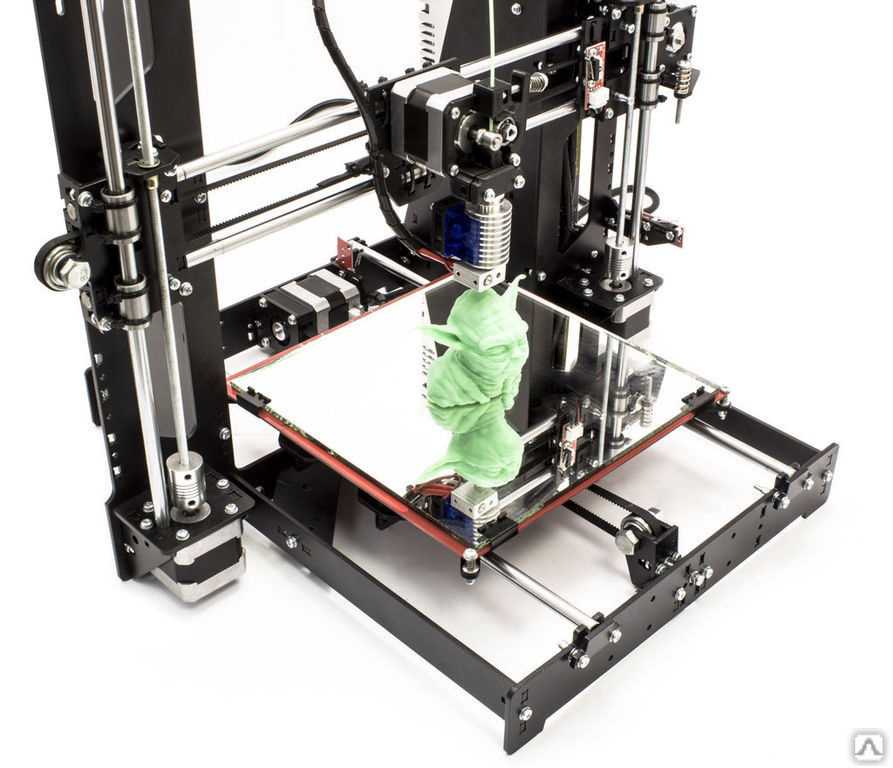

I tried to print Baby Groot, but every time I print the head, there are always layer shifts, like in the photos below. I printed three chapters and the layer shifts all happened in the same place.

I tried to print something else (more or less) the same height and the layer shifted as well.

I thought maybe because the z-bar was bent. But, apparently, the shift of the layer occurred at a different height.

What is my problem and how can I solve it? I am using Ender 3 with BLTouch. @notalentgeek

I thought maybe a different slicer would lead to a different result.

I thought maybe a different slicer would lead to a different result. All this does not solve this problem. Then I realized that while my z motor was spinning, there were some cases where the rod wasn't spinning. I replaced the hex bolts and tightened them correctly to fix the issue.

, @ notalentgeek

▲ 3

Layer misalignment has two main causes: the partially printed part moves or flexes, or the Y table or carriage (almost always - they seem rather odd on the x-axis) misses one or more steps in that or a different direction.

Permanent layer shifts - that is, where the entire print above the shift is shifted and remains shifted - is more likely to be last; temporary shifts (when the shear creates a bulge or groove, and then the layers above this area again coincide with those below) are more likely due to movement of the part.

In your case, it looks like you have temporary shifts. The ones on Groot's head appear (in photographs) to match the height at which some of the tops on the head end; they may be the result of changes in the nozzle's interaction with the print, which becomes tall enough to flex as the trajectory changes due to the finish of these areas. The ones on the pink block look more like a temporary surge, but since we can't see the opposite side of what they are, I can't say for certain that they're not the same thing.

One thing you can try is to re-apply both of these objects with the Z transition turned on. This will reduce the nozzle dragging over earlier parts of the current layer, which can cause the part to bend (or temporarily block the nozzle, resulting in increased pressure, resulting in momentary overstress).

To save time, you can look to see if you have any objects that expose it's not so much hours of time stamp (tens of grams of thread) already spent .... perhaps you can dive into Groot's virtual desktop in a slice, since to print it just out of the eyes (or even higher) - though that might reduce the flex enough that producing spikes on the head won't make much of a difference.

perhaps you can dive into Groot's virtual desktop in a slice, since to print it just out of the eyes (or even higher) - though that might reduce the flex enough that producing spikes on the head won't make much of a difference.

, @ Zeiss Ikon

▲ 1

Zeiss Ikon's answer is good, but just in case that doesn't solve the problem, have you printed larger/longer prints before? There is a well-known issue with the Ender 3 4.2.2 motherboard that causes layers to shift when overheated on longer prints. You can try lifting the printer up and placing a fan under it to see if anything changes. (I had this problem and it drove me crazy until I got a 4.2.7 motherboard)0003

- https://www.reddit.com/r/ender3v2/comments/lmf1v2/an_faq_on_layer_shifts_and_mainboards/

- https://www.reddit.com/r/ender3v2/comments/kn8u72/layer_shift_investigation_data_and_video/

- https://www.

reddit.com/r/ender3v2/comments/kxeikz/as_promised_thermal_camera_captures_of_a_layer/

reddit.com/r/ender3v2/comments/kxeikz/as_promised_thermal_camera_captures_of_a_layer/

However, I see some other issues with the head layer down the print. I would probably loosen and readjust all the portals again, check all the belt tensions, make another table level (you changed the springs to yellow, right?). It's not uncommon for a glitch to occur after a few hours of use, perhaps a piece of plastic/dust stuck in the track.

If you have double checked and adjusted all portals and none of them are loose or too tight, look at your desk where the printer is sitting. If possible, place the printer on something really heavy (concrete slab, thick wood) with a little padding underneath that heavy surface. Place half a glass of water on the topmost surface (not the printer) to see if the table vibrates while printing (the water must be still at all times). It's possible that the table moves a bit while the printer is printing - with fractions of a mm it won't take too long.

, @ Gisto

▲ 1

These are (at least almost certainly) not layer shifts. Layer shift is when the physical position of the tool head becomes inconsistent with the logical one, because the stepper motor missed a step, or the table surface moved, or something else went wrong. They can reverse if the same happens in the opposite direction at a later level, but is very unlikely.

What you have looks like an inconsistent geometry dependent extrusion. If you look at the output of the slicer in the analyzer, you probably have some geometry difference in terms of number of components, necessary moves, etc. in affected layers, causing more or less material to seep/lose in the interior of the model, thereby creating a thinner extrusion thickness in subsequent walls compared to other layers.

While there are probably other ways to reduce the impact, the correct way to fix this is to find the cause of the discharge and stop it. These are almost certainly unrecorded movements within the interior of the model, which Kura calls "combing"; I don't know Prussianlitz terminology for this. You can either turn it off (which will make your printing much slower and may hurt quality in some way) or set the "Maximum Retract Comb Distance" to something very small, like 1mm. This will create a lot of extra retractions and you need to make sure your retraction settings are correct (in terms of distance and speed) so as not to make the problem worse - you can also seep material while waiting for a slow retraction to occur. Doing a turret to adjust the retraction can help you fix them if you don't already have them. On an ender 3 you should be able to set the retract (and retract) speed to at least 100mm/s, with a distance somewhere around 4.0-6.5.

These are almost certainly unrecorded movements within the interior of the model, which Kura calls "combing"; I don't know Prussianlitz terminology for this. You can either turn it off (which will make your printing much slower and may hurt quality in some way) or set the "Maximum Retract Comb Distance" to something very small, like 1mm. This will create a lot of extra retractions and you need to make sure your retraction settings are correct (in terms of distance and speed) so as not to make the problem worse - you can also seep material while waiting for a slow retraction to occur. Doing a turret to adjust the retraction can help you fix them if you don't already have them. On an ender 3 you should be able to set the retract (and retract) speed to at least 100mm/s, with a distance somewhere around 4.0-6.5.

For readers using Cura, also remember to set the "Minimum Extrusion Distance Window" to 0. Otherwise, Cura will start skipping indents again when there are too many of them, which will immediately return the problem, possibly much worse, since it may miss them even in places where they matter the most. I don't think Prusaslicer has this problem, but I'm not sure.

I don't think Prusaslicer has this problem, but I'm not sure.

, @ R.. GitHub STOP HELPING ICE

Offset (shift) of layers when printing on a 3D printer. Reasons and solutions.

3D printer layer shift is not the most discussed printing error, but it is certainly one of the most annoying. Check out three easy ways to avoid this.

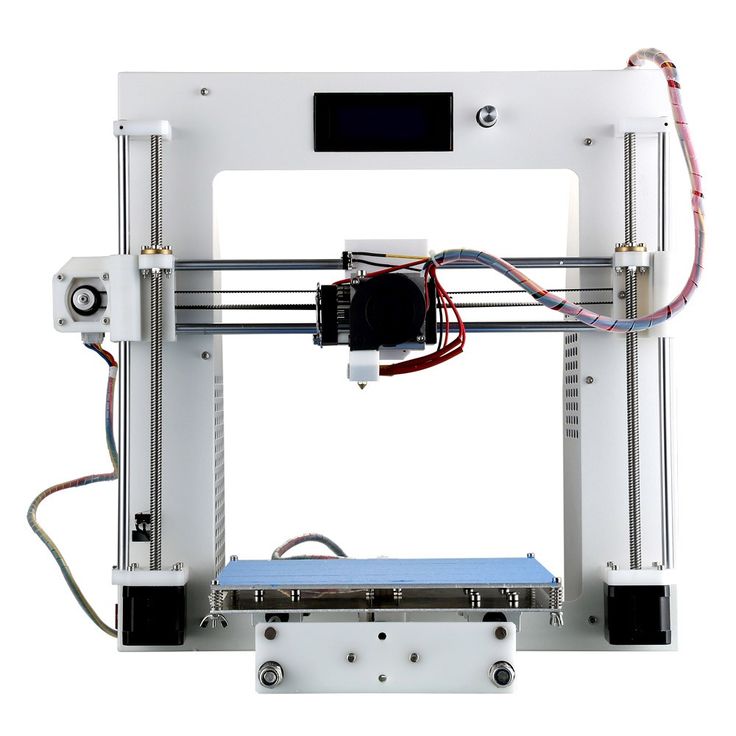

Layer misalignment is when the layers of your 3D print are not properly aligned, leaving behind a stepped "staircase" appearance. This often only happens in a few places, but usually renders the entire print useless. And it's frustrating that the rest of the model can be perfect.

If the layers are slightly shifted, "knocked", shifted layers will occur, as in the case of Benchy above. At a significant value, this can cause your printer to extrude in the air, leaving a plastic bird's nest.

Driver current too low

Reducing the current leads to a decrease in motor torque. Rapid starts and stops may exceed motor torque. Note that the torque decreases rapidly at speed

Rapid starts and stops may exceed motor torque. Note that the torque decreases rapidly at speed

Solution

Before increasing the driver current, first make sure it is not too high.

Increase current.

Driver current too high

- Driver chip is hot.

- The motor can also be very hot.

- When the stepper motor is running, you may hear repeated knocking sounds.

Solution

- Reduce motor current.

- add a fan to cool the drivers. Perhaps the fan needs to be powerful so that it is always on.

- Add heatsinks to the stepper and if possible a fan.

Drive belt loose

- Belt rubbing

- Belt loose

Solution

Tighten the belt.

Use a belt tension spring.

Poor quality pulleys

Pulleys have a shallower depth that cannot hold the belt while driving at high speed, causing slippage

Solution

Replace it with a good one.

Pulley rotates on motor shaft

Drive pulley rotates on shaft under load.

For diagnosis: draw a line on the stepper shaft and the end of the drive pulley. See if the pulley has moved relative to the control line after the layer has been moved.

Solution

Two things must be done to ensure that the drive pulleys do not come loose:

Tighten the set screw on the pulley.

- Add a drop of nail polish to the set screw threads before tightening.

Kinematics bearing sticking

Dirt on rails/guides

- Move the axles by hand with power off to feel for sticking.

- You may need to temporarily remove the belt to make it easier to feel the movement without engine vibration.

- Hairspray or other contaminants on the rails or rails can cause them to bind and jam.

Solution

- Remove all dirt.

- Remove lacquer residue from guides or guides with Windex.

- Remove other residues with alcohol or acetone. Be careful not to get acetone on the ABS parts.

Be careful not to get acetone on the ABS parts.

- Lubricate bearings or guides.

Speed too high

- High travel speeds create large forces that must be overcome by the motors. This, combined with acceleration, can cause the layer to shift.

- 8-bit controllers have a limited overall step rate that varies depending on their overall computational load. Exceeding this step can result in uneven steps and skipped steps.

Solution

- Reduce the travel and print speed of your slicer.

- Default speed, jerk and acceleration in firmware are often too high.

Acceleration too high

- The motor torque at this speed must be greater than the inertia force.

- If the required torque is higher than the motor can deliver at that speed, the layers will be shifted.

- Please note that the stepper motor cannot instantly go from stop to high speed, it must be increased, otherwise it will squeal and vibrate without moving.

Solution

Reduce firmware acceleration.

Y-Axis Offset Layers

(Any Heavy-Axis Offset Layers)

- For printers that move the build plate in the Y-axis, the Y-axis motor needs more force.

- Too much acceleration in this direction causes displacement.

Solution

Decrease Y axis acceleration/jerk settings in firmware.

If the bed is spring-loaded, it may wobble - use springs with whiter springs or another way to secure it (for example, one fixed point on the table).

Play

Play can be caused by loose belts, excessive friction, etc.

This can manifest itself in many ways, such as uneven perimeters or circles that are not round.

Solution

- Make sure the straps are tight but not too tight.

- Try to move the axle back and forth by hand, keeping the motor shaft stationary, there should be no play.

- Move the axis back and forth with the stepper motor disconnected from the drive (turn off the power when the wires are connected or disconnected!). This will allow you to feel the binding and extra friction without significant interference from the engine.

This will allow you to feel the binding and extra friction without significant interference from the engine.

- Check that the belt and pulley are correctly aligned.

- Check that the belts do not rub against the guide bearing flanges.

- Lubricate bearings and guides.

- Use a low backlash belt and pulley, such as GT2.

- Use a pulley large enough so that at least 6 teeth are in contact.

Acceleration settings too high

The jerk setting is mainly used at the very beginning and at the end of the movement.

Solution

Change acceleration settings (lower)

Mid Frequency Resonance

Stepper motors have resonant frequencies where they are difficult to control - they lose torque and may not accelerate causing skipped steps.

Solution

- Use lower speeds

- Use larger pulleys if resolution allows

- Use external DSP based stepper motor drivers. This allows the motor to be driven faster and quieter, as well as to use higher voltage.